1 Introduction

The environmental awareness has promoted the development of green synthesis routes and in this way, waterborne polyurethane (WBPU) and polyurethane-urea (WBPUU) dispersions have gained attention due to the reduction of volatile organic compounds generation [1]. Furthermore, their versatility and tailorable properties become them attractive for their use in different applications [2-4]. In addition, the waterborne character of the dispersions offers the opportunity of incorporating renewable water soluble additives, becoming an interesting approach towards the challenge of preparing new eco-friendly materials [5-6], providing improved or even additional properties, opening the range of applicability. In this context, among others, the use of plant extracts incorporated as biologically active agents can modulate the properties of the WBPUU films besides enhancing their antimicrobial properties.

Therefore, in this work, Melissa officinalis L. plant extract was selected for the incorporation to a WBPUU dispersion. In this way, three addition routes were designed for the incorporation of the extract in different weight contents (1, 3 and 5 wt%). WBPUU based dispersions were used for preparing bioactive films, which were characterized from the viewpoint of physicochemical, thermal and mechanical properties. Furthermore, a preliminary antibacterial test was performed against common pathogens (Staphylococcus aureus, Escherichia coli and Pseudomonas aeruginosa).

2 Experimental

2.1 Synthesis of waterborne polyurethane-urea

For the synthesis of WBPUU, poly(ɛ-caprolactone) diol (PCL) (Mw = 2000 g mol-1), purchased from BASF, ethylenediamine (EDA) supplied by Panreac, isophorone diisocyanate (IPDI) kindly provided by Covestro and 2,2-bis(hydroxymethyl) propionic acid (DMPA) purchased from Aldrich, were employed.

The synthesis of waterborne polyurethane-urea was carried out by two steps polymerization process and the reaction progress was followed by dybutilamine back titration method (ASTM D 2572-97), using an isocyanate/hydroxyl groups ratio of 1.67 in the prepolymer and 5 wt% of DMPA, resulting in a hard segment content around 32 wt%. In the first step PCL and DMPA (previously neutralized with TEA) were reacted with IPDI. The resultant prepolymer was cooled and the dispersion formation step was carried out by adding distilled water dropwise. In the second step, the chain extension was carried out with EDA. A WBPUU dispersion with a solid content about 35-40 wt% was obtained.

2.2 Plant extracts infusions

Plant extract was obtained from Melissa officinalis L. by infusion method. The plant was added to boiling distilled water. The mixture was filtered and the resultant solution was lyophilized.

2.3 Bioactive films preparation

Three alternative incorporation routes were designed for the preparation of the Melissa-based WBPUU at contents of 1, 3 and 5% (wt%, prepolymer-basis):

1. In the first method, post-method, the required amount of extract was dissolved in distilled water and incorporated dropwise to the synthesized WBPUU under mechanical stirring.

2. In the second method, in-situ method, the extract was dissolved in the amount of distilled water employed for the phase inversion step.

3. In the third method, pre-method, the extract was dissolved in a small amount of distilled water and incorporated to the reactor just before water addition. .

Melissa-based WBPUU films were prepared by solvent casting. The dispersion was poured into a Teflon mold and allowed to dry at room conditions during 1 week. The resultant films were stored in a desiccator before characterization. Samples were coded as MelissaXy, where “X” was referred to Melissa weight content in the polyurethane-urea and “y” specifies extract incorporation route “post”, “in-situ” or “pre” Furthermore, neat polyurethane-urea was coded as WBPUU.

2.4 Characterization

Particle size and distribution of base WBPUU and WBPUU dispersions containing Melissa extract were analyzed using a Mastersizer 3000 Hydro particle size analyzer of Marlvern by averaging 5 measurements of the diluted dispersions at 25 ºC.

Thermal behavior of bioactive films were analyzed by differential scanning calorimetry (DSC) using a DSC 204 F1 Phoenix equipment of Netzsch. Samples were subjected to a heating scan from -75 to 250 ºC at a scanning rate of 10 ºC min-1.

