“Structural engineering is the art of molding materials we don't wholly understand, into shapes we can't fully analyze, so as to withstand forces we can't really assess, in such a way that the community at large has no reason to suspect the extent of our ignorance”

James E. Amrhein

Resumen

El comportamiento estructural de edificios y otras construcciones bajo severas excitaciones sísmicas es muy complejo e implica temas como, la interacción suelo-estructura, grandes esfuerzos y desplazamientos, daños, plasticidad y el comportamiento de la estructura cerca del colapso. Por otra parte, en estructuras de hormigón armado, existen varios modos de fallo y de degradación: agrietamiento, aplastamiento y desprendimiento del hormigón, plastificación y extracción de las armaduras traccionadas y plastificación y pandeo de las armaduras comprimidas. Además, otras circunstancias hacen que la situación sea más alarmante: dada la creciente conciencia y preocupación por el enorme riesgo sísmico mundial, la ingeniería sísmica ha experimentado en los últimos años avances sustanciales, para lo cual se han propuesto nuevas estrategias de análisis y diseño, lo que conduce a desarrollos relevantes. Estos desarrollos se basan en pruebas y simulaciones numéricas basadas principalmente en modelos simplificados referidos en este trabajo como modelo basados en la estructura, resultando un costo computacional moderado. Por lo tanto, existen una gran necesidad de verificar la fiabilidad de los nuevos desarrollos en comparación con los análisis realizados utilizando herramientas de simulación más avanzadas y con ensayos. Esta trabajo se organiza en dos partes; en la primera se describe un modelo preciso basado en la mecánica del medio continuo y en la segunda se presenta otro modelo más simplificado basado en los componentes de la estructura.

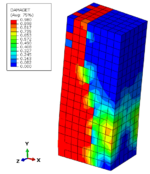

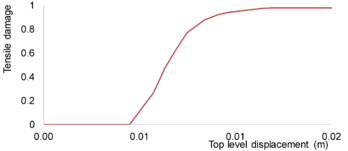

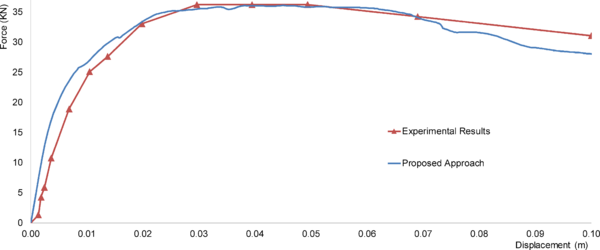

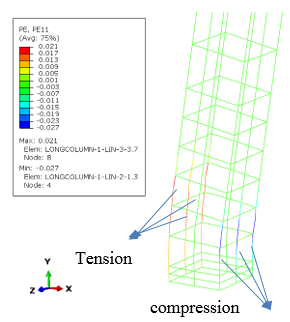

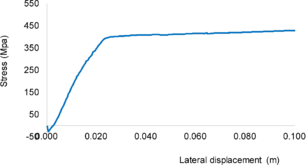

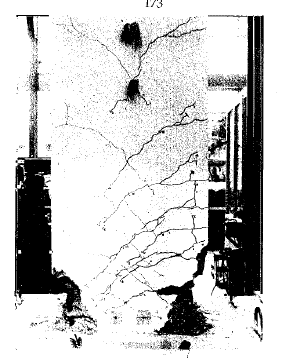

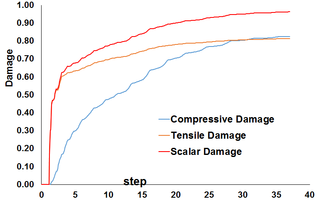

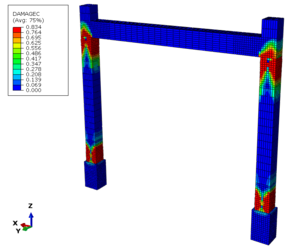

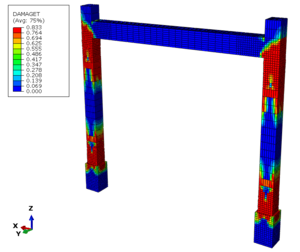

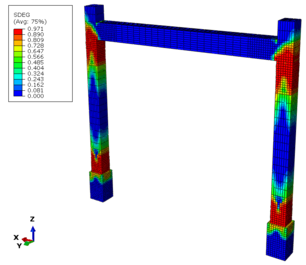

Primera parte. En esta parte se desarrolla un nuevo modelo basado en la mecánica del medio continuo para simular el comportamiento monotónico y cíclico de estructuras de hormigón armado. El modelo desarrollado combina una nueva metodología para el cálculo de las variables del daño en el Modelo de Daño Plástico del Hormigón “CPDM”, y un nuevo enfoque para integrar el CPDM con un modelo de interface de 3-D desarrollado en otra investigación. También se presenta un nuevo esquema para implementar la interfaz del modelo en un modelo FEM continuo de regiones con armaduras que se cruzan en varias direcciones. La precisión, la fiabilidad y la insensibilidad a la malla del modelo propuesto se verifican simulando varias pruebas incrementales y cíclicas; los resultados obtenidos se comparan con experimentales, lográndose un ajuste satisfactorio.

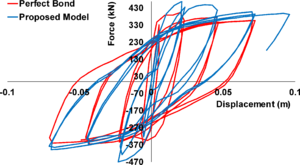

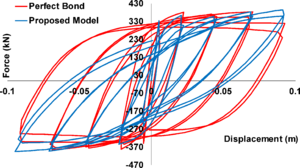

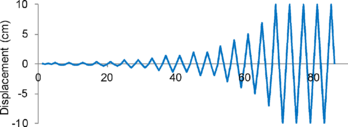

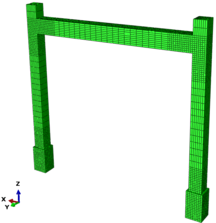

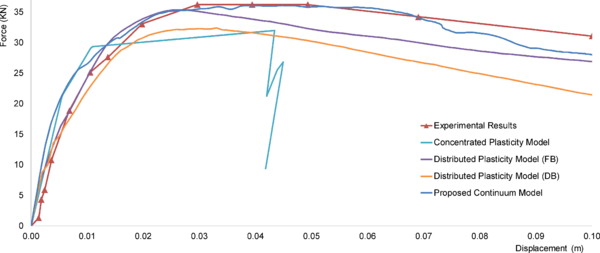

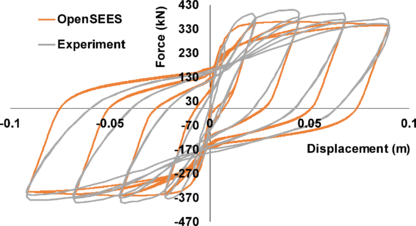

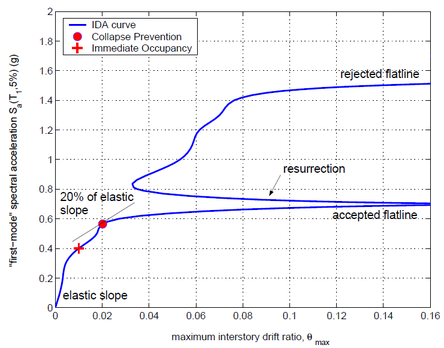

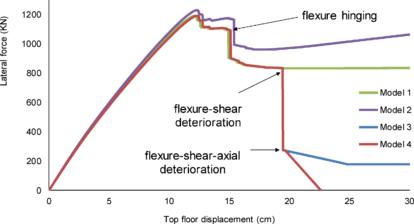

Segunda parte. El modelo desarrollado en el Primer Parte ha sido comparado con modelos simplificados basados en los componentes estructurales de uso común en la ingeniería sísmica, los resultados mostraron la superioridad del modelo propuesto para predecir el comportamiento real de los elementos y pórticos RC altamente dañados, capturando la reducción de la resistencia, la degradación de la rigidez y el efecto pinzamiento (“pinching”). Sin embargo, algunos de los modelos basados en componentes estructurales han mostrado un desempeño aceptable teniendo en cuenta el costo computacional de la ley en comparación con el modelo avanzado basado en la mecánica del medio continuo. Con de esta conclusión, este parte de este trabajo presenta un estudio numérico sobre la relación entre los modos de deterioro no-simulados de pórticos de hormigón sin ductilidad y su capacidad última. Se ha desarrollado un modelo avanzado basado en los componentes de la estructura para simular el comportamiento dinámico no lineal de las estructuras sin ductilidad, teniendo en cuenta los modos de deterioro de flexión, corte y axial. El modelo desarrollado es numéricamente eficiente, siendo pues adecuado para el uso profesional en ingeniería sísmica. La capacidad del modelo desarrollado se verifica mediante la simulación del comportamiento dinámico no lineal de un edificio no dúctil existente y del edificio prototipo. Los resultados obtenidos muestran que el desarrollado, a pesar de su coste computacional moderado, detecta y reproduce con precisión el comportamiento dinámico no lineal de estructuras RC no dúctiles, capturando también los modos de deterioro que no contemplan los modelos más simplificados. La comparación con los resultados de modelos más simplificados resalta la importancia de los modos de falla no considerados en el comportamiento de cada elemento y en los mecanismos generales de colapso. Se aborda la relación entre los modos de fallo no simulados y el fenómeno de la “Resurrección Estructural”.

Summary

Under severe seismic excitation, structural behavior of buildings and other constructions is highly complex. It involves, among other issues, soil-structure interaction, large strains and displacements, damage, plasticity, and near-collapse behavior. Moreover, in reinforced concrete structures, there are several coupled degradation and failure modes: cracking, crushing and spalling of concrete, yielding and pull-out of tensioned reinforcement, yielding and buckling of compressed reinforcement. Furthermore, another circumstance makes the situation more alarming: given the increasing awareness and concern on the huge worldwide seismic risk, earthquake engineering has experienced in last years substantial advances. New design and analysis strategies have been proposed, leading to relevant developments. These developments rely on extensive testing and numerical simulation mainly based on oversimplified models referred in this work as structural component-based models, as a result of their moderate computational cost. Therefore, there is a strong need of verifying the reliability of the new developments by comparison with analyses performed using more advanced simulation tools and with experiments. This work is organized in two parts. First part presents an accurate model, while the second part deals with a more simplified model, although highly computational efficient.

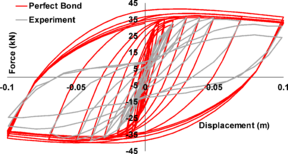

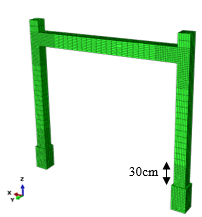

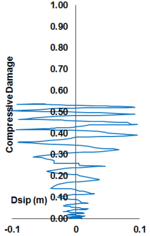

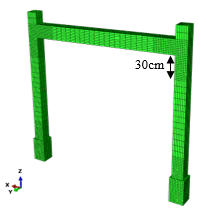

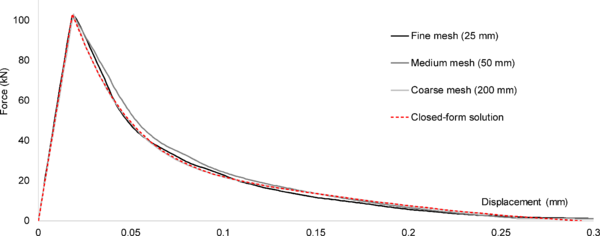

First part. This research clarifies the aforementioned issues by developing a new continuum mechanics-based model for simulating the monotonic and cyclic behavior of reinforced concrete structures. The developed model combines a new methodology for calculating the damage variables in Concrete Plastic Damage Models “CPDM”, and a new approach to integrate CPDM with a 3-D interface bond-slip model developed by other researchers. A new scheme to implement the interface model in a continuum FEM model of regions with crossing reinforcement bars is also presented in this research. Mesh-insensitivity, accuracy and reliability of the proposed model are verified by simulating several monotonic and cyclic tests; the obtained results are compared with experimental ones, satisfactory agreement has been accomplished.

Second part. The developed model in the First Part is compared with oversimplified structural component-based models that are commonly used in earthquake engineering; results have shown the superiority of the proposed model to predict the actual behavior of highly damaged RC elements and frames, capturing strength reduction, stiffness degradation and pinching phenomena. However, some of the structural component-based models have shown an acceptable performance considering the law computationally cost in comparison with the advanced continuum mechanics-based model. After this conclusion, this part presents a numerical study on the relation among the non-simulated deterioration modes of the elements in non-ductile RC frames and their final capacity. A structural component-based model has been developed for simulating the nonlinear dynamic behavior of non-ductile reinforced structures, accounting for flexure, shear and axial deterioration modes. The developed model is numerically efficient, thus being suitable for day use in earthquake engineering. The capacity of the developed model is verified by simulating the nonlinear dynamic behavior of an existing non-ductile building and the prototype building. Obtained results show that the developed model, despite its moderate computational cost, detects and reproduces accurately the nonlinear dynamic behavior of non-ductile RC structures, as well, capturing the deterioration modes that are blind to the simplified models. Comparison with results from more simplified models highlights the importance of hidden failure modes in the behavior of each element and in the overall collapse mechanisms. The relation between the non-simulated failure modes and the so-called "Structural Resurrection" is addressed.

