1 Introduction

Regulatory constraints and the increase in the environmental awareness make the automotive industry take different strategies to reduce greenhouse gas emissions and air pollutants, such as electric and hybrid-drive technologies, efficiency improvements in the conventional internal combustion engines, alternative fuels and lightweight construction.

It has been estimated that saving 100 kg in the bodywork cuts CO2 emissions by 10 g CO2/km [1], so current trends focus on replacing conventional materials with lighter ones. Nowadays, plastic materials represent around 18% of the overall vehicle weight and its use in automotive is expected only to grow [2]. Therefore, foaming injection molding techniques arises as a promising method to reduce weight in plastic components.

The present work deals with the characterization of microcellular thermoplastic composites obtained by injection molding, as a preliminary approach towards lighter, cheaper and more environmentally friendly automotive interior parts. The effect of mold cavity expansion through the Core Back tool technology on the foaming behavior was studied. Moreover, a comparison between MuCell® and IQ Foam® foaming injection molding technologies is presented, in terms of morphology and tensile, flexural and impact properties of microcellular parts resulted from both processes.

2 Foaming injection molding

Among the different technologies for foaming through injection molding developed, this study focuses on MuCell® and IQ Foam® processes, whose operating principles are as follows:

2.1 MuCell®

The microcellular injection molding MuCell® process was developed by the Massachusetts Institute Technology (MIT) in the 1990s and since then it is licensed and commercialized by Trexel Inc (USA) [3]. The fundamentals of MuCell® technology consist basically of dissolving the blowing agent under supercritical conditions (SCF) in the molten polymer at the plasticizing unit, forming a single-phase solution. The pressure drops inducing cell nucleation and growth occurs at the entrance of the mold, so foaming takes place inside the mold cavity.

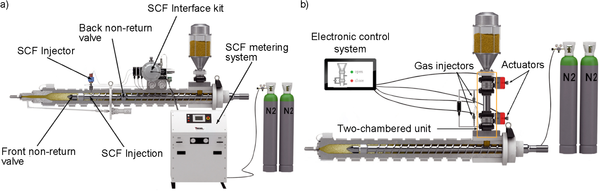

The advantages offered by MuCell® include weight reduction, improved dimensional stability, energy and clamping force decrease and cycle time shortening [4]. However, there are few limitations, like worse surface quality and deterioration of mechanical properties. Additionally, as illustrated in Figure 1a), applying MuCell® involves new equipment and modifications in reference to conventional injection molding. Specifically, a SCF metering unit, a special and longer reciprocating screw as well as back and front check valves are required. Regarding control of the process, additional variables, like the Microcellular Plasticizing Pressure (MPP) and the opening and closing of the gas injectors, must be regulated.

2.2 IQ Foam®

IQ Foam® has been recently developed and it is expected to be integrated in industrial production in forthcoming years. It was conceived by Volkswagen AG (Germany) with the aim of reducing complexity and cost as compared to other available processes. The main equipment consists of a two-chambered unit assembled between the hopper and the feed of any conventional injection molding machine (Figure 1b)), where polymer is impregnated with gas before melting. This unit was patented in 2014 [6] and contains two gas injectors to introduce the physical blowing agent, valves to regulate the flow of gas and two actuators to allow polymer pellets to pass through the unit and to lock each chamber. IQ Foam® incorporates the gas at the feeding area of the plasticizing unit together with the polymer in pellets form. It is worth to notice that gas is supplied under moderate-low pressure [7] directly from the bottle, without requiring gas-metering equipment. The only important modification of the injection machine is sealing the back of the screw to avoid gas escaping.

On the other hand, the foaming process can be controlled only by the gas pressure, so it can be easily automated and driven by an electronic system managing actuators and gas injectors regardless the original software control of the injection molding machine.

Consequently, IQ Foam® arises as a potentially cost-effective and machine-independent process, easy to start up and reducing both weight and cost of plastic products significantly.

2.3 Core Back®

The Core Back Expansion Molding is a complementary tool technology able to improve surface quality, but also increase density reduction, stiffness-to-weight ratio and save weight in foamed thermoplastic parts. First, the cavity is volumetrically filled close to solid weight by polymer/gas mixture. The cavity is filled at high injection speed, so as to prevent pressure drop and foaming. After a delay time within which a solid skin is formed, the cavity is expanded and the increase in volume induces a sudden pressure drop, promoting foam generation inside the part [8]. As the thickness increases, lower densities are reached. The entire cavity can be expanded, or only partially in determined areas of interest.

