1 Introduction

Today the massive application of carbon fiber reinforced polymers (CFRP) in aircrafts is a fact. Best example is the last generation A350, with a CFRP structural weight of around 53% (wings, fuselage…) and a high production rate (13 aircrafts per month). All of this leads to special issues regarding the material waste obtained during the production of this airplane. Current manufacturing processes of aeronautical composite structures, although fully automatic, still involve a buy to fly ratio in the area of 1.1 – 1.4, which means that only 90 – 70% of the used raw material will fly, being the rest scrapped. To make the comparison, in case of metals this scrap ratio is even higher, but in contrast they show much lower cost. Then, taking into account the scenario of A350, it is expected that more than 1 ton of raw material per year will be scrapped by Airbus plants in the next years. That is why different levels of effective solutions need to be implemented in the near future to decrease or even eliminate the material scrap obtained during composite airframe production, as it has been done in automotive composite sector [1], and effort has started in all of them:

- Material scrap decrease, e.g. net shape production…

- Material scrap reuse, mainly focused on uncured prepreg, where usually a previous transformation / processing of the material is needed, as it will be worked out from this article.

This article summarizes the research carried out to develop an effective process to reuse uncured A350 scrap prepreg, with a clear environmental objective or priority, rather than a pure associated business case. The final aim is to apply the reused material in airframe field and / or other field (automotive, sport, civil works…), depending on its final quality and properties, being the first priority applications focused on low loaded or non-loaded aircraft structures, which are extensive in A350 (solid fillers, brackets…).

2 Uncured prepreg scrap

Aeronautical composite components are usually manufactured from continuous carbon fiber reinforced epoxy prepreg, mainly tapes or tows due to automatic production, although fabrics are still in use mainly for legacy programs. Currently, during part manufacturing with prepreg a percentage of uncured waste is discarded. Among the different types of uncured prepreg scrap, following ones are the largest in production plants:

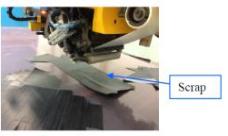

- ATL (Automatic Tape Lay-up) scrap (Figure 1):

- ATL production discards scrap out of the part in order to prepare the next cut to adapt the shape to the final pattern course contour. This scrap can be mono or multi-ply (MO-P/MU-P) and unidirectional (UD) or multidirectional (MD).

- Trimming off-cuts: this waste is the extra material to be cut in size following the final part contour. It is usually multi-ply and multidirectional and it can be generated by the ATL or the trimming machines.

For these both waste types the orientation of the plies do not follow any equilibrated formula, thus, the orientation 0, 90, 45º, -45º is random.

- FP (Fiber Placement) also generates waste to adapt the contour to the final part.

- Ends of rolls and raw material manufacturing defects (ATL and FP).

- Expired rolls: out of date material (Figure 1).

a) |

b) |

c) |

d) |

Among these prepreg scrap types, after different trials and studies carried out within this project, A350 tape mono-ply scrap has been selected as first priority. This involves mostly end of rolls from Fiber Placement production, which represent also a significant quantity in production plants (Illescas, Stade).

3 Prepreg reuse process

Once the different types of uncured prepreg scrap and the first priority for this study were defined, the process to obtain a new virgin material from this waste, and, finally, a new complex part, was developed.

3.1 New virgin material

The new virgin material was obtained by a cutting or chopping process. Different techniques were considered:

- A die cutting press process for laminates (multi-ply scrap).

- A cutting machine specially designed to cut end of rolls (mono-ply scrap).

Different sizes of chips were studied (from 5x5mm to 20x20mm, 50x12.7mm, 50x5mm, 135x3.2mm…), depending on the used scrap type. Finally, in function of the results obtained with the different chip sizes, the selection was 50x12.7mm for mono-ply A350 scrap. Additionally, the cutting process was finally set up at low temperature (10-12ºC) in order to avoid uncured material agglomeration issues. After cutting, the material was stored in the climatic chamber (-18ºC) to avoid the curing reaction progress. Then, before being used, it needs to be tempered at room temperature, allowing its correct manipulation without tacking issues and the full fill-up of the tooling surface. Several storage material formats were tried, being the selection finally driven by the solution cost.

3.2 New part manufacturing process

Proposed technologies to be considered for the production of parts by using the new virgin chopped material, coming from the uncured prepreg scrap, are Bulk Molding Compound (BMC) and Sheet Molding Compound (SMC). Both techniques are based on the manufacturing of parts with chopped material and a press molding process. SMC involves the use of longer fibers and, then, the resulting material or part is, therefore, stronger. BMC is divided into two different technologies, first one named as Bulk Molding Compound (BMC) and second one as Hybrid Bulk Molding Compound (HBMC). The main difference is that HBMC includes an additional second step, where one ply is placed over and beneath the part or the panel, so the final appearance is similar to a standard prepreg composite part.

Several press molding cycles were analyzed to optimize the curing cycle, being the final selection the following one:

- Pre-curing cycle: a pre-cured step of 10 minutes, 120 bar at 190ºC in a hot plate press. The aim is to keep the press at 125ºC between different processes, saving time and energy when several curing cycles are planned.

- Post-curing cycle: step in oven during 1h at 180ºC. This cycle can be used to cure several parts or panels at the same time.