List of symbols

Roman letters. Lower case

ac / at / bc / bt: dimensionless coefficients in equations

b: ratio

c / c1 / c2: cohesion / coefficients in the uniaxial tensile behavior of concrete

d / dc / dt: damage variable / compression damage variable / tension damage variable

b´´/d´´: are the width and depth of the confined core respectively

f / fcm / ftm / fc0 / ft0 / fck: stress strength / concrete compressive stress strength / concrete tensile stress strength / limit stress of linear compressive branch / limit stress of linear tensile branch / characteristic value of concrete compressive strength

f / fb0 / fc0 / fcm / ftm / fc0 / ft0 / fck/f'c: stress strength / biaxial compressive yield strength / uniaxial compressive yield strength / concrete compressive stress strength / concrete tensile stress strength / limit stress of linear compressive branch / limit stress of linear tensile branch / characteristic value of concrete compressive strength/concrete compressive strength.

fy / fu: longitudinal reinforcing bars stresses yield / ultimate

fyh / fu: transverse reinforcing bars yield stress

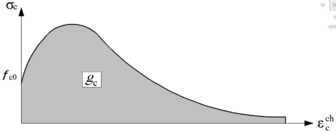

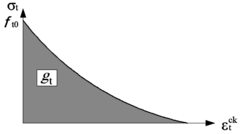

gc / gt: compressive / tensile energies per unit volume dissipated by damage along entire deterioration process

/ : weighting factors accounting for stiffness recovery

leq: mesh size (finite element characteristic length)

r*: stress state; for uniaxial stress r*(σ11) = 1 for tension and r*(σ11) = 0 for compression

sc / st: coefficients accounting for stress state and stiffness recovery effects

p: hydrostatic pressure stress

q: Von Mises-equivalent effective stress

r*: stress state; for uniaxial stress r*(σ11) = 1 for tension and r*(σ11) = 0 for compression

sc / st: coefficients accounting for stress state and stiffness recovery effects

w / wc: crack opening / crack opening at fracture

Roman letters. Upper case

Db: reinforcement bar diameter

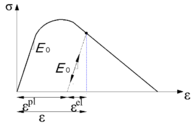

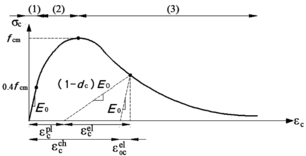

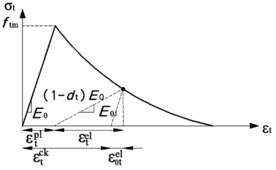

E / E0 / Eci: modulus of deformation / undamaged modulus of deformation / tangent modulus of deformation of concrete for zero stress

Es / Esh: steel modulus of elasticity / slope of hardening branch

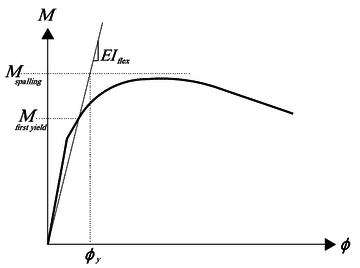

EIflex : column effective flexural rigidity

F: loading (yield) function

G / Gch / GF: flow potential / crushing energy per unit area / fracture energy per unit area

H: Mohr-Coulomb yield surface function

I1: first invariant of stress tensor

J2 / J3: second / third invariants of deviatoric stress tensor

Kc: ratio of second stress invariants on tensile and compressive meridians

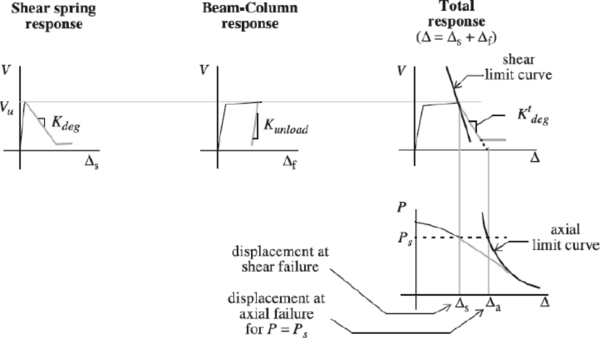

Kdeg: shear degradation stiffness (Elwood 2005 mode [1])

Cslip: Stiffness of linear slip spring

L: column height

L: mesh size for the spring bond-slip model.

MSP: moment at spalling of concrete

Fbs : is the equitant bond force

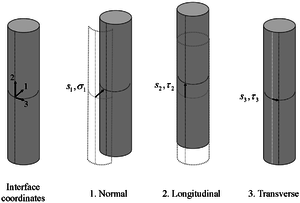

S1 / S2 / S3: relative normal displacement / longitudinalslip / transverse slip

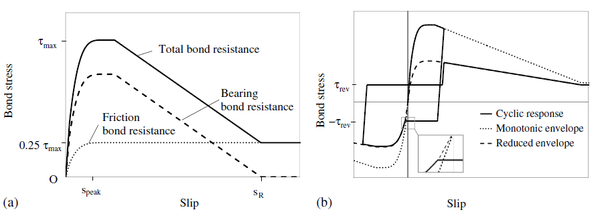

Speak / : peak slip / maximum positive slip / maximum negative slip / cumulated slip

SR:clear spacing between bar ribs

S: is the center to center spacing of the hoops

As´´: is the cross-sectional area of the hoop bar

Ag/Aeff: are the gross section area/ the effective shear section area.

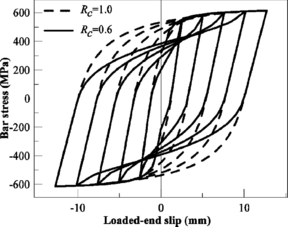

Rc : is the pinching parameter of [124] model.

M: fourth-order tensor for anisotropic damage model

I identity tensor

Greek letters

ε / εc / εt / εel / εpl / εcm / εtm: strain / compression strain / tensile strain / elastic strain / plastic strain / strain at compressive strength / strain at tensile strength

/ / / / / / / : strains at Figure 27; subindexes “c”, “t”, “0c” and “0t” and refer to compression, tension, undamaged compression and undamaged tension, respectively; superindexes “pl”, “el”, “ch” and “ck” and refer to plastic, elastic, crushing and cracking, respectively

εs / εy /εsh /εu: axial steel strain / yielding steel strain / hardening steel strain / ultimate steel strain

/ : crushing compressive strain / cracking tensile strain

/ : plastic compressive / tensile strain

εsh / εu: steel strain that corresponds to onset of hardening / ultimate strain

ε50u /ε50c: are the strain corresponds to 50% of concrete maximum compressive strength for unconfined and confined concrete respectively

ρb,s / ρf,s: reduction factor in bar bearing resistance accounting for steel yielding in tension / reduction factor in bar friction resistance accounting for steel yielding in tension

ρb,c / ρf,c: reduction factor in bar bearing resistance accounting for slip history / reduction factor in bar friction resistance accounts for slip history

ρn: reduction factor accounting for opening of splitting cracks

ρsh: is the transverse reinforcement ratio

ρ´´ : is the volumetric ratio of confining hoops to volume of concrete core measured to the outside of the perimeter hoops.

ϵ: eccentricity of the plastic potential surface

ϕ: friction angle

θ: Lode similarity angle

θ: is the critical crack angle (Elwood 2005 mode [1])

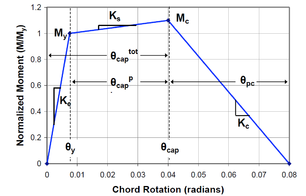

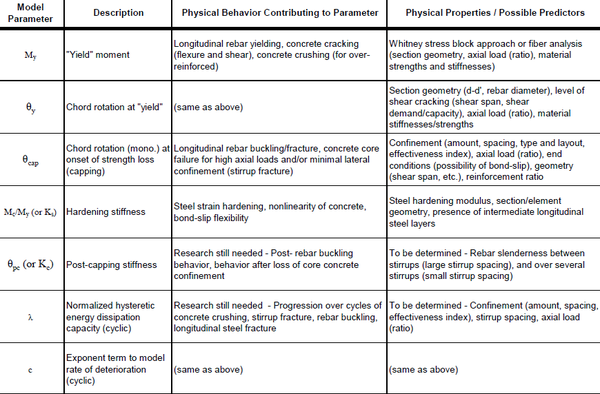

θcap: is the plastic rotation at onset of strength loss (Ibarra et al model [2])

θpc: is the post-capping stiffness (Ibarra et al model [2])

λ: is the energy dissipation parameter Ibarra et al model [2])

ρ: octahedral radius

σ / σ11 / σt0 / σc(1) / σc(2) / σc(3): stress / first principal uniaxial stress / uniaxial tensile stress at failure / concrete compressive stress at first / second / third segment

σ' /α' : the deviatoric parts of the stress and backstress tensors σ /α respectively

σ0 : the effective stresses tensor

ε/ εe/ εpl: are tensors of (total strain, elastic strain, plastic strain)

/ : effective compressive / tensile cohesion stress

σ1:normal bond stress

σ / σ11: normal stress / first principal uniaxial stress

τ2 / τmax / τb/ τf:longitudinalshear bond stress / peak bond strength / due to bar bearing resistance/ due to friction resistance

τ3:transverseshear bond stress

ξ: distance from origin of stress space to stress plan

ѱ: dilatancy angle

: Steel material parameters

Φy: Yield curvature

Δy/Δflex/Δslip/Δshear: are the yield drift displacement/ displacement due to flexure/ displacement due to slip/ displacement due to shear.

Δy/L, Δy/L: Are the drift limit angle at flexure-shear and flexure-shear-axial deterioration (Elwood 2005 mode [1])

General introduction to earthquake engineering

This section presents a brief introduction and a concise historical review of earthquake-resistant design of structures and the nonlinear analysis of RC structures.

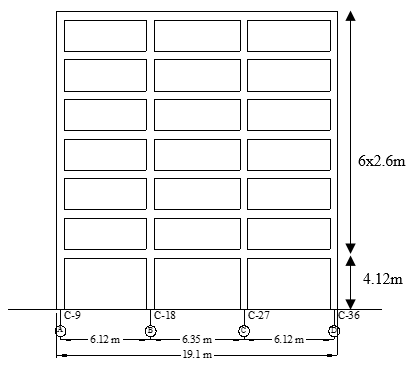

The first seismic analysis methods appear on the year 1923 in Japan (after the earthquake in Kanto [3] and can be included within the package of so-called Earthquake Analysis Methods Based on Resistance. These procedures were intended to provide buildings with lateral (horizontal) resistance; it was believed that if the structure of the building had enough lateral resistance it should be capable to survive the design earthquake. This resistance is guaranteed by designing the structure to be able to withstand horizontal forces applied at each floor level and in each direction of the building (usually two orthogonal directions). Figure 1 illustrates this concept.

|

| Figure 1. Lateral forces that are equivalent to a seismic input. |

In Figure 1, V is the sum of the forces acting at each floor level; in other words, the horizontal interaction force between the ground and the building. V is also known as base shear. Obviously, the value of V quantifies the severity of the earthquake effect on the building.

In the firstly developed earthquake-resistant design methods, horizontal forces represented in Figure 1 were obtained by multiplying the weight of each floor by a constant coefficient. This ratio between the horizontal and vertical forces was called seismic coefficient and in the first 1923 Japanese Seismic Code [3] it was estimated as 0.1. This value gradually increased as it was experienced that structures designed with this resistance value failed when an earthquake stronger than expected occurred. This ratio took to the values of 0.10, 0.15 and 0.20 until, thanks to the development of computers and by having more and more seismic experiences, it was concluded that structures that had been designed with a certain lateral resistance, did not reach collapse but could suffer damage in the case of a larger earthquake. After that, resistance was not the primary goal and everybody started paying more attention to the ductility; it can be roughly defined as the ability of a given structure to resist after the onset of damage. The ductility of a given building can be estimated from observed damages. The regulations began to introduce the concept of ductility by quantifying it with a response reduction factor, which reduces the equivalent lateral forces shown in Figure 1; it was mentioned in the 1957 American design code [4]. Thus, this approach has been incorporated to the current worldwide regulations. In summary, most of the earthquake-resistant regulations require to provide buildings with a certain level of lateral resistance. This resistance is obtained by dividing the resistance that a given building should have to remain in the elastic range under the design input by the aforementioned response reduction factor. This factor should obviously be equal to or greater than the unity. This coefficient is represented by different symbols in each standard; in the European standard [5] it is named q, in the United States [6]it is known as R. It is remarkable that, in fact, this ratio does not take into account only the ductile behavior of the structure but also includes the over-resistance of the building due to the conservative considerations that are regularly considered (safety factors, among others) and the increase of the material resistance under dynamic inputs (“strain rate effect”).

In any case, it should be kept in mind that in these methods the effect of the earthquake on the structure is characterized by means of equivalent static forces Figure 1; they are determined as those that generate a lateral displacement equal to the maximum one that would occur along the duration of the earthquake. However, another possible strategy is to represent the seismic action by a much more direct way: as input accelerograms. In this case, dynamic analysis must be performed to determine the time-history responses; then, the maximum values will be selected, they would represent the design demands. This formulation is often referred to as earthquake-resistant design based on dynamic calculations. This strategy seems appropriate and has apparently shown to be quite capable of simulating the actual seismic behavior of structures with great accuracy and reliability; however, there are some drawbacks that hinder the use of such formulations: (1) the information about the earthquakes that may occur for a particular structure during its lifetime is limited, which severely impairs the accuracy of the study, (2) for economic reasons, structures are designed to behave nonlinearly during the design earthquake (the most severe earthquake expected with a reasonable probability) and, hence, nonlinear dynamic analyses are a must. Dynamic analyses in the nonlinear regime are much more complex than the, already complex, dynamic linear calculations.

