m (Cinmemj moved page Draft Samper 908356597 to Baumgartner et al 2015a) |

|||

| (37 intermediate revisions by the same user not shown) | |||

| Line 821: | Line 821: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

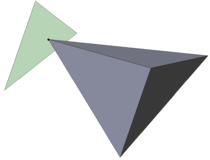

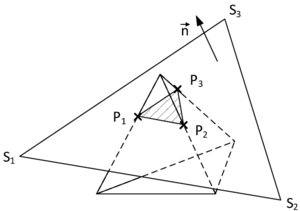

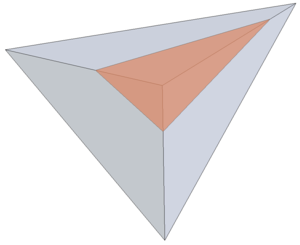

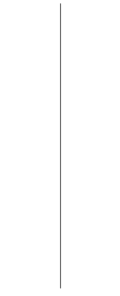

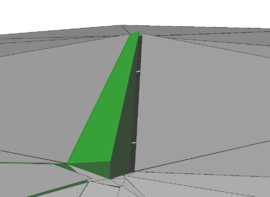

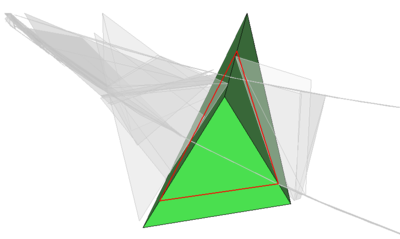

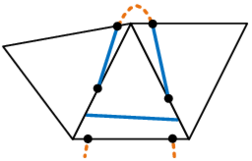

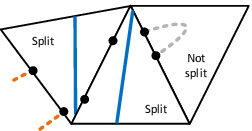

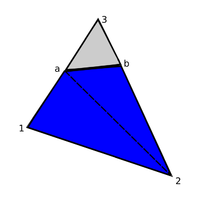

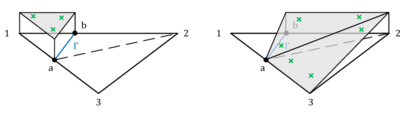

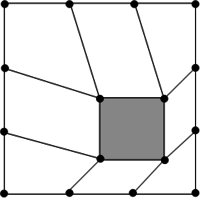

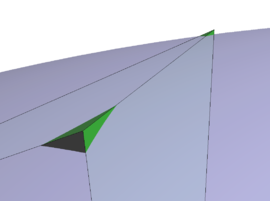

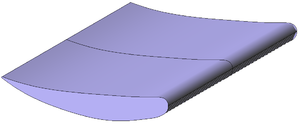

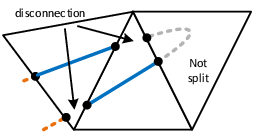

| − | |[[Image:draft_Samper_908356597-monograph-D01_ShapeFunctionConcept.png| | + | |[[Image:draft_Samper_908356597-monograph-D01_ShapeFunctionConcept.png|200px|'''Virtual subdivision of split element''' ]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

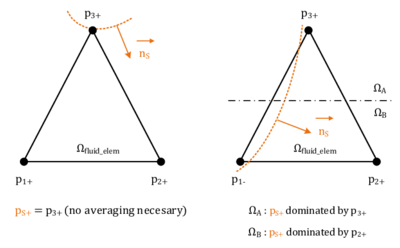

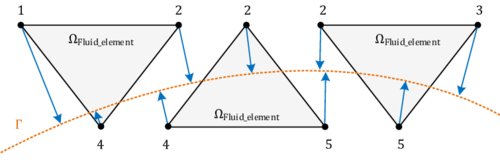

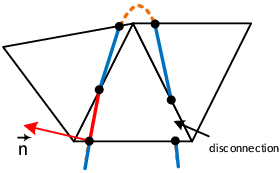

| colspan="1" | '''Figure 11:''' '''Virtual subdivision of split element''' | | colspan="1" | '''Figure 11:''' '''Virtual subdivision of split element''' | ||

| Line 861: | Line 861: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

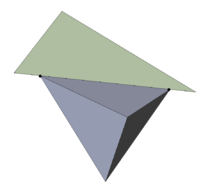

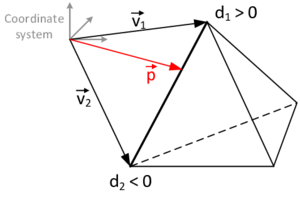

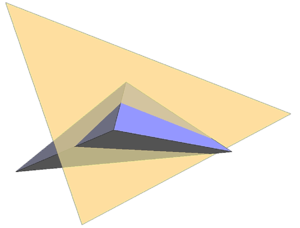

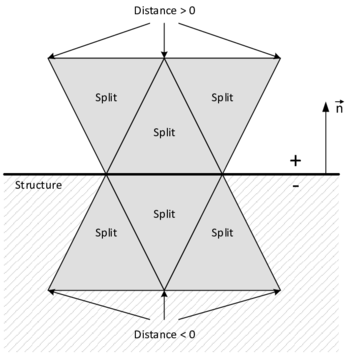

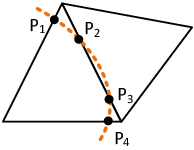

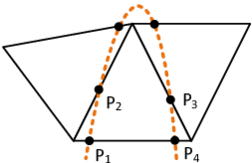

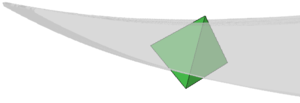

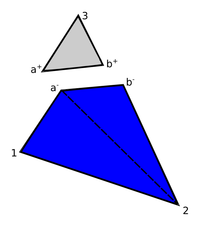

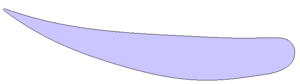

| − | |[[Image:draft_Samper_908356597-monograph-D02_ShapeFunctionConcept_Duplication.png| | + | |[[Image:draft_Samper_908356597-monograph-D02_ShapeFunctionConcept_Duplication.png|200px|'''Separation of domain by duplication of nodes''' ]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

