(Created page with " ==EXPLICIT DYNAMIC ANALYSIS OF THIN MEMBRANE STRUCTURES== <span id='_Toc284589275'></span> ==Roberto Flores, Enrique Ortega and Eugenio Oñate== <span style="text-align: c...") |

m (Cinmemj moved page Draft Samper 793606474 to Flores et al 2011a) |

||

| (22 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | ==Abstract== | ||

| − | + | An explicit dynamic structural solver developed at CIMNE for the analysis of parachutes is presented. The canopy fabric has a negligible out-of-plane stiffness, therefore its numerical study presents important challenges. Both the large changes in geometry and the statically indeterminate character of the system are problematic from the numerical point of view. This report covers the reasons behind the particular choice of solution scheme as well as a detailed description of the underlying algorithm. Both the theoretical foundations of the method and details of implementation aiming at improving computational efficiency are given. Benchmark cases to assess the accuracy of the solution as well as examples of practical application showing the performance of the code are finally presented. | |

| − | |||

| − | |||

| − | + | ==1 Problem overview== | |

| − | <span id=' | + | This report describes the theoretical foundation as well as applications of PUMI_MEM, an explicit dynamics structural solver developed at CIMNE. This code is part of the PARAFLIGHT parachute simulation suite <span id='cite-_Ref284604132'></span>[[#_Ref284604132|[1]]] which also includes a potential flow solver <span id='cite-_Ref284604146'></span>[[#_Ref284604146|[2]]]. The mechanical analysis of thin membrane structures braced with cables (e.g. parachutes) is a challenging task. Two effects entail a host of numerical problems <span id='cite-_Ref284616324'></span>[[#_Ref284616324|[3]]]: |

| − | <span | + | |

| − | + | :* In general the structure is not statically determinate for an arbitrary set of loads (i.e. it behaves like a mechanism). Thus, it might be impossible to reach an equilibrium state without drastic changes in geometry. The structural response is therefore highly nonlinear and may cause severe convergence problems. | |

| − | < | + | :* Due to the virtually zero bending stiffness of the components the material behaviour is irreversible. The fabric is able to resist tensile stresses but buckles (wrinkles) almost immediately under compressive loads. This asymmetric behaviour further complicates the mechanical analysis <span id='cite-_Ref284688748'></span>[[#_Ref284688748|[4]]]<span id='cite-_Ref284688750'></span>[[#_Ref284688750|[5]]]. |

| − | + | ||

| − | + | In the particular case of parachutes there is an additional complication due to the nature of the applied forces. These being mostly pressure loads, their direction is not known ''a priori'' but is a function of the deformed shape and must therefore be computed as part of the solution. This is an additional source of non-linearity. Finally, matters are further complicated by the extreme sensitivity of the pressure field to changes in geometry <span id='cite-_Ref284688881'></span>[[#_Ref284688881|[6]]]. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | </ | + | |

| − | + | In view of these challenges it was decided to use a finite element (FE) dynamic structural solver. An unsteady analysis is insensitive to the problems caused by the lack of a definite static equilibrium configuration. In a dynamic problem the structure is constantly in equilibrium with the inertial forces so the solution is always unique. Even if only the long-term static response is sought the dynamic study offers clear advantages. Furthermore, the extension to transient dynamic problems becomes trivial. There are two basic kinds of dynamic solvers, implicit and explicit <span id='cite-_Ref284617109'></span>[[#_Ref284617109|[7]]]. Their main features are: | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | </ | + | |

| − | + | :* Implicit: Can be made unconditionally stable (allows for large time steps). Cost per time step is large, each step requires solving a non linear problem using an iterative algorithm. The radius of convergence of the iterative algorithms is however limited so the time step cannot be made arbitrarily large. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | :* Explicit: Only conditionally stable. The stability limit is determined by the material properties and the geometry of the FE mesh. Cost per time step is low. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | When the structural response does not deviate much from linearity the implicit treatment is advantageous as it allows advancing in time quickly. Also, the static equilibrium (when it exists) can be reached in a small number of iterations. However, when the behaviour is heavily non-linear, the time increment must be cut back in order for the iterative schemes to converge and the computational increases quickly. There is also a loss of robustness caused by the possibility of the algorithms failing to converge. On the other hand, the explicit method is extremely insensitive to these effects and requires a number of time steps that does not change substantially as the system response becomes more complex. Material non-linearities and large displacements which are extremely detrimental for the convergence behaviour of the implicit scheme do not affect so adversely the explicit algorithm. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

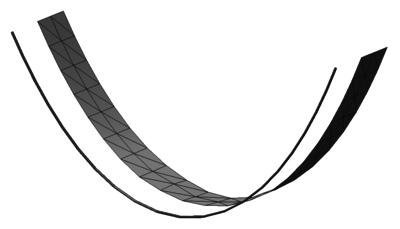

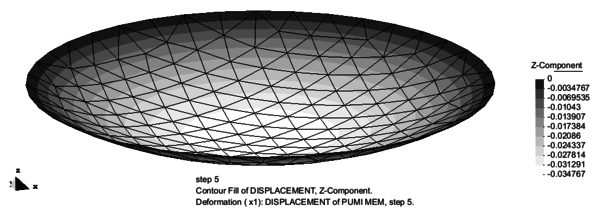

| − | + | In view of the difficulties expected the choice was made to use an Explicit FE structural solver. A further advantage is the ability of the algorithm to be easily vectored and thus take advantage of modern parallel processing architectures. Linear cable and membrane elements where selected due to their ease of implementation. The fabric is modelled using three-node membrane elements due to their geometric simplicity. As the three nodes of the element can be always assumed to lie in a plane, the definition of the local coordinate systems is straightforward. When a quadrilateral element is passed from the aerodynamic solver, it is internally transformed into a pair of triangular elements in order to carry the analysis. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | A local corrotational reference frame is used for each cable and membrane element in order to remove the large rigid-body displacement field and isolate the material strains. Inside each element a simple small-strain formulation is used due to the properties of the fabric. Tensile deformations are always small, on the other hand compressive strains can become extremely large due to the inclusion of a wrinkling model (zero compression stiffness). There is however no stress associated with the compressive strains and, correspondingly, no strain energy. The small-strain formulation is therefore adequate, as only the small tensile deformations must be into account to calculate the stress state. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | While not strictly necessary to model the parachute behaviour, tetrahedral solid (3D) elements have been included in the code. They prove useful in modelling the dynamic interaction between the parachute and its payload. As they are meant to model bodies undergoing only small deformations a linear formulation is considered adequate for the task at hand. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | <span id='_Toc284943808'></span> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ==2 Problem Formulation== | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | <span id='_Toc284943809'></span> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ===2.1 Weak equilibrium statement=== | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | We start using the internal equilibrium statement for a continuum which relates the gradient of the stress field to the applied loads | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | {| | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

|- | |- | ||

| − | | | + | | |

| − | + | {| style="text-align: center; margin:auto;" | |

| − | | style="text-align: | + | |

| − | + | ||

| − | + | ||

| − | + | ||

|- | |- | ||

| − | | | + | | <span id='ZEqnNum878772'></span> <math>\begin{array}{c} |

| − | + | \sum_j\frac{\partial {\sigma }_{ij}}{\partial x_j}+b_i=0\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\forall \mbox{ }\mbox{ }\mbox{ }\boldsymbol{x}\in \Omega \mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }i=1,2,3\\ | |

| − | + | u_i={\overline{u}}_i(\boldsymbol{x})\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\forall \mbox{ }\mbox{ }\mbox{ }\boldsymbol{x}\in {\Gamma }_D\\ | |

| + | \sum_j{\sigma }_{ij}\cdot n_j={\overline{t}}_i(\boldsymbol{x})\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\forall \mbox{ }\mbox{ }\mbox{ }\boldsymbol{x}\in {\Gamma }_N\mbox{ }\mbox{ }\mbox{ }\mbox{ } | ||

| + | \end{array}</math> | ||

|} | |} | ||

| − | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.1) | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

|} | |} | ||

| − | |||

| − | {| | + | |

| + | were <math display="inline">{\overline{u}}_i</math> and <math display="inline">{\overline{t}}_i</math> stand for prescribed surface displacements and tractions. In the case of a dynamic problem the body forces (b<sub>i</sub>) include the inertial loads given by: | ||

