1. Introduction

With the increase in energy consumption in recent decades and its consequent increase in greenhouse gas emissions into the atmosphere, technological advances that help improve the impact on the carbon footprint are more present every day. The insulation materials have a big impact in the energy used in heating or cooling a building. This study proposes to use stalk, a hemp crop waste as an insulating material due to its properties. It can replace synthetic materials in certain applications and reducing the energy consumption that it would cost to produce these materials. Moreover, use a "carbon storing" material thus obtaining a positive carbon footprint.

At present, applications of stalk are beginning to be given, as is the case with hempcrete [1], which is beginning to be used in buildings in the United States and Canada. It is a non-structural material for construction with good insulating properties. This study proposes to use hemp in the same way but using 100% green materials. Getting to manufacture insulating panels that are easy to transport, place and environment-friendly.

With this in mind, scientific advances have been made that help to better understand the insulating properties of biomaterials such as the project carried out by Zhu et. al. [2], which highlights progress in sound transmission properties of bio-based materials, such as porosity and structured multilayers. Due to the great insulation properties of the hemp particles Glé et. al. [3] shown that the basic parameters can be directly used to model the acoustical properties of the mixes, then that acoustical data can be very useful to characterize the shape and microstructure of these hemp aggregates.

In addition, studies are being carried out to use bio-materials in the manufacture of insulating materials. According to EN 601, a thermal insulating material requires a thermal conductivity coefficient lower than 0.1 W/m K. Wei et. al. [4] produce a thermal insulation material based in rice straw, with a low thermal conductivity ( 0.051-0.053 W/m K). Liu et. al. [5] studied the physical properties and thermal insulation of a material base in wheat straw and geopolymer producing a material with a thermal conductivity of 0.101 W/m K. Corn stalk is also a crop waste that can be used for insulation materials mixing it with epoxy resin to obtain a thermal and acoustic insulating material [6]. Canto et. al. [7] produce a material combining rice husk with cassava starch with a thermal conductivity of 0.026 W/m K.

With all these studies, it is clear that it is possible to use materials that are currently considered crop waste to manufacture insulators. Furthermore, this study has as an initiative to manufacture a material 100% vegetable for these applications

2. Materials and methods

In order to face the experimental campaign some samples of the insulating material were produced according to the next conditions.

2.1 Stalk

Stalk is the woody part of the plant's trunk. Currently it is crop waste and it represent more than 50% of the total weight of the plant, for that reason the study proposes to use it in insulation applications due to its properties. It was provided by the company Planteles Lloveras.

2.2 Eucalyptus pulp

The paper fiber is a lignin-based material. It was used as a binder for the stalk. The ECF (elementary chlorine free) bleached eucalyptus kraft pulp was provided by the company ENCE. By being two materials of plant origin and with very similar compositions, hydrogen bonding bonds would appear more easily and facilitate the connection between the two components to obtain the new biomaterial.

2.3 Carboard fiber

Cardboard fiber is a more resistant and longer fiber than paper that is also not bleached. The bleaching process degrades the mechanical properties of paper fiber. Cardboard from packing boxes was used. Disintegration process was carried out to obtain the pulp.

Initially, eucalyptus pulp is used to check the compatibility of stalk with paper fiber using a commercial material. But once a good compatibility has been obtained, the goal is to use recycled paper fiber to obtain a plant material that is also produced entirely from waste.

2.4 Coating

The main problem with this material is its resistance to contact with water and moisture. In contact with water, the material disintegrates, so it is necessary to add a protection.

In this case, it is proposed to add a superficial vegetal coating that protects the interior of the material from moisture. To apply the resin as a coating, the gum arabic is dissolved in water with a proportion of 1g of colophony for every 2g of water. While colophony dissolves in acetone with the same ratio.