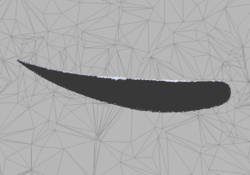

| colspan="1" | '''Figure 12:''' '''Separation of domain by duplication of nodes''' | | colspan="1" | '''Figure 12:''' '''Separation of domain by duplication of nodes''' | ||

| Line 869: | Line 869: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

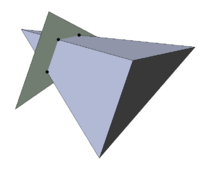

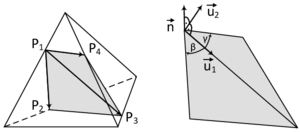

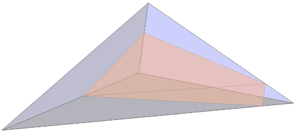

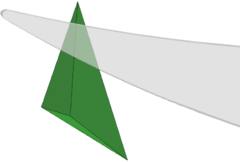

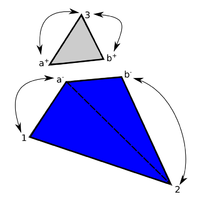

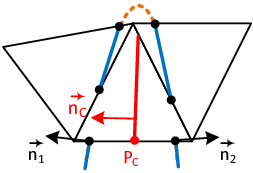

| − | |[[Image:draft_Samper_908356597-monograph-D03_ShapeFunctionConcept_Constraint.png| | + | |[[Image:draft_Samper_908356597-monograph-D03_ShapeFunctionConcept_Constraint.png|200px|'''Constraints on virtual nodes in a discontinuous element formulation''' ]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

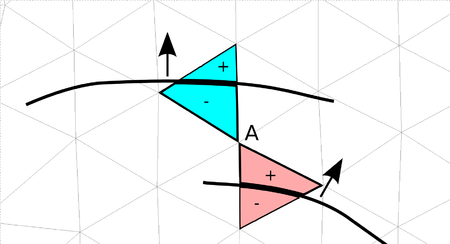

| colspan="1" | '''Figure 13:''' '''Constraints on virtual nodes in a discontinuous element formulation''' | | colspan="1" | '''Figure 13:''' '''Constraints on virtual nodes in a discontinuous element formulation''' | ||