Mechanical behavior of bioactive films was determined using a MTS Insight 10 testing machine provided with a 250 N load cell and pneumatic grips to hold samples. Five specimens were averaged for each system at room temperature. Films tensile modulus (E), yield stress (σy), stress at break (σb) and strain at break (εb) were determined from stress–strain curves obtained at a crosshead speed of 50 mm min-1.

Antibacterial properties of films were analyzed by static tests. The assays were performed using Gram positive bacteria Staphylococcus aureus ATCC 19213 and Gram negative bacteria Escherichia coli ATCC 10536 and Pseudomonas aeruginosa ATCC 9027 as test microorganisms. The method was based on the Kirby-Bauer modified test [7]. Briefly, the bacteria inoculums were prepared by aseptically transferring 4 isolated colonies of each one, to separate test tubes containing nutrient broth, which were then incubated for 1 day at 37 °C. The inoculums were diluted to 0.5 McFarland turbidity standard (corresponding to a concentration of 1.5–3.0 x 108 CFU/mL) using sterilized Ringer solution. The concentration of the bacteria dilutions were also controlled by UV-visible spectrophotometry by measuring the absorbance at 625 nm. Then, the bacteria solutions were inoculated in Mueller Hinton Agar plates, using a sterilized swab. The inoculated plates were left to dry for a short period of time. After that, a piece of sample with 1.5 cm of diameter of the waterborne polyurethane-urea films containing plant was placed in the center of the plate. The plates were incubated at 37 °C for 24 h. After this period, the plates were analyzed to measure the diameter of the inhibition zone and the growth of the bacteria on the surface or behind the film. After, the incubation maintained for a further 4 days in order to evaluate the possible growth of the inhibition zone caused by the extract diffusion and the bacteria biofilm formation on the films surface

3 Results and discussion

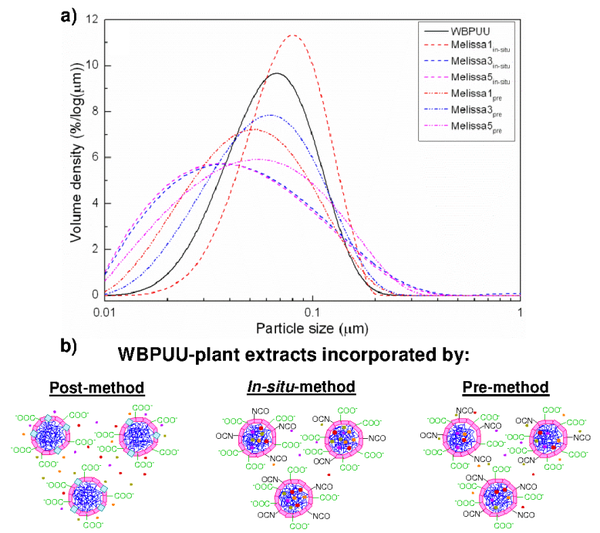

The particle size distribution of the base WBPUU and Melissa-based WBPUU dispersions prepared by in-situ and by the pre-methods and distribution profiles are shown in Figure 1a. It was observed that, in general, and in comparison with the base WBPUU, the addition of extract to the WBPUU dispersion contributed to the broadening of the particle size distribution towards smaller particle sizes, acting as natural surfactants [8-10], favoring the dispersion formation and thus contributing to the achievement of smaller particles. However, the effect varied attending to the incorporation route due to the intercalation of the extract in among WBPUU nanoparticles, as can be seen in Figure 1b. In the case of in-situ method a progressive decrease in particle size was observed with increasing extract content, whereas by pre-method, the reduction in the particle size remained similar without relying on the extract content.

