1 Introduction

To fully exploit the advantages of fiber reinforced plastics, it is essential to combine the appropriate fiber with the best possible matrix material. Next to the conventional matrices, like epoxies (EP) or unsaturated polyesters (UP), polyurethane (PU) materials are constantly gaining importance in the manufacturing of lightweight materials.

Polyurethane materials boast with very high reactivity, tunable processing viscosity and the possibility to construct customized component properties. Due to this, different applications within various industries ranging from building and construction, across transportation, up to renewable energy could be addressed.

Recently, Covestro presented introduced Desmocomp® (awarded with the JEC Innovation Award for the most innovative material at the JEC World composite trade show in March 2017), its new aliphatic PU resin material especially designed for an efficient pultrusion process. Desmocomp® can be used as high performance thermoset matrix material for composite solutions. Its unique performance profile – excellent mechanical properties combined with inherent UV- weathering as well as chemical and flame resistance – opens new opportunities for fiber-reinforced plastics, specifically for the use in exterior applications. Based on that development, Covestro was also able to introduce a bio-based PU system for the pultrusion industry with comparable performance. The following part, shows the challenges as well as the finding of using these PU systems in pultrusion process.

2 Desmocomp® for Pultrusion

The pultrusion process is the only established continuous process for producing continuous fiber reinforced composite profiles. It was developed in the 1960s and is used worldwide in countless applications (infrastructure, consumer goods, automotive). The basic process principle (impregnation of continuous fibers in the open resin bath) and the mainly used materials (such as unsaturated polyester, vinyl ester) have hardly changed since its introduction. Only in the last years, due to increased performance demands on pultruded profiles more efficient resin systems – such as aromatic polyurethanes (PU) and epoxy systems – gain importance in development and in applications. All of these systems require a closed injection and impregnation chamber for processing due to their high reactivity and their short pot lives of a few minutes compared to conventional matrix materials such as UP. It is not possible to process large quantities of these resins in an open impregnation bath. Depending on the complexity of the profiles, resin processing in closed injection and impregnation chambers presents a considerable challenge.

Polyurethanes have numerous advantages, in particular the good mechanical properties and a high process speed within the pultrusion processing. Comparatively new is the processing of aliphatic polyurethanes (Desmocomp®) in pultrusion. In addition to the above stated advantages of polyurethanes, aliphatic polyurethanes have strong UV and weather resistance, very good fire and smoke behavior and high chemical resistance.

Due to the long open pot life (>8h) of the aliphatic PU systems, processing in an open impregnation bath is also possible. The mentioned advantages of the aliphatic PU system led to a promotion of the project PuLaCeLL – “Bio-basierte Polyurethan Verstärkungslamelle mit Cellulosefasern für Holzkonstruktionen – (Bio-based polyurethane reinforcing lamella with cellulose fibers for Wood constructions) (PuLaCell)” by the Bundesministerium für Ernährung und Landwirtschaft (BMEL). The focus is on the large-scale pultrusion processing developed by Covestro Deutschland AG and the Fraunhofer IGCV together with other project partners. The focus is on the production of up to 90% bio-based composites based on an aliphatic bio-based PU matrix and cellulose regenerated fibers as reinforcing fibers.

The composites include high-viscosity bio-based polyurethane formulations (>10 Pa·s). Challenges in this context are the uniform mixing of the high-viscosity components, as well as the undesirable introduction of energy by rotating mixing elements, which lead to a reduction of the critical pot life and the difficult processing of natural fibers with reactive polyurethane formulations. The targeted variables of the development project are the adaptation of the viscosity to enable a uniform and fast impregnation of the fibers. Alternative to this, the pultrusion process must be modified to the extent that a continuous processing is possible. At the same time, the desired characteristic properties of the product such as a glass transition temperature of >100°C and an open working time of the polyurethane formulation at room temperature of >2 h combined with a high reaction rate at process temperature (200 ° C) of <1 min must not be adversely affected.

These requirements could only be met by the further development of the resin system by Covestro and the good cooperation in optimizing the processing procedure on a pultrusion plant on an industrial scale at the Fraunhofer IGCV in Augsburg. All predefined target values could be met. As a result of the processing trials even significant improvements of the material characteristics could be determined.

The second major challenge is the incorporation of cellulose fibers in the PU matrix, for which to the best of our knowledge was no previous knowledge in the literature. Therefore, a variety of bio-based fibers and natural fibers were screened such as flax fibers, hemp fibers or cellulose regenerated fibers. Finally cellulose regenerated fibers were identified as suitable reinforcing fiber for pultrusion of PU systems. The fibers were treated with a suitable sizing for the PU system. All developed fibers were characterized by E-modulus, fiber diameter and the surface roughness of the fiber or the yarn. After measuring the fiber properties, the decision was made to use cellulose regenerated fibers. A big advantage of these fibers is that they are present as endless filament rovings. The challenges presented by these fibers were the impregnation due to their fine filaments and their entrainment into the tool inlet. Process modifications of the impregnation and fiber feed leads to excellent results and finally the project team succeeded in producing efficient, predominantly (>90%) bio-based pultrudates by pultrusion. Due to the long pot life of these PU systems, processing was possible in both the closed impregnation chamber and the open bath. This was very challenging given the higher viscosity resin and the large resin uptake of the fibers.