Gum arabic and colophony are used for the coating, carrying out a partial submersion test in water for 10 minutes. The results obtained were the following:

The uncoated material takes 3 minutes to disintegrate on contact with water. In the case of gum arabic, after 10 minutes the specimen was moist inside and doubled in weight due to absorbed water. Gum arabic dissolves in water so that in direct contact the surface layer is lost and over time the sample will disintegrate. In the case of colophony, after 10 minutes the sample increased its weight by 5% and the inner part remained dry, moisture is absorbed in the surface layer, obtaining a good coating. In addition, another sample was made with a duration of 90 days submerged in water, obtaining the same results.

However, a disintegration of the material due to contact with water has an advantage. Once the material has deteriorated, broken or exceeded its lifespan it can be disintegrated with water to obtain the raw material and be manufactured again.

For this study, the 2 proposed materials will be studied due to their great recycling potential, in the case of colophony, applying a mechanical process that removes the superficial part, the interior zone can be reused as raw material to manufacture the material again.

While in the case of gum arabic it can be completely reused by separating the coating using water. Although it is not a good coating in direct contact with water, it does protect the material from moisture, so it can be use depending on the applications.

2.5 Fabrication method

The manufacturing process used in all samples is as follows:

First, the stalk is soaked for 1 day to moisten it, in this way the subsequent union with the paste is improved and the density is increased. The increase in density favours the homogeneity of the material since, due to the manufacturing process used, if the stalk floats, it would all remain on top of the material. The fiber to be used (recycled cardboard or kraft pulp) is disintegrated in distilled water. And it is mixed with the wet hemp according to the proportion of the sample, taking into account the dry weights of both materials.

Once it has been mixed, the excess water is removed by introducing the mixture into a laboratory sheet former that follows the Rapid-Köthen method. In this way, vacuum is applied in the lower area. Cylindrical specimens of 20 cm in diameter are obtained, the thickness being able to vary according to the amount of material used. 180 g of dry material is used to produce a 5 cm thick sample.

After forming the sample, it is left to dry in the open air for 24h and then placed in an oven at 50ºC for 48h to dry the sample completely. When it is dry, the coating is applied, if necessary, with a brush applying 40g of resin and it is left to cure for 48 hours in ambient conditions. Once the sample has been completed, they are left in a room conditioned at 23 ºC and 50% humidity until the corresponding test is carried out.

Nomenclature structure of the samples:

| %wt of Stalk | %wt of kraft pulp | %wt of carboard fiber | Coating |

| 70S | 30ECF | 30C | Without |

| 60S | 40ECF | 40C | C (Colophony) |

| 50S | 50ECF | 50C | GA (Gum Arabic) |

| 30S | 70ECF | 70C | - |

2.6 Test methods

The tests carried out correspond to the study of its acoustic and thermal insulation properties, in addition to its mechanical behaviour under compression and shear. The following normative tests have been carried out:

- Acoustic Insulation. EN 10534.

- Thermal Insulation. EN 12664.

- Compression. EN 826.

- Shear. EN 12236.

All the tests correspond to insulating materials except the shear test, which has been adapted to be used.

3. Discussion

3.1 Acoustic Insulation

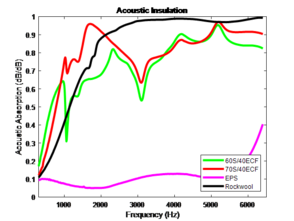

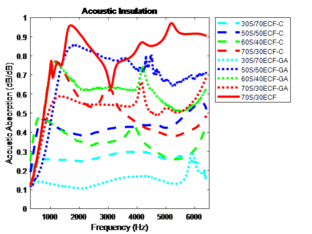

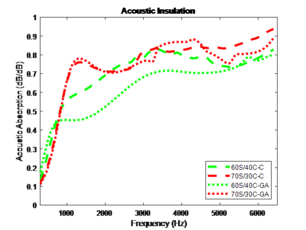

To calculate the acoustic insulation of the material, a Kundt tube is used to calculate the absorption of sound waves in a range of 0 to 6500 Hz and compare it with other synthetic commercial materials.

From the stalk-kraft samples with a composition of 60 and 70% stalk, Figure 3, it is obtained that for low frequencies greater absorption is obtained than rock wool, from 2000 Hz it decreases although the material is in an acceptable range (greater than 0.7) to be used as acoustic insulation.