| Line 934: | Line 934: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

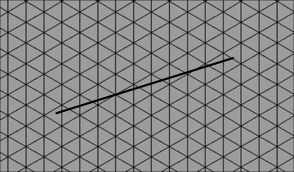

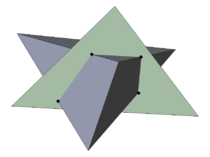

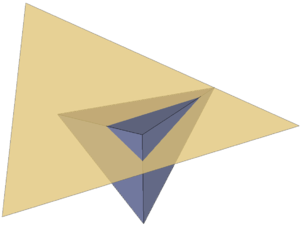

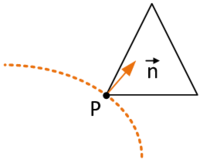

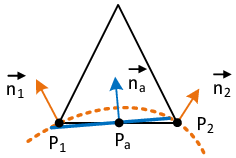

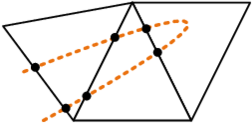

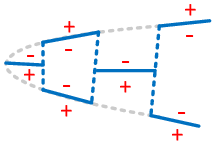

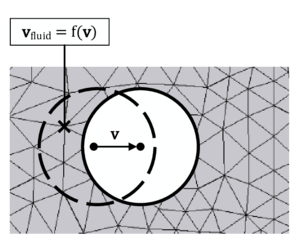

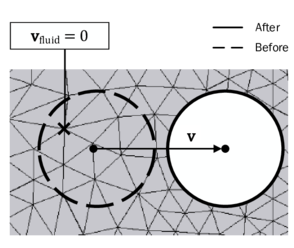

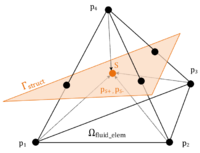

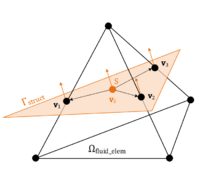

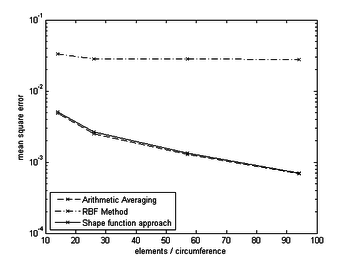

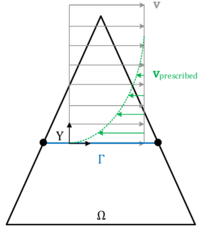

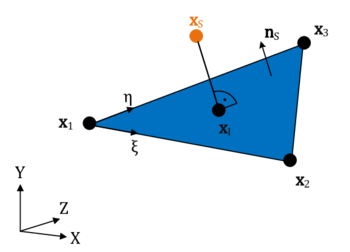

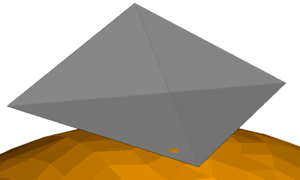

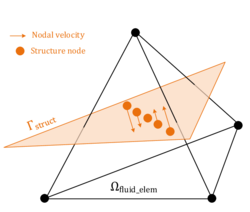

| − | |[[Image:draft_Samper_908356597-monograph-D06_EM_SlipCondition.png| | + | |[[Image:draft_Samper_908356597-monograph-D06_EM_SlipCondition.png|300px|'''Assumption of embedded velocity''' - Orange depicts the structure that is intersecting the fluid element and leading to the embedded boundary Γ in blue. Note that the embedded velocity is a function of the nodal velocities of the structure. ]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

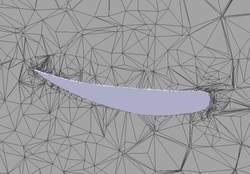

| colspan="1" | '''Figure 16:''' '''Assumption of embedded velocity''' - Orange depicts the structure that is intersecting the fluid element and leading to the embedded boundary <math>\Gamma </math> in blue. Note that the embedded velocity is a function of the nodal velocities of the structure. | | colspan="1" | '''Figure 16:''' '''Assumption of embedded velocity''' - Orange depicts the structure that is intersecting the fluid element and leading to the embedded boundary <math>\Gamma </math> in blue. Note that the embedded velocity is a function of the nodal velocities of the structure. | ||

| Line 1,532: | Line 1,532: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

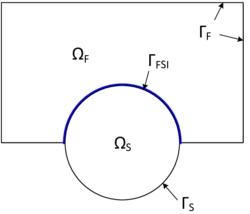

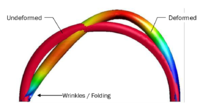

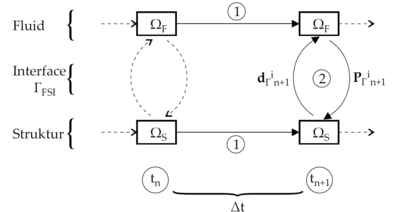

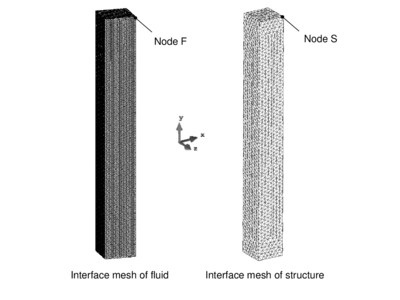

| − | |[[Image:draft_Samper_908356597-monograph-J01_FSI_coupling_interface.png| | + | |[[Image:draft_Samper_908356597-monograph-J01_FSI_coupling_interface.png|250px|'''FSI coupling interface''' - The fluid domain Ω<sub>F</sub> with the boundary Γ<sub>F</sub> and the structure domain Ω<sub>S</sub> with the boundary Γ<sub>S</sub> share the FSI interface Γ<sub>FSI</sub>.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 18:''' '''FSI coupling interface''' - The fluid domain <math>\Omega _F</math> with the boundary <math>\Gamma _F</math> and the structure domain <math>\Omega _S</math> with the boundary <math>\Gamma _S</math> share the FSI interface <math>\Gamma _{FSI}</math>. | | colspan="1" | '''Figure 18:''' '''FSI coupling interface''' - The fluid domain <math>\Omega _F</math> with the boundary <math>\Gamma _F</math> and the structure domain <math>\Omega _S</math> with the boundary <math>\Gamma _S</math> share the FSI interface <math>\Gamma _{FSI}</math>. | ||

