ABSTRACT

The traveling wave reactor (TWR) is a once-through reactor that uses in situ breeding to greatly reduce the need for enrichment and reprocessing. Breeding converts incoming subcritical reload fuel into new critical fuel, allowing a breed-burn wave to propagate. The concept works on the basis that breed-burn waves and the fuel move relative to one another. Thus either the fuel or the waves may move relative to the stationary observer. The most practical embodiments of the TWR involve moving the fuel while keeping the nuclear reactions in one place−sometimes referred to as the standing wave reactor (SWR). TWRs can operate with uranium reload fuels including totally depleted uranium, natural uranium, and low-enriched fuel (e.g., 5.5% 235 U and below), which ordinarily would not be critical in a fast spectrum. Spent light water reactor (LWR) fuel may also serve as TWR reload fuel. In each of these cases, very efficient fuel usage and significant reduction of waste volumes are achieved without the need for reprocessing. The ultimate advantages of the TWR are realized when the reload fuel is depleted uranium, where after the startup period, no enrichment facilities are needed to sustain the first reactor and a chain of successor reactors. TerraPowers conceptual and engineering design and associated technology development activities have been underway since late 2006, with over 50 institutions working in a highly coordinated effort to place the first unit in operation by 2026. This paper summarizes the TWR technology: its development program, its progress, and an analysis of its social and economic benefits.

Keywords

Nuclear energy ; Electricity generation ; Advanced reactor ; Traveling wave reactor ; Sustainability

1. Introduction

The beginnings of TerraPower and its nuclear innovations are found in the deliberations between Bill Gates, Nathan Myhrvold, Lowell Wood, and experts during 2006 brainstorming sessions in Bellevue, Washington. The central focus of the discussions was how to provide sustainable, scalable low-carbon energy for all the earths inhabitants. All forms of energy production were considered, including broad classes of solar and wind. Though these and other technologies were perceived as very important, it became clear that nuclear is the only known technology that can play the needed central role in providing base load power in an environmentally acceptable manner and on any type of relevant time scale.

The group also concluded that nuclear power could realize significant improvements by rigorous applications of 21st century technologies, data, and modeling capabilities. Nuclear powers unique potential and its perceived need for improvements are consistent with the recently published conclusions of the global Ecomodernist group† .

A small group, which eventually became TerraPower LLC, started organized activities in early 2007. The objective was to make improvements in as many areas of the nuclear enterprise as possible: safety, waste, efficiency, economics, weapons-proliferation resistance, terrorist-risk reduction, and overall social acceptance. The group considered many types of reactors, including both existing and new concepts. As the assessments progressed, it became increasingly apparent that the concept of the traveling wave reactor (TWR), advocated at that time by Lowell Wood, offered improvements in all of these areas.

In the earliest versions of the TWR, waves that breed and in turn burn fissile material propagate in a cylindrical medium of depleted or natural uranium. In 2007, several dozen fuels and coolants were considered in order to gain insights into which embodiment of the concept might prove most practical.

A sodium-cooled reactor utilizing metal uranium fuel was found to offer the most promise. This combination offered the thermal conductivity and cooling efficiency needed to support the required energy density in the core while maintaining realistic fuel and structural designs. Additional practical considerations of fuel shuffling and of cooling-system simplicity called for moving the fuel in the core rather than letting breed/burn waves travel within it.

The benefits of n th-of-a-kind TWRs have been extensively studied and quantified. The ability of the TWR to use depleted and natural uranium as reload fuel effectively extends the domestic reserves of both China and the United States by hundreds of years. This can be achieved without the need to first develop, fund, and construct reprocessing facilities. After the use of a low-enriched core to start the first reactor, an indefinite series of TWRs can be continued for hundreds of years without a need for any 235 U enriched starter fuel. Section 6 summarizes the economic advantages of this highly efficient, simple once-through nuclear infrastructure, and shows that the cumulative savings of a large deployment of TWRs are potentially trillions of dollars over the next 75 years.

Safety is, of course, of paramount importance in the concepts development. The advantages of a high-temperature low-pressure system, in the context of metal fuels and coolant, offer inherent safety features well beyond those of current reactors.

Nuclear waste from the TWR is approximately 80% less by weight of heavy metal than that from a light water reactor (LWR) for each unit of electrical energy produced. This is very compatible with the bore-hole approach to nuclear waste disposal now under development and testing in the United States and elsewhere.

Weapons-proliferation risks are reduced because of the reduction in need for enrichment facilities, long-term isolation of the fuel in the nuclear island between infrequent decadal refueling outages, and the avoidance of reprocessing facilities.

All of the above features of the TWR and its reduced infrastructure requirements simplify global deployment. A purchasing nation does not need to develop a complex and massive supporting network of facilities to ensure sustainability. It is projected that International Atomic Energy Agency (IAEA) prequalification steps for new nuclear member nations will be significantly simplified.

The TWR development program has been underway for approximately nine years. Several hundred million dollars have been spent on a focused, tightly coordinated design and development effort. The commercialization of the TWR has three main components: design and construction of a first reactor that will serve to qualify full-scale TWR commercial fuels, components, and systems [ 2 ]; commercial reactor designs and construction; and the integrated and focused technology development program to support these objectives on a sound and licensable basis.