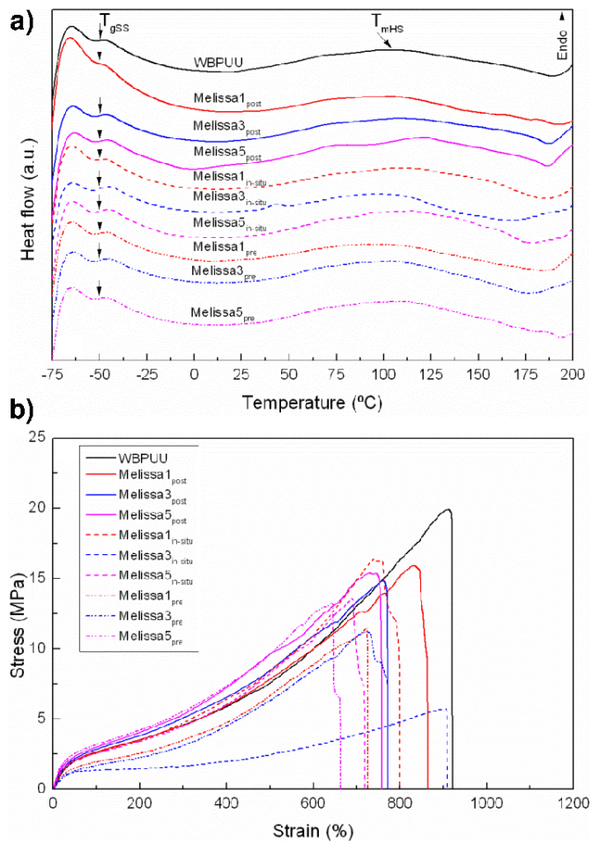

The thermal behavior of base WBPUU and WBPUU containing Melissa extract bioactive films was analyzed by DSC, and thermograms are shown in Figure 2a. Analyzing the base WBPUU film, it was appreciated that the polyurethane-urea film presented a TgSS around -50 °C, which remained similar in the bioactive films series. Furthermore, a broad transition related with the long range order of hard segment domains [11] was observed. In general, it was observed that Melissa extract incorporation favored the ordering of hard segment domains, resulting in a progressive increase of both, TmHS and ∆HmHS values, except in Melissa3in-situ sample. It is thought that in this case different extract intercalation mechanisms were developed.

Mechanical behavior of base WBPUU and Melissa-based WBPUU bioactive films is shown by stress-strain curves in Figure 2b. It was observed that in general, Melissa extract conferred stiffness to the bioactive films presenting slightly higher E values and lower σb and εb values, except in the case of the use of 3 wt% content in in-situ and pre-methods. It is thought that at this percentage, greater extract quantity would result embedded inside nanoparticles, conferring flexibility to the system.

The antibacterial properties of the base WBPUU and Melissa-based WBPUU films were analyzed against Staphylococcus aureus, Escherichia coli and Pseudomonas aeruginosa microorganisms. It was observed that after 1 day of incubation, the base WBPUU and Melissa-based WBPUU film presented bacteriostatic properties against the three bacteria, hindering their growth on the film. Nevertheless, none of the samples showed an inhibition zone. However, it was observed that after 4 days of incubation the base WBPUU sample did not show inhibitory power against none of the assayed bacteria, whereas the addition of Melissa extract, as well as the incorporation route, resulted in different behaviors, which could be related with the bioactive components constituting the extracts and the different intercalation mechanisms [12-13]. The obtained results are summarized in Table 1. In the case of Staphylococcus aureus bacteria, Melissa-based films maintained the bacteriostatic effect in all analyzed samples, attributable to the composition of the extract [14]. Instead, in the case of Escherichia coli and Pseudomonas aeruginosa bacteria, at 1 and 3 wt% of extract incorporated by pre-method was not enough in order to maintain the bacteriostatic effect of the film. It could be related with the intercalation of the extract among and inside the WBPUU nanoparticles, as well as in 1 wt% of extract against Pseudomonas aeruginosa bacteria, taking into consideration that these bacteria is a more resistant pathogen.

