Abstract

In the present study, indium doped nano sized nickel zinc cobalt based ferrite ceramics with composition Ni0.5 Zn0.3 Co0.2 Inx Fe2-x O4 (x = 0.2 and 0.4) were synthesized by a co-precipitation technique. Powdered sample has been pre-sintered at 800 °C, pressed into toroids and finally sintered at 1000 °C. The single phase formation of the presintered powder has been confirmed by X ray diffraction (XRD). The average particle size of the presintered powder has been estimated by field emission scanning electron microscope (FESEM) and found to be about ~60 nm for x = 0.2 and ~80 nm at x = 0.4. The electromagnetic characterization has been made using vector network analyzer. High value of permeability (17.3 and 15.2 for x = 0.2 and 0.4 respectively) with low magnetic loss tangent of 10−1 order were obtained. Permittivity of 8.2 and 10, and dielectric loss tangent of the order of 10−2 were also achieved. With the measured electromagnetic parameters, miniaturization factor of 12.32 and normalized characteristic impedance close to unity (1.23) were obtained up to 100 MHz frequency. These fascinating parameters definitely propose Ni0.5 Zn0.3 Co0.2 In0.4 Fe1.6 O4 ceramics as a substrate material for miniaturized antenna in very high frequency band. Possible reasons and mechanisms of electromagnetic properties for different concentrations of indium are discussed in the paper.

Keywords

Powder ; Chemical preparation ; Magnetic properties ; Ferrites ; Substrates ; Ni-Zn-Co-In

1. Introduction

Continuous advancement in the research field of materials science is producing new and innovative materials. This is resulting in either up gradation and advancement of existing products and technologies or bringing new technologies for the development of our society and environment, directly or indirectly [1] and [2] . Among various materials, nano ferrites attracted the attention of researchers, scientists and technologists due to their wide range of applications in the field of electronics, communication, drug delivery, sensors, actuators etc. [3] , [4] , [5] , [6] , [7] and [8] . Considerable efforts have been made toward miniaturization of electronics and radio frequency (RF) circuits [9] , [10] , [11] and [12] . In electronics, size of antenna is a major bottleneck in further reduction in the size of communication packages at very high frequency (VHF) band. For space borne and defense applications, the constraint is on small form factor i.e. reduction in volume, rugged and long shelf life, with no deterioration in performance [13] , [14] and [15] . The size of an antenna, being proportional to the half wavelength, increases drastically at low frequencies, for its practical application in portable, mobile and size constraint applications [16] .

Microstrip antenna due to its inherent advantages of planer structure, conformal to any surface, small size, low cost and ease of fabrication have been a subject of research interest over the last many years [17] , [18] , [19] , [20] , [21] and [22] . Scientists have investigated a variety of high dielectric materials and various topologies to miniaturize the antenna size [23] , [24] , [25] , [26] , [27] and [28] . High dielectric constant substrate materials can reduce the size, but suffers from two disadvantages: (i) field remains highly concentrated in high permittivity medium and (ii) decrease in characteristic impedance of substrate material results in impedance mismatch, hence, resulting in an antenna with low efficiency. These limitations and disadvantages can be overcome by loading antenna with magneto-dielectric materials [29] , [30] and [31] . These are engineered materials having both dielectric and magnetic properties. The properties can be suitably tailored with proper selection of ingredients, chemicals, synthesis process and proper doping for its effective use as substrate for microstrip antenna [32] and [33] . Miniaturization factor for microstrip antenna is a function of permittivity and permeability of substrate material and is given by Eq. (1) .

|

|

( 1) |

where n is miniaturization factor, is relative permeability and is relative permittivity of the substrate material. Hence, using moderate value of permittivity and permeability, the size of an antenna can be reduced significantly. High permeability substrate adds to the inductance, reducing the effect of capacitance and thereby reducing the problem of field confinement. Characteristic impedance of the substrate material ( ) should be close to characteristic impedance of the surrounding medium (Z0 ) for proper impedance matching [34] , [35] , [36] and [37] . These ceramic materials also have high electrical resistivity, good chemical stability, do not absorb moisture, and therefore, do not show performance degradation over their useful life.

