| Line 1: | Line 1: | ||

| + | <!-- metadata commented in wiki content | ||

==Possibilities of the particle finite element method in computational mechanics== | ==Possibilities of the particle finite element method in computational mechanics== | ||

| − | ''' | + | '''Eugenio Oñate, Sergio R. Idelsohn<math>^*</math>, Miguel Angel Celigueta, |

| − | + | Riccardo Rossi and Salvador Latorre''' | |

| − | + | ||

| − | < | + | {| |

| + | |- | ||

| + | |International Center for Numerical Methods in Engineering (CIMNE) | ||

| + | |- | ||

| + | | Technical University of Catalonia | ||

| + | |- | ||

| + | | Campus Norte UPC, 08034 Barcelona, Spain | ||

| + | |- | ||

| + | | [mailto:onate@cimne.upc.edu onate@cimne.upc.edu] | ||

| + | |- | ||

| + | | [http://www.cimne.com www.cimne.com] | ||

| + | |- | ||

| + | | <math>^*</math> ICREA Research Professor at CIMNE | ||

| + | |} | ||

| + | --> | ||

==Abstract== | ==Abstract== | ||

We present some developments in the formulation of the Particle Finite Element Method (PFEM) for analysis of complex coupled problems in fluid and solid mechanics accounting for fluid-structure interaction and coupled thermal effects. The PFEM uses an updated Lagrangian description to model the motion of nodes (particles) in both the fluid and the structure domains. Nodes are viewed as material points which can freely move and even separate from the main analysis domain representing, for instance, the effect of water drops. A mesh connects the nodes defining the discretized domain where the governing equations are solved as in the standard FEM. The necessary stabilization for dealing with the incompressibility of the fluid is introduced via the finite calculus (FIC) method. An incremental iterative scheme for the solution of the non linear transient coupled fluid-structure problem is described. Extensions of the PFEM to allow for frictional contact conditions at fluid-solid and solid-solid interfaces via mesh generation are described. A simple algorithm to treat erosion in the fluid bed is presented. Examples of application of the PFEM to solve a number of coupled problems such as the effect of large wave on structures, the large motions of floating and submerged bodies, bed erosion situations and melting and dripping of polymers under the effect of fire are given. | We present some developments in the formulation of the Particle Finite Element Method (PFEM) for analysis of complex coupled problems in fluid and solid mechanics accounting for fluid-structure interaction and coupled thermal effects. The PFEM uses an updated Lagrangian description to model the motion of nodes (particles) in both the fluid and the structure domains. Nodes are viewed as material points which can freely move and even separate from the main analysis domain representing, for instance, the effect of water drops. A mesh connects the nodes defining the discretized domain where the governing equations are solved as in the standard FEM. The necessary stabilization for dealing with the incompressibility of the fluid is introduced via the finite calculus (FIC) method. An incremental iterative scheme for the solution of the non linear transient coupled fluid-structure problem is described. Extensions of the PFEM to allow for frictional contact conditions at fluid-solid and solid-solid interfaces via mesh generation are described. A simple algorithm to treat erosion in the fluid bed is presented. Examples of application of the PFEM to solve a number of coupled problems such as the effect of large wave on structures, the large motions of floating and submerged bodies, bed erosion situations and melting and dripping of polymers under the effect of fire are given. | ||

| + | |||

| + | '''keywords''' | ||

==1 Introduction== | ==1 Introduction== | ||

| Line 37: | Line 54: | ||

The quality of the numerical solution depends on the discretization chosen as in the standard FEM. Adaptive mesh refinement techniques can be used to improve the solution in zones where large motions of the fluid or the structure occur. | The quality of the numerical solution depends on the discretization chosen as in the standard FEM. Adaptive mesh refinement techniques can be used to improve the solution in zones where large motions of the fluid or the structure occur. | ||

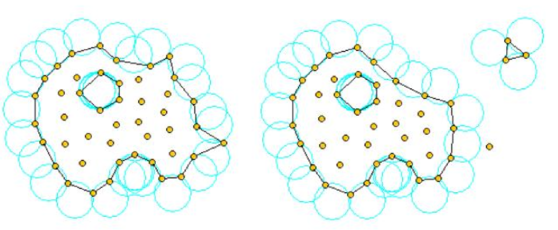

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | <div id='img-1'></div> |

| + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_283227388-Figure1.png| | + | |[[Image:draft_Samper_283227388-Figure1.png|600px|Updated lagrangian description for a continuum containing a fluid and a solid domain]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

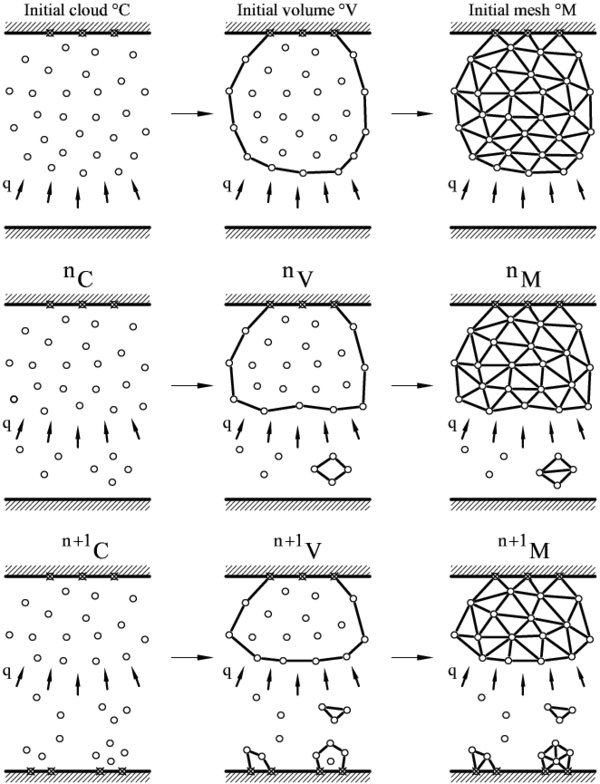

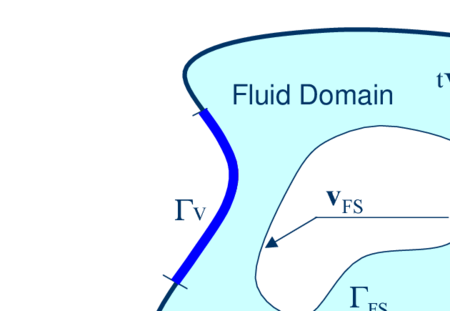

| − | | colspan="1" | '''Figure 1''' | + | | colspan="1" | '''Figure 1:''' Updated lagrangian description for a continuum containing a fluid and a solid domain |

|} | |} | ||

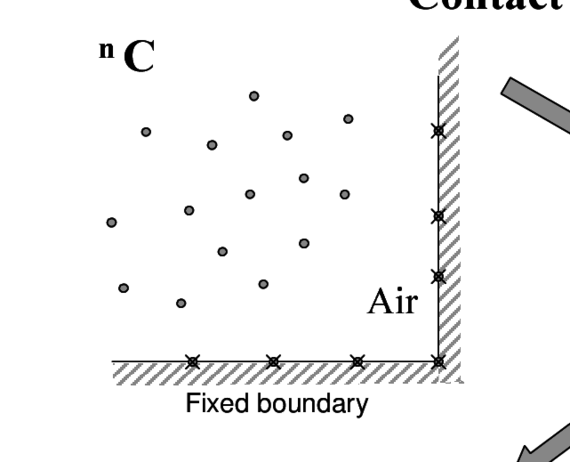

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | <div id='img-2'></div> |

| + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

|[[Image:draft_Samper_283227388-Figure2.png|600px|Sequence of steps to update a “cloud” of nodes representing a domain containing a fluid and a solid part from time n (t=tₙ) to time n+2 (t=tₙ+2∆t) ]] | |[[Image:draft_Samper_283227388-Figure2.png|600px|Sequence of steps to update a “cloud” of nodes representing a domain containing a fluid and a solid part from time n (t=tₙ) to time n+2 (t=tₙ+2∆t) ]] | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

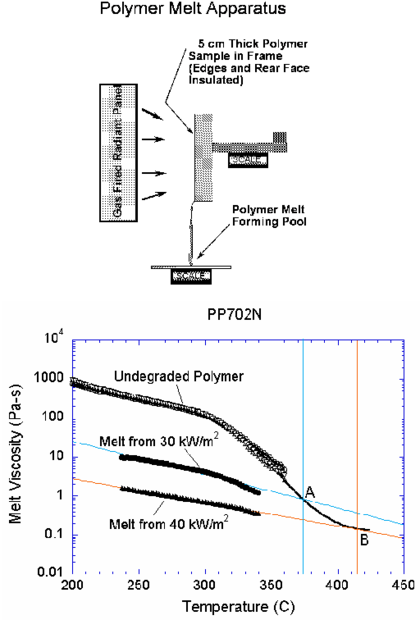

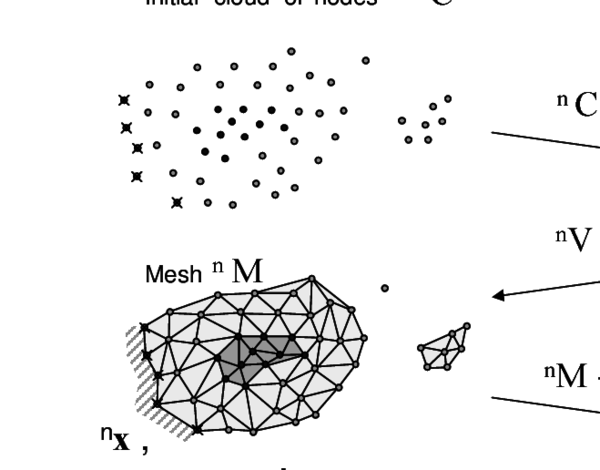

| − | | colspan="1" | '''Figure 2''' | + | | colspan="1" | '''Figure 2:''' Sequence of steps to update a “cloud” of nodes representing a domain containing a fluid and a solid part from time <math>n</math> (<math>t=t_n</math>) to time <math>n+2</math> (<math>t=t_n +2\Delta t</math>) |

|} | |} | ||

| Line 76: | Line 95: | ||

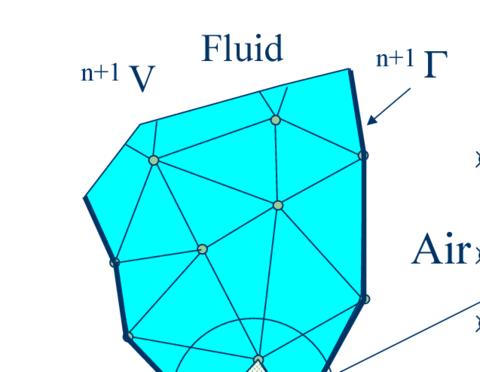

<div id='img-3'></div> | <div id='img-3'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