| Sample | Melissa | ||

| S. aureus | E. coli | P. aeruginosa | |

| 1 post | V | V | X |

| 3 post | V | V | V |

| 5 post | V | V | V |

| 1 in-situ | V | V | X |

| 3 in-situ | V | V | V |

| 5 in-situ | V | V | V |

| 1 pre | V | X | X |

| 3 pre | V | X | X |

| 5 pre | V | V | X |

4 Conclusions

Different contents (1, 3 and 5 wt%) of Melissa officinalis L. extract were incorporated into the polyurethane-urea dispersions by using three different incorporation routes: post-method, in-situ method and pre-method, in order to prepare films with antibacterial properties. It was observed that the extract content, as well as the incorporation route, influenced the final properties of the prepared films. Regarding dispersions particle size, results revealed that the WBPUU particle size distributions broaden to lower values, which was related to the surfactant effect attributed to the used extract. Thermal properties of the films showed that extract promoted the ordering ability of hard domains. This fact influenced the mechanical properties of the films, where it was observed a stiffening effect in Melissa-based WBPUU films. In the case of in-situ and the pre-method (with 3 wt% of extract), films became more flexible, which was related with the intercalation mechanism of the extract within the polyurethane-urea nanoparticles. Antibacterial tests revealed that after 1 day of incubation, all base WBPUU and Melissa-based WBPUU series, showed bacteriostatic effect against the analyzed S. aureus, E. coli and P. aeruginosa bacteria. After 4 days of incubation, only some samples presented bacteriostatic effect, being the magnitude of the effect dependent on the extract content and incorporation route.

Acknowledgements

Financial support from the Basque Government (IT-776-13), the Spanish Ministry of Economy and Competitiveness (MINECO) (MAT2013-43076-R), (MAT2016-76294-R), POCI–01–0145–FEDER-006984 (LA LSRE-LCM) funded by ERDF through POCI-COMPETE2020 and FCT and NORTE-01-0145-FEDER-000006, funded by NORTE 2020, under PT2020 through ERDF is gratefully acknowledged. We also wish to acknowledge the “Macrobehaviour- Mesostructure-Nanotechnology” SGIker units from the University of the Basque Country, for their technical support. A.S-E thanks the University of the Basque Country for Ph.D. grant (PIF/UPV/12/201).

References

[1] D.K. Chattopadhyay, K.V.S.N. Raju, Progress in Polymer Science 32 pag 352–418 (2007)

[2] G. Yu-hua, G. Jian-jun, M. Hui, T. Li-jun, H. Zhen, Progress in Organic Coatings 77 pag 988–996 (2014)

[3] H. Hao, J. Shao, Y. Deng, S. He, F. Luo, Y. Wu, J. Li, H. Tan, J. Li, Q. Fu, Biomaterials Science 4 pag 1682-1690 (2016)

[4] M.M. Rahman, H.D. Kim, Journal of Applied Polymer Science 102 pag 5684-5691 (2006)

[5] N. Martins, L. Barros, C. Santos-Buelga, M. Henriques, S. Silva, I.C.F.R. Ferreira, Food Chemistry 170 pag 378–385 (2015)

[6] M. Carocho, L. Barros, R.C. Calhelha, A. Ćirić, M. Socović, C. Santos-Buelga, P. Morales, I.C.F.R. Ferreira, Food and Function 6 pag 2240-2248 (2015)

[7] A. Piozzi, I. Francolini, L. Occhiaperti, M. Venditti, W. Marconi, International Journal of Pharmaceutics 280 pag 173–183 (2004)

[8] L. Tmáková, S. Sekretár, Š. Schmidt, Chemical Papers 70 pag 188-196 (2016)

[9] K. Holmberg, Current Opinion in Colloid and Interface Science 6 pag 148–159 (2001)

[10] S. Salati, G. Papa, F. Adani, Biotechnology Advances 29 pag 913–922 (2011)

[11] C. Fang, X. Zhou, Q. Yu, S. Liu, D. Guo, R. Yu, J. Hu, Progress in Organic Coatings 77 pag 61–71 (2014)

[12] M.I. Okeke, C.U. Iroegbu, E.N. Eze, A.S. Okoli, C.O. Esimone, Journal of Ethnopharmacology 78 pag 119–127 (2001)

[13] D. Chamundeeswari, J. Vasantha, S. Gopalakrishnan, E. Sukumar, Fitoterapia 75 pag 85–88 (2004)

[14] H.H. Elkamali, S.E. Mahjoob, American Journal of Life Science 3 pag 230–237 (2015)

Document information

Published on 20/01/19

Accepted on 20/01/19

Submitted on 20/01/19

Volume 03 - Comunicaciones Matcomp17 (2019), Issue Núm. 1 - Materiales (2), 2019

DOI: 10.23967/r.matcomp.2019.01.010

Licence: Other

Share this document

claim authorship

Are you one of the authors of this document?