m (Cinmemj moved page Draft Samper 795975371 to Cardoso et al 2019a) |

|||

| (12 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | |||

| − | |||

| − | |||

| − | |||

==Abstract== | ==Abstract== | ||

| Line 22: | Line 18: | ||

And last but not least, I want to thank to my beloved wife, Jimena, for all his support, tremendous patience and unconditional love since the beginning of this project, and to my Champion for teaching me every day how valuable is life. If angels exist, I already have a pair in my life. | And last but not least, I want to thank to my beloved wife, Jimena, for all his support, tremendous patience and unconditional love since the beginning of this project, and to my Champion for teaching me every day how valuable is life. If angels exist, I already have a pair in my life. | ||

| − | |||

=1 Introduction= | =1 Introduction= | ||

| Line 149: | Line 144: | ||

|} | |} | ||

| − | where <math display="inline">\delta _{ij}</math> is the Kronecker delta. This tensor is symmetric, <math display="inline">C_{ijkl} = C_{klij}</math> (major symmetry), <math display="inline">C_{ijkl} = C_{ijlk}</math> (minor symmetry), and positive definite. The equation [[#eq-2.5|2.5]] is equivalent to | + | where <math display="inline">\delta _{ij}</math> is the Kronecker delta. This tensor is symmetric, <math display="inline">C_{ijkl} = C_{klij}</math> (major symmetry), <math display="inline">C_{ijkl} = C_{ijlk}</math> (minor symmetry), and positive definite. The equation [[#eq-2.5|(2.5)]] is equivalent to |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 176: | Line 171: | ||

where <math display="inline">\mathbf{I}</math> is the identity matrix, defined <math display="inline">\mathbf{I}_{ij} = \delta _{ij}</math> in tensorial notation. | where <math display="inline">\mathbf{I}</math> is the identity matrix, defined <math display="inline">\mathbf{I}_{ij} = \delta _{ij}</math> in tensorial notation. | ||

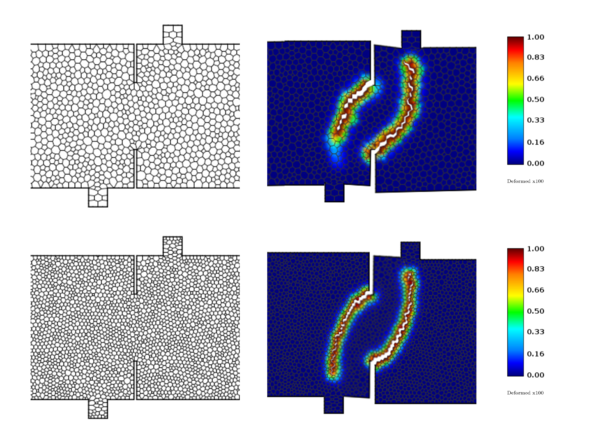

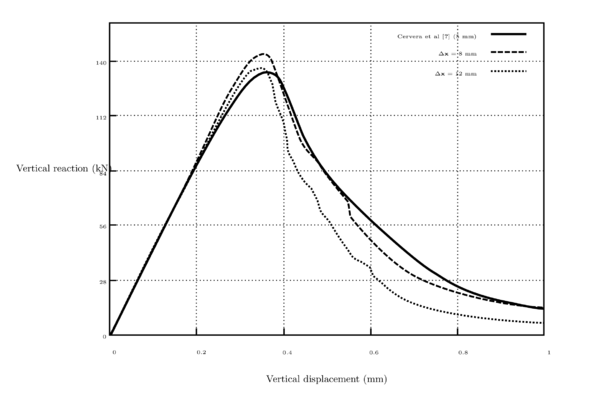

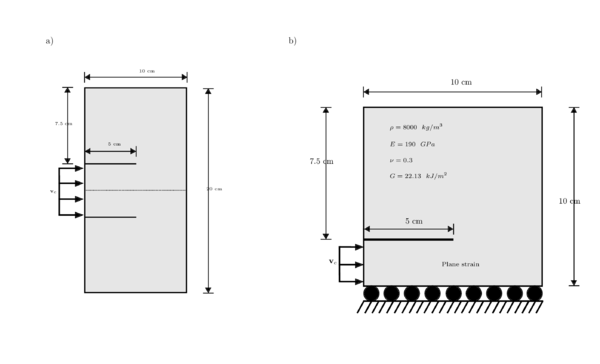

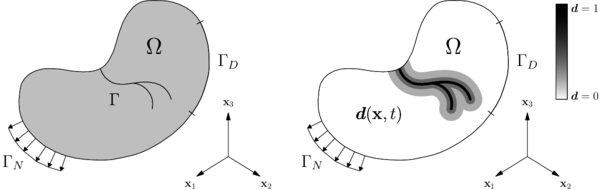

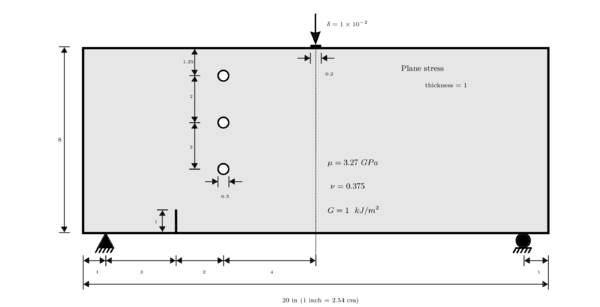

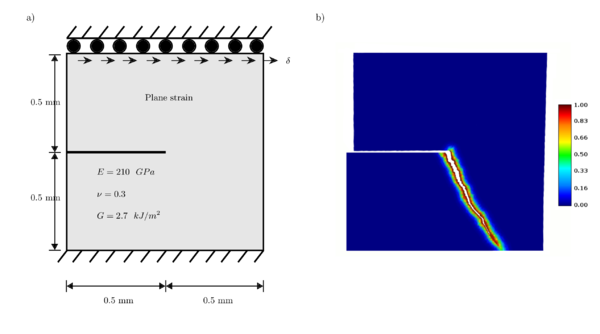

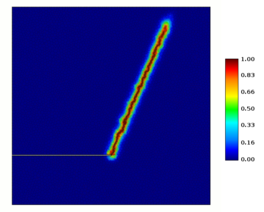

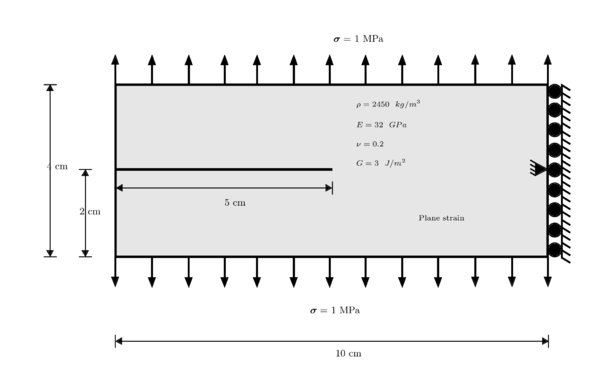

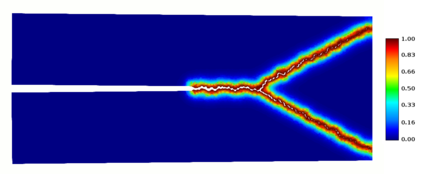

| − | To model the loss of stiffness and the rupture of the material we use the damage field, denoted <math display="inline">\boldsymbol{d}(\mathbf{x}, t)\in [0,1]</math>, which goes to one in the failure zones and it is equal to zero in the rest of the domain, as illustrated in | + | To model the loss of stiffness and the rupture of the material we use the damage field, denoted <math display="inline">\boldsymbol{d}(\mathbf{x}, t)\in [0,1]</math>, which goes to one in the failure zones and it is equal to zero in the rest of the domain, as illustrated in Figure [[#img-1|1]]. We redefine the elastic energy density, <math display="inline">\psi _e</math>, to consider the damage field effects <div id='img-1'></div> |

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| Line 238: | Line 233: | ||

|} | |} | ||

| − | with <math display="inline">\langle \lambda \rangle = \max (\lambda _i,0)</math>. The equation [[#eq-2.14|2.14]] implies | + | with <math display="inline">\langle \lambda \rangle = \max (\lambda _i,0)</math>. The equation [[#eq-2.14|(2.14)]] implies |

<span id="eq-2.15"></span> | <span id="eq-2.15"></span> | ||

| Line 251: | Line 246: | ||

|} | |} | ||

| − | Observe that if there is not damage, <math display="inline">\boldsymbol{d}= 0</math>, the energy density of the equation [[#eq-2.9|2.9]] is equivalent to the elastic energy density of the equation [[#eq-2.2|2.2]]. The energy contribution due to tension is obtained from | + | Observe that if there is not damage, <math display="inline">\boldsymbol{d}= 0</math>, the energy density of the equation [[#eq-2.9|(2.9)]] is equivalent to the elastic energy density of the equation [[#eq-2.2|(2.2)]]. The energy contribution due to tension is obtained from |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 263: | Line 258: | ||

|} | |} | ||

| − | using the equation [[#eq-2.15|2.15]], the contribution due to compression is given by | + | using the equation [[#eq-2.15|(2.15)]], the contribution due to compression is given by |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 275: | Line 270: | ||

|} | |} | ||

| − | The stress of equation [[#eq-2.5|2.5]] is now calculated as | + | The stress of equation [[#eq-2.5|(2.5)]] is now calculated as |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 314: | Line 309: | ||

From here, we are going to use the symbol <math display="inline">\boldsymbol{\sigma }^e</math> to refer the linear elastic stress. | From here, we are going to use the symbol <math display="inline">\boldsymbol{\sigma }^e</math> to refer the linear elastic stress. | ||

| − | Observe that for <math display="inline">\boldsymbol{d}= 0</math> the equation [[#eq-2.20|2.20]] is equal to [[#eq-2.8|2.8]], however for <math display="inline">\boldsymbol{d}= 1</math> we have only the compression contribution. | + | Observe that for <math display="inline">\boldsymbol{d}= 0</math> the equation [[#eq-2.20|(2.20)]] is equal to [[#eq-2.8|(2.8)]], however for <math display="inline">\boldsymbol{d}= 1</math> we have only the compression contribution. |

==2.2 Fracture mechanics== | ==2.2 Fracture mechanics== | ||

| Line 357: | Line 352: | ||

|} | |} | ||

| − | where <math display="inline">h</math> is a length scale parameter to control the smooth approximation of the crack. We take [[#eq-2.23|2.23]] as the Euler equation of the general form of the variational calculus problem | + | where <math display="inline">h</math> is a length scale parameter to control the smooth approximation of the crack. We take [[#eq-2.23|(2.23)]] as the Euler equation of the general form of the variational calculus problem |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 382: | Line 377: | ||

|} | |} | ||

| − | By substituting [[#eq-2.25|2.25]] into [[#eq-2.22|2.22]] we approximate the fracture energy without a priori knowledge of the fracture surface, <math display="inline">\Gamma </math>, with an integral over the entire domain, <math display="inline">\Omega </math>, | + | By substituting [[#eq-2.25|(2.25)]] into [[#eq-2.22|(2.22)]] we approximate the fracture energy without a priori knowledge of the fracture surface, <math display="inline">\Gamma </math>, with an integral over the entire domain, <math display="inline">\Omega </math>, |

<span id="eq-2.26"></span> | <span id="eq-2.26"></span> | ||

| Line 397: | Line 392: | ||

==2.3 Formulation of the equations of motion== | ==2.3 Formulation of the equations of motion== | ||

| − | Replacing [[#eq-2.26|2.26]] into [[#eq-2.21|2.21]] we get the potential energy using only integrals over the domain <math display="inline">\Omega </math>, | + | Replacing [[#eq-2.26|(2.26)]] into [[#eq-2.21|(2.21)]] we get the potential energy using only integrals over the domain <math display="inline">\Omega </math>, |