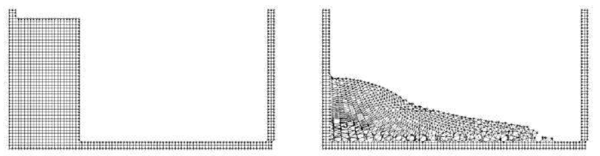

|[[Image:draft_Samper_283227388-Cloud_nodes.png|600px|Sequence of steps to update in time a “cloud” of nodes representing a polymer object under thermal loads represented by a prescribed boundary heat flux q using the PFEM. Crossed circles denote prescribed nodes at the boundary ]] | |[[Image:draft_Samper_283227388-Cloud_nodes.png|600px|Sequence of steps to update in time a “cloud” of nodes representing a polymer object under thermal loads represented by a prescribed boundary heat flux q using the PFEM. Crossed circles denote prescribed nodes at the boundary ]] | ||

| Line 84: | Line 103: | ||

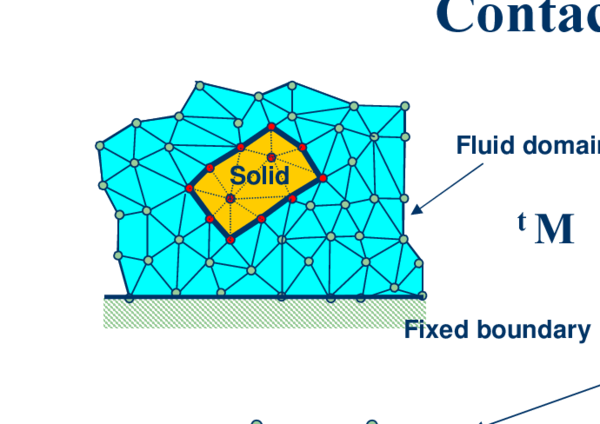

<div id='img-4'></div> | <div id='img-4'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-Figure2a_b.png|600px|]] | |[[Image:draft_Samper_283227388-Figure2a_b.png|600px|]] | ||

| − | + | |[[Image:draft_Samper_283227388-Fig2c.png|420px|Breakage of a water column. (a) Discretization of the fluid domain and the solid walls. Boundary nodes are marked with circles. (b) and (c) Mesh in the fluid domain at two different times]] | |

| − | |[[Image:draft_Samper_283227388-Fig2c.png| | + | |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| − | | colspan=" | + | | colspan="2" | '''Figure 4:''' Breakage of a water column. (a) Discretization of the fluid domain and the solid walls. Boundary nodes are marked with circles. (b) and (c) Mesh in the fluid domain at two different times |

|} | |} | ||

| Line 107: | Line 125: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>\rho {\partial v_i \over \partial t}={\partial \sigma _{ij} \over \partial x_j}+b_i\qquad \hbox{in } \Omega </math> | | style="text-align: center;" | <math>\rho {\partial v_i \over \partial t}={\partial \sigma _{ij} \over \partial x_j}+b_i\qquad \hbox{in } \Omega </math> | ||

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | (1) | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (1) |

|} | |} | ||

| Line 120: | Line 138: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>{\partial v_i \over \partial x_i}=0 \qquad \hbox{in } \Omega </math> | | style="text-align: center;" | <math>{\partial v_i \over \partial x_i}=0 \qquad \hbox{in } \Omega </math> | ||

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | (2) | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2) |

|} | |} | ||

| Line 133: | Line 151: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>\rho c {\partial T \over \partial t}= {\partial \over \partial x_i} \left(k_i {\partial T \over \partial x_i}\right)+Q \qquad \hbox{in } \Omega </math> | | style="text-align: center;" | <math>\rho c {\partial T \over \partial t}= {\partial \over \partial x_i} \left(k_i {\partial T \over \partial x_i}\right)+Q \qquad \hbox{in } \Omega </math> | ||

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | (3) | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (3) |

|} | |} | ||

In above equations <math display="inline">v_{i}</math> is the velocity along the ''i''th global (cartesian) axis, <math display="inline">T</math> is the temperature, <math display="inline">\rho </math>, <math display="inline">c</math> and <math display="inline">k_i</math> are the density (assumed constant), the specific heat and the conductivity of the material along the ith coordinate direction, respectively, <math display="inline">b_i</math> and <math display="inline">Q</math> are the body forces and the heat source per unit mass, respectively and <math display="inline">\sigma _{ij}</math> are the (Cauchy) stresses related to the velocities by the standard constitutive equation (for incompressible Newtonian material) | In above equations <math display="inline">v_{i}</math> is the velocity along the ''i''th global (cartesian) axis, <math display="inline">T</math> is the temperature, <math display="inline">\rho </math>, <math display="inline">c</math> and <math display="inline">k_i</math> are the density (assumed constant), the specific heat and the conductivity of the material along the ith coordinate direction, respectively, <math display="inline">b_i</math> and <math display="inline">Q</math> are the body forces and the heat source per unit mass, respectively and <math display="inline">\sigma _{ij}</math> are the (Cauchy) stresses related to the velocities by the standard constitutive equation (for incompressible Newtonian material) | ||

| − | <span id="eq-4"></span> | + | <span id="eq-4.a"></span> |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>\sigma _{ij} =s _{ij} - p \delta _{ij} </math> | | style="text-align: center;" | <math>\sigma _{ij} =s _{ij} - p \delta _{ij} </math> | ||

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | (4) | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.a) |

|} | |} | ||

| − | <span id="eq- | + | <span id="eq-4.b"></span> |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>s _{ij}=2\mu \left(\dot \varepsilon _{ij}-\frac{1}{3}\delta _{ij}\dot \varepsilon _{ii} \right)\quad ,\quad \dot \varepsilon _{ij}=\frac{1}{2} \left({\partial v_i \over \partial x_j}+ {\partial v_j \over \partial x_i}\right) </math> | | style="text-align: center;" | <math>s _{ij}=2\mu \left(\dot \varepsilon _{ij}-\frac{1}{3}\delta _{ij}\dot \varepsilon _{ii} \right)\quad ,\quad \dot \varepsilon _{ij}=\frac{1}{2} \left({\partial v_i \over \partial x_j}+ {\partial v_j \over \partial x_i}\right) </math> | ||

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | ( | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.b) |

|} | |} | ||

| Line 170: | Line 188: | ||

Eqs.([[#eq-1|1]])–([[#3.1 Governing equations|3.1]]) are completed with the standard boundary conditions of prescribed velocities and surface tractions in the mechanical problem and prescribed temperature and prescribed normal heat flux in the thermal problem <span id='citeF-2'></span><span id='citeF-7'></span>[[#cite-2|[2,7]]]. | Eqs.([[#eq-1|1]])–([[#3.1 Governing equations|3.1]]) are completed with the standard boundary conditions of prescribed velocities and surface tractions in the mechanical problem and prescribed temperature and prescribed normal heat flux in the thermal problem <span id='citeF-2'></span><span id='citeF-7'></span>[[#cite-2|[2,7]]]. | ||

| − | We note that Eqs.([[#eq-1|1]])–([[#eq-3|3]]) are the standard ones for modeling the deformation of viscoplastic materials using the so called “flow approach” <span id='citeF-38'></span><span id='citeF-39'></span>[[#cite-38|[38,39]]]. In our work the dependence of the viscosity with the strain typical of viscoplastic flows has been simplified to the Newtonian form of Eq.([[#eq- | + | We note that Eqs.([[#eq-1|1]])–([[#eq-3|3]]) are the standard ones for modeling the deformation of viscoplastic materials using the so called “flow approach” <span id='citeF-38'></span><span id='citeF-39'></span>[[#cite-38|[38,39]]]. In our work the dependence of the viscosity with the strain typical of viscoplastic flows has been simplified to the Newtonian form of Eq.([[#eq-4.b|4.b]]). |

===3.2 Discretization of the equations=== | ===3.2 Discretization of the equations=== | ||

| Line 176: | Line 194: | ||

A key problem in the numerical solution of Eqs.([[#eq-1|1]])–([[#3.1 Governing equations|3.1]]) is the satisfaction of the incompressibility condition (Eq.([[#eq-2|2]])). A number of procedures to solve his problem exist in the finite element literature <span id='citeF-7'></span><span id='citeF-37'></span>[[#cite-7|[7,37]]]. In our approach we use a stabilized formulation based in the so-called finite calculus procedure <span id='citeF-19'></span>[[#cite-19|[19]]]–<span id='citeF-21'></span>[[#cite-21|[21]]],<span id='citeF-28'></span><span id='citeF-30'></span><span id='citeF-32'></span>[[#cite-28|[28,30,32]]]. The essence of this method is the solution of a ''modified mass balance'' equation which is written as | A key problem in the numerical solution of Eqs.([[#eq-1|1]])–([[#3.1 Governing equations|3.1]]) is the satisfaction of the incompressibility condition (Eq.([[#eq-2|2]])). A number of procedures to solve his problem exist in the finite element literature <span id='citeF-7'></span><span id='citeF-37'></span>[[#cite-7|[7,37]]]. In our approach we use a stabilized formulation based in the so-called finite calculus procedure <span id='citeF-19'></span>[[#cite-19|[19]]]–<span id='citeF-21'></span>[[#cite-21|[21]]],<span id='citeF-28'></span><span id='citeF-30'></span><span id='citeF-32'></span>[[#cite-28|[28,30,32]]]. The essence of this method is the solution of a ''modified mass balance'' equation which is written as | ||

| − | <span id="eq- | + | <span id="eq-5"></span> |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>{\partial v_i \over \partial x_i}+\sum \limits _{i=1}^{3}\tau {\partial \over \partial x_i}\left[{\partial p \over \partial x_i} +\pi _i\right]=0 </math> | | style="text-align: center;" | <math>{\partial v_i \over \partial x_i}+\sum \limits _{i=1}^{3}\tau {\partial \over \partial x_i}\left[{\partial p \over \partial x_i} +\pi _i\right]=0 </math> | ||

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | ( | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (5) |

|} | |} | ||

where <math display="inline">\tau </math> is a stabilization parameter given by [10] | where <math display="inline">\tau </math> is a stabilization parameter given by [10] | ||

| − | <span id="eq- | + | <span id="eq-6"></span> |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| − | | style="text-align: center;" | <math>\tau = \left(\frac{2\rho \vert \ | + | | style="text-align: center;" | <math>\tau = \left(\frac{2\rho \vert \mathbf{v}\vert }{h}+\frac{8\mu }{3h^2} \right)^{-1} </math> |