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

|- | |- | ||

| − | | | + | | |

| − | + | {| style="text-align: center; margin:auto;" | |

| − | | style="text-align: | + | |

| − | + | ||

| − | + | ||

| − | + | ||

|- | |- | ||

| − | | | + | | <span id='ZEqnNum740733'></span> <math>{b_i\vert }_{inertial}=-\rho \frac{d^2u_i}{dt^2}</math> |

| − | | | + | |} |

| − | | style="text-align: right; | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.2) |

|} | |} | ||

| − | {| | + | |

| + | where ρ is the density of the solid. Note that the time derivative in <span id='cite-ZEqnNum740733'></span>[[#ZEqnNum740733|(2.2)]] is a total one, i.e. tracking the material particles. To obtain the Finite Element (FE) formulation of the problem we construct the weak formulation of <span id='cite-ZEqnNum878772'></span>[[#ZEqnNum878772|(2.1)]]. Let δu<sub>i</sub> be an arbitrary test function (representing in this case a virtual displacement field). We may thus write: | ||

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

|- | |- | ||

| − | | | + | | <span id='ZEqnNum272009'></span> <math>\begin{array}{c} |

| − | + | \left(\frac{\partial {\sigma }_{ij}}{\partial x_j}+b_i\right)\delta u_i=0\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\forall \mbox{ }\mbox{ }\mbox{ }\boldsymbol{x}\in \Omega \mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }i=1,2,3\\ | |

| − | | style="text-align: right; | + | \left(u_i-{\overline{u}}_i\right)\delta u_i=0\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\forall \mbox{ }\mbox{ }\mbox{ }\boldsymbol{x}\in {\Gamma }_D\\ |

| + | \left({\sigma }_{ij}\cdot n_j-{\overline{t}}_i\right)\delta u_i=0\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\forall \mbox{ }\mbox{ }\mbox{ }\boldsymbol{x}\in {\Gamma }_N | ||

| + | \end{array}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.3) | ||

|} | |} | ||

| − | {| | + | |

| + | Note that in <span id='cite-ZEqnNum272009'></span>[[#ZEqnNum272009|(2.3)]] implicit summation has been used in order to keep the notation compact. Now, the weighted average of the equations is taken over the relevant domains | ||

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

|- | |- | ||

| − | | | + | | <span id='ZEqnNum284786'></span> <math>\int_{\Omega }\left(\frac{\partial {\sigma }_{ij}}{\partial x_j}\delta u_i+\right. </math><math>\left. b_i\delta u_i\right)d\Omega +\int_{{\Gamma }_D}\left(u_i\delta u_i-\right. </math><math>\left. {\overline{u}}_i\delta u_i\right)d\Gamma +\int_{{\Gamma }_N}\left({\overline{t}}_i\delta u_i-\right. </math><math>\left. {\sigma }_{ij}\cdot n_j\delta u_i\right)d\Gamma =</math><math>0</math> |

| − | + | ||

| − | + | ||

|} | |} | ||

| − | + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.4) | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

|} | |} | ||

| − | |||

| − | < | + | |

| − | + | If <span id='cite-ZEqnNum284786'></span>[[#ZEqnNum284786|(2.4)]] holds for any virtual displacement field, the equation becomes equivalent to (2.5). To keep the expressions simple without loss of generality it is common practice to assume that the virtual displacement field is compatible with any existing prescribed displacement constraints. This way the integrals over Γ<sub>D</sub> can be dropped (i.e. <math>\delta u_i=0\mbox{ }\mbox{ }\forall \mbox{ }\mbox{ }\boldsymbol{x}\in {\Gamma }_D</math> ) but care must be taken to ensure that the solution is indeed compatible with the constraints. The term containing the internal stresses can be integrated by parts yielding | |

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

|- | |- | ||

| − | | style=" | + | | |

| − | | | + | {| style="text-align: center; margin:auto;" |

| − | | style="" | | + | |- |

| + | | <span id='ZEqnNum460769'></span> <math>\int_{\Omega }\left(-{\sigma }_{ij}\frac{\partial \delta u_i}{\partial x_j}+\right. </math><math>\left. b_i\delta u_i\right)d\Omega +\int_{{\Gamma }_N}{\overline{t}}_i\delta u_i\mbox{ }d\Gamma =</math><math>0</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.6) | ||

|} | |} | ||

| − | |||

| − | + | ||

| − | + | The deformation gradient can be split into a symmetric and an antisymmetric part: | |

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

|- | |- | ||

| − | | style=" | + | | |

| − | | | + | {| style="text-align: center; margin:auto;" |

| − | | style="" | | + | |- |

| + | | <span id='_GoBack'></span><span id='ZEqnNum154457'></span> <math>\frac{\partial \delta u_i}{\partial x_j}=\frac{1}{2}\left(\frac{\partial \delta u_i}{\partial x_j}+\right. </math><math>\left. \frac{\partial \delta u_j}{\partial x_i}\right)+</math><math>\frac{1}{2}\left(\frac{\partial \delta u_i}{\partial x_j}-\right. </math><math>\left. \frac{\partial \delta u_j}{\partial x_i}\right)=</math><math>\delta {\epsilon }_{ij}+\delta {\omega }_{ij}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.7) | ||

|} | |} | ||

| − | |||

| − | |||

| − | |||

| − | + | In the expression above ε<sub>ij</sub> represents the virtual strain field and ω<sub>ij</sub> is the virtual local rotation. Given that the stress tensor is symmetric the product <math>{\sigma }_{ij}{\omega }_{ij}</math> vanishes. Expression <span id='cite-ZEqnNum460769'></span>[[#ZEqnNum460769|(2.6)]] then becomes the virtual work principle | |

| − | : | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum471288'></span> <math>\sum_{i,j}\int_{\Omega }{\sigma }_{ij}\delta {\epsilon }_{ij}\mbox{ }d\Omega =</math><math>\sum_i\int_{\Omega }b_i\delta u_i\mbox{ }d\Omega +</math><math>\sum_i\int_{{\Gamma }_N}{\overline{t}}_i\delta u_i\mbox{ }d\Gamma </math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.8) | ||

| + | |} | ||

| − | |||

| − | + | Eq. <span id='cite-ZEqnNum471288'></span>[[#ZEqnNum471288|(2.8)]] states that when the system is in equilibrium the change in strain energy caused by an arbitrary virtual displacement field equals the work done by the external forces. | |

| − | + | <span id='_Toc284943810'></span> | |

| − | + | ===2.2 Finite element discretization=== | |

| − | + | To obtain the FE discretization we build an approximate solution interpolating the nodal values of the displacements <span id='cite-_Ref284617545'></span>[[#_Ref284617545|[8]]]. A virtual displacement field can be obtained in the same way | |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum836024'></span> <math>{\tilde{u}}_i(\boldsymbol{x})=N^k(\boldsymbol{x})\mbox{ }{\tilde{u}}_i^k\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\delta u_i(\boldsymbol{x})=</math><math>N^l(\boldsymbol{x})\mbox{ }\delta u_i^l</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.9) | ||

| + | |} | ||

| − | |||

| − | + | In <span id='cite-ZEqnNum836024'></span>[[#ZEqnNum836024|(2.9)]] <math display="inline">\tilde{u}</math> represents the approximate solution and N<sup>k</sup> is the interpolation function corresponding to the k<sup>th</sup> node (called a shape function). From now on supra-indexes will be used to indicate nodal values. The virtual strain field is a linear function of the virtual displacement field so it also a linear function of <math display="inline">\delta u_i^l</math> , it is possible therefore to write | |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\delta {\epsilon }_{ij}=A_{ij,m}^l\delta u_m^l\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }A_{ij,m}^l=</math><math>\frac{\partial {\epsilon }_{ij}}{\partial u_m^l}=L(N^l)</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.10) | ||

| + | |} | ||

| − | |||

| − | |||

| − | <span id=' | + | With the <math>A_{ij,k}^l</math> coefficients being linear functions of the shape function gradients. For a dynamic problem the inertial term <span id='cite-ZEqnNum740733'></span>[[#ZEqnNum740733|(2.2)]] is discretized as |