3 Materials and methods

3.1 Material and injection molding

A 20% chemically coupled high performance Glass Fiber reinforced Polypropylene compound (PP 20GF Fibremod™ GE277Al) supplied by Borealis AG (Germany) was used. It has a density of 1.04 g/cm3 (ISO 1183) and a melt flow index of 12 g/10 min (ISO 1133).

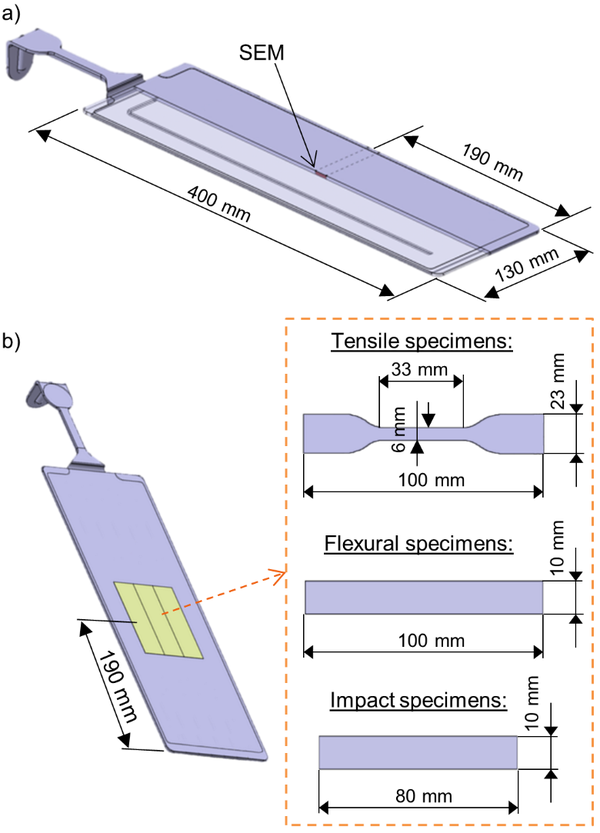

The PP 20GF compound was pre-dried at 80 ºC for a minimum of 3 hours, as recommended by the supplier. Rectangular plates of 400x130 mm2 (Figure 2) and variable thickness were injection molded through MuCell® and IQ Foam® processes, combined with the Core Back technology. First, solid and foamed 3 mm-thick plates were obtained, reducing the weight by 10% as compared to the unfoamed part. Then, two series of foamed samples combined with the Core back technology were injection molded, with an enlargement of the cavity from a basic wall thickness of 3 mm up to 3.3 mm and 3.7 mm.

The solid and MuCell® foamed plates were obtained in an Arburg 570C Allrounder 2000-675 injection machine with a clamping force of 2000 kN (Arburg GmbH, Germany), whereas the IQ Foam® foamed plates were injection molded using a KraussMaffei 200-1000/390/CZ Multinject injection molding machine (KraussMaffei Group GmbH, Germany) with 2000 kN of clamping force and equipped with the IQ Foam® foaming devices. In order to make a direct comparison, the same injection molding parameters were employed to produce all samples: melt temperature profile of 40-210-230-240 ºC from hopper to nozzle, injection speed of 100 cm3/s, mold temperature of 30 ºC and cooling time of 45 s. The shot volume for solid plates was 190 cm3, with a holding pressure of 300 bar applied for 10 s, whereas foamed samples were injected at 165 cm3 of shot volume, and using nitrogen as blowing agent. A 0.5% content of gas was introduced at 34 bar of pressure during MuCell® processing. As the IQ Foam® equipment is only controlled by the gas pressure, which was 25 bar, the amount of gas introduced was not measured.

3.2 Characterization methods

3.2.1 Morphology and apparent density

After the injection procedure, the apparent density of the plates was calculated by weighing and measuring their volume. The morphology of the foamed specimens was analyzed at 10 mm-width cross sections taken at middle distance from the injection gate in the melt direction (MD) (Figure 2a)). Fracture surfaces resulting from cryogenic fracture were examined by Scanning Electron Microscopy (SEM) using a JEOL JSM-560 microscope (Jeol Ltd., Japan). Micrographs were adjusted for an appropriate level of contrast and morphological parameters, such as cell size, cell density and skin thickness were determined with the aid of Igor Pro® (Wavemetrics Inc., USA) and Matlab® (The MathWorks Inc., USA) software.

Computed Tomography technique was employed to analyse the fiber orientation and distribution. Samples were scanned with a micro-computerized tomography MultiTom Core system, (XRE bvba, Belgium), at tube conditions of 90kV and 10W, for a total of 2500 projections and an exposure time of 400 ms.