Because of all the universally desirable benefits outlined above, the governments of China and the United States authorized technical exchanges on the TWR. Intensive joint reviews over the past year have been successfully carried out and discussions of joint development are now underway.

2. Reactor and plant design

The TWR is a large sodium-cooled fast reactor (SFR) designed to supply large quantities of base load electricity to population centers. The TWR builds on successful US and international experience with SFRs, with key innovations employed to allow extremely clean, safe, and economic operation without a need for fuel reprocessing.

2.1. Reactor and plant parameters

The TWR uses a conventional sodium reactor architecture, consisting of a sodium primary coolant loop, a sodium intermediate coolant loop, and a steam power conversion cycle. Fission energy generated in the TWR core is transferred in series through the primary and intermediate loops to steam generators, which produce superheated steam. This steam powers a steam turbine-generator set to produce electricity, and low-temperature heat is rejected through a set of water-cooled vacuum condensers.

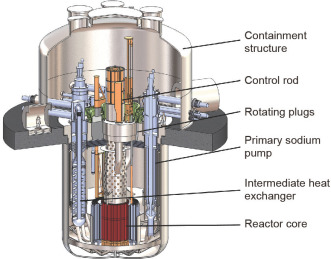

The intermediate loop acts as a barrier between the primary coolant loop and the high-pressure steam cycle, so that even if there is a leak or break in any of the components, the integrity of the core and primary sodium boundary can be ensured. Fig. 1 shows an illustration of the TWR plant primary components and containment.

|

|

|

Fig. 1. Illustration of TWR components inside the containment. |

The TWR uses a pool-type configuration, in which the primary system components (core, intermediate heat exchangers, and pumps) all reside in a large pool of atmospheric-pressure sodium contained within a reactor vessel. The reactor vessel is surrounded by an independent guard vessel, so that the sodium level is maintained even if the reactor vessel leaks. This arrangement has been employed in a wide range of reactors, including Experimental Breeder Reactor-II (EBR-II) in the United States, Phénix and SuperPhénix in France, BN-600 and BN-800 in Russia, China Experimental Fast Reactor (CEFR) in China, and Prototype Fast Breeder Reactor (PFBR) in India. Using a pool has the advantage of reducing the amount of piping and space needed, providing a large thermal inertia, and greatly reducing the likelihood and consequences of a coolant leak.

Designs for commercial TWRs have net power ratings ranging from 600 MW to 1200 MW electric. This range of power levels permits a gradual evolution from the first 600 MW electric prototype plant to larger units that achieve improved economies of scale. Core inlet and outlet temperatures are 360 ℃ and 510 ℃, respectively, corresponding to a plant net efficiency of approximately 41%, a significant improvement over the ~33% efficiencies typical of current commercial LWRs.

The TWR plant is being designed with consideration of construction, maintenance, and operation in order to minimize costs and maximize availability. The plant design team includes highly experienced architect-engineers, designers, and operators of past SFRs, using best practices drawn from over 1100 human-years of industry experience. Processes have been developed as part of an American Society of Mechanical Engineers (ASME) Nuclear Quality Assurance-1 (NQA-1) compliant program, including control of software, testing, design, procurement, and limited fabrication activities. By using a graded approach, TerraPower has been able to make significant progress in design work while maintaining appropriate design control.

The TWRs overall core arrangement is typical of SFRs, and is composed of hexagonal assemblies of wire-wrapped cylindrical fuel pins surrounded by an outer steel duct. Control of the core is accomplished through control rods that are inserted into the core, with a redundant bank of shutdown rods to ensure independent shutdown of the reactor. A number of innovations have been employed in the fuel pins, fuel assemblies, and safety systems to achieve excellent safety and extremely good fuel utilization.

2.2. Core technologies

Typical SFR designs require relatively high enriched reload fuel (in many cases>20% transuranics or 235 U) to achieve criticality, and have a relatively low discharge burnup (typically<50% of initial fissile atoms consumed). This results in a low once-through fuel utilization, so a closed fuel cycle with fuel reprocessing is needed to reuse the fuel. Once-through fuel utilization is limited in SFR designs both by fuel performance−the ability of the fuel to operate without failure at high irradiation doses; and by reactivity−the ability of the fuel to sustain a chain reaction as it burns up and accumulates fission products.

The TWR core design improves both fuel performance and reactivity to allow reload fuel enrichments as low as zero: depleted uranium with near-zero fissile content. Key new technologies include:

- An optimized clad material;

- A high uranium-content metal fuel alloy;

- A high burnup, low-distortion fuel pin design;

- An advanced, low-distortion assembly duct;

- A very low-leakage core and fuel management scheme; and

- Systems that improve core inherent response.

The combination of these technologies gives the TWR the unique ability to directly burn fissile fuel that is bred in the core, thus producing energy from unenriched uranium without relying on a separate reprocessing and transuranic fuel fabrication infrastructure. The corresponding once-through fuel utilization for a TWR is 170 GW thermal days (70 GW electric days) per ton of unenriched fuel. This corresponds to a waste reduction of 80% by weight of heavy metal relative to LWRs, and an improvement in natural uranium utilization that approaches 35× at equilibrium.

The clad material used in a TWR is a ferritic-martensitic steel with a microstructure optimized to resist swelling due to irradiation dose. The TWRs fuel material combines a high-uranium alloy that maximizes reactivity with a microstructure that minimizes anisotropic growth, and can be produced using a high-throughput manufacturing process.