Earthquake-resistant design based on spectra:

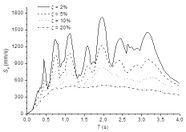

In general terms, these methods are based on estimating the equivalent static forces (which characterize the effect of the seismic action) in terms of the fundamental period of the structure. This is done by using response spectra; they are plots whose ordinates are certain response magnitudes and whose abscissas are the natural periods of SDOF systems that represent the structure. Up to date, three types of spectra have been basically proposed: absolute acceleration, relative displacement, and energy spectra. In the absolute acceleration spectra, the ordinates are the ratio between the maximum absolute acceleration in the top of the building and the maximum input acceleration in the base of the building. In the relative displacement spectra, the ordinates are the ratio between the maximum relative displacement between the top and the base of the building and the maximum input relative displacement. In the energy spectra, the ordinates are the input energy introduced by the seismic input in the building. It is noteworthy that each of these three spectra considers a meaningful response magnitude: the relative displacement is an indicator of the apparent structural damage level (i.e. not cumulative), the absolute acceleration is related the human perception of the motion and the damage to the facilities (and, more generally, to all the non-structural elements) and the energy reports on the accumulated structural damage.

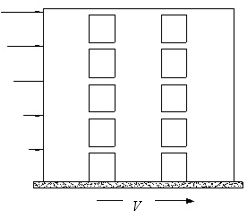

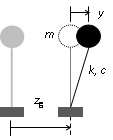

Linear spectra plot the ratio between the maximum values of the response of an elastic single-degree-of-freedom system and of the input acceleration. Figure 2 shows an elastic model of a single-degree-of freedom system undergoing a horizontal ground motion zg.

|

| Figure 2. Elastic single-degree-of-freedom systems. |

In Figure 2, m, c and k are the mass, damping and stiffness coefficients, respectively, y is the relative displacement between the mass and the base (degree-of-freedom) and zg is the displacement of the ground. Noticeably that the model in Figure 2 can incorporate the relative displacement between the foundation and soil, this is termed as Soil Structure Interaction SSI . Yet this formulation is commonly applied to horizontal motion, can be also considered for vertical vibrations.

The equation of motion of the system described in Figure 2, is given by

|

|

(1) |

By dividing both sides by m, (1) becomes

|

|

(2) |

In this relationship, is the undamped natural frequency of the system and ζ is the critical damping factor. These coefficients are given by

|

|

(3) |

The damped natural frequency is related to and to ζ by

|

|

(4) |

It is remarkable that, unless the damping ζ takes extremely high values, and are nearly coincident.

The acceleration, velocity and displacement spectra are obtained, for each input zg(t), as the maximum values of the absolute acceleration (where ), relative velocity and relative displacement y. They depend on the natural period T (T = 2 π/ ω0) and on the damping factor ζ. These quantities are obtained by the following linear relationships [7]:

|

|

(5) | |

|

|

(6) | |

|

|

(7) |

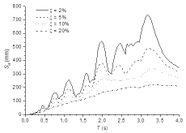

Figure 3.a.b.c show, relative displacement, relative velocity and absolute acceleration spectra, respectively. Such spectra correspond to the accelerogram registered in the ICA2 station (E-W component) during the Pisco earthquake, 15 august 2007.

|

|

|

| 1) Relative displacement spectra | 2) Relative velocity spectra | 3) Absolute acceleration spectra |

| Figure 3. Displacement, velocity and acceleration spectra for Pisco earthquake 2007- ICA2-EW | ||

Figure 3.a.b.c show that the spectral ordinates decrease with the increasing damping ratio; this shows that damping has a beneficial effect, since it contributes to reduce relevant response magnitudes (relative displacement, relative velocity and absolute acceleration). Moreover, the spectrum corresponding to zero damping exhibits sharper peaks than the spectra for non-zero damping; it means damping contributes to smoothen the spectra, e.g. making it less sensitive to small period changes.

It has been demonstrated [8] that for small values of damping and not too long periods (under 10 seconds), the velocity spectra are obtained by multiplying the acceleration spectra by T / 2π and that the displacement spectra are obtained in the same way from the velocity ones:

|

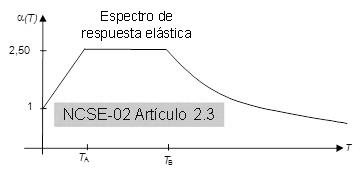

Absolute acceleration response spectra

As discussed in the previous subsection, the absolute acceleration response spectra are curves that represent, in ordinates, the ratio between the maximum values of the absolute acceleration of the SDOF system that represents the dynamic behavior of the structure in a given vibration mode and the ground acceleration. The design spectra are smoothed envelopes obtained from a number of individual records. Figure 4 shows the design spectrum of the Spanish regulation [NCSE-02 2002].

|

| Figure 4. Design acceleration spectrum [NCSE-02 2002]. |

The spectrum shown in Figure 4 consists of three branches: a linearly increasing one, a constant one and a hyperbolically decreasing one. Periods TA and TB depend on the characteristics of the soil, being higher as it has less stiffness; in some codes, the spectral ordinate (e.g. the height of spectrum) also grows as the flexibility of the soil does. The interpretation of each of these branches in terms of the effect of the earthquake on the structure is quite clear: (1) short-period structures are very rigid and tend to behave as the surrounding soil, but its motion is amplified as its rigidity decreases, (2) in the medium period range, the ground motion reaches its highest amplification inside the building and, (3) in the long periods range, structures are flexible enough so that its stiffness is not capable of overcoming the high inertia forces. This interpretation helps us to understand the influence of the soil stiffness in TA and TB: for stiff soil the range of building periods whose motion is highly amplified (in between TA and TB) is narrow, while this range widens and encompasses higher rise buildings as the soil becomes less stiff. This spectrum is commonly presented in dimensionless form (the ordinates Sa are dimensionless).

Performance-based earthquake-resistant design

The objective of the current seismic design codes is to prepare the structure to resist the design seismic input only under ultimate limit state; in other words, the structure is intended to resist the design earthquake with an acceptable level of serious damage but without collapse (in other words, avoiding at all costs the loss of human lives). Remarkably, that approach does not include any requirement about the behavior under seismic actions with lower or higher level of severity; this contrasts with the usual strategy against other type of actions (gravity, for example) where two types of limit states (ultimate and service) are considered. This approach is broadly valid and has been used for decades but was in shortage especially after the Northridge earthquake in 1994 and Kobe in 1995; after these highly severe earthquakes it was found that some structures, even those relatively new and that had been designed with the latest seismic standards, did not collapse (and in them there were no human casualties), but the damage to buildings (both structural and non-structural) was very serious. In the Kobe earthquake, some hospitals had been so intensely reinforced that effectively its structure did not collapse but absolute accelerations in the building were so high that it damaged the installations and were unusable at the time of greatest need (a few hours after the earthquake). After these events, the earthquake engineering was directed not only to prevent loss of human lives but also to quantify, reduce and prevent the damage. Depending on the damage, we are able to accept when an earthquake occurs, different solutions can be proposed. This strategy is commonly known as “Performance Based Design”; it is mainly described in the references [9], [10], [11], [12]. These documents present different seismic design methodologies oriented to control and to quantify the level of structural damage due to seismic action and to design structures that do not exceed the corresponding level.

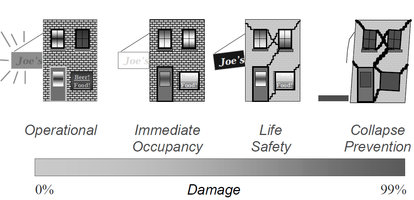

Based on structural and non-structural damage, the following four levels of performance (“Performance States”) are defined according to SEAOC 1995 [9]:

- Fully Operational. Uninterrupted service. Negligible structural and non-structural damage.

- Operational. Most of the activities can be resumed immediately. The structure is safe and can be inhabited. The essential activities are maintained while the non-essential ones are interrupted. Repairs are necessary to resume the non-essential activities. Slight damage.

- Life Safe. Moderate damage, the structure remains safe. Some elements or components of the building may be protected to avoid damage. The risk of loss of life is low. The building may need to be evacuated after the earthquake. The repair is possible, but can be economically unfeasible.

- Near Collapse. Severe damage, but without risk of collapse. Possible fall of non-structural elements.

More recently, another similar classification is considered according to ATC-40 [10] and FEMA 356 [12];

- Immediate Occupancy. Achieve essentially elastic behavior by limiting structural damage (e.g., yielding of steel, significant cracking of concrete, and non-structural damage.). Important services are not uninterrupted. The period of lack of functionality (“down time”) is about 14 hours.

- Damage Control. Slight structural damage. Achievable occupants’ safety. The essential activities are repairable. Moderate overall damage. The period of lack of functionality (“down time”) is about 2 or 3 weeks.

- Life Safety. Limit damage of structural and non-structural components but no collapse. No risk from falling non-structural elements. The evacuation of the occupants can be done without risk. Possibility of irreparable building.

- Collapse Prevention. Severe structural damage, with risk of collapse. Likely fall of non-structural elements. The evacuation of the occupants may involve risk. Building likely irreparable.

These four levels are often represented by their initials: IO, DC, LS and CP. The three levels IO, LS and CP are the most commonly used for seismic design; Figure 5 presents a graphical and easily understandable way, the practical significance of these levels and their relationship with the percentage of damage. The case “operational” in this case refers to a building without any damage.

|

| Figure 5. Damage levels [13] |

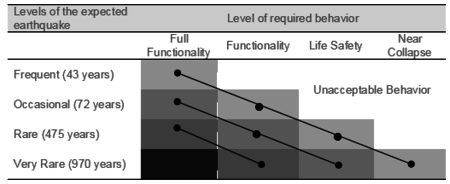

Regarding the seismic action, four levels of severity a defined as specified in Table 1.

| Design Earthquake | Return Periods (years) | Probability of Occurrence |

| Frequent | 43 | 50% in 30 years |

| Occasional | 72 | 50% in 50 years |

| Rare | 475 | 10% in 50 years |

| Very rare | 970 | 10% in 100 years |

Table 1 shows that the severity of the earthquakes is quantified in terms of their return period; it is understood as the average of the elapsed time among earthquakes with the same magnitude or, almost equivalently, as the inverse of the probability of occurrence in one year. In some cases, seismic actions more severe than those contained in Table 1 are considered; the so-called MCE (“Maximum Considered Earthquake”) corresponds to a return period of about 2475 years. The relationship between the return period T and the probability pn of being exceeded n years is given by the expression ; it is often used to indicate the severity of an earthquake by the probability p50 to be exceeded in 50 years, for example, in the case of MCE

is and in the case of an earthquake “Rare” is .

Table 2 shows the demand levels for each of the four performance levels previously described [9] , when the earthquakes that have the probability of occurrence specified in Table 1 occur.

Table 2 shows three levels of protection (expressed by the three represented diagonals): less intense for systems of moderate importance (“Basic Facilities”), more intense for major facilities (“Essential / Hazardous Facilities”) and even more intense for crucial facilities (“Safety critical Facilities”). For example, in “Essential / Hazardous Facilities” (diagonal terms) it is required that for an earthquake of return period of 75 years the building remains fully operational, for an earthquake of return period of 475 years the building keeps operating in its major functions and for a return period of 970 years the building is able to preserve the lives of its occupants.

Nonlinear static analysis (Pushover)

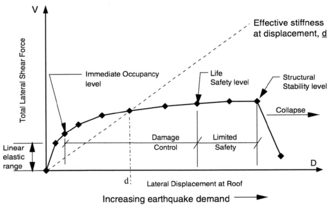

The method of earthquake-resistant design based on nonlinear static analyses consists basically of comparing the capacity of the structure, characterized by a capacity curve representing its behavior under pushing incremental forces, with the effect of the design earthquake, characterized by a demanding spectrum. The intersection between both curves is termed as target drift or target displacement or the most common “the performance point”; in other words, that point indicates the effect produced by the earthquake on the structure ATC-40 1996 [10]. The capacity curve is usually expressed by representing on the vertical axis the base shear force V and on the horizontal axis the displacement of the top floor. The analysis that generates this curve is static, monotonic, and obviously is nonlinear, being commonly known as push-over. Figure 6 shows an example of a capacity curve obtained from a push-over analysis.

|

| Figure 6. Capacity curve obtained from push-over analyses ATC-40 1996 [10] |

In the push-over analyses the base shear force is distributed along the floors according to certain patterns; the most commonly used are the first modal shape, uniform or linear (“triangular”) distributions. The push-over analyses are made incrementally, in other words, the lateral forces are increased progressively. For small values of V, the behavior of the structure is linear and as V increases, the structure is becoming gradually more damaged; the stiffness of the structure decreases and its capacity curve becomes more flat. The smallest slope of the capacity curve with the increasing displacement illustrates clearly the elongation of the natural period of the structure.

Some researchers [14], [15] have proposed techniques to modify the distribution of the lateral forces among the floors to take into account the variation of the modal properties and the contribution of higher modes " Modal Push-Over Analysis".

The demand is characterized by the design spectrum for the considered level of seismic action Table 1; to be able to intersect it with the capacity curve, it is represented as the absolute acceleration spectrum Sa (vertical axis) vs. the relative displacement spectrum Sd (horizontal axis). This type of representation is commonly known as “Acceleration-Displacement Response Spectra” (ADRS).