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | ( | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (6) |

|} | |} | ||

| − | In the above, <math display="inline">h</math> is a characteristic length of each finite element (such as <math display="inline">[A^{(e)}]^{1/2}</math> for 2D elements) and <math display="inline">\vert \ | + | In the above, <math display="inline">h</math> is a characteristic length of each finite element (such as <math display="inline">[A^{(e)}]^{1/2}</math> for 2D elements) and <math display="inline">\vert \mathbf{v}\vert </math> is the modulus of the velocity vector. In Eq.([[#eq-5|5]]) <math display="inline">\pi _i</math> are auxiliary pressure projection variables chosen so as to ensure that the second term in Eq.([[#eq-5|5]]) can be interpreted as weighted sum of the residuals of the momentum equations and therefore it vanishes for the exact solution. The set of governing equations for the velocities, the pressure and the <math display="inline">\pi _i</math> variables is completed by adding the following constraint equation to the set of governing equations <span id='citeF-28'></span><span id='citeF-32'></span>[[#cite-28|[28,32]]] |

| − | <span id="eq- | + | <span id="eq-7"></span> |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>\int _V \tau w_i\left({\partial p \over \partial x_i} +\pi _i\right)dV=0 \quad i=1,n_d </math> | | style="text-align: center;" | <math>\int _V \tau w_i\left({\partial p \over \partial x_i} +\pi _i\right)dV=0 \quad i=1,n_d </math> | ||

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | ( | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (7) |

|} | |} | ||

| Line 221: | Line 239: | ||

==Momentum== | ==Momentum== | ||

| − | <span id="eq- | + | <span id="eq-8"></span> |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| − | | style="text-align: center;" | <math>\ | + | | style="text-align: center;" | <math>\mathbf{M} \dot{\bar{v}} + \mathbf{K} (\mu )\bar {v} - \mathbf{G} \bar {p}= {f} </math> |

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | ( | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (8) |

|} | |} | ||

==Mass balance== | ==Mass balance== | ||

| − | <span id="eq- | + | <span id="eq-9"></span> |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| − | | style="text-align: center;" | <math>\ | + | | style="text-align: center;" | <math>\mathbf{G}\bar{v}+ \mathbf{L}\bar {p}+ \mathbf{Q} \bar {\boldsymbol \pi }=\mathbf{0} </math> |

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | ( | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (9) |

|} | |} | ||

==Pressure gradient projection== | ==Pressure gradient projection== | ||

| − | <span id="eq- | + | <span id="eq-10"></span> |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| − | | style="text-align: center;" | <math>\hat {M} \bar {\boldsymbol \pi }+\ | + | | style="text-align: center;" | <math>\hat {M} \bar {\boldsymbol \pi }+\mathbf{Q}^T\bar {p}=\mathbf{0} </math> |

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | ( | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (10) |

|} | |} | ||

==Heat transport== | ==Heat transport== | ||

| − | <span id="eq- | + | <span id="eq-11"></span> |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| − | | style="text-align: center;" | <math>\ | + | | style="text-align: center;" | <math>\mathbf{C}\dot{\bar{T}} + \mathbf{H} \bar {T} = {q} </math> |

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | ( | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (11) |

|} | |} | ||

| − | In Eqs.([[#eq- | + | In Eqs.([[#eq-8|8]])–([[#eq-11|11]]) <math display="inline">\bar{(\cdot )}</math> denotes nodal variables, <math display="inline">\dot{\bar{(\cdot )}}= {\partial \over \partial t}\bar{(\cdot )}</math>. The different matrices and vectors are given in the Appendix. |

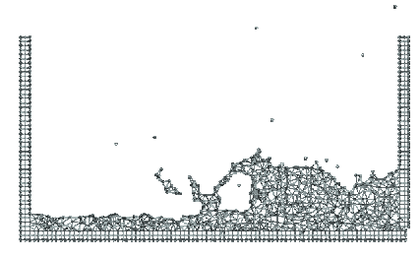

| − | The solution in time of Eqs.([[#eq- | + | The solution in time of Eqs.([[#eq-8|8]])–([[#eq-11|11]]) can be performed using any time integration schemes typical of the updated Lagrangian finite element method. A basic algorithm following the conceptual process described in Section 2.1 is presented in Box I. <math display="inline">^{n+1}(\bar{a})^{j+1}</math> denotes the values of the nodal variables <math display="inline">\bar{a}</math> at time <math display="inline">n+1</math> and the <math display="inline">j+1</math> iterations. We note the coupling of the flow and thermal equations via the dependence of the viscosity <math display="inline">\mu </math> with the temperature. |

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-Box_I.png|480px|]] | |[[Image:draft_Samper_283227388-Box_I.png|480px|]] | ||

| Line 285: | Line 303: | ||

<div id='img-5'></div> | <div id='img-5'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

| − | |[[Image:draft_Samper_283227388-Figure3a.png| | + | |[[Image:draft_Samper_283227388-Figure3a.png|450px|]] |

| − | |[[Image:draft_Samper_283227388-Figure3b.png| | + | |[[Image:draft_Samper_283227388-Figure3b.png|450px|Split of the analysis domain V into fluid and solid subdomains. Equality of surface tractions and kinematic variables at the common interface]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="2" | '''Figure 5:''' Split of the analysis domain <math>V</math> into fluid and solid subdomains. Equality of surface tractions and kinematic variables at the common interface | | colspan="2" | '''Figure 5:''' Split of the analysis domain <math>V</math> into fluid and solid subdomains. Equality of surface tractions and kinematic variables at the common interface | ||

| Line 298: | Line 316: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| − | | style="text-align: | + | | style="text-align: center;" | <math>{}^t S := [{}^t {x}_s,{}^t {u}_s, {}^t {v}_s, {}^t {a}_s, {}^t {\boldsymbol \varepsilon }_s, {}^t {\boldsymbol \sigma }_s,{}^t {T}_s ]^T</math> |

| − | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (12) | |

| − | + | ||

| − | | style="width: 5px;text-align: right;" | ( | + | |

|- | |- | ||

| − | | style="text-align: | + | | style="text-align: center;" | <math> {}^t F := [{}^t {x}_F,{}^t {u}_F, {}^t {v}_F, {}^t {a}_F, {}^t \dot{\boldsymbol \varepsilon }_F, {}^t {\boldsymbol \sigma }_F,{}^t {T}_F]^T </math> |

| − | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (13) | |

| − | + | ||

| − | | style="width: 5px;text-align: right;" | ( | + | |

|} | |} | ||

|} | |} | ||

| Line 328: | Line 342: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>{M}_s \bar {a}_s +{g}_s - {f}_s = {0} </math> | | style="text-align: center;" | <math>{M}_s \bar {a}_s +{g}_s - {f}_s = {0} </math> | ||

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | ( | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (14) |

|} | |} | ||

| Line 343: | Line 357: | ||

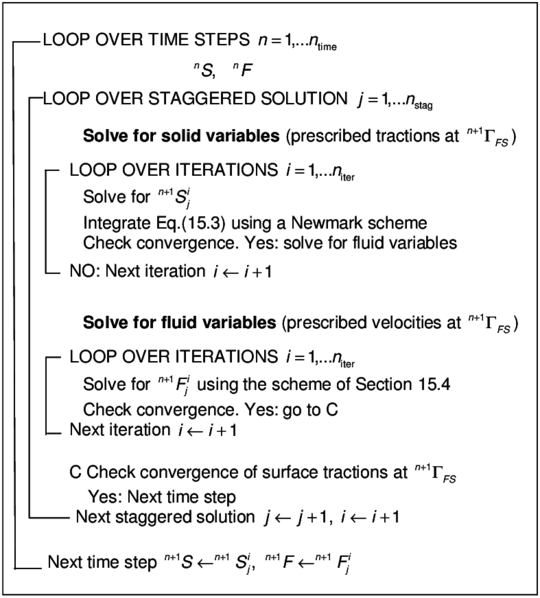

The above FSI solution algorithm is shown schematically in Box II. | The above FSI solution algorithm is shown schematically in Box II. | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-Box_II.png|540px|]] | |[[Image:draft_Samper_283227388-Box_II.png|540px|]] | ||

| Line 353: | Line 367: | ||

<div id='img-6'></div> | <div id='img-6'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-polygon.png|330px|Generation of non standard meshes combining different polygons (in 2D) and polyhedra (in 3D) using the extended Delaunay technique.]] | |[[Image:draft_Samper_283227388-polygon.png|330px|Generation of non standard meshes combining different polygons (in 2D) and polyhedra (in 3D) using the extended Delaunay technique.]] | ||

| Line 363: | Line 377: | ||

<div id='img-7'></div> | <div id='img-7'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-etiquetas.png|540px|3D flow problem solved with the PFEM. CPU time for meshing, assembling and solving the system of equations at each time step in terms of the number of nodes]] | |[[Image:draft_Samper_283227388-etiquetas.png|540px|3D flow problem solved with the PFEM. CPU time for meshing, assembling and solving the system of equations at each time step in terms of the number of nodes]] | ||

| Line 377: | Line 391: | ||

<div id='img-8'></div> | <div id='img-8'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-Identification.png|558px|Identification of individual particles (or a group of particles) starting from a given collection of nodes.]] | |[[Image:draft_Samper_283227388-Identification.png|558px|Identification of individual particles (or a group of particles) starting from a given collection of nodes.]] | ||

| Line 401: | Line 415: | ||

<div id='img-9'></div> | <div id='img-9'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

| − | |[[Image:draft_Samper_283227388-Figure6_1.png| | + | |[[Image:draft_Samper_283227388-Figure6_1.png|570px|]] |

| − | |[[Image:draft_Samper_283227388-Figure8.png| | + | |[[Image:draft_Samper_283227388-Figure8.png|480px|Automatic treatment of contact conditions at the fluid-wall interface]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="2" | '''Figure 9:''' Automatic treatment of contact conditions at the fluid-wall interface | | colspan="2" | '''Figure 9:''' Automatic treatment of contact conditions at the fluid-wall interface | ||

| Line 418: | Line 432: | ||

<div id='img-10'></div> | <div id='img-10'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-Contact_conditions.png|600px|Contact conditions at a solid-solid interface]] | |[[Image:draft_Samper_283227388-Contact_conditions.png|600px|Contact conditions at a solid-solid interface]] | ||

| Line 426: | Line 440: | ||

<div id='img-11'></div> | <div id='img-11'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

| − | |[[Image:draft_Samper_283227388-bola.png| | + | |[[Image:draft_Samper_283227388-bola.png|410px|Bumping of a ball within a container. The layer of contact elements is shown at each contact instant]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 11:''' Bumping of a ball within a container. The layer of contact elements is shown at each contact instant | | colspan="1" | '''Figure 11:''' Bumping of a ball within a container. The layer of contact elements is shown at each contact instant | ||

| Line 434: | Line 448: | ||

<div id='img-12'></div> | <div id='img-12'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

| − | |[[Image:draft_Samper_283227388-arch.png| | + | |[[Image:draft_Samper_283227388-arch.png|351px|Failure of an arch formed by stone blocks under seismic loading]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 12:''' Failure of an arch formed by stone blocks under seismic loading | | colspan="1" | '''Figure 12:''' Failure of an arch formed by stone blocks under seismic loading | ||

| Line 442: | Line 456: | ||

<div id='img-13'></div> | <div id='img-13'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