| − | + | ||

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum941837'></span> <math>{{\tilde{b}}_i\vert }_{inertial}=-\rho N^k\frac{d^2u_i^k}{dt^2}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.11) | ||

| + | |} | ||

| − | |||

| − | |||

| − | + | As the shape functions are not functions of time (their value does not change for a given material point) the time derivative in <span id='cite-ZEqnNum941837'></span>[[#ZEqnNum941837|(2.11)]] affects only the nodal displacements. Rearranging equation <span id='cite-ZEqnNum471288'></span>[[#ZEqnNum471288|(2.8)]] so only the inertial term remains on the LHS yields | |

| − | < | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| − | + | |- | |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\int_{\Omega }\rho N^k\frac{d^2u_i^k}{dt^2}N^l\delta u_i^l\mbox{ }d\Omega =</math><math>\int_{\Omega }b_iN^l\delta u_i^l\mbox{ }d\Omega +</math><math>\int_{{\Gamma }_N}{\overline{t}}_iN^l\delta u_i^l\mbox{ }d\Gamma -</math><math>\int_{\Omega }{\sigma }_{ij}A_{ij,m}^l\delta u_m^l\mbox{ }d\Omega </math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.12) | ||

| + | |} | ||

| − | |||

| − | + | As the virtual nodal displacements are arbitrary, it is possible to set all but one of them to zero. This way as many equations as degrees of freedom existing on the system are obtained. By setting | |

| − | + | ||

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math display="inline">\delta u_a^b=1\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ };\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\delta u_a^b=</math><math>1\mbox{ }\mbox{ }:\mbox{ }\mbox{ }i\not =a\mbox{ }\mbox{ },\mbox{ }\mbox{ }j\not =</math><math>b</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.13) | ||

| + | |} | ||

| − | |||

| − | |||

| − | + | The following set of equations is obtained: | |

| − | <span id=' | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| − | + | |- | |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum310531'></span><span id='_Toc284354663'></span> <math>\int_{\Omega }\rho N^bN^kd\Omega \frac{d^2u_a^k}{dt^2}=</math><math>\int_{\Omega }b_aN^bd\Omega +\int_{{\Gamma }_N}{\overline{t}}_aN^bd\Gamma -</math><math>\int_{\Omega }{\sigma }_{kj}A_{kj,a}^bd\Omega \mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\lbrace \begin{array}{c} | ||

| + | a=1,2,3\\ | ||

| + | b=1,...,n_{nod} | ||

| + | \end{array}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.14) | ||

| + | |} | ||

| − | |||

| − | + | In the equation above sum is assumed over ''j'' & ''k''. The equations can also be written in matrix form as | |

| − | + | ||

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='_Toc284354664'></span><span id='ZEqnNum930710'></span><span id='_Toc284354665'></span> <math>\boldsymbol{M\ddot{u}}=\boldsymbol{b}+\boldsymbol{t}-</math><math>\boldsymbol{I}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.15) | ||

| + | |} | ||

| − | |||

| − | |||

| − | + | '''M''' is called the mass matrix, '''b''' and '''t''' are the external nodal generalized forces and '''I''' is the internal force vector. If the mechanical response is linear the stress tensor can be written as a linear combination of the nodal displacements. The internal force vector can then be recast as | |

| − | <span id=' | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| − | ===2. | + | |- |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='_Toc284354666'></span><span id='_Toc284354667'></span> <math>\boldsymbol{I=Ku}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.16) | ||

| + | |} | ||

| − | |||

| − | <span id=' | + | <span id='_Toc284354668'></span>where '''K''' is the stiffness matrix of the system. Even if the behaviour of the structure is not truly linear, this may be useful as a linearization around some base state. |

| − | + | ||

| − | + | It is possible to solve for the acceleration in <span id='cite-ZEqnNum930710'></span>[[#ZEqnNum930710|(2.15)]] by inverting the mass matrix | |

| − | [ | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='_Toc284354669'></span><span id='ZEqnNum363786'></span> <math>\boldsymbol{\ddot{u}}=\boldsymbol{M}^{\boldsymbol{-1}}\left[\boldsymbol{b}+\right. </math><math>\left. \boldsymbol{t}-\boldsymbol{I}\right]</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.17) | ||

| + | |} | ||

| − | |||

| − | <span id=' | + | The system of ODEs <span id='cite-ZEqnNum363786'></span>[[#ZEqnNum363786|(2.17)]] together with the suitable initial conditions |

| − | [[ | + | |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum711586'></span> <math>\begin{array}{c} | ||

| + | {\boldsymbol{u}\vert }_{t=o}=\boldsymbol{u}_\boldsymbol{0}\\ | ||

| + | {\boldsymbol{\dot{u}}\vert }_{t=o}={\boldsymbol{\dot{u}}}_\boldsymbol{0} | ||

| + | \end{array}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.18) | ||

| + | |} | ||

| − | |||

| − | + | can be advanced in time to yield the displacement field at every instant. Solving for the acceleration term in <span id='cite-ZEqnNum363786'></span>[[#ZEqnNum363786|(2.17)]] requires inverting the mass matrix. To speed up the computations without significant loss of accuracy, the mass matrix is usually replaced by its lumped (diagonal) counterpart | |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>M_{ij}^d={\delta }_{ij}\sum_jM_{ij}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.19) | ||

| + | |} | ||

| − | |||

| − | < | + | In the expression above <math display="inline">{\delta }_{ij}</math> represents the Kronecker delta function (i.e. one when i=j and zero otherwise). |

| − | + | ||

| − | In the | + | In order to form the matrix and load vectors appearing in <span id='cite-ZEqnNum930710'></span>[[#ZEqnNum930710|(2.15)]] an element-by-element approach is used. As the shape function of node k is nonzero only inside elements containing said node, the integrals need only evaluated in the appropriate elements, for example: |

| − | <span id=' | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| − | + | |- | |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum184303'></span> <math>M_{ij}=\int_{\Omega }\rho N^iN^jd\Omega =\sum_{el}\int_{{\Omega }_{el}}\rho N^iN^jd\Omega \mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ }/\mbox{ }\mbox{ }\mbox{ }i,j\subset el</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.20) | ||

| + | |} | ||

| − | |||

| − | <span id=' | + | <span id='_Toc284943811'></span> |

| − | + | ||

| − | + | ===2.3 Time integration=== | |

| − | + | ||

| − | + | The integration of the system <span id='cite-ZEqnNum363786'></span>[[#ZEqnNum363786|(2.17)]] can be performed using both implicit and explicit schemes <span id='cite-_Ref284617109'></span>[[#_Ref284617109|[7]]]. For the reasons outlined previously, the explicit method has been chosen. The explicit second order central differencing scheme has been selected due to its high efficiency coupled with acceptable accuracy. Given a series of points in time and their corresponding time increments | |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| − | + | |- | |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\begin{array}{c} | ||

| + | t^{\left(0\right)}\mbox{ }\mbox{ }\mbox{ },\mbox{ }\mbox{ }\mbox{ }...\mbox{ }\mbox{ }\mbox{ },\mbox{ }\mbox{ }\mbox{ }t^{\left(i-1\right)}\mbox{ }\mbox{ }\mbox{ },\mbox{ }\mbox{ }\mbox{ }t^{\left(i\right)}\mbox{ }\mbox{ }\mbox{ },\mbox{ }\mbox{ }\mbox{ }t^{\left(i+1\right)}\mbox{ }\mbox{ }\mbox{ },\mbox{ }\mbox{ }\mbox{ }...\\ | ||

| + | ...\mbox{ }\mbox{ }\mbox{ },\mbox{ }\mbox{ }\mbox{ }\Delta t^{\left(i\right)}=t^{\left(i\right)}-t^{\left(i-1\right)}\mbox{ }\mbox{ }\mbox{ },\mbox{ }\mbox{ }\mbox{ }\Delta t^{\left(i+1\right)}=t^{\left(i+1\right)}-t^{\left(i\right)}\mbox{ }\mbox{ }\mbox{ },\mbox{ }\mbox{ }\mbox{ }... | ||