The content of glass fiber reinforcement was carried out by the determination of ash through the direct calcination method, following the guidelines set by the ISO 3451-1 standard.

3.2.2 Mechanical properties

The specimens for mechanical tests were machined out of the rectangular plates according to the schemes shown in Figure 2b). At least five samples of solid and foamed materials were tested under room temperature.Tensile tests were carried out on a universal testing machine Zwick/Roell Z010 (Zwick GmbH & Co. KG, Germany) using a 10 kN load cell, at a crosshead speed of 50 mm/min and an initial distance between clamps of 72 mm, as indicated in the ISO 527 standard.

Flexural tests were conducted following the ISO 178 standard, on a Galdabini Sun 2500 (Galdabini SPA, Italy) testing machine equipped with a 5 kN load cell, at a crosshead speed of 10 mm/min and a span length of 80 mm

Charpy impact tests were made on unnotched samples in flatwise configuration, using an instrumented Ceast Resil impactor (Instron Ltd., UK) equipped with a 15J hammer. The pendulum had a length of 0.374 m and a reduced mass of 3.654 kg. It was impacted at an angle of 99º, resulting in an impact rate of 2.91 m/s. The span length was 62 mm, and tests were performed according to the recommendations given by ISO 179-2 standard.

4 Results and discussion

4.1 Morphology and apparent density

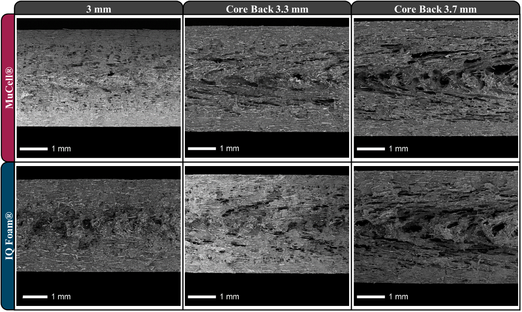

SEM micrographs taken from MuCell® and IQ Foam® microcellular samples are plotted on Figure 3. All samples exhibited a material structure consisting of a solid external layers and a foamed core, which is inherent to the injection molding process. It has been reported that foaming PP is very difficult because of its low melt strength and crystalline regions [9]. However, SEM pictures exhibit uniform cell structure, because of fibers acting as cell nucleation agents (heterogenous nucleation [10]). undissolved gas trapped at the filled/polymer interface promotes the occurrence of multitude of sites for cell formation requiring much lower activation energy for bubble nucleation, accelerating cell nucleation and the development of a large number of cells with small cell size. Moreover, the added fillers increase melt strength of the material [11], contributing to prevent cell coalescence and improving its foaming behavior.

The morphological parameters and apparent density results are contained in Table 1. The apparent density of the solid plates ranged around 1.04 ± 0.01 g/cm3. By foaming, it was decreased by 10% without using Core Back technology. As the final thickness and overall volume increased by mold opening, the apparent density decreased up to 14% and 21% for the final thickness of 3.3 mm and 3.7 mm respectively.

Mostly spherical cells can be observed at the starting thickness of 3 mm without enlarging the cavity thickness. In the Core Back method, the cavity was volumetrically filled with the polymer/gas system, then the thickness of the mold cavity was quickly increased up to 3.3 mm and 3.7 mm reducing the pressure and thus, enhancing cell nucleation [8]. Stretching forces caused by the mold opening could cause cell elongation and distortion, also accompanied by shrinkage of cell walls while polymer cooling, resulting in higher diameters [12]. As the thickness increased, the core region remained at the molten state for a longer time, leading to thinner solid skin layers.

Regarding the comparison between MuCell® and IQ Foam® injected parts, well defined and uniform cell structures can be observed from the micrographs of Figure 3, which indicate that microcellular reinforced thermoplastics can be successfully developed by both foaming technologies. Slightly thicker solid skins of IQ Foam® without Core Back expansion were determined from Table 1. Despite the cell density measured in all samples was in the order of 105 cells/cm3, those obtained by IQ Foam® process were slightly lower. Since the same injection molding parameters were employed for processing with both methods, differences in the amount of blowing agent used for each foaming process arises as the main reason for these morphological differences.