The methods mostly used to obtain the target displacements are: Capacity Spectrum Method ATC-40 1996 [10], Displacement Coefficient Method FEMA-356 2000 [12], Equivalent linearization method FEMA-440 2005 [16], Modified displacement coefficient method FEMA-440 2005 [16], Modified Capacity Spectrum ATC-40 1996 [10].

The analysis push-over characterizes the nonlinear dynamic behavior of the structure by means of increasing static forces. The main drawback of this strategy is that the response of the structure to a given input is not incremental but cyclical and the push-over analyses cannot take into account the accumulated plastic strain, in other words, the cumulated damage. Therefore, we cannot establish a clear relationship between the maximum displacement of the structure and the energy stored during plastic deformation cycles. When the structure enters the inelastic range, deterioration occurs by the accumulation of plastic incursions; that can produce the complete breakdown of structural elements for deformations smaller than those that could be resisted under monotonic forces. This type of failure is called low cycle fatigue or plastic fatigue. Another drawback of the earthquake design strategy based on displacements is that the hysteretic behavior is interpreted as an equivalent viscous damping (ζeq); this introduces a relevant error, especially for significant levels of damping. Moreover, such identification is not based on any physical principle that justifies, in inelastic systems, the existence of a direct relationship between the energy corresponding to the maximum displacement and the equivalent viscous damping.

Dynamic analysis:

This procedure evaluates the effect of earthquakes on buildings based on determining the dynamic response (commonly known as “time history”) to the expected accelerograms. The most relevant response quantities are; the maximum relative displacements in between consecutive floors (inter-story drifts), and the maximum absolute accelerations. The maximum relative displacements report about the experienced level of structural damage, the maximum absolute accelerations are directly correlated with the non-structural damage and the human comfort conditions. Since the dynamic calculations take into account the performance of buildings under seismic inputs in a more direct way than in the methodologies based on response spectra, in general the dynamic analyses are able to provide more accurate results. In particular, the comparison between the nonlinear static methods (push-over) and the nonlinear dynamic methods is clearly favorable to them because, besides being more accurate in general, they have two important advantages: (i) by considering the cyclical behavior they are able to reproduce the accumulated plastic damage and (ii) the consideration of the effect of damping (both the present in the undamaged structure and the generated for increasing damage) is more direct.

In zones of medium or high seismicity, buildings are often designed by accepting a given level of structural damage under the design earthquake. Accordingly, in these cases the dynamic analyses should be nonlinear, in other words, must be able to reproduce the behavior of the structure when it been damaged and therefore has experienced significant reductions in its strength and rigidity. Moreover, second-order analyses may be necessary because of the significant relative horizontal displacements, this being another source of complexity and increased computational cost. Although the nonlinear dynamic analyses are increasingly used in the earthquake-resistant design of important structures, this procedure is rarely used in the design of ordinary structures, this is due to the high computational cost involved and to the effort required to properly interpret the large amount of generated information.

Incremental Dynamic Analysis IDA

With the main purpose of alleviating the problem derived from the fact that the push-over analysis cannot take into account the accumulated plastic strain, the so-called Incremental Dynamic Analysis IDA has been proposed [17]. It is remarkable that the incremental dynamic analyses require making several nonlinear dynamical calculations, which are expensive in computational time; on the other hand, it may be necessary to perform second-order analyses. However, the incremental dynamic analyses, especially when applied to several earthquakes, constitute powerful formulations, which may provide greater and more useful information than the rest of approaches that have been described in this section.

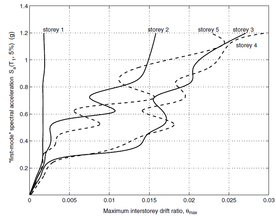

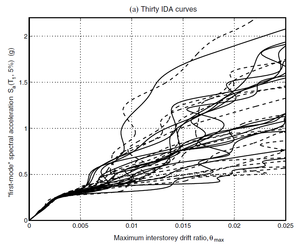

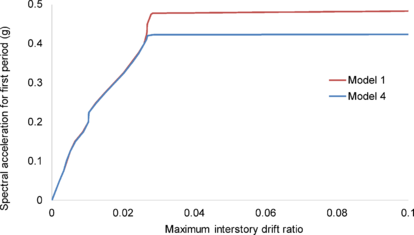

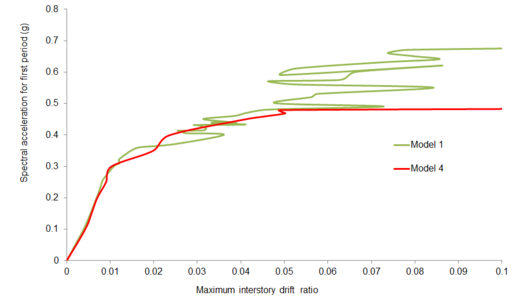

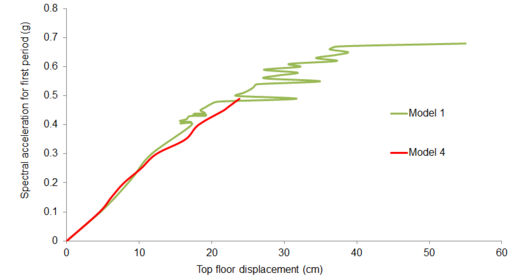

The results of these procedures are usually represented by the so-called IDA curves. These representations consist of capacity curves similar to the result of the push-over analyses; on the horizontal axis, an index related to the magnitude of the response is usually represented and the vertical axis usually contains an index related to the severity of excitation. Figure 7 shows the results of this kind; Figure 7.(a) corresponds to a single record and Figure 7.(b) corresponds to multiple (30) records. In both representations the severity of the seismic action is quantified by the ordinate of acceleration response spectrum for the first mode Sa(T1, 0.05) and the magnitude of the response is quantified by the maximum value (along the duration of the earthquake) of the relative displacement between floors (inter-story drift). Figure 7.(a) shows both increases and decreases of the damage on the upper floors with increasing severity of excitation, this effect is obviously due to the “protection” provided by the lower floors. None of the other methods described in this section are able to predict this phenomenon so clearly. Figure 7.(b) shows the remarkable variability in the response of a determined structure to records that have, in first approximation, a comparable level of severity.

|

|

| 1) Single Register | 2) Thirty Registers |

| Figure 7. Examples of IDA curves [17] | |

Usually the damage thresholds IO, LS and CP are related with certain values of the index that quantify the magnitude of the excitation (ordinate in Figure 7); in this way performance-based analyses can be made from incremental dynamic calculations.

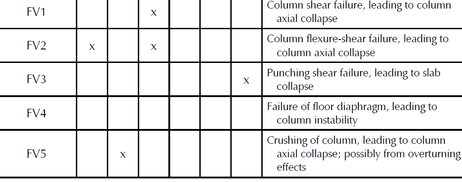

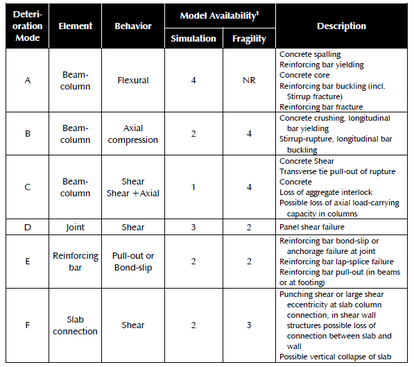

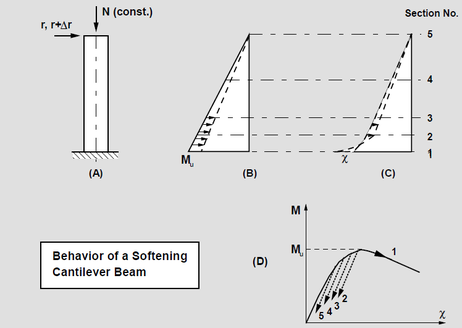

Deterioration modes in RC structures

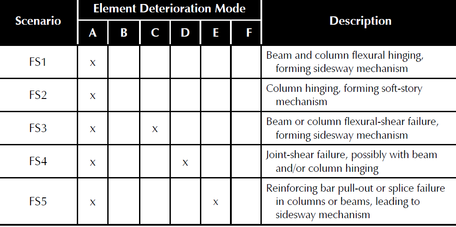

While buildings are usually designed for seismic resistance using elastic analysis, most will experience significant inelastic deformations under large earthquakes. Deterioration modes for RC frame components have been identified in [18] based on a review of experimental tests, published information and observation from past earthquakes. They are classified into six modes depending on the type of structural element and the physical behavior associated with deterioration shown in Figure 8. For each mode, currently available nonlinear components models are rated from low to high confidence “1 to 5” for their ability to simulate the deterioration.

|

| Figure 8. Deterioration modes for reinforced concrete frame components [18] |

Progressive deterioration can cause structural collapse, this can be generated in two forms; Local Collapse; identified as part of structure has been collapsed in result of ground shaking causes elements deterioration modes form a collapse mechanism, the localized part in RC frame structures is one floor that is usually the so called “soft story”, vertical loads still can be transmited by the non-damaged component. Second form is the Global Collapse; the entire structure collapsed and cannot transmit any vertical neither lateral loading. In regards to structure collapse, two possible mechanisms “scenarios” are defined; Sidesway Collapse induced by dynamic instability as result of unlimited story drifts amplified by a combination of P-Δ effects and deterioration in strength of the structural components. Vertical Collapse; this kind of collapse occurs as a result of the loss of one or several elements the vertical load carrying capacity causes a local collapse, and eventually entire vertical collapse due to a developed progressive collapse mechanism. These possible collapse mechanisms are principally dependent on the developed deterioration modes at the components level. Contribution of the predefined deterioration modes on the collapse mechanism "scenario" is defined in Figure 9 according to [18].

|

| Figure 9. Deterioration modes for reinforced concrete frame components [18] |

Nonlinear Analysis

Modern performance-based design methods require ways to determine the realistic behavior of structures under strong earthquakes. Enabled by advancements in computing technologies and available test data, nonlinear analyses provide the means for calculating structural response beyond the elastic range, including strength and stiffness deterioration associated with inelastic material behavior and large displacements. As such, nonlinear analysis plays an important role in the seismic assessment of new and existing buildings. In contrast to linear elastic analysis and design methods that are well established, nonlinear inelastic analysis techniques and their application to design are still evolving and may require engineers to develop new skills. Nonlinear analyses require thinking about inelastic behavior and limit states that depend on deformations as well as forces, different degradation modes among their interaction at the structural components must to be captured.

Depending on the structural configuration, the results of nonlinear analyses can be extremely sensitive to the assumed input parameters and of implemented numerical models, these models must confirm the locations of expected or observed inelastic deformations and trace the structural behavior up to the onset of collapse. This requires sophisticated models that are validated against physical tests to capture the highly nonlinear response approaching collapse.

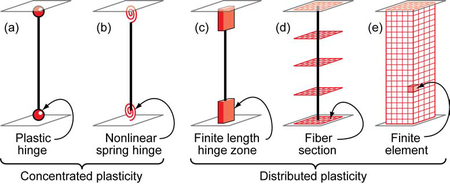

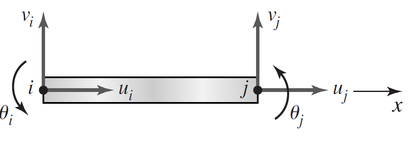

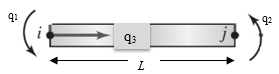

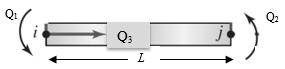

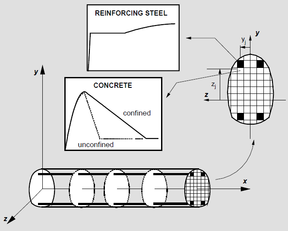

Capturing the aforementioned deterioration models and collapse mechanisms requires that the numerical model has the capacity to represent; the behavior of concrete and steel materials at high level of monotonic and cyclic loading, as well the interaction between both materials during the loading process characterized by the bond-slip behavior. Numerical models can be differentiated by the way that plasticity is distributed through the member cross sections and along its length. Figure 10 illustrates several idealized model types for simulating the nonlinear response of beam-column elements, same concepts can be applied for other element (e.g. braces and shear walls).

|

| Figure 10. Beam-Column nonlinear models [19] |

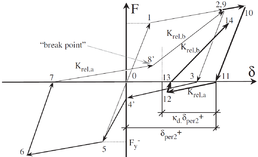

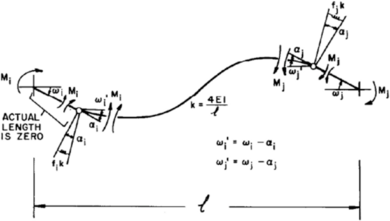

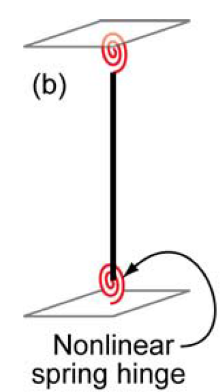

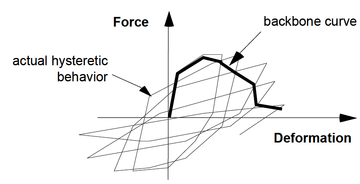

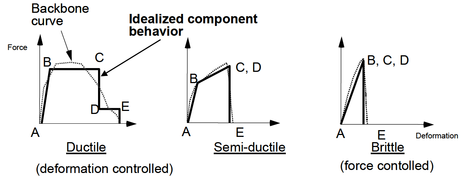

Concentrated Plasticity Models are the simplest formulation, representation of such models are shown in Figure 10-a,b. these models are based on concentrating the inelastic deformations at a specific location where the damage is expected to be located (e.g. ends of beams and columns). Numerically this is represented by attaching zero-length or spring element at location of the inelastic deformation, the behavior of this nonlinear element is governed by the so-called “backbone” or capacity curve that can be represented by moment-rotation or force-deformation relation for ductile and brittle behavior respectively. For cyclic loading, a hysteretic behavior is also incorporated in the behavior of the nonlinear element. Both the capacity curve and the hysteretic properties in these models are usually calibrated after experimental results and observation of past earthquakes. This formulation can be used to reflect the effect of some degradation phenomena such as bond-slip or bar buckling.