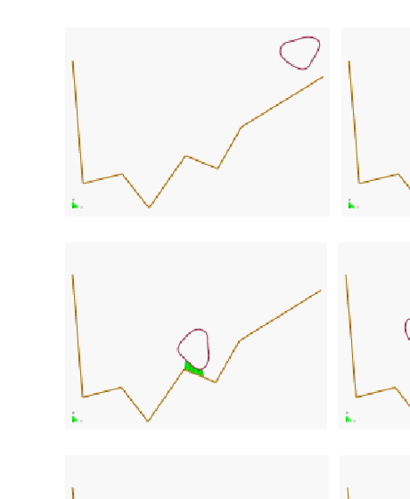

| − | |[[Image:draft_Samper_283227388-tetrapods-six.png| | + | |[[Image:draft_Samper_283227388-tetrapods-six.png|336px|Motion of five tetrapods on an inclined plane]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 13:''' Motion of five tetrapods on an inclined plane | | colspan="1" | '''Figure 13:''' Motion of five tetrapods on an inclined plane | ||

| Line 464: | Line 478: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| − | | style="text-align: center;" | <math>\tau _t =\mu \gamma _t</math> | + | | style="text-align: center;" | <math> |

| + | |||

| + | \tau _t =\mu \gamma _t</li> | ||

| + | |||

| + | </math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (15.a) | ||

|} | |} | ||

| − | |||

| − | |||

with | with | ||

| Line 476: | Line 494: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| − | | style="text-align: center;" | <math>\gamma _t ={1\over 2}{\partial v_t\over \partial n} ={v_t^k\over 2h_k}</math> | + | | style="text-align: center;" | <math> |

| + | |||

| + | \gamma _t ={1\over 2}{\partial v_t\over \partial n} ={v_t^k\over 2h_k} | ||

| + | |||

| + | </math> | ||

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | ( | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (15.b) |

|} | |} | ||

| Line 490: | Line 512: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| − | | style="text-align: center;" | <math>W_f =\int _\circ ^t \tau _t \gamma _t\, dt = \int _\circ ^t {\mu \over 4} \left({v_t^k\over h_k}\right)^2 dt </math> | + | | style="text-align: center;" | <math> |

| + | |||

| + | W_f =\int _\circ ^t \tau _t \gamma _t\, dt = \int _\circ ^t {\mu \over 4} \left({v_t^k\over h_k}\right)^2 dt </li> | ||

| + | |||

| + | </math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (16) | ||

|} | |} | ||

| − | |||

| − | |||

Eq.(16) is integrated in time using a simple scheme as | Eq.(16) is integrated in time using a simple scheme as | ||

| Line 502: | Line 528: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| − | | style="text-align: center;" | <math>{}^n W_f ={}^{n-1} W_f + \tau _t \gamma _t\, \Delta t </math> | + | | style="text-align: center;" | <math> |

| + | |||

| + | {}^n W_f ={}^{n-1} W_f + \tau _t \gamma _t\, \Delta t | ||

| + | |||

| + | </math> | ||

|} | |} | ||

| − | | style="width: 5px;text-align: right;" | ( | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (17) |

|} | |} | ||

| Line 514: | Line 544: | ||

<div id='img-14'></div> | <div id='img-14'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-detail-tetrapods.png|540px|Detail of five tetrapods on an inclined plane. The layer of elements modeling the frictional contact conditions is shown]] | |[[Image:draft_Samper_283227388-detail-tetrapods.png|540px|Detail of five tetrapods on an inclined plane. The layer of elements modeling the frictional contact conditions is shown]] | ||

| Line 522: | Line 552: | ||

<div id='img-15'></div> | <div id='img-15'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

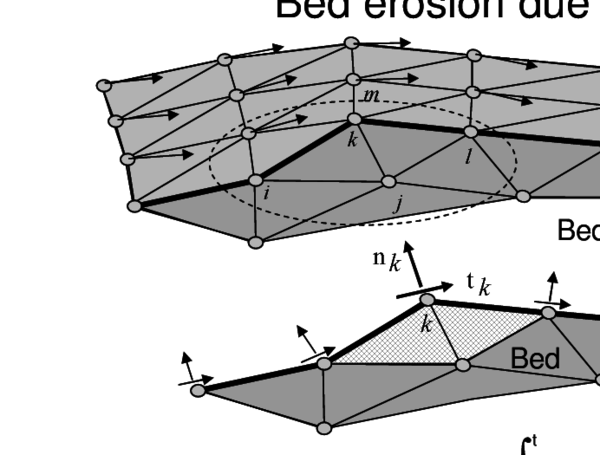

|[[Image:draft_Samper_283227388-Erosion_fluid_forces.png|600px|Modeling of bed erosion by dragging of bed material]] | |[[Image:draft_Samper_283227388-Erosion_fluid_forces.png|600px|Modeling of bed erosion by dragging of bed material]] | ||

| Line 550: | Line 580: | ||

<div id='img-16'></div> | <div id='img-16'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

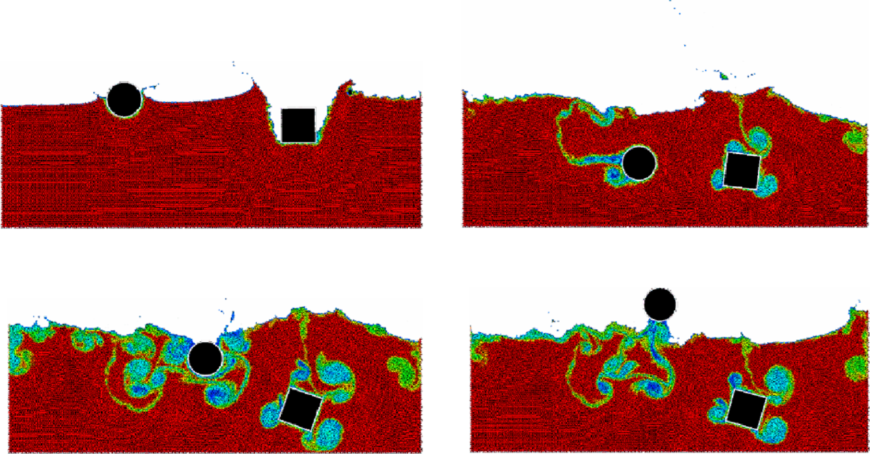

| − | |[[Image:draft_Samper_283227388-fig16.png| | + | |[[Image:draft_Samper_283227388-fig16.png|870px|2D simulation of the penetration and evolution of a cube and a cylinder in a water container. The colours denote the different sizes of the elements at several times]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 16:''' 2D simulation of the penetration and evolution of a cube and a cylinder in a water container. The colours denote the different sizes of the elements at several times | | colspan="1" | '''Figure 16:''' 2D simulation of the penetration and evolution of a cube and a cylinder in a water container. The colours denote the different sizes of the elements at several times | ||

| Line 558: | Line 588: | ||

<div id='img-17'></div> | <div id='img-17'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

| − | |[[Image:draft_Samper_283227388-Figure6.png|600px|Detail of element sizes during the motion of a rigid cylinder within | + | |[[Image:draft_Samper_283227388-Figure6.png|600px|Detail of element sizes during the motion of a rigid cylinder within a water container]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| − | | colspan="1" | '''Figure 17:''' Detail of element sizes during the motion of a rigid cylinder within | + | | colspan="1" | '''Figure 17:''' Detail of element sizes during the motion of a rigid cylinder within a water container |

|} | |} | ||

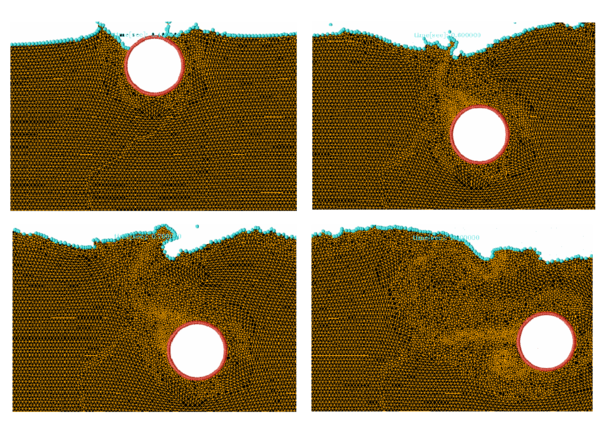

<div id='img-18'></div> | <div id='img-18'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-diap9.png|600px|]] | |[[Image:draft_Samper_283227388-diap9.png|600px|]] | ||

| − | + | |[[Image:draft_Samper_283227388-diap10.png|600px|Evolution of a water column within a prismatic container including a vertical cylinder]] | |

| − | |[[Image:draft_Samper_283227388-diap10.png|600px|Evolution of a water column within a prismatic container including a | + | |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

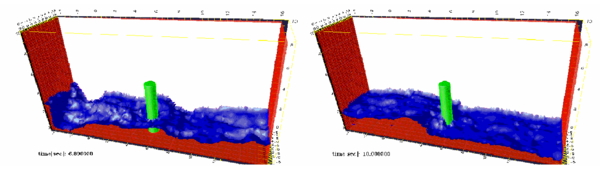

| − | | colspan=" | + | | colspan="2" | '''Figure 18:''' Evolution of a water column within a prismatic container including a vertical cylinder |

|} | |} | ||

<div id='img-19'></div> | <div id='img-19'></div> | ||

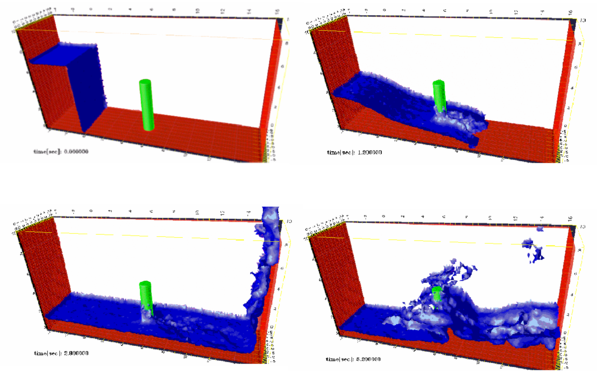

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

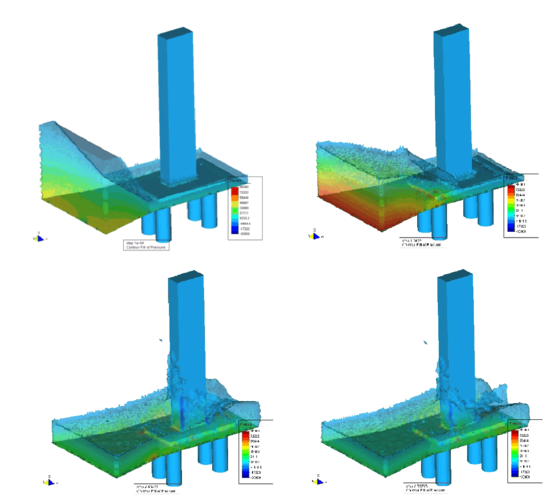

| − | |[[Image:draft_Samper_283227388-diap17.png| | + | |[[Image:draft_Samper_283227388-diap17.png|555px|Impact of a wave on a prismatic column on a slab sustained by four pillars.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| − | | colspan="1" | '''Figure 19:''' Impact of a wave on a prismatic column on a slab sustained by four | + | | colspan="1" | '''Figure 19:''' Impact of a wave on a prismatic column on a slab sustained by four pillars. |

|} | |} | ||

<div id='img-20'></div> | <div id='img-20'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-Figure11.png|570px|Dragging of a cubic object by a water stream.]] | |[[Image:draft_Samper_283227388-Figure11.png|570px|Dragging of a cubic object by a water stream.]] | ||

| Line 592: | Line 621: | ||

<div id='img-21'></div> | <div id='img-21'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-Fig15.png|600px|Interaction of a wave with a vertical pier formed by reinforced concrete cylinders.]] | |[[Image:draft_Samper_283227388-Fig15.png|600px|Interaction of a wave with a vertical pier formed by reinforced concrete cylinders.]] | ||

| Line 600: | Line 629: | ||

<div id='img-22'></div> | <div id='img-22'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