The TWR fuel pins incorporate several novel features to permit high burnup while minimizing parasitic neutron losses. First, a low smear density (ratio of fuel area to total available area) is employed to minimize stress on the cladding and allow a reduced cladding thickness. A barrier is employed on the inside of the cladding to prevent fuel clad chemical interaction from damaging the clad during its residence in the core. A cesium getter and fission gas venting system are employed to reduce the pressure inside the pin and reduce the amount of mobile radioactivity present in the core.

The TWR fuel assemblies use a novel duct geometry and advanced steel−features that reduce the amount of duct material needed, improving reactivity. To further improve reactivity, the TWR has a relatively large, low-leakage core with several rows of peripheral low-power assembly positions where new reload fuel is introduced for fuel breeding.

Two measures are taken to reduce the amount of sodium present in the core: use of mechanically bonded instead of sodium-bonded fuel, and use of a tight pin lattice. Reducing sodium improves both reactivity and the cores safety characteristics, a topic discussed further in Section 4.1.

3. Design and modeling tool development

Because of its high neutron fluences, the TWRs performance is particularly sensitive to the relative fractions of fuel, structure, and coolant present in the core. Therefore, the TWR design has especially benefitted from high-fidelity analysis tools that permit a greater degree of optimization. These design tools take advantage of advances in both computing capacity and experimental data since the design of earlier SFRs. Improvements in analysis capabilities not only allow for better designs, but also permit faster design iterations by permitting concepts to be explored in silico prior to experimental testing.

The TWR design takes advantage of computational progress in the following areas:

- Neutronics and depletion;

- Thermal hydraulics;

- Fuel performance;

- Mechanical and seismic analyses;

- Safety and transient analyses; and

- Data management, automation, and optimization.

Neutronics analyses are performed using fully featured 3D diffusion and Monte Carlo codes, permitting homogenized and full-detail models, with on-the-fly Doppler broadening of neutron cross-sections and movable meshes to account for temperature and geometry changes. Results have been benchmarked against critical experiments and past SFRs, including the US “ZPPR” and Russian “BFS” tests and the Fast Flux Test Facility (FFTF).

In thermal hydraulics, fuel bundle analyses are performed using an updated subchannel code implementing recent experimental correlations for pressure drop and heat transfer [ 3 ,4 ] and benchmarked against heated bundle sodium flow experiments, such as the one described in Ref. [ 5 ]. Commercial computational fluid dynamics codes are applied to characterize the hydraulic characteristics of complex flow geometries, such as the core inlet plenum and upper internal structure.

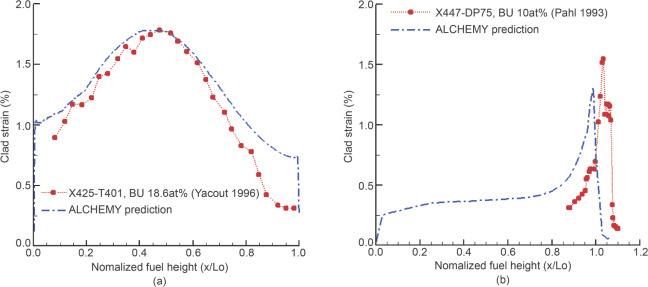

Fuel performance analyses are performed using the proprietary finite element code ALCHEMY [ 6 ], which calculates fuel pin deformations due to eight different mechanisms, and has been successfully benchmarked against a fuel performance database from the US fast reactor program, in which over 219 000 metal fuel pins were irradiated (Fig. 2 ). Mechanical analyses of assembly duct deformation, assembly withdrawal forces, and core seismic response are performed using the commercial finite element codes. Assembly thermal bowing is computed using the code OXBOW, a modern, finite element-based version of core mechanical codes like NUBOW [ 7 ].

|

|

|

Fig. 2. Example benchmark results of ALCHEMY code† [ 9 ,10 ]. (a) Prediction for high burnup fuel; (b) prediction for high temperature fuel. |

Transient analyses to characterize plant safety under different conditions are performed using a combination of SASSYS−an Argonne National Laboratory systems code; and RELAP-5 3D−an industry-standard systems code for LWRs adapted for use in SFRs. These codes have been successfully benchmarked against transient data from the EBR-II and FFTF SFRs [ 8 ].

These modeling tools are tied together using a data management framework called ARMI: the Advanced Reactor Modeling Interface [ 11 ,12 ]. ARMI creates an abstract model of the core that can be used to perform versatile couplings between different codes. For example, fuel performance effects (fission gas migration, fuel axial expansion) can be incorporated into neutronics models. In another example, thermal-hydraulics results are used in computing assembly bowing, which is used in turn by neutronics models to compute a reactivity feedback curve that can be input into systems analysis codes. All these capabilities are automated, greatly improving the efficiency of TWR design. This efficiency is further increased via the use of sophisticated surrogate models, which allow the results of complex analyses to be predicted in advance.

These modeling tools are governed by a software management plan that sets requirements for their development, configuration control, and verification and validation. The plan implements the requirements from the NQA-1 standard and helps ensure that the software can support the licensing of a nuclear reactor.