<span id="eq-2.27"></span> | <span id="eq-2.27"></span> | ||

| Line 523: | Line 518: | ||

where <math display="inline">\tau </math> is the dummy time variable. | where <math display="inline">\tau </math> is the dummy time variable. | ||

| − | Replacing the elastic energy density due to tension, <math display="inline">\psi _e^{+}</math>, by the strain history field, <math display="inline">{H}</math>, in [[#eq-2.33.b|2.33.b]] we get the system to be solved | + | Replacing the elastic energy density due to tension, <math display="inline">\psi _e^{+}</math>, by the strain history field, <math display="inline">{H}</math>, in [[#eq-2.33.b|(2.33.b)]] we get the system to be solved |

<span id="eq-2.36.a"></span> | <span id="eq-2.36.a"></span> | ||

| Line 607: | Line 602: | ||

|} | |} | ||

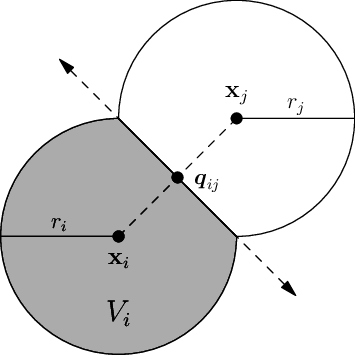

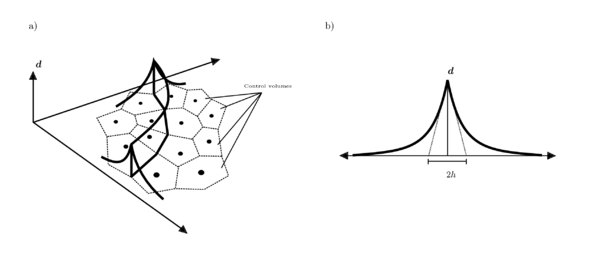

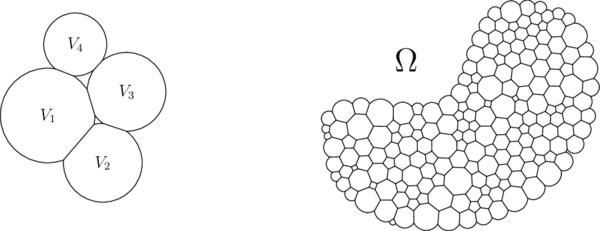

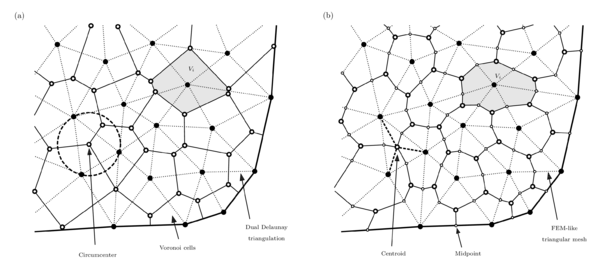

| − | + | Figure [[#img-2|2]] helps to visualize the discrete volume defined by the equation [[#eq-2.40|(2.40)]]. The left side of Figure [[#img-3|3]] illustrates the domain of the discrete volume <math display="inline">V_i</math> with respect to the remaining volumes <math display="inline">V_j</math>, and the right side shows the discrete volumes forming a continuum in the domain, <math display="inline">\Omega </math>. | |

<div id='img-2'></div> | <div id='img-2'></div> | ||

| Line 650: | Line 645: | ||

|} | |} | ||

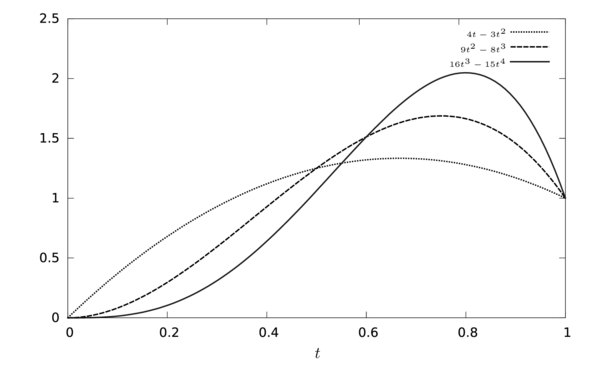

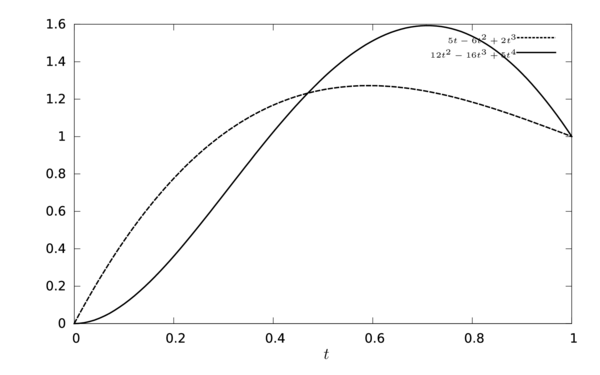

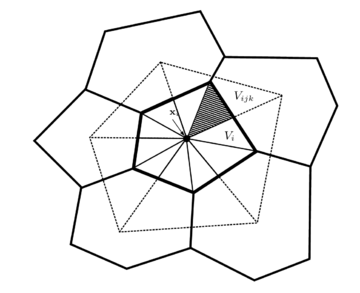

| − | + | Figure [[#img-4|4]] shows the density of <math display="inline">V_i</math> calculated from [[#eq-2.42|(2.42)]] for three cases. | |

<div id='img-4'></div> | <div id='img-4'></div> | ||

| Line 672: | Line 667: | ||

|} | |} | ||

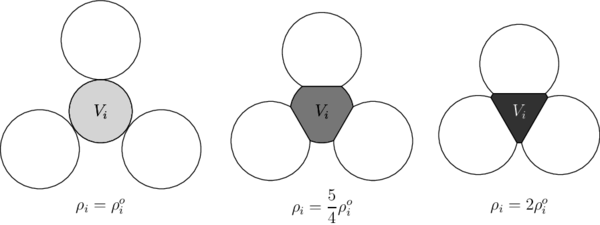

| − | We want to remark that the elastic energy is transferred from one volume to its neighbours through the shared faces and the size of such faces has a non-linear behaviour with respect to the distance between its adjacent centroids. Most of the methodologies dealing with discrete bodies, such as the Discrete Element Method, assumes that this behaviour is linear. | + | We want to remark that the elastic energy is transferred from one volume to its neighbours through the shared faces and the size of such faces has a non-linear behaviour with respect to the distance between its adjacent centroids. Most of the methodologies dealing with discrete bodies, such as the Discrete Element Method, assumes that this behaviour is linear. Figure [[#img-5|5]] shows the surface area of the face shared by two discrete volumes with the same radius as a function of the distance between their centroids. |

<div id='img-5'></div> | <div id='img-5'></div> | ||

| Line 716: | Line 711: | ||

|} | |} | ||

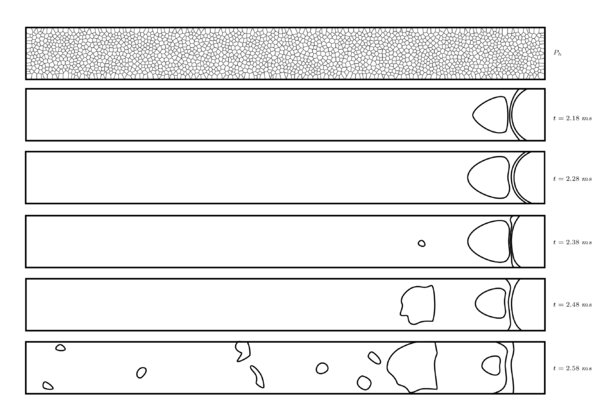

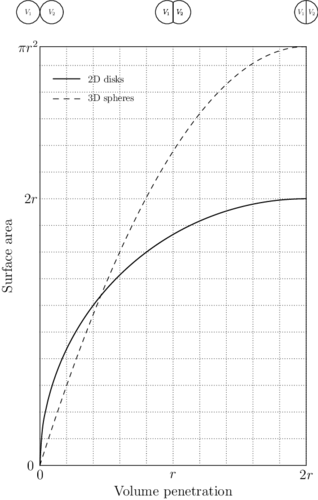

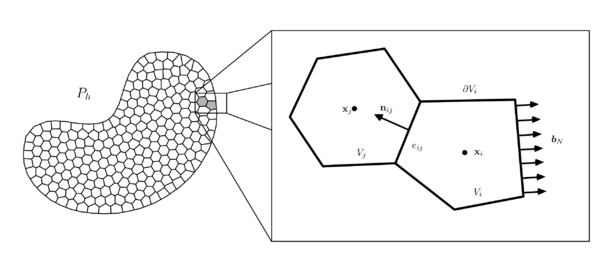

| − | + | Figure [[#img-6|6]] illustrates the partition <math display="inline">P_h</math> of <math display="inline">\Omega </math> into <math display="inline">N</math> control volumes defined in the equations [[#eq-3.1|(3.1)]] and [[#eq-3.2|(3.2)]]. <div id='img-6'></div> | |

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| Line 723: | Line 718: | ||

| colspan="1" | '''Figure 6:''' The partition <math>P_h</math> is the discretization of the domain <math>\Omega </math> into <math>N</math> control volumes. The boundary of the control volumes, <math>\partial V_i</math>, is conformed by <math>N_{i}</math> flat faces, denoted <math>e_{ij}</math>. The unit vector <math>\mathbf{n}_{ij}</math> is normal to the face <math>e_{ij}</math>. The faces of the volumes adjacent to the boundary <math>\Gamma _N</math> are integrated using the condition <math>\boldsymbol{b}_N</math>. | | colspan="1" | '''Figure 6:''' The partition <math>P_h</math> is the discretization of the domain <math>\Omega </math> into <math>N</math> control volumes. The boundary of the control volumes, <math>\partial V_i</math>, is conformed by <math>N_{i}</math> flat faces, denoted <math>e_{ij}</math>. The unit vector <math>\mathbf{n}_{ij}</math> is normal to the face <math>e_{ij}</math>. The faces of the volumes adjacent to the boundary <math>\Gamma _N</math> are integrated using the condition <math>\boldsymbol{b}_N</math>. | ||

|} | |} | ||

| − | + | ||

| + | |||

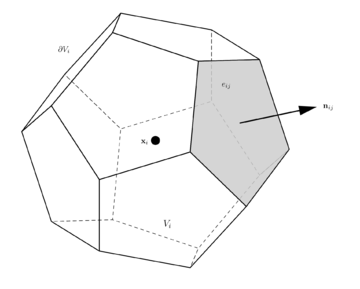

| + | Figure [[#img-7|7]] shows a three dimensional control volume. <div id='img-7'></div> | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| Line 759: | Line 756: | ||

==3.2 Control volumes integration== | ==3.2 Control volumes integration== | ||

| − | In this chapter we will focus our attention on the spatial discretization and numerical treatment of the stress term in first equation of motion[[#eq-2.36.a|2.36.a]], for simplicity assume <math display="inline">\ddot{\boldsymbol{u}}= 0</math>, later we will remove this assumption. | + | In this chapter we will focus our attention on the spatial discretization and numerical treatment of the stress term in first equation of motion [[#eq-2.36.a|(2.36.a)]], for simplicity assume <math display="inline">\ddot{\boldsymbol{u}}= 0</math>, later we will remove this assumption. |