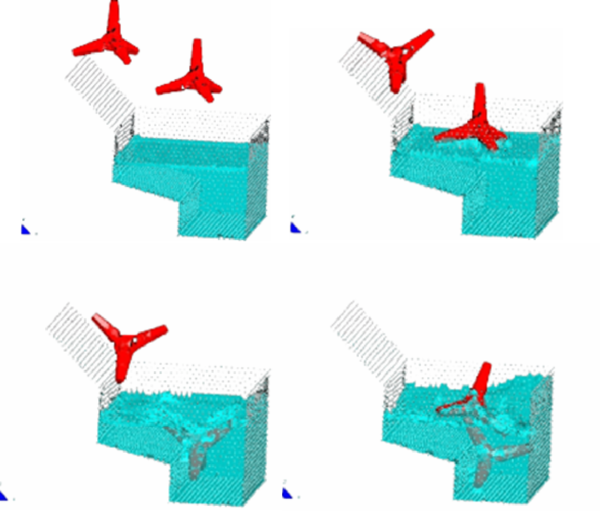

|[[Image:draft_Samper_283227388-Fig16two.png|600px|Motion of two tetrapods falling in a water container.]] | |[[Image:draft_Samper_283227388-Fig16two.png|600px|Motion of two tetrapods falling in a water container.]] | ||

| Line 608: | Line 637: | ||

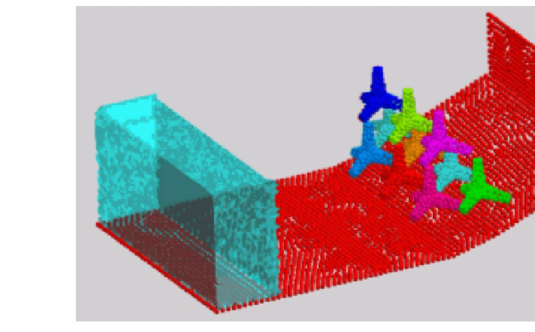

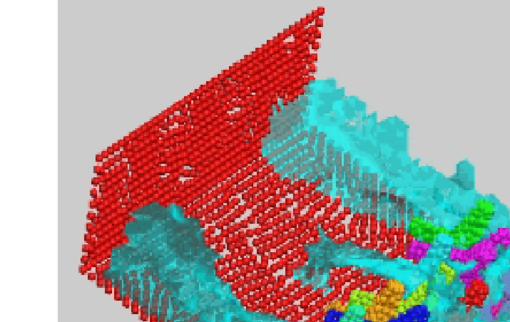

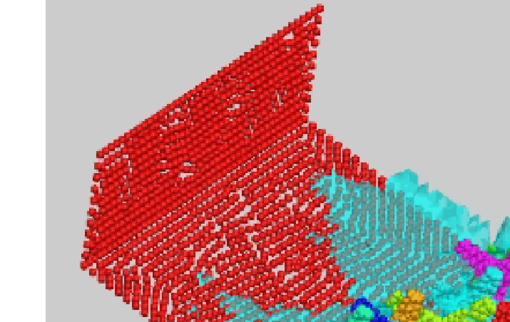

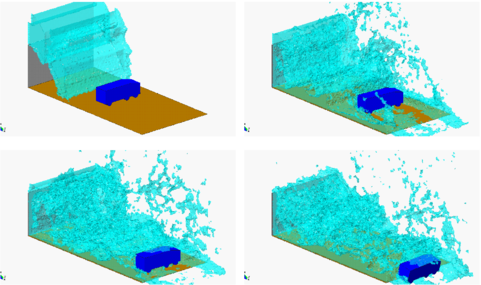

<div id='img-23'></div> | <div id='img-23'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

| − | + | ||

| − | + | ||

|- | |- | ||

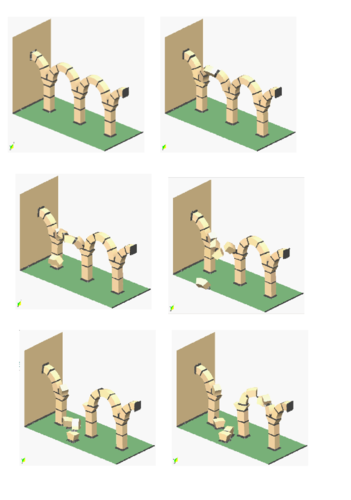

| − | |[[Image:draft_Samper_283227388-diap26.png| | + | |[[Image:draft_Samper_283227388-diap25.png|535px|]] |

| + | |[[Image:draft_Samper_283227388-diap26.png|535px|Motion of ten tetrapods on a slope under an incident wave.]] | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

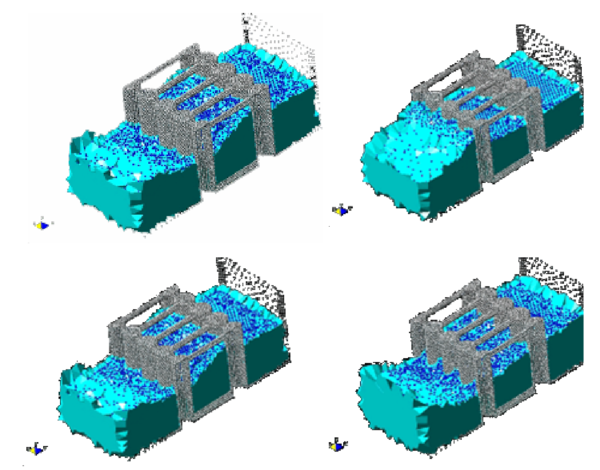

| − | | colspan=" | + | | colspan="2" | '''Figure 23:''' Motion of ten tetrapods on a slope under an incident wave. |

|} | |} | ||

<div id='img-24'></div> | <div id='img-24'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

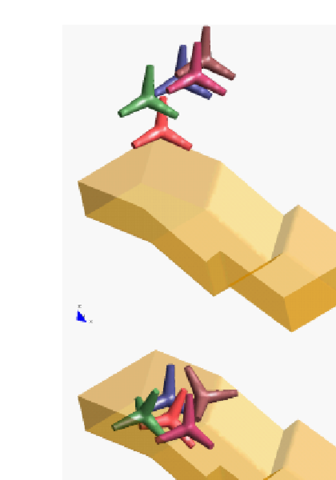

| − | |[[Image:draft_Samper_283227388-Figure24a.png| | + | |[[Image:draft_Samper_283227388-Figure24a.png|510px|]] |

| − | |[[Image:draft_Samper_283227388-Figure24b.png| | + | |[[Image:draft_Samper_283227388-Figure24b.png|510px|Detail of the motion of ten tetrapods on a slope under an incident wave. The figure shows the complex interactions between the water particles and the tetrapods.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="2" | '''Figure 24:''' Detail of the motion of ten tetrapods on a slope under an incident wave. The figure shows the complex interactions between the water particles and the tetrapods. | | colspan="2" | '''Figure 24:''' Detail of the motion of ten tetrapods on a slope under an incident wave. The figure shows the complex interactions between the water particles and the tetrapods. | ||

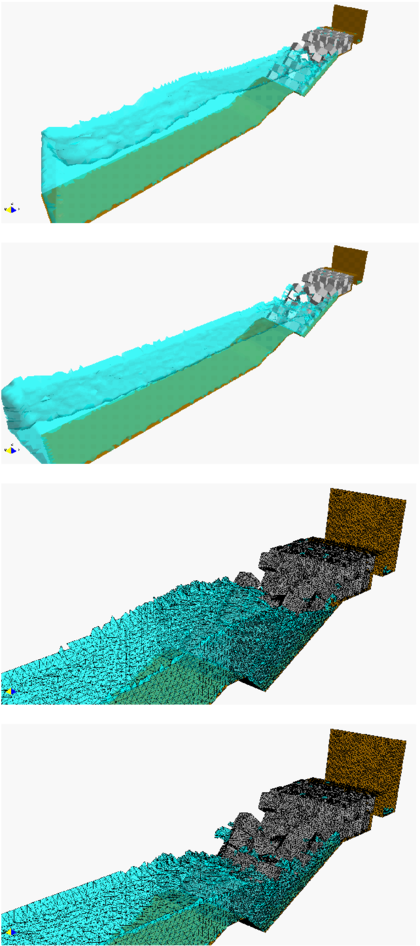

| Line 627: | Line 655: | ||

<div id='img-25'></div> | <div id='img-25'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-Dique_bloques.png|420px|Effect of breaking waves on a breakwater slope containing reinforced concrete blocks. Detail of the mesh of 4-noded tetrahedra near the slope at two different times]] | |[[Image:draft_Samper_283227388-Dique_bloques.png|420px|Effect of breaking waves on a breakwater slope containing reinforced concrete blocks. Detail of the mesh of 4-noded tetrahedra near the slope at two different times]] | ||

| Line 663: | Line 691: | ||

<div id='img-26'></div> | <div id='img-26'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-Dique_invernada.png|480px|Study of breaking waves on the edge of a breakwater structure formed by reinforced concrete blocks]] | |[[Image:draft_Samper_283227388-Dique_invernada.png|480px|Study of breaking waves on the edge of a breakwater structure formed by reinforced concrete blocks]] | ||

| Line 671: | Line 699: | ||

<div id='img-27'></div> | <div id='img-27'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

| − | |[[Image:draft_Samper_283227388-camion.png| | + | |[[Image:draft_Samper_283227388-camion.png|481px|Effect of an overtopping wave on a truck passing by the perimetral road of a harbour adjacent to the breakwater]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 27:''' Effect of an overtopping wave on a truck passing by the perimetral road of a harbour adjacent to the breakwater | | colspan="1" | '''Figure 27:''' Effect of an overtopping wave on a truck passing by the perimetral road of a harbour adjacent to the breakwater | ||