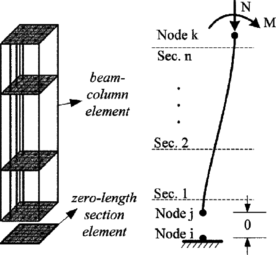

Distributed Plasticity Models are more complex to represent the distribution of the inelastic deformation. The distribution varies as well between the simple and the more complex. The Finite Length Hinge Model Figure 10-c is an efficient distributed plasticity formulation with designated hinge zones at the member ends. Cross sections in the inelastic hinge zones are characterized through either nonlinear moment-curvature relationships or explicit fiber-section integrations that enforce the assumption that plane sections remain plane. The inelastic hinge length may be fixed or variable, as determined from the moment-curvature characteristics of the section together with the concurrent moment gradient and axial force. Integration of deformations along the hinge length captures the spread of yielding more realistically than the concentrated hinges, while the finite hinge length facilitates calculation of hinge rotations.

Another more complex distributed plasticity formulation is the Fiber Section Model Figure 10-d. This model distributes plasticity by numerical integrations through the member cross sections and along the member length. The section is discretized by several fibers “portions”. Uniaxial material models are defined to capture the nonlinear hysteretic axial stress-strain characteristics in the cross sections, each fiber is assigned to a material (e.g. steel, confined and unconfined concrete). The plane-sections-remain-plane assumption is enforced, where uniaxial material “fibers” are numerically integrated over the cross section to obtain stress resultants (axial force and moments) and incremental moment-curvature and axial force-strain relations. The cross section parameters are then integrated numerically at discrete sections along the member length, using displacement or force interpolation functions. The most complex models are the Continuum Models Figure 10-e. These models discretize the continuum along the member length and through the cross sections into small (micro) finite elements with nonlinear hysteretic constitutive properties. This fundamental level of modeling offers the most versatility since the inelastic behavior can be captured in all the location and for different material, moreover the relation between concrete and steel “bond-slip” can be treated also by a constitutive model. The big challenge for Continuum formulation is providing integrated efficient model for RC simulation.

From the previous literature; two main modeling formulations can be defined to simulate the complex inelastic behavior of RC structures, the definition is based on the method each model presents the degradation at the components and material levels. The most commonly used formulation in earthquake engineering and performance based design is the Structural Component-Based Formulation represented by the models in Figure 10-a,b,c,d, and the most complex and general formulation is the Continuum-Based Formulation represented by Figure 10-e. In this dissertation, the simple and advanced formulations are verified and used to develop an appropriate tool for simulating the nonlinear dynamic behavior of RC frame structures.

Objectives

Main objective

To establish the requirements of developing a computationally efficient model for nonlinear cyclic behavior for RC structures. This study will consider advanced models derived from continuum mechanics-based formulations, and the simplified structural component-based models. This research will focus on RC frames behavior.

Particular objectives

This global objective will be pursued through the following particular objectives:

- Review the numerical models commonly used for describing the nonlinear dynamic behavior of RC frames under earthquake excitation. This study encompasses the most spread models based on structural component-based approaches (e.g. Lumped Plastic, Distributed Plastic).

- Review the more sophisticated numerical models derived from continuum mechanics formulations. This study encompasses the models for concrete, reinforcing bars and the models to describe the relation between both materials under monotonic and cyclic loading.

- Development of 3D continuum mechanics-based model for simulating the nonlinear cyclic behavior of RC structures, the model uses concrete plastic damage model and phenomenological interface bond-slip model.

- Verifying the capacity of the developed 3D continuum mechanics-based model, as well the simplified components-based models with experimental results of RC structures subjected to monotonic and cyclic loading.

- Development of an advanced and day use structural component-based model to simulate the nonlinear dynamic behavior of non-ductile RC structures.

- Performing Incremental Dynamic Analysis (IDA) study using the developed structural component-based model. The study investigates the importance of hidden failure modes as well as the relation between these modes and the so called “Structural Resurrection Phenomena”

Outline

This dissertation is organized in two parts, description of each part as well the new contribution is presented as follow:

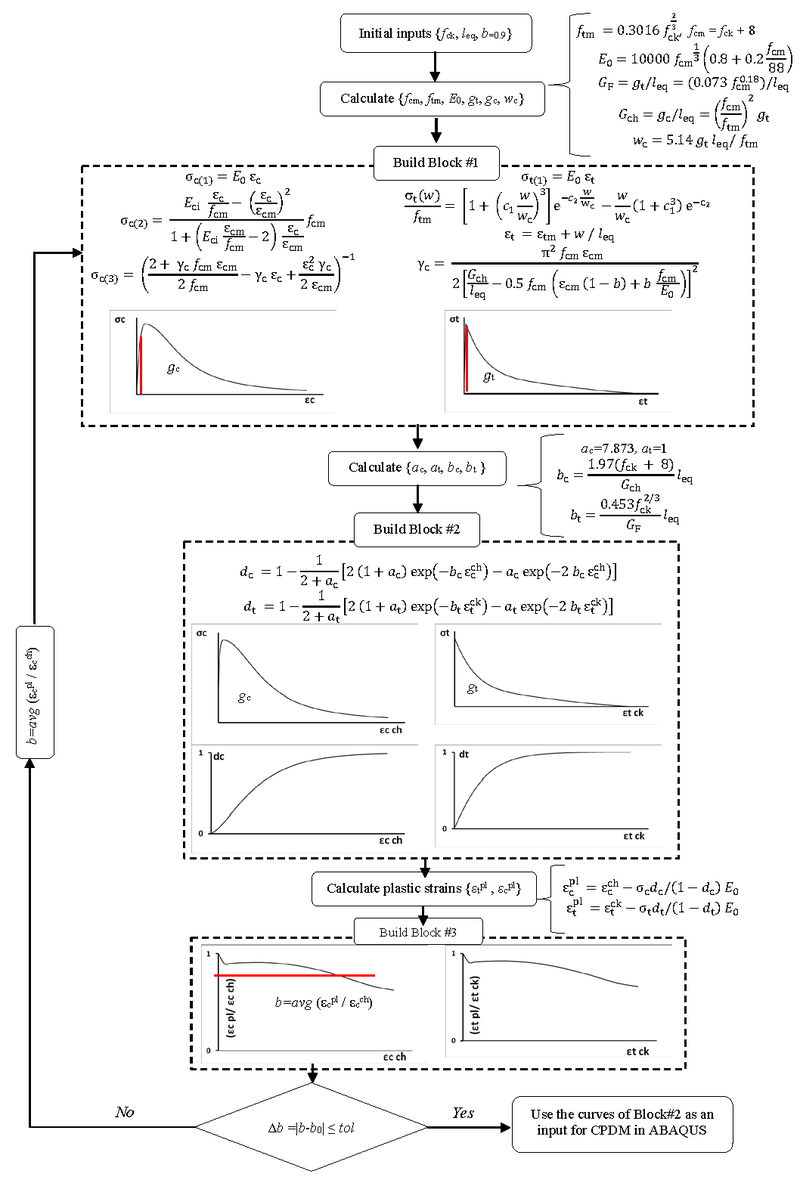

Part I focuses on the "numerical models of RC structure that are based on continuum mechanics-based formulations". Two major contributions are developed in this part. First contribution is a new methodology for calculating the damage variables "damage evolution" in Concrete Plastic Damage Models (CPDM), implementation of this methodology for CPDM of ABAQUS finite element analysis program is described as well. The second contribution is a new modeling scheme for 3D implementation of an interface bond-slip model developed by [20] and implemented in ABAQUS. Combining the methodology for calculating damage evolution in CPDM, as well the modeling scheme of the bond-slip model, results in an integrated continuum-based model for monotonic and cyclic simulation of RC structure. Proposed model is implemented in ABAQUS and verified with experimental results. Part I is organized in seven chapters as follow:

Chapter 1 provides an introduction to Part I, motivation and new contribution are also described. Chapter 2 describes in general the modeling of concrete material, models derived from plasticity, damage and coupled plastic-damage are described in this part, as well as the used concrete plastic damage model. Chapter 3 presents the proposed methodology for calculating the damage evolution in concrete plastic damage models. Chapter 4 describes the used model of steel material, while Chapter 5 describes the bond-slip phenomena and the implemented interface model in this work, the new modeling scheme is described in the subsection 5.4. Chapter 6 presents numerical simulation of real experiments conducted on reinforced concrete structures, experimental results are compared with ones obtained by the proposed models, finally Chapter 7 addresses a general concluding remarks about Part I.

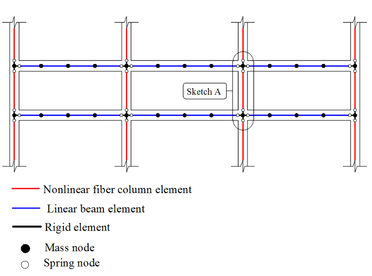

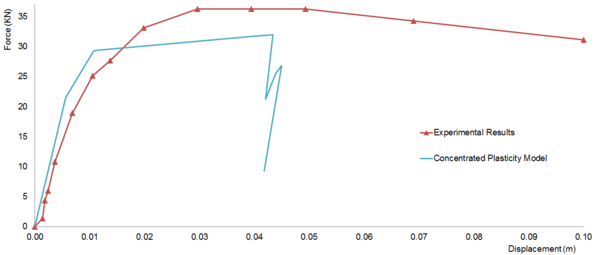

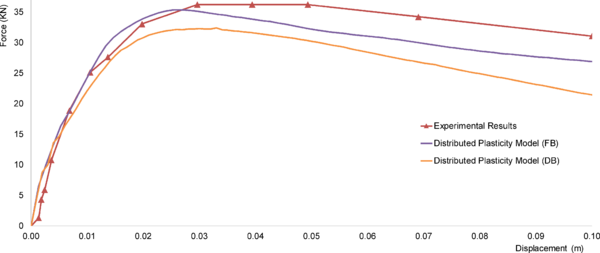

Part II focuses on numerical models that are based on simplified formulations referred as "structural component-based approaches" models. In this part the oversimplified models and commonly used in earthquake engineering are verified with experimental results and compared with the advanced model derived in Part I. The main contribution in this part is developing an advanced structural component-based model for nonlinear dynamic simulation of non-ductile RC framed structures. A numerical study is conducted using the developed model on the relation among the non-simulated deterioration modes of the elements of non-ductile RC frames and their final capacity. Part II is organized in six chapters as follow:

Chapter 1 provides an introduction to Part II, motivation and new contribution are also described. Chapter 2 describes the structural component-based models commonly used in the simulation of reinforced concrete structures. Chapter 3 verifies the capacity of the models presented in chapter 2 to capture the nonlinear behavior of the simulated experiments in Part I, obtained results are also compared with the ones from the continuum mechanics-based model developed in Part I. Chapter 4 presents the developed model to simulate the nonlinear dynamic behavior of non-ductile reinforced concrete structures. Chapter 5 verifies the capacity of the presented model in chapter 4 by performing numerical simulation of a two non-ductile structures, obtained results are also compared with experimental ones. Conclusions of this part are addressed in Chapter 6.

In the final conclusions chapter, the achievements of the present study are exposed along with concluding remarks and future works derived from this dissertation.

PART I-CONTINUUM MECHANICS-BASED APPROACHES

1 Introduction and motivation

Under severe seismic excitation, structural behavior of buildings and other constructions is highly complex. It involves, among other issues, soil-structure interaction, large strains and displacements, damage, plasticity, and near-collapse behavior. Moreover, in reinforced concrete structures, there are several coupled degradation and failure modes: cracking, crushing and spalling of concrete, yielding and pull-out of tensioned reinforcement, yielding and buckling of compressed reinforcement. Numerical model must be able to predict the global behavior of the elements among the interaction of the forces acting on each element. In other words, the model must capture the interaction between axial, shear, torsion and flexural moment, as well the subsequent degradation modes represented in strength reduction, stiffness degradation and pinching. Models based on simplified theories referred in this work as structural component-based models are commonly used in earthquake engineering, as a result of their moderate computational cost. Such models might serve to predict the seismic behavior of RC structures in some particular cases. However, in many cases the oversimplified models are not capable to capture adequately the entire range of deformation till the structure reaches its collapse state.

Therefore, in earthquake engineering, advanced numerical simulations based on continuum mechanics are strongly necessary. These models are commonly used in small size simulation due to their expensive computationally cost. The motivation in this part is to developed computationally efficient model based on advanced formulations. The developed model can be used for simulating small size structures or to investigate particular joints or some parts in reinforced concrete structures. Another application of the proposed model is to improve the performance of existing simplified models, as well to calibrate new models that can be used afterwards to simulate large scale models.