We begin by integrating the stress divergence over the control volume | We begin by integrating the stress divergence over the control volume | ||

| Line 801: | Line 798: | ||

making use of a group of piece-wise polynomial interpolators, denoted <math display="inline">\varphi _q</math>. We are going to discuss these interpolators later in this section. | making use of a group of piece-wise polynomial interpolators, denoted <math display="inline">\varphi _q</math>. We are going to discuss these interpolators later in this section. | ||

| − | For that reason, the displacement field is decoupled from the stress tensor by using the strain [[#eq-2.1|2.1]] and stress [[#eq-2.8|2.8]] definitions. Taking advantage of the stress tensor symmetry <math display="inline">~\boldsymbol{\sigma }</math>, we rewrite the stress normal to the boundary as | + | For that reason, the displacement field is decoupled from the stress tensor by using the strain [[#eq-2.1|(2.1)]] and stress [[#eq-2.8|(2.8)]] definitions. Taking advantage of the stress tensor symmetry <math display="inline">~\boldsymbol{\sigma }</math>, we rewrite the stress normal to the boundary as |

<span id="eq-3.8"></span> | <span id="eq-3.8"></span> | ||

| Line 814: | Line 811: | ||

|} | |} | ||

| − | where <math display="inline">\mathbf{T}</math> is the face orientation matrix and <math display="inline">~\vec{\boldsymbol{\sigma }}</math> is the engineering stress vector. Developing the stress definition [[#eq-2.8|2.8]] component-wise we can decompose it into the constitutive matrix, denoted <math display="inline">\mathbf{D}</math>, and the engineering strain vector, denoted <math display="inline">\vec{\boldsymbol{\varepsilon }}</math>, as follows | + | where <math display="inline">\mathbf{T}</math> is the face orientation matrix and <math display="inline">~\vec{\boldsymbol{\sigma }}</math> is the engineering stress vector. Developing the stress definition [[#eq-2.8|(2.8)]] component-wise we can decompose it into the constitutive matrix, denoted <math display="inline">\mathbf{D}</math>, and the engineering strain vector, denoted <math display="inline">\vec{\boldsymbol{\varepsilon }}</math>, as follows |

<span id="eq-3.10"></span> | <span id="eq-3.10"></span> | ||

| Line 830: | Line 827: | ||

|} | |} | ||

| − | then the components of the strain vector are retrieved from the equation [[#eq-2.1|2.1]], and it is decomposed into the matrix differential operator <math display="inline">\mathbf{S}</math> and the displacement function <math display="inline">\boldsymbol{u}</math>. | + | then the components of the strain vector are retrieved from the equation [[#eq-2.1|(2.1)]], and it is decomposed into the matrix differential operator <math display="inline">\mathbf{S}</math> and the displacement function <math display="inline">\boldsymbol{u}</math>. |

<span id="eq-3.11"></span> | <span id="eq-3.11"></span> | ||

| Line 843: | Line 840: | ||

|} | |} | ||

| − | Summarizing the equations [[#eq-3.8|3.8]], [[#eq-3.10|3.10]] and [[#eq-3.11|3.11]] we have | + | Summarizing the equations [[#eq-3.8|(3.8)]], [[#eq-3.10|(3.10)]] and [[#eq-3.11|(3.11)]] we have |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 857: | Line 854: | ||

where <math display="inline">\mathbf{T}\mathbf{D}\mathbf{S}</math> is the stiffness of the volume boundary. | where <math display="inline">\mathbf{T}\mathbf{D}\mathbf{S}</math> is the stiffness of the volume boundary. | ||

| − | Once the displacement field is decoupled, we rewrite the equation [[#eq-3.6|3.6]] as | + | Once the displacement field is decoupled, we rewrite the equation [[#eq-3.6|(3.6)]] as |

<span id="eq-3.13"></span> | <span id="eq-3.13"></span> | ||

| Line 870: | Line 867: | ||

|} | |} | ||

| − | Using the fact that the control volume boundary is divided into flat faces, as in equation [[#eq-3.2|3.2]], we split the integral [[#eq-3.13|3.13]] into the sum of the flat faces integrals | + | Using the fact that the control volume boundary is divided into flat faces, as in equation [[#eq-3.2|(3.2)]], we split the integral [[#eq-3.13|(3.13)]] into the sum of the flat faces integrals |

<span id="eq-3.14"></span> | <span id="eq-3.14"></span> | ||

| Line 895: | Line 892: | ||

|} | |} | ||

| − | With <math display="inline">\mathbf{T}_{ij}</math> and <math display="inline">\mathbf{D}_{ij}</math> we simplify the equation [[#eq-3.14|3.14]] as | + | With <math display="inline">\mathbf{T}_{ij}</math> and <math display="inline">\mathbf{D}_{ij}</math> we simplify the equation [[#eq-3.14|(3.14)]] as |

<span id="eq-3.16"></span> | <span id="eq-3.16"></span> | ||

| Line 925: | Line 922: | ||

==3.3 Calculating face integrals== | ==3.3 Calculating face integrals== | ||

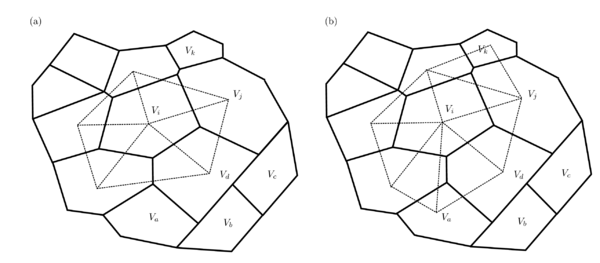

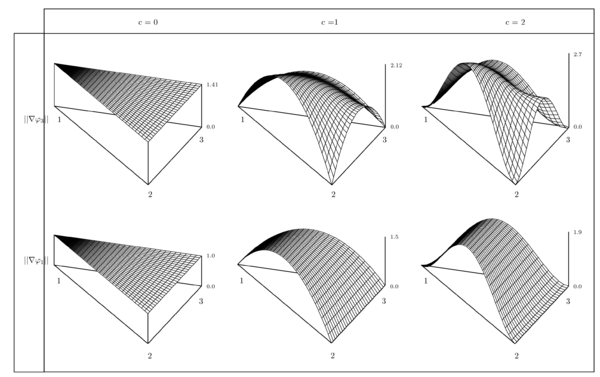

| − | The surface integrals <math display="inline">\mathbf{H}_{ij}</math> along the flat faces <math display="inline">e_{ij}</math> are calculated using an auxiliary piece-wise polynomial approximation of the displacement field. This approximation is based on the simplices (triangles in 2D or tetrahedra in 3D) resulting from the Delaunay triangulation of the calculation points <math display="inline">\mathbf{x}_i</math> from the neighborhood of <math display="inline">V_i</math>. The Delaunay triangulation is the best triangulation for numerical interpolation, since it maximizes the minimum angle of the simplices, which means that its quality is maximized as well. We define the neighborhood <math display="inline">{B}_i</math> of volume <math display="inline">V_i</math> as the minimum set of calculation points <math display="inline">\mathbf{x}_j</math> such that the simplices intersecting <math display="inline">V_i</math> does not change if we add another calculation point to the set. Observe that the neighborhood <math display="inline">{B}_i</math> does not always coincide with the set of calculation points in volumes adjacent to <math display="inline">V_i</math>, as in most of the FV formulations. Once the neighborhood <math display="inline">{B}_i</math> is triangulated, we ignore the simplices with angles smaller than <math display="inline">10</math> degrees, and the simplices formed outside the domain, which commonly appear in concavities of the boundary <math display="inline">\partial \Omega </math>. The local set of simplices resulting from the neighborhood of <math display="inline">V_i</math> is denoted <math display="inline">P_\alpha </math>. | + | The surface integrals <math display="inline">\mathbf{H}_{ij}</math> along the flat faces <math display="inline">e_{ij}</math> are calculated using an auxiliary piece-wise polynomial approximation of the displacement field. This approximation is based on the simplices (triangles in 2D or tetrahedra in 3D) resulting from the Delaunay triangulation of the calculation points <math display="inline">\mathbf{x}_i</math> from the neighborhood of <math display="inline">V_i</math>. The Delaunay triangulation is the best triangulation for numerical interpolation, since it maximizes the minimum angle of the simplices, which means that its quality is maximized as well. We define the neighborhood <math display="inline">{B}_i</math> of volume <math display="inline">V_i</math> as the minimum set of calculation points <math display="inline">\mathbf{x}_j</math> such that the simplices intersecting <math display="inline">V_i</math> does not change if we add another calculation point to the set. Observe that the neighborhood <math display="inline">{B}_i</math> does not always coincide with the set of calculation points in volumes adjacent to <math display="inline">V_i</math>, as in most of the FV formulations. Once the neighborhood <math display="inline">{B}_i</math> is triangulated, we ignore the simplices with angles smaller than <math display="inline">10</math> degrees, and the simplices formed outside the domain, which commonly appear in concavities of the boundary <math display="inline">\partial \Omega </math>. The local set of simplices resulting from the neighborhood of <math display="inline">V_i</math> is denoted <math display="inline">P_\alpha </math>. Figure [[#img-8|8]] illustrates the difference between (a) the simplices resulting from the triangulation of the calculation points in adjacent volumes and (b) those resulting from the triangulation of the proposed neighborhood <math display="inline">{B}_i</math>. |

<div id='img-8'></div> | <div id='img-8'></div> | ||

| Line 948: | Line 945: | ||

|} | |} | ||

| − | these subfaces result from the intersection between <math display="inline">P_\alpha </math> and the control volume <math display="inline">V_i</math>. | + | these subfaces result from the intersection between <math display="inline">P_\alpha </math> and the control volume <math display="inline">V_i</math>. Figure [[#img-8|8]].b illustrates six key points of this approach, 1) the simplices are used to create a polynomial interpolation of <math display="inline">\boldsymbol{u}(\mathbf{x})</math> over the boundary of the control volume, 2) most of the faces are intersected by several simplices, such faces must be divided into subfaces to be integrated, 3) some few faces are inside a single simplex, as illustrated in the face formed by <math display="inline">V_i</math> and <math display="inline">V_k</math>, 4) there are volumes that require information of non-adjacent volumes to calculate its face integrals, such as <math display="inline">V_i</math> requires <math display="inline">V_k</math>, 5) the dependency between volumes is not always symmetric, which means that if <math display="inline">V_i</math> requires <math display="inline">V_k</math> does not implies that <math display="inline">V_k</math> requires <math display="inline">V_i</math>, and 6) non conforming meshes are supported, as shown in the faces formed by <math display="inline">V_a</math>, <math display="inline">V_b</math>, <math display="inline">V_c</math>, <math display="inline">V_d</math> and <math display="inline">V_j</math>. |

| − | The integral [[#eq-3.17|3.17]] is now rewritten in terms of the subfaces | + | The integral [[#eq-3.17|(3.17)]] is now rewritten in terms of the subfaces |

<span id="eq-3.19"></span> | <span id="eq-3.19"></span> | ||

| Line 963: | Line 960: | ||

|} | |} | ||

| − | Each subface <math display="inline">e_{ijk}</math> is bounded by a simplex, where the displacement <math display="inline">\boldsymbol{u}_{ijk}</math>, and it derivatives, <math display="inline">~(\mathbf{S}\boldsymbol{u})_{ijk}</math>, are a polynomial interpolation. Hence the integrals in equation [[#eq-3.19|3.19]] are solved exactly by using the Gauss-Legendre quadrature with the required number of integration points, denoted <math display="inline">N_g</math>, depending on the polynomial degree, | + | Each subface <math display="inline">e_{ijk}</math> is bounded by a simplex, where the displacement <math display="inline">\boldsymbol{u}_{ijk}</math>, and it derivatives, <math display="inline">~(\mathbf{S}\boldsymbol{u})_{ijk}</math>, are a polynomial interpolation. Hence the integrals in equation [[#eq-3.19|(3.19)]] are solved exactly by using the Gauss-Legendre quadrature with the required number of integration points, denoted <math display="inline">N_g</math>, depending on the polynomial degree, |

