Abstract

The objective of this work is the derivation and implementation of a unified Finite Element formulation for the solution of fluid and solid mechanics, Fluid-Structure Interaction (FSI) and coupled thermal problems.

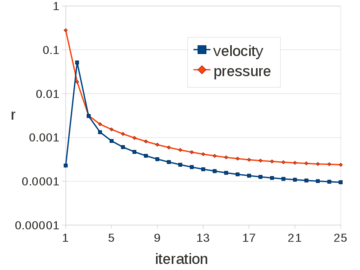

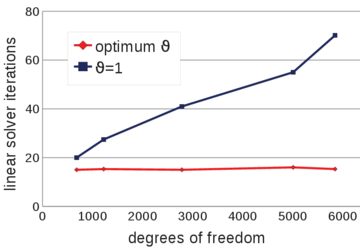

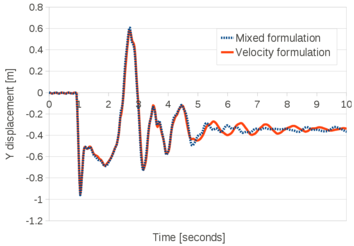

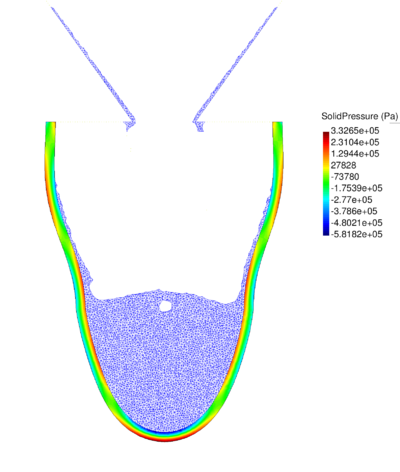

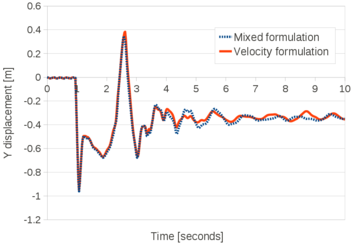

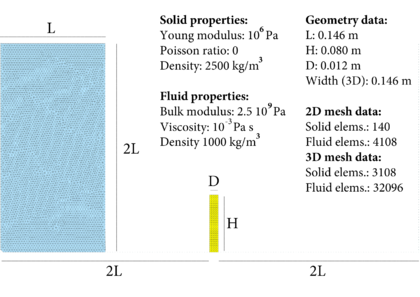

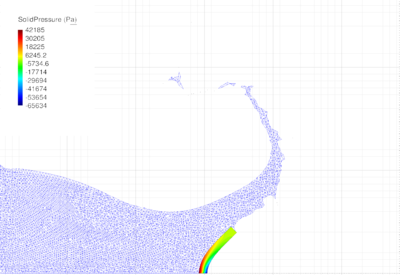

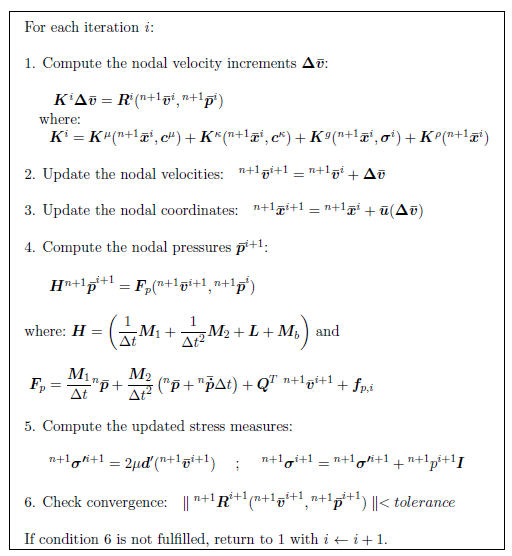

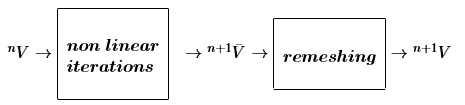

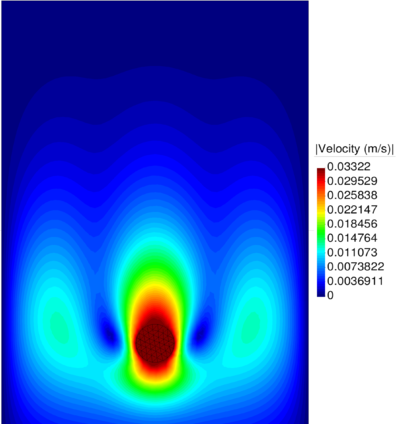

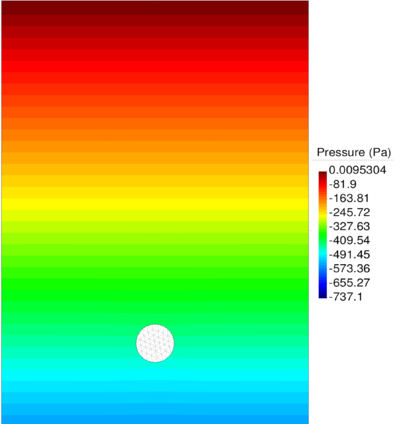

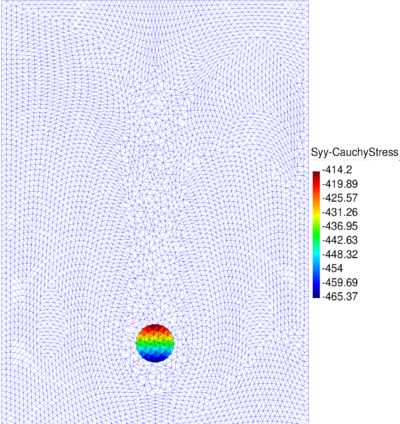

The unified procedure is based on a stabilized velocity-pressure Lagrangian formulation. Each time step increment is solved using a two-step Gauss-Seidel scheme: first the linear momentum equations are solved for the velocity increments, next the continuity equation is solved for the pressure in the updated configuration.

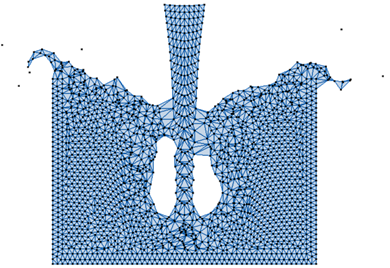

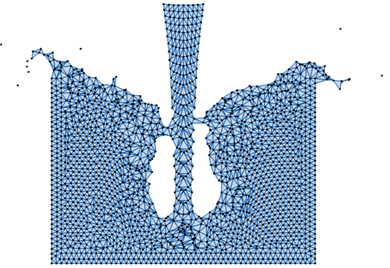

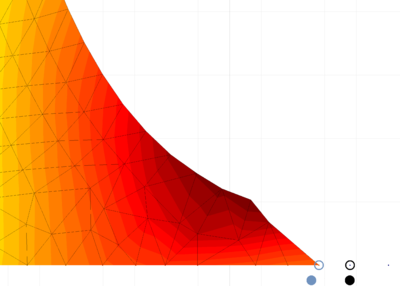

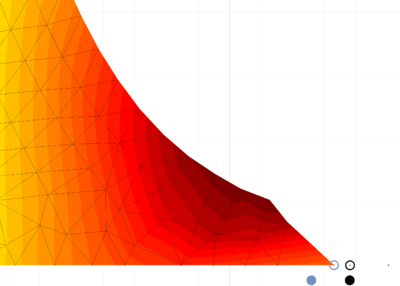

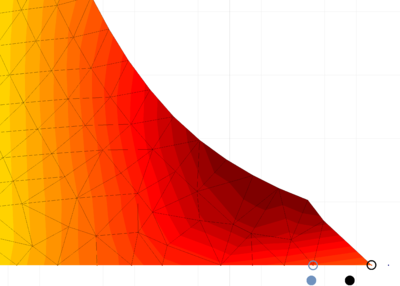

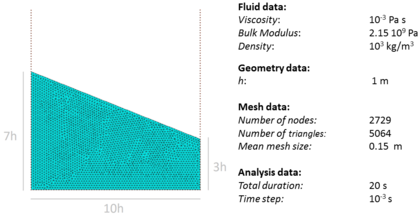

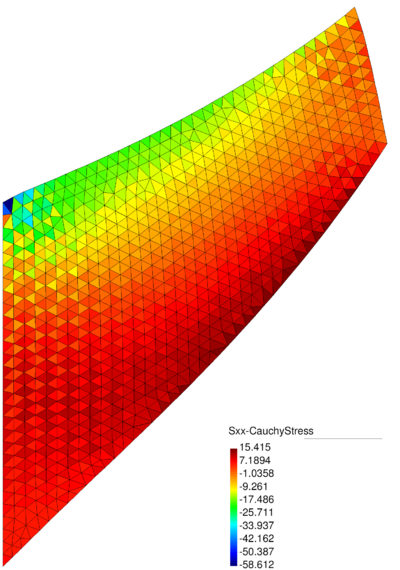

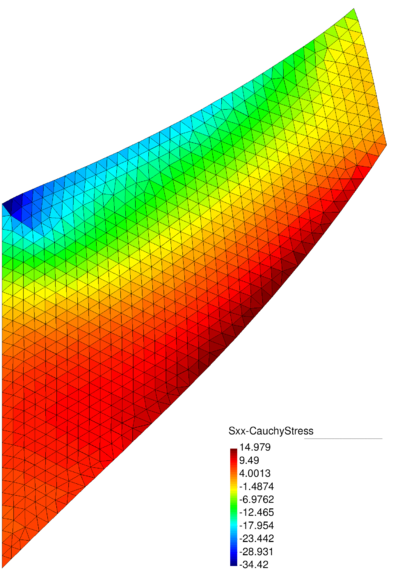

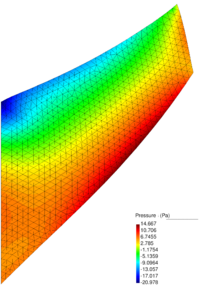

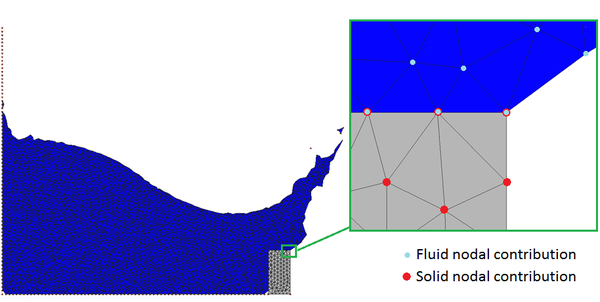

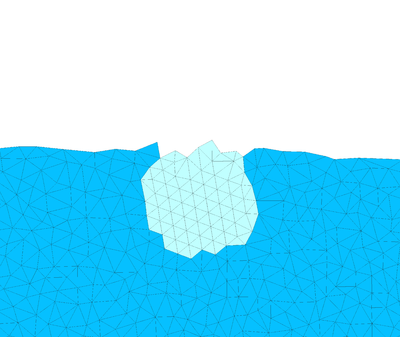

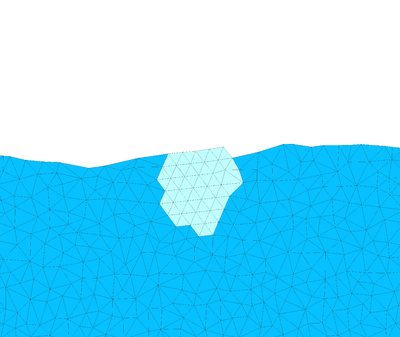

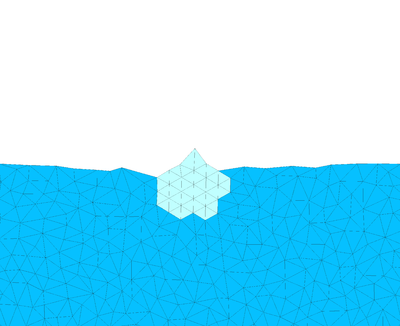

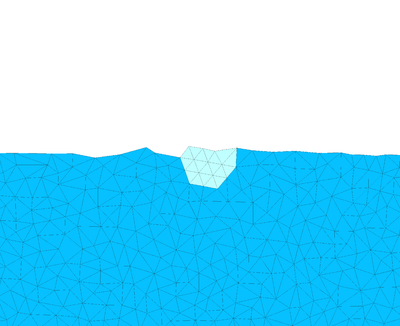

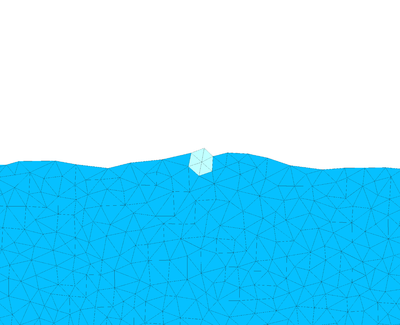

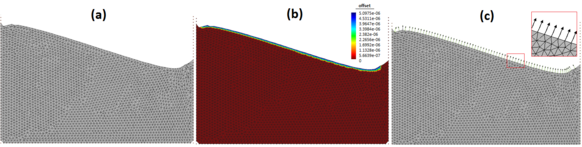

The Particle Finite Element Method (PFEM) is used for the fluid domains, while the Finite Element Method (FEM) is employed for the solid ones. As a consequence, the domain is remeshed only in the parts occupied by the fluid.

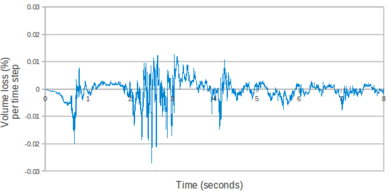

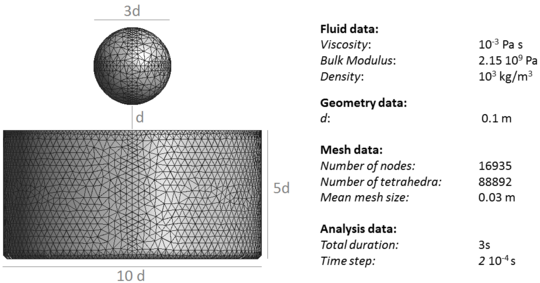

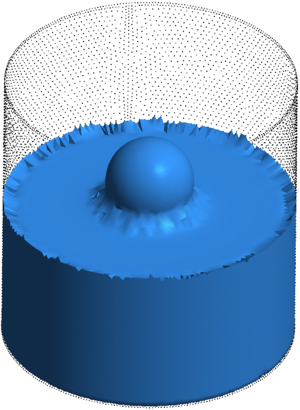

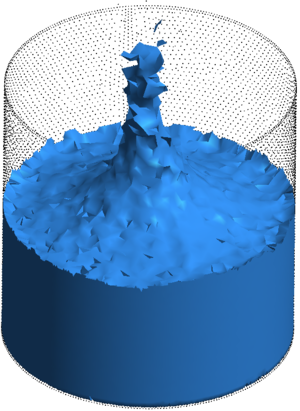

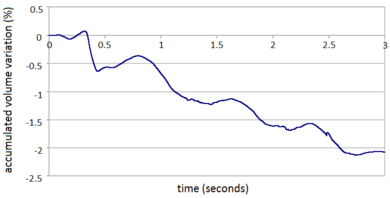

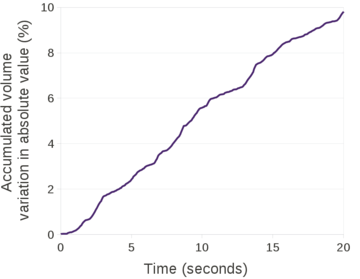

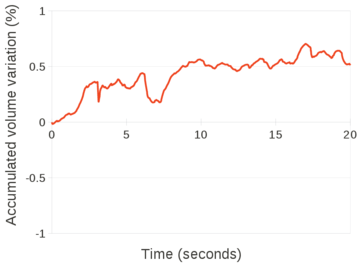

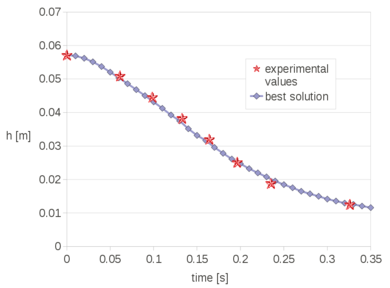

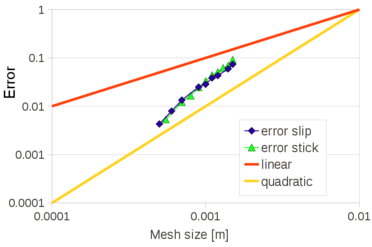

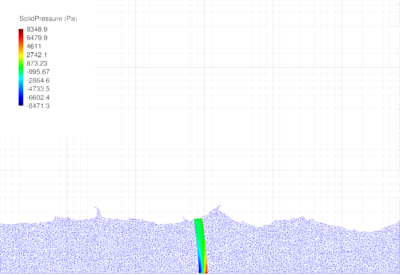

Linear shape functions are used for both the velocity and the pressure fields. In order to deal with the incompressibility of the materials, the formulation has been stabilized using an updated version of the Finite Calculus (FIC) method. The procedure has been derived for quasi-incompressible Newtonian fluids. In this work, the FIC stabilization procedure has been extended also to the analysis of quasi-incompressible hypoelastic solids. Specific attention has been given to the study of free surface flow problems. In particular, the mass preservation feature of the PFEM-FIC stabilized procedure has been deeply studied with the help of several numerical examples. Furthermore, the conditioning of the problem has been analyzed in detail describing the effect of the bulk modulus on the numerical scheme. A strategy based on the use of a pseudo bulk modulus for improving the conditioning of the linear system is also presented.

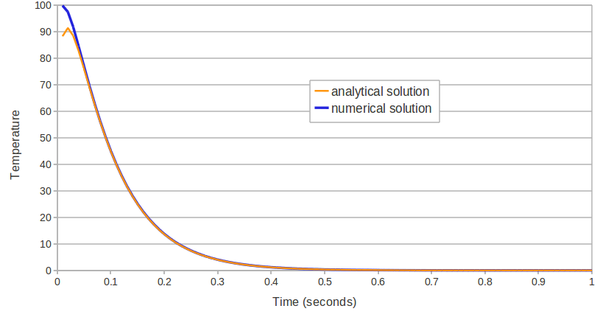

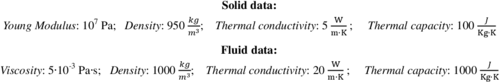

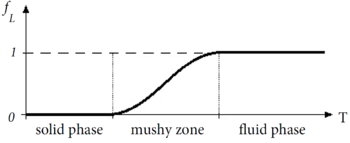

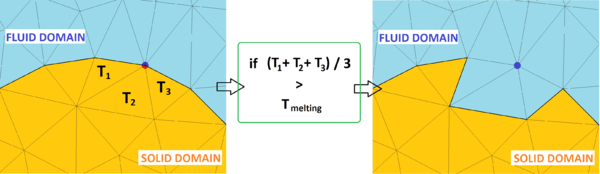

The unified formulation has been validated by comparing its numerical results to experimental tests and other numerical solutions for fluid and solid mechanics, and FSI problems. The convergence of the scheme has been also analyzed for most of the prob- lems presented. The unified formulation has been coupled with the heat tranfer problem using a staggered scheme. A simple algorithm for simulating phase change problems is also described. The numerical solution of several FSI problems involving the temperature is given.