| Line 2,330: | Line 2,330: | ||

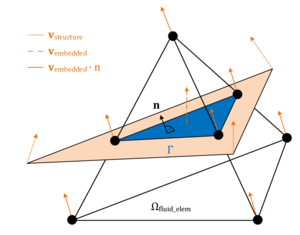

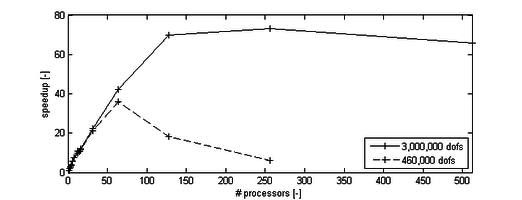

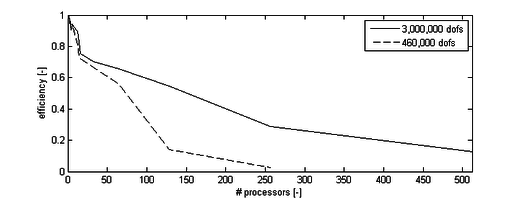

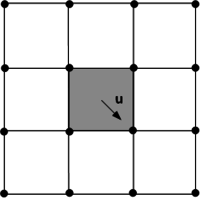

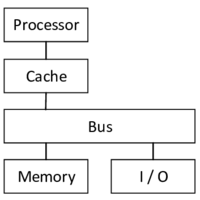

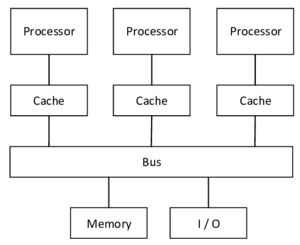

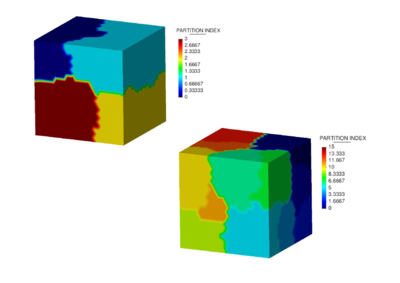

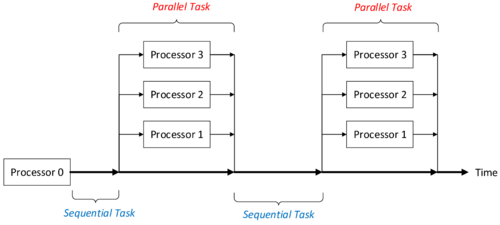

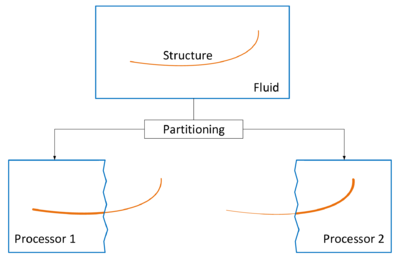

* ''Parallelization of FEM'': The idea of the spatial discretization of a fluid or a structure into small elements allows to decompose the domain into pieces which are assigned to multiple processors. Due to the fact that the element-wise contributions are separately assembled into the global stiffness matrix, the finite element computations can be executed on each processor separately. | * ''Parallelization of FEM'': The idea of the spatial discretization of a fluid or a structure into small elements allows to decompose the domain into pieces which are assigned to multiple processors. Due to the fact that the element-wise contributions are separately assembled into the global stiffness matrix, the finite element computations can be executed on each processor separately. | ||

* ''Making use of the powerful Spanish Supercomputing Network (Red Española de Supercomputación)'' | * ''Making use of the powerful Spanish Supercomputing Network (Red Española de Supercomputación)'' | ||

| + | <br /> | ||

Distributing the tremendous computational effort for a complex FSI simulation to multiple processors such that the computational efficiency improves, however, also brings some tricky challenges. The following list shows just the most significant challenges which we will face within this monograph: | Distributing the tremendous computational effort for a complex FSI simulation to multiple processors such that the computational efficiency improves, however, also brings some tricky challenges. The following list shows just the most significant challenges which we will face within this monograph: | ||

| Line 2,361: | Line 2,362: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

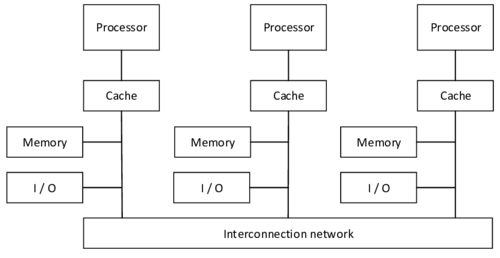

| − | |[[Image:draft_Samper_908356597-monograph-J01_SharedMemory.png| | + | |[[Image:draft_Samper_908356597-monograph-J01_SharedMemory.png|300px|'''Architecture of shared memory machines''' - All processors share the same memory.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 26:''' '''Architecture of shared memory machines''' - All processors share the same memory. | | colspan="1" | '''Figure 26:''' '''Architecture of shared memory machines''' - All processors share the same memory. | ||