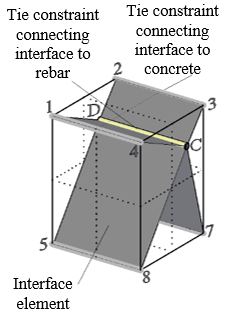

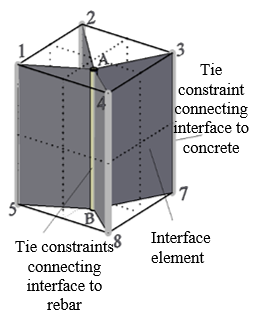

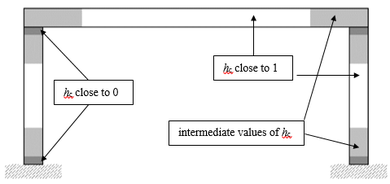

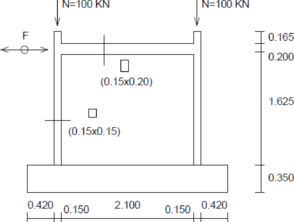

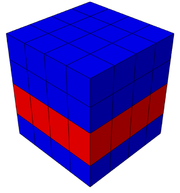

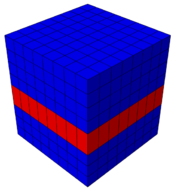

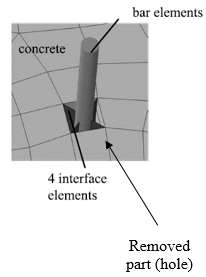

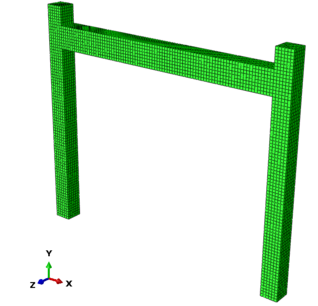

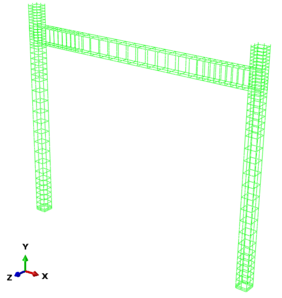

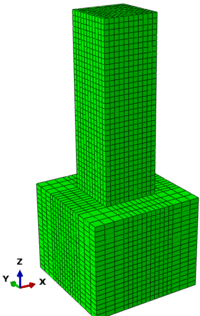

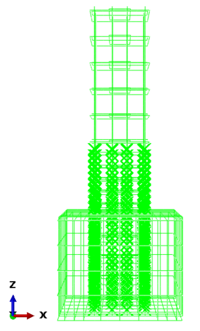

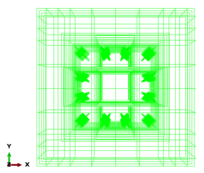

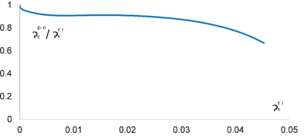

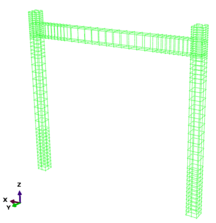

Using continuum mechanics-based formulations to describe the behavior of a mixed material such concrete implies that each material is assigned to a set of elements, the relation between materials must be also described by incorporating new elements or by imposing some bond conditions. In the developed model, concrete material is simulated by solid finite elements, steel bars are simulated by truss finite element and bond between steel and concrete is simulated by either; an interface elements or by assuming perfect bond conditions for cyclic and monotonic loading respectively. This part of the work describes shortly the bases of concrete constitutive modeling, as well the used damage-plastic model. Regarding steel bars, the basic plasticity model is described with its implementation. The complex relation between concrete and steel bars "bond-slip" is revised under monotonic and cyclic loading, modeling these phenomena in a 3D continuum model is explained.

The main contributions in this part are: Developing a new methodology for calculating the damage variables "damage evolution" in Concrete Plastic Damage Models "CPDM" [21] [22] [23] [24] [25] [26] [27] [28] [29] [30], this methodology is described in section 3. As well as a new scheme to implement interface bond-slip model in 3D FEM simulation described in subsection 5.4. As a final contribution, a new approach to integrate CPDM and bond-slip model in simulating the cyclic and monotonic behavior of RC structures is presented in subsection 6.1

2 Concrete modeling

2.1 Introduction

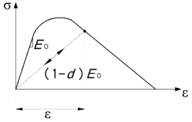

Quasi-brittle materials, as concrete, exhibit nonlinear stress-strain response mainly because of micro-cracking. Cracks are oriented as the stress field and generate the failure modes. In tension, failure is localized in a narrow band; stress-strain behavior is characterized by sudden softening accompanied with reduction in the unloading stiffness. In compression, failure begins usually in the outside and is more complex, involving volumetric expansion, strain localization, crushing, inclined slipping and spalling; stress-strain behavior involves ductile hardening followed by softening and reduction in the unloading stiffness. In mixed stress states, failure depends usually on the ratio between the principal stresses. Nonlinear concrete response can be represented using plasticity or damage theory. However, none of these formulations alone is able to describe adequately this phenomenon. Plastic models [31] [32] might represent realistically the observed deformation in high confined concrete but do not capture the stiffness degradation observed in experiments [21]. Damage-based models [33] [34] [35] [36] are based on gradual reduction of the elastic stiffness; they can describe the stiffness degradation in tension and low confined compression, but are not suitable to capture the irreversible deformations observed in experiments and the inelastic volumetric expansion in compression. In addition, fracture propagation can be represented by embedded crack models, where standard FEM interpolations are enriched with strain or displacement discontinuities [37] [38] [39]. These models can be used for high strain localization problems (fracture). The mechanical behavior among the constitutive modeling of concrete are described in the next sections.

2.2 Mechanical behavior

The fundamental characteristics of concrete behavior are established through experimental testing of plain concrete specimens subjected to specific, relatively simple load histories. Continuum mechanics provides a framework for developing an analytical model that describe these fundamental characteristics. Experimental data provide additional information for refinement and calibration of the analytical model. Some important mechanical features of concrete are summarized in this section. This furnishes a background for the review and further study on the constitutive modelling of concrete in the following subsections.

2.2.1 Uniaxial behavior

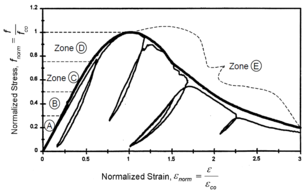

The behavior of concrete is highly nonlinear in both uniaxial tension and compression. Under uniaxial compression stress state, five different deformational stages can be observed as shown in Figure 11.a. For axial stresses up to about 30% of the maximum compressive stress, the uniaxial compressive behavior of concrete can be considered linear with existing micro-cracks in the material remaining nearly unchanged (Zone A). The second stage is between 30 % and 50% of the maximum compressive stress, results in some reduction in the initial stiffness due to the significant increase in crack imitation (Zone B). noticeably that crack does not continue to grow under constant load. Third stage is between 50 % and 75% of maximum compressive stress, results also in more reduction in the initial stiffness due to further initiation and growth of crack (Zone C). At this stage crack continue to grow under constant load. For stress state more than 75% of the maximum compressive strength, results in increasing compressive strain under constant loading (Zone D). After reaching the maximum compressive stress, softening behavior is observed with crack localization that varies according to the boundary conditions (Zone E). The softening under compression is more complicated than tension one and no general model is yet accepted such the crack model in tension. This is because of many factors such as the size and shape of the specimen, concrete strength and boundary conditions.

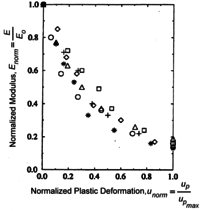

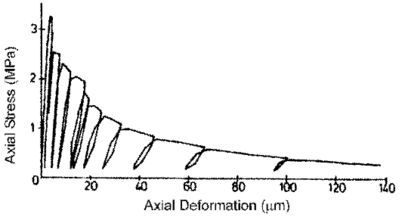

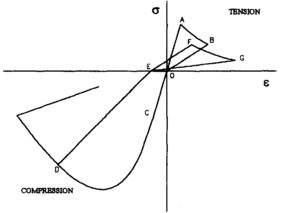

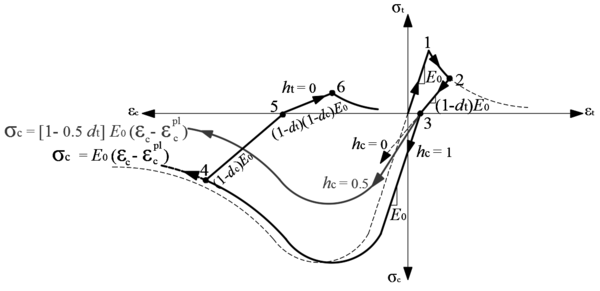

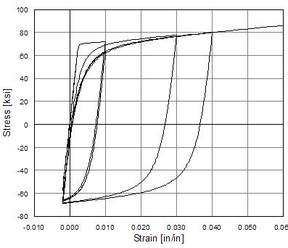

Uniaxial compression under cyclic loading shows important characteristics as shown in Figure 11.a; the developed stress follows the path of monotonic stress response, initial stiffness in each unloading and reloading stiffness faces a progressive deterioration with increasing the demand. The phenomena of stiffness degradation upon increasing the demand is referred as damage. Figure 11.b; shows a plot a data from [41] of normalized unloading stiffness as a function of normalized plastic compressive deformation. Plastic deformation is defined as the deformation that is not recovered upon unloading to zero compressive stress and this deformation is normalized with respect to the deformation at approximately zero compressive strength.

In uniaxial tension stress state, observed deformation process is different from that in compression. The low tensile strength of concrete is primarily due to the low tensile strength of the aggregate-mortar interface, which has a significantly lower strength than the mortar. This interface is known to be the weakest link in this composite material, with cracks usually occurring at the interface. Figure 12 shows typical concrete stress stain response under cyclic loading [42]. The response is essentially linear before reaching the maximum tensile strength capacity, corresponds to stable microcracks. After reaching the maximum strength, softening is observed due to the development of localized continuous crack system mainly perpendicular to the stress direction. Unloading and reloading after reaching the maximum capacity showed also degradation in the initial stiffness.

|

| Figure 12. Uniaxial concrete response under cyclic tension loading [42] |

2.2.2 Multiaxial behavior

Since plain concrete in RC elements is usually subjected to multi-dimensional stresses, developed constitutive models are not only based on the uniaxial behavior of concrete. A number of researchers have studied the biaxial and triaxial behavior of concrete experimentally and analytically.

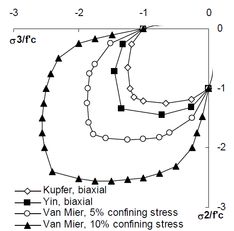

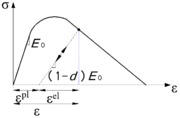

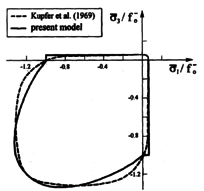

Investigations by [43] and [44] mainly focused on biaxial loading and developed experimentally a failure surface as shown in Figure 13. The 2D failure surfaces were extended by data from [45] by studying the effect of low levels of confinement pressure in the third direction. Results obtained by [45] showed that relatively small confinement pressure can significantly increase the concrete strength in the direction perpendicular to the confinement pressure up to 2.5 times the uniaxial compressive strength Figure 13.

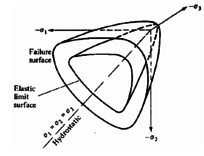

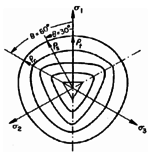

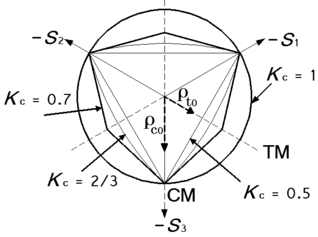

Tow envelopes must be considered to describe the behavior of concrete; elastic limit surface defining the elastic region and the failure surface characterizing the maximum-strength envelope as shown in Figure 14.a. It's been wildly accepted that concrete behavior can be considered as isotropic, therefore both surfaces can be described in terms of stress invariants; I1 the first invariant of the stress tensor, J2 and J3 the second and third invariants of deviatoric stress tensor respectively. Haigh-Westergaard space can be used to define the failure surface in principal stress space Figure 14.a.b, in which the position of a stress point is determined by three coordinates ρ , ξ and θ, where ρ is the octahedral radius, ξ is the distance from the origin of stress space to the stress plan, θ is the Lode similarity angle.

|

|

(9) |

|

|

(10) |

|

|

(11) |

|

|

(12) |

|

|

|

| a) In principal stress space [52] | b) In deviatoric plans [53] | c) In the meridian sections [53] |

| Figure 14. Concrete failure surfaces in different views | ||

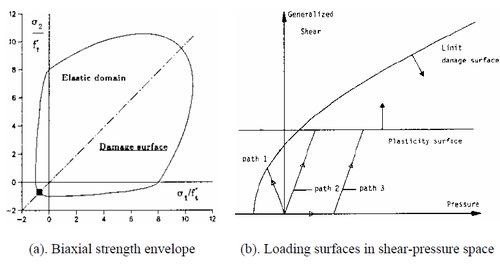

From experimental results in Figure 13, it can been seen that the failure surface has an open shape. The shapes of the failure surface in the deviatoric and meridians plans is shown respectively in Figure 14.b.c, it can be seen that the deviatoric plans are different in size and shape according to the level of the hydrostatic pressure. ρs, ρt and ρc correspond respectively to shear, tension and compression meridians and are determined according to Lode angle.