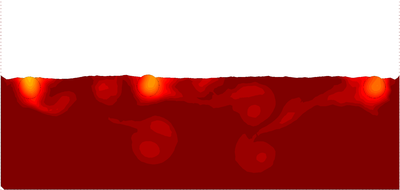

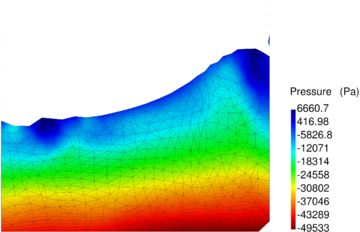

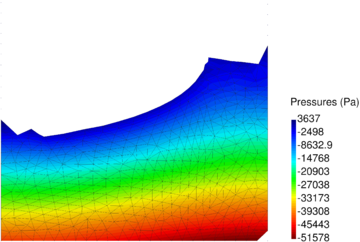

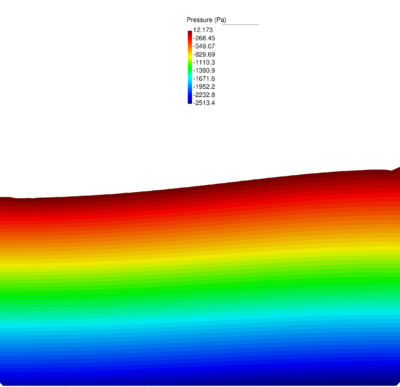

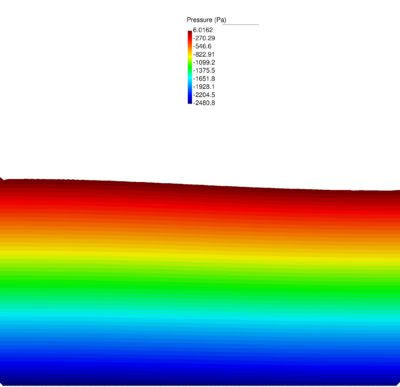

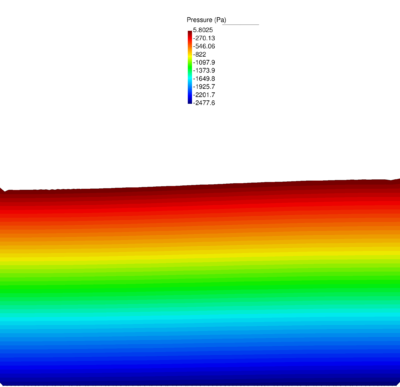

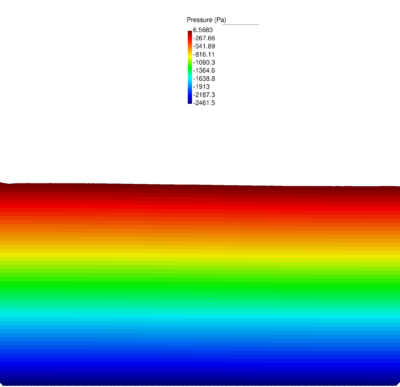

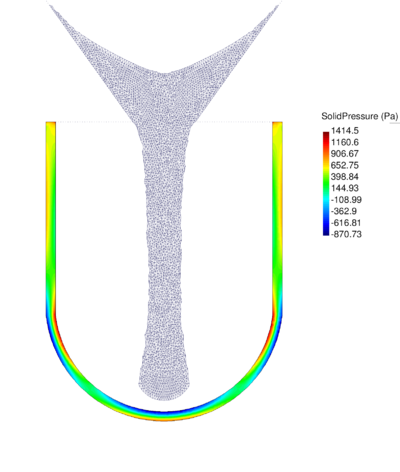

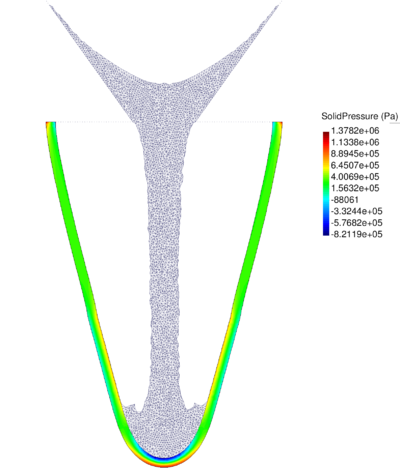

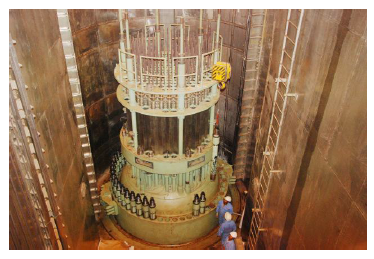

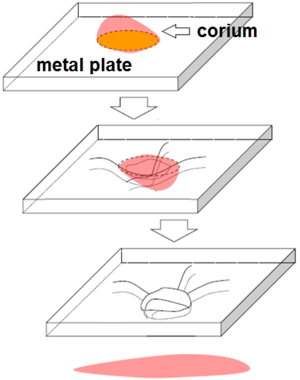

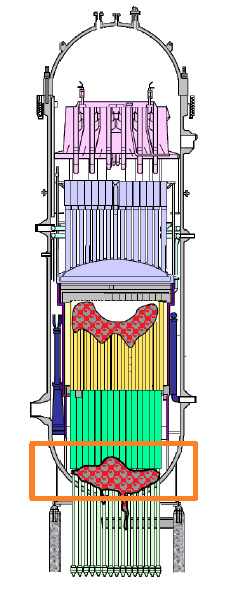

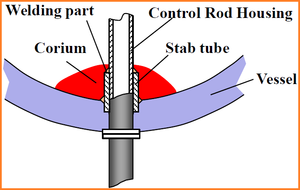

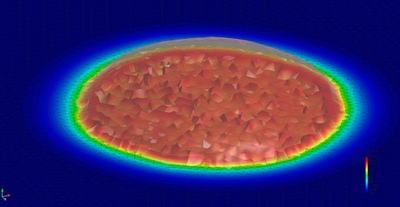

The thermal coupled scheme has been used successfully for the solution of an industrial problem. The objective of study was to analyze the damage of a nuclear power plant pressure vessel induced by a high viscous fluid at high temperature, the corium. The numerical study of this industrial problem has been included in this work.

Resumen

El objectivo de la presente tesis es la derivación e implementación de una formulación unificada con elementos finitos para la solución de problemas de mecánica de fluidos y de sólidos, interacción fluido-estructura (Fluid-Structure Interaction (FSI)) y con acoplamiento térmico. El método unificado está basado en una formulación Lagrangiana estabilizada y las variables incçognitas son las velocidades y la presión. Cada paso de tiempo se soluciona a través de un esquema de dos pasos de tipo Gauss-Seidel. Primero se resuelven las ecuaciones de momento lineal por los incrementos de velocidad, luego se calculan las presiones en la configuración actualizada usando la ecuación de continuidad. Para los dominios fluidos se utiliza el método de elementos finitos de partículas (Particle Finite Element Method (PFEM)) mientras que los sólidos se solucionan con el método de elementos finitos (Finite Element Method (FEM)). Por lo tanto, se ramalla sólo las partes del dominio ocupadas por el fluido. Los campos de velocidad y presión se interpolan con funciones de forma lineales. Para poder analizar materiales incompresibles, la formulación ha sido estabilizada con una nueva versión del método Finite Calculus (FIC). La técnica de estabilización ha sido derivada para fluidos Newtonianos casi-incompresibles. En este trabajo, la estabilización con FIC se usa también para el análisis de sólidos hipoelásticos casi-incompresibles. En la tesis se dedica particular atención al estudio de flujo con superficie libre. En particular, se analiza en profundidad el tema de las pérdidas de masa y se muestra con varios ejemplos numéricos la capacidad del método de garantizar la conservación de masa en problemas de flujos en superficie libre. Además se estudia con detalle el condicionamiento del esquema numérico analizando particularmente el efecto del módulo de compresibilidad. Se presenta también una estrategia basada en el uso de un pseudo módulo de compresibilidad para mejorar el condicionamiento del problema. La formulación unificada ha sido validada comparando sus resultados numéricos con pruebas de laboratorio y resultados numéricos de otras formulaciones. En la mayoría de los ejemplos también se ha estudiado la convergencia del método. En la tesis también se describe una estrategia segregada para el acoplamiento de la formulación unificada con el problema de transmisión de calor. Además se presenta una simple estrategia para simular el cambio de fase. El esquema acoplado ha sido utilizado para resolver varios problemas de FSI donde se incluye la temperatura y su efecto. El esquema acoplado con el problema térmico ha sido utilizado con éxito para resolver un problema industrial. El objetivo del estudio era la simulación del daño y la fusión de la vasija de un reactor nuclear provocados por el contacto con un fluido altamente viscoso y a gran temperatura. En la tesis se describe con detalle el estudio numérico realizado para esta aplicación industrial.

Acknowledgements

I would like to thank all the people that in some way have helped me to complete this doctoral thesis. I would like to express my gratitude to Prof. Eugenio Oñate for many reasons. Thanks to him, four years ago I could come to Barcelona and start my PhD at CIMNE. He gave me the balanced doses of freedom and pressure and he encouraged me to test innovative technologies. I would like thank Prof. Oñate also for giving me the opportunity and the material support to spend a three-month period at the College of Engineering of Swansea. Special thanks go to Dr Josep Maria Carbonell. Without his support I could not realize this work. He devoted me innumerable hours of his time and he gave me technical and not technical suggestions that helped me to make the right choices during my PhD. Moltes gràcies Josep Maria! I would like to thank Prof. Javier Bonet for giving me the possibility to work with his group during my stay at Swansea. Special thanks go to Prof. Antonio Gil y Dr. Aurelio Arranz for their very kind treatment, for improving my knowledge of the Immersed Boundary Potential Method and for the useful discussions about FSI strategies. I really hope that this is just the first step for a future fruitful collaboration. I would like to thank also Mr. Kazuto Yamamura and the Nippon Steel & Sumimoto Metal Corporation for giving us the possibility to publish the PFEM simulation of the damages of a nuclear power plant pressure vessel. I also acknowledge the Agencia de Gestió d'Ajuts Universitaris i de Recerca (AGAUR) for the financial support. I would like to thank also Riccardo, Antonia, Jordi, Pablo and Lorenzo for their contributions for this thesis. This thesis is dedicated to my parents that still represent to me a fundamental and unique support. Grazie per tutti gli sforzi che avete fatto in questi anni e per le numerose visite a Barcellona. Questa tesi è per voi. Finally, I would like to thank Lucía simply for staying by my side during these years. Her smile has been the gasoline I used for dealing with all this work.

Abbreviations

AL Augmented Lagrangian

ASGS Algebraic SubGrid Scale

FCM Fuel Containing Material

FEM Finite Element Method

FIC Finite Increment Calculus

FSI Fluid-Structure Interaction

GLS Galerkin Least-Squares

IBM Immersed Boundary Method

IFEM Immersed Finite Element Method

ISPM Immersed Structural Potential Method

LBB Ladyzenskaya-Babuzka-Brezzi

LFCM Lava-like Fuel Containing Material

NPP Nuclear Power Plant

OSS Orthogonal SubScale

PFEM Particle Finite Element Method

SPH Smooth Particle Hydrodynamics

SUPG Streamline Upwind Petrov Galerkin

TL Total Lagrangian

UL Updated Lagrangian

V Velocity

VMS Variational Multi-Scale

VP Velocity-Pressure

VPS Velocity-Pressure-Stabilized

Dai diamanti non nasce niente,

dal letame nascono i fior.

"Nothing grows out of precious diamonds,

Out of dung the flowers do grow."

Fabrizio De Andrè

Chapter 1. Introduction

1.1 Objectives

The objective of this work is to develop a unified formulation for the solution of the fluid and solid mechanics, fluid-structure interaction (FSI) and thermal coupled problems. The aim is to analyze the continuum in a unified manner trying to reduce at minimum the differences between the analysis of fluids and solids. For this purpose the numerical model has been planned in order to meet the specific requirements of solid and fluid mechanics and their approximation with the Finite Element Method (FEM) [136], but without limiting excessively the capability of the model. In fact the computational method should be capable to deal with critical problems such as those involving elasto-plastic solids, quasi-incompressible materials, free surface fluids and phase change due to heat transfer solutions.

According to these considerations, the computational model has been designed for using a stabilized Velocity-Pressure formulation. The formulation has been particularized for hypoelasto-plastic, compressible and quasi-incompressible solids and quasi-incompressible Newtonian fluids. The algorithm for the FSI problems has been inspired by the analogous unified strategy presented in [63]. For the fluid phase, the Particle Finite Element Method (PFEM) [88] has been used, while for the solid the classical FEM is adopted. The scheme has been stabilized with an updated version of the Finite Calculus (FIC) technique [82]. For dealing with thermal coupled problems, this unified formulation has been extended to treat the heat transfer problem via a staggered scheme. For the modeling of the phase change, a simplified procedure has been developed. The whole formulation has been implemented in a C++ code.

1.2 State of the art

In this section, an overview of the numerical methods used for simulating a free surface fluid flow interacting with deformable solids is given. For the sake of clarity, the section is divided in three parts representing the main fields involved by this work. First the Eulerian and Lagrangian approaches for free surface fluid dynamics problems are presented. Then an overview of the stabilization for incompressible, or quasi-incompressible, material is given. Finally, the principal algorithms for solving FSI problems are described.

1.2.1 Eulerian and Lagrangian approaches for free surface flow analysis

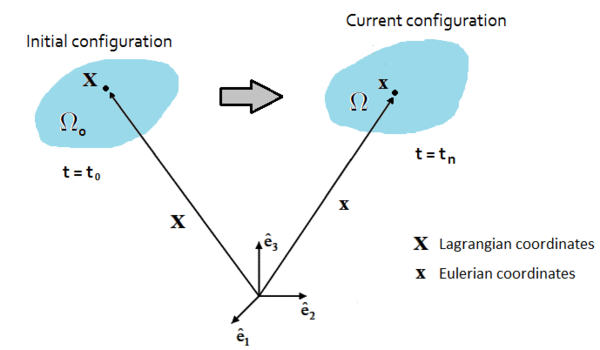

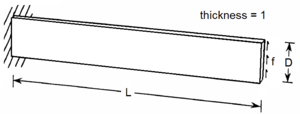

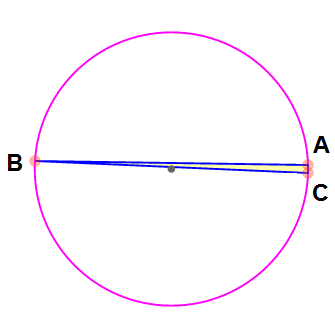

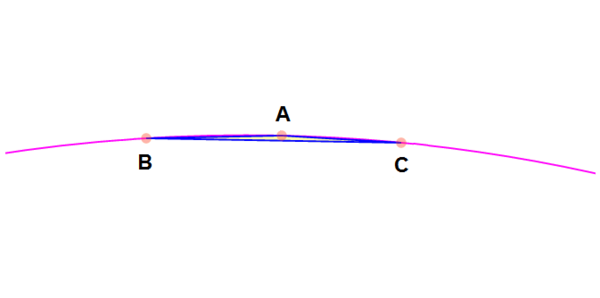

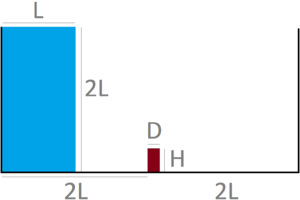

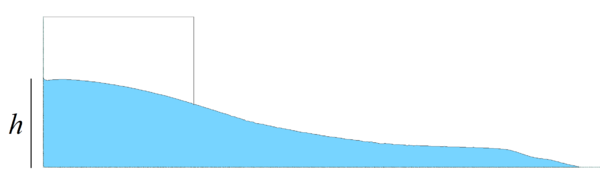

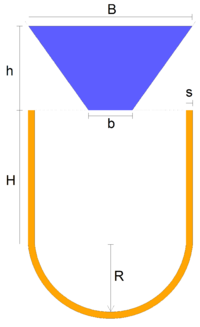

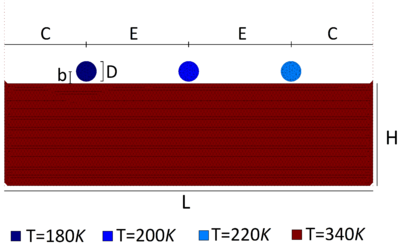

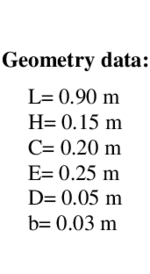

Consider the description of the motion of a general continuum represented in Figure 1. The domain represents the body at the initial state at time while the domain represents the same body at time after deformation. The domain is called initial configuration, whereas is the current, or deformed, configuration. In order to describe the kinematics and the deformation of the body, the reference configuration has to be defined because the motion is defined with respect to this configuration.

|

| Figure 1: Description of the motion of a general continuum body |

|

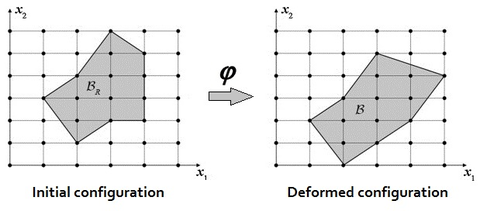

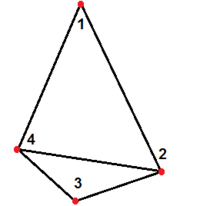

| Figure 2: Motion description using an Eulerian mesh |

|

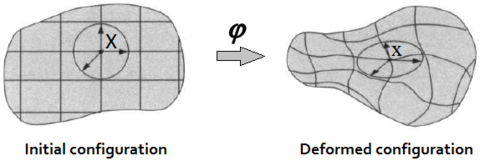

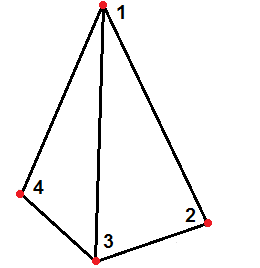

| Figure 3: Motion description using a Lagrangian mesh |

Consequently, on the one hand the non-linear convective term disappears from the problem and on the other hand the mesh undergoes large distortions and it requires to be regenerated.

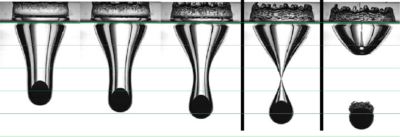

In the analysis of free surface flows, the detection of the free surface contours represents a crucial task. Its position is unknown and it has to be determined at each time increment in order to solve properly the boundary value problem. For these problems, the Lagrangian description may be preferred to the Eulerian one. In fact, with a Lagrangian approach the free surface is detected automatically by the position of the mesh nodes, while an Eulerian approach requires the implementation of a specific technology for this task.

Several strategies have been developed in the literature for tracking the free surface in an Eulerian framework. One of the earliest contributions was given by the so called marker and cell method [53]. In this approach a set of marker particles that move according the flow are used to detect which regions are occupied by the fluid and which not. An evolution of this technique is the volume of fluid method [55]. In this case the free surface boundary is detected using a scalar function that assumes the unit value in the fluid cells and the value zero in those ones with no fluid. The cells with an intermedium value are the ones that contain the free surface. Another possibility is the level set method [100]. This technique is used in various fields, not only in continuum mechanics, and it allows for detecting shapes or surfaces on a fixed grid without making any parametrization of them. For this reason, this procedure has been also used for matching the free surface contour on an Eulerian mesh [106]. A similar idea was used in [7] where the position of the free surface is detected using a cloud of Lagrangian particles moving over an Eulerian mesh.