<span id="eq-3.20"></span> | <span id="eq-3.20"></span> | ||

| Line 976: | Line 973: | ||

|} | |} | ||

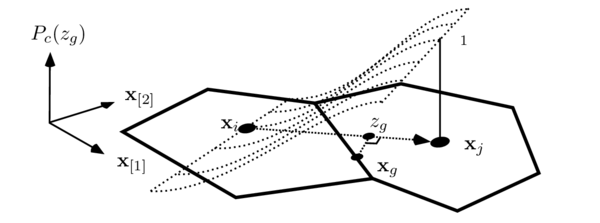

| − | where <math display="inline">w_g</math> is the corresponding quadrature weight and <math display="inline">(\mathbf{S}\boldsymbol{u})_{ijk}|_{\mathbf{x}_g}</math> is the strain evaluation of the Gauss point with the proper change of interval, denoted <math display="inline">\mathbf{x}_{g}</math>. | + | where <math display="inline">w_g</math> is the corresponding quadrature weight and <math display="inline">(\mathbf{S}\boldsymbol{u})_{ijk}|_{\mathbf{x}_g}</math> is the strain evaluation of the Gauss point with the proper change of interval, denoted <math display="inline">\mathbf{x}_{g}</math>. Figure [[#img-9|9]] shows the change of interval required for a 2D face. A 3D face (a polygon) must be subdivided to be integrated with a triangular quadrature. <div id='img-9'></div> |

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| Line 1,002: | Line 999: | ||

|} | |} | ||

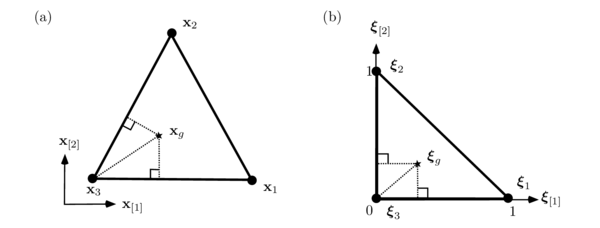

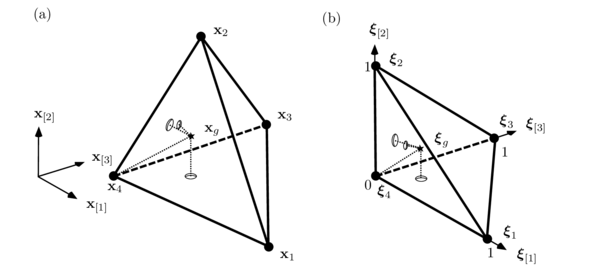

| − | where <math display="inline">\mathbf{e}_q</math> is the <math display="inline">q^{th}</math> standard basis vector. | + | where <math display="inline">\mathbf{e}_q</math> is the <math display="inline">q^{th}</math> standard basis vector. Figures [[#img-10|10]] and [[#img-11|11]] illustrate the original and the normalized simplices with the corresponding node numeration for 2D and 3D respectively. <div id='img-10'></div> |

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| Line 1,090: | Line 1,087: | ||

|} | |} | ||

| − | In order to calculate the normalized point, denoted <math display="inline">\boldsymbol{\xi }_g</math>, associated to the integration point <math display="inline">\mathbf{x}_g = \boldsymbol{p}\left(\boldsymbol{\xi }_g\right)</math>, we use the shape functions definitions to rewrite the equation [[#eq-3.27|3.27]] in matrix form | + | In order to calculate the normalized point, denoted <math display="inline">\boldsymbol{\xi }_g</math>, associated to the integration point <math display="inline">\mathbf{x}_g = \boldsymbol{p}\left(\boldsymbol{\xi }_g\right)</math>, we use the shape functions definitions to rewrite the equation [[#eq-3.27|(3.27)]] in matrix form |

<span id="eq-3.29"></span> | <span id="eq-3.29"></span> | ||

| Line 1,118: | Line 1,115: | ||

|} | |} | ||

| − | Now, from equation [[#eq-3.29|3.29]] we retrieve the point <math display="inline">\mathbf{x}_g</math> as | + | Now, from equation [[#eq-3.29|(3.29)]] we retrieve the point <math display="inline">\mathbf{x}_g</math> as |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 1,144: | Line 1,141: | ||

where <math display="inline">{Q}_c</math> is the inverse function of <math display="inline">{P}_c</math> applied component-wise to the product of the matrix-vector operation. | where <math display="inline">{Q}_c</math> is the inverse function of <math display="inline">{P}_c</math> applied component-wise to the product of the matrix-vector operation. | ||

| − | Similar to the approximation in equation [[#eq-3.27|3.27]], within the simplex enclosing the subface <math display="inline">e_{ijk}</math>, the displacement field evaluated at <math display="inline">\mathbf{x}_g</math> is defined as, | + | Similar to the approximation in equation [[#eq-3.27|(3.27)]], within the simplex enclosing the subface <math display="inline">e_{ijk}</math>, the displacement field evaluated at <math display="inline">\mathbf{x}_g</math> is defined as, |

<span id="eq-3.33"></span> | <span id="eq-3.33"></span> | ||

| Line 1,157: | Line 1,154: | ||

|} | |} | ||

| − | Hence, when calculating the quadrature of equation [[#eq-3.20|3.20]], the strain evaluated at the integration point is given by | + | Hence, when calculating the quadrature of equation [[#eq-3.20|(3.20)]], the strain evaluated at the integration point is given by |

<span id="eq-3.35"></span> | <span id="eq-3.35"></span> | ||

| Line 1,192: | Line 1,189: | ||

|} | |} | ||

| − | where <math display="inline">\nabla _{\boldsymbol{\xi }}\boldsymbol{p}</math> is the geometric jacobian evaluated at <math display="inline">\boldsymbol{\xi }</math>. This jacobian relates both spaces, captures the distortion of the simplex, and is derivated from equation [[#eq-3.27|3.27]], | + | where <math display="inline">\nabla _{\boldsymbol{\xi }}\boldsymbol{p}</math> is the geometric jacobian evaluated at <math display="inline">\boldsymbol{\xi }</math>. This jacobian relates both spaces, captures the distortion of the simplex, and is derivated from equation [[#eq-3.27|(3.27)]], |

<span id="eq-3.37"></span> | <span id="eq-3.37"></span> | ||

| Line 1,209: | Line 1,206: | ||

==3.5 Pair-wise polynomial approximation== | ==3.5 Pair-wise polynomial approximation== | ||

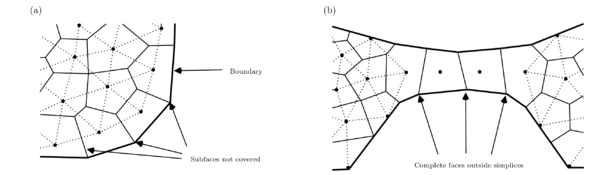

| − | Since we are not making any assumption about the volumes distribution through the mesh, neither about the internal location of its calculation points, then we have to deal with portions of the mesh that are no covered by any simplex. | + | Since we are not making any assumption about the volumes distribution through the mesh, neither about the internal location of its calculation points, then we have to deal with portions of the mesh that are no covered by any simplex. Figure [[#img-12|12]] illustrates the two most common cases. The first case takes place in meshes where the calculation points of volumes contiguous to the boundary are in the interior of such volumes, producing subfaces not intersected by any simplex, and the second case occurs when elongated sections of the domain are discretized with a queue of aligned volumes, where each volume has only two neighbors on opposite faces and no simplex can be formed. |

<div id='img-12'></div> | <div id='img-12'></div> | ||

| Line 1,244: | Line 1,241: | ||

|} | |} | ||

| − | When calculating the quadrature of equation [[#eq-3.20|3.20]], the pairwise strain is given by | + | When calculating the quadrature of equation [[#eq-3.20|(3.20)]], the pairwise strain is given by |

<span id="eq-3.42"></span> | <span id="eq-3.42"></span> | ||

| Line 1,277: | Line 1,274: | ||

==3.6 Homeostatic spline== | ==3.6 Homeostatic spline== | ||

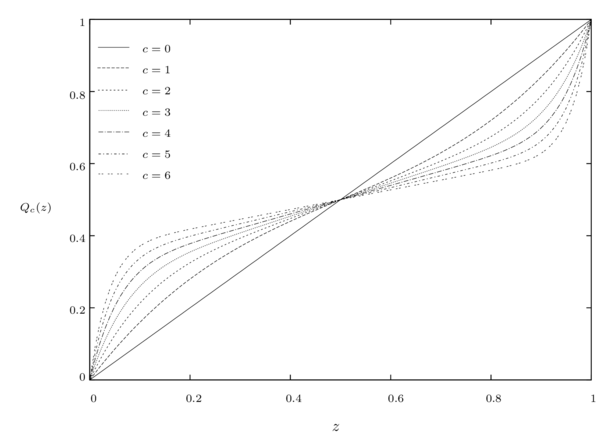

| − | The homeostatic spline is a function of a single variable defined from <math display="inline">z=0</math> to <math display="inline">z=1</math>, denoted <math display="inline">{P}_c(z)</math>, and curved by the parameter <math display="inline">~c</math>, which indicates the level of smoothness. This spline is the simplest polynomial with <math display="inline">~c~</math> derivatives equal to zero at the endpoints <math display="inline">z=0</math> and <math display="inline">z=1</math>. The polynomial degree is given by <math display="inline">2c+1</math>, and such a polynomial requires <math display="inline">N_g = c+1</math> integration points to calculate the exact integral in equation [[#eq-3.20|3.20]] using the Gauss-Legendre quadrature. | + | The homeostatic spline is a function of a single variable defined from <math display="inline">z=0</math> to <math display="inline">z=1</math>, denoted <math display="inline">{P}_c(z)</math>, and curved by the parameter <math display="inline">~c</math>, which indicates the level of smoothness. This spline is the simplest polynomial with <math display="inline">~c~</math> derivatives equal to zero at the endpoints <math display="inline">z=0</math> and <math display="inline">z=1</math>. The polynomial degree is given by <math display="inline">2c+1</math>, and such a polynomial requires <math display="inline">N_g = c+1</math> integration points to calculate the exact integral in equation [[#eq-3.20|(3.20)]] using the Gauss-Legendre quadrature. |

When designing this spline, we wanted to gain accuracy by building a piece-wise bell-shaped interpolation function around the calculation points, inspired on the infinitely smooth kernels used in other numerical techniques. Therefore, we force the derivatives of the polynomial to be zero over such points in order to homogenize the function. For that reason, we use the term ''homeostatic spline'' when referring to this spline. | When designing this spline, we wanted to gain accuracy by building a piece-wise bell-shaped interpolation function around the calculation points, inspired on the infinitely smooth kernels used in other numerical techniques. Therefore, we force the derivatives of the polynomial to be zero over such points in order to homogenize the function. For that reason, we use the term ''homeostatic spline'' when referring to this spline. | ||

| Line 1,373: | Line 1,370: | ||

|} | |} | ||

| − | Since the derivatives of the homeostatic spline [[#eq-3.43|3.43]] are zero at the endpoints of the interval <math display="inline">[0,1]</math>, the inverse function is not defined in that points. However, we estimate a pseudo-inverse within this interval, <math display="inline">{Q}_c\approx {P}_c^{-1}</math>, by finding the coefficients of a polynomial of the same degree, <math display="inline">2c+1</math>, such that the endpoints coincide with the spline and the first derivative at the midpoint is equivalent to the inverse of the spline first derivative, that is | + | Since the derivatives of the homeostatic spline [[#eq-3.43|(3.43)]] are zero at the endpoints of the interval <math display="inline">[0,1]</math>, the inverse function is not defined in that points. However, we estimate a pseudo-inverse within this interval, <math display="inline">{Q}_c\approx {P}_c^{-1}</math>, by finding the coefficients of a polynomial of the same degree, <math display="inline">2c+1</math>, such that the endpoints coincide with the spline and the first derivative at the midpoint is equivalent to the inverse of the spline first derivative, that is |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 1,409: | Line 1,406: | ||

|} | |} | ||

| − | respectively. | + | respectively. Figure [[#img-15|15]] exhibits the curves for the first seven levels of smoothness. The null higher derivatives requirement is noticeable at the midpoint. |