4. Safety characteristics

The TWR is designed to have an extremely high degree of safety, surpassing that of the present-day fleet of LWRs. Safe operation and response to accidents is achieved through a combination of several layers of protection:

- Systems that assure reactor shutdown, including control systems, inherent reactivity feedbacks, and passive shutdown systems;

- Multiple heat removal pathways that rely on natural circulation of low-pressure coolant to transfer decay heat to the atmosphere; and

- Multiple barriers that prevent radionuclides in the core from reaching the environment.

Each of these features is designed to operate in an inherent fashion, without requiring external power or operator actions. The following subsections describe these features and their benefits.

4.1. Assuring shutdown

During an accident, the normal route of full-power heat removal may become unavailable. Therefore, it is important to shut the reactor down, so that only a smaller amount of decay heat needs to be removed from the core.

The TWR employs a reactivity control system and a redundant standby shutdown system that insert neutron absorbers into the core to shut it down. Similar to existing reactors, these systems function both automatically−for example, if the temperature or power exceeds a certain level−and extremely reliably.

In addition to these systems, the TWR has additional means to shut the reactor down in case of an accident. One is the cores natural reactivity feedbacks. The TWR, like other large SFRs, has a positive coolant temperature coefficient of reactivity: Increasing coolant temperature alone causes the fission rate to increase. However, the other sources of feedback−including fuel temperature feedback, fuel axial expansion, and assembly radial bowing−act in the opposite direction and cause the net feedback to be negative, so the core tends to be self-stabilizing.

Together with the low operating temperature of the metal fuel, this quality allows the TWR to endure an “unprotected” loss of heat sink, a beyond-design-basis accident in which normal heat removal capability is lost and the reactor is not shut down by either the control rods or shutdown rods. In such a situation, the TWR core would stabilize itself at a near-zero power level and a slightly elevated average temperature.

In the case of an unprotected loss of flow, another extremely low-likelihood event in which all coolant pumping is lost and the control and shutdown rods do not insert, natural feedbacks may not reduce core power quickly enough to counter the sudden loss of flow. In this scenario, a system that passively responds to loss-of-coolant flow can be used to quickly shut the core down. This approach is similar to the gas expansion module approach that was successfully demonstrated at FFTF for addressing the same type of event [ 13 ].

4.2. Decay heat removal

The primary reason that the TWR has enhanced safety relative to LWRs is that it is simpler to remove decay heat from the core following shutdown, which prevents core damage from occurring. This is because the TWR uses a large pool of low-pressure sodium coolant instead of pressurized water. The low-pressure, large margin to coolant boiling and the redundant below-ground vessels effectively eliminate the potential for a loss-of-coolant accident. The large thermal inertia of the pool means that temperature changes occur gradually during a transient, and the higher temperature and greater heat transfer properties of the sodium mean that it is possible to use simple natural circulation systems to reject all decay heat into the atmosphere.

In addition to the normal heat rejection pathway through the main condensers, decay heat removal can be accomplished through two sets of auxiliary systems. First, a high-pressure condenser system is available to reject heat from the steam cycle into the atmosphere; this system removes heat from the reactor via the usual intermediate heat exchangers and steam generators. Second, a set of four separate direct reactor auxiliary cooling systems (DRACSs) are used. Each DRACS consists of a simple natural circulation coolant loop, with one heat exchanger removing heat from the primary coolant, and another heat exchanger rejecting this heat to the atmosphere. Any two DRACS loops out of four are sufficient to remove all decay heat, making the DRACS a highly reliable and fully independent means of heat removal. Because heat is rejected to the atmosphere−an effectively limitless heat sink−decay heat removal can be assured for an indefinite period with no need for external power, makeup water, or operator actions.

4.3. Preventing radionuclide escape

The TWR also possesses several features that help prevent radionuclides from escaping into the environment, mitigating the impact of severe accidents or fuel failures. Metal fuel is chemically compatible with sodium, so even if the cladding is breached, relatively few fission products escape. As part of its fuel pin venting system, the TWR employs getter materials that chemically bond to cesium, which would ordinarily be a significant component in radionuclide releases due to its volatility and water solubility. Xenon and krypton released through the pin vents are similarly retained in filtering systems, reducing the radioactive source term present in the core. The metal fuel and sodium coolant also strongly retain otherwise mobile radionuclides, such as iodine.

The sodium pool itself is protected by multiple barriers, including an inert argon cover gas, the reactor vessel with its top closure and guard vessel, and the intermediate coolant loop. Finally, the entire primary system is surrounded by a sealed containment structure that prevents any radioactive materials from escaping, and protects the reactor equipment from external events such as wind-borne objects, vehicle impacts, and floods.

4.4. Preventing and mitigating sodium fires

While sodium possesses excellent nuclear and thermo-physical properties, precautions must be taken in its use to prevent and mitigate sodium fires, which can occur if sodium reacts with air, water, and some types of concrete. The TWR builds on successful past experience of using sodium as a coolant and managing its chemical reactivity.

In the TWR, any systems handling primary sodium, which becomes radioactive after neutron activation, are enclosed in monitored steel-lined spaces filled with inert gas, to avoid any sodium reactions should a leak occur. Systems and piping containing intermediate sodium are also protected from sodium fires by using steel catch pans with self-extinguishing smother plates, which are designed to ensure oxygen is consumed and not replenished to stop the reaction. The steam generators themselves employ systems to detect leaks or breaks and quickly shut off the water supply, isolate the steam generator, and blowdown the system to tanks, thereby minimizing the amount of water available to react with sodium.