2.3 Concrete constitutive models

In principle, it is desired that the above-mentioned macroscopic features of the

material behavior be reflected in any constitutive models dedicated to concrete

modelling. However, it is quite difficult to incorporate all of these aspects of material

behavior in a constitutive model. Those experimentally observed features are all of

macroscopic nature, which can only be characterized through some material and

structural quantities and cannot always represent what truly happens at the microscopic

level. This is the disadvantage of the macroscopic approach to constitutive modelling. However, developing an analytical model for concrete has been the aim of many researchers in the last thirty years. Early models were based on elastic theory, more recent use plasticity, damage and fracture mechanics. Majority of the models capture particular aspects concrete response under different type of loading, however, most of the models have acceptable accuracy and efficiency.

2.3.1 Models based on plasticity

Plasticity in material can be defined as the accumulation of uncovered deformation upon loading beyond the yield limit. Experimental results showed that concrete exhibits plastic strain when it's subjected to compression and tension, therefore, constitutive model must incorporate plastic theory.

Developing a plasticity-based constitutive model requires defining; rule for decomposition of the total stain, elastic material constitutive relationship, yield/failure surfaces law and flow rule.

The total stain is usually assumed to be the sum of elastic and accumulated plastic strain

|

|

(13) |

Elastic constitutive relationship follows Hook's law

|

|

(14) |

is the elastic stiffness tensor, and are the stress and strain tensors.

For concrete, the available material data facilitated definition of the yield surface in stress space and it is most appropriate to consider a yield surface that evolves as a function of the load history. A hardening rule defines the evolution of the yield surface. The flow rules define the evolution of a set of internal variables that uniquely define the material state. In particular, a flow rule defines the orientation of plastic strain which may be associated, defined as normal to the yield surface, or non-associate. Proposed plastic models for concrete vary in the definition of the yield surface, the hardening rules and the flow rules.

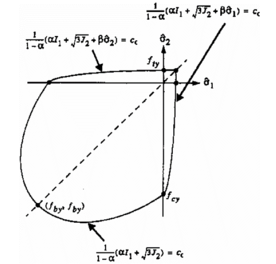

Regarding the distinction of the yield surface and the failure surface Figure 14.a, we can see that these two surfaces coincide in plasticity theory. In other words, a single loading surface acts as a yield-failure surface in plasticity theory. This combined surface is often a scaled down version of the failure envelope of the material. Numerous forms of yield surfaces have been proposed and can be classified based on either the number of model parameters [53] or on the shape of the surface in principal stress space.

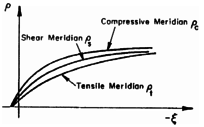

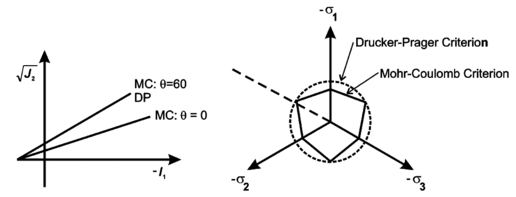

The first yield criteria to characterize the behavior of plain concrete were Mohr-Columb and Druker-Prager [42] shown in Figure 15, these criteria were developed to describe the response of material such as sand, rock and concrete for which hydrostatic pressure affects the material yield and failure strengths.

The Mohr-Coulomb criterion is defined as follows:

|

|

(15) | |

|

|

(16) |

In the previous, ϕ is the friction angle, and c is the material cohesion. Equations (15) and (16) represent a straight line of variable slope in the meridian plane and an irregular hexagon in the plane as shown in Figure 15.

|

| Figure 15. Mohr-Coulomb and Drucker-Prager Failure Criteria [42] |

The Drucker-Prager criterion represents moderately well the response of plain concrete

subjected to multi-axial compression and provides a smooth yield surface Figure 15. This criterion is defined as follows:

|

|

(17) |

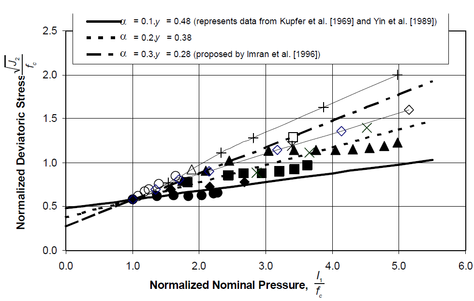

In the previous criterion, α and y are material constants. The values of theses constants significantly change the yield surface as shown in Figure 16.

|

| Figure 16. Drucker-Prager Failure Criterion Compared with Experimental Data as presented by [51] |

As indicated in Figure 16, Imran and Pantazopoulou 1996 [48] propose α =0.3 for characterizing the response of concrete subjected to triaxial compression. The response of concrete subjected to biaxial compressive loading Kupfer et al. 1969 [43] and Yin et al. 1989 [44] is characterized well by α =0.1. All of the presented yield criteria are calibrated to predict the observed uniaxial compressive strength.

Comparison of the Drucker-Prager criterion with experimental data shows that while

the criterion may be used to represent the response of concrete subjected to multi-axial

compression, the model over-estimates the capacity of concrete subjected to compression-tension or tension-tension type loading. Variation in concrete response under various load regimes has been addressed by a number of researcher through the use of multi-surface plasticity models. Murray et al. 1997 [54] model proposes a three surface model to characterize the response of plain concrete subjected to biaxial loading, this approach was extended to concrete loaded in three-dimensions by Chen and Chen 1975 [31] and Lubliner et al. 1989 [30].

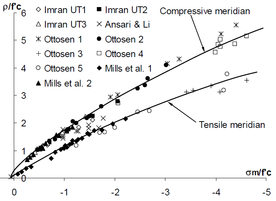

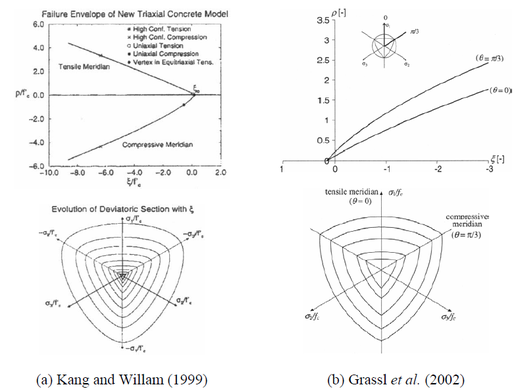

The main shortcoming of Mohr-Columb and Druker-Prager surfaces is that they assume a linear relationship between J2 and I1 (between ρ and ξ in the meridian plan), although this relationship has been experimentally shown to be nonlinear Figure 14.c. More recent failure criteria with nonlinear relation between J2 and I1 with incorporating Lode angel θ in the formulation have incorporated the [53], [55], [51], [56]. The typical deviatoric and meridian sections of those failure surfaces are shown in Figure 17

|

| Figure 17. Deviatoric and meridian sections of two typical failure surfaces |

In plasticity theory, the definition of a yield surface, the shape of which is usually similar to that of the failure surface (i.e. the yield surface by Grassl et al. 2002 [56]), is required. However, as pointed out by [53] yield surfaces as scaled down versions of failure surfaces at maximum loading are inadequate for concrete modelling. The open shape of such yield surfaces does not reflect the true behavior of concrete under hydrostatic loading. A solution for this is the use of an additional “cap surface” for the behavior of the model under hydrostatic compressive pressure.

The volumetric expansion of concrete under compression makes the application of the associated flow rule for concrete inappropriate. A non-associated flow rule, which is defined by the plastic potential other than the yield function should be used instead. This feature is included in the model developed by [53], [22], [55]. Deterioration in the initial stiffness beyond unloading and reloading has a significant impact on the response of RC structures. Such aspect should be captured by the analytical model that aims to represent the behavior under cyclic loading. Conventional plasticity models are not able to represent this degradation as plastic theory was invented for metallic materials.

2.3.2 Models based on damage mechanic

The damage "stiffness degradation" of a continuous solid is an alteration of the elastic properties during load application due to a decrease of the effective strength area. This effective area loss is normally caused by the increase of voids and/or micro fractures [57]. The continuous damage theory was first introduced by Kachanov in 1958 [58], further contribution was given by Rabotnov in 1963 [59] by introducing the concept of effective stresses. However, the basic development of continuum damage mechanics only began in the 1970s and then in the 1980s with a more rigorous basis, based on thermodynamics and micromechanics. Since then there have been numerous continuum damage mechanics models proposed for the constitutive modelling of materials in general and concrete in particular.

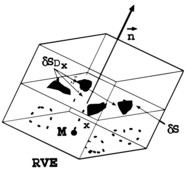

The quantities of continuum mechanics are defined at a mathematical point. However, from the physical point of view, and accounting for the heterogeneity of the material in reality, these quantities should be considered in two scale [60] to have been averaged over a certain volume called a “Representative Volume Element” whose size depends on each material [61]. To define the material damage at a mathematical point M in Figure 18, let us consider a Representative Volume Element (RVE) oriented by a plane defined by its normal and its abscissa x along the direction .

|

| Figure 18. Definition of damage variable [61] |

The damage value D(M, , x) at point M in the direction and at abscissa x is defined as:

|

|

(18) |

δS is the area of the intersection considered plan and the RVE, and is the effective area of intersections of all microcracks and microcavities in δS as illustrated in Figure 18. The anisotropic aspect of damage can be understood by assuming that the failure of the RVE depends on the direction on . If microcracks and microcavities are uniformly distributed in the RVE, it's adequate to assume isotropic damage and damage variable D(M, , x) doesn't depend on the direction, thus and scalar damage will control the deterioration.

To understand better the damage concept, let's consider the case of uniaxial tension force F with scalar damage variable. After reaching the maximum tensile strength and after occur of damage, the cross sectional area is reduced and becomes the effective cross sectional area S – SD. Where S is the original cross sectional area and SD is the total area of microcracks. The stress is no longer σ = F/ S but replaced by the effective stress σ0 = F / (S − SD) = σ (1− D) ≥ σ. This concept can be extended to multiaxial stress state.

Physically, the degradation process of the virgin materials is due to the presence and growth of small fractures and micro voids. This growth process can be simulated within the context of the mechanics of continuous media, taking into consideration the theory of internal state variables, introducing an internal variable of damage represented by a scalar, vector or tensor. This internal variable of damage characterizes the level of damage in the material and transforms the stress real tensor into the so called "effective stress tensor" as follow:

|

|

(19) |

Mis a fourth-order tensor for anisotropic damage model. It's well approved that damage in concrete can be accepted to be isotropic. However, damage models using scalar damage variables are still preferred because of their simplicity in the formulation.

For isotropic damage mode, the material degradation is alike in all direction and the tensor M is reduced to M = (1-d) I, where I is an identity tensor. The equation (19) can be written for scalar-damage model:

|

|

(20) |

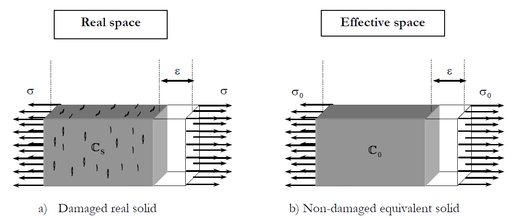

where d is an internal scalar variable range between 0 for no damage state and 1 for full distortion, σ0 is effective stress tensor measured in the non-damaged space. The effective stress concept was formulated for the first time in connection with the equivalent deformation hypothesis by [62] as follow " The deformation associated to a damaged state subjected to a stress σ is equivalent to the deformation associated to the non-damage state subjected to an effective stress σ0). A graphical representation of the effective and real space is illustrated in Figure 19.