| Line 679: | Line 707: | ||

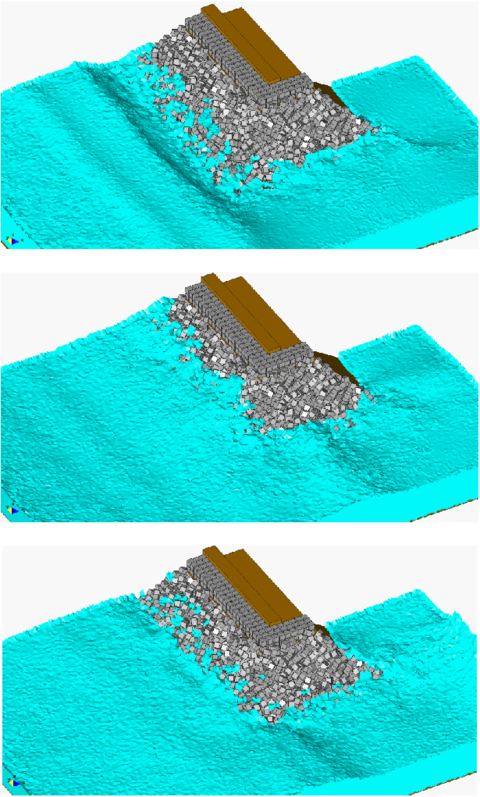

<div id='img-28'></div> | <div id='img-28'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-erosion_3D.png|600px|Erosion of a 3D earth dam due to an overspill stream.]] | |[[Image:draft_Samper_283227388-erosion_3D.png|600px|Erosion of a 3D earth dam due to an overspill stream.]] | ||

| Line 695: | Line 723: | ||

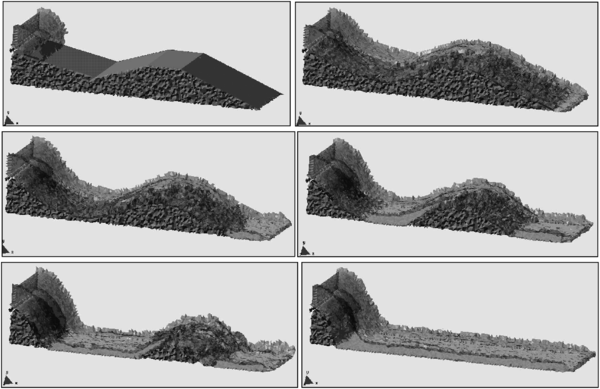

<div id='img-29'></div> | <div id='img-29'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

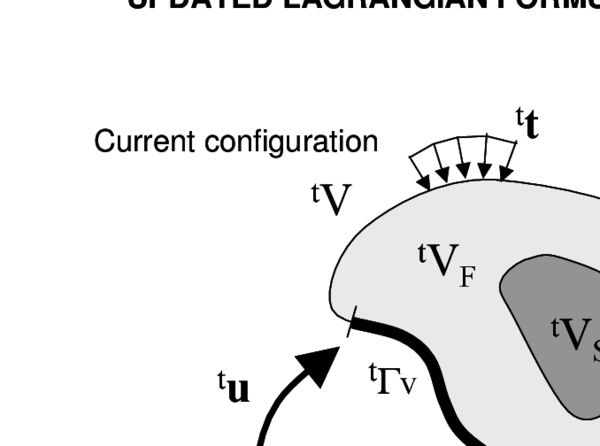

|[[Image:draft_Samper_283227388-Fig3_polymers.png|420px|Polymer melt experiment. Viscosity vs. temperature for PP702N polypropylene in its initial undegraded form and after exposure to 30 kW/m² and 40 kW/m² heat fluxes. The black curve follows the extrapolation of viscosity to high temperatures.]] | |[[Image:draft_Samper_283227388-Fig3_polymers.png|420px|Polymer melt experiment. Viscosity vs. temperature for PP702N polypropylene in its initial undegraded form and after exposure to 30 kW/m² and 40 kW/m² heat fluxes. The black curve follows the extrapolation of viscosity to high temperatures.]] | ||

| Line 707: | Line 735: | ||

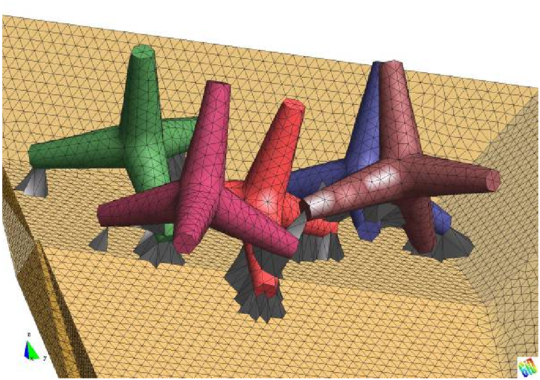

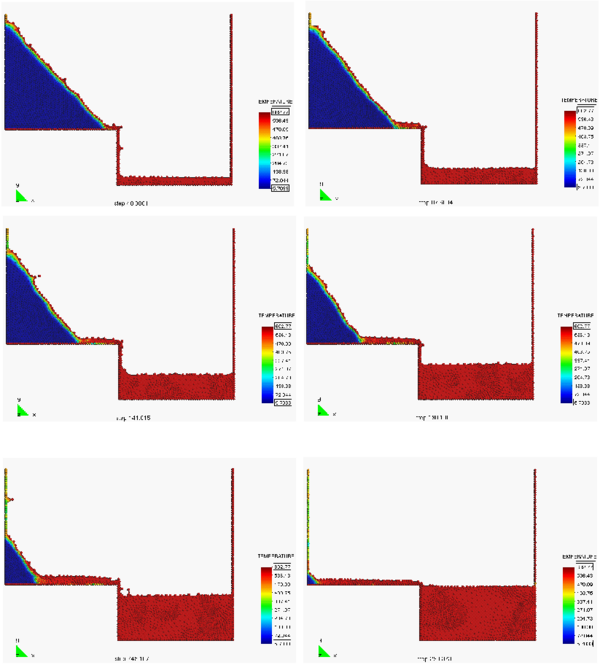

<div id='img-30'></div> | <div id='img-30'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

| − | |[[Image:draft_Samper_283227388-Evolution_melt_1.png| | + | |[[Image:draft_Samper_283227388-Evolution_melt_1.png|600px|]] |

| − | |[[Image:draft_Samper_283227388-Evolution_melt_2.png| | + | |[[Image:draft_Samper_283227388-Evolution_melt_2.png|600px|]] |

|- | |- | ||

| − | |[[Image:draft_Samper_283227388-Evolution_melt_3.png| | + | |[[Image:draft_Samper_283227388-Evolution_melt_3.png|600px|]] |

| − | |[[Image:draft_Samper_283227388-Evolution_melt_4.png| | + | |[[Image:draft_Samper_283227388-Evolution_melt_4.png|600px|Evolution of the melt flow into the catch pan at t = 400s, 550s, 700s and 1000s]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="2" | '''Figure 30:''' Evolution of the melt flow into the catch pan at t = 400s, 550s, 700s and 1000s | | colspan="2" | '''Figure 30:''' Evolution of the melt flow into the catch pan at t = 400s, 550s, 700s and 1000s | ||

| Line 725: | Line 753: | ||

<div id='img-31'></div> | <div id='img-31'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-Fig9_polymers.png|600px|Melt flow of a heated triangular object into a catch pan.]] | |[[Image:draft_Samper_283227388-Fig9_polymers.png|600px|Melt flow of a heated triangular object into a catch pan.]] | ||

| Line 733: | Line 761: | ||

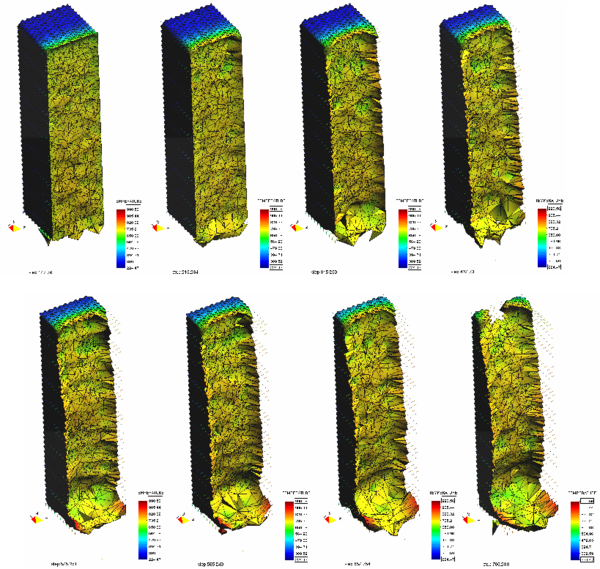

<div id='img-32'></div> | <div id='img-32'></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" |

|- | |- | ||

|[[Image:draft_Samper_283227388-Fig7_polymers.png|600px|Solution of a 3D polymer melt problem with the PFEM. Melt flow from a heated prismatic sample at different times.]] | |[[Image:draft_Samper_283227388-Fig7_polymers.png|600px|Solution of a 3D polymer melt problem with the PFEM. Melt flow from a heated prismatic sample at different times.]] | ||

| Line 877: | Line 905: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| − | | style="text-align: center;" | <math>\ | + | | style="text-align: center;" | <math>\mathbf{M}_{ij} =\int _{V^{e}} \rho \mathbf{N}_{i}^{T} \mathbf{N}_{j} dV \quad , \quad \mathbf{K}_{ij}=\int _{V^{e}} \mathbf{B}_{i}^{T} \mathbf{D} \mathbf{B}_{j} dV </math> |

|} | |} | ||

|} | |} | ||

| Line 886: | Line 914: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| − | | style="text-align: center;" | <math> \ | + | | style="text-align: center;" | <math> \mathbf{G}_{ij} = \int _{V^{e}} \mathbf{B}_{i}^{T} \mathbf{m}\mathbf{N}_{j} dV \quad , \quad \mathbf{f}_{i}=\int _{V^{e}} \mathbf{ N}_{i}^{T}\mathbf{b}dV+ \int _{\Gamma ^e} \mathbf{ N}_{i}^{T}\mathbf{t}d\Gamma </math> |

|} | |} | ||

|} | |} | ||

| Line 895: | Line 923: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>{L}_{ij} = \int _{V^e} {\boldsymbol \nabla }^T N_i \tau {\boldsymbol \nabla }N_j dV \quad ,\quad {\boldsymbol \nabla } = \left[{\partial \over \partial x_1},{\partial \over \partial x_2},{\partial \over \partial x_3}\right]^T</math> | | style="text-align: center;" | <math>{L}_{ij} = \int _{V^e} {\boldsymbol \nabla }^T N_i \tau {\boldsymbol \nabla }N_j dV \quad ,\quad {\boldsymbol \nabla } = \left[{\partial \over \partial x_1},{\partial \over \partial x_2},{\partial \over \partial x_3}\right]^T</math> | ||

| Line 904: | Line 932: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| − | | style="text-align: center;" | <math>{Q}= [{Q}_1,{Q}_2,{Q}_3]\quad ,\quad [\ | + | | style="text-align: center;" | <math>{Q}= [{Q}_1,{Q}_2,{Q}_3]\quad ,\quad [\mathbf{Q}_{k}]_{ij} = \int _{V^e}\tau {\partial N_i \over \partial x_k} \mathbf{N}_j dV</math> |