Even in the case of a sodium fire, the safety measures described above would not be compromised. Both the containment structure and the decay heat removal systems are capable of accommodating a major beyond-design-basis sodium fire or leak without any core damage occurring.

4.5. Probabilistic risk analysis

The safety advantages of TWRs are borne out by probabilistic risk assessments (PRAs), which estimate a core damage frequency due to internal initiating events to be lower than 1 × 10−8 per reactor year [ 14 ], a value several orders of magnitude lower than those computed for currently operating reactors.

At these very low levels of risk, the primary hazard to the plant is due to very rare but catastrophic external events, primarily earthquakes. Such events are safeguarded against by hardening the reactor and decay heat removal equipment to withstand earthquake magnitudes corresponding to a desired return period (typically ten thousand to one million years), and employing seismic isolation in high-seismicity locations. Because the plant is designed to remain safely shut down without external assistance, the loss of supporting infrastructure associated with such an event would not endanger the plant.

With this very high level of safety, the TWR is an energy source with an extremely small effect on public health, and would continue the history of nuclear energy having a far lower health impact than any form of fossil fuel combustion [ 15 ].

5. Development program

Extensive work is being performed in the development and testing programs of the TWR in order to reduce the technical risk associated with its design, development, and deployment. The programs can be divided into the following categories:

- Fuels and materials (e.g., fuel, cladding, duct);

- Other in-core and in-vessel systems and components (e.g., control rods, fuel-handling machines, heat exchangers);

- Intermediate sodium systems and components (e.g., pumps, valves, steam generators); and

- Balance-of-plant (BOP) systems and components (e.g., turbine-generator, condensers).

Selected systems, subsystems, and components were evaluated using detailed technology readiness levels (TRLs) that were originally developed by the National Aeronautics and Space Administration (NASA) for evaluating and assigning maturity levels for systems, subsystems, and components. TerraPower conducted a technology readiness assessment (TRA) consistent with the methodology to establish TRL rankings for each nuclear island system and subsystem, as well as for select components of the TWR. These rankings were used to provide guidance for the development, testing, and equipment qualification programs with regard to priority and technical risk reduction.

To date, TerraPower has contracted with more than 50 industrial, national laboratories, and academic institutions around the world to perform work that lines up with the TRA as described above. This work includes international collaboration with entities such as Kobelco (Kobe Steel) in Japan, and the Research Institute of Atomic Reactors (NIIAR or RIAR) in Russia, as well as US companies, many of the national laboratories, and universities (Fig. 3 ).

|

|

|

Fig. 3. Map of TerraPower collaborations in the US. |

The sections below highlight work being performed in the fuels and materials area, as well as work being performed by TerraPower locally in Bellevue, Washington, to support the other major categories described above.

5.1. Materials and metal fuel development

In order to achieve ultimate breed-and-burn equilibrium, where only depleted or natural uranium is needed as additional fuel (i.e., no addition of enriched material), the fuels and materials will need to achieve high burnup and fluence−on the order of 30% peak burnup for the fuel, and ~1.1 × 1024 fast neutrons (E>0.1 MeV) per cm2 fluence (~550 dpa) on cladding and in-core components. These burnups and fluences are far beyond what was achieved previously [ 16 ], and require additional testing.

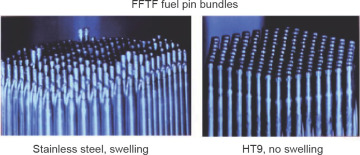

TerraPower has embarked on a fuels and materials development and qualification program, which includes fuel fabrication development, irradiation testing, and post-irradiation examination (PIE) programs to provide information necessary for the licensing and eventual construction of a TWR. The ferritic-martensitic stainless steel HT9 has been selected as the TWR fuel clad and fuel assembly duct material, for these reasons: ① It has the largest body of irradiation data; ② it has demonstrated the best swelling performance when compared to austenitic stainless steel (Fig. 4 ); and ③ it has an operating and fabrication history for use in fast reactors−both as cladding and duct material.

|

|

|

Fig. 4. Irradiation-induced swelling of SS316 and HT9 pins from FFTF (image courtesy Pacific Northwest National Laboratory). |

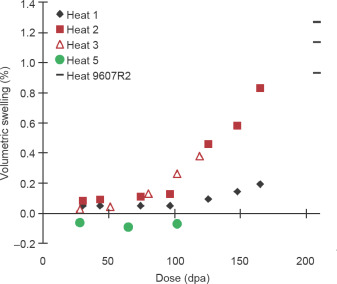

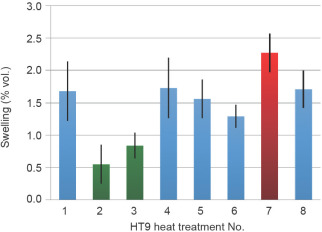

However, historically there was variability in the swelling performance of HT9, as seen in Fig. 5 . As part of the development program, an optimized type of HT9 was developed by TerraPower to withstand even higher neutron fluence with minimal swelling, and to be reproducible.