<div id='img-15'></div> | <div id='img-15'></div> | ||

| Line 1,419: | Line 1,416: | ||

|} | |} | ||

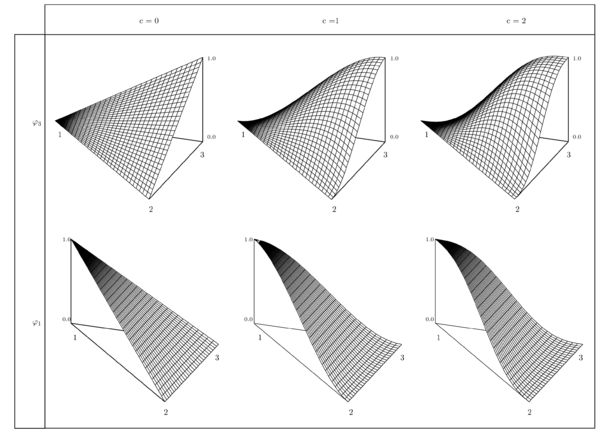

| − | + | Figure [[#img-16|16]] shows the shape functions for the 2D case. The top displays the last node function and the bottom the first node function, the function of the second node is equivalent to that of the first one. The columns separate the first three levels of smoothness. Top and bottom functions coincides at the edges in order to create a continuous field, but only the bottom functions decay uniformly from the node to the opposite edge. The shape functions with <math display="inline">c=0</math> are the only case where all the shape functions are indistinguishable, these are planes. <div id='img-16'></div> | |

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| Line 1,427: | Line 1,424: | ||

|} | |} | ||

| − | + | Figure [[#img-17|17]] shows the magnitude of the gradient with respect to the normalized space. With the same tabular configuration of Figure [[#img-16|16]], the columns separate the first three levels of smoothness, the top displays the last node gradient and the bottom the first node gradient, the gradient of the second node is equivalent to that of the first one. Only the gradient magnitude at the bottom has a uniform variation from the node to the opposite face, and the value of the node does not contribute to the value of such a face. On the contrary, in the top can be observed that the value of the node contributes to the gradient at the opposite face, which means that using <math display="inline">~c > 0~</math> the continuity on the stress field is only guaranteed at the calculation points, but not in the simplices edges. <div id='img-17'></div> | |

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| Line 1,437: | Line 1,434: | ||

==3.7 Assembling volume's equation== | ==3.7 Assembling volume's equation== | ||

| − | By using the simplex-wise [[#eq-3.35|3.35]] or the pair-wise [[#eq-3.42|3.42]] approximation, the strain face integral [[#eq-3.19|3.19]] is reformulated as | + | By using the simplex-wise [[#eq-3.35|(3.35)]] or the pair-wise [[#eq-3.42|(3.42)]] approximation, the strain face integral [[#eq-3.19|(3.19)]] is reformulated as |

<span id="eq-3.51"></span> | <span id="eq-3.51"></span> | ||

| Line 1,450: | Line 1,447: | ||

|} | |} | ||

| − | then, the volume equilibrium equation [[#eq-3.16|3.16]] is | + | then, the volume equilibrium equation [[#eq-3.16|(3.16)]] is |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 1,491: | Line 1,488: | ||

==3.8 Boundary conditions== | ==3.8 Boundary conditions== | ||

| − | The Neumann boundary conditions are imposed over the volume faces <math display="inline">e_{ij}</math> intersecting the boundary, by replacing the corresponding term in the sum of equation [[#eq-3.14|3.14]] with the integral of the function provided in [[#eq-2.37.a|2.37.a]], | + | The Neumann boundary conditions are imposed over the volume faces <math display="inline">e_{ij}</math> intersecting the boundary, by replacing the corresponding term in the sum of equation [[#eq-3.14|(3.14)]] with the integral of the function provided in [[#eq-2.37.a|(2.37.a)]], |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 1,503: | Line 1,500: | ||

|} | |} | ||

| − | The Dirichlet conditions are imposed over the volumes calculation points by fixing the displacement as it is evaluated in the function given in [[#eq-2.37.b|2.37.b]], | + | The Dirichlet conditions are imposed over the volumes calculation points by fixing the displacement as it is evaluated in the function given in [[#eq-2.37.b|(2.37.b)]], |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 1,528: | Line 1,525: | ||

| colspan="1" | '''Figure 18:''' (a) The initial mesh is equivalent to the Voronoi diagram and the Voronoi centres correspond to the calculation points <math>\mathbf{x}_i</math>. (b) The initial mesh is generated from a FEM-like triangular mesh. The calculation points <math>\mathbf{x}_i</math> are defined to be the nodes of the triangular mesh, and the volume faces are created by joining the centroids of the triangles with the midpoint of the segments. | | colspan="1" | '''Figure 18:''' (a) The initial mesh is equivalent to the Voronoi diagram and the Voronoi centres correspond to the calculation points <math>\mathbf{x}_i</math>. (b) The initial mesh is generated from a FEM-like triangular mesh. The calculation points <math>\mathbf{x}_i</math> are defined to be the nodes of the triangular mesh, and the volume faces are created by joining the centroids of the triangles with the midpoint of the segments. | ||

|} | |} | ||

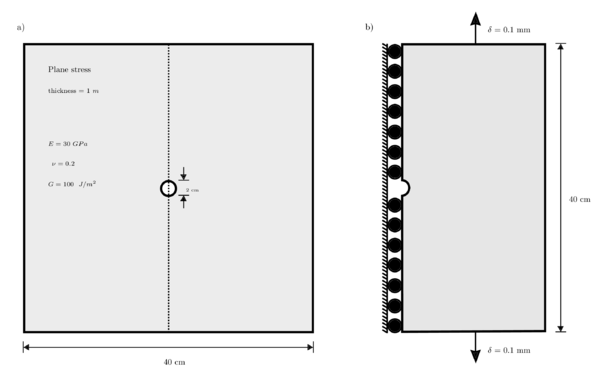

| − | In the first case, we assume that the initial mesh is equivalent to the Voronoi diagram and that the Voronoi centres correspond to the calculation points <math display="inline">\mathbf{x}_i</math>. Hence, the subdivision of the neighborhood <math display="inline">{B}_i</math> is already given by the Delaunay triangulation which is dual to the Voronoi mesh, as illustrated in | + | In the first case, we assume that the initial mesh is equivalent to the Voronoi diagram and that the Voronoi centres correspond to the calculation points <math display="inline">\mathbf{x}_i</math>. Hence, the subdivision of the neighborhood <math display="inline">{B}_i</math> is already given by the Delaunay triangulation which is dual to the Voronoi mesh, as illustrated in Figure [[#img-18|18]].a. Moreover, the integrals of subfaces <math display="inline">e_{ijk}</math> using pair-wise approximations can be exactly integrated with the midpoint rule, since the faces are orthogonal to the vector joining the calculation points <math display="inline">\mathbf{x}_{\vec{ij}}</math>, and the derivatives along the subface are constants. |

In the second case, the initial mesh is generated from a FEM-like triangular mesh and the approximations are assumed to be linear. In such a case, the calculation points <math display="inline">\mathbf{x}_i</math> are defined to be the nodes of the triangular mesh, and the volume faces are created by joining the centroids of the triangles with the midpoint of the segments, as presented in Figure [[#img-18|18]].b. This particular version is equivalent to the cell-centred finite volume scheme introduced by Oñate et al <span id='citeF-7'></span>[[#cite-7|[7]]], who proved that the global linear system produced by this FV scheme is identical to that produced by FEM if the same mesh is used. | In the second case, the initial mesh is generated from a FEM-like triangular mesh and the approximations are assumed to be linear. In such a case, the calculation points <math display="inline">\mathbf{x}_i</math> are defined to be the nodes of the triangular mesh, and the volume faces are created by joining the centroids of the triangles with the midpoint of the segments, as presented in Figure [[#img-18|18]].b. This particular version is equivalent to the cell-centred finite volume scheme introduced by Oñate et al <span id='citeF-7'></span>[[#cite-7|[7]]], who proved that the global linear system produced by this FV scheme is identical to that produced by FEM if the same mesh is used. | ||

| Line 1,534: | Line 1,531: | ||

=4 Second equation of motion= | =4 Second equation of motion= | ||

| − | In this chapter we will focus on the numerical treatment of the second equation of motion [[#eq-2.36.b|2.36.b]], this equation describes the damage mechanics within the physical system by considering the potential energy produced by tensile stress. | + | In this chapter we will focus on the numerical treatment of the second equation of motion [[#eq-2.36.b|(2.36.b)]], this equation describes the damage mechanics within the physical system by considering the potential energy produced by tensile stress. |

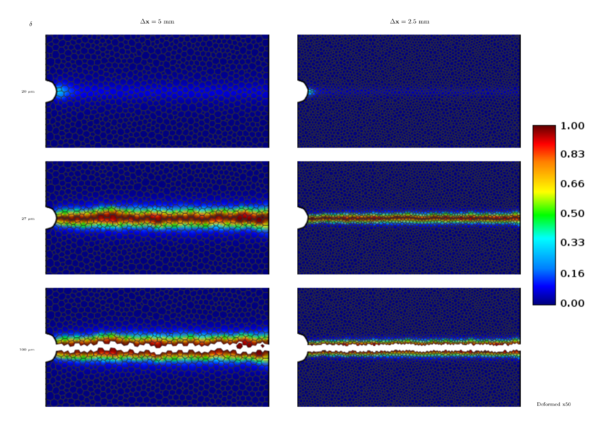

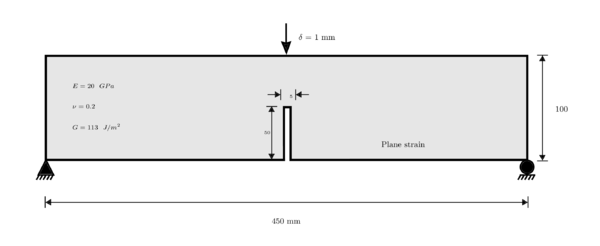

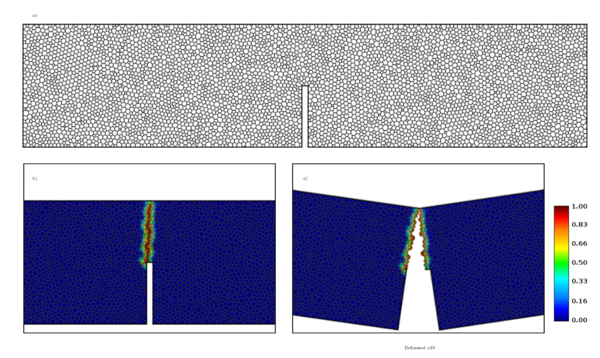

As discussed in the mathematical formulation, the damage field is a smooth approximation of the fracture surface, a benefit of this approach is that fracture morphology is completely defined by the solution of this equation and we do not have to track the crack propagation with auxiliary checking procedures neither to check for new crack nucleations. However, it is important to be aware about the effects over the stress field produced by the scale length parameter <math display="inline">h</math> which controls the smoothness of damage field solution. We observe that a length parameter proportional to the average size of control volumes, denoted <math display="inline">\Delta \mathbf{x}</math>, produces accurate results, these mesh size is taken as | As discussed in the mathematical formulation, the damage field is a smooth approximation of the fracture surface, a benefit of this approach is that fracture morphology is completely defined by the solution of this equation and we do not have to track the crack propagation with auxiliary checking procedures neither to check for new crack nucleations. However, it is important to be aware about the effects over the stress field produced by the scale length parameter <math display="inline">h</math> which controls the smoothness of damage field solution. We observe that a length parameter proportional to the average size of control volumes, denoted <math display="inline">\Delta \mathbf{x}</math>, produces accurate results, these mesh size is taken as | ||

| Line 1,548: | Line 1,545: | ||

|} | |} | ||

| − | Figure [[#img-19|19]] illustrates the graphical meaning of scale length parameter . <div id='img-19'></div> | + | Figure [[#img-19|19]] illustrates the graphical meaning of scale length parameter. <div id='img-19'></div> |