| Line 3,724: | Line 3,725: | ||

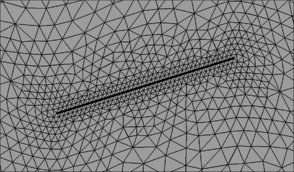

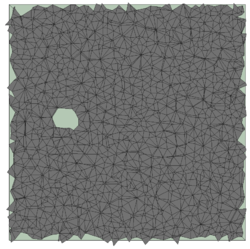

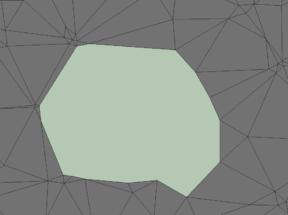

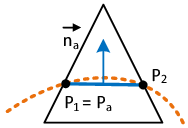

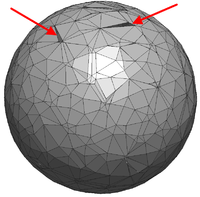

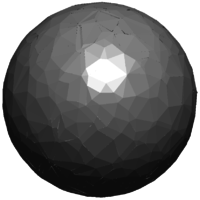

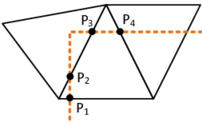

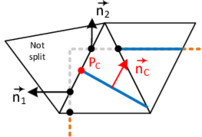

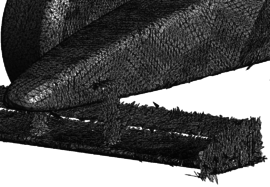

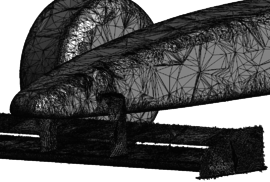

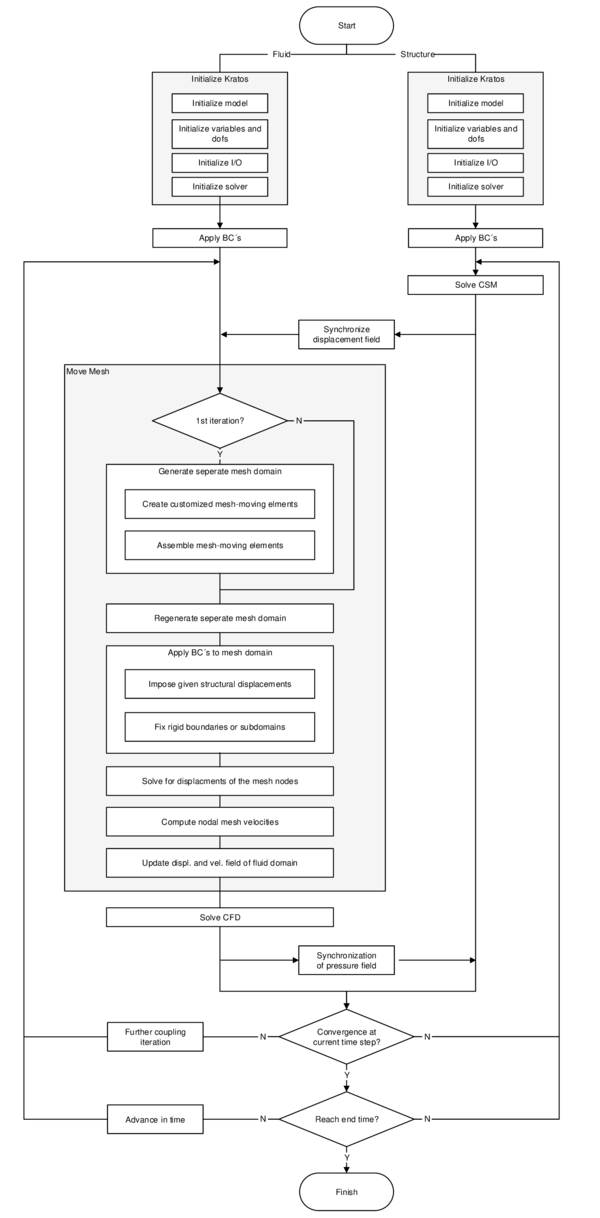

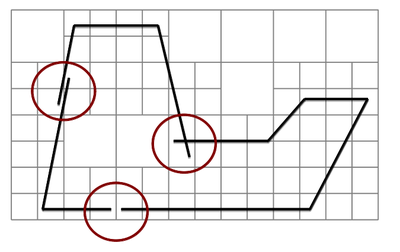

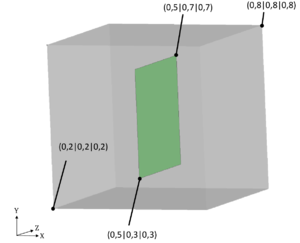

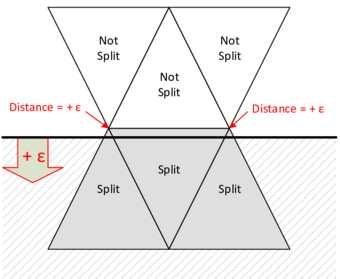

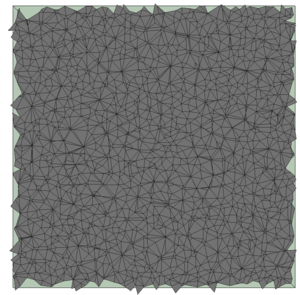

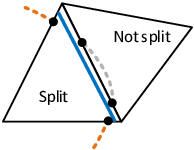

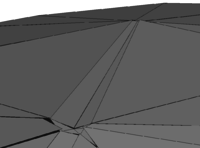

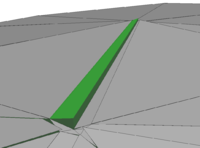

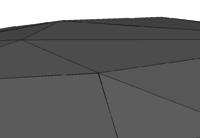

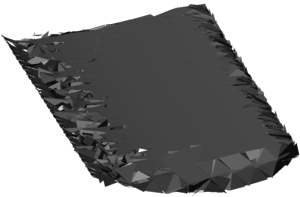

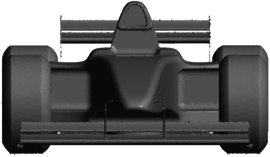

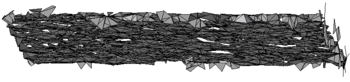

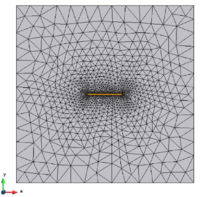

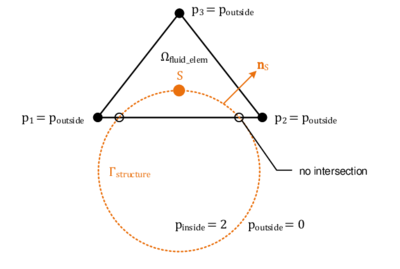

However, another obvious deficit is dominating in figure [[#img-68|68a]]. In the mesh interior there is a clear void without any triangles. Therefore it can not be the influence of the edge-near problem zone. Instead the reason turned out to be that some nodes of the fluid mesh coincide with the structure plane. This leads to an intersection pattern with one, two or even three intersection nodes directly located on a tetrahedron node as shown before in figures [[#img-55|55a]] and [[#img-55|55b]]. A simplified 2D visualization of this situation is shown in figure [[#img-69|69]]. | However, another obvious deficit is dominating in figure [[#img-68|68a]]. In the mesh interior there is a clear void without any triangles. Therefore it can not be the influence of the edge-near problem zone. Instead the reason turned out to be that some nodes of the fluid mesh coincide with the structure plane. This leads to an intersection pattern with one, two or even three intersection nodes directly located on a tetrahedron node as shown before in figures [[#img-55|55a]] and [[#img-55|55b]]. A simplified 2D visualization of this situation is shown in figure [[#img-69|69]]. | ||

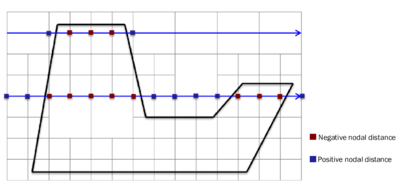

| − | Basically, all the visualized fluid elements are marked as split and the elemental distance vector contains one or two zero distance values. The problem with zero distances is that emanating from these structure-coinciding nodes no intersection point can be interpolated along the edges to that node as this requires a negative and a positive signed distance value. This implies that within the