Among magneto-dielectric materials, it is the versatility of application and ease of preparation that makes Nickel–Zinc a very important material from research as well as production point of view. Significant work has been done to understand and characterize Ni-Zn soft ferrites [38] , [39] and [40] . Ni-Zn ferrite applications are limited to low frequencies only. To increase the operational frequency, effect of various dopants like cobalt, aluminum, copper, barium, indium, strontium etc. had been studied [41] , [42] , [43] and [44] . Doping of cobalt, due to its high positive crystalline anisotropy and due to it being a fast relaxer, is preferred for high frequency application. Since indium has larger ionic radii than Fe ion, its substitution can lead to expansion of cell and may result in high permeability. To further get high and consistent permeability in VHF region, effect of substitution of indium with Fe ion is analyzed in this present research. Wet chemical method is preferred to synthesize the ferrite material as it adds flexibility in varying the stoichiometry of the base materials [45] , [46] and [47] . Since the suitably tailored structural and electromagnetic properties of doped Ni-Zn soft ferrites make them a potential candidate for miniaturized microstrip antenna in space, defense and communication industry at VHF frequency region, the same is chosen for the present research work.

2. Experimental details

2.1. Synthesis and characterization

Ni0.5 Zn0.3 Co0.2 Inx Fe(2-x) O4 spinel ferrite was synthesized by a co-precipitation method from nickel chloride, zinc chloride, cobalt (III) chloride, iron (III) chloride, indium chloride and sodium hydroxide (Merck/Aldrich make with purity greater than 99%). These ingredients were mixed in stoichiometric proportion and processed. Two samples for x = 0.2 (sample 1) and x = 0.4 (sample 2) were prepared. The solution was stirred with a magnetic stirrer and was dried for 12 h in a furnace at 200 °C, to obtain nanosized ferrite powder. The powder was pre-sintered at 800 °C for 4 h. The experimental details are explained elsewhere [48] , [49] and [50] . Structural characterization on the pre-sintered powder samples was done by X-ray diffraction (XRD) using Rigaku Geiger Diffractometer with a step scan of 0.02, 5 °C/min from 25° < 2θ < 70° Cu K(alpha) radiation having wavelength of 1.54 Å. Scanning electron microscope (SEM) images were taken (Model: EVO-50, Make: ZEISS) for the powdered samples. For electromagnetic characterization, toroidal pellets with an internal diameter of 3.2 mm and external diameter of 7 mm were prepared with poly vinyl alcohol as binder, die and hydraulic press. Measurements were done using vector network analyzer (VNA) (Model No. E5071C, make: Agilent). Pellets for both the samples were loaded one by one into suitable test fixture connected to VNA through APC 7 connector. Relative complex permittivity and relative complex permeability values were obtained directly from the measurements of transmission and reflection parameters on the samples from material measurement software of Agilent using coaxial line method. Measurement was done in 10 MHz to 400 MHz frequency band. The small air gap between the pellet and the coaxial line was taken cared of by gap correction feature of the material measurement software.

3. Results and discussion

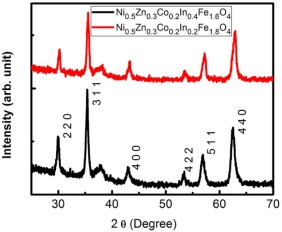

Fig. 1 shows the XRD patterns of Ni0.5 Zn0.3 Co0.2 In0x Fe(2-x) O4 (for x = 0.2 and 0.4) for samples presintered at 800 °C. The peaks observed at (220), (311), (400), (420), (511) and (440) are unique signature of cubic spinel ferrite. The XRD result, without any extra peaks, indicates the formation of uniform material without any unreacted constituents. Formation of single phase nano particles was confirmed from broadening of the peak. With increase in indium concentration from x = 0.2 to x = 0.4, a sharp increase in the intensity of most prominent peaks (311) was observed. This is attributed to the crystalline nature of spinel ferrite. Average crystallite size is obtained from (311), (440), and (511) peaks by Scherrers formula given by Eq. (2) .

|

|

( 2) |

where d is the diameter of the crystallite, w and w1 are the half intensity width of the peak with maximum orientation and instrumental broadening, is the x-ray wavelength (0.154 nm), and θ is Braggs angle of reflection. Average crystallite size of 60 nm was obtained at x = 0.2 and it increases with indium ion concentration to 65 nm at x = 0.4. The lattice parameter increases with increase in doping concentration and hence the volume also increased slightly as calculated in Table 1 . This may be attributed to the fact that indium ions are effective in replacing Fe3+ ions. Since the size of In3+ ion (0.91 Å) is higher than that of Fe3+ (0.67 Å), it is expected that doping of indium leads to expansion of unit cell [51] . The XRD pattern obtained for the above samples matches closely with PDF card number 00–008-0234 for NZFO using MATCH software.