The free surface flows can be solved also using an hybrid Eulerian-Lagrangian technique. This is the so termed Arbitrary Lagrangian-Eulerian (ALE) approach [137]. The aim of this method is to exploit the best features of the Eulerian and the Lagrangian procedures and to combine them. The mesh nodes can arbitrary be fixed or can move with the fluid [38]. Generally, far from the moving boundaries a fixed Eulerian grid is used, while near to the interface the mesh moves according to the motion of the boundary [25]. However if the boundary motion is large or unpredictable, also in the ALE methods the grid may suffer large distortions and may require a proper remeshing procedure [116].

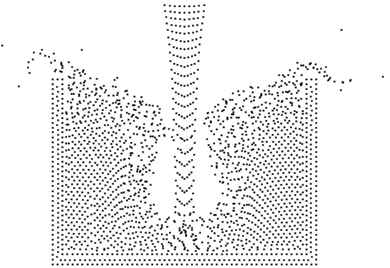

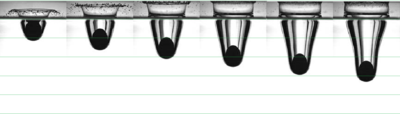

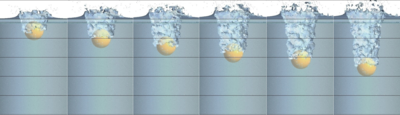

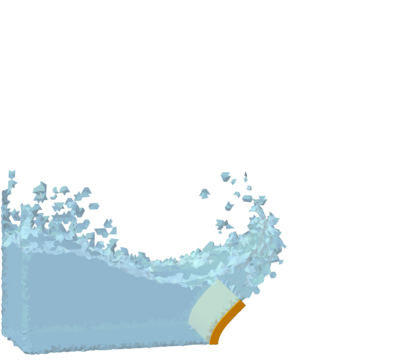

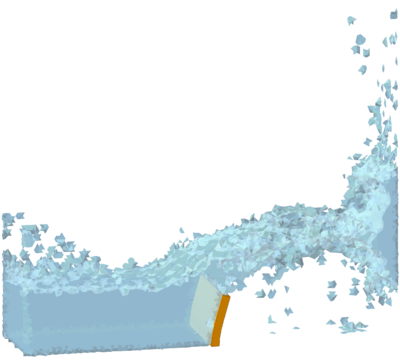

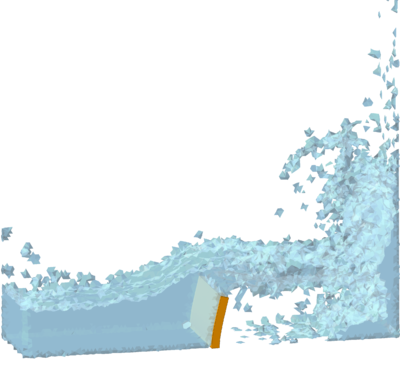

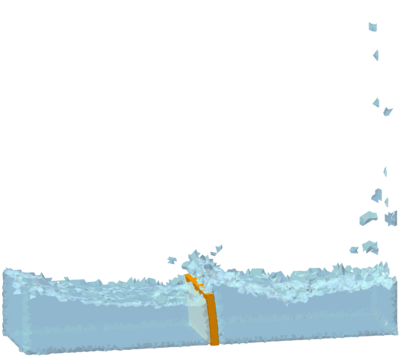

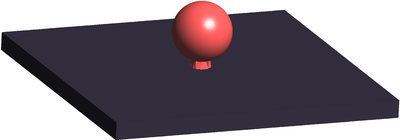

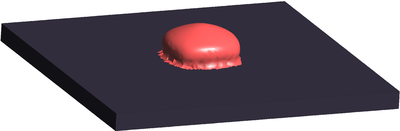

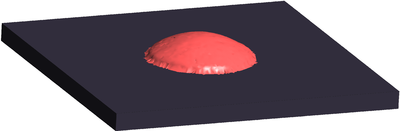

In purely Lagrangian approaches, the mesh needs to be regenerated whenever a threshold limit for the distortion is exceeded. This is the basis of a particular class of Lagrangian finite element formulation called the Particle Finite Element Method (PFEM). The method was initially developed by the group of professors Idelsohn and Oñate [66,67]. The PFEM treats the mesh nodes of the domain as particles which can freely move and even separate from the rest of the fluid domain representing, for instance, the effect of water drops. A mesh connects the nodes discretizing the domain where the governing equations are solved using a classical finite element method. These features make the PFEM the ideal numerical procedure to model and simulate free surface flows. In the last years, many scientific publications have shown the efficacy of the PFEM for solving free surface flow problems, see among others [32,68,117]. The PFEM has also been tested successfully in other kind of problems, such as fluid mechanics including thermal convection-diffusion [5,80,95], multi-fluids [36,62], granular materials [131], FSI [81,132] and excavation [19].

Mesh free methods are other class of Lagrangian techniques. In this strategy the remeshing is not required because the governing equations are solved over a set of nodes without referring to a mesh. One of the first meshfree techniques is the Smooth Particle Hydrodynamics (SPH) method. This method was introduced independently by Gingold and Monaghan [50] and Lucy [70] for the simulation of astrophysical problems such as fission of stars. SPH is a particle-based Lagrangian technique where discrete smoothed particles are used to compute approximate values of needed physical quantities and their spatial derivatives. The particles have assigned a characteristic distance, called ‘smoothing length’, over which their properties are ”smoothed” by a kernel function. A typical drawback of the SPH method is that it is hard to reproduce accurately the incompressibility of the materials. The SPH technique has been used successfully for solving fluid-structure interaction problems [3].

1.2.2 Stabilization techniques

A FEM-based procedure may require to be stabilized when incompressible, or quasi- incompressible, materials are analyzed. For example from the finite element solution of the Navier Stokes equations numerical instabilities may arise from two sources. The first one is due to the presence of the convective term in the linear momentum equations. This term introduces a non-linearity in the equations and it needs a proper stabilization for solving high Reynolds number flows with the FEM [38]. Furthermore, the orders of interpolation of pressure and velocity fields cannot be chosen freely but they have to satisfy the so called (LBB), or , condition [15]. If the orders of interpolation of the unknown fields do not satisfy this restriction, a stabilization technique is required in order to avoid numerical instabilities, as the spurious oscillations of the pressure field.

It is well known that the weak form generated by Galerkin approximation leads to a less diffusive solution than the strong problem. So the main idea of many stabilization techniques consists of adding an artificial diffusion to the problem. The first attempt was made by Von Neumann and Richtmyer [75]. Their solution adds an artificial diffusion to the strong form of the problem. This technique introduces an excessive dissipation to the problem because the diffusivity is added in every direction. An important evolution of this approach was the Streamline Upwind Petrov Galerkin (SUPG) [58]. In this approach, the artificial diffusion is added by means of the test functions and only on the direction of the streamlines. Furthermore, this is performed in a consistent way: the stabilization terms vanish when the solution is reached. An extension of the SUPG method is the Galerking Least-Squares (GLS) method [60]. The main difference between the two is that in the GLS method the stabilization terms are applied not only to the convective term but to all the terms of the equation. The Variational Multi-Scale (VMS) methods [59] split the problem variables in a large-scale and a subscale terms. The large-scale terms represent the part of the solution that can be captured by the finite element mesh, while the subscale part consists of an approximate solution that has to be added to the large-scale term in order to obtain the correct solution. This idea represents the basis of other stabilization methods. Among these, the most largely used are the Algebraic Subgrid Scale Formulation (ASGS) and the Orthogonal Subscales (OSS) methods, respectively introduced in [28,29]. Another efficient stabilization technique is the Finite Calculus (also termed Finite Increment Calculus) (FIC) approach (see among others [76,77,85,86]). This method has some analogies with the SUPG technique (for a comparison between these methods see [89]). The FIC approach is based on expressing the equations of balance of mass and momentum in a space-time domain of finite size and retaining higher order terms in the Taylor series expansion typically used for expressing the change in the transported variables within the balance domain. In addition to the standard terms of infinitesimal theory, the FIC form of the momentum and mass balance equations contains derivatives of the classical differential equations in mechanics multiplied by characteristic distances in space and time. In this work an updated version of the FIC method has been derived and tested.

In solid mechanics a stabilization procedure may be required for the solution of problems involving incompressible, or quasi-incompressible solids. Situations of this type are common in forming processes or in the analysis of the rubber-type materials. Many of the stabilization procedures for fluid dynamics have been also used also for solid dynamics. For example, the VMS method has been applied in quasi-incompressible solid mechanics in [22,24], the OSS in [26]. In [48,49] a stabilized multi-field Petrov-Galerkin procedure is used. Finally, the application of the FIC in solid mechanics is reported [94,103].

1.2.3 Algorithms for FSI problems

Many approaches have been developed for solving FSI problems. Typically the computational techniques for FSI are distinguished in monolithic and staggered, or partitioned, approaches. In a monolithic approach the fluid and the solid domains are solved in a single system of equations (see among others [57], or [73]). In this technique the flow of information between the solid and the fluid parts is implicitly performed by the procedure. On the contrary, in staggered schemes the fluid and the solid dynamics are solved separately and boundary conditions are transferred from a domain to the other at the interface. From the algebraic point of view, the solution is achieved by solving two different linear systems which are coupled by means of the boundary conditions defined along the interface. Within partitioned schemes, depending on the level of coupling between the fluid and the solid dynamics, a further classification can be done. In a weakly coupled segregated schemes when the transfer of information through the interface is performed only once for each time step, (for example see [42]), whereas in strongly coupled schemes this operation is performed within a convergence loop (as a reference see [34]). Clearly, a weakly coupled scheme has a lower computational cost but it can be used only when the interaction between the solid and the fluid domains is not strong or complex. Otherwise the algorithm may not find the correct numerical solution of the problem.

Partitioned methods allow the reutilization of existing solvers. Furthermore, the solid and the fluid solvers can be updated independently. Staggered schemes lead to smaller and better conditioned linear systems than the ones obtained with monolithic approaches. On the other hand, monolithic strategies are generally more stable and fast than staggered schemes, and they lead to a more accurate solution of FSI problems, because a stronger coupling is ensured.

Another general classification of the FSI algorithms is based upon the treatment of meshes. In conforming mesh methods, in order to allow the transfer of information, the fluid and the solid meshes must have in common the nodes along the interface. Consequently, if the position of the interface nodes changes in a domain, also the other domain must modify its grid in order to guarantee the conformity of the two meshes along the interface. On the contrary, in non-conforming mesh methods the interface and the related conditions are treated as constraints imposed on the model equations so that the fluid and solid equations can be solved independently from each other with their respective grids [21]. This represents an important advantage because, typically, the mesh used for the fluid has an average size lower than the one used for the solid and so it is not necessary to refine the solid finite element grid near to the interface. However, non-conforming mesh algorithms are more complex to implement and it is not trivial to guarantee their robustness.

In the so-called Immersed Boundary Method (), the fluid is solved using an Eulerian grid and the solids are immersed on top of this mesh [101,104]. The interaction is ensured by penalizing the Navier-Stokes equations with the momentum forcing sources of the immersed structures. An evolution of the IBM is the () where the structure is modeled as a potential energy functional solved over a cloud of integration points that move within the fixed fluid mesh [47,104]. Also in the () [54,129] the structure acts as a momentum forcing source for the fluid governing equations, but in this case a Lagrangian mesh is employed for the solid domains.

1.3 Numerical model

The aim of this work is to derive a finite element formulation capable to solve, through a unique set of equations and unknown variables, the mechanics of a general continuum. The term 'general continuum' refers to a domain that may include compressible and quasi-incompressible solids, fluids or both interacting together. For this reason, the formulation is termed . The Unified formulation is based on a mixed Velocity-Pressure Stabilized procedure and it has been implemented in a sequential code.

1.3.1 Reasons

There are many reasons for undertaking the above objective.

The first advantage of the Unified formulation is that it allows for solving fluid and solid dynamics problems by implementing and using a single calculation code.

Furthermore, if solids and fluids are solved via the same scheme, it is simpler to implement the solver for FSI problems because it is not required neither changing the variables, neither implementing the transfer of transmission conditions through the interface. With this formulation solids and fluids represent regions of the same continuum and they differ only by the specific values of the material parameters. As a consequence, the FSI solver requires a small computational effort and it can be implemented by introducing just a few specific functions. This will be explained in detail in the section dedicated to FSI problems.

Additionally, with the Unified formulation the most natural approach for solving FSI problem is the monolithic one. This brings in the further advantage that the coupling is ensured strongly and an iteration loop is not required, as for staggered procedures.

Finally, using the same set of unknowns for the fluid and the solid domains reduces the ill-conditioning of the FSI solver, because the solution system does not include variables of different units of measure.

1.3.2 Essential features

The Unified formulation is a compromise between a fluid and a solid formulation and it should be capable to satisfy the requirements of each problem mechanics and finite element approximations. In other words, in order to solve adequately fluids and solids with the same formulation, the solution procedure must take into account the constraints that both models impose.

Concerning the choice of the unknown variables, these are generally selected depending on the constitutive law of the materials. For Newtonian fluids, the Cauchy stress tensor is related directly to the deformation rate tensor. This implies that the velocities are the most useful unknowns in fluid mechanics. Conversely, in solid mechanics the displacements are generally preferred as variables, as the stresses are related to the deformations. However, for solids there also exist constitutive laws expressed in rate form, as for hypoelastic models.

For the analysis of incompressible, or quasi-incompressible, materials a mixed formulation is required in order to overcome the associated numerical instabilities, both in solids and

fluids. In fluids, the most popular combination of unknown variables is the velocity-pressure

scheme. In solid mechanics, there are several mixed approaches, as the displacement-stress [16],

the displacement-strain [23], the displacement-deformation gradient [49], the

displacement-deformation gradient-jacobian [48], the displacement-pressure [26] and the

velocity-pressure formulation [110]. The combination of unknowns is selected depending on the

desired accuracy for the stress and strain fields and the associated computational cost. Among

the mentioned mixed approaches, the displacement- pressure and the velocity-pressure formulations

lead to the lowest computational cost, because the number of unknowns is smaller. However the

velocity-pressure formula- tion has the further advantage that is the canonical scheme for fluid

mechanics. Hence, according to these considerations, the Unified formulation has been based on a

mixed

velocity-pressure scheme.

Another key decision in the design of the Unified formulation concerns the choice of the description framework. Solids are typically solved using a (total or updated) Lagrangian description, while for fluids, due to the large deformations they undertake, the Eulerian framework is generally preferred. However, for free surface flows, as the ones treated in this work, a Lagrangian description has the important advantage that the free surface boundaries are detected automatically, because the particles of the fluid coincide with the nodes of the mesh. The price for this is that a remeshing procedure is required in order to avoid the excessive distortion of the mesh. According to these considerations, the Unified formulation has been implemented using an updated Lagrangian description.

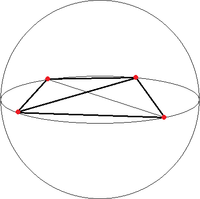

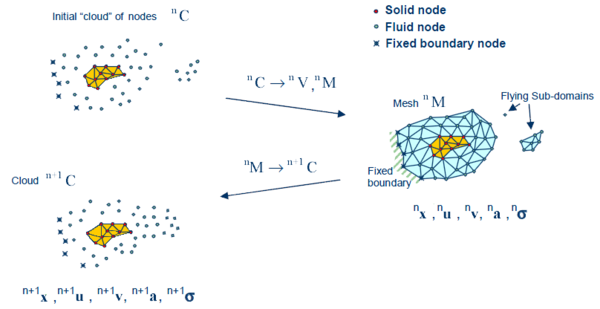

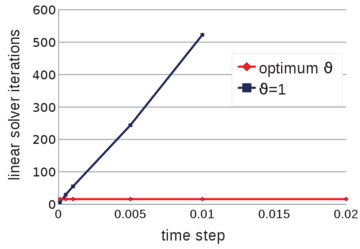

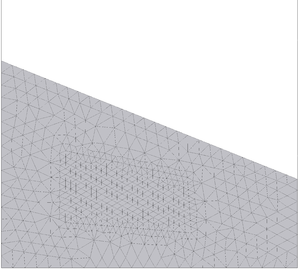

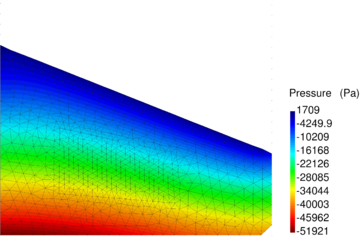

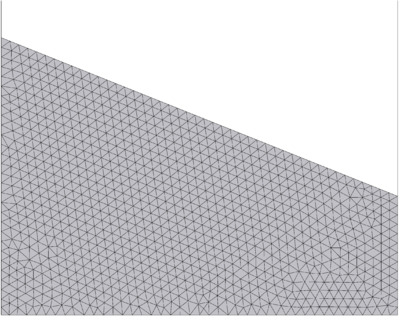

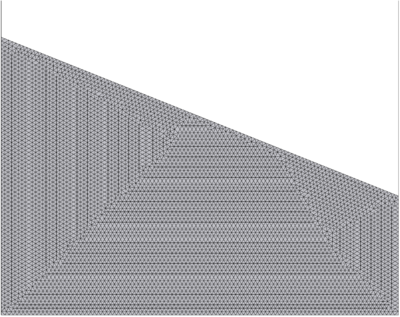

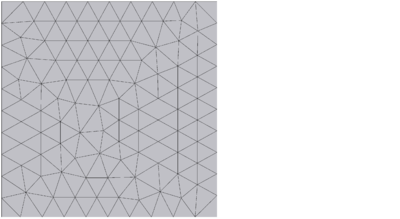

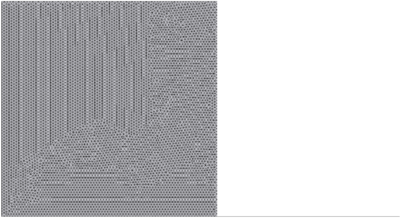

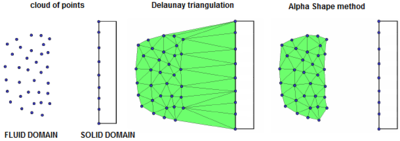

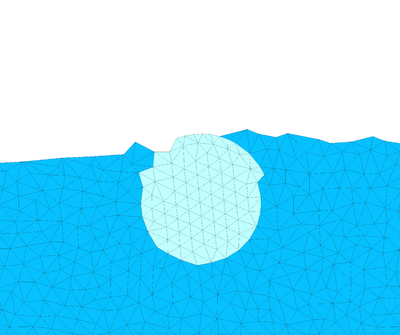

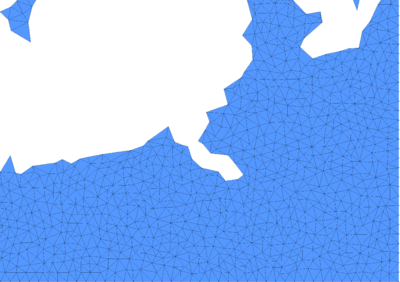

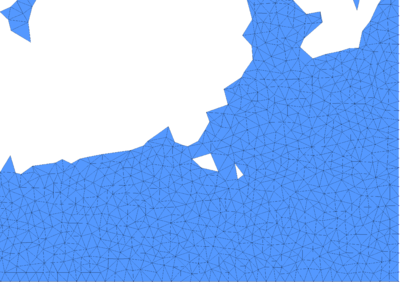

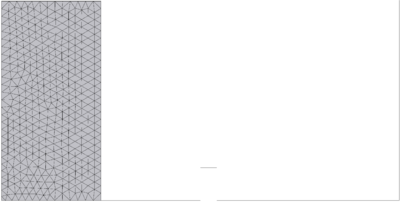

In this work, the Particle Finite Element Method (PFEM) [88] has been used for solving the fluid domain only. The PFEM is a Langrangian numerical technique that treats the mesh nodes as moving points which can freely move and even separate from the domain to which they are initially attached representing, for instance, the effect of water drops. The PFEM is based on a remeshing procedure that efficiently combines the Delaunay tessellation and the Alpha Shape method [39]. In order to reduce the computational cost associated to the remeshing step, all the unknowns are stored in the nodes and linear shape functions are used for the finite element interpolation. Conversely, the solid domain keeps a fixed mesh during the whole analysis. The reason for this is that in non-linear solid mechanics it is required to preserve not only the nodal unknowns but also elemental information as the stress state of the previous time step. A remeshing implies the elimination of the previous discretization and the creation of new elements. In order to keep the elemental information in the remeshing step, a projection procedure from the elements of the previous mesh to its nodes, and from these to the elements of the new mesh is required. These operations may introduce an interpolation error in the scheme that affects the solution of solid mechanics problems. In the analysis of Newtonian fluids all the information can be stored in the nodes, so the remeshing does not affect the accuracy of the scheme. For these reasons, in this work the PFEM is used only for the fluid, while solids are solved via the classical FEM.