tetrahedron no triangle can be generated as no intersection point can be computed. Related to figure | + | Basically, all the visualized fluid elements are marked as split and the elemental distance vector contains one or two zero distance values. The problem with zero distances is that emanating from these structure-coinciding nodes no intersection point can be interpolated along the edges to that node as this requires a negative and a positive signed distance value. This implies that within the tetrahedron no triangle can be generated as no intersection point can be computed. Related to figure [[#img-68|68a]] there is one node which is coinciding with the structure plane. All tetrahedron which share this node will be neglected in the visualization function and therefore a hole is arising. A remedy for this is presented in the following section. |

====7.1.1.8 Strategy to eliminate zero-distance values==== | ====7.1.1.8 Strategy to eliminate zero-distance values==== | ||

| Line 3,753: | Line 3,754: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_908356597-monograph-J22_PlaneNoZeroDistances.png| | + | |[[Image:draft_Samper_908356597-monograph-J22_PlaneNoZeroDistances.png|300px|'''Representation of the plane after eliminating zero-distances''' - Compared to figure [[#img-69|69]] the hole does not appear any more.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 71:''' '''Representation of the plane after eliminating zero-distances''' - Compared to figure [[#img-69|69]] the hole does not appear any more. | | colspan="1" | '''Figure 71:''' '''Representation of the plane after eliminating zero-distances''' - Compared to figure [[#img-69|69]] the hole does not appear any more. | ||

|} | |} | ||

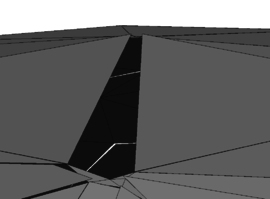

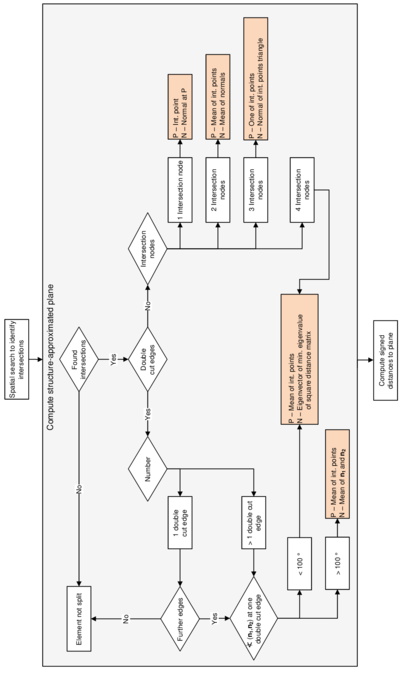

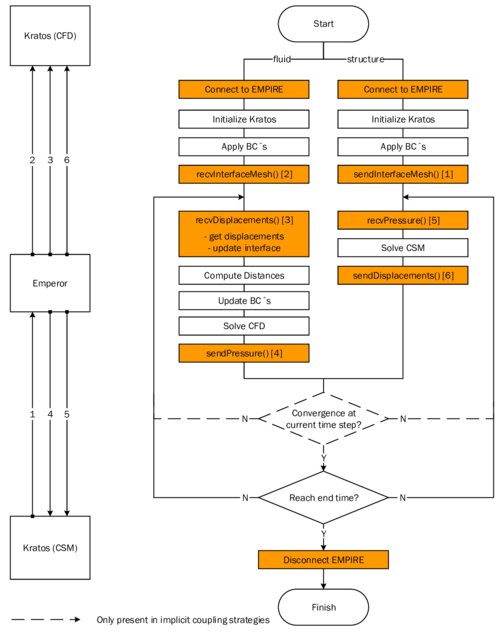

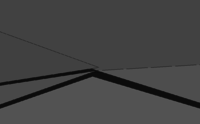

| − | The region around the node with a zero-distance is now completely closed as all the tetrahedra are able to represent the intersection pattern. The difference can be better shown in a direct comparison of this region - once without the local structure movement (figure | + | The region around the node with a zero-distance is now completely closed as all the tetrahedra are able to represent the intersection pattern. The difference can be better shown in a direct comparison of this region - once without the local structure movement (figure [[#img-72|72b]]) and with the zero distance correction (figure [[#img-72|72b]]). The right figure shows clearly that there was one node with a zero distance which is now forming numerous triangles to close the hole. |