|

|

|

Fig. 1. X ray diffraction image of Ni0.5 Zn0.3 Co0.2 Inx Fe(2-x) O4 for (x = 0.2 and 0.4) nano ferrite. |

| Sample | Parameters for Ni0.5 Zn0.3 Co0.2 Inx Fe(2-x) O4 | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| x | Lattice parameter (Å) | Volume (Å)3 | Sin. temp (°C) | Crystallite size (nm) |

|

|

Tanδε | Tanδµ | (Zi ) |

|

(MHz) |

| ||||||||||||||

| (311) | (440) | (551) | ||||||||||||||||||||||||

| 1 | 0.2 | 8.37 | 586.37 | 1000 | 60 | 56 | 63 | 8.2 | 17.3 | 0.15 | 0.81 | 1.47 | 11.9 | 275 | 4.45 | |||||||||||

| 2 | 0.4 | 8.39 | 590.58 | 1000 | 65 | 62 | 67 | 10 | 15.2 | 0.10 | 0.34 | 1.25 | 12.32 | 320 | 4.54 | |||||||||||

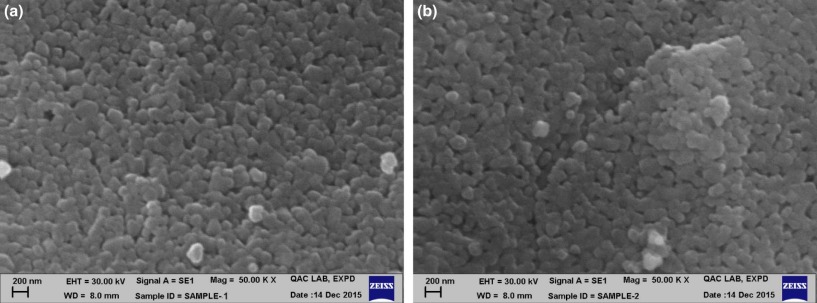

Fig. 2 (a) and (b) shows SEM image of the powdered samples pre-sintered at 800 °C (for In3+ concentration of x = 0.2 and x = 0.4). The images confirm the formation of nano particles with an average size of about ~60 nm for x = 0.2 and ~80 nm at x = 0.4. Some agglomeration was also observed in the powder sample; however, the agglomeration reduces with the formation of pellets as can be seen in Fig. 2 (a) and (b). With an increase in indium concentration, the powder (sample-2) became densely packed. The difference in particle size between SEM and XRD images is due to the dependency of measured reflected intensity on sixth power of radii of the crystal [52] .

|

|

|

Fig. 2. (a) SEM image of Ni0.5 Zn0.3 Co0.2 In0.2 Fe1.8 O4 nano ferrite powder; (b) SEM image of Ni0.5 Zn0.3 Co0.2 In0.4 Fe1.6 O4 nano ferrite powder. |

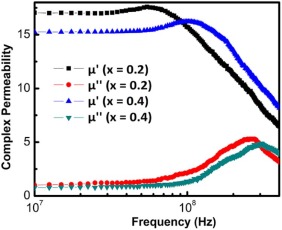

Fig. 3 shows the variation of complex permeability with frequency range of 10 MHz–400 MHz for both the samples. Structural and electromagnetic properties of nano ferrites are a function of microstructure and strongly depend upon processing parameters like stoichiometry, purity of raw materials, mixing and sintering. Therefore, electromagnetic parameter varies with indium concentration. As Ni-Zn ferrite has low but consistent permeability at low frequencies, therefore, to make it efficient at higher frequencies, it is doped with cobalt. Cobalt provides positive contribution to anisotropy due to its very high positive magnetic crystalline anisotropy and ability to increase the magnetic saturation [53] and [54] . In3+ ion has a tendency to occupy A site as well as B site. Up to x = 0.2, In3+ occupies B site and with further increase in concentration, In3+ ions also go in A site, hence, altering the net magnetic moment [55] . The permeability of ferrite is due to two different magnetizing mechanisms: spin rotation and domain wall motion. This can be described by Eq. (3) .

|

|

( 3) |

where is complex permeability, is real part of permeability, is imaginary part of permeability, is susceptibility due to domain wall and is intrinsic rotational susceptibility. The spin susceptibility is a direct function of frequency and is of relaxation type. The domain wall susceptibility is of resonance type and is proportional to the square of frequency. In our present study, the particle size is very small in terms of domain size, so, the domain wall susceptibility having very small effect can be neglected. The net permeability observed is due to spin rotation only. For sample 1, remains constant up to 50 MHz having a value of 17.3, thereafter increases slightly up to a value of 18 at 75 MHz and then decreases. The value of remains low ~0.9 up to 50 MHz and then increases to a maximum at 275 MHz. However, for sample 2, has a slightly lower value of 15.2, which remains constant up to 70 MHz, increases to a value of 16.5 and gradually reduces. has a lower value of 0.8 and remained constant up to 100 MHz. It reaches a maximum at 320 MHz and then decreases. The peaks in correspond to the dispersion in . The material shows only one peak in the measured frequency band corresponding to spin rotational resonance. The spinel ferrites follow Snoeks law, which states that the static permeability ( ) and resonant frequency ( ) for soft ferrites are closely related to saturation magnetization ( ) as given by Eq. (4)