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| Line 1,560: | Line 1,557: | ||

==4.1 Discretization== | ==4.1 Discretization== | ||

| − | We start by integrating the strong form equation of motion [[#eq-2.36.b|2.36.b]] over the control volumes of the partition <math display="inline">P_h</math>, | + | We start by integrating the strong form equation of motion [[#eq-2.36.b|(2.36.b)]] over the control volumes of the partition <math display="inline">P_h</math>, |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 1,617: | Line 1,614: | ||

|} | |} | ||

| − | The surface integral is solved along subfaces <math display="inline">e_{ijk}</math> defined in [[#eq-3.18|3.18]], and the remaining volume integrals are solved using partition [[#eq-4.5|4.5]], | + | The surface integral is solved along subfaces <math display="inline">e_{ijk}</math> defined in [[#eq-3.18|(3.18)]], and the remaining volume integrals are solved using partition [[#eq-4.5|(4.5)]], |

<span id="eq-4.6"></span> | <span id="eq-4.6"></span> | ||

| Line 1,632: | Line 1,629: | ||

|} | |} | ||

| − | The damage field is estimated using the same shape functions, [[#eq-3.22.a|3.22.a]] and [[#eq-3.22.b|3.22.b]], that we use for the displacement field, | + | The damage field is estimated using the same shape functions, [[#eq-3.22.a|(3.22.a)]] and [[#eq-3.22.b|(3.22.b)]], that we use for the displacement field, |

<span id="eq-4.7"></span> | <span id="eq-4.7"></span> | ||

| Line 1,661: | Line 1,658: | ||

|} | |} | ||

| − | where <math display="inline">\nabla \varphi _{q}</math> is calculated from the chain rule in [[#eq-3.36|3.36]]. Now the equation is fully discretized, the next step is to solve the integrals. | + | where <math display="inline">\nabla \varphi _{q}</math> is calculated from the chain rule in [[#eq-3.36|(3.36)]]. Now the equation is fully discretized, the next step is to solve the integrals. |

==4.2 Assembling system of equations== | ==4.2 Assembling system of equations== | ||

| − | The first integral in equation [[#eq-4.6|4.6]] is approximated using the midpoint rule, | + | The first integral in equation [[#eq-4.6|(4.6)]] is approximated using the midpoint rule, |

<span id="eq-4.10"></span> | <span id="eq-4.10"></span> | ||

| Line 1,698: | Line 1,695: | ||

|} | |} | ||

| − | where <math display="inline">N_p</math> is the number of points in the quadrature, and <math display="inline">{H}_{ijk}|_{\mathbf{x}_p}</math> is the strain history field evaluated with the strain information of the simplex corresponding to subface <math display="inline">e_{ijk}</math>. Last but not least, we solve the surface integral that unfolds the damage gradient defined in [[#eq-4.9|4.9]], using again Gauss-Legendre quadrature | + | where <math display="inline">N_p</math> is the number of points in the quadrature, and <math display="inline">{H}_{ijk}|_{\mathbf{x}_p}</math> is the strain history field evaluated with the strain information of the simplex corresponding to subface <math display="inline">e_{ijk}</math>. Last but not least, we solve the surface integral that unfolds the damage gradient defined in [[#eq-4.9|(4.9)]], using again Gauss-Legendre quadrature |

<span id="eq-4.17"></span> | <span id="eq-4.17"></span> | ||

| Line 1,725: | Line 1,722: | ||

where <math display="inline">\mathbf{Z}_{ijk}|_{\mathbf{x}_g}</math> is the matrix containing the derivatives of the shape functions evaluated at <math display="inline">\mathbf{x}_g</math>. For simplicity, the matrix notation in previous equation shows only values for 2D case. | where <math display="inline">\mathbf{Z}_{ijk}|_{\mathbf{x}_g}</math> is the matrix containing the derivatives of the shape functions evaluated at <math display="inline">\mathbf{x}_g</math>. For simplicity, the matrix notation in previous equation shows only values for 2D case. | ||

| − | Substituting, equations [[#eq-4.10|4.10]], [[#eq-4.12|4.12]], [[#eq-4.13|4.13]] and [[#eq-4.17|4.17]] into [[#eq-4.6|4.6]] we get | + | Substituting, equations [[#eq-4.10|(4.10)]], [[#eq-4.12|(4.12)]], [[#eq-4.13|(4.13)]] and [[#eq-4.17|(4.17)]] into [[#eq-4.6|(4.6)]] we get |

<span id="eq-4.19"></span> | <span id="eq-4.19"></span> | ||

| Line 1,764: | Line 1,761: | ||

|} | |} | ||

| − | Now we can rewrite the damage equation [[#eq-4.19|4.19]] for the <math display="inline">i^{th}</math> control volume as follows | + | Now we can rewrite the damage equation [[#eq-4.19|(4.19)]] for the <math display="inline">i^{th}</math> control volume as follows |

<span id="eq-4.22"></span> | <span id="eq-4.22"></span> | ||

| Line 1,781: | Line 1,778: | ||

=5 Time discretization= | =5 Time discretization= | ||

| − | In this chapter we will remove the assumption done in equation [[#eq-3.5|3.5]] about null acceleration, <math display="inline">\ddot{\boldsymbol{u}}= 0</math>, and we will discuss in detail the discretization of time derivatives. | + | In this chapter we will remove the assumption done in equation [[#eq-3.5|(3.5)]] about null acceleration, <math display="inline">\ddot{\boldsymbol{u}}= 0</math>, and we will discuss in detail the discretization of time derivatives. |

A common approach to approximate these derivatives in dynamic stress analysis is a staggered scheme by means of Finite Differences (FD), such as in <span id='citeF-11'></span>[[#cite-11|[11]]], <span id='citeF-34'></span>[[#cite-34|[34]]] and <span id='citeF-52'></span>[[#cite-52|[52]]]. The simplicity of FD makes easy the incorporation of spatial non-linear phenomena, for instance fracture and damage, nevertheless FD does not consider the stress state within its approximation and we are forced to use tiny time steps to diminish spurious stress waves that produce undesired artifical internal forces. | A common approach to approximate these derivatives in dynamic stress analysis is a staggered scheme by means of Finite Differences (FD), such as in <span id='citeF-11'></span>[[#cite-11|[11]]], <span id='citeF-34'></span>[[#cite-34|[34]]] and <span id='citeF-52'></span>[[#cite-52|[52]]]. The simplicity of FD makes easy the incorporation of spatial non-linear phenomena, for instance fracture and damage, nevertheless FD does not consider the stress state within its approximation and we are forced to use tiny time steps to diminish spurious stress waves that produce undesired artifical internal forces. | ||

| Line 1,789: | Line 1,786: | ||

==5.1 Time variation== | ==5.1 Time variation== | ||

| − | In order to analyze the dynamic component of elasticity equation [[#eq-2.36.a|2.36.a]] we define the stress state of control volume <math display="inline">i</math> as a function of time, | + | In order to analyze the dynamic component of elasticity equation [[#eq-2.36.a|(2.36.a)]] we define the stress state of control volume <math display="inline">i</math> as a function of time, |

<span id="eq-5.1"></span> | <span id="eq-5.1"></span> | ||

| Line 1,815: | Line 1,812: | ||

|} | |} | ||

| − | Equation [[#eq-5.2|5.2]] is an ordinary differential equation that can be solved analytically for a time step <math display="inline">t\in [0,\Delta t]</math> with the following Dirichlet conditions | + | Equation [[#eq-5.2|(5.2)]] is an ordinary differential equation that can be solved analytically for a time step <math display="inline">t\in [0,\Delta t]</math> with the following Dirichlet conditions |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 1,850: | Line 1,847: | ||

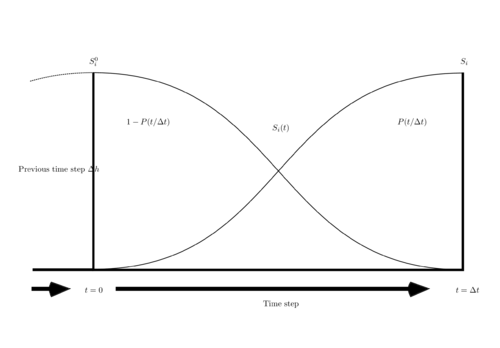

| colspan="1" | '''Figure 21:''' The time variation of the stress state is defined by the shape function <math>{P}</math> that interpolates the stress states of two contiguous time steps. During this work we found that continuous functions like the shown here produces more accurate approximations in the stress field than the numerical schemes that does not consider this variation. | | colspan="1" | '''Figure 21:''' The time variation of the stress state is defined by the shape function <math>{P}</math> that interpolates the stress states of two contiguous time steps. During this work we found that continuous functions like the shown here produces more accurate approximations in the stress field than the numerical schemes that does not consider this variation. | ||

|} | |} | ||

| − | where <math display="inline">S_i^{0}</math> is the stress state calculated at <math display="inline">t=0</math>, <math display="inline">S_i</math> is the stress state which will be estimated at time <math display="inline">t=\Delta t</math>, and <math display="inline">{P}(\cdot )</math> is the shape function modelling time variation between concecutive stress states. This shape function has only two constraints <math display="inline">{P}(0) = 0</math> and <math display="inline">{P}(1) = 1</math>, for that reason we use <math display="inline">\Delta t</math> as a normalizer in equation [[#eq-5.4|5.4]]. In the discussion of this chapter we utilize “stress state” and “internal forces” as synonyms to refer the same term in equation [[#eq-5.1|5.1]]. | + | where <math display="inline">S_i^{0}</math> is the stress state calculated at <math display="inline">t=0</math>, <math display="inline">S_i</math> is the stress state which will be estimated at time <math display="inline">t=\Delta t</math>, and <math display="inline">{P}(\cdot )</math> is the shape function modelling time variation between concecutive stress states. This shape function has only two constraints <math display="inline">{P}(0) = 0</math> and <math display="inline">{P}(1) = 1</math>, for that reason we use <math display="inline">\Delta t</math> as a normalizer in equation [[#eq-5.4|(5.4)]]. In the discussion of this chapter we utilize “stress state” and “internal forces” as synonyms to refer the same term in equation [[#eq-5.1|(5.1)]]. |

Figure [[#img-21|21]] illustrates the variation of the stress state in terms of the shape function <math display="inline">{P}</math> that is used as interpolator between the value at two contiguous time steps. | Figure [[#img-21|21]] illustrates the variation of the stress state in terms of the shape function <math display="inline">{P}</math> that is used as interpolator between the value at two contiguous time steps. | ||

| Line 1,856: | Line 1,853: | ||

==5.2 Analytical solution== | ==5.2 Analytical solution== | ||

| − | Using the asumption in [[#eq-5.4|5.4]], we get the analytical solution of the equation [[#eq-5.2|5.2]] for the interval <math display="inline">t\in [0,\Delta t]</math> by means of the Laplace transform (see appendix [[# | + | Using the asumption in [[#eq-5.4|(5.4)]], we get the analytical solution of the equation [[#eq-5.2|(5.2)]] for the interval <math display="inline">t\in [0,\Delta t]</math> by means of the Laplace transform (see appendix [[#A Analytical solution for time|A]] for details), |