|

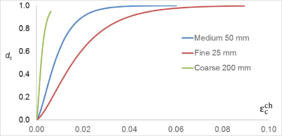

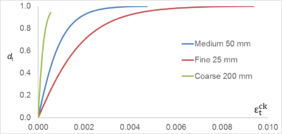

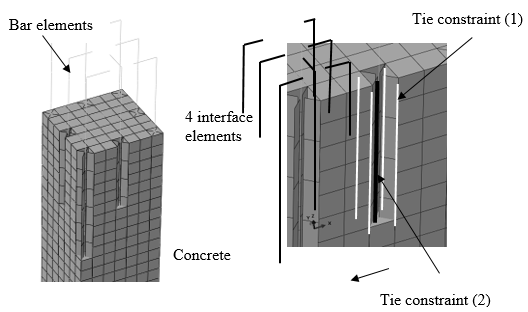

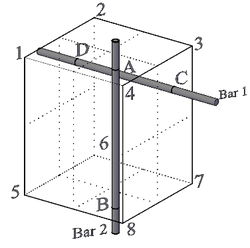

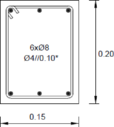

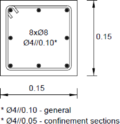

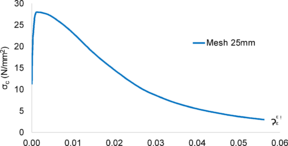

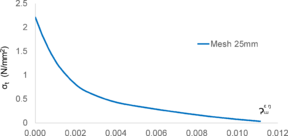

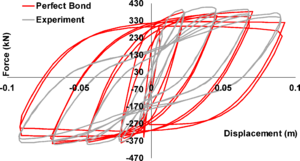

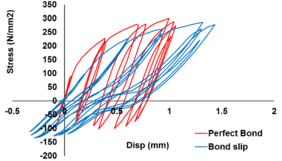

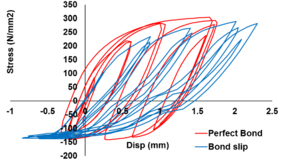

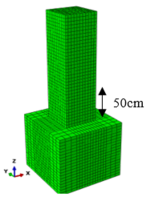

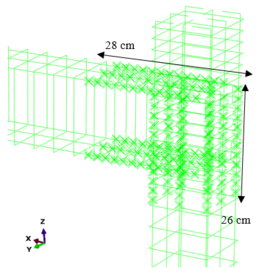

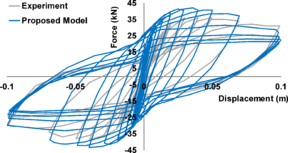

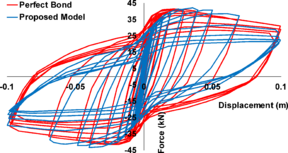

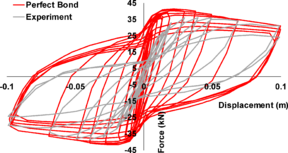

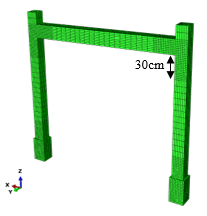

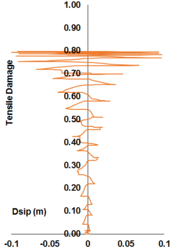

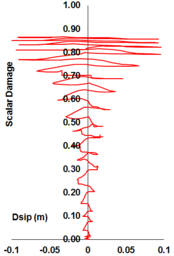

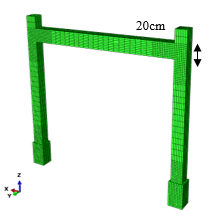

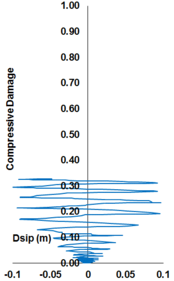

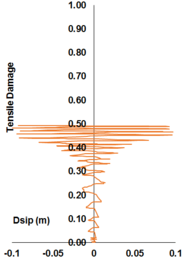

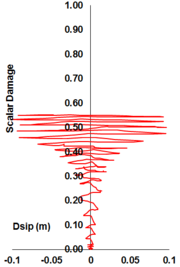

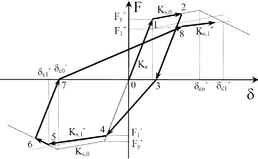

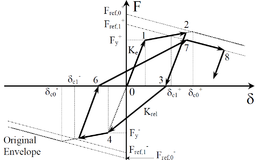

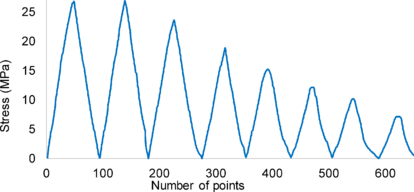

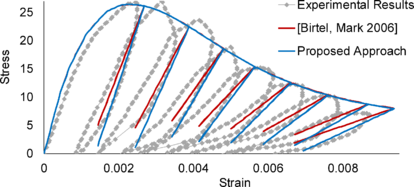

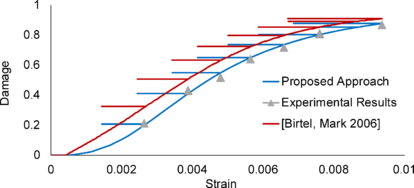

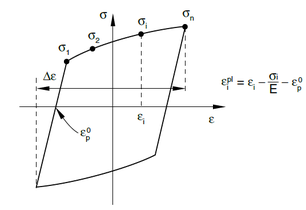

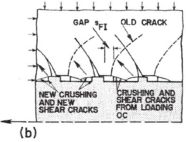

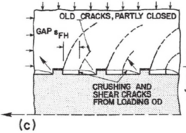

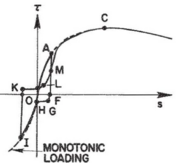

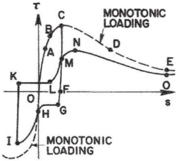

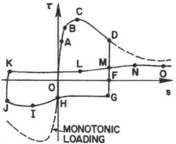

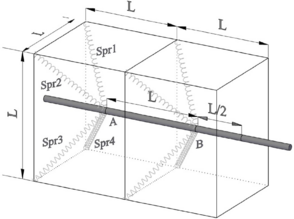

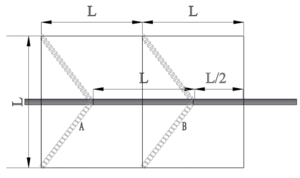

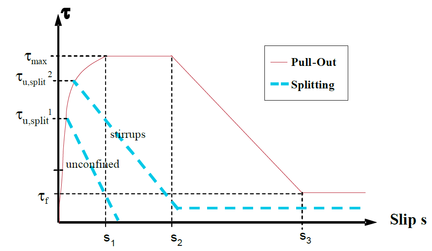

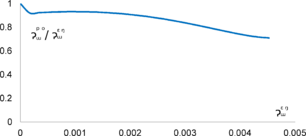

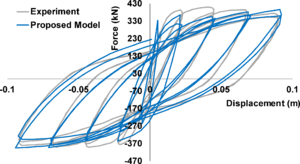

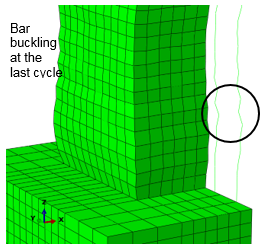

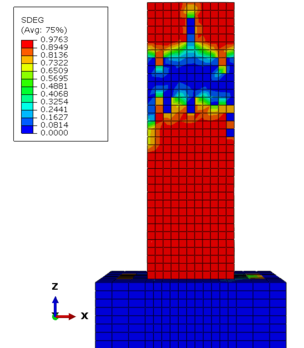

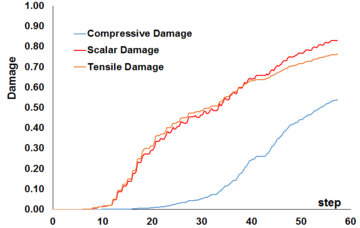

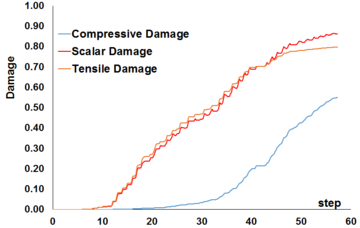

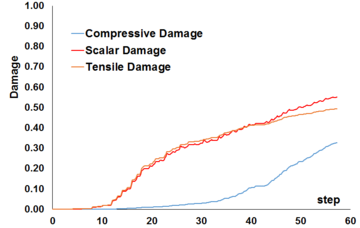

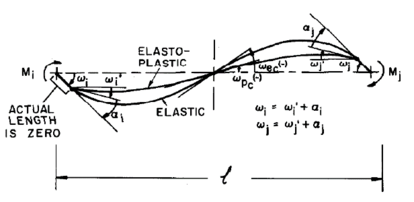

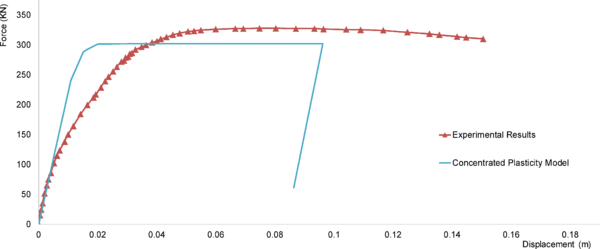

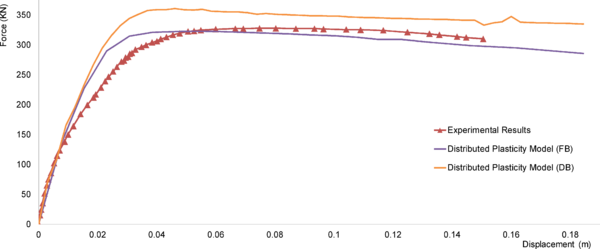

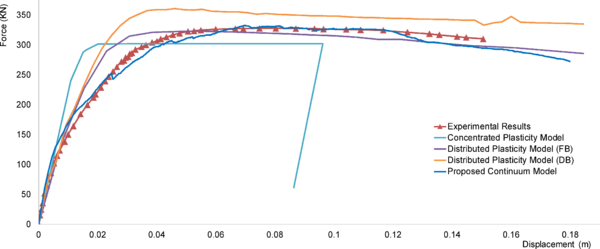

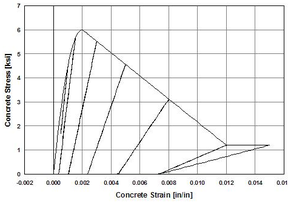

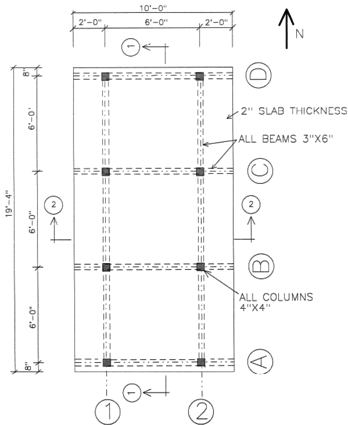

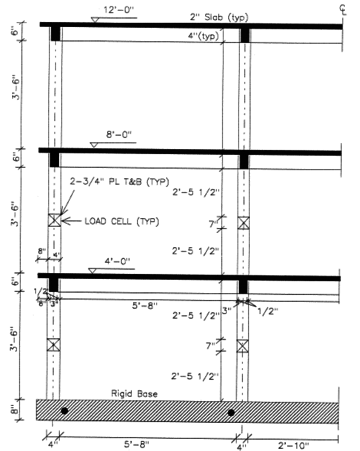

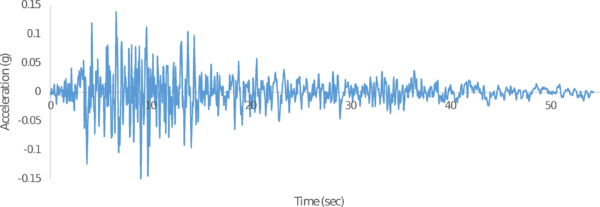

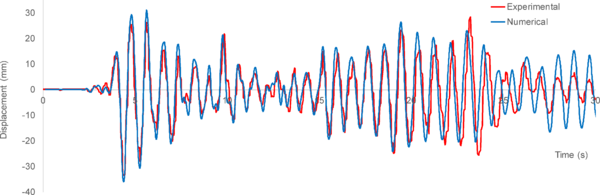

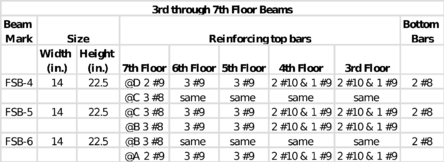

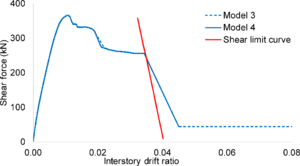

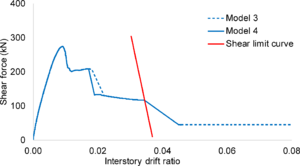

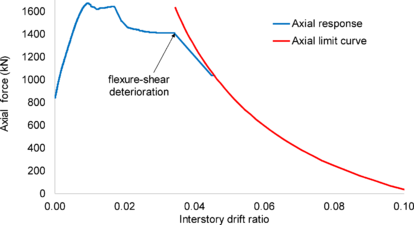

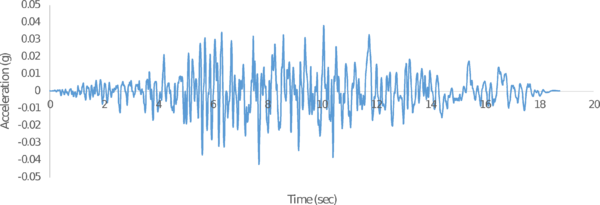

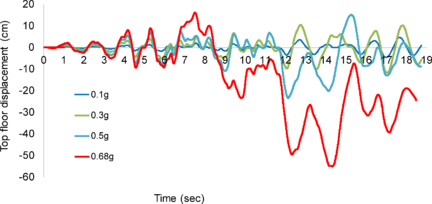

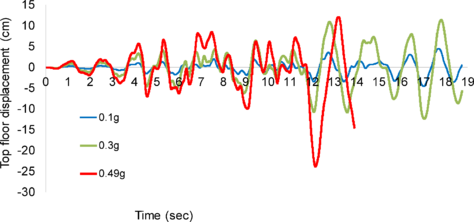

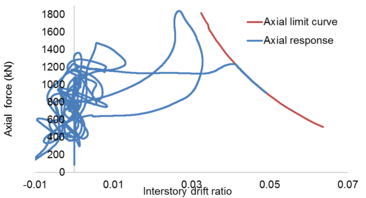

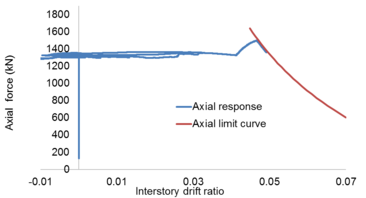

| Figure 19. Graphic representation of the effective stress hypothesis presented by [57] |