This method conveys more advantages which go far beyond this demonstrated purpose. In the embedded method the nodes with zero-distance can be physically seen as part of the fluid <u>and</u> structure at the same time. There is no clear distinction between the properties which should be assigned to this node. How to treat these nodes in the formulation of the embedded approach? The set of modified shape functions of the split fluid elements - as explained in chapter [[#2.2.4.2 Element technology|2.2.4.2]] - is based on a clear distinction of each node to either fluid or structure, which is provided in any situation by the just discussed local interface-movement approach. | This method conveys more advantages which go far beyond this demonstrated purpose. In the embedded method the nodes with zero-distance can be physically seen as part of the fluid <u>and</u> structure at the same time. There is no clear distinction between the properties which should be assigned to this node. How to treat these nodes in the formulation of the embedded approach? The set of modified shape functions of the split fluid elements - as explained in chapter [[#2.2.4.2 Element technology|2.2.4.2]] - is based on a clear distinction of each node to either fluid or structure, which is provided in any situation by the just discussed local interface-movement approach. | ||

| − | |||

<div id='img-72'></div> | <div id='img-72'></div> | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

| Line 3,768: | Line 3,768: | ||

|[[Image:draft_Samper_908356597-monograph-J23_PlaneZeroZoom.png|288px|]] | |[[Image:draft_Samper_908356597-monograph-J23_PlaneZeroZoom.png|288px|]] | ||

|[[Image:draft_Samper_908356597-monograph-J24_PlaneNoZeroZoom.png|288px|'''Closer view to the region around a node with zero-distance - a comparison''' - The left figure is the result of the distance function which does not handle zero distance values - leading to a hole. The right figure solves this problem by a zero-distance correction.]] | |[[Image:draft_Samper_908356597-monograph-J24_PlaneNoZeroZoom.png|288px|'''Closer view to the region around a node with zero-distance - a comparison''' - The left figure is the result of the distance function which does not handle zero distance values - leading to a hole. The right figure solves this problem by a zero-distance correction.]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" | (a) No zero-distance correction | ||

| + | | colspan="1" | (b) With zero-distance correction | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="2" | '''Figure 72:''' '''Closer view to the region around a node with zero-distance - a comparison''' - The left figure is the result of the distance function which does not handle zero distance values - leading to a hole. The right figure solves this problem by a zero-distance correction. | | colspan="2" | '''Figure 72:''' '''Closer view to the region around a node with zero-distance - a comparison''' - The left figure is the result of the distance function which does not handle zero distance values - leading to a hole. The right figure solves this problem by a zero-distance correction. | ||

| Line 4,003: | Line 4,006: | ||

|- | |- | ||

| style="text-align: center;" | <math>\frac{\partial L}{\partial \boldsymbol{n}} = 2 \boldsymbol{A} \boldsymbol{n} + 2 \lambda \boldsymbol{n} = 0 </math> | | style="text-align: center;" | <math>\frac{\partial L}{\partial \boldsymbol{n}} = 2 \boldsymbol{A} \boldsymbol{n} + 2 \lambda \boldsymbol{n} = 0 </math> | ||

| + | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (7.21) | | style="width: 5px;text-align: right;white-space: nowrap;" | (7.21) | ||

| + | |} | ||

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| style="text-align: center;" | <math> \frac{\partial L}{\partial \lambda } = \boldsymbol{n}^T \boldsymbol{n} - 1 = 0 </math> | | style="text-align: center;" | <math> \frac{\partial L}{\partial \lambda } = \boldsymbol{n}^T \boldsymbol{n} - 1 = 0 </math> | ||

| − | |||

|} | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (7.22) | ||

|} | |} | ||

| Line 4,456: | Line 4,466: | ||

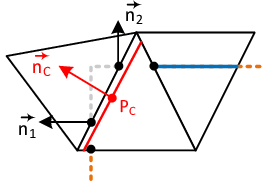

<math display="inline">P_{C} \gets </math> mean(<math display="inline">nodes\_container</math>) | <math display="inline">P_{C} \gets </math> mean(<math display="inline">nodes\_container</math>) | ||

| + | |||

<math display="inline">\boldsymbol{n}_{C} \gets </math> mean(<math display="inline">normals\_container</math>) | <math display="inline">\boldsymbol{n}_{C} \gets </math> mean(<math display="inline">normals\_container</math>) | ||

| Line 4,470: | Line 4,481: | ||

|- | |- | ||

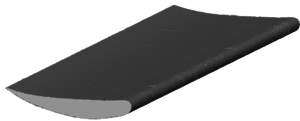

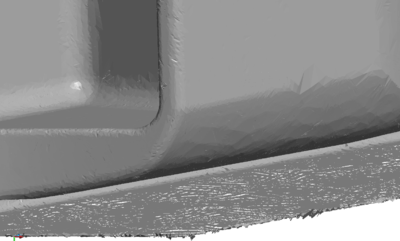

|[[Image:draft_Samper_908356597-monograph-J21_WingAfter_Solution2_Side.png|300px|]] | |[[Image:draft_Samper_908356597-monograph-J21_WingAfter_Solution2_Side.png|300px|]] | ||