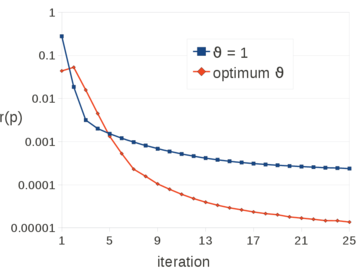

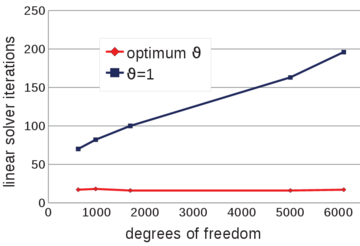

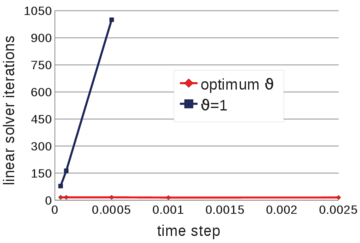

In order to improve the conditioning of the solution system, a Gauss-Seidel segregated scheme is used. This means that the problem is solved iteratively and separating the unkwown variables, the velocities and the pressure. The solution method consists of two steps. In the first one the linear momentum equations are solved for the velocity increments and considering the pressure of the previous non-linear iteration in the residual term. In the second step, the continuity equation is solved for the pressure in the updated configuration using the velocities computed at the first step. This two-step algorithm leads to a smaller and better conditioned linear system than using a monolithic approach. A crucial point of this scheme is the derivation of the tangent matrix of the linear momentum equations. The velocity increments are solved by condensing the pressure. According to this procedure, the tangent matrix for the linear momentum equations of the mixed velocity-pressure formulation does not differ from the one of a velocity formulation. Furthermore, the derivation of the tangent matrix for the velocity formulation is easier, as it does not involve the pressure. For these reasons, the first step towards the unified scheme is the derivation of the Velocity formulation. The mixed Velocity-Pressure formulation will be derived by exploiting the linearization performed for the Velocity formulation. In [79] another procedure for the derivation of the exact tangent matrix for an Updated Lagrangian scheme is described.

The condensation of the pressure in the tangent matrix of the linear momentum equations may induce the ill-conditioning of the linear system for the analysis of quasi-incompressible materials. This ill-conditioning emanates from the volumetric counterpart of the tangent matrix that is governed by the bulk modulus, that typically has high values that may compromise the conditioning of the linear system. In this work, a thorough study of the conditioning drawbacks associated to this scheme has been performed and a useful and easy to implement technique to overcome these inconveniences has been tested and validated.

The numerical method proposed in this work is an improvement versus other numerical schemes for quasi-incompressible materials where an arbitrarily defined pseudo-bulk modulus was used in both the linear momentum and the mass conservation equations [110,109,108]. .

The method can be also related to the so-called Augmented Lagrangian (AL) procedures for solving the Navier-Stokes equations for incompressible [10,11,41,44,124] and weakly compressible [14,123].

In order to deal with incompressible (or quasi-incompressible) materials a mixed formulation is required. In this work both the velocities and the pressure are interpolated using linear shape functions. This combination does not fulfil the condition [15] and the problem needs to be stabilized. The required stabilization is ensured using an updated version of the FIC technique [82] applied to the mixed Velocity-Pressure formulation. The FIC stabilization method has a small intrusivity because its terms only affect the continuity equation. In fact for solving the linear momentum equations the same scheme as for the (not stabilized) mixed Velocity-Pressure formulation is used. It will be shown that the PFEM-FIC stabilized procedure guarantees a good accuracy for the mass conservation of the free surface flows. The stabilization procedure is derived for quasi-incompressible fluids, but it can be easily extended to quasi-incompressible hypoelastic solids.

The derivation of the Unified stabilized formulation is carried on trying to maintain as much as possible the generality of the scheme. For this reason the constitutive relations are introduced only as the last step. The Velocity (V) and the mixed Velocity-Pressure (VP) formulations are derived first for a general material and then particularized for specific constitutive laws. For quasi-incompressible materials only the mixed Velocity-Pressure Stabilized (VPS) formulation can be used while for compressible materials the Velocity and the standard (not stabilized) mixed Velocity-Pressure formulations are both suitable. In particular, for compressible solids, the hypoelastic model has been chosen.

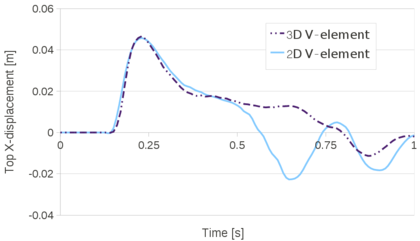

The FSI problem is solved in a monolithic way, hence solids and fluids are solved by the same linear system. For the solid domain it is possible to choose which formulation to use. Depending on the problem, one may chose the V, the VP or the VPS element.

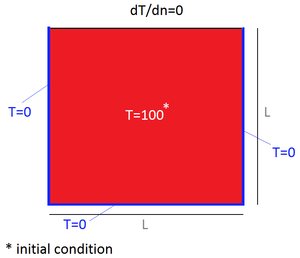

The Unified formulation for FSI problems can be easily coupled with the heat transfer problem in order to solve coupled thermal mechanical problem. The coupling is performed via a staggered scheme. The effect of the heat is taken into account by considering the material properties depending on the temperature and including in the strain tensor the deformations induced by the temperature. With the PFEM Unified formulation also phase change problems can be modeled.