When adding the coating, it can be seen that the acoustic absorption coefficient is reduced, Figure 3. This is due to the fact that when the resin cures on the surface of the material, it crystallizes and the sound waves bounce off the material, reducing the absorption of the waves.

On the other hand, in both figures it can be verified that the absorption coefficient increases when the percentage of stalk in the samples increases, due to the acoustic properties of hemp and the increased porosity of the material. Furthermore, the coating of gum arabic have an acoustic absorption coefficient up to 20% better than colophony.

When coating the material with colophony, values below 0.6 were obtained, for that reason it would not be a good acoustic use; however, in the case of gum arabic, values above 0.7 were obtained, taking into account that it will not have direct contact with water it is possible to use this type of coating.

By using recycled cardboard fiber, the absorption coefficient is higher, Figure 4. In this case it is possible to manufacture an acoustically insulating material with 100% recycled material.

Although the coating worsens the acoustic insulation properties of the material, it is necessary to add it to prevent the degradation that would be produced by humidity in construction applications that would end up disintegrating the material.

3.2 Thermal Insulation

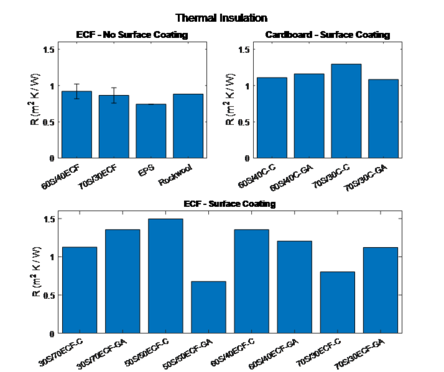

Regarding thermal insulation, a square test piece is placed in a thermal chamber in order to measure the temperature difference between the 2 surfaces using 2 K-type thermocouples as sensors.

In this case, higher values are obtained than conventional commercial materials. Adding the coating improves the values. Despite the fact that the cardboard fiber is slightly decreased, its value is still 30% than rock wool, obtaining the best case with the sample of 70% stalk and colophony coating, Figure 5.

The best cardboard-sample 70D/30C-C have a thermal conductivity coefficient of 0.025 W/m K improving the results shown in the literature [4]–[7].

3.3 Compression test

Once the insulating capacities of the material were verified, mechanical resistance tests were carried out with the aim of validating whether it complies with the regulatory requirements. In this case, the values will be compared with the EPS so that the material is resistant enough not to be damaged during transport or placement of the panels.

The first case was a compression test, where the material (10x10x5 cm) is compressed between two metal plates, calculating the resistance up to 10% compression as indicated by the regulations. EPS has a compressive strength of 0.5 MPa, so in the first case with uncoated Kraft pulp these values are exceeded, Table 2.

By adding the cardboard fiber, despite being a more resistant fiber, the compressive strength is reduced, Table 2. When applying the coating the surface area of the specimen is moistened, softening the bonds of the material that are more present in a test or until the 10% compression. This also increases the variation between the different samples.

However, the best cases remain in the EPS range. For future samples it will be necessary to study the effect of curing speed.

3.4 Shear Test

In the cut test, a static puncture test is performed to compare it with the EPS in this case it has a value of 30kPa.

This test is the main reason to use recycled cardboard instead of recycled paper in the material made from 100% waste, since its initial shear strength is much lower than EPS and it could also have low flexural strength, so it was decided to use cardboard fiber. Recycled cardboard mechanically more resistant and treated with longer fibers than paper.

In the cardboard samples it is noticed a drastic increase in resistance, being 3 times greater and exceeding the resistance of EPS, Table 2.