|

|

( 4) |

where is gyromagnetic ratio. Saturation magnetization is a function of composition of the material [56] . Therefore, at low frequencies, higher value of permeability can be achieved. Alternately, for the same composition and stoichiometry, it can be simply given by Eq. (5)

|

|

( 5) |

|

|

|

Fig. 3. Measured complex permeability of Ni0.5 Zn0.3 Co0.2 Inx Fe(2-x) O4 (x = 0.2 and 0.4) nano ferrite. |

Thus, Snoeks law is applicable to our results also and is verified for both the samples as given in Table 1 . High value of permeability obtained with indium concentration (x = 0.2) is due to increase in saturation magnetization. With further increase in concentration of indium from 0.2 to 0.4, In3+ ions replace Fe3+ ions at B site, which decreases the magnetization of B site and hence, the overall saturation decreases, resulting in decrease in permeability.

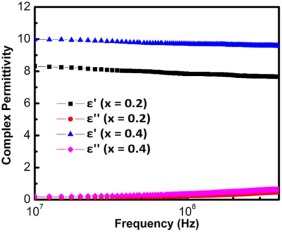

Fig. 4 shows variation of complex permittivity with frequency in 10 MHz–400 MHz band. The permittivity decreases slightly with an increase in frequency, a typical behavior of ferrites. Dielectric constant is found to be high at low frequencies and its value decreases with an increase in frequency and hence, the permittivity decreases slightly. The dielectric constant is due to polarization and is governed by four mechanisms i.e. dipole polarization, interfacial polarization, ionic polarization and electronic polarization. The first two polarizations contribute to at a low frequency, whereas the other two contributes at very high frequencies. In our study, interfacial polarization may be the reason for the observed dielectric behavior, since they contribute to polarization in low frequency band [41] , [42] , [43] , [44] , [45] , [46] , [47] , [48] , [49] , [50] , [51] , [52] , [53] and [54] . It is known that ferrites have well conducting grains with insulating or poor conducting grain boundaries. With an increase in frequency, the hopping electron between Fe3+ and Fe2+ fails to follow the alternating field resulting in low permittivity at high frequencies. Hence, the permittivity drops slightly with the increase in frequency. The increase in permittivity for sample 2 can be attributed to the fact that with an increase in indium content, more and more In3+ ions replace Fe3+ ions. Thus, hopping of electrons from Fe3+ to Fe2+ decreases, which results in an increase in resistivity [57] . Hence, the dielectric constant increases with the indium concentration from 0.2 to 0.4. The imaginary part of permittivity also remains very low (<0.02) in the complete measured frequency band. The large value of permittivity may be attributed to the bigger grain size and better compositional stoichiometry with a relative smaller concentration of easily polarizable Fe3+ ions.

|

|

|

Fig. 4. Measured complex permittivity of Ni0.5 Zn0.3 Co0.2 Inx Fe(2-x) O4 (x = 0.2 and 0.4) nano ferrite. |

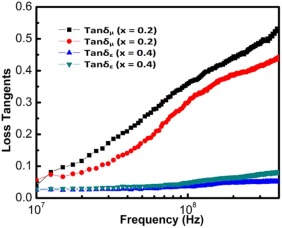

Fig. 5 shows the calculated dielectric and magnetic loss tangent for the composite ferrite. A much lower value of dielectric loss tangent of the order of 10−2 and magnetic loss tangent of the order of 10−1 was observed at the measured frequency. The magnetic loss tangent account for the losses associated with the magnetic parameter of the sample. In the measured frequency, the magnetic loss tangent increases with frequency. Since more energy gets dissipated with an increase in frequency in the medium and dispersive energy also decreases with frequency for the reasons explained above, the magnetic loss tangent increases with frequency. The dielectric loss tangent is due to lag in polarization with alternating field. This may be due to impurities, imperfection, and electron hopping from Fe2+ to Fe3+ and conduction loss due to poor densification. The losses due to conduction appear at low frequencies. The low loss tangents are one of the prime requirements for high efficient antenna, since the total radiation efficiency gets enhanced due to reduction in losses [58] and [59] .

|

|

|

Fig. 5. Calculated magnetic and dielectric loss tangent of Ni0.5 Zn0.3 Co0.2 Inx Fe(2-x) O4 (x = 0.2 and 0.4) nano ferrite. |