| + | \end{array}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.21) | ||

| + | |} | ||

| − | |||

| − | + | let us define the change in midpoint velocity as | |

| − | + | ||

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum535178'></span> <math>{\frac{d\boldsymbol{u}}{dt}}^{\left(i+\frac{1}{2}\right)}-</math><math>{\frac{d\boldsymbol{u}}{dt}}^{\left(i-\frac{1}{2}\right)}=</math><math>\frac{\Delta t^{\left(i+1\right)}+\Delta t^{\left(i\right)}}{2}\cdot \frac{d^2\boldsymbol{u}^{\left(i\right)}}{dt^2}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.22) | ||

| + | |} | ||

| − | |||

| − | + | Observe that in <span id='cite-ZEqnNum535178'></span>[[#ZEqnNum535178|(2.22)]] the accelerations and velocities are expressed at different instants. This scheme provides second order time-accuracy by virtue of using a centered approximation for the time derivative. Once the intermediate velocities have been computed, the displacements can be updated | |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum589584'></span> <math>\boldsymbol{u}^{\left(i+1\right)}=\boldsymbol{u}^{\left(i\right)}+</math><math>\Delta t^{\left(i+1\right)}\cdot \frac{d\boldsymbol{u}^{\left(i+\frac{1}{2}\right)}}{dt}=</math><math>\boldsymbol{u}^{\left(i\right)}+\Delta t^{\left(i+1\right)}\cdot \left[{\frac{d\boldsymbol{u}}{dt}}^{\left(i-\frac{1}{2}\right)}+\right. </math><math>\left. \frac{\Delta t^{\left(i+1\right)}+\Delta t^{\left(i\right)}}{2}\cdot \frac{d^2\boldsymbol{u}^{\left(i\right)}}{dt^2}\right]</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.23) | ||

| + | |} | ||

| − | |||

| − | |||

| − | <span id=' | + | This scheme is fully explicit in that sense that if <math>\boldsymbol{u}^{\left(i\right)}\mbox{ },\mbox{ }{\frac{d\boldsymbol{u}}{dt}}^{\left(i-\frac{1}{2}\right)}\mbox{ },\mbox{ }\frac{d^2\boldsymbol{u}^{\left(i\right)}}{dt^2}</math> are kwon, it is possible to compute the updated displacement and velocity without the need to solve any equations. That is, <span id='cite-ZEqnNum589584'></span>[[#ZEqnNum589584|(2.23)]] yields the new values without the need to solve any additional equation. Obviously the method is not self-starting, as at the initial time step the value of <math>{\frac{d\boldsymbol{u}}{dt}}^{\left(-\frac{1}{2}\right)}</math> is not known (the initial conditions <span id='cite-ZEqnNum711586'></span>[[#ZEqnNum711586|(2.18)]] are specified for i=0). To deal with this inconvenience we may use one sided differencing to estimate the velocity at i=+1/2 |

| − | + | ||

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>{\frac{d\boldsymbol{u}}{dt}}^{\left(+\frac{1}{2}\right)}=</math><math>{\frac{d\boldsymbol{u}}{dt}}^{\left(0\right)}+\frac{\Delta t^{\left(1\right)}}{2}\cdot \frac{d^2\boldsymbol{u}^{\left(0\right)}}{dt^2}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.24) | ||

| + | |} | ||

| − | |||

| − | + | Using this value together with <span id='cite-ZEqnNum535178'></span>[[#ZEqnNum535178|(2.22)]] gives | |

| − | < | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| − | + | |- | |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>{\frac{d\boldsymbol{u}}{dt}}^{\left(-\mbox{ }\frac{1}{2}\right)}=</math><math>{\frac{d\boldsymbol{u}}{dt}}^{\left(0\right)}-\frac{\Delta t^{\left(0\right)}}{2}\cdot \frac{d^2\boldsymbol{u}^{\left(0\right)}}{dt^2}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.25) | ||

| + | |} | ||

| − | |||

| − | < | + | Using this dummy velocity value the time integration can be started. Please remark that the choice of <math>\Delta t^{\left(0\right)}</math> has no effect on the final result. The method outlined has an extremely low computational cost per time step, however it shows a very important limitation. The explicit scheme is only conditionally stable meaning the time step cannot be made arbitrarily large lest the solution diverges. The maximum allowable time step is given by |

| − | + | ||

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum414904'></span> <math>\Delta t\leq \frac{2}{{\omega }_{max}}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.26) | ||

| + | |} | ||

| − | |||

| − | + | with ω<sub>max</sub> being the angular frequency of the highest eigenmode of the system. The expression <span id='cite-ZEqnNum414904'></span>[[#ZEqnNum414904|(2.26)]] is truly valid only for undamped systems. If damping is included in the model (it always is for practical reasons) then its effect can be accounted for trough | |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum328773'></span> <math>\Delta t\leq \frac{2}{{\omega }_{max}}\cdot \left(\sqrt{1+{\xi }^2}-\right. </math><math>\left. \xi \right)</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.27) | ||

| + | |} | ||

| − | |||

| − | <span id=' | + | In the expression above ξ is the damping ratio of the highest eigenmode. From <span id='cite-ZEqnNum328773'></span>[[#ZEqnNum328773|(2.27)]] it becomes obvious that damping can have a very detrimental effect on the stability limit. While <span id='cite-ZEqnNum328773'></span>[[#ZEqnNum328773|(2.27)]] provides a very good estimate of the allowable time step, it is not practical to calculate the highest eigenvalue of the system as this calls for solving a complex problem (the number of degrees of freedom in the model can be very large). Fortunately there is a simple upper bound estimate of ω<sub>max</sub> |

| − | [[ | + | |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>{\omega }_{max}\leq {\omega }_{max}^{elem}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.28) | ||

| + | |} | ||

| − | |||

| − | |||

| − | + | with <math>{\omega }_{max}^{elem}</math> being the highest elemental eigenfrequency in the model. The interaction with neightbouring elements always causes the highest system eigenmode to be slower than the highest isolated-element normal mode. Thus a conservative stability limit can be used in place of <span id='cite-ZEqnNum414904'></span>[[#ZEqnNum414904|(2.26)]] | |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\Delta t\leq \frac{2}{{\omega }_{max}^{elem}}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.29) | ||

| + | |} | ||

| − | |||

| − | |||

| − | |||

The maximum frequency is associated with dilatational modes. An alternative estimate of the maximum time step is given by the minimum transit time of the dilatational waves across the elements of the mesh: | The maximum frequency is associated with dilatational modes. An alternative estimate of the maximum time step is given by the minimum transit time of the dilatational waves across the elements of the mesh: | ||

| − | <span id='ZEqnNum805396'></span> | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| − | + | |- | |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum805396'></span> <math>\Delta t\leq min\left(\frac{L_e}{c_d}\right)</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.30) | ||

| + | |} | ||

| − | |||

| − | <span id=' | + | In <span id='cite-ZEqnNum805396'></span>[[#ZEqnNum805396|(2.30)]] L<sub>e</sub> is some characteristic element dimension and c<sub>d</sub> is the dilatational wave speed. For an isotropic linear elastic solid |

| − | [[ | + | |

| − | where | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum159868'></span> <math>\begin{array}{c} | ||

| + | c_d=\sqrt{\frac{\lambda +2\mu }{\rho }}\\ | ||

| + | \lambda =K-\frac{2}{3}G\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ };\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mu =G=\frac{E}{2(1+\nu )}\mbox{ }\mbox{ }\mbox{ }\mbox{ }\mbox{ };\mbox{ }\mbox{ }\mbox{ }\mbox{ }K=\frac{E}{3\left(1-2\nu \right)} | ||

| + | \end{array}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.31) | ||

| + | |} | ||

| + | |||

| + | |||

| + | where λ and μ are the Lamé constants which can be calculated from the shear modulus (G) and bulk modulus (K) as stated above. | ||