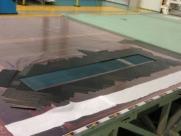

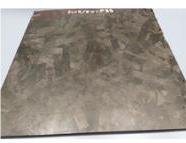

Here below some representative pictures of produced chopped material panels are shown (Figure 2). In addition, different aged materials and contaminated waste (mainly with glass fiber or bronze mesh) have been also chopped and studied.

| a) |

|

| b) |

|

4 Results

4.1 Material characterization

Panels produced with described prepreg reuse process were evaluated by means of physic-chemical testing. Cure degree and glass transition temperature (Tg) were measured by DSC (Differential Scanning Calorimetry), morphology observed by microscopy and fiber, resin and void content obtained by acid digestion. The compression molding processes provide semi-cured composites with 80-90% cure degree and Tg of 90ºC-210ºC. After the post-cure cycle in oven, the panels reached an extent of cure of 100% and a Tg in accordance with the relevant material specification.

Mechanical testing (tensile and Compression After Impact, CAI), considering different variables (multi-ply vs. mono-ply, multidirectional vs. unidirectional, fiber or chip length, raw prepreg type), were also performed and results compared with the reference HexMC® (molding compound material made of chopped virgin prepreg, with Standard Modulus carbon fiber). The main outcomes of the reused material mechanical behavior are:

- Tensile results (see Figure 3), performed under EN2561 for multi-ply scrap and AITM1.0007 for mono-ply scrap, show that the higher fiber length the higher strength and modulus results. Additionally, the presence of a continuous ply above and below the chopped panel (HBMC) improves highly the tensile values, nevertheless, no significant difference was obtained between multi-ply scrap multidirectional and unidirectional for the same raw prepreg material. The highest tensile values were obtained for the mono-ply chopped material panel manufactured with the longest chip dimension, although tensile strength is still lower (-43%), the modulus is higher (+53%) than the reference figure. Finally, it is also remarkable the high scatter obtained for some values, mainly for mono-ply chopped material.

- CAI results (AITM1.0010) are promising since some panels show values quite close or even higher to those reached by HexMC® impacted at 30J, as it can be seen in next graph (Figure 4). Mono-ply chopped scrap shows again highest CAI property, with a value even higher (+20%) than the reference. As in case of tensile results, high scatter is observed for mono-ply scrap.

4.2 Demonstrators

Several demonstrators were manufactured with the developed compression molding process from uncured prepreg chopped scrap, by using special tooling designed for the purpose, in order to demonstrate part manufacturing feasibility. Results obtained with these demonstrators point out that:

- Reused uncured A350 prepreg can be used to manufacture non-flying parts: drilling, support templates or even part production tooling.

- Besides, curved, complex part demonstrators show that the chopped material copies the mold, being able to adapt to the geometry and size of complex aeronautical parts (see Figure 5), which are difficult to be produced with continuous fiber materials.

- From produced aeronautical demonstrators, it is remarkable that automotive or sport parts can be potential candidates for application of the chopped material and press molding manufacturing process.

a) |

b) |

5 Conclusions

Within this study the processes of chopping and curing (two steps: compression molding + oven) of A350 uncured prepreg tape or tow scrap were fully defined. During this definition the continuous improvement of mechanical properties of the produced new virgin material was pursued, by increasing the size of the prepreg chips, at expenses of a lower material workability, or by using HBMC technology. Among the different chip sizes considered final selection was 50x12.7mm, due to the selected first priority mono-ply A350 scrap type (FP end of rolls) and the mechanical performance obtained with it. HBMC improves substantially tensile properties, up to 2.6 times the lowest BMC tensile strength value, however, it is less appropriate for complex geometry parts. Additionally, some mechanical results, above all from mono-ply scrap, can be compared to those reached by other chopped commercially available materials as HexMC®, but the scatter obtained in this case needs to be highly reduced (e.g. higher specimen surface…).

A clear conclusion is that the degree of material chopping, the scrap mono-ply versus multi-ply format and the presence of a continuous fiber ply on top and below the panels (HMBC) will define the possible applications of the reused material. It is also noticeable that this material be customized for the final use. Then, an interesting application for this new chopped material would be the manufacturing of low cost and weight tooling (drilling, support, manufacturing tooling…), system supports (brackets with complex geometries..), non-loaded or low loaded aircraft parts (fillers, gaskets…), and other non-aeronautical parts (sewer or drain, dashboard, case, automotive bar, sport racket…).

Currently, as result of this project, there is an available cutting machine prototype for prepreg end of rolls at Fidamc facilities and a full chopped material characterization program is on-going, with the aim of finding, assessing and demonstrating an industrial process and optimal aeronautical and/or other applications.

Acknowledgments

This work was funded and supported by Airbus and especially by Philip Harrison, Airbus Structure Technologies and Methods Research Manager, and Jose Sánchez Gómez, Airbus Executive Expert of Composite Materials, who bet on this type of project in order to improve our current environment and world.

References

[1] J.P. Snudden, C. Ward, K. Potter, Reinforced Plastics, “Reusing automotive composites production waste (Part 2)”, (December 2014).

[2] E. Asmatulu, J. M. Twomey, M. Overcash, Journal of Composite Materials, 48 (5), 593 - 608 (2014).

[3] A. M. Cunliffe , N. Jones, P. T. Williams, Journal of Enviromental Technology, 24 (5), 653 – 663 (2003).

[4] C. Morin, A. Loppinet-Serani, F. Cansell, C. Aymonier. Journal of Supercritical Fluids, 66, 232-240 (2012).

Document information

Published on 15/07/18

Accepted on 15/07/18

Submitted on 15/07/18

Volume 02 - Comunicaciones Matcomp17 (2018), Issue Núm. 3 - Reciclaje y Sostenibilidad y Procesos de Fabricación I, 2018

DOI: 10.23967/r.matcomp.2018.07.001

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?