|

|

|

Fig. 5. Swelling behavior of different HT9 heats in FFTF. |

To further reduce uncertainty, TerraPower is working with the University of Michigan to perform heavy ion irradiation of HT9−both the historic and the new/improved version. Heavy ion irradiation of materials is used to quickly obtain key performance data on behavior (e.g., radiation-induced swelling), informing our decisions on material fabrication parameters. An advantage of using heavy ions is the reduced time it takes to achieve high doses. To date, the TerraPower samples have received doses up to 1.3 × 1024 neutrons per cm2 (650 dpa), with very low swelling observed. A comparison of the swelling of historic and new/improved HT9 under heavy ion irradiation can be seen in Fig. 6 , where the green bars are the optimized HT9 samples.

|

|

|

Fig. 6. Reduced swelling behavior of optimized HT9 under heavy ion irradiation, as seen in samples 2 and 3 [ 17 ]. Swelling at 440 ℃. |

At the Idaho National Laboratory (INL), TerraPower has contracts that range from performing PIE on historical FFTF fuel pins, to developing and constructing a pilot-scale fuel fabrication facility. Also included in the work being done at INL is the TerraPower advanced fuel test in the Advanced Test Reactor. These pins are being irradiated in conjunction with the US Department of Energy (US-DOE) fuels program, and will undergo PIE beginning in late 2015 and continuing for the next two years as additional tests are completed.

The BOR-60 reactor at NIIAR (RIAR) in Russia is being used to irradiate materials samples [ 18 ], where irradiation rigs in the reactor contain a total of almost 1500 material specimens. These include previously irradiated material that had received neutron doses up to 155 dpa, in addition to TerraPower specimens.

BOR-60 will also be used to irradiate test pins to support the fuel licensing effort. The expectation is that the first set of test pins will begin irradiations in 2018, and that the pilot fuel fabrication facility at INL will be used to make the test pins. The INL will also perform the PIE once the pins have reached the desired burnup.

Finally, TerraPower contracted AREVA to build a full-size TWR fuel assembly as a proof-of-fabrication test and pressure-drop test (Fig. 7 ). This assembly demonstrated that the tight tolerances could be handled from a fabrication standpoint, and was used to successfully benchmark thermal-hydraulic models for this large SFR fuel assembly.

|

|

|

Fig. 7. Full-size TWR proof-of-fabrication fuel assembly. |

5.2. TerraPower testing

TerraPower uses ~10 000 ft2 (~929 m2 ) of dedicated laboratory space in Bellevue, Washington, for engineering testing, which is sufficiently large to handle full-sized components. It also includes a flow test loop and the ability to study mechanical, structural, vibration, integrated system, sodium, and materials behaviors. There are reconfigurable stations in the lab space, with a current setup that supports experiments for assembly and core design as well as for specific functions of various plant systems (see Fig. 8 ).

|

|

|

Fig. 8. TerraPower mechanical testing apparatus at the laboratory. |

The lab space is flexible enough to provide experiment and testing setup for different systems and components, and is capable of handling sufficient quantities of liquid sodium to support planned equipment and process development. This “in-house” testing capability is important as TerraPower continues to validate the codes being used for design and analysis.

5.3. TWR prototype

The commercialization plan for the TWR first involves building a prototype reactor called TWR-P, described in detail in Ref. [ 2 ]. The prototype will demonstrate the construction, operation, and maintenance of a commercial-size SFR with full-scale systems and equipment, including the core, pumps, heat exchangers, and steam turbines. The core of the prototype is based on established fuel technology, and will serve as a versatile platform for qualifying advanced fuel technologies that can be employed in later units. TWR-P will thereby enable the deployment of subsequent generations of commercial TWRs.

6. Benefits

The TWR is designed to offer multiple advantages relative to current forms of nuclear and non-nuclear energy generation. Benefits have been evaluated in the following areas:

- Safety

- Economics

- Proliferation resistance

- Energy security

- Health and environment

Taken together, this set of benefits means that TWR technology can play a major role in humanitys energy future through this century and beyond.

6.1. Safety

As described in Section 4, the TWR possesses a very high level of nuclear safety, with an extremely small probability of a significant radiation event, and no possibility of Fukushima-type events occurring. On account of its simpler and more efficient fuel cycle, the TWR also reduces the likelihood of an accident during fuel processing, transportation, and disposal, and removes opportunities for the diversion of radioactive material to make radiological dispersion devices.

6.2. Economics

The TWR is projected to have a levelized cost of electricity that is lower than that of LWRs being built today. Capital cost estimates for the TWR yield overnight costs that are similar to equivalent estimates for modern LWRs. Meanwhile, the TWR holds large advantages in its operating costs due to lower fueling and disposal requirements. Over its 60-year life, a 1.15 GW electric TWR refueled with unenriched uranium would cost between 4 billion and 5 billion dollars less to operate than an equivalent LWR or traditional SFR. Eliminating the need for reprocessing plants and reducing the need for enrichment saves additional hundreds of billions of dollars in infrastructure development costs. In scenarios where TWRs represent a part of the future projected growth of nuclear energy, beginning in the 2030s (~450 GW of TWR capacity by 2100), these cost reductions would total more than 1 trillion dollars.

6.3. Proliferation resistance

The TWRs proliferation resistance has been analyzed using frameworks that evaluate proliferation resistance at each stage of the nuclear fuel cycle, such as Ref. [ 19 ]. These analyses demonstrate that the TWRs strategy of avoiding fuel reprocessing and reducing fuel enrichment strengthens overall proliferation resistance, and reduces the amount of nuclear weapons material production capacity that exists in the world.