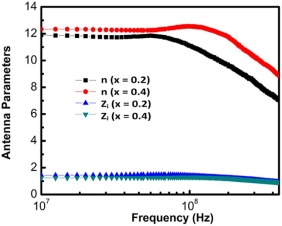

In Fig. 6 , the calculated miniaturization factor and the normalized characteristic impedance with frequency for both the samples are shown. Miniaturization factors of 11.9 for sample 1 and 12.32 for sample 2 were achieved and remain almost constant with frequency up to around 100 MHz. Hence, the antenna with above magneto-dielectric substrate can be used in any frequency band from 10 MHz to 100 MHz and will have same form factor reduction in comparison to pure dielectric substrate material. This is due to the constant and consistent value of permittivity and permeability over the desired frequency range. Therefore, patch antenna synthesized by composite ferrite will have almost 68% less area (reduction in size) than that of fabricated by using FR 4 dielectric material. Hence, the synthesized magneto-dielectric materials can be effectively used for significant reduction in size of antenna. The normalized characteristic impedance is calculated over the measured frequency band and is plotted in Fig. 6 . Due to close and approaching values for permeability and permittivity, is close to for sample 1 and for sample 2 in the measured frequency range. Close values of and result in close to unity and hence, better impedance matching of substrate with that of free space. This results in lower reflection losses and hence higher radiation from the antenna. It is one of the desirable factors for a high efficient antenna. For sample 2, normalized characteristic impedance is 1.23 (close to 1), has high miniaturization factor, low losses and high ferromagnetic resonance frequency as compared to that of sample 1, and hence is more suitable for antenna substrate.

|

|

|

Fig. 6. Calculated miniaturization factor and normalized characteristic impedance of Ni0.5 Zn0.3 Co0.2 Inx Fe(2-x) O4 (x = 0.2 and 0.4) nano ferrite. |

Kong et al. synthesized cobalt doped magnesium soft ferrite with permittivity and permeability as high as 10 but the operational frequency was limited up to 30 MHz only [60] . Thakur et al. obtained high and matching permittivity and permeability of Ni-Zn-In ferrite but again limited up to 30 MHz [45] . Martin et al. synthesized Z phase cobalt hexaferrite in silicone matrix having permeability of ~2.5 up to 400 MHz [61] . Although the operational frequency was increased, the permeability values obtained were too low for effective miniaturization of antenna. Mathur et al., using citrate precursor method, synthesized Ni0.49 Zn0.49 Co0.02 Fe2 O4 having complex permeability ~9.1 − j0.51 and permittivity ~4.4 − j0.16 up to 200 MHz only [53] . The value of relative permeability obtained was still low and the ratio of relative permeability to relative permittivity was much less than unity for proper impedance matching. In our research work, we were able to attain very high value of relative permeability and matching with relative permittivity values for effective antenna miniaturization with better impedance matching. The proper stoichiometry and sintering condition results in better performance parameters of the antenna as observed through simulations. Hence, microstrip antenna fabricated using Ni0.5 Zn0.3 Co0.2 In0.4 Fe1.6 O4 ferrite material reduces the physical size of the antenna, and can be effectively utilized in space constraint applications of defense and satellites.

4. Conclusion

Ni0.5 Zn0.3 Co0.2 Inx Fe(2-x) O4 nano ferrite material with x = 0.2 and 0.4 was successfully synthesized to analyze the effect of indium concentration. XRD and SEM characterizations show that the desired nano particles synthesized by a co-precipitation method have spinel structure without any unreacted constituents. XRD confirms the formation of nano sized ferrites with an average crystallite size of 60 nm. Electromagnetic characterization shows that the high and consistent value of permittivity and permeability of 10 and 15.2 can be achieved for x = 0.4. Dielectric and magnetic loss tangent values of the order of 10−2 and 10−1 were also achieved. Low losses can be attributed to better stoichiometry and homogeneous structure. Ferromagnetic resonance for sample 2 was observed at 320 MHz. The miniaturization factor of 12.32 for the sample shows a lot of potential of the reduction of form factor of the antenna. The size of the antenna can be reduced by 68% at frequency around 100 MHz and lower frequencies. This may be effectively used in miniaturization of antenna used for portable deep ground penetration radar that works on frequency around 100 MHz for the identification of bunkers and deep buried targets. Also for sample 2, the characteristic impedance of substrate is closer to characteristic impedance of air, and hence, offers better impedance match with the free space. This results in better efficiency of an antenna. Based on the above detailed discussion and results, the Ni0.5 Zn0.3 Co0.2 In0.4 Fe1.6 O4 material could be a very promising and potential candidate for antenna substrate of microstrip antenna in VHF range, with miniaturized size, and very good impedance matching to the free space.