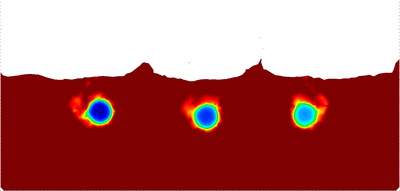

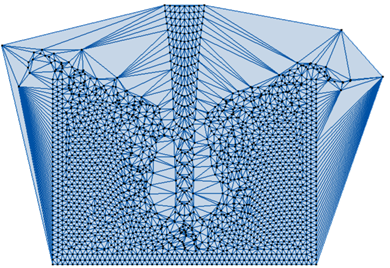

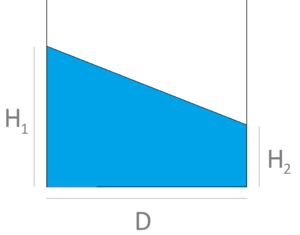

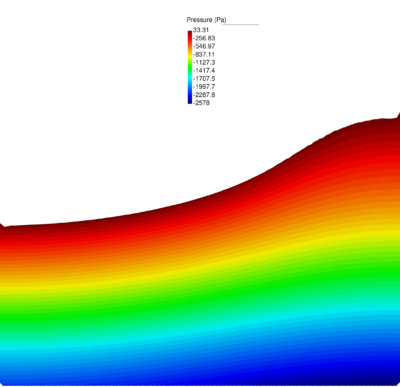

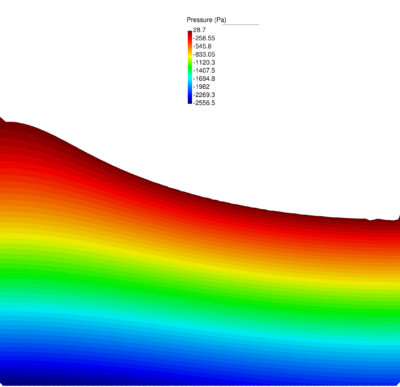

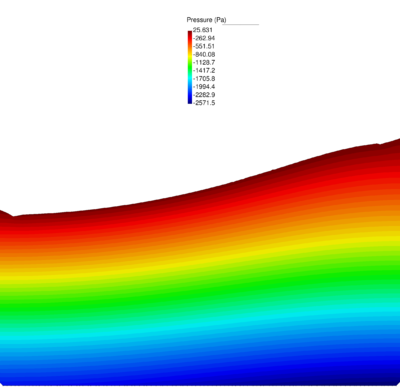

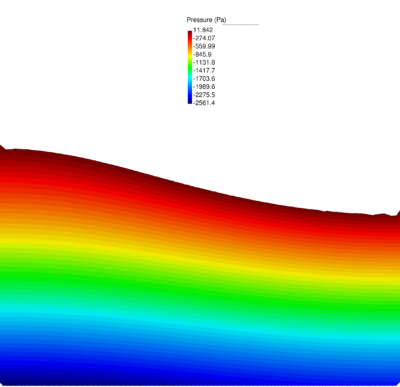

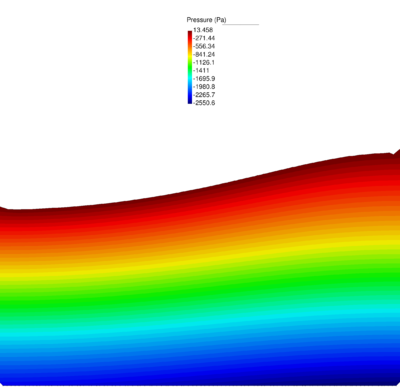

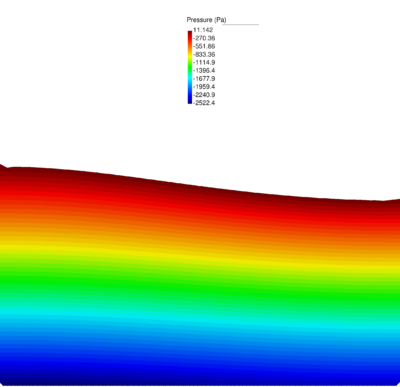

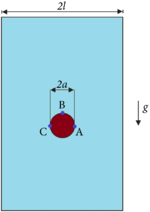

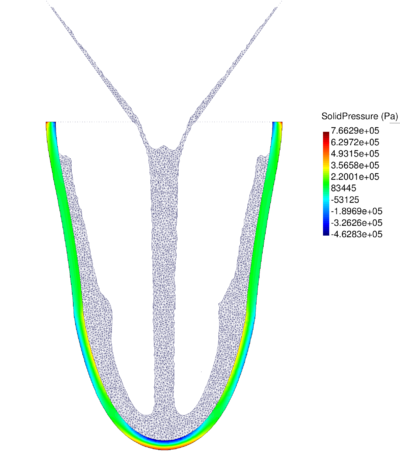

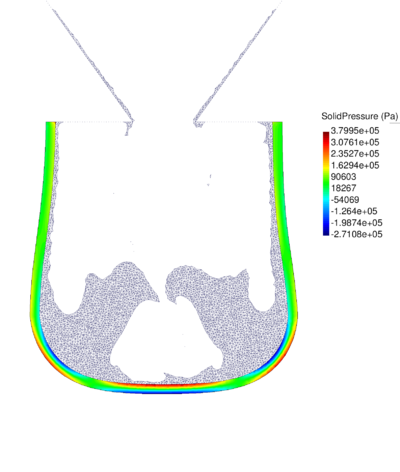

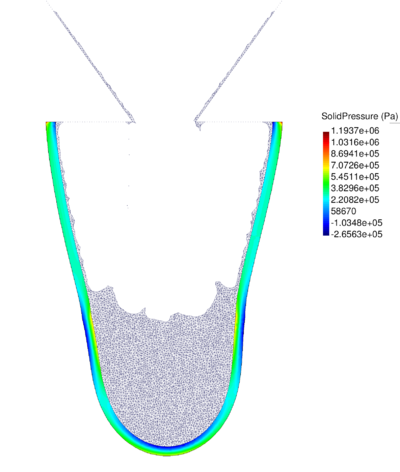

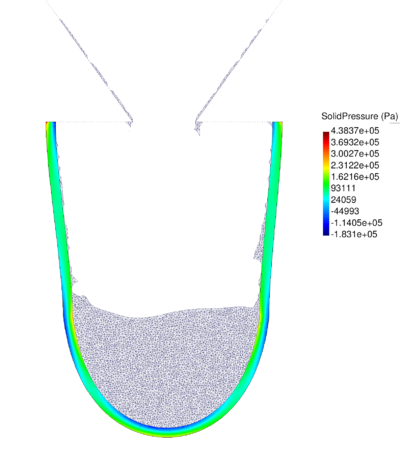

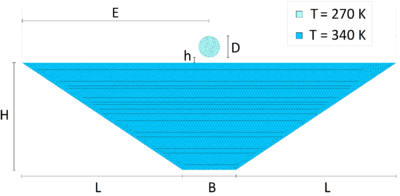

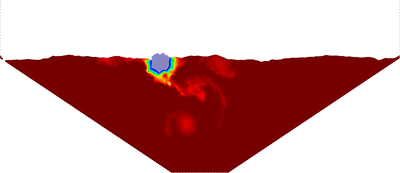

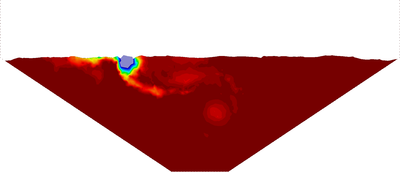

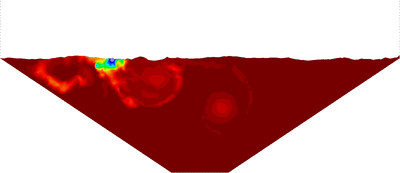

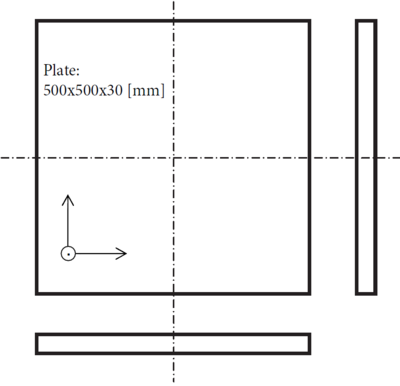

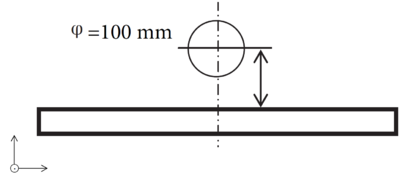

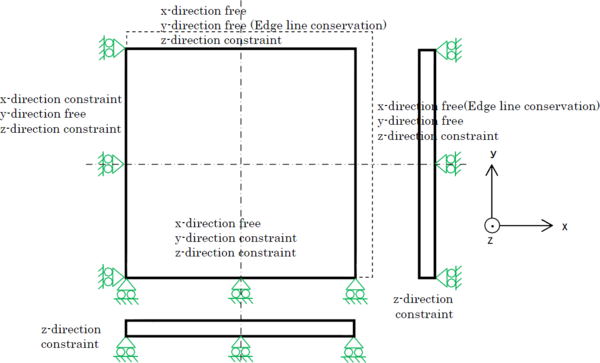

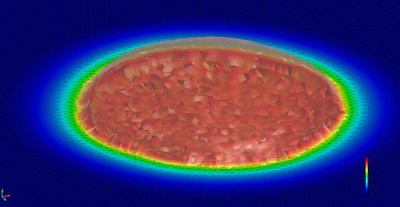

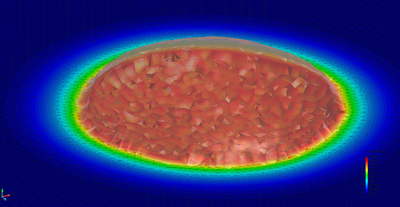

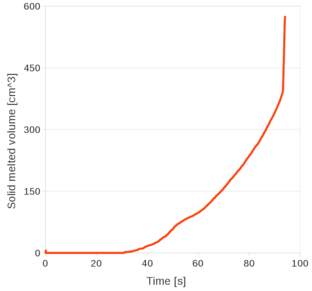

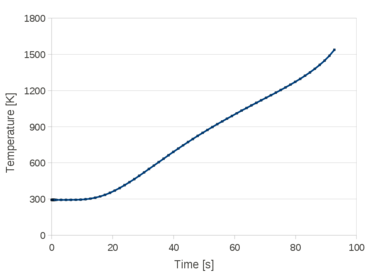

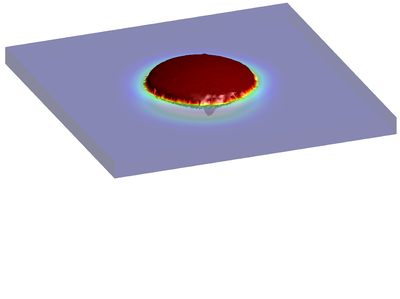

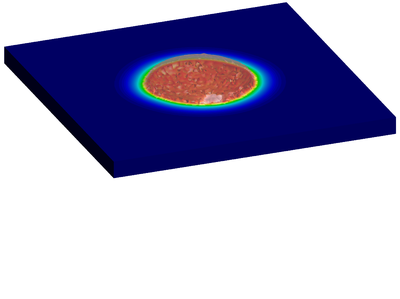

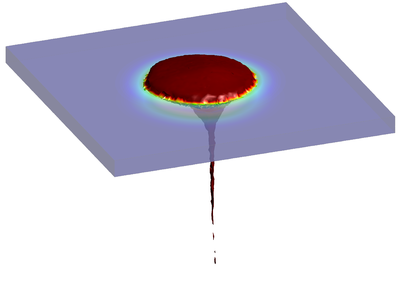

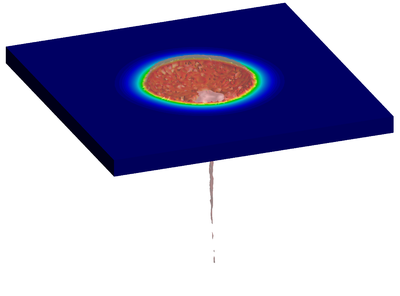

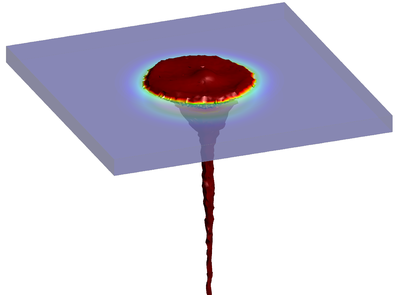

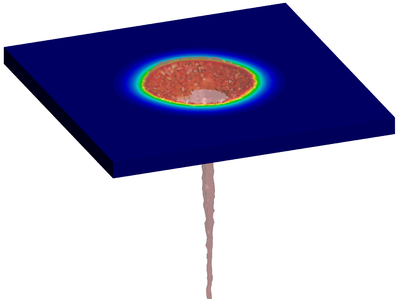

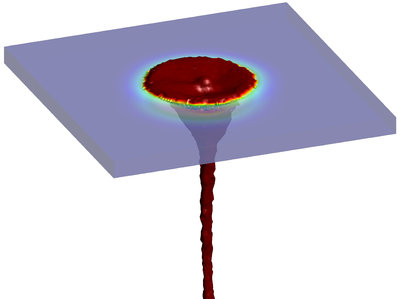

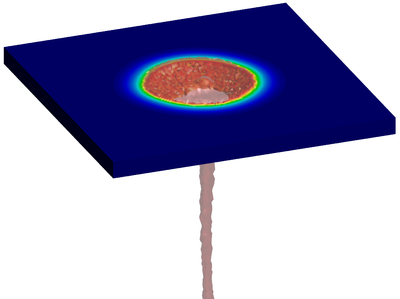

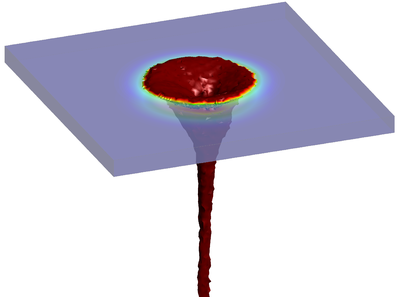

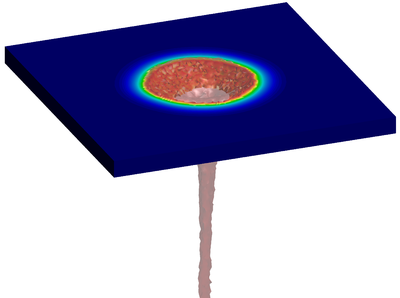

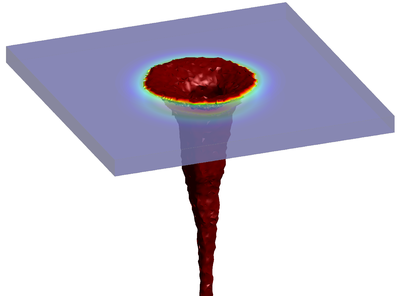

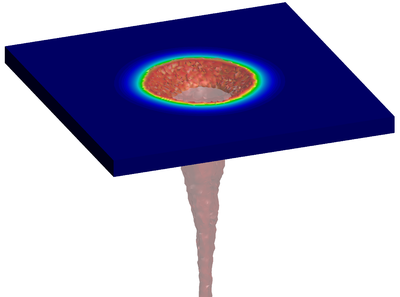

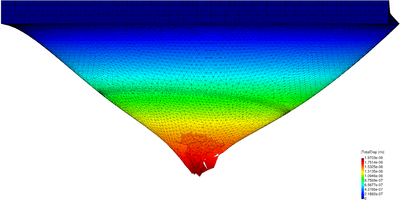

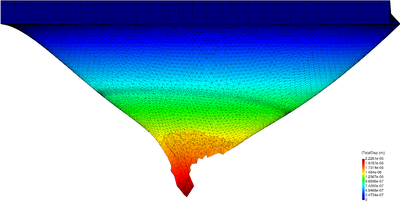

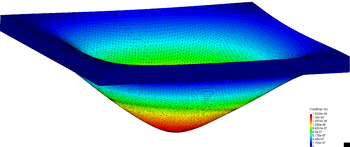

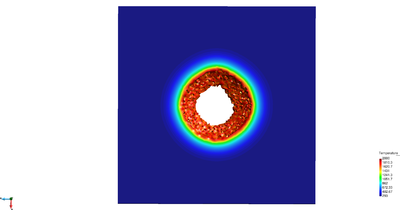

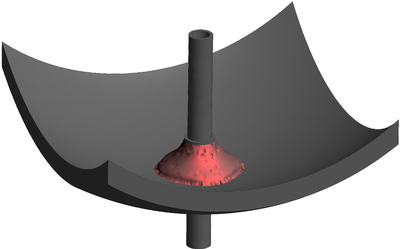

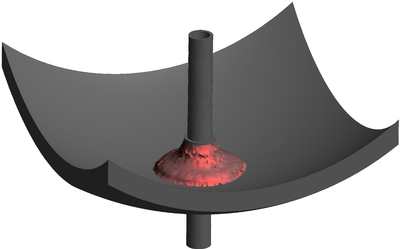

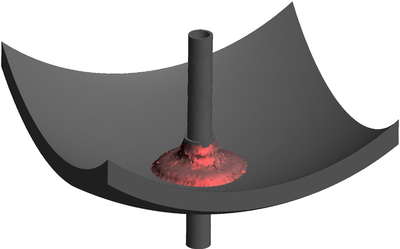

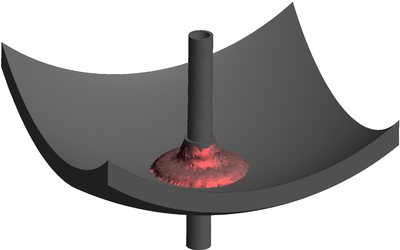

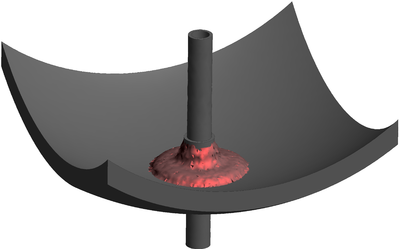

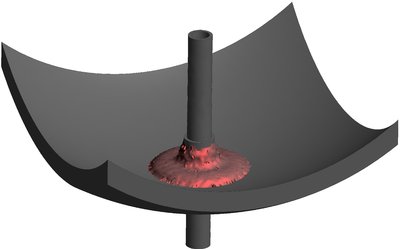

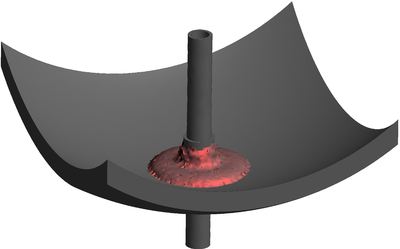

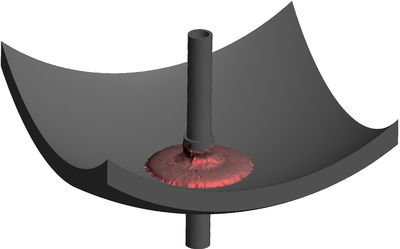

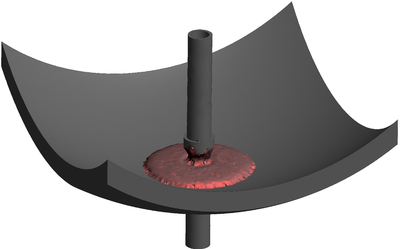

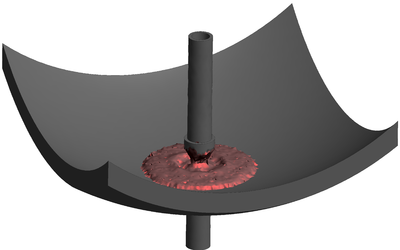

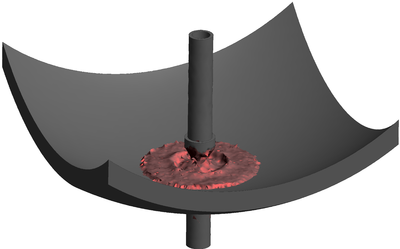

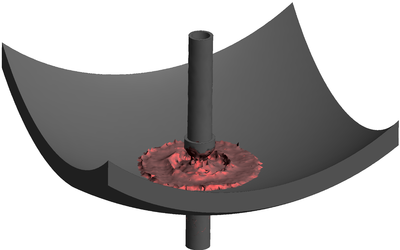

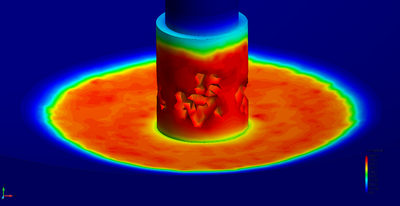

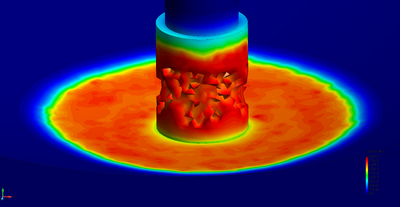

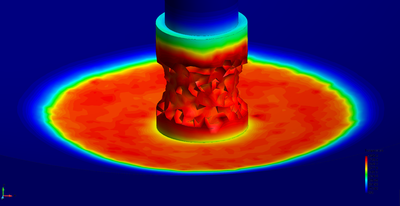

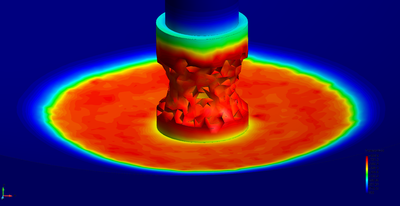

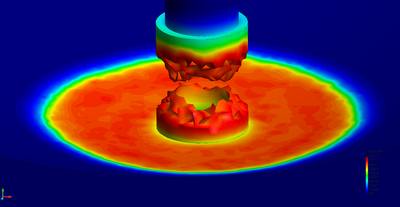

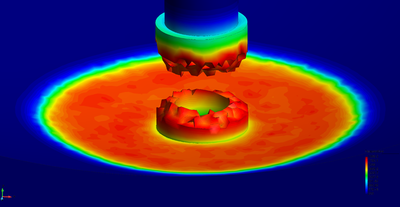

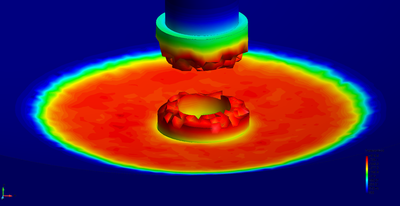

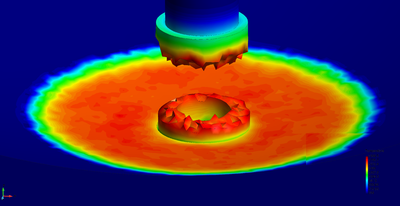

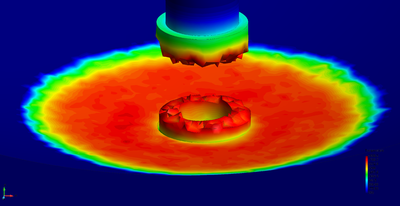

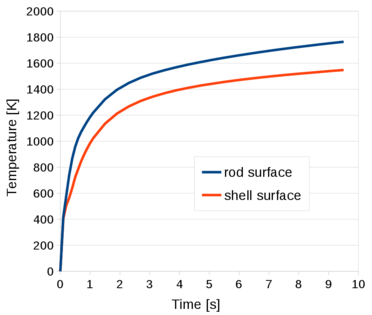

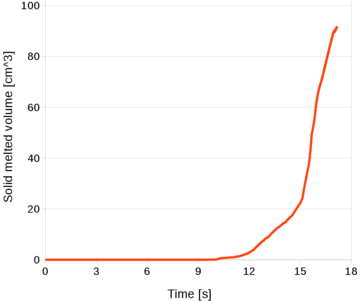

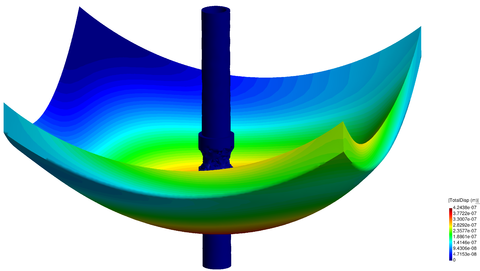

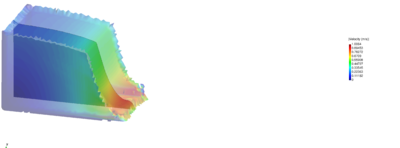

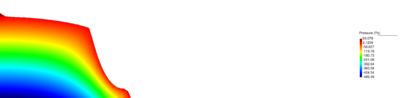

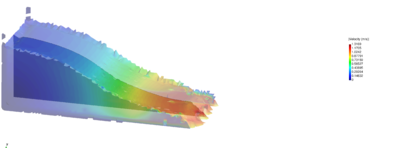

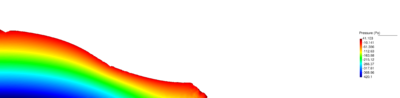

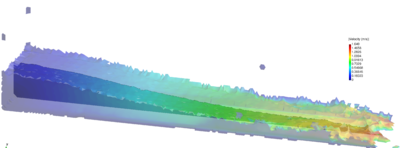

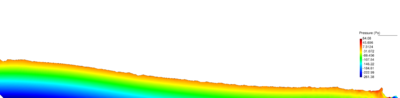

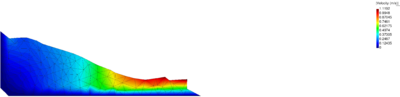

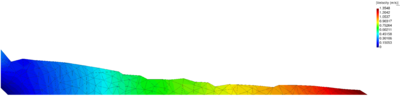

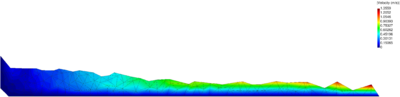

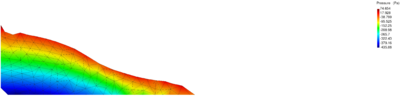

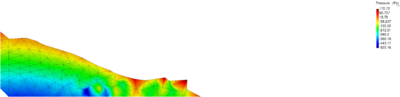

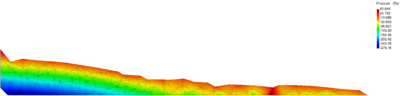

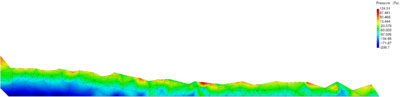

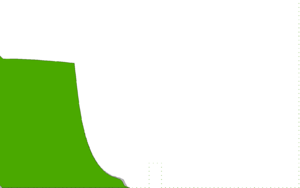

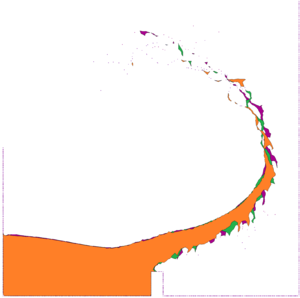

The Unified stabilized VP formulation with thermal coupling has been used for the analysis of an industrial application. The study concerned the analysis of the damages caused by the dropping of a volume of corium at high temperature on the structure of the pressure vessel in a Nuclear Power Plant (NPP).

1.3.3 Outline

This text is split in the following chapters.

In the next chapter two velocity-based FEMs are derived for a general compressible material. In the first section the Velocity formulation is derived and the incremental solution scheme is given. Then, the standard mixed Velocity-Pressure formulation is obtained as an extension of the Velocity formulation. The constitutive laws are not introduced for any scheme. In the third section the formulations are adapted for hypoelastic-plastic compressible solids. The chapter ends with several validation examples for non-linear solid mechanics.

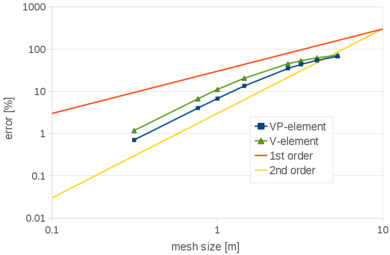

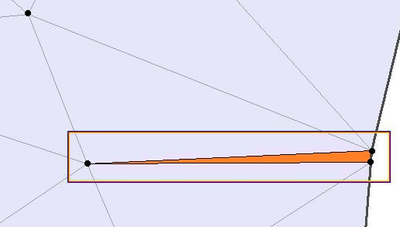

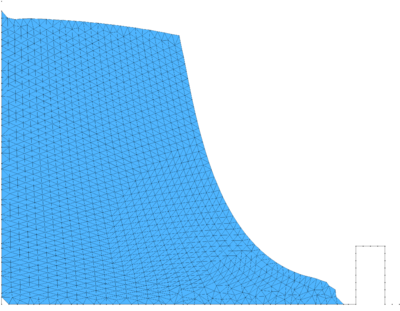

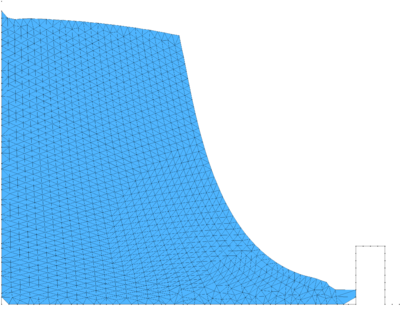

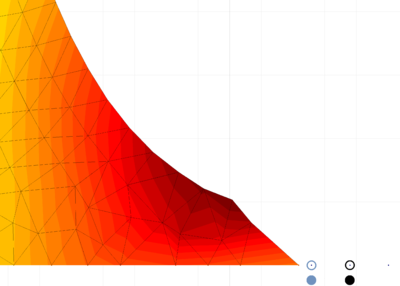

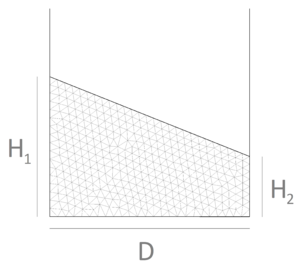

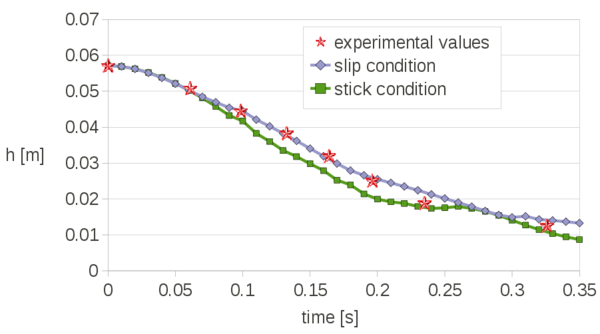

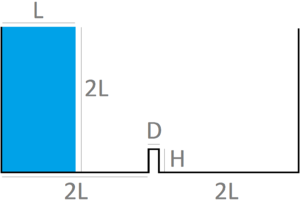

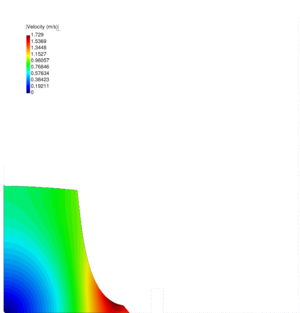

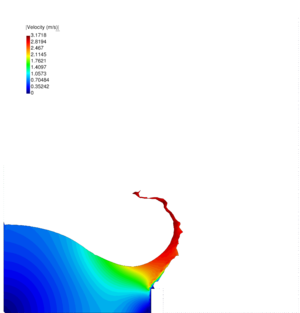

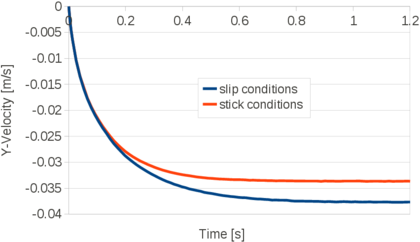

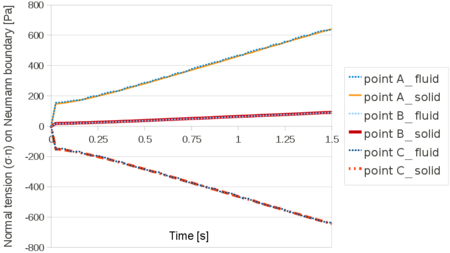

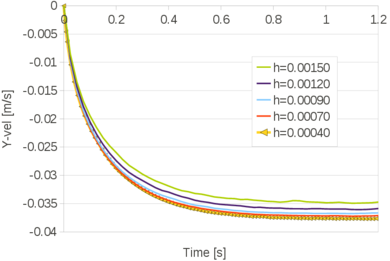

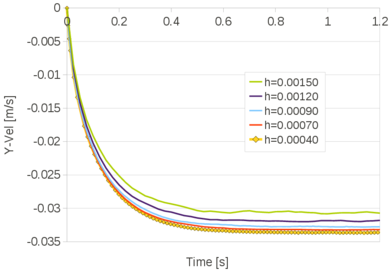

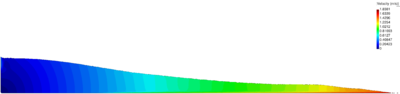

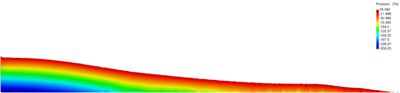

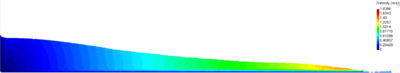

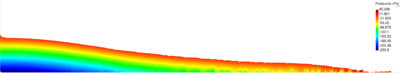

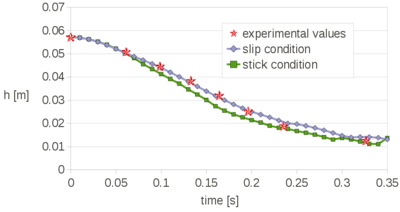

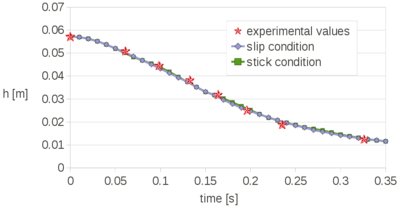

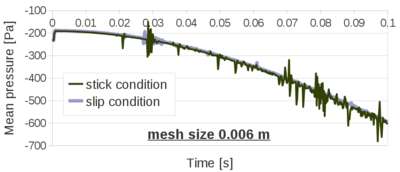

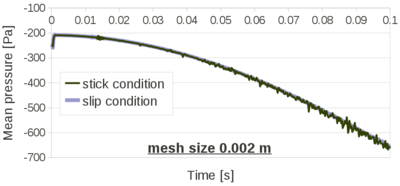

In Chapter 3, the FIC stabilization strategy is introduced in the mixed stabilized VP scheme. This scheme is adapted for quasi-incompressible Newtonian fluids and hypoelastic solids, in this order. Then the free surface problem is studied in detail. First the PFEM is described highlighting the advantages and the disadvantages of the method. A useful technique for modeling the slip conditions in Lagrangian flows is also explained. Next the mass conservation feature and the conditioning of the scheme are analyzed in detail. Concerning the former point, it will be shown that the PFEM-FIC formulation guarantees a good preservation of the mass in free surface flows. Regarding the latter point, a practical strategy for improving the conditioning of the linear system is explained and tested. At the end of the chapter several validation examples for quasi-incompressible Newtoninan fluids and hypoelastic solids are given.