|} | |} | ||

|} | |} | ||

| Line 913: | Line 941: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>\hat {M}= \left[\hat {M}_1, \hat {M}_2,\hat {M}_3\right]\,,\, [\hat {M}_i]_{kl}=\left(\int _{V^e} \tau {N}_i{N}_j dV \right)\delta _{kl}\quad k,l=1,2,3</math> | | style="text-align: center;" | <math>\hat {M}= \left[\hat {M}_1, \hat {M}_2,\hat {M}_3\right]\,,\, [\hat {M}_i]_{kl}=\left(\int _{V^e} \tau {N}_i{N}_j dV \right)\delta _{kl}\quad k,l=1,2,3</math> | ||

| Line 922: | Line 950: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>{B}=[{B}_1,{B}_2,{B}_3,{B}_4];\, {B}_i =\left[\begin{matrix} \displaystyle {\partial N_i \over \partial x}&0&0\\ 0 & \displaystyle {\partial N_i \over \partial y} &0\\ 0&0& \displaystyle {\partial N_i \over \partial z} \\ \displaystyle {\partial N_i \over \partial y} & \displaystyle {\partial N_i \over \partial x}&0\\\\ \displaystyle {\partial N_i \over \partial z} &0&\displaystyle {\partial N_i \over \partial x}\\\\ 0& \displaystyle {\partial N_i \over \partial z} &\displaystyle {\partial N_i \over \partial y} \end{matrix} \right]</math> | | style="text-align: center;" | <math>{B}=[{B}_1,{B}_2,{B}_3,{B}_4];\, {B}_i =\left[\begin{matrix} \displaystyle {\partial N_i \over \partial x}&0&0\\ 0 & \displaystyle {\partial N_i \over \partial y} &0\\ 0&0& \displaystyle {\partial N_i \over \partial z} \\ \displaystyle {\partial N_i \over \partial y} & \displaystyle {\partial N_i \over \partial x}&0\\\\ \displaystyle {\partial N_i \over \partial z} &0&\displaystyle {\partial N_i \over \partial x}\\\\ 0& \displaystyle {\partial N_i \over \partial z} &\displaystyle {\partial N_i \over \partial y} \end{matrix} \right]</math> | ||

| Line 931: | Line 959: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>{D} =\mu \left[\begin{matrix}2 &0&0&0&0&0\\ 0&2&0&0&0&0\\ 0&0&2&0&0&0\\ 0&0&0&1&0&0\\ 0&0&0&0&1&0\\ 0&0&0&0&0&1\end{matrix}\right]</math> | | style="text-align: center;" | <math>{D} =\mu \left[\begin{matrix}2 &0&0&0&0&0\\ 0&2&0&0&0&0\\ 0&0&2&0&0&0\\ 0&0&0&1&0&0\\ 0&0&0&0&1&0\\ 0&0&0&0&0&1\end{matrix}\right]</math> | ||

| Line 940: | Line 968: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>{N}=[{N}_1,{N}_2,{N}_3,{N}_4] \quad , \quad {N}_i={N}_i {I}_3\quad ,\quad {I}_3 \quad \hbox{is the unit matrix}</math> | | style="text-align: center;" | <math>{N}=[{N}_1,{N}_2,{N}_3,{N}_4] \quad , \quad {N}_i={N}_i {I}_3\quad ,\quad {I}_3 \quad \hbox{is the unit matrix}</math> | ||

| Line 949: | Line 977: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>{C}_{ij}=\int _{V^e} \rho {c}{N}_i {N}_j dV \quad ,\quad {H}_{ij}= \int _{V^e}{\boldsymbol \nabla }^T {N}_i [k] {\boldsymbol \nabla }{N}_j dV \quad ,\quad {m} =[1,1,1,0,0,0]^T</math> | | style="text-align: center;" | <math>{C}_{ij}=\int _{V^e} \rho {c}{N}_i {N}_j dV \quad ,\quad {H}_{ij}= \int _{V^e}{\boldsymbol \nabla }^T {N}_i [k] {\boldsymbol \nabla }{N}_j dV \quad ,\quad {m} =[1,1,1,0,0,0]^T</math> | ||

| Line 958: | Line 986: | ||

|- | |- | ||

| | | | ||

| − | {| style="text-align: left; margin:auto;" | + | {| style="text-align: left; margin:auto;width: 100%;" |

|- | |- | ||

| style="text-align: center;" | <math>[k]= \left[\begin{matrix}k_1 &0 &0 \\ 0 & k_2&0\\ 0&0& k_3\end{matrix}\right]\quad , \quad q_i =\int _{V^e}N_iQdV - \int _{\Gamma _q^{e}} N_i q_n d\Gamma </math> | | style="text-align: center;" | <math>[k]= \left[\begin{matrix}k_1 &0 &0 \\ 0 & k_2&0\\ 0&0& k_3\end{matrix}\right]\quad , \quad q_i =\int _{V^e}N_iQdV - \int _{\Gamma _q^{e}} N_i q_n d\Gamma </math> | ||

| Line 964: | Line 992: | ||

|} | |} | ||

| − | In above equations indexes <math display="inline">i,j</math> run from 1 to the number of element nodes (4 for a tetrahedron), <math display="inline">q_n</math> is the heat flow prescribed at the external boundary <math display="inline">\Gamma _q</math>, '''t''' is the surface traction vector <math display="inline">\ | + | In above equations indexes <math display="inline">i,j</math> run from 1 to the number of element nodes (4 for a tetrahedron), <math display="inline">q_n</math> is the heat flow prescribed at the external boundary <math display="inline">\Gamma _q</math>, '''t''' is the surface traction vector <math display="inline">\mathbf{t}=[t_x,t_y,t_z]^T</math> and <math display="inline">V^{e}</math> and <math display="inline">\Gamma ^e</math> are the element volume and the element boundary, respectively. |

Revision as of 11:26, 13 March 2018

Abstract

We present some developments in the formulation of the Particle Finite Element Method (PFEM) for analysis of complex coupled problems in fluid and solid mechanics accounting for fluid-structure interaction and coupled thermal effects. The PFEM uses an updated Lagrangian description to model the motion of nodes (particles) in both the fluid and the structure domains. Nodes are viewed as material points which can freely move and even separate from the main analysis domain representing, for instance, the effect of water drops. A mesh connects the nodes defining the discretized domain where the governing equations are solved as in the standard FEM. The necessary stabilization for dealing with the incompressibility of the fluid is introduced via the finite calculus (FIC) method. An incremental iterative scheme for the solution of the non linear transient coupled fluid-structure problem is described. Extensions of the PFEM to allow for frictional contact conditions at fluid-solid and solid-solid interfaces via mesh generation are described. A simple algorithm to treat erosion in the fluid bed is presented. Examples of application of the PFEM to solve a number of coupled problems such as the effect of large wave on structures, the large motions of floating and submerged bodies, bed erosion situations and melting and dripping of polymers under the effect of fire are given.

keywords

1 Introduction

The analysis of problems involving the interaction of fluids and structures accounting for large motions of the fluid free surface and the existence of fully or partially submerged bodies which interact among themselves is of big relevance in many areas of engineering. Examples are common in ship hydrodynamics, off-shore and harbour structures, spill-ways in dams, free surface channel flows, environmental flows, liquid containers, stirring reactors, mould filling processes, etc.

Typical difficulties of fluid-multibody interaction analysis in free surface flows using the FEM with both the Eulerian and ALE formulation include the treatment of the convective terms and the incompressibility constraint in the fluid equations, the modelling and tracking of the free surface in the fluid, the transfer of information between the fluid and the moving solid domains via the contact interfaces, the modeling of wave splashing, the possibility to deal with large motions of the bodies within the fluid domain, the efficient updating of the finite element meshes for both the structure and the fluid, etc. For a comprehensive list of references in FEM for fluid flow problems see [7,37] and the references there included. A survey of recent works in fluid-structure interaction analysis can be found in [18], [27] and [35].

Most of the above problems disappear if a Lagrangian description is used to formulate the governing equations of both the solid and the fluid domains. In the Lagrangian formulation the motion of the individual particles are followed and, consequently, nodes in a finite element mesh can be viewed as moving material points (hereforth called “particles”). Hence, the motion of the mesh discretizing the total domain (including both the fluid and solid parts) is followed during the transient solution.

The authors have successfully developed in previous works a particular class of Lagrangian formulation for solving problems involving complex interaction between fluids and solids. The method, called the particle finite element method (PFEM, www.cimne.com/pfem), treats the mesh nodes in the fluid and solid domains as particles which can freely move and even separate from the main fluid domain representing, for instance, the effect of water drops. A mesh connects the nodes discretizing the domain where the governing equations are solved using a stabilized FEM.

The FEM solution of the variables in the (incompressible) fluid domain implies solving the momentum and incompressibility equations. This is not such as simple problem as the incompressibility condition limits the choice of the FE approximations for the velocity and pressure to overcome the well known -stability condition [7,37]. In our work we use a stabilized mixed FEM based on the Finite Calculus (FIC) approach which allows for a linear approximation for the velocity and pressure variables.

An advantage of the Lagrangian formulation is that the convective terms disappear from the fluid equations. The difficulty is however transferred to the problem of adequately (and efficiently) moving the mesh nodes. We use a mesh regeneration procedure blending elements of different shapes using an extended Delaunay tesselation with special shape functions [11,13]. The theory and applications of the PFEM are reported in [2,6,11,12,14,15,26,27,28,30,31,32].

The aim of this paper is to describe recent advances of the PFEM for a) the analysis of the interaction between a collection of bodies which are floating and/or submerged in the fluid, b) the modeling of bed erosion in open channel flows and c) the analysis of melting and dripping of polymer objects in fire situations. These problems are of great relevance in many areas of civil, marine and naval engineering, among others. It is shown that the PFEM provides a general analysis methodology for treat such a complex problems in a simple and efficient manner.

The layout of the paper is the following. In the next section the key ideas of the PFEM are outlined. Next the basic equations for an incompressible thermal flow using a Lagrangian description and the FIC formulation are presented. Then an algorithm for the transient solution is briefly described. The treatment of the coupled FSI problem and the methods for mesh generation and for identification of the free surface nodes are outlined. The procedure for treating at mesh generation level the contact conditions at fluid-wall interfaces and the frictional contact interaction between moving solids is explained. A methodology for modeling bed erosion due to fluid forces is described. Finally, the potencial of the PFEM is shown in its application to problems involving large flow motions, surface waves, moving bodies in water, bed erosion and melting and dripping of polymers in fire situations.

2 The basis of the particle finite element method

Let us consider a domain containing both fluid and solid subdomains. The moving fluid particles interact with the solid boundaries thereby inducing the deformation of the solid which in turn affects the flow motion and, therefore, the problem is fully coupled.