<span id='_Toc284943812'></span> | <span id='_Toc284943812'></span> | ||

| + | |||

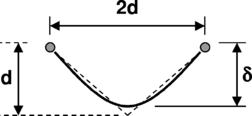

===2.4 Mass scaling=== | ===2.4 Mass scaling=== | ||

| − | If a poor quality mesh is used, some degenerate elements (i.e. having close to zero volume) might be present. These can be extremely detrimental to the performance of the algorithm as their associated characteristic lengths will be very small. Hence, the global stability limit given by <span id='cite-ZEqnNum805396'></span>[[#ZEqnNum805396|]] becomes extremely low, calling for a large number of time steps in order to finish the simulation. To overcome this problem the code includes a selective mass scaling options which introduces local changes in the element density in order to keep the stability limit within acceptable levels. For those elements where the value given by <span id='cite-ZEqnNum805396'></span>[[#ZEqnNum805396|]] is considered excessively small the density is artificially augmented in order to decrease the wave speed <span id='cite-ZEqnNum159868'></span>[[#ZEqnNum159868|]]. The user can select the maximum acceptable scatter in the elemental stability limits and the code (using the statistics for the complete model) automatically corrects the elements falling outside the established bounds. It must be stressed that the effect of the increased density on the global dynamic response is very small because the elements affected are only those with very small volumes. As the mass of these elements, even after scaling, is a negligible fraction of the total system mass the overall behaviour of the structure is almost unchanged (i.e. the inertial properties remain basically the same). In those cases where only the system’s static response in sought, mass scaling can be used in a more aggressive manner without altering the solution. | + | If a poor quality mesh is used, some degenerate elements (i.e. having close to zero volume) might be present. These can be extremely detrimental to the performance of the algorithm as their associated characteristic lengths will be very small. Hence, the global stability limit given by <span id='cite-ZEqnNum805396'></span>[[#ZEqnNum805396|(2.30)]] becomes extremely low, calling for a large number of time steps in order to finish the simulation. To overcome this problem the code includes a selective mass scaling options which introduces local changes in the element density in order to keep the stability limit within acceptable levels. For those elements where the value given by <span id='cite-ZEqnNum805396'></span>[[#ZEqnNum805396|(2.30)]] is considered excessively small the density is artificially augmented in order to decrease the wave speed <span id='cite-ZEqnNum159868'></span>[[#ZEqnNum159868|(2.31)]]. The user can select the maximum acceptable scatter in the elemental stability limits and the code (using the statistics for the complete model) automatically corrects the elements falling outside the established bounds. It must be stressed that the effect of the increased density on the global dynamic response is very small because the elements affected are only those with very small volumes. As the mass of these elements, even after scaling, is a negligible fraction of the total system mass the overall behaviour of the structure is almost unchanged (i.e. the inertial properties remain basically the same). In those cases where only the system’s static response in sought, mass scaling can be used in a more aggressive manner without altering the solution. |

<span id='_Toc284943813'></span> | <span id='_Toc284943813'></span> | ||

| + | |||

==3 Numerical damping== | ==3 Numerical damping== | ||

To achieve a smooth solution it is always needed to introduce some amount of damping into the numerical model. In a real structure different types of damping are always present (e.g. material, aerodynamic, etc…) so the observed behaviour is usually smooth. On the other hand, the dissipation provided by the basic explicit algorithm is really small. This is a problem when a steady state solution is sought but is also undesirable when simulating transient events as high frequency noise can contaminate the solution. To allow greater flexibility controlling the solution process two forms of user-adjustable damping are provided; Rayleigh damping and bulk viscosity. In the first case a damping matrix is built from the mass and stiffness matrices: | To achieve a smooth solution it is always needed to introduce some amount of damping into the numerical model. In a real structure different types of damping are always present (e.g. material, aerodynamic, etc…) so the observed behaviour is usually smooth. On the other hand, the dissipation provided by the basic explicit algorithm is really small. This is a problem when a steady state solution is sought but is also undesirable when simulating transient events as high frequency noise can contaminate the solution. To allow greater flexibility controlling the solution process two forms of user-adjustable damping are provided; Rayleigh damping and bulk viscosity. In the first case a damping matrix is built from the mass and stiffness matrices: | ||

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\boldsymbol{C}=\alpha \boldsymbol{M}+\beta \boldsymbol{K}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.1) | ||

| + | |} | ||

| − | |||

| − | [[ | + | The equation system <span id='cite-ZEqnNum930710'></span>[[#ZEqnNum930710|(2.15)]] supplemented with this damping term becoming |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\boldsymbol{M\ddot{u}}=\boldsymbol{b}+\boldsymbol{t}-</math><math>\boldsymbol{I}-\boldsymbol{C\dot{u}}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.2) | ||

| + | |} | ||

| − | |||

| − | |||

| − | From <span id='cite-ZEqnNum979336'></span>[[#ZEqnNum979336|]] it is apparent that the | + | The α term creates a damping force which is proportional to the absolute velocity of the nodes. This is roughly equivalent to having the nodes of the structure move trough a viscous fluid. The damping ratio introduced by the mass proportional damping term on a mode of frequency ω is |

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum979336'></span> <math>\xi =\frac{\alpha }{2\omega }</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.3) | ||

| + | |} | ||

| + | |||

| + | |||

| + | From <span id='cite-ZEqnNum979336'></span>[[#ZEqnNum979336|(3.3)]] it is apparent that the α term affects mainly the low frequency components of the solution. It can be useful to accelerate convergence to a static solution when only the long-term response is sought. However, when the transient response must be accurately determined this factor should not be included (or at least the α parameter must be chosen in order to ensure the damping ratio for the lowest mode is very small). The β term on the other hand introduces forces that are proportional to the material strain rate. An extra stress '''σ<sub>d</sub>''' is added to the constitutive law | ||

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>{\boldsymbol{\sigma }}_\boldsymbol{d}=\beta \boldsymbol{D}^{\boldsymbol{el}}\boldsymbol{:\dot{\epsilon }}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.4) | ||

| + | |} | ||

| − | |||

with '''D<sup>e</sup>'''<sup>l</sup> being the tangent stiffness tensor of the material. The fraction of critical damping for a given mode is: | with '''D<sup>e</sup>'''<sup>l</sup> being the tangent stiffness tensor of the material. The fraction of critical damping for a given mode is: | ||

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\xi =\frac{\beta \mbox{ }\omega }{2}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.5) | ||

| + | |} | ||

| − | In this case only the high order modes are affected appreciably. This is desirable as it prevents high frequency noise from propagating while leaving the low order response (which is usually the part sought) almost unchanged. The | + | |

| + | In this case only the high order modes are affected appreciably. This is desirable as it prevents high frequency noise from propagating while leaving the low order response (which is usually the part sought) almost unchanged. The β parameter however must be used sparingly, as it has a very detrimental effect on the stability limit (because its effect is greatest for the highest eigenmode of the system). | ||

An additional form of damping is included to prevent high frequency “ringing”. This is caused by excitation of element dilatational modes which are always associated with the highest eigenvalues of the system. An additional hydrostatic stress is included in the constitutive routines which is proportional to the volumetric strain rate. This volumetric viscous stress is given by | An additional form of damping is included to prevent high frequency “ringing”. This is caused by excitation of element dilatational modes which are always associated with the highest eigenvalues of the system. An additional hydrostatic stress is included in the constitutive routines which is proportional to the volumetric strain rate. This volumetric viscous stress is given by | ||

| − | <span id='ZEqnNum431138'></span> | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| − | + | |- | |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum431138'></span> <math>{\sigma }_h=b_1\mbox{ }\rho \mbox{ }c_d\mbox{ }L_e\mbox{ }{\dot{\epsilon }}_{vol}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.6) | ||

| + | |} | ||

| + | |||

In the expression above b<sub>1</sub> is the desired damping ratio for the dilatational mode. A suitable value is b<sub>1</sub>=0,06. | In the expression above b<sub>1</sub> is the desired damping ratio for the dilatational mode. A suitable value is b<sub>1</sub>=0,06. | ||