Acknowledgement

Authors would like to thank Department of Atomic Energy (DAE) , Govt. of India, for financial support vide Sanction No. 2012/34/30/BRNS-1029 .

References

- [1] R.B. Nikodem; New generation solar control coated products; J. Vac. Sci. Technol. A., 10 (1992), pp. 1884–1891

- [2] J.E. Hilland, F.V. Stuhr, A. Freeman, D. Imel, Y. Shen, R.L. Jordan, et al.; Future NASA spaceborne SAR missions; IEEE Aerosp. Electron. Syst. Mag, 13 (1998), pp. 9–16

- [3] S.E. Lyshevski; Nano-, NanoBio- and NanoBioMedical- Technologies: Enabling sensing, communication and processing paradigms; (2012) 12th IEEE Conference on Nanotechnology, 1-2

- [4] M.F.L. De Volder, S.H. Tawfick, R.H. Baughman, A.J. Hart; Carbon nanotubes: present and future commercial applications; Science, 339 (2013), pp. 535–539

- [5] K.M. Krishnan; Biomedical nanomagnetics: a spin through possibilities in imaging, diagnostics, and therapy; IEEE Trans. Magn, 46 (2010), pp. 2523–2558

- [6] T.L. Chang, Y.W. Lee; Applications of magnetic nanoparticles in engineering and biomedical science; 7th IEEE Conference on Nanotechnology (2007), pp. 656–659

- [7] S.E. Lyshevski, K.S. Martirosyan; Ferrite nanoparticles for MEMS technology sensors and actuators; 11th IEEE Conference on Nanotechnology (2011), pp. 1252–1256

- [8] S. Bhattacharya, S. Maity, S.K. Metya, C.T. Bhunia; Performance enhancement of implantable medical antenna using differential feed technique; Eng. Sci. Technol. Int. J. (2015) http://dx.doi.org/10.1016/j.jestch.2015.09.001 In press

- [9] I. Bibyk, R. Romanofsky, E. Wintucky; RF technologies for advancing space communication infrastructure; (2006) IEEE Aero. Conference

- [10] D.A. Grier; The innovation curve [Moores law in semiconductor industry]; Computer, 39 (2006), pp. 8–10

- [11] R.R. Schaller; Moores law: past, present and future; IEEE Spectrum, 34 (1997), pp. 52–59

- [12] R. Bala, A. Marwaha; Investigation of graphene based miniaturized tetra hertz antenna for novel substrate materials; Eng. Sci. Technol. Int. J. (2015) http://dx.doi.org/10.1016/j.jestch.2015.08.004 In press

- [13] C.A. Balanis; Antenna Theory: Analysis and Design; (third ed.)Wiley, India (2011)

- [14] L. Brown; The origins of proximity fuze; Microwave Symp. 2, 425–428 (1998)

- [15] M.A. Kolodny; Radar proximity fuzing and the Cold War paradigm; Microwave Symp. 1-4 (2011)

- [16] R.C. Hansen; Fundamental limitations in antennas; Proc. IEEE., 69 (1982), pp. 170–182

- [17] K.R. Carver, J.W. Mink; Microstrip antenna technology; IEEE Trans. Antennas Propag, 29 (1981), pp. 2–24

- [18] R. Bancroft; Microstrip and Printed Antenna; (second ed.)Scitech Publishing, Inc., Raleigh, NC (2008)

- [19] R. Garg, P. Bhartia, I. Bahl, A. Ittipiboon; Microstrip Antennas Design Handbook; Artech House, Norwood, MA (2001)

- [20] R. Araneo, S. Celozzi; Analysis and design of low-frequency microstrip antennas; IEEE International Symposium Antennas and Propagation Society 4 (2004), pp. 3824–3827

- [21] R.V.S. Ramkrishna, R. Kumar; Design and investigation of microstrip fed open V-shape slot antenna for wide band dual slant polarization; Eng. Sci. Technol. Int. J., 18 (2015), pp. 513–523

- [22] A. Khanna, D.K. Srivastava, J.P. Saini; Bandwidth enhancement of modified square fractal microstrip patch antenna using gap coupling; Eng. Sci. Technol. Int. J., 18 (2015), pp. 286–293

- [23] F. Kuroki, Y. Takigawa, S. Kashihara; Radiation Characteristics of Integrated Traveling-Wave Antenna Etched on Heavily-High Permittivity Substrate for Size Reduction; IEEE Symposium on Radio and Wireless (2007), pp. 169–172