The FSI solution strategy is described in Chapter 4. The monolithic scheme for coupling the mechanics of fluids and solids is explained in detail. Finally several validation examples of FSI problems are given.

Chapter 5 is dedicated to couple the Unified formulation for FSI with the heat problem. In the first section the heat problem is introduced and discretized using the FEM. Then the coupling strategy is explained and validated with numerical examples. Next, the procedure for modeling phase change problems is described and an explicative numerical example is presented.

Chapter 6 is fully devoted to the industrial application of the Unified stabilized and thermally coupled strategy. The damages of the pressure vessel structure caused by the fall of a volume corium at high temperature are studied using two simplified models where the solid structure melts due to the heat transfer from the corium.

In Chapter 7 the innovative contributions of the work are summarized and the lines of research opened by this thesis are presented.

1.4 Publications

The following publications have emanated from the work carried out in this doctoral thesis

- E. Oñate and A. Franci and J.M. Carbonell, Lagrangian formulation for finite ele-ment analysis of quasi-incompressible fluids with reduced mass losses, International Journal for Numerical Methods in Fluids, 74 (10), 699-731, 2014;

- E. Oñate and A. Franci and J.M. Carbonell, A particle finite element method (PFEM) for coupled thermal analysis of quasi and fully incompressible flows and fluid-structure interaction problems, Numerical Simulations of Coupled Problems in Engineering. S.R. Idelsohn (Ed.), 33, 129-164, 2014;

- E. Oñate and A. Franci and J.M. Carbonell, A particle finite element method for analysis of industrial forming processes, Computational Mechanics, DOI: 10.1007/s00466-014-1016-2, 2014;

- A. Franci and E. Oñate and J.M. Carbonell, On the effect of the bulk tangent ma-trix in partitioned solution schemes for nearly incompressible fluids, International Journal for Numerical Methods in Engineering, DOI: 10.1002/nme.4839, 2014;

- A. Franci and E. Oñate and J.M. Carbonell, Unified formulation for solid and fluid mechanics and FSI problems, Computer Methods in Applied Mechanics and Engineering, (in preparation).

Chapter 2. Velocity-based formulations for compressible materials

In this chapter two velocity-based finite element formulations for compressible materials are presented, namely the Velocity (V) and the mixed Velocity-Pressure (VP) formulations. For both schemes the linear momentum equations are solved iteratively for the velocity increments. The linearization of the governing equations is performed without specifying any constitutive law. The aim of this chapter is to maintain as much as possible the generality of the algorithms, leaving the formulations open to different material models. It will be shown that the only requirement demanded to the constitutive laws is that the rate of stress must be linearly related with the rate of deformation.

There are several reasons that justify the presentation of the Velocity formulation. First of all, the tangent matrix of the linear momentum equations for the Velocity formulation holds also for the mixed Velocity-Pressure formulation but the linearization procedure is easier because the pressure does not appear. Furthermore, the Velocity formulation is useful for making some interesting and didactic comparisons with the mixed formulations.

After deriving the solution scheme for the Velocity formulation, the mixed Velocity-Pressure method is presented. The governing equations are the linear momentum and the linear pressure-deformation rate equations. The latter is called continuity, or mass balance, equation for its similarity with the incompressibility constraint of the Navier-Stokes problem. As for the velocity scheme, in the mixed formulation the constitutive law is not specified. In Section 2.3 the hypoelastic-plastic model is presented and this constitutive law is inserted in both the Velocity and the mixed Velocity-Pressure schemes. The incremental solution scheme is explained in detail for both formulations. At the end of the chapter some validation examples for hypoelastic-plastic solids in statics as in dynamics are given.

2.1 Velocity formulation

In this section, the velocity formulation for solving transient problems for a general continuum is derived. The governing equations are the linear momentum equations and they are derived in the updated Lagrangian (UL) framework. This means that the governing equations are integrated over the unknown configuration (the so-called updated configuration). As a consequence, the space derivatives for the UL description are computed with respect to the spatial coordinates.

2.1.1 From the local form to the spatial semi-discretization

In this section the spatial semi-discretization of the linear momentum equations is derived.

For a general continuum, the local form of the linear momentum equations using the UL description reads

|

|

(1) |

where is the density of the material, are the velocity vector, is the Cauchy stress tensor and is the body force vector. The variables within the brackets are the independent variables: X are the Lagrangian or material coordinates vector, x the Eulerian or spatial coordinates vector and is the time. For simplicity, in what follows the independent variables are not specified. The spatial and material coordinates are related through the motion tensor as

|

|

(2) |

The set of governing equations is completed by the following conditions at the Dirichlet () and Neumann () boundaries

|

|

(3) |

|

|

(4) |

where and are the prescribed velocities and the prescribed tractions, respectively, and is the unit normal vector.

In the following summation of terms for repeated indices is assumed, unless otherwise specified.

The spaces for the trial and test functions are defined, respectively, as

|

|

(5) |

|

|

(6) |

Multiplying Eqs.(1) by the test functions and integrating over the updated configuration domain, the following global integral form is obtained

|

|

(7) |

where the symbol represents the material time derivative.

Integrating by parts the term involving in Eq.(7) and using the Neumann boundary conditions (4) yields the weak variational form of the momentum equations as

|

|

(8) |

Eq.(8) is the standard form of the Principle of Virtual Power [9].

The spatial discretization is introduced using the classical FEM-Galerkin procedure [136]. Hence both the trial and the test functions are interpolated in space in terms of their nodal values by means of the same shape functions

|

|

(9) |

where, assuming the use of simplicial elements, for 2D/3D problems is the number of the nodes of the element, denotes a nodal value, the capital subscript specifies the node and the lower case subscript represents the cartesian direction. In this work, linear shape functions have been used for .

Since Eq.(9) must hold for all the test functions in the interpolation space, introducing the spatial discretization (9) into Eq.(8), the spatial semi-discretized form of the momentum equations in the UL framework for the node reads

|

|

(10) |

where , and are the dynamic, internal and external forces, respectively, expressed in the UL framework.

For convenience, the semi-discretized form of the momentum equations in the total Lagrangian (TL) framework is also presented here. This is written as [9]

|

|

(11) |

where is the first Piola-Kirchhoff stress tensor, or the nominal stress tensor, and , and are the dynamic, internal and external forces, respectively, expressed in the TL framework. All the variables with vectors subscript refer to the last known configuration. Note that Eq.(11) can be obtained from Eq.(10) by pull back transformations on all its terms [9].

For the sake of clarity in the notation, the terms referred to the TL description are denoted with the left index . Unless otherwise specified, the variables belong to the UL description.

2.1.2 Time integration

In this work, the kinematic variables have been integrated in time using a second order scheme. In particular, the implicit Newmark's integration rule has been adopted. For the general case, this rule states that accelerations and displacements are computed as

|

|

(12) |

Where and are the so-called Newmark's parameters [9]. This time integration scheme is unconditionally stable if the following relation holds

|

|

(13) |

In the present work, the Newmark's parameters chosen are and .

Replacing the numerical values of the constants in Eq.(12) yields

|

|

(14) |

|

|

(15) |

2.1.3 Linearization

Although the problem is set out in the UL framework, the linearization for the velocities increment of the momentum equations is performed first on the TL semi-discretized form (11). The UL linearized form is obtained by performing a push-forward transformation on the TL form. This is justified by the easier derivation of the tangent matrix in the TL framework. In fact, in Eq.(11) the only variable that depends on time is the nominal stress , while in the UL form (10) the time-dependent variables are the updated domain , the Cauchy stress tensor and the spatial derivatives . For the sake of clarity, the linearization of the internal and dynamic forces will be performed separately.

Internal component of the tangent matrix

From Eq.(11) the internal forces in the TL description are defined as

|

|

(16) |

The constitutive relation is expressed in rate form. Hence it is more convenient to perform the linearization of the material derivative of the internal forces and then integrate for the time step increment . The material time derivative of (16) is

|

|

(17) |

The infinitesimal increment of Eq.(17) is

|

|

(18) |

The first Piola-Kirchhoff stress tensor is not typically used because it is not symmetric and its rate is a non-objective measure. For these reasons, in the TL framework it is more convenient to work with the second Piola-Kirchhoff stress tensor and its rate. These stress rate measures are related each other through the following relation

|

|

(19) |

where is the deformation gradient tensor defined as

|

|

(20) |

Substituting Eq.(19) into (18) yields

|

|

(21) |

Eq.(21) shows that the increment of the material time derivative of the internal forces can be split into material and geometric parts, and , respectively. The former accounts for the material response through the rate of the second Piola-Kirchhoff stress tensor and the second term is the initial stress term that contains the information of the updated stress field. Note that, up to now, no constitutive relationships have been introduced and the above derivation holds for a general continuum.

Material tangent matrix

From Eq.(21), the material part of the material time derivative of the internal forces reads

|

|

(22) |

For the derivation of the material tangent matrix, the constitutive relation between the stress and the strain measures is required. In order to maintain the formulation as general as possible, the stress rate measure is related to the deformation rate through a tangent constitutive tensor, as

|

|

(23) |

where is a fourth-order tensor and is the Green-Lagrange strain tensor. Eq.(23) can also be expressed in Voigt notation as

|

|

(24) |

where denotes a vector with components . As it will be shown in the following sections, Eq.(23) can represent both a Kirchhoff solid material and a Newtonian fluid. If different constitutive laws are used, Eq.(23) should be modified accordingly in order to derive the material part of the tangent matrix.

The Green-Lagrange strain tensor can be expressed in terms of the nodal velocities as

|

|

(25) |

In Voigt notation

|

|

(26) |

where for a plane strain problem

|

|

(30) |

Substituting Eq.(25) in Eq.(23), yields

|

|

(31) |

Similarly, substituting Eq.(26) in Eq.(24)

|

|

(32) |

Substituting Eq.(31) into Eq.(22) yields

|

|

(33) |

where is the -component of the velocity of node . In Voigt notation Eq.(33) reads

|

|

(34) |

In order to obtain the increment of the internal forces, the material time derivative of the internal forces increment is integrated over a time step increment as

|

|

(35) |

From Eq.(35) and Eq.(33), yields

|

|

(36) |

and, similarly, from Eq.(35) and Eq.(34)

|

|

(37) |

From Eq.(36) and Eq.(37), the material tangent matrix in the TL description can be computed as

|

|

(38) |

|

|

(39) |

The material tangent matrix for the UL framework is obtained by applying a push-forward transformation on each term of Eq.(38) and integrating over the updated domain . The following relations hold

|

|

(40) |

|

|

(41) |

|

|

(42) |

where is the tangent moduli corresponding to the material time derivative of the Kirchhoff stress tensor and is the tangent moduli for the rate of the Cauchy stress . The rate of the Cauchy stress tensor is related to the rate of deformation through the fourth-order tensor by the following expression

|

|

(43) |

Substituting Eqs.(40-42) into (38) and using the minor symmetries, the material tangent matrix for the UL reads

|

|

(44) |

Using Voigt notation, the same matrix reads

|

|

(45) |

For the node of a 3D element, matrix is

|

|

(51) |

The geometric tangent matrix for the UL framework is derived next using the same procedure adopted for the material components. Hence, first the linearization is performed using the TL form and then the UL tangent matrix is obtained by performing the required transformation over the TL terms.

From Eq.(21)

|

|

(52) |

where the rate of the deformation gradient is defined as

|

|

(53) |

Substituting Eq.(53) into Eq.(52), the geometric components of the internal power in the TL description can be written as

|

|

(54) |

Integrating Eq.(54) on time for a time step increment yields

|

|

(55) |

From Eq.(55) the geometric tangent matrix is obtained as

|

|

(56) |

In order to recover the UL form, the Piola identity has to be recalled,

|

|

(57) |

The geometric tangent matrix in the UL framework is obtained by substituting Eqs.(40), (41) and (57) into (56) and using the symmetries. This leads to

|

|

(58) |

or also

|

|

(59) |

where is the second order identity tensor and matrix for 3D problems is

|

|

(60) |

Dynamic component of the tangent matrix

The dynamic component of the tangent matrix in the UL description can be derived directly from the UL dynamic term of Eq.(10). This reads

|

|

(61) |

Eq.(61) has to be discretized in time with the purpose of replacing the accelerations by the velocities using the time integration scheme described in Eq.(14).

Introducing Eq.(14) into (61) and differentiating for the increment of velocities, the dynamic components of the tangent matrix are obtained as

|

|

(62) |

Or also

|

|

(63) |

2.1.4 Incremental solution scheme

The problem is solved through an implicit iterative scheme. At each iteration the velocity increments are computed as

|

|

(64) |

where is the tangent matrix computed as the sum of the internal, the geometric and the dynamic components, given by Eqs. (45), (59) and (63) respectively, as

|

|

(65) |

is the residual and it is computed from Eq.(10) as

|

|

(66) |

In Eq.(66) is the residual of the momentum equations referred to node and the cartesian direction . Note that the Cauchy stress tensor still appears in its 'continuum' form because up to now it has not been written as a function of the nodal unknowns. This is done for keeping the generality of the formulation. Only after the introduction of the constitutive laws, it will be possible to compute the Cauchy stress tensor as a function of the nodal unknowns.

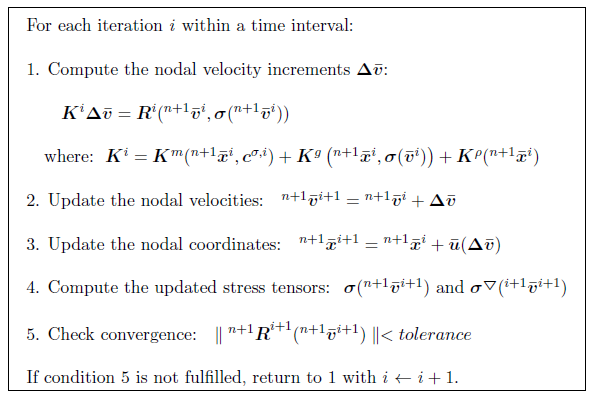

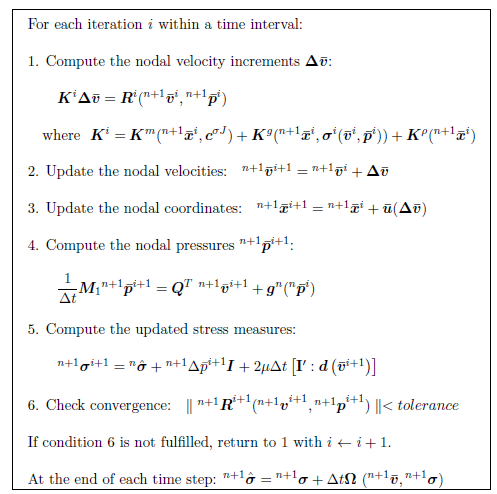

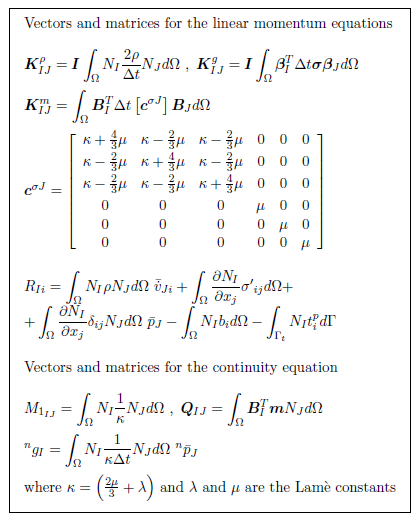

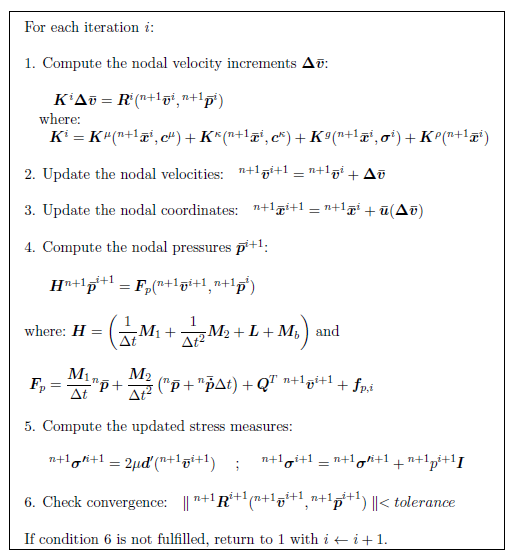

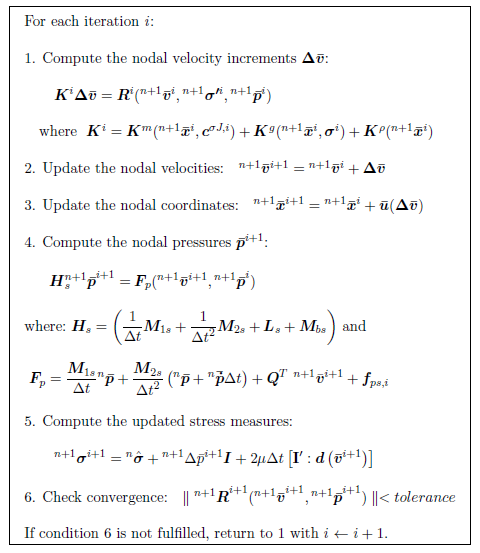

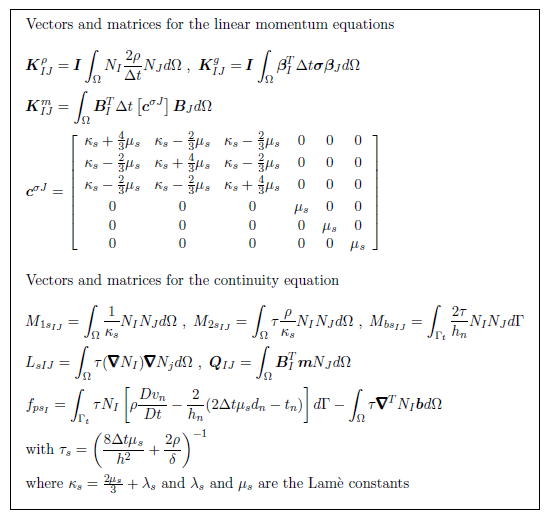

In Box 1 the iterative solution incremental scheme of the velocity formulation for a generic time interval of duration is described.