6.4. Energy security

Table 1 compares fueling and disposal/reprocessing requirements for the TWR with those of LWRs and closed-cycle SFRs. The TWRs advances in core technologies and design permit it to have much lower resource requirements, allowing countries with TWRs to be less dependent on mining or importing uranium. Conventional reserves of natural uranium together with existing stocks of depleted uranium would be sufficient to power a 1000 GWe (2.5× present-day nuclear-generating capacity) fleet for approximately 2000 years. At the same time, eliminating the need for enrichment and reprocessing greatly reduces the need for countries to establish politically sensitive fuel cycle facilities.

| Reactor type | Uranium mining (Mt) | Enrichment (Mt SWU) | Reprocessing (Mt) | Secondary reprocessing wastes (m3 ) | Disposal (Mt) |

|---|---|---|---|---|---|

| LWR | 210 | 160 | 0 | 0 | 21 |

| SFR[[#tbl1fn1|a]] | 27 | 25 | 8 | 100 | 1 |

| TWR | 32 | 30 | 0 | 0 | 5 |

| Successor TWR | 0[[#tbl1fn2|b]] | 0 | 0 | 0 | 5 |

a. Assumes startup and 15 years of initial operation with enriched uranium, followed by a closed fuel cycle using reprocessed SFR fuel.

b. Zero if depleted uranium stockpiles are used for reload fuel; 5 Mt if natural uranium is used instead.

6.5. Health and environment

The TWR is a non-polluting and carbon-free source of energy that helps preserve the health and well-being of our planet and its inhabitants. With an extremely low probability of accidents and the ability to mitigate their consequences, the TWR has even lower potential public health impact than todays nuclear plants, which are already credited with improving life expectancy by displacing fossil fuel generation [ 20 ]. Nuclear energy is a major contributor to avoiding negative environmental effects and greenhouse gas emissions, and the TWR can lower these footprints even further by permitting an 84% reduction in mining, a 100% reduction in fuel reprocessing, and an 80% reduction in waste transportation and disposal.

6.6. Nearer- and longer-term benefits

The benefits described here pertain to a TWR that is started up using enriched uranium, and then sustained with unenriched uranium reload fuel. Even prior to the deployment of TWRs that burn unenriched uranium, significant benefits can be still gained by using TWRs that burn low-enrichment feed. For example, a TWR fueled with 5% enriched uranium (similar to present-day LWRs) can reduce mining, enrichment, and disposal requirements by a factor of two relative to LWRs, while requiring comparatively modest advances in fuel technology (e.g., 300 dpa materials).

The above benefits become even better for a “successor” TWR: a second generation reactor that replaces a first generation plant at its end of life. In this scenario, the core of the first generation plant is transferred to a new successor plant. The new plant can start without the need for a 235 U enriched starter core. The lifetime enrichment requirement for this plant is zero. Those who are experienced in refueling and shuffling in fast reactors and in the LWR refueling business consider this practical for same-site reactors. Further fuel development could also allow the use of spent LWR fuel, converted to metal form, as an additional reload fuel for TWRs.

It is important to note here the remarkable fleet-wide benefit when the number of plants in the fleet reaches equilibrium (where the number of retiring plants equals the number of new plants). Under such a condition, no enrichment or reprocessing is needed to maintain operation of the entire fleet. Furthermore, because of the efficient use of all mined uranium, this beneficial equilibrium can be maintained for many centuries.

7. Conclusions

An extensive TWR development program has made good progress. Deep design activities have been carried out making use of extensive previous relevant data and experience as well as 21st century design tools and technologies. The required development activities are being managed through the use of very detailed and formal TRAs. A matrix of tests and demonstrations have already been successfully carried out in key areas of materials and fuel development and components.

Approaches to the licensing of the new reactor have been outlined and are under discussion. These considerations have in turn helped to shape the required development program.

The good technical progress to date, combined with economic and technical sensitivity studies, are confirming the great potential of the traveling wave reactor.

Acknowledgements

The authors would like to acknowledge their colleagues for providing numerous technical and editorial contributions to this paper, including Mark Werner, Bao Truong, Nick Touran, Pat Schweiger, Phil Schloss, Chris Regan, Mark Reed, Larry Raklios, Sam Miller, Lee McIntire, Graham Malmgren, Chris Levesque, Ryan Latta, Jeff Latkowski, Brian Johnson, Bruce Hilton, Pavel Hejzlar, Stephanie Hayes, Micah Hackett, Craighton Goeppele, Jesse Cheatham, Carole Boelitz, Marcia Burkey, Doug Adkisson, and others.

Compliance with ethics guidelines

John Gilleland, Robert Petroski, and Kevan Weaver are employed by TerraPower LLC, which is working to commercialize traveling wave reactor technology.

John Gilleland, Robert Petroski, and Kevan Weaver declare that they have no conflict of interest or financial conflicts to disclose.