In the PFEM both the fluid and the solid domains are modelled using an updated Lagrangian formulation. That is, all variables in the fluid and solid domains are assumed to be known in the current configuration at time . The new set of variables in both domains are sought for in the next or updated configuration at time (Figure 1). The finite element method (FEM) is used to solve the continuum equations in both domains. Hence a mesh discretizing these domains must be generated in order to solve the governing equations for both the fluid and solid problems in the standard FEM fashion. Recall that the nodes discretizing the fluid and solid domains are treated as material particles which motion is tracked during the transient solution. This is useful to model the separation of fluid particles from the main fluid domain in a splashing wave, or soil particles in a bed erosion problem, and to follow their subsequent motion as individual particles with a known density, an initial acceleration and velocity and subject to gravity forces. The mass of a given domain is obtained by integrating the density at the different material points over the domain.

The quality of the numerical solution depends on the discretization chosen as in the standard FEM. Adaptive mesh refinement techniques can be used to improve the solution in zones where large motions of the fluid or the structure occur.

|

| Figure 1: Updated lagrangian description for a continuum containing a fluid and a solid domain |

|

| Figure 2: Sequence of steps to update a “cloud” of nodes representing a domain containing a fluid and a solid part from time () to time () |

2.1 Basic steps of the PFEM

For clarity purposes we will define the collection or cloud of nodes (C) pertaining to the fluid and solid domains, the volume (V) defining the analysis domain for the fluid and the solid and the mesh (M) discretizing both domains.

A typical solution with the PFEM involves the following steps.

- The starting point at each time step is the cloud of points in the fluid and solid domains. For instance denotes the cloud at time (Figure 2).

- Identify the boundaries for both the fluid and solid domains defining the analysis domain in the fluid and the solid. This is an essential step as some boundaries (such as the free surface in fluids) may be severely distorted during the solution, including separation and re-entering of nodes. The Alpha Shape method [8] is used for the boundary definition (Section 5).

- Discretize the fluid and solid domains with a finite element mesh . In our work we use an innovative mesh generation scheme based on the extended Delaunay tesselation (Section 4) [11,12,14].

- Solve the coupled Lagrangian equations of motion for the fluid and the solid domains. Compute the state variables in both domains at the next (updated) configuration for : velocities, pressure, viscous stresses and temperature in the fluid and displacements, stresses, strains and temperature in the solid.

- Move the mesh nodes to a new position where denotes the time , in terms of the time increment size. This step is typically a consequence of the solution process of step 4.

- Go back to step 1 and repeat the solution process for the next time step to obtain . The process is shown in Figure 2.

Figure 3 shows another conceptual example of application of the PFEM to model the melting and dripping of a polymer object under a heat source acting at a boundary.

|

|

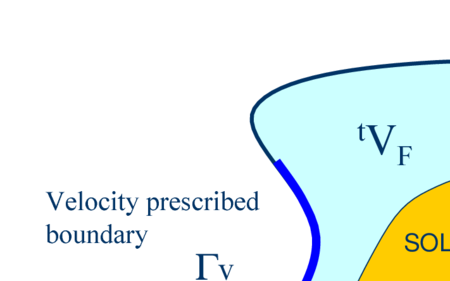

| Figure 4: Breakage of a water column. (a) Discretization of the fluid domain and the solid walls. Boundary nodes are marked with circles. (b) and (c) Mesh in the fluid domain at two different times | |

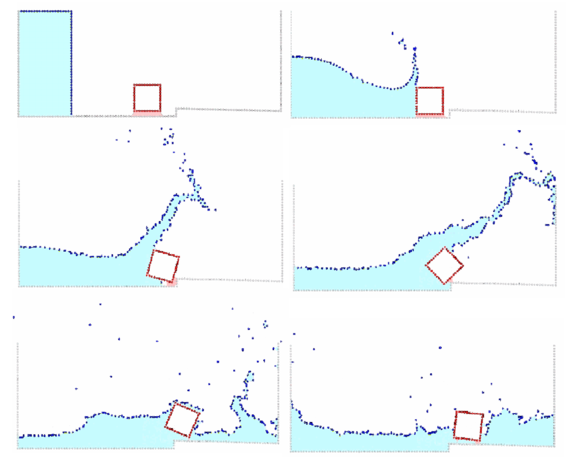

Figure 4 shows a typical example of a PFEM solution in 2D. The pictures correspond to the analysis of the problem of breakage of a water column [14,28]. Figure 4a shows the initial grid of four node rectangles discretizing the fluid domain and the solid walls. Figures 4b and 4c show the mesh for the solution at two later times.

3 FIC/FEM formulation for a lagrangian incompressible thermal fluid

3.1 Governing equations

The key equations to be solved in the incompressible thermal flow problem, written in the Lagrangian frame of reference, are the following:

Momentum

|

|

(1) |

Mass balance

|

|

(2) |

Heat transport

|

|

(3) |

In above equations is the velocity along the ith global (cartesian) axis, is the temperature, , and are the density (assumed constant), the specific heat and the conductivity of the material along the ith coordinate direction, respectively, and are the body forces and the heat source per unit mass, respectively and are the (Cauchy) stresses related to the velocities by the standard constitutive equation (for incompressible Newtonian material)

|

|

(4.a) |

|

|

(4.b) |

In Eqs.(3.1), is the deviatoric stresses, is the pressure (assumed to be positive in compression), is the rate of deformation, is the viscosity and is the Kronecker delta. In the following we will assume the viscosity to be a known function of temperature, i.e .

Indexes in Eqs.(1)–(3.1) range from , where is the number of space dimensions of the problem (i.e. for two-dimensional problems).

Eqs.(1)–(3.1) are completed with the standard boundary conditions of prescribed velocities and surface tractions in the mechanical problem and prescribed temperature and prescribed normal heat flux in the thermal problem [2,7].

We note that Eqs.(1)–(3) are the standard ones for modeling the deformation of viscoplastic materials using the so called “flow approach” [38,39]. In our work the dependence of the viscosity with the strain typical of viscoplastic flows has been simplified to the Newtonian form of Eq.(4.b).

3.2 Discretization of the equations

A key problem in the numerical solution of Eqs.(1)–(3.1) is the satisfaction of the incompressibility condition (Eq.(2)). A number of procedures to solve his problem exist in the finite element literature [7,37]. In our approach we use a stabilized formulation based in the so-called finite calculus procedure [19]–[21],[28,30,32]. The essence of this method is the solution of a modified mass balance equation which is written as

|

|

(5) |

where is a stabilization parameter given by [10]

|

|

(6) |

In the above, is a characteristic length of each finite element (such as for 2D elements) and is the modulus of the velocity vector. In Eq.(5) are auxiliary pressure projection variables chosen so as to ensure that the second term in Eq.(5) can be interpreted as weighted sum of the residuals of the momentum equations and therefore it vanishes for the exact solution. The set of governing equations for the velocities, the pressure and the variables is completed by adding the following constraint equation to the set of governing equations [28,32]

|

|

(7) |

where are arbitrary weighting functions (no sum in ).

The rest of the integral equations are obtained by applying the standard Galerkin technique to the governing equations (1), (2), (3) and (5) and the corresponding boundary conditions [28,32].

We interpolate next in the standard finite element fashion the set of problem variables. For 3D problems these are the three velocities , the pressure , the temperature and the three pressure gradient projections . In our work we use equal order linear interpolation for all variables over meshes of 3-noded triangles (in 2D) and 4-noded tetrahedra (in 3D) [28,32,40]. The resulting set of discretized equations has the following form

Momentum

|

|

(8) |

Mass balance

|

|

(9) |

Pressure gradient projection

|

|

(10) |

Heat transport

|

|

(11) |

In Eqs.(8)–(11) denotes nodal variables, . The different matrices and vectors are given in the Appendix.

The solution in time of Eqs.(8)–(11) can be performed using any time integration schemes typical of the updated Lagrangian finite element method. A basic algorithm following the conceptual process described in Section 2.1 is presented in Box I. denotes the values of the nodal variables at time and the iterations. We note the coupling of the flow and thermal equations via the dependence of the viscosity with the temperature.

|

4 Overview of the coupled FSI algoritm

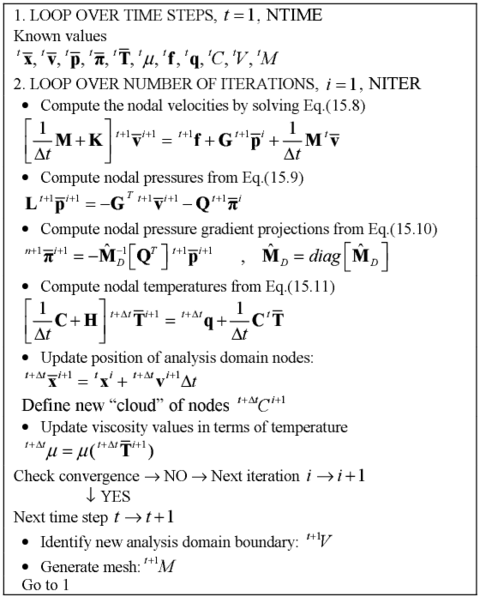

Figure 5 shows a typical domain with external boundaries and where the velocity and the surface tractions are prescribed, respectively. The domain is formed by fluid () and solid () subdomains (i.e. ). Both subdomains interact at a common boundary where the surface tractions and the kinematic variables (displacements, velocities and acelerations) are the same for both subdomains. Note that both set of variables (the surface tractions and the kinematic variables) are equivalent in the equilibrium configuration.

|

|

| Figure 5: Split of the analysis domain into fluid and solid subdomains. Equality of surface tractions and kinematic variables at the common interface | |

Let us define and the set of variables defining the kinematics and the stress-strain fields at the solid and fluid domains at time , respectively, i.e.

|

where is the nodal coordinate vector, u, v and a are the vector of displacements, velocities and accelerations, respectively, and are the strain vector, the strain-rate (or rate of deformation) vectors and the Cauchy stress vector, respectively, is the temperature and subscripts and denote the variables in the fluid and solid domains, respectively. In the discretized problem, a bar over these variables denotes nodal values.

The coupled fluid-structure interaction (FSI) problem of Figure 4 is solved, in this work, using the following strongly coupled staggered scheme:

- We assume that the variables in the solid and fluid domains at time ( and ) are known.

- Solve for the variables at the solid domain at time () under prescribed surface tractions at the fluid-solid boundary . The boundary conditions at the part of the external boundary intersecting the domain are the standard ones in solid mechanics.

The variables at the solid domain are found via the integration of the equations of dynamic motion in the solid written as [40]

|

|

(14) |

where is the vector of nodal accelerations and and are the mass matrix, the internal node force vector and the external nodal force vector in the solid domain. The time integration of Eq.(14) is performed using a standard Newmark method.

Solve for the variables at the fluid domain at time () under prescribed surface tractions at the external boundary and prescribed velocities at the external and internal boundaries and , respectively. An incremental iterative scheme is implemented within each time step to account for non linear geometrical and material effects.

Iterate between 1 and 2 until convergence.

The above FSI solution algorithm is shown schematically in Box II.

|

5 Generation of a new mesh