<span id='_Toc284943814'></span> | <span id='_Toc284943814'></span> | ||

| + | |||

==4 Element formulation== | ==4 Element formulation== | ||

| Line 426: | Line 562: | ||

<span id='_Toc284943815'></span> | <span id='_Toc284943815'></span> | ||

| + | |||

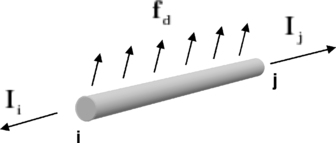

===4.1 Two-node linear cable element=== | ===4.1 Two-node linear cable element=== | ||

| Line 431: | Line 568: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:draft_Samper_793606474-image49.png|336px]] </div> | ||

| − | + | <div id="_Ref256696030" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | |

| − | </div> | + | <span style="text-align: center; font-size: 75%;">'''Fig. 1''' – Linear cable element internal and external loads</span></div> |

| − | |||

| − | |||

| − | |||

| − | An external distributed loading per unit length | + | An external distributed loading per unit length <math display="inline">\boldsymbol{f}_\boldsymbol{d}</math> acts on the element whose cross sectional area will be denoted by A. As we shall be facing a large displacement problem, the position of the nodes can be written either on the undeformed (reference) configuration or in the deformed (current) configuration. From now on we shall use upper-case letters to denote the original coordinates while lower-case will be reserved for the current configuration. For example, the original length of the cable element is given by |

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum657209'></span> <math>L_0=\Vert \boldsymbol{X}_\boldsymbol{j}-\boldsymbol{X}_i\Vert </math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.1) | ||

| + | |} | ||

| − | |||

| − | |||

while the actual length at any given time is | while the actual length at any given time is | ||

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>L(t)=\Vert \boldsymbol{x}_\boldsymbol{j}-\boldsymbol{x}_\boldsymbol{i}\Vert </math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.2) | ||

| + | |} | ||

| + | |||

The unit vector along the element is | The unit vector along the element is | ||

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\boldsymbol{e}_\boldsymbol{l}=\frac{\boldsymbol{x}_\boldsymbol{j}-\boldsymbol{x}_\boldsymbol{i}}{\Vert \boldsymbol{x}_\boldsymbol{j}-\boldsymbol{x}_\boldsymbol{i}\Vert }</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.3) | ||

| + | |} | ||

| + | |||

From the change in length of the element the axial strain and stress can be obtained. Assuming linear elastic behaviour: | From the change in length of the element the axial strain and stress can be obtained. Assuming linear elastic behaviour: | ||

| − | <span id='ZEqnNum376275'></span> | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| − | + | |- | |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum376275'></span> <math>\epsilon =\frac{L-L_0}{L_0}\mbox{ }\mbox{ }\mbox{ }\mbox{ };\mbox{ }\mbox{ }\mbox{ }\mbox{ }\sigma =</math><math>max(0\mbox{ },\mbox{ }E\epsilon )</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.4) | ||

| + | |} | ||

| − | |||

| − | <span id=' | + | As we assume the cables buckle instantly under compressive loads, there is a lower bound on the allowable stresses. Therefore in <span id='cite-ZEqnNum376275'></span>[[#ZEqnNum376275|(4.4)]] a minimum stress value of zero is enforced. Using this result the internal forces at the nodes become: |

| − | [[ | + | |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum666516'></span> <math>\boldsymbol{I}_\boldsymbol{i}=-\sigma A\boldsymbol{e}_\boldsymbol{l}\mbox{ }\mbox{ }\mbox{ }\mbox{ };\mbox{ }\mbox{ }\mbox{ }\mbox{ }\boldsymbol{I}_\boldsymbol{j}=</math><math>+\sigma A\boldsymbol{e}_\boldsymbol{l}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.5) | ||

| + | |} | ||

| − | |||

| − | + | The nodal generalized external force due to the distributed loading is calculated as indicated in <span id='cite-ZEqnNum310531'></span>[[#ZEqnNum310531|(2.14)]]. If the load <math display="inline">\boldsymbol{f}_\boldsymbol{d}</math> is constant across the element it reduces to: | |

| − | < | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| − | + | |- | |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\boldsymbol{b}_\boldsymbol{i}=\int_0^LN_i\boldsymbol{f}_\boldsymbol{d}dL=</math><math>\frac{L}{2}\boldsymbol{f}_\boldsymbol{d}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.6) | ||

| + | |} | ||

| − | |||

| − | < | + | When numerical damping is included the stress term in <span id='cite-ZEqnNum376275'></span>[[#ZEqnNum376275|(4.4)]] is augmented with the viscous contributions |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| − | </ | + | |- |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum568137'></span> <math>\frac{d\epsilon }{dt}=\frac{({\boldsymbol{\dot{x}}}_\boldsymbol{j}-{\boldsymbol{\dot{x}}}_\boldsymbol{i})\cdot \boldsymbol{e}_\boldsymbol{1}}{L_0}\mbox{ }\mbox{ }\mbox{ }\mbox{ };\mbox{ }\mbox{ }\mbox{ }\mbox{ }\sigma =</math><math>E\left(max(0\mbox{ },\mbox{ }\epsilon )+\beta \dot{\epsilon }\right)+</math><math>b\mbox{ }\rho \mbox{ }c_d\mbox{ }L_0\mbox{ }\dot{\epsilon }</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.7) | ||

| + | |} | ||

| + | |||

| + | |||

| + | Note that in <span id='cite-ZEqnNum568137'></span>[[#ZEqnNum568137|(4.7)]] the bulk viscosity term is slightly modified as it includes the axial strain rate instead of the volumetric strain rate. While using equations <span id='cite-ZEqnNum657209'></span>[[#ZEqnNum657209|(4.1)]]-<span id='cite-ZEqnNum568137'></span>[[#ZEqnNum568137|(4.7)]] is the most efficient way to calculate the internal forces for the element in a large displacement problem, it is also useful to have a closed expression for the elemental stiffness matrix (if the Rayleigh damping matrix is needed for example). This is specially simple if a local reference frame aligned with the element is chosen: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <span style="text-align: center; font-size: 75%;">'''Fig. 2 – Cable local reference frame | + | [[Image:draft_Samper_793606474-image58.png|210px]] </div> |

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | <span style="text-align: center; font-size: 75%;">'''Fig. 2''' – Cable local reference frame</span></div> | ||

| + | |||

For a virtual displacement of the end nodes we can calculate the change in length and in stress as | For a virtual displacement of the end nodes we can calculate the change in length and in stress as | ||

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\delta L=\delta u_{\zeta }^j-\delta u_{\zeta }^j\mbox{ }\mbox{ }\mbox{ }\Rightarrow \mbox{ }\mbox{ }\mbox{ }\delta \sigma =</math><math>\frac{E}{L_0}\left(\delta u_{\zeta }^j-\delta u_{\zeta }^j\right)</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.8) | ||

| + | |} | ||

| + | |||

Thus, the element stiffness matrix in the local coordinate system is given by | Thus, the element stiffness matrix in the local coordinate system is given by | ||

| − | [ | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\boldsymbol{K}=\frac{EA}{L_0}\left[\begin{array}{cc} | ||

| + | 1 & -1\\ | ||

| + | -1 & 1 | ||

| + | \end{array}\right]</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.9) | ||

| + | |} | ||

| − | |||

| − | <span id=' | + | Of course, the stiffness matrix is taken as zero whenever compressive strains exist in the element. The mass matrix can be obtained using <span id='cite-ZEqnNum184303'></span>[[#ZEqnNum184303|(2.20)]] and the expressions of the shape functions in the local reference frame |

| − | [[ | + | |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum748831'></span> <math>\begin{array}{c} | ||

| + | N^i=1-\frac{\xi }{L}\mbox{ }\mbox{ }\mbox{ }\mbox{ };\mbox{ }\mbox{ }\mbox{ }\mbox{ }N^j=\frac{\xi }{L}\\ | ||

| + | \boldsymbol{M}=\rho AL\left[\begin{array}{cc} | ||

| + | \frac{1}{3} & \frac{1}{6}\\ | ||

| + | \frac{1}{6} & \frac{1}{3} | ||

| + | \end{array}\right] | ||

| + | \end{array}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.10) | ||

| + | |} | ||

| − | |||

| − | The element characteristic size used to estimate the allowable time step <span id='cite-ZEqnNum805396'></span>[[#ZEqnNum805396|]] for the case of a simple cable element is taken as ''L<sub>0</sub>'' (the cable reference length). Note that it is not necessary to consider the possibility of smaller values as a cable under compression shows no stiffness and therefore has a vanishing elastic wave speed. Due to the one-dimensional character of the problem, the dilatational wave speed can be safely replaced with the longitudinal wave speed | + | As previously stated, the diagonal form of the mass matrix is usually preferred, thus <span id='cite-ZEqnNum748831'></span>[[#ZEqnNum748831|(4.10)]] is replaced with: |