<span id="eq-5.5"></span> | <span id="eq-5.5"></span> | ||

| Line 1,869: | Line 1,866: | ||

|} | |} | ||

| − | where <math display="inline">\dot{\boldsymbol{u}}_i^0</math> is the velocity at time <math display="inline">t=0</math>, and <math display="inline">{C}_{P}(t)</math> is the convolution between the spline <math display="inline">{P}(t/\Delta t)</math> and the function <math display="inline">t</math>, as defined in appendix [[# | + | where <math display="inline">\dot{\boldsymbol{u}}_i^0</math> is the velocity at time <math display="inline">t=0</math>, and <math display="inline">{C}_{P}(t)</math> is the convolution between the spline <math display="inline">{P}(t/\Delta t)</math> and the function <math display="inline">t</math>, as defined in appendix [[#A Analytical solution for time|A]]. |

| − | By setting the second boundary condition, <math display="inline">\boldsymbol{u}_i(\Delta t) = \boldsymbol{u}_i</math>, into the analytical solution [[#eq-5.5|5.5]], we can find the velocity required to fulfill both Dirichlet conditions | + | By setting the second boundary condition, <math display="inline">\boldsymbol{u}_i(\Delta t) = \boldsymbol{u}_i</math>, into the analytical solution [[#eq-5.5|(5.5)]], we can find the velocity required to fulfill both Dirichlet conditions |

<span id="eq-5.6"></span> | <span id="eq-5.6"></span> | ||

| Line 1,884: | Line 1,881: | ||

|} | |} | ||

| − | where <math display="inline">{C}_{P}^{\Delta t}</math> is the convolution evaluated at <math display="inline">\Delta t</math>. Thus, we replace equation [[#eq-5.6|5.6]] into [[#eq-5.5|5.5]] to get the analytical solution in terms of the known Dirichlet conditions | + | where <math display="inline">{C}_{P}^{\Delta t}</math> is the convolution evaluated at <math display="inline">\Delta t</math>. Thus, we replace equation [[#eq-5.6|(5.6)]] into [[#eq-5.5|(5.5)]] to get the analytical solution in terms of the known Dirichlet conditions |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 1,913: | Line 1,910: | ||

|} | |} | ||

| − | where <math display="inline">\dot{{C}}_{P}</math> is the time derivative of <math display="inline">{C}_{P}</math>. Since the analytical solution [[#eq-5.5|5.5]] requires the initial conditions (displacement and velocity), we calculate the initial velocity by using equation [[#eq-5.8|5.8]] for a previous time interval <math display="inline">t \in [-\Delta h, 0]</math>, | + | where <math display="inline">\dot{{C}}_{P}</math> is the time derivative of <math display="inline">{C}_{P}</math>. Since the analytical solution [[#eq-5.5|(5.5)]] requires the initial conditions (displacement and velocity), we calculate the initial velocity by using equation [[#eq-5.8|(5.8)]] for a previous time interval <math display="inline">t \in [-\Delta h, 0]</math>, |

<span id="eq-5.9"></span> | <span id="eq-5.9"></span> | ||

| Line 1,926: | Line 1,923: | ||

|} | |} | ||

| − | where <math display="inline">\boldsymbol{u}_i^{00} = \boldsymbol{u}_i(-\Delta h)</math> and <math display="inline">S_i^{00} = S_i(-\Delta h)</math>. Finally, we replace equation [[#eq-5.9|5.9]] into [[#eq-5.5|5.5]] in order to get an analytical solution for <math display="inline">t\in [0,\Delta t]</math> as a function of two history system states, | + | where <math display="inline">\boldsymbol{u}_i^{00} = \boldsymbol{u}_i(-\Delta h)</math> and <math display="inline">S_i^{00} = S_i(-\Delta h)</math>. Finally, we replace equation [[#eq-5.9|(5.9)]] into [[#eq-5.5|(5.5)]] in order to get an analytical solution for <math display="inline">t\in [0,\Delta t]</math> as a function of two history system states, |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 1,959: | Line 1,956: | ||

|} | |} | ||

| − | observe that even in the simplest case this approximation is more accurate than simple central finite differences applied directly on equation [[#eq-5.2|5.2]], because it takes into account variable time steps and the time variation of the system internal forces. | + | observe that even in the simplest case this approximation is more accurate than simple central finite differences applied directly on equation [[#eq-5.2|(5.2)]], because it takes into account variable time steps and the time variation of the system internal forces. |

==5.3 Numerical scheme== | ==5.3 Numerical scheme== | ||

| − | The analytical solution [[#eq-5.11|5.11]] of the ordinary differential equation [[#eq-5.2|5.2]] can be used to generate a family of numerical approximations, these approximations has a similar structure but distinct coefficients that depend on the shape function <math display="inline">{P}</math> used for time variation of stress state. In this work we explore distinct families of functions in order to get a continuous stress state in contiguous time steps. | + | The analytical solution [[#eq-5.11|(5.11)]] of the ordinary differential equation [[#eq-5.2|(5.2)]] can be used to generate a family of numerical approximations, these approximations has a similar structure but distinct coefficients that depend on the shape function <math display="inline">{P}</math> used for time variation of stress state. In this work we explore distinct families of functions in order to get a continuous stress state in contiguous time steps. |

===5.3.1 Harmonic oscillator sensibility=== | ===5.3.1 Harmonic oscillator sensibility=== | ||

| Line 1,980: | Line 1,977: | ||

|} | |} | ||

| − | where <math display="inline">k</math> is the stiffness of the system, <math display="inline">m</math> is the mass of the body and <math display="inline">u</math> is the one-dimensional displacement. The analytical solution of equation [[#eq-5.12|5.12]] is | + | where <math display="inline">k</math> is the stiffness of the system, <math display="inline">m</math> is the mass of the body and <math display="inline">u</math> is the one-dimensional displacement. The analytical solution of equation [[#eq-5.12|(5.12)]] is |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 2,026: | Line 2,023: | ||

====5.3.1.1 Central Finite Differences==== | ====5.3.1.1 Central Finite Differences==== | ||

| − | By using a central finite differences scheme, equation [[#eq-5.12|5.12]] can be rewritten as | + | By using a central finite differences scheme, equation [[#eq-5.12|(5.12)]] can be rewritten as |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 2,054: | Line 2,051: | ||

|} | |} | ||

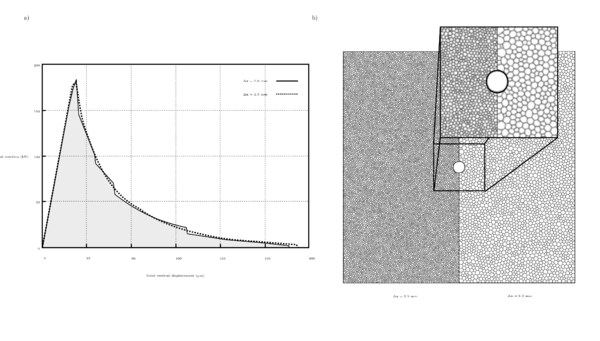

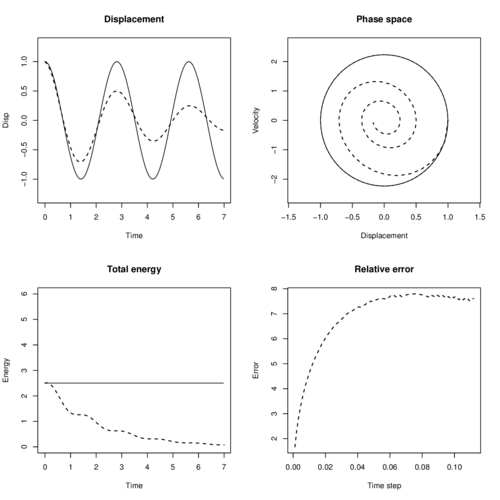

| − | To measure the relative error with respect to analytical solution, we used [[#eq-5.20|5.20]] to compute the solution in the interval <math display="inline">t \in [0,7]</math>. To make evident the numerical drawbacks of FD we utilized a big enough <math display="inline">\Delta t= 0.1</math>. In Figure [[#img-22|22]] we show the experiment results in four plots, the first one shows the displacement against time with a solid line for analytical solution and a dashed line for the numerical one, in this plot is clear that the system is loosing energy through time, no matter how small is <math display="inline">\Delta t</math> the system will always loose energy proportionally to the time step. The second plot shows the phase space (solid line is analytical solution), which is velocity against displacement, in this plot we see the closing spiral when displacement and velocity decreases. The third plot shows the total energy in the system to emphasize that it is loosing energy, while total energy of analytical solution (solid line) remains constant. The fourth plot shows the cumulative relative error for distinct <math display="inline">\Delta t</math>, such an error remains almost consant for <math display="inline">\Delta t> 0.06</math> since the numerical system looses all its energy in the first few time steps. In this plot we compute the comulative error as | + | To measure the relative error with respect to analytical solution, we used [[#eq-5.20|(5.20)]] to compute the solution in the interval <math display="inline">t \in [0,7]</math>. To make evident the numerical drawbacks of FD we utilized a big enough <math display="inline">\Delta t= 0.1</math>. In Figure [[#img-22|22]] we show the experiment results in four plots, the first one shows the displacement against time with a solid line for analytical solution and a dashed line for the numerical one, in this plot is clear that the system is loosing energy through time, no matter how small is <math display="inline">\Delta t</math> the system will always loose energy proportionally to the time step. The second plot shows the phase space (solid line is analytical solution), which is velocity against displacement, in this plot we see the closing spiral when displacement and velocity decreases. The third plot shows the total energy in the system to emphasize that it is loosing energy, while total energy of analytical solution (solid line) remains constant. The fourth plot shows the cumulative relative error for distinct <math display="inline">\Delta t</math>, such an error remains almost consant for <math display="inline">\Delta t> 0.06</math> since the numerical system looses all its energy in the first few time steps. In this plot we compute the comulative error as |