2.2 Mixed velocity-pressure formulation

In this work, the mixed Velocity-Pressure formulation is derived as an extension of the Velocity formulation presented in the previous section. The governing equations are the linear momentum equations and the linear relation between the time variation of pressure and the volumetric strain rate. The latter represents a limit for the generality of this formulation because only materials which constitutive law satisfies this relation can be modeled through the mixed Velocity-Pressure formulation.

The problem is solved using a two-step Gauss-Seidel partitioned iterative scheme. First the momentum equations are solved in terms of velocity increments and including the (known) pressures at the previous iteration in the residual expression. Then the continuity equation is solved for the pressure using the updated velocities computed from the momentum equations. It will be shown that using this not intrusive scheme, it is possible to take advantage of most of the velocity formulation derived in the previous section. In particular, the incremental velocity scheme for the momentum equations (Box 1) and the structure of the tangent matrix (65) hold also for the mixed Velocity-Pressure formulation. The same linear interpolation has been used for the velocity and the pressure fields. It is well known that, for incompressible (or quasi-incompressible) problems, this combination does not fulfill the condition [15] and a stabilization method is required. However, as mentioned in the section devoted to the velocity formulation, the aim of this part is to keep the formulation as general as possible without referring to a specific material. Hence only in the next chapter, when the mixed Velocity-Pressure formulation is used for solving quasi-incompressible problems, the required stabilization will be introduced in the scheme.

2.2.1 Quasi-incompressible form of the continuity equation

Mixed formulations are often used for dealing with incompressible materials. In these problems it is useful to write the stress and the strain measures as the sum of deviatoric and hydrostatic, or volumetric, parts. Hence the Cauchy stress tensor is decomposed as

|

|

(67) |

with

|

|

(68) |

where and are the deviatoric and the hydrostatic parts of the Cauchy stress tensor, respectively. The pressure is defined positive in the tensile state and equal to the hydrostatic parts of the Cauchy stress tensor . Hence

|

|

(69) |

The Cauchy stress tensor can be computed as

|

|

(70) |

The same decomposition is done for the spatial strain rate tensor . So

|

|

(71) |

with

|

|

(72) |

where and are the deviatoric and the hydrostatic parts of the strain rate tensor, respectively. The strain rate tensor is computed from the velocities as

|

|

(73) |

The volumetric strain rate is defined from Eqs.(68) and (73) as

|

|

(74) |

The closure equation for the mixed Velocity-Pressure formulation is the linear relation between the change in time of the pressure and the volumetric strain rate. This reads as

|

|

(75) |

where is a parameter that depends on the constitutive equation. Typically is the bulk modulus of the material.

In conclusion, the local form of the whole problem for the mixed Velocity-Pressure formulation is formed by the linear momentum equations (Eq.(1)) and the pressure-strain rate relation given by Eq.(75). The linear momentum equations have been already discretized and linearized for the increments of velocities in the previous section devoted to the Velocity formulation. That form holds also for the mixed formulation. So, in the following, only the discretization of Eq.(75) is given. This equation is a restriction on the generality of the constitutive laws that can be analyzed with the mixed Velocity-Pressure formulation. It will be shown that the constitutive models for hypoelastic solids and quasi-incompressible Newtonian fluids fulfill this relation. In fluid dynamics, Eq.(75) represents the , or , equation for quasi-incompressible fluids. In fact, Eq.(75) with is the canonical form of the continuity equation of the Navier-Stokes problem. For this reason, from here on Eq.(75) will be called 'continuity equation'.

Multiplying Eq.(75) by arbitrary test functions (with dimensions of pressure), integrating over the analysis domain and bringing all the terms at the left hand side gives

|

|

(76) |

Both the trial and the test functions for the pressure are interpolated in space using the same shape functions .

|

|

(77) |

where for 2D/3D problems is the number of the nodes of the simplex. In this work, linear shape functions have been used for , as for the velocity.

Combining Eq.(77) with Eq.(76) and solving for all the admissible test functions q, yields

|

|

(78) |

Regarding the time integration a first order scheme has been adopted for the pressure. Hence, for a time interval of duration the first and the second variations in time of the pressure are computed as

|

|

(79) |

|

|

(80) |

Introducing Eq.(79) in Eq.(78), the discretized form of the continuity equation is

|

|

(81) |

where

|

|

(82) |

|

|

(83) |

|

|

(84) |

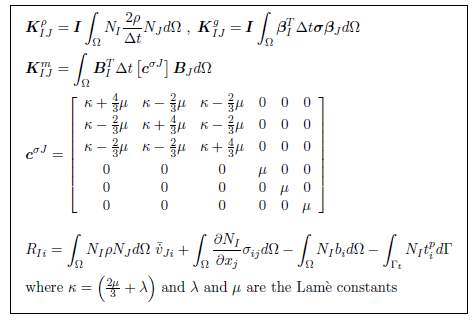

where has been defined in Eq.(51) and .

2.2.2 Solution method

In the mixed Velocity-Pressure formulation the problem is solved through a partitioned iterative scheme. Specifically, the linear momentum equations are solved for the velocity increments as in the Velocity formulation. On the other hand, the continuity equation is solved for the pressure in the updated configuration using the velocity field computed with the linear momentum equations. In order to guarantee the coupling between the continuity equation and the linear momentum equations (or equally between the pressure and the velocities) the pressure must appear in the right hand side of the linear momentum equations. For this purpose the Cauchy stress tensor must be computed as the sum of its deviatoric part and the pressure, as Eq.(70). Otherwise, the Velocity-Pressure formulation would be uncoupled and totally equivalent to the Velocity formulation.

In conclusion, for a general time interval of duration the following linear systems are solved for each iteration

|

|

(85) |

|

|

(86) |

where is the same tangent matrix as for the Velocity formulation (Eq.(65)) and the residual is computed using the pressure of the previous iteration and the deviatoric part of the Cauchy stress as

|

|

(87) |

In Box 2, the iterative incremental solution scheme for a generic continuum via the mixed velocity-pressure formulation is shown for a time interval .

Box 2. Iterative solution scheme for a generic continuum using the mixed velocity-pressure

formulation.2.3 Hypoelasticity

Using the definition of Truesdell [118], a hypoelastic body is a material which may soften or harden in strain but in general has neither preferred state nor preferred stress. The hypoelastic laws were created with the purpose of transferring the linear theory of elasticity from the small to the finite strains regime [118]. In [120] a deep dissertation about the differences between elasticity and hypoelasticity is given.

A hypoelastic body is defined by the constitutive equation [119]

|

|

(88) |

In the rate theory it is crucial to guarantee the and the , or , of the scheme. A material is frame invariant if its properties do not depend on the change of observer. An objective constitutive equation is defined to be invariant for all changes of the observer [56]. For guaranteeing the frame indifference, the constitutive law has to be isotropic [121]. This represents a constraint for hypoelastic models. This limitation is even more severe if also plasticity is included in the model. In fact, for hypoelastic-plastic materials, also the yield condition is required to be isotropic [112].

The stress rate cannot be computed simply as a material derivative because it leads to a non-objective measure of stress [9]. In particular, rigid rotations may originate a wrong state of stress if the stress rate is computed as the material time derivative of the Cauchy stress [9]. However, many objective measures of rate of stress are available. The most common ones are the Truesdell's and Jaumann's Cauchy stress rate measures. From here on, an objective rate measure will be denoted by the upper inverse triangle index .

Most of hypoelastic laws relate linearly the stress rate to the rate of deformation. Hence, Eq.(88) is now rewritten in the following form

|

|

(89) |

where is the Cauchy stress rate tensor, is the tangent moduli tensor and is the deformation rate tensor.

From Eq.(89) it can be deduced that this class of hypoelastic materials has a rate-independent and incrementally linear and reversible behavior. So, as for the elastic materials, in the small deformation regime, the strains and the stresses are totally recovered upon the unloading process. Nevertheless, for large deformations the hypoelastic laws do not guarantee that the work done in a closed deformation path is zero [102]. However this error can be considered negligible if the elastic deformations are small with respect to the total deformations [9]. For this reason the hypoelastic laws are often used for describing the elastic part of elastic-plastic materials: the plastic deformations in fact represent usually the largest part of the overall deformations.

The Jaumann measure for the rate of the Kirchhoff stress tensor is

|

|

(90) |

where the tangent moduli fourth-order tensor for the Jaumann measure of the Kirchhoff stress rate is

|

|

(91) |

where and are the Lamé constants and they are computed from the Young modulus and the Poisson ratio as

|

|

(92) |

|

|

(93) |

and is the fouth-order symmetric identity tensor defined as

|

|

(94) |

Separating the volumetric from the deviatoric part, yields

|

|

(95) |

where is the bulk modulus and it is computed from the Lamé parameters as

|

|

(96) |

and is the fouth-order tensor computed as

|

|

(97) |

The Jaumann stress rate measure is defined as

|

|

(98) |

where is the Jaumann's tangent moduli tensor.

For a anisotropic material the tangent moduli for the Jaumann rate depends on the stress state and it is related to as follows

|

|

(99) |

Instead, for isotropic materials, the Jaumann's tangent moduli tensors for the Cauchy stress rate and for the Kirchhoff stress rate are identical [9]. So can be computed as

|

|

(100) |

or equally

|

|

(101) |

For a 3D problem tensor is

or, equally,

A material is said to be isotropic if its behavior is uniform in all directions, so it has no preferred orientations or directions. Many materials, such as metals and ceramics, can be modeled as isotropic for small strains [9]. From the computational point of view, an isotropic constitutive law is much easier to manage than an anisotropic one and it has a lower computational cost. Isotropic laws are preferred, for example, for their symmetry properties. In fact the anisotropic tangent moduli (Eq.(99)) is not symmetric while, the isotropic one (Eq.(101)) has both minor and major symmetries, in fact

|

|

(102) |

|

|

(103) |

For all these reasons, in this work the isotropic law has been used for the hypoelastic model.

The tangent moduli will be introduced into the material part of the global tangent matrix Eq.(45) for the Velocity and the mixed Velocity-Pressure formulations indifferently.

As it has already pointed out, the Cauchy stress rate does not coincide with the material derivative of the Cauchy stress tensor. In fact, the following relation holds between both measures

|

|

(104) |

where is a tensor that accounts for the rotations and it is defined as

|

|

(105) |

where is the spin tensor defined as

|

|

(106) |

In this work the tensor is computed at the end of each time step. Discretizing in time Eq.(104) for the time step interval and expanding the Cauchy stress rate, yields

|

|

(107) |

can be viewed as a correction of the Cauchy stress tensor. So it can be related to the Cauchy stress tensor of the previous time step as follows

|

|

(108) |

Replacing Eq.(108) in Eq.(107), yields

|

|

(109) |

Substituting in Eq.(109) the relation for using Eq.(101), yields

|

|

(110) |

Hence,

|

|

(111) |

The first and the second terms of the right hand side of Eq.(111) represent the increment in the time step of the volumetric and deviatoric parts of the Cauchy stress tensor. From Eq.(111) it can be deduced that for isotropic hypoelastic solids described using the Jaumann measure, the following relation holds

|

|

(112) |

Eq.(112) will be used as the closure equation of the mixed Velocity-Pressure formulation for hypoelastic solids. Note that Eq.(112) has the same structure as Eq.(75) analyzed in the previous section. From Eq.(112) using linear shape functions and integrating on time the pressure with a first order scheme, the same matrix form of Eq.(81) obtained for a general material is obtained.

In conclusion the updated stresses can be computed using the velocities only or both the pressure and the velocities, as follows

|

|

(113) |

|

|

(114) |

Eqs.(113) and (114) will be used for computing the Cauchy stress tensor in the Velocity and mixed Velocity-Pressure formulations, respectively.

2.3.1 Velocity formulation for hypoelastic solids

The solution scheme for hypoelastic solids is the one derived in Section 2.1.4 for a general continuum. The only modifications required are the definition of the tangent moduli in matrix (Eq.(45)) and the computation of the Cauchy stress tensor from the nodal velocities according to the hypoelastic model. This tensor appears in the geometric part of the tangent matrix (Eq.(59)) and into the residual (Eq.(66)). The tangent moduli tensor is taken from the Jaumann isotropic description and it is the tensor of Eq.(101). Concerning the Cauchy stresses, these are computed with Eq.(113). The finite element implemented with this hypoelastic velocity formulation is named V-element.

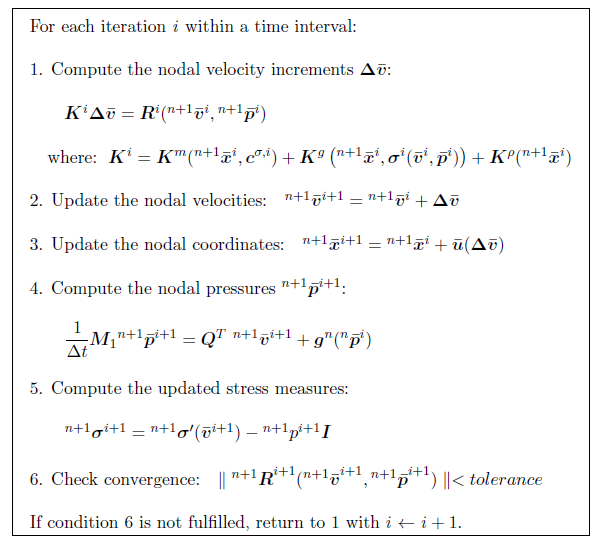

The iterative solution incremental solution scheme for hypoelastic solids using the velocity formulation for a generic time interval is given in Box 3.

All the matrices and vectors in Box 3 are collected in Box 4.

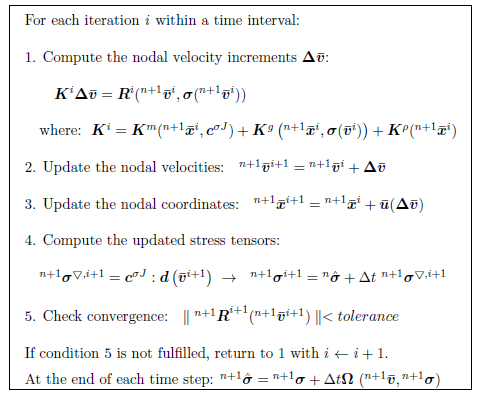

2.3.2 Mixed Velocity-Pressure formulation for hypoelastic solids

The solution scheme is like the one presented in Section 2.2.2. As already explained, the tangent matrix of the mixed Velocity-Pressure formulation is the same as for the Velocity formulation. However the Cauchy stress tensor is computed from the nodal velocities and the nodal pressures using Eq.(114). The governing equations are Eqs.(85-86) particularized with the material parameters of a hypoelastic solid. The finite element implemented with this hypoelastic mixed velocity-pressure formulation is called VP-element.

In Box 5, the iterative solution incremental scheme for hypoelastic solids using the mixed velocity-pressure formulation is given for a generic time interval .

All the matrices and vectors that appear in Box 5 are collected in Box 6.

Note that for the mixed velocity-pressure formulation the material part of the tangent matrix is defined by the same tangent moduli of the velocity scheme ().

In the mixed formulation, the momentum and the continuity equations can be easily decoupled. This is obtained by computing the Cauchy stress tensor using the velocities only (Eq.(113)) and not as the sum of its deviatoric part and the pressure (Eq.(114)). The uncoupled mixed velocity-pressure formulation is totally equivalent to the velocity formulation. In fact, although the pressures are still computed by solving the continuity equation, they do not appear in the momentum equations and, hence, they do not affect the solution for each the time step.

2.3.3 Theory of plasticity

The theory of plasticity is dedicated to those solids that, after being subjected to a loading process, may sustain permanent () deformations when completely unloaded [74]. The plasticity is defined if the permanent deformations of the material do not depend on the rate of application of the loads. The materials whose behavior can be adequately described by this theory are called materials.

Elastic-plastic laws are characterized for being path-dependent and dissipative. The stresses cannot be computed as a single-valued function of the strains because they depend on the entire history of the deformation [9].

The most important properties of the theory of plasticity can be summarized as follows:

- The increments of strain are assumed to be additively decomposed into an elastic (reversible) part and a plastic (irreversible) part , such that

(115) - There exists an elastic domain where the behavior of the material is purely elastic and permanent deformations are not produced;

- The yield function delimits the elastic domain. It governs the onset and the continuity of the plastic deformations and it is a functions of the state of stress and of the internal variables . So

(116) - The plastic strain increments are governed by the so called flow rule;

- is the plastic strain parameter and it is positive for a plastic loading and equal to zero for elastic loading or unloading;

- The loading-unloading process is described by the Khun-Tucker conditions

(117)

The yield function cannot be positive: it is negative when the stress state is below the yield value and null otherwise (yield condition: );

The third condition can also be expressed in the rate form through the so-called , . For plastic loading () the stress state lies on the yield surface (), instead for elastic loading or unloading the yield condition is not reached () and there is not plastic flow ().

2.3.3.1 Hypoelastic-plastic materials

Hypoelastic-plastic models are typically used when the elastic strains represent only a small part of the total strains. In other words, when the plastic strains are much larger than the elastic ones. This is because of the inaccuracy of the hypoelastic models in the large strain regime. However, if the elastic strains are small, the energy error introduced by the hypoelastic description of the elastic response is limited and can be considered adequate [9].

Depending on the problem, the yield function can be based on a different constitutive model. For example, for soil plasticity the Drucker-Prager model is the most used, while for porous plastic solids the Gurson model is more adequate. In this work, the flow model is used. This model is particularly indicated for the metal plasticity [I9].

The hypoelastic-plastic model described in this section has been taken from [9]. According to the von Mises criterion [125], plastic yielding begins when the stress deviator invariant reaches a critical value. The stress deviator invariant is defined as

|

|

(118) |

The key assumption of the von Mises model is that the plastic flow is not affected by the pressure but only by the deviatoric stress. This hypothesis has been experimentally verified for metals [17]. For this reason the von Mises model is called to be .

A yield function for the von Mises criterion can be defined as

|

|

(119) |

where is the uniaxial yield stress and it is related to the shear yield stress as follows

|

|

(120) |

and in Eq.(119) is the or defined as

|

|

(121) |

Concerning the deformation, the elastic-plastic decomposition described in Eq.(115) is rewritten in terms of rates as

|

|

(122) |

where and are the deformation rates associated to the elastic and plastic responses, respectively.