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\boldsymbol{M}^\boldsymbol{d}=\frac{\rho AL}{2}\left[\begin{array}{cc} | ||

| + | 1 & 0\\ | ||

| + | 0 & 1 | ||

| + | \end{array}\right]</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.11) | ||

| + | |} | ||

| + | |||

| + | |||

| + | The element characteristic size used to estimate the allowable time step <span id='cite-ZEqnNum805396'></span>[[#ZEqnNum805396|(2.30)]] for the case of a simple cable element is taken as ''L<sub>0</sub>'' (the cable reference length). Note that it is not necessary to consider the possibility of smaller values as a cable under compression shows no stiffness and therefore has a vanishing elastic wave speed. Due to the one-dimensional character of the problem, the dilatational wave speed can be safely replaced with the longitudinal wave speed | ||

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='OLE_LINK1'></span><span id='OLE_LINK2'></span> <math>c_l=\sqrt{\frac{E}{\rho }}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.12) | ||

| + | |} | ||

| − | |||

| − | |||

<span id='_Toc284943816'></span> | <span id='_Toc284943816'></span> | ||

| + | |||

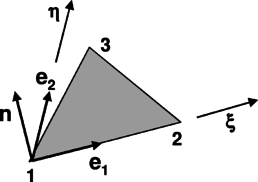

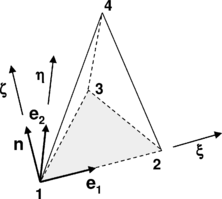

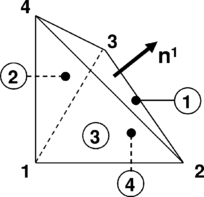

===4.2 Three-node linear membrane element=== | ===4.2 Three-node linear membrane element=== | ||

| Line 509: | Line 758: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | + | [[Image:draft_Samper_793606474-image64.png|258px]] </div> | |

| − | [[Image:draft_Samper_793606474-image64.png| | + | |

| − | </div> | + | |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <span style="text-align: center; font-size: 75%;">'''Fig. 3 – Triangle local reference frame | + | <span style="text-align: center; font-size: 75%;">'''Fig. 3''' – Triangle local reference frame</span></div> |

| + | |||

The three unit vectors along the local axes are obtained from | The three unit vectors along the local axes are obtained from | ||

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\boldsymbol{e}_\boldsymbol{1}=\frac{\boldsymbol{x}^{2}{-}\boldsymbol{x}^{1}}{\Vert \boldsymbol{x}^{2}{-}\boldsymbol{x}^{1}\Vert }~;~\boldsymbol{n}=\frac{\boldsymbol{e}_{1}\times (\boldsymbol{x}^3{-}\boldsymbol{x}^{1})}{\Vert \boldsymbol{e}_{1}\times (\boldsymbol{x}^3{-}\boldsymbol{x}^{1})\Vert }\mbox{ };\mbox{ }\boldsymbol{e}_{2}=\boldsymbol{n}\times \boldsymbol{e}_{1}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.13) | ||

| + | |} | ||

| − | |||

| − | + | Any point of the triangle can now be identified by its two local coordinates (ξ,η) | |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>(\xi ,\eta )=\left((\boldsymbol{x-}\boldsymbol{x}^{1})\cdot \boldsymbol{e}_{1},(\boldsymbol{x}-\boldsymbol{x}^{1})\cdot \boldsymbol{e}_{2}\right)</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.14) | ||

| + | |} | ||

| − | |||

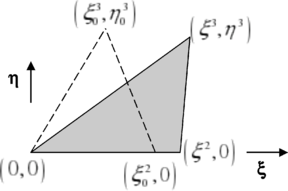

| − | + | As a linear triangle always remains flat, the problem is greatly simplified by analysing the stress state on the ξ-η plane. | |

| − | + | ||

| − | |||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <span style="text-align: center; font-size: 75%;">'''Fig. 4 – Nodal coordinates in the local triangle reference frame | + | [[Image:draft_Samper_793606474-image67.png|288px]] </div> |

| + | |||

| + | <div id="_Ref256699627" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | <span style="text-align: center; font-size: 75%;">'''Fig. 4''' – Nodal coordinates in the local triangle reference frame</span></div> | ||

| + | |||

It is worth mentioning that the strain state of the triangle depends only on three parameters, as some of the nodal coordinates vanish in the corrotational reference frame (<span id='cite-_Ref256699627'></span>[[#_Ref256699627|Fig. 4]]). In <span id='cite-_Ref256699627'></span>[[#_Ref256699627|Fig. 4]] the original (undeformed) geometry has been denoted with the subindex 0. The material strain is obtained from the interpolated displacement field | It is worth mentioning that the strain state of the triangle depends only on three parameters, as some of the nodal coordinates vanish in the corrotational reference frame (<span id='cite-_Ref256699627'></span>[[#_Ref256699627|Fig. 4]]). In <span id='cite-_Ref256699627'></span>[[#_Ref256699627|Fig. 4]] the original (undeformed) geometry has been denoted with the subindex 0. The material strain is obtained from the interpolated displacement field | ||

| − | <span id='ZEqnNum806260'></span> | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| − | + | |- | |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum806260'></span> <math>(u_{\xi },u_{\eta })=\sum_{j=2}^3N^j(u_{\xi }^j,u_{\eta }^j)</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.15) | ||

| + | |} | ||

| − | |||

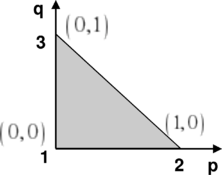

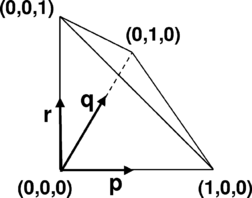

| − | < | + | Note that in <span id='cite-ZEqnNum806260'></span>[[#ZEqnNum806260|(4.15)]] node 1 has been excluded from the sum as it is fixed at the origin of the local reference system. To calculate the strain the gradients of the shape functions must be known. While it is possible to obtain a closed expression for the shape functions of an arbitrary triangle it is somewhat simpler to operate on a “canonical” element shape where the functions have a simpler form. To this effect we use an additional transformed coordinate system (p-q) |

| − | [[Image:draft_Samper_793606474-image69.png| | + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> |

| − | </div> | + | [[Image:draft_Samper_793606474-image69.png|222px]] </div> |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <span style="text-align: center; font-size: 75%;">'''Fig. 5 - Transformed coordinate system | + | <span style="text-align: center; font-size: 75%;">'''Fig. 5''' - Transformed coordinate system</span></div> |

| + | |||

The shape functions now become: | The shape functions now become: | ||

| − | <span id='ZEqnNum463081'></span> | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| − | + | |- | |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum463081'></span> <math>N^1=1-p-q\mbox{ }\mbox{ }\mbox{ }\mbox{ };\mbox{ }\mbox{ }\mbox{ }\mbox{ }N^2=</math><math>p\mbox{ }\mbox{ }\mbox{ }\mbox{ };\mbox{ }\mbox{ }\mbox{ }\mbox{ }N^3=</math><math>q</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.16) | ||

| + | |} | ||

| − | |||

| − | <span id='ZEqnNum435267'></span> | + | The transform from the p-q plane to the <math display="inline">\xi - \eta </math>; system is given by the isoparametric transform |

| − | + | ||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum435267'></span> <math>(\xi ,\eta )=\sum_{j=2}^3({\xi }^j,{\eta }^j)N^j</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.17) | ||

| + | |} | ||

| + | |||

The gradients of the shape functions can be recovered from | The gradients of the shape functions can be recovered from | ||

| − | <span id='ZEqnNum521193'></span> | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| − | [[ | + | |- |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum521193'></span> <math>\left[\begin{array}{c} | ||

| + | \frac{\partial N^i}{\partial p}\\ | ||

| + | \frac{\partial N^i}{\partial q} | ||

| + | \end{array}\right]=\left[\begin{array}{cc} | ||

| + | \frac{\partial \xi }{\partial p} & \frac{\partial \eta }{\partial p}\\ | ||