Contrary to MuCell® technology, the gas in IQ Foam® process was incorporated into the polymer in pellets form. The key parameter controlling the process was the gas pressure, so the gas content injected into the polymer was not measured and cannot be directly compared.

| Condition | Density

(g/cm3) |

Skin thickness

(mm) |

Cell density

(cells/cm3) |

Cell size

(µm) |

| MuCell® 3 mm | 0.94 ± 0.01 | 0.41 | 7.1·105 | 9 - 165 |

| MuCell® / Core Back 3.3 mm | 0.90 ± 0.01 | 0.46 | 8.4·105 | 9 - 263 |

| MuCell® / Core Back 3.7 mm | 0.82 ± 0.01 | 0.41 | 6.1·105 | 4 - 286 |

| IQ Foam® 3 mm | 0.94 ± 0.01 | 0.70 | 4.4·105 | 6 - 195 |

| IQ Foam® / Core Back 3.3 mm | 0.90 ± 0.01 | 0.41 | 4.5·105 | 4 - 234 |

| IQ Foam® / Core Back 3.7 mm | 0.82 ± 0.01 | 0.40 | 5.5·105 | 3 - 276 |

Nevertheless, a lower amount of blowing agent in the IQ Foam® molded parts is expected due to the low solubility of the gas in the solid pellets, which would explain the increased solid layer determined in the 3 mm-thick specimens, as well as the decrease in cell density. However, no differences in cell size between both processing technologies were reported.

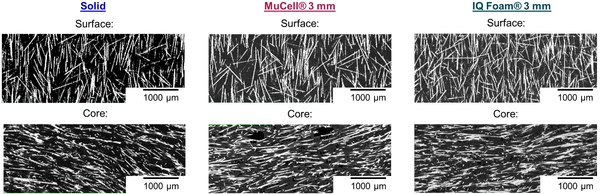

Another important morphological feature of fiber-filled composites is the orientation and distribution of the fibers. According to the analysis carried out by Computed Tomography, fibers in the surface layer remain oriented in the direction of filling, while they appear aligned in the transversal direction in the core. The same pattern is observed in all samples, regardless the process of injection molding and foaming from which were produced.

Of particular interest could be the analysis of fiber length from the comparison between both foaming technologies. As described above, MuCell® equipment requires a special design of the screw for optimizing the polymer/gas mixture. Increased shear stresses in this zone could result in higher fiber breakage. Contrarily, the blowing agent in IQ Foam® process is introduced in the feeding region of a conventional injection machine, which means that fibers are no longer subject to additional shear efforts. Nevertheless, measurements of fiber length provided values contained in the range of 748 ± 174 µm for all solid, MuCell® and IQ Foam® derived samples, which suggests that special machinery designed for MuCell® did not affect fiber length in case of short fiber reinforced thermoplastics. Fiber content remained in all specimens in the range of 20.1 ± 0.2 %.

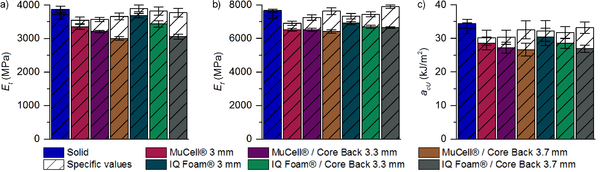

4.2 Mechanical properties

The mechanical properties obtained from tensile, flexural and impact tests are plotted on Figure 5. It is clearly observed that foamed samples showed lower properties than the solid counterparts, because cells in the core effectively led to a decrease in density and in the effective cross-sectional area. With increasing density reduction by Core Back expansion, the reduction of both tensile and flexural modulus was nearly linear, as indicated by the closed specific values to those of solid specimens. Impact resistance decreased by around 15% when foaming without core expansion, and by 22% and 35% while increasing the thickness to 3.3 mm and 3.7 mm, respectively. That is, foamed material is more sensitive to impact loads than to tension and bending.

In reference to the comparison between foaming technologies, tensile and flexural modulus as well as impact resistance of samples obtained by IQ Foam® process were higher and differed from the corresponding ones to MuCell® in approximately 10%. The thicker solid skins seems to be the most likely reason for this results. On the basis of the lower blowing agent incorporated in the IQ Foam® plates, the consequent reduction in cell density led to wider cell struts and higher effective bearing area able to withstand higher mechanical loads. These differences between foamed samples through both processes were lowered when Core Back was applied and the volume cavity was increased, which suggests that, as the part gets thicker, the mechanical properties became more dependent on apparent density and the overall thickness than upon skin thickness and cell density.