<span id="eq-5.21"></span> | <span id="eq-5.21"></span> | ||

| Line 2,153: | Line 2,150: | ||

for velocity. | for velocity. | ||

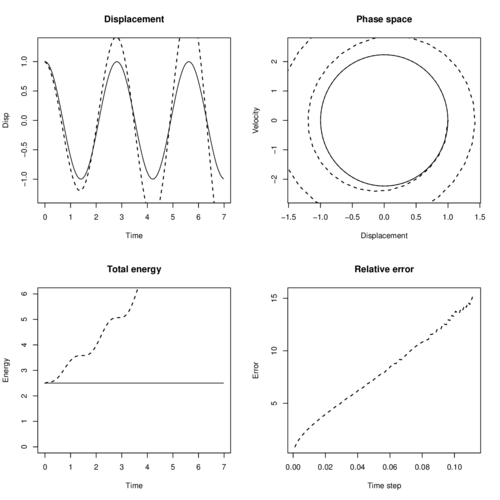

| − | In our experiments we used the same <math display="inline">\Delta t=0.1</math> than with Finite Differences. Figure [[#img-23|23]] shows the experimental results in four plots, analytical solution is the solid line and numerical results are depicted with a dashed line. In the first plot we show the direct numerical solution, displacement vs time, and we see how the system gains energy through time, reducing time step alleviates the problem but it does not solve it, since the artificial energy increasing is proportional to the time step. The second plot shows the phase space, which is velocity against displacement, here we observe how the artificial generated energy creates an opening spiral producing greater waves as the simulation moves in time. The third plot reflects how the total energy in the system grows with respect to time. The fourth plot shows the cumulative relative error [[#eq-5.21|5.21]] in the interval <math display="inline">t \in [0,7]</math> with respect to <math display="inline">\Delta t</math>. From here we noticed that for <math display="inline">\Delta t< 0.05</math> this scheme is slightly better than Finite Differences, and for <math display="inline">\Delta t> 0.05</math> both schemes are useless in long term simulations, at least that we use a numerical mechanism to rebalance the energy (dampers for instance). | + | In our experiments we used the same <math display="inline">\Delta t=0.1</math> than with Finite Differences. Figure [[#img-23|23]] shows the experimental results in four plots, analytical solution is the solid line and numerical results are depicted with a dashed line. In the first plot we show the direct numerical solution, displacement vs time, and we see how the system gains energy through time, reducing time step alleviates the problem but it does not solve it, since the artificial energy increasing is proportional to the time step. The second plot shows the phase space, which is velocity against displacement, here we observe how the artificial generated energy creates an opening spiral producing greater waves as the simulation moves in time. The third plot reflects how the total energy in the system grows with respect to time. The fourth plot shows the cumulative relative error [[#eq-5.21|(5.21)]] in the interval <math display="inline">t \in [0,7]</math> with respect to <math display="inline">\Delta t</math>. From here we noticed that for <math display="inline">\Delta t< 0.05</math> this scheme is slightly better than Finite Differences, and for <math display="inline">\Delta t> 0.05</math> both schemes are useless in long term simulations, at least that we use a numerical mechanism to rebalance the energy (dampers for instance). |

<div id='img-23'></div> | <div id='img-23'></div> | ||

| Line 2,165: | Line 2,162: | ||

====5.3.1.3 Numerical equilibrium==== | ====5.3.1.3 Numerical equilibrium==== | ||

| − | Using the general scheme in [[#eq-5.11|5.11]] and considering constant time steps, <math display="inline">\Delta h= \Delta t</math>, we define a numerical approximation for harmonic oscillator in terms of the convolution and its derivative | + | Using the general scheme in [[#eq-5.11|(5.11)]] and considering constant time steps, <math display="inline">\Delta h= \Delta t</math>, we define a numerical approximation for harmonic oscillator in terms of the convolution and its derivative |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 2,202: | Line 2,199: | ||

|} | |} | ||

| − | In equation [[#eq-5.29|5.29]], observe that by choosing <math display="inline">{P}=2</math> , we get a convolution of <math display="inline">{C}(t) = t^2</math> and a convolution derivative of <math display="inline">\dot{{C}}(t) = 2t</math>, which produces the very same numerical scheme that finite differences in [[#eq-5.20|5.20]]. | + | In equation [[#eq-5.29|(5.29)]], observe that by choosing <math display="inline">{P}=2</math> , we get a convolution of <math display="inline">{C}(t) = t^2</math> and a convolution derivative of <math display="inline">\dot{{C}}(t) = 2t</math>, which produces the very same numerical scheme that finite differences in [[#eq-5.20|(5.20)]]. |

| − | Notice that no matter which shape function we choose, the convolution evaluated at <math display="inline">\Delta t</math> always have the form of <math display="inline">{C}_{P}^{\Delta t} = \beta \Delta t^2</math> and its derivative the form of <math display="inline">\dot{{C}_{P}^{\Delta t}} = \alpha \Delta t</math>, where <math display="inline">\alpha </math> and <math display="inline">\beta </math> are variations of <math display="inline">\Delta t</math> and <math display="inline">\Delta t^2</math> respectively. From this fact we will use <math display="inline">\alpha </math> as an optimization variable for minimizing the error, and we set <math display="inline">\beta=1</math> for simplificate the formula (since <math display="inline">\beta </math> is not involved in the minimization). Now we simplify equation [[#eq-5.29|5.29]] as | + | Notice that no matter which shape function we choose, the convolution evaluated at <math display="inline">\Delta t</math> always have the form of <math display="inline">{C}_{P}^{\Delta t} = \beta \Delta t^2</math> and its derivative the form of <math display="inline">\dot{{C}_{P}^{\Delta t}} = \alpha \Delta t</math>, where <math display="inline">\alpha </math> and <math display="inline">\beta </math> are variations of <math display="inline">\Delta t</math> and <math display="inline">\Delta t^2</math> respectively. From this fact we will use <math display="inline">\alpha </math> as an optimization variable for minimizing the error, and we set <math display="inline">\beta=1</math> for simplificate the formula (since <math display="inline">\beta </math> is not involved in the minimization). Now we simplify equation [[#eq-5.29|(5.29)]] as |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 2,228: | Line 2,225: | ||

|} | |} | ||

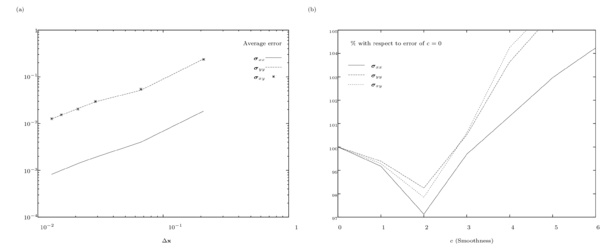

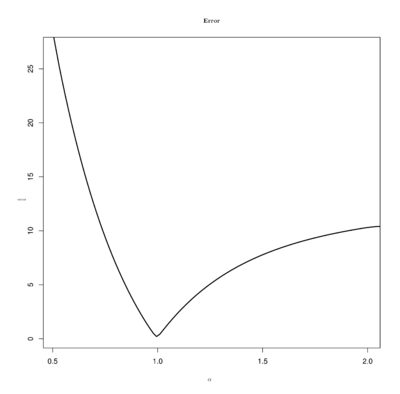

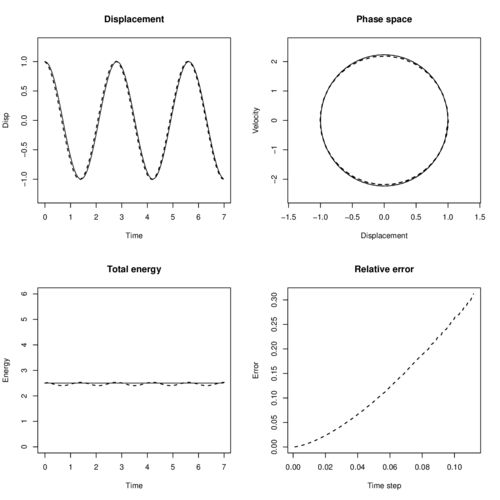

| − | where Error() is the function defined in [[#eq-5.21|5.21]]. Figure [[#img-24|24]] shows the Error as a function of <math display="inline">\alpha </math>, in this plot is evident that the optimal value is <math display="inline">\alpha=1</math>. <div id='img-24'></div> | + | where Error() is the function defined in [[#eq-5.21|(5.21)]]. Figure [[#img-24|24]] shows the Error as a function of <math display="inline">\alpha </math>, in this plot is evident that the optimal value is <math display="inline">\alpha=1</math>. <div id='img-24'></div> |

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

|[[Image:Draft_Samper_795975371_6271_monograph-picture-b64c8e.png|400px|The plot shows the cumulative relative error of equation [[#eq-5.21|5.21]] as a function of the optimization variable α. It is clear that the minimum is in α=1. The error curve is asymptotic to zero in the left and converges to some constant to the right.]] | |[[Image:Draft_Samper_795975371_6271_monograph-picture-b64c8e.png|400px|The plot shows the cumulative relative error of equation [[#eq-5.21|5.21]] as a function of the optimization variable α. It is clear that the minimum is in α=1. The error curve is asymptotic to zero in the left and converges to some constant to the right.]] | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| − | | colspan="1" | '''Figure 24:''' The plot shows the cumulative relative error of equation [[#eq-5.21|5.21]] as a function of the optimization variable <math>\alpha </math>. It is clear that the minimum is in <math>\alpha=1</math>. The error curve is asymptotic to zero in the left and converges to some constant to the right. | + | | colspan="1" | '''Figure 24:''' The plot shows the cumulative relative error of equation [[#eq-5.21|(5.21)]] as a function of the optimization variable <math>\alpha </math>. It is clear that the minimum is in <math>\alpha=1</math>. The error curve is asymptotic to zero in the left and converges to some constant to the right. |

|} | |} | ||

Since <math display="inline">\alpha </math> is the proportion of <math display="inline">\Delta t</math> in convolution derivative, <math display="inline">\dot{{C}_{P}^{\Delta t}} = \alpha \Delta t</math>, from this experiment we found out that | Since <math display="inline">\alpha </math> is the proportion of <math display="inline">\Delta t</math> in convolution derivative, <math display="inline">\dot{{C}_{P}^{\Delta t}} = \alpha \Delta t</math>, from this experiment we found out that | ||

| Line 2,255: | Line 2,252: | ||

|} | |} | ||

| − | Examples of energy state of conditions [[#eq-5.33|5.33]] and [[#eq-5.35|5.35]] can be observed in Figures [[#img-22|22]] and [[#img-23|23]] respectively. | + | Examples of energy state of conditions [[#eq-5.33|(5.33)]] and [[#eq-5.35|(5.35)]] can be observed in Figures [[#img-22|22]] and [[#img-23|23]] respectively. |

In our experiments we notice that the variation of <math display="inline">\beta </math> has a little impact on the results, but values of <math display="inline">\beta \leq 1</math> produce smaller oscillations of total energy than <math display="inline">\beta > 1</math>. For that reason, we constrain our search of shape functions <math display="inline">{P}</math> to those functions that produce <math display="inline">\dot{{C}}_{P}^{\Delta t} = \Delta t</math> and <math display="inline">{C}_{P}^{\Delta t} < \Delta t^2</math>. | In our experiments we notice that the variation of <math display="inline">\beta </math> has a little impact on the results, but values of <math display="inline">\beta \leq 1</math> produce smaller oscillations of total energy than <math display="inline">\beta > 1</math>. For that reason, we constrain our search of shape functions <math display="inline">{P}</math> to those functions that produce <math display="inline">\dot{{C}}_{P}^{\Delta t} = \Delta t</math> and <math display="inline">{C}_{P}^{\Delta t} < \Delta t^2</math>. | ||

| Line 2,284: | Line 2,281: | ||

|} | |} | ||

| − | The appendix [[# | + | The appendix [[#B Polynomial shape functions for time|B]] discuss another proposals based on polynomials that produces accurate results, nevertheless this trigonometric function introduces less artificial energy that impact results in long term simulations. |

| − | The convolution corresponding to [[#eq-5.36|5.36]] is | + | The convolution corresponding to [[#eq-5.36|(5.36)]] is |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 2,338: | Line 2,335: | ||

===5.3.3 Dynamic stress analysis=== | ===5.3.3 Dynamic stress analysis=== | ||

| − | Considering discretized stress equation [[#eq-3.53|3.53]] into this numerical scheme, we have that | + | Considering discretized stress equation [[#eq-3.53|(3.53)]] into this numerical scheme, we have that |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 2,350: | Line 2,347: | ||

|} | |} | ||

| − | replacing [[#eq-5.36|5.36]] into such stress equation we get our final numerical system for the first equation of motion [[#eq-2.36.a|2.36.a]] | + | replacing [[#eq-5.36|(5.36)]] into such stress equation we get our final numerical system for the first equation of motion [[#eq-2.36.a|(2.36.a)]] |

<span id="eq-5.42"></span> | <span id="eq-5.42"></span> | ||

| Line 2,413: | Line 2,410: | ||

=6 Coupled system= | =6 Coupled system= | ||