| + | \frac{\partial \xi }{\partial q} & \frac{\partial \eta }{\partial q} | ||

| + | \end{array}\right]\left[\begin{array}{c} | ||

| + | \frac{\partial N^i}{\partial \xi }\\ | ||

| + | \frac{\partial N^i}{\partial \eta } | ||

| + | \end{array}\right]=\boldsymbol{J}\left[\begin{array}{c} | ||

| + | \frac{\partial N^i}{\partial \xi }\\ | ||

| + | \frac{\partial N^i}{\partial \eta } | ||

| + | \end{array}\right]</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.18) | ||

| + | |} | ||

| − | where '''J''' is the Jacobian of the isoparametric transform. Its value can be obtained from <span id='cite-ZEqnNum463081'></span>[[#ZEqnNum463081|]] & <span id='cite-ZEqnNum435267'></span>[[#ZEqnNum435267|]] and is constant across the element (due to its linear nature) | + | where '''J''' is the Jacobian of the isoparametric transform. Its value can be obtained from <span id='cite-ZEqnNum463081'></span>[[#ZEqnNum463081|(4.16)]] & <span id='cite-ZEqnNum435267'></span>[[#ZEqnNum435267|(4.17)]] and is constant across the element (due to its linear nature) |

| − | [ | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\boldsymbol{J}=\left[\begin{array}{cc} | ||

| + | {\xi }^2 & 0\\ | ||

| + | {\xi }^3 & {\eta }^3 | ||

| + | \end{array}\right]</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.19) | ||

| + | |} | ||

| − | |||

| − | [[ | + | Inverting the system <span id='cite-ZEqnNum521193'></span>[[#ZEqnNum521193|(4.18)]] yields the gradients sought |

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <math>\left[\begin{array}{c} \frac{\partial N^i}{\partial \xi }\\ \frac{\partial N^i}{\partial \eta } \end{array}\right]= {\bf J}^{-1} \left[\begin{array}{c} \frac{\partial N^i}{\partial p}\\ \frac{\partial N^i}{\partial q} \end{array}\right]= \frac{1}{\xi_2\eta_3}\left[\begin{array}{cc} | ||

| + | \eta_3 & 0\\ | ||

| + | -{\xi}_3 & {\xi }_2 | ||

| + | \end{array}\right] \left[\begin{array}{ccc} -1 & 1 & 1\\-1 & 0 & 1 \end{array}\right]= \frac{1}{\xi_2\eta_3}\left[\begin{array}{ccc}-{\eta }_3 & {\eta }_3 & 0\\{\xi }_3-{\xi }_2 & -{\xi }_3 & {\xi }_2\end{array}\right] | ||

| + | </math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.20) | ||

| + | |} | ||

| + | |||

The components of the strain tensor can now be determined easily | The components of the strain tensor can now be determined easily | ||

| − | <span id='ZEqnNum581759'></span> | + | {| class="formulaSCP" style="width: 100%; text-align: center;" |

| − | [ | + | |- |

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum581759'></span> <math>\left[\begin{array}{c} | ||

| + | {\epsilon }_{\xi }\\ | ||

| + | {\epsilon }_{\eta }\\ | ||

| + | {\gamma }_{\xi \eta } | ||

| + | \end{array}\right]=\left[\begin{array}{l} | ||

| + | \frac{\partial N^2}{\partial \xi }u_{\xi }^2\\ | ||

| + | \frac{\partial N^3}{\partial \eta }u_{\eta }^3\\ | ||

| + | \frac{\partial N^2}{\partial \eta }u_{\xi }^2+\frac{\partial N^3}{\partial \eta }u_{\xi }^3 | ||

| + | \end{array}\right]</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.21) | ||

| + | |} | ||

| − | |||

| − | <span id=' | + | Note that in <span id='cite-ZEqnNum581759'></span>[[#ZEqnNum581759|(4.21)]] the null terms have been dropped in order to achieve an efficient algorithm. The corresponding stresses are calculated assuming a plane stress state (an acceptable hypothesis for thin surface elements) and linear elastic isotropic behaviour. |

| − | [[ | + | |

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||

| + | |- | ||

| + | | <span id='ZEqnNum267232'></span> <math>\left[\begin{array}{c} | ||

| + | {\sigma }_{\xi }\\ | ||

| + | {\sigma }_{\eta }\\ | ||

| + | {\tau }_{\xi \eta } | ||

| + | \end{array}\right]=\frac{E}{1-{\nu }^2}\left[\begin{array}{c} | ||

| + | {\epsilon }_{\xi }+\nu {\epsilon }_{\eta }\\ | ||

| + | {\epsilon }_{\eta }+\nu {\epsilon }_{\xi }\\ | ||

| + | \frac{1-\nu }{2}{\gamma }_{\xi \eta } | ||

| + | \end{array}\right]</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.22) | ||

| + | |} | ||

| − | |||

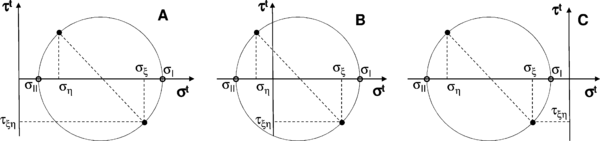

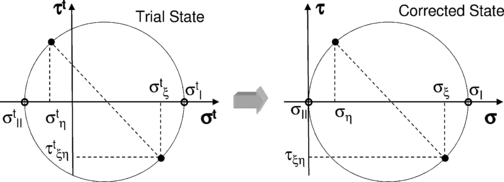

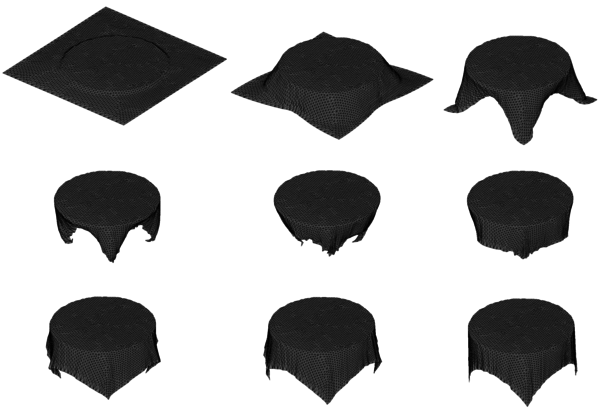

| − | + | As the membrane buckles under compressive loads, the stresses given by the expression above must be corrected to account for this fact. To this end we shall refer to <span id='cite-ZEqnNum267232'></span>[[#ZEqnNum267232|(4.22)]] as the trial stress state (σ<sup>t</sup>). Three different membrane states are considered <span id='cite-_Ref284690302'></span>[[#_Ref284690302|[10]]]: | |

| − | :* | + | :* Taut: The minimum principal trial stress is positive. No corrections are needed (<span id='cite-_Ref257199388'></span>[[#_Ref257199388|Fig. 6]]-A) |

| − | < | + | :* Wrinkled: Membrane is not taut, but the maximum principal strain is positive. Trial state is replaced with a uniaxial stress state (<span id='cite-_Ref257199388'></span>[[#_Ref257199388|Fig. 6]]-B) |

| − | + | :* Slack: The maximum principal strain is negative. The corrected stresses are zero (<span id='cite-_Ref257199388'></span>[[#_Ref257199388|Fig. 6]]-C) | |

| − | </ | + | |

| − | |||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <span style="text-align: center; font-size: 75%;">'''Fig. 6 – Trial membrane stress states - Taut (A) Wrinkled (B) and Slack (C) | + | [[Image:draft_Samper_793606474-image77.png|600px]] </div> |

| + | |||

| + | <div id="_Ref257199388" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | <span style="text-align: center; font-size: 75%;">'''Fig. 6''' – Trial membrane stress states - Taut (A) Wrinkled (B) and Slack (C)</span></div> | ||

| + | |||

To calculate the correct stress state the average in-plane direct strain and maximum shear strain are first found: | To calculate the correct stress state the average in-plane direct strain and maximum shear strain are first found: | ||

| − | + | {| class="formulaSCP" style="width: 100%; text-align: center;" | |

| + | |- | ||

| + | | | ||

| + | {| style="text-align: center; margin:auto;" | ||