A material that meets the mechanical resistance requirements has been obtained using the 70% stalk composition, and is also a good thermal and acoustic insulation, using the 2 different coating.

| Sample | Compression test | Shear test | ||

| Young Modulus (MPa) | (C.V.) | Young Modulus (kPa) | (C.V.) | |

| 60S/40ECF | 0.678 (45%) | 13.0 (51%) | ||

| 70S/30ECF | 0.856 (18%) | 12.2 (45%) | ||

| 60S/40C-C | 0.221 (7%) | 30.4 (4%) | ||

| 70S/30C-C | 0.726 (43%) | 30.2 (13%) | ||

| 60S/40C-GA | 0.541 (42%) | 30.2 (17%) | ||

| 70S/30C-GA | 0.239 (55%) | 39.0 (-) | ||

4. Conclusion

In this work, and experimental research was conducted to investigate an insulating hemp-based bio-material using stalk, eucalyptus pulp, recycled cardboard fiber and 2 different vegetal coatings (colophony and gum arabic). According the achieved results:

- At least 30% by weight of fibrous material based on cellulose is needed to hold the stalk particles together, in this way a consistent material is obtained that does not come off when handled.

- The proposed insulating material is a hemp-based material composed of the following materials: 70% by weight of stalk and 30% by weight of recycled cardboard fiber, which is added a surface coating that can be colophony or gum arabic according to the application.

- It necessary to use a coating to protect the material against moisture. Gum arabic provides protection against moisture. Colophony protects against direct contact with water for a long period of time. Once the material is damaged, it can be disintegrated with water and reused as a raw material, obtaining great recycling and increasing the useful life of the materials and a circular economy.

- The final material obtained has a high coefficient of acoustic insulation 0.8, although it is 10% lower than commercial materials. The proposed vegetable coatings reduce the acoustic insulation properties of the material.

- In the case of thermal insulation, the proposed material is between 20 and 30% higher than conventional commercial synthetic materials. Obtaining a material with thermal conductivity coefficient of 0.025 W/m K.

- The proposed material meets the mechanical resistance requirements necessary to be used as an insulating panel in construction. Reaching compressive and shear strength values higher than EPS.

5. References

[1] U. Dhakal, U. Berardi, M. Gorgolewski, and R. Richman, “Hygrothermal performance of hempcrete for Ontario (Canada) buildings,” J. Clean. Prod., vol. 142, pp. 3655–3664, 2017, doi: 10.1016/j.jclepro.2016.10.102.

[2] X. Zhu, B. J. Kim, Q. W. Wang, and Q. Wu, “Recent advances in the sound insulation properties of bio-based materials,” BioResources, vol. 9, no. 1. 2014, doi: 10.15376/biores.9.1.1764-1786.

[3] P. Glé, E. Gourdon, and L. Arnaud, “Modelling of the acoustical properties of hemp particles,” Constr. Build. Mater., vol. 37, pp. 801–811, 2012, doi: 10.1016/j.conbuildmat.2012.06.008.

[4] K. Wei, C. Lv, M. Chen, X. Zhou, Z. Dai, and D. Shen, “Development and performance evaluation of a new thermal insulation material from rice straw using high frequency hot-pressing,” Energy Build., vol. 87, pp. 116–122, 2015, doi: 10.1016/j.enbuild.2014.11.026.

[5] L. Liu et al., “Experimental physical properties of an eco-friendly bio-insulation material based on wheat straw for buildings,” Energy Build., vol. 201, pp. 19–36, 2019, doi: 10.1016/j.enbuild.2019.07.037.

[6] H. Binici, O. Aksogan, and C. Demirhan, “Mechanical, thermal and acoustical characterizations of an insulation composite made of bio-based materials,” Sustain. Cities Soc., vol. 20, pp. 17–26, 2016, doi: 10.1016/j.scs.2015.09.004.

[7] A. Canto, M. Batista, J. Sanchez, M. Moreno, and A. James, “Aislante térmico a base de materiales orgánicos,” Rev. Iniciación Científica, vol. 4, pp. 48–51, 2018, doi: 10.33412/rev-ric.v4.0.1819.

Document information

Published on 18/07/22

Accepted on 20/06/22

Submitted on 09/06/22

Volume 07 - COMUNICACIONES MATCOMP21 (2022), Issue Núm. 1 - Sostenibilidad y reciclaje - Fabricación, 2022

DOI: 10.23967/r.matcomp.2022.07.045

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?