Combining Eq.(122) with Eq.(98), yields

|

|

(123) |

The rate of plastic deformations is given by

|

|

(124) |

where the plastic flow rate is a scalar and represents the plastic flow direction.

Substituting Eq.(124) in Eq.(123), yields

|

|

(125) |

During plastic loading the plastic flow rate is positive and the state of stress remains on the yield surface . This is consistent with the third Khun-Tucker condition . The consistency condition has the same meaning. Using the chain rule on the consistency condition, yields

|

|

(126) |

If the yield function depend on the invariant, the following relation holds [9,102]

|

|

(127) |

Combining Eqs.(127) and (125) and substituting in Eq.(126), yields

|

|

(128) |

In the most plastic models the evolution of the function of the internal variables can be expressed as a function of the plastic strain parameter as follows

|

|

(129) |

where are the internal variables.

Substituting Eqs.(124) and (129) in 128, the following relation for the plastic strain parameter is obtained

|

|

(130) |

The plastic flow vector is often derived from a plastic flow potential. If the plastic flow potential coincides with the yield function, the plastic flow is termed . In this case is proportional to the normal of the yield surface, that is . An associative plastic flow has the important advantage that it can lead to a symmetric stiffness matrix [9]. In this work an associative plasticity and a constant plastic modulus (for perfect plasticity, ) have been considered. Using these hypotheses the plastic strain parameter is expressed as

|

|

(131) |

Substituing this relation in Eq.(125), yields

|

|

(132) |

The same can be computed using a tangent moduli over the whole deformation rate as

|

|

(133) |

where is the elasto-plastic tangent modulus.

For associative plasticity, the von Mises plastic flow is computed as

|

|

(134) |

Because the plastic flow vector is deviatoric it follows that

|

|

(135) |

Form Eqs.(101), (133) and (135), the following expression of the elastoplastic modulus is obtained

|

|

(136) |

with

|

|

(137) |

|

|

(138) |

For perfect plasticity , so and Eq.(136) simplifies to

|

|

(139) |

Note that the continuum elasto-plastic tangent modulus conserves the symmetry properties of its elastic counterpart. For elastic loading or unloading, .

For a plane strain state, is

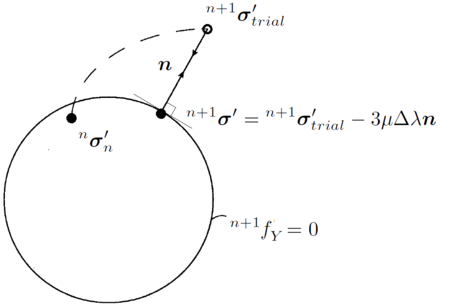

In order to guarantee the consistency of the elastoplastic incremental scheme, the so-called algorithm has to be introduced. With this technique, the Khun-Tucker conditions (Eq.(117)) are enforced at the end of a plastic time step in order to recover exactly the yield condition . The return mapping algorithm consists of an initial trial elastic step followed by a plastic corrector one that is activated when the yield function takes a positive value. In Figure 4 from [13], a graphical representation of the return mapping algorithm is shown.

![Graphical representation of the return mapping algorithm [13].](/wd/images/thumb/b/b5/Draft_Samper_722607179-returnMapping.png/390px-Draft_Samper_722607179-returnMapping.png)

|

| Figure 4: Graphical representation of the return mapping algorithm [13]. |

For associative plasticity, during the plastic corrector step driven by the increment of the plasticity parameter , the plastic flow direction is normal to the yield surface.

For the flow theory and associative plasticity, the return mapping is characterized to be [114]. This because the von Mises yield surface is circular, thus its normal is also radial. In Figure 5 a graphical representation of the radial return algorithm for plasticity is shown.

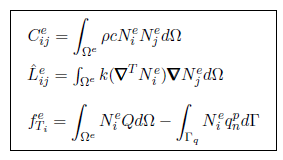

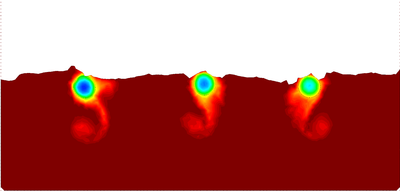

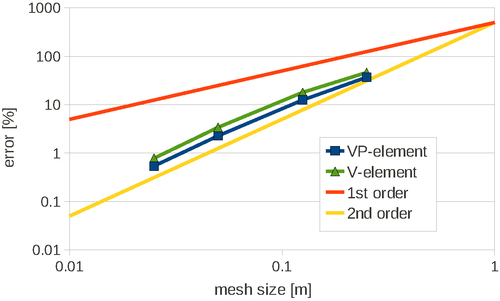

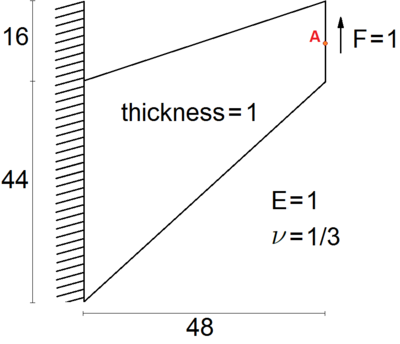

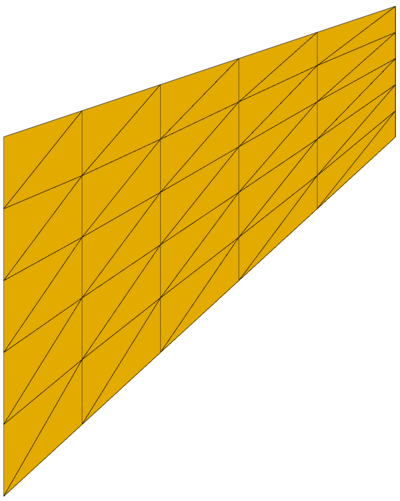

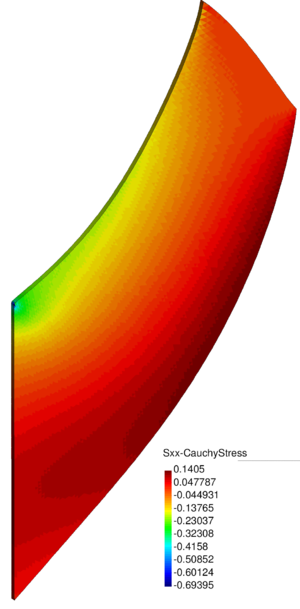

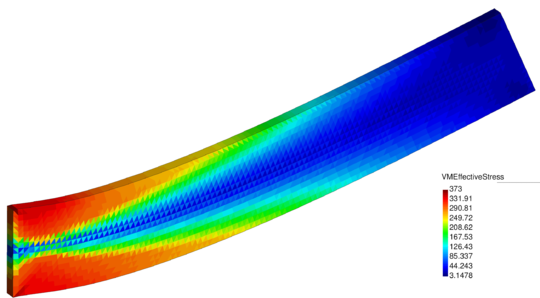

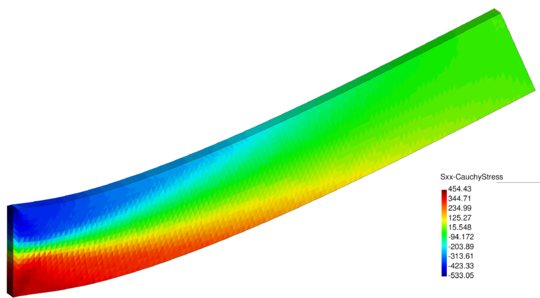

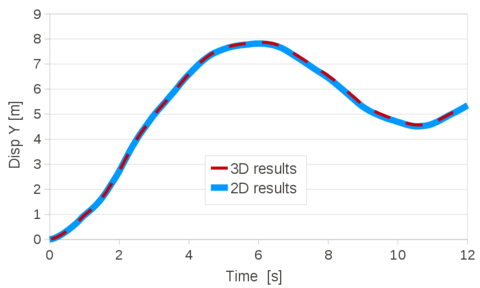

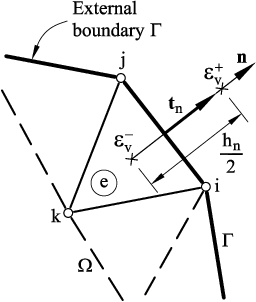

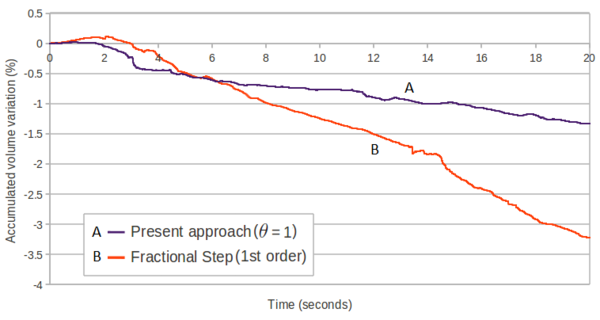

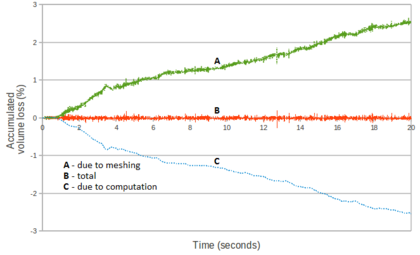

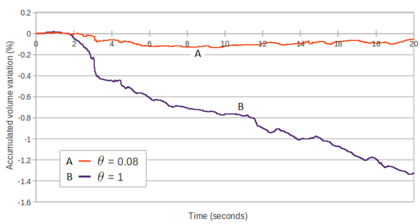

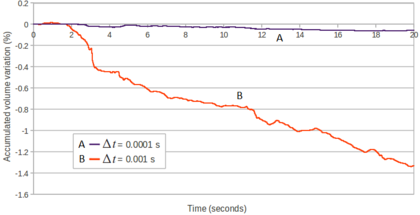

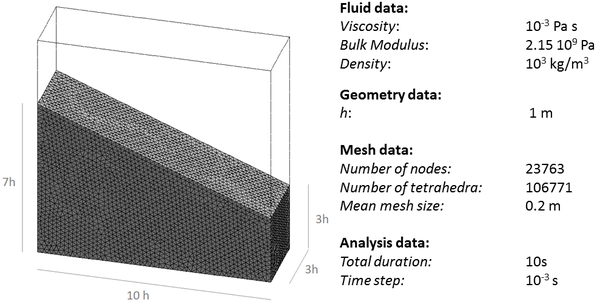

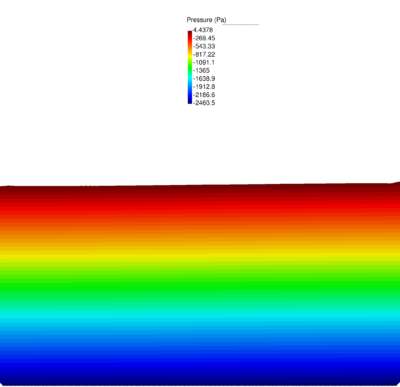

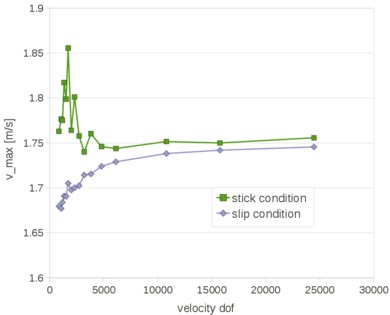

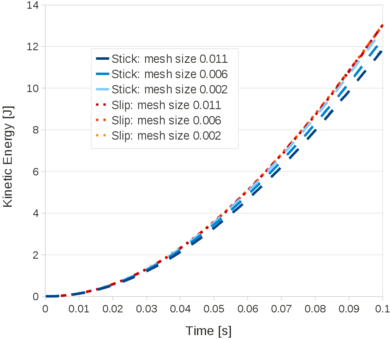

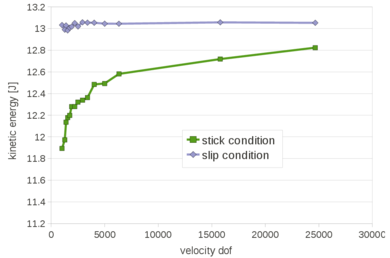

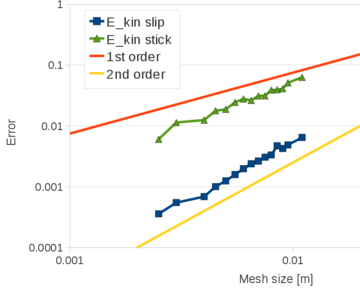

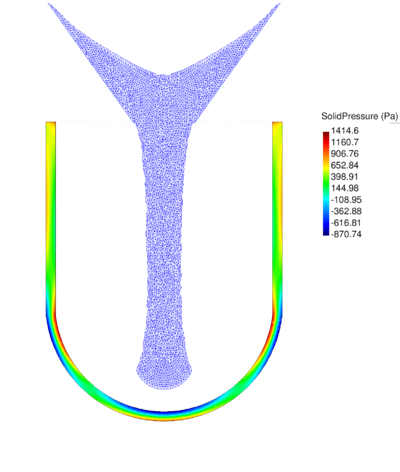

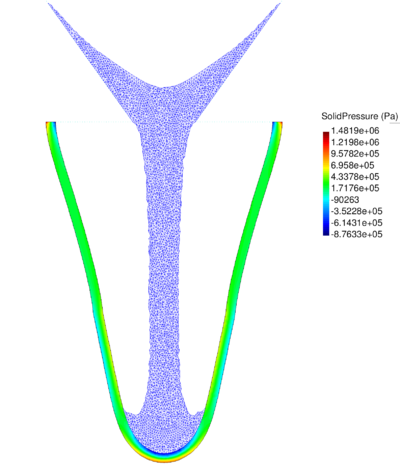

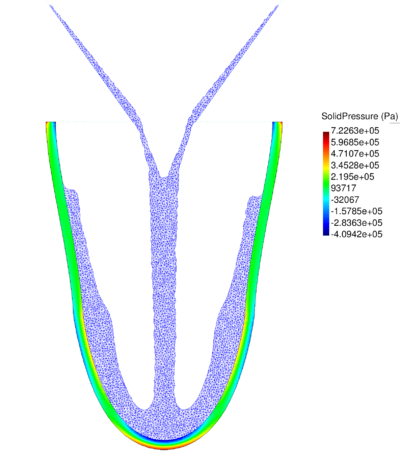

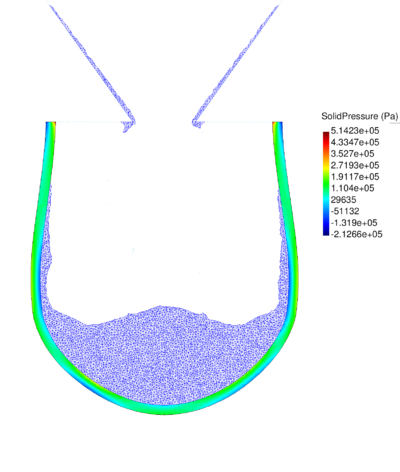

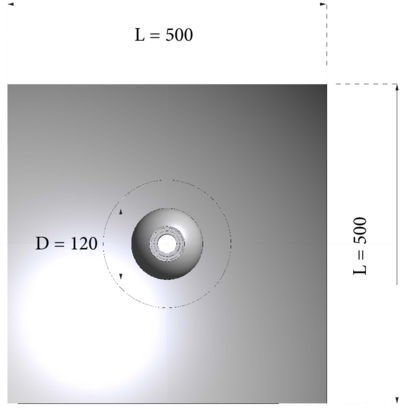

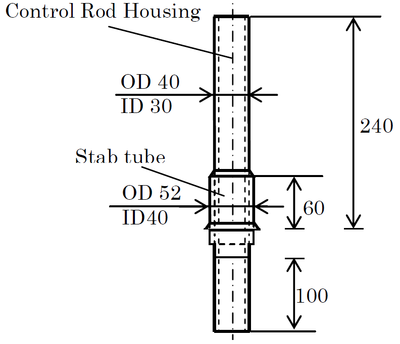

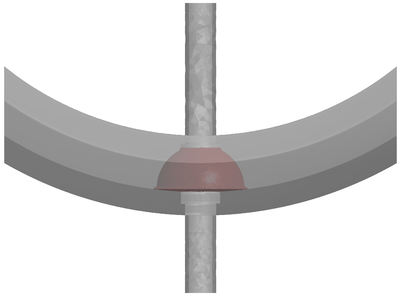

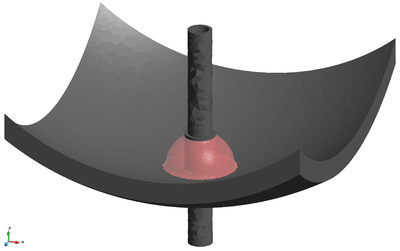

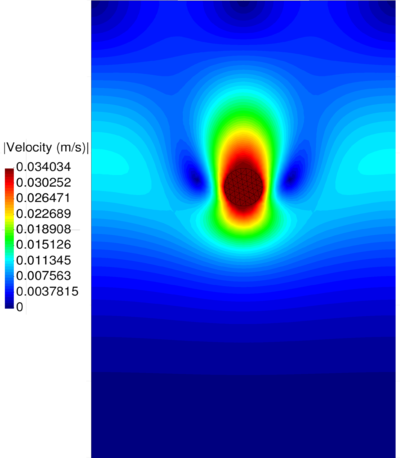

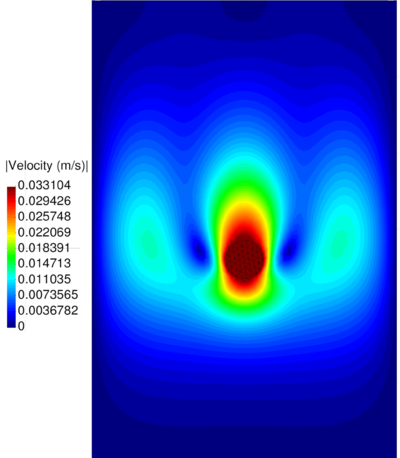

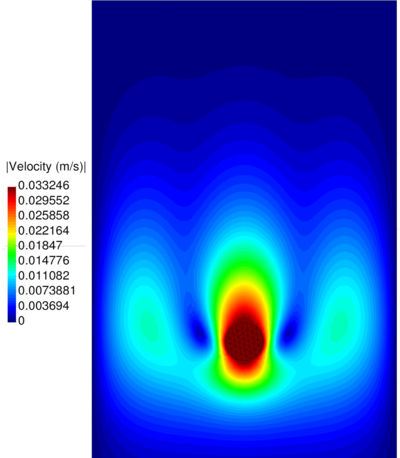

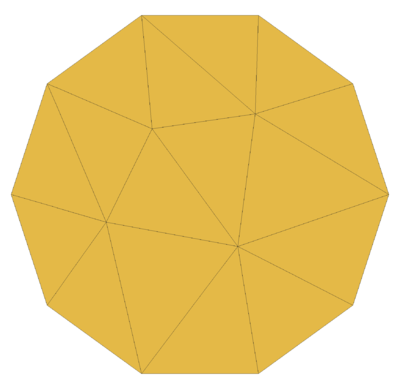

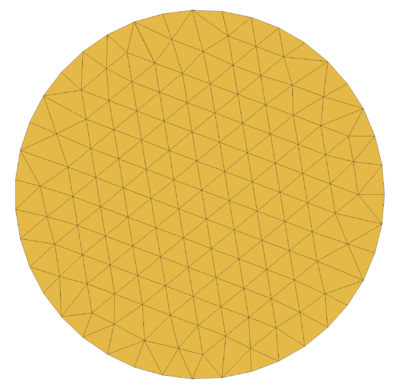

|