- [24] B. Ghosh, S.M. Haque, D. Mitra; Miniaturization of slot antennas using slit and strip loading; IEEE Trans. Antennas Propag, 59 (2011), pp. 3922–3927

- [25] O.H. Jungsuek, K. Sarabandi; A topology-based miniaturization of circularly polarized patch antennas; IEEE Trans. Antennas Propag, 61 (2013), pp. 1422–1426

- [26] A. An, T. Yoshimasu, K. Yamaoka, S. Kurachi; A Novel Microstrip Meander- Line Antenna With A Very High Relative Permeability Substrate For 315-MHz band applications; 7th International Symposium on Antennas, Propagation and EM Theory, 1–3 (2006)

- [27] L. Byungje, F.J. Harackiewicz; Miniature microstrip antenna with a partially filled high-permittivity substrate; IEEE Trans. Antennas Propag, 50 (2002), pp. 1160–1162

- [28] E. Chang, S.A. Long, W.F. Richards; An experimental investigation of electrically thick rectangular microstrip antenna; IEEE Trans. Antennas Propag, 34 (1986), pp. 767–772

- [29] R.C. Hansen, M. Burke; Antennas with magneto-dielectrics; Microw. Opt. Techno. Lett, 26 (2000), pp. 75–78

- [30] H. Mosallaei, K. Sarabandi; Magneto-dielectrics in electromagnetics: concept and applications; IEEE Trans. Antennas Propag, 52 (2004), pp. 1558–1567

- [31] K. Min, T. Hong; Miniaturization of antenna using magneto-dielectric materials; IEEE Asia-Pacific Conf. Commun., 1–5 (2006)

- [32] P. Mathur, A. Thakur, M. Singh; A study of nano structured Zn-Mn soft spinel ferrites by citrate precursor method; Phys. Scripta, 77 (2008), p. 045701

- [33] S. Chaimool, A. Pinsakul, P. Akkaraekthalin; Patch antenna miniaturization using artificial magneto-dielectric metasubstrate; International Symposium on Antennas and Propagation, 906–909 (2012)

- [34] P.M.T. Ikonen, S.A. Tretyakov; On the advantages of magnetic materials in microstrip antenna miniaturization; Microw. Opt. Technol. Lett, 52 (2008), pp. 3131–3134

- [35] A. Thakur, P. Thakur, J.H. Hsu; Novel magneto-dielectric nanomaterials with matching permeability and permittivity for the very-high-frequency applications; Script. Mater, 64 (2011), pp. 205–208

- [36] A. Thakur, A. Chevalier, J.L. Mattei, P. Queffélec; Low-loss spinel nanoferrite with matching permeability and permittivity in the ultrahigh frequency range; J. Appl. Phys, 108 (2010), pp. 14301–14304

- [37] A.O. Karilainen, P.M.T. Ikonen, C.R. Simovski, S.A. Tretyakov, A.N. Lagarkov, S.A. Maklakov, et al.; Experimental studies on antenna miniaturisation using magneto-dielectric and dielectric materials; IET Microw. Antennas Propag, 5 (2011), pp. 495–502

- [38] A. Goldman; Modern Ferrite Technology; (2nd ed.)Van Nostrand Reinhold, New York (1990)

- [39] J.L. Mattei, L. Huitema, P. Queffelec, J.F. Pintos, P. Minard, A. Sharahia, et al.; Suitability of Ni-Zn ferrites ceramics with controlled porosity as granular substrates for mobile handset miniaturized antennas; IEEE Trans. Magn, 47 (2011), pp. 3720–3723

- [40] A. Saini, K. Rana, A. Thakur, P. Thakur, J.L. Mattei, P. Queffelec; Low loss Composite nano ferrite with matching permittivity and permeability in UHF band; Mater. Res. Bull, 76 (2016), pp. 94–99

- [41] K. Rana, P. Thakur, P. Sharma, M. Tomar, V. Gupta; Improved structural and magnetic properties of cobalt nanoferrites: influence of sintering temperature; Ceram. Int, 41 (2015), pp. 4492–4497

- [42] P. Mathur, A. Thakur, M. Singh; Low temperature synthesis of Mn0.4 Zn0.6 In0.5 Fe1.5 O4 nanoferrite for high-frequency applications ; J. Phys. Chem. Solids, 69 (2008), pp. 187–192

- [43] L.B. Kong, M.L.S. Teo, Z.W. Li, G.Q. Lin, Y.B. Gan; Development of magneto-dielectric materials based on Li-ferrite ceramics; J. Alloy. Compd, 459 (2008), pp. 576–582