3 Aliphatic PU Matrix Material

Aliphatic PU systems from Covestro such as Desmocomp® are reacting differently to conventional PU systems.[6] Typical reactions with isocyanates require polyols to form PU and are catalyzed by tin catalysts like Dibutyltin dilaurate. Desmocomp® on the other hand nearly exclusively forms so called polyisocyanurates using simple catalysts like e.g. potassium acetate activated by 18-crown-6.

The properties of these new polyisocyanurates can be easily adjusted by the mixing ratio of a broad variation of isocyanates and isocyanate prepolymers. Depending on the mixture, the mechanical properties and thermal properties can be adjusted to exceed the typical glass transition point of other thermoset materials as depicted in Figure 1.

4 Composite based on Desmocomp®

Due the fact that the petro-based PU system (Desmocomp®) as well as the bio-based PU system from Covestro show comparable results the focus will be only on Desmocomp® based semi-finished part.

As discussed in part 2 Desmocomp® can be also used in general in an open-bath impregnation mode. The curing in the heated die can be performed at die temperatures of up to 250 °C and enables high line speeds depending on the profile geometry.

Desmocomp® based resins and composites show specifically high performance with regard to their bending tensile properties not only in fiber direction but also transversal to that. Compared to other commonly used matrix materials such as unsaturated Polyesters, Vinyl esters or Epoxy, the Desmocomp® composites outperform with regard to their mechanical properties. An example is the high transversal bending strength as shown in Figure 2.

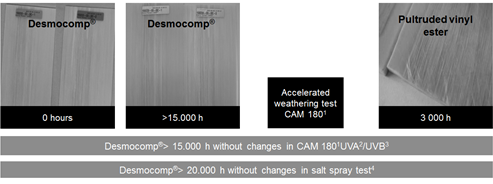

Besides the excellent processing and physical properties which were discussed the aliphatic character of these polyurethanes as matrix material as well as the resulting composites are characterized by their inherent UV weathering resistance (see Figure 3), which makes them especially suitable for outdoor applications. While other commonly used composite materials typically undergo fast degradation in hot humid weathering climate (e.g. Florida) Desmocomp® shows a clearly excellent extent of stability in this regard.

5 Conclusions

Polymer-based composites have established themselves in almost all industries due to their lightweight construction potential. A combination of the new bio-based PU with reinforcing cellulose based fibers leads for the first time to a composite matrix with up to 90% organic content.

Due to the aliphatic character of these aliphatic PU Systems, the resulting composites are characterized by their inherent UV and weather resistance, which makes them especially suitable for outdoor use and saves additional work steps such as an UV protection coating.

The observed high thermal and UV/weathering resistance can be directly attributed to the homogeneous highly crosslinked aliphatic PU network and the careful avoidance of all chemically and thermally “weak” molecular structures.

The new PU system shows a very economical manufacturing process of composites by pultrusion. It was especially designed as a drop-in solution for pultrusion technology using either the injection box or the open-bath impregnation of fibers.

Acknowledgements

We would like to thank Dr. Karsten Danielmeier for reviewing this manuscript and providing valuable input. We also thank the Bundesministerium für Ernährung und Landwirtschaft (BMEL) for funding the PuLaCell project.

References

[1] T. Flipsen, PhD Thesis (2000), University of Groeningen

[2] P. Fabbri et al., Polymer 55 (2014), 488−494.

[3] T. Endo et al., J. Polym. Sci. Part A: Polym Chem. 51 (2013), 2631−2637.

[4] U. Scherf et al., ACS Macro Lett. 4 (2015), 1268−1272.

[5]http://www.jeccomposites.com/events/past-events/jec-world-2017/innovation-awards/winners-profiles.

[6] U. Meier-Westhues et al., Polyurethanes –Coatings, Adhesives and Sealants, 2nd Revised Edition (2019), Vincentz Network, p. 105-109.

Document information

Published on 08/05/22

Accepted on 08/05/22

Submitted on 08/05/22

Volume 03 - Comunicaciones Matcomp17 (2019), Issue Núm. 4 - País invitado: Colombia. Materiales Multifuncionales. Reciclaje y Sostenibilidad, 2022

DOI: 10.23967/r.matcomp.2022.05.007

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?