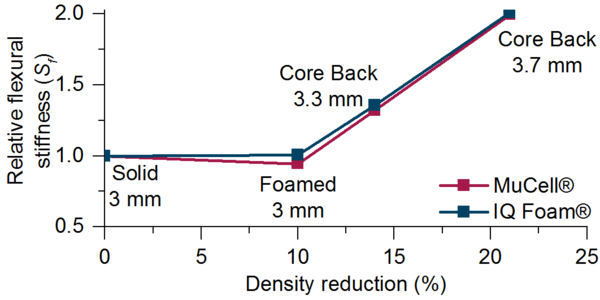

Most of the works dealing with Core Back expansion molding process focuses on the flexural properties of the resulted foams [15]. For engineering purposes, design criteria is based on the flexural stiffness rather than on the flexural modulus. This parameter involves the geometry of the part by means of the moment of inertia. For flat panel geometries, the flexural stiffness (Sf) is calculated as follows:

|

|

(1) |

Where I is the moment of inertia, Ef is the flexural modulus and b and h the part width and thickness, respectively. Thus, flexural stiffness is significantly increased by the third power of the thickness. Figure 6 illustrates the evolution of the relative, flexural strength by foaming and increasing thickness with Core Back technology. It should be noted that despite the drop in flexural modulus, the stiffness was improved up to 200% as compared to that of the solid counterpart by increasing the thickness to 3.7 mm.

5 Conclusions

In this work the morphology and mechanical properties of PP 20GF foams obtained through injection molding techniques and combined with tool technologies were analyzed. By pulling the core and increasing the final thickness of the part with the Core Back tool process, the apparent density decreased, solid skins got thinner but cells became bigger. Absolute mechanical properties decreased with the apparent density but specific ones remained close to that of the solid material. Furthermore, design criteria parameters such as the bending stiffness were greatly enhanced due to the build-up in the overall thickness.

On the other hand, a new foaming technology, called IQ Foam® and developed by Volkswagen AG, was employed in this work and compared to the already well-known MuCell® process. By using a minimum amount of blowing agent, foamed plastic parts obtained through IQ Foam® exhibited thicker solid skins and lower cell densities, but consequently higher mechanical properties. Additional benefits such as cost-effectiveness, easy-operation and machine-independence enable IQ Foam® to produce lightweight parts with comparable properties to that of the MuCell® technology.

Acknowledgements

The authors are grateful to the Research Lab of Covestro AG (Leverkusen, Germany) and the Institut für Recycling of the Ostfalia Hochschule (Wolfsburg, Germany) for their cooperation with the injection molding experiments, as well as to the Ministerio de Economía y Competitividad from Spain for the MAT2013-40730P and MAT2016-80045R projects.

References

[1] Automotive The world moves with plastics, Plastics Europe (2013).

[2] Plastics The future for automakers and chemical companies, A.T. Kearny Inc (2012).

[3] EU-P 0952908.

[4] J. Xu, Microcellular Injection Molding. Hoboken: John Wiley & Sons (2010).

[5] http://www.plasticportal.eu/en/thermoplastic-foam-injection-molding/c/2416.

[6] DE-P 102014212048.

[7] J. Hain, Thermoplastschaum-Spritzguss - neue Möglichkeiten durch IQ-Foam, Kunstofftrends im Automobil, Wolfsburg (2015).

[8] H.P. Heim and M. Tromm, Polymer 56, pág. 111-118 (2015).

[9] A.K. Bledzki, O. Faruk, H. Kirschling, J. Kühn and A. Jaszkiewicz, Polimery-W 52, pág. 3-12 (2007).

[10] J.S. Colton and N.P. Suh, Polymer Engineering and Science 27, pág. 485-492 (1987).

[11] J. Mueller, J.A. Spoerrer and V. Altstaedt, AIP Conference Proceedings 1593, pág. 367-373 (2014).

[12] H.P. Heim and M. Tromm, Journal of Cellular Plastics 52, pág. 299-319 (2016).

[13] K.S. Kumar, N. Bhatnagar and A.K. Ghosh, Journal of Reinforced Plastics and Composites 26, pág. 239-249 (2007).

[14] J.L. Thomason, M.A. Vlug, G. Schipper and H. Krikor, Composites Part A-Applied Science and Manufacturing 27, pág. 1075-1084 (1996).

[15] A.N.J. Spörrer and V. Altstädt, Journal of Cellular Plastics 43, pág. 313-330 (2007).

Document information

Published on 29/04/18

Accepted on 29/04/18

Submitted on 29/04/18

Volume 02 - Comunicaciones Matcomp17 (2018), Issue Num. 2 - Aplicaciones y compuestos multifuncionales, 2018

DOI: 10.23967/r.matcomp.2018.04.007

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?