- [44] A. Saini, A. Thakur, P. Thakur; Matching permeability and permittivity of Ni0.5 Zn0.3 Co0.2 In0.1 Fe1.9 O4 ferrite for substrate of large bandwidth miniaturized antenna ; J. Mater. Sci (2015) http://dx.doi.org/10.1007/s10854-015-4095-8 In press

- [45] A. Thakur, P. Thakur, J.-H. Hsu; Enhancement in dielectric and magnetic properties of In3+ substituted Ni-Zn nano-ferrites by coprecipitation method ; IEEE Trans. Magn, 47 (2011), pp. 4336–4339

- [46] A. Thakur, P. Thakur, J.-H. Hsu; Magnetic behaviour of Ni0.4 Zn0.6 Co0.1 Fe1.9 O4 spinel nano-ferrite ; J. Appl. Phys, 111 (2012), p. 078305

- [47] S.S. Thakur, A. Pathania, P. Thakur, A. Thakur, J.H. Hsu; Improved structural, electrical and magnetic properties of Mn–Zn–Cd nanoferrites; Ceram. Int, 41 (2015), pp. 5072–5078

- [48] A. Thakur, P. Mathur, M. Singh; Processing of nano-crystallite spinel ferrite prepared by co-precipitation method; Int. J. Mod. Phys. B, 23 (2009), pp. 365–374

- [49] A. Thakur, A. Chevalier, J.-L. Mattei, P. Queffélec; Suitability of Ni-Zn ferrites ceramics with controlled porosity as granular substrates for mobile handset miniaturized antennas; IEEE Trans. Magn, 47 (2011), pp. 3720–3723

- [50] A. Pathania, P. Thakur, A. Sharma, J.H. Hsu, A. Thakur; Investigation of iron deficient and manganese doped Ni-Mg nano-ferroxide ceramics; Ceram. Int, 41 (2015) (2015), pp. 10803–10809

- [51] A. Thakur, P. Mathur, M. Singh; Controlling the properties of Mn-Zn ferrites at high frequency by substituting In3+ and Al3+ ions ; Ind. J. Pure Appl. Phys, 46 (2008), pp. 47–53

- [52] P. Mathur, A. Thakur, M. Singh; Effect of nanoparticles on the magnetic properties of Mn-Zn soft ferrite; J. Magn. Magn. Mater, 320 (2008), pp. 1364–1369

- [53] P. Mathur, A. Thakur, J.H. Lee, M. Singh; Sustained electromagnetic properties of Ni-Zn-Co nano-ferrites for the high frequency applications; Mater. Lett, 64 (2010), pp. 2738–2741

- [54] J. Smit, H.P.J. Wijn; Ferrites; Philips Technical Library, Eindhoven, The Netherlands (1959)

- [55] P. Mathur, A. Thakur, M. Singh; Study of low temperature sintered nano crystalline Mn-Cu-Zn ferrite prepared by co-precipitation method; Mod. Phys. Lett. B, 21 (2007), pp. 1425–1430

- [56] J.L. Snoek; Dispersion and absorption in magnetic ferrites at frequencies above one Mc/s; Physica, 14 (1948), pp. 207–217

- [57] P. Mathur, A. Thakur, M. Singh; Impact of processing and polarization on dielectric behavior of Nix Mn0.4-x Zn0.6 Fe2 O4 spinel ferrites ; Int. J. Mod. Phys. B, 23 (2009), pp. 2523–2533

- [58] C. Niamien, S. Collardey, A. Sharaiha, K. Mahdjoubi; Compact expressions for efficiency and bandwidth of patch antennas over lossy magneto-dielectric materials; IEEE Antennas Wireless Propag. Lett, 10 (2011), pp. 63–66

- [59] A.A. Kishk, L. Shafai; The effects of various parameters of circular microstrip antennas on their radiation efficiency and the mode excitation; IEEE Trans. Antennas Propag, 34 (1986), pp. 969–976

- [60] L.B. Kong, Z.W. Li, G.Q. Lin, Y.B. Gan; Mg1-xCoxFe1.98O4 ceramics with promising magnetodielectric properties for antenna miniaturization; IEEE Trans. Magn, 44 (2008), pp. 559–565

- [61] L.J. Martin, S. Ooi, D. Staiculescu, M.D. Hill, C.P. Wong, M.M. Tentzeris; Effect of permittivity and permeability of a flexible magnetic composite material on the performance and miniaturization capability of planar antennas for RFID and wearable wireless applications; IEEE Trans. Comp. Packaging Technol, 32 (2009), pp. 849–858

Document information

Published on 10/04/17

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?