References

- 1 J Asafu-Adjaya, L Blomqvist, S Brand, B Brook, R DeFries, E Ellis, et al.; An ecomodernist manifesto [Internet]. [cited 2015 Oct 28]; Available from: http://www.ecomodernism.org/ (2015)

- 2 P Hejzlar, R Petroski, J Cheatham, N Touran, M Cohen, B Truong, et al.; TerraPower, LLC traveling wave reactor development program overview; Nucl Eng Technol, 45 (6) (2013), pp. 731–744

- 3 SK Chen, R Petroski, NE Todreas; Numerical implementation of the Cheng and Todreas correlation for wire wrapped bundle friction factors-desirable improvements in the transition flow region; Nucl Eng Des, 263 (2013), pp. 406–410

- 4 K Mikityuk; Heat transfer to liquid metal: review of data and correlations for tube bundles; Nucl Eng Des, 239 (4) (2009), pp. 680–687

- 5 FC Engel, B Minushkin, RJ Atkins, RA Markley; Characterization of heat transfer and temperature distributions in an electrically heated model of an LMFBR blanket assembly; Nucl Eng Des, 62 (1–3) (1980), pp. 335–347

- 6 SJ Miller, R Latta; Fuel performance modeling of traveling wave reactor fuel elements [poster session]; Materials Modeling and Simulation for Nuclear Fuels 2013 Workshop; 2013 Oct 14–16; Chicago, IL, USA (2013)

- 7 M Cohen, M Werner, C Johns; Mechanical model of a TerraPower, traveling wave reactor fuel assembly duct; 22nd International Conference on Structural Mechanics in Reactor Technology; 2013 Aug 18–23; San Francisco, CA, USA, Curran Associates, Inc., Red Hook (2014)

- 8 Bates E, Truong B, Huddar L. Phase II of the EBR-II SHRT-45R benchmark study–TerraPowers SAS4A/SASSYS-1 results. In: Proceedings of 2016 Advances in Reactor Physics–Linking Research, Industry, and Education (PHYSOR 2016); 2016 May 1–5; Sun Valley, ID, USA; Forthcoming 2016.

- 9 R Pahl, CE Lahm, SL Hayes; Performance of HT9 clad metallic fuel at high temperature; J Nucl Mater, 204 (1993), pp. 141–147

- 10 AM Yacout, S Salvatores, Y Orechwa; Degradation analysis estimates of the time-to-failure distribution of irradiated fuel elements; Nucl Tech, 113 (2) (1996), pp. 177–189

- 11 N Touran, J Cheatham, R Petroski; Model biases in high-burnup fast reactor simulations [CD-ROM]; Proceedings of 2012 Advances in Reactor Physics–Linking Research, Industry, and Education (PHYSOR 2012); 2012 Apr 15–20, American Nuclear Society, Knoxville, TN, USA. LaGrange Park (2012)

- 12 J Cheatham, B Truong, N Touran, R Latta, M Reed, R Petroski; Fast reactor design using the advanced reactor modeling interface; Proceedings of 2013 21st International Conference on Nuclear Engineering: Volume 2; 2013 Jul 29–Aug 2, American Society of Mechanical Engineers, Chengdu, China. New York (2013) V002T05A072

- 13 JB Waldo, A Padilla Jr, DH Nguyen, SW Claybrook; Application of the GEM shutdown device to the FFTF reactor; Trans Am Nucl Soc, 53 (1986), pp. 312–313

- 14 BC Johnson; Preliminary results of the TerraPower-1 probabilistic risk assessment; Proceedings of the 11th International Probabilistic Safety Assessment and Management Conference and the Annual European Safety and Reliability Conference 2012; 2012 Jun 25–29, Curran Associates, Inc., Helsinki, Finland. Red Hook (2012), pp. 3543–3549

- 15 P Bickel, R Friedrich; ExternE: externalities of energy: methodology 2005 update, Office for Official Publications of the European Communities, Luxembourg (2005)

- 16 KD Weaver, J Gilleland, C Whitmer, G Zimmerman; High burn-up fuels for fast reactors: Past experience and novel applications; Proceedings of 2009 International Congress on Advances in Nuclear Power Plants; 2009 May 10–14, Curran Associates, Inc., Tokyo, Japan. Red Hook (2010), pp. 795–802

- 17 MJ Hackett, G Povirk, J Vollmer; Materials development for the traveling wave reactor [presentation]; TMS 2012: 141st Annual Meeting and Exhibition; 2012 Mar 11–15; Orlando, FL, USA (2012)

- 18 BA Hilton, P Hejzlar, DG McAlees, KD Weaver, SA Maloy, TA Saleh, et al.; Traveling wave reactor: material requirements and development program; Proceedings of New Materials for Innovative Development of Nuclear Power Engineering Conference; 2014 Mar 24–27; Dimitrovgrad, Russia (2014)

- 19 WS Charlton, RF LeBouf, C Gariazzo, D Grant Ford, C Beard, S Landsberger, et al.; Proliferation resistance assessment methodology for nuclear fuel cycles; Nucl Technol, 157 (2) (2007), pp. 143–156

- 20 PA Kharecha, JE Hansen; Prevented mortality and greenhouse gas emissions from historical and projected nuclear power; Environ Sci Technol, 47 (9) (2013), pp. 4889–4895

Notes

. ALCHEMY results are shown relative to the final (taller) fuel heights, while data are relative to the original fuel height.

†. See Ref. [ 1 ] for a consensus view of several recognized professional experts on the relationship of energy and the environment.

Document information

Published on 06/04/17

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?