| − | |||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | (a) Side view | | colspan="1" | (a) Side view | ||

| + | |- | ||

| + | |[[Image:draft_Samper_908356597-monograph-J22_WingAfter_Solution2_Front.png|300px|'''Wing model tested with the proposed approach''' - The applied approach is illustrated in figure [[#img-104|104]].]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | (b) Front view | | colspan="1" | (b) Front view | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| − | |||

| colspan="2" | '''Figure 105:''' '''Wing model tested with the proposed approach''' - The applied approach is illustrated in figure [[#img-104|104]]. | | colspan="2" | '''Figure 105:''' '''Wing model tested with the proposed approach''' - The applied approach is illustrated in figure [[#img-104|104]]. | ||

|} | |} | ||

| Line 4,858: | Line 4,870: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

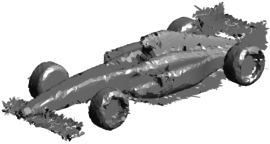

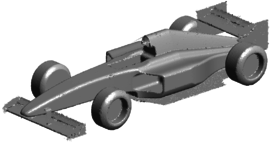

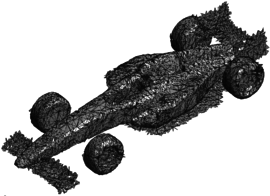

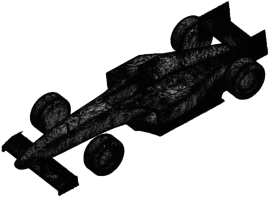

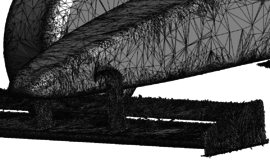

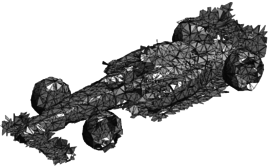

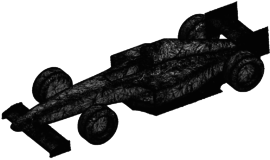

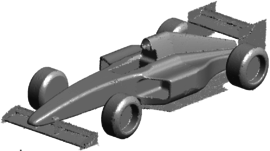

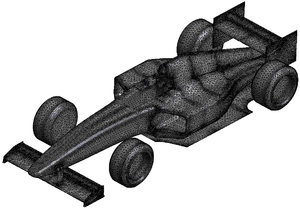

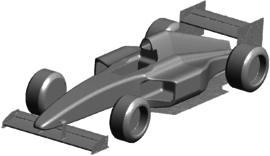

| − | |[[Image:draft_Samper_908356597-monograph-J01_FerrariStructureMesh.png| | + | |[[Image:draft_Samper_908356597-monograph-J01_FerrariStructureMesh.png|300px|'''Structure mesh of Formula 1 car''' - The surface model is meshed with 2.8e5 triangle elements.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 126:''' '''Structure mesh of Formula 1 car''' - The surface model is meshed with <math>2.8e5</math> triangle elements. | | colspan="1" | '''Figure 126:''' '''Structure mesh of Formula 1 car''' - The surface model is meshed with <math>2.8e5</math> triangle elements. | ||

| Line 5,037: | Line 5,049: | ||

# Refinement strategy 1: 1 step | # Refinement strategy 1: 1 step | ||

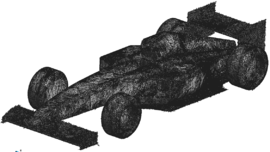

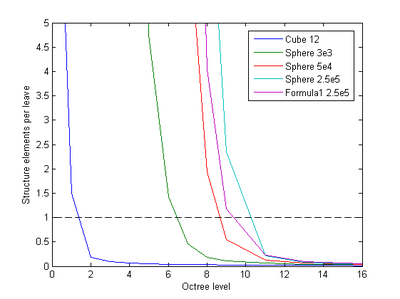

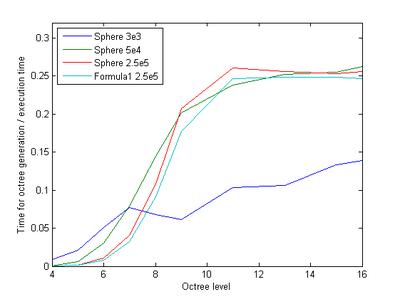

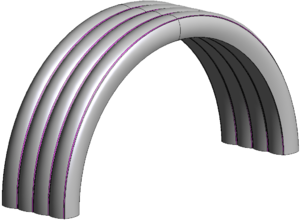

| − | Applying this strategy to the fine-meshed structure (<math>2.5e5</math> elements) yields the approximation shown in figure [[#img-136|136]]. Already without any refinement, the shape of the tubes can be roughly captured (figure [[#img-136|136a]]). The curvature and the sharp edges at the base, however, can not be represented accurately. After the first three refinement steps (figure [[#img-136|136c]]) the hangar approximation converges very well to the original model. Solely the surface of the tube exhibits some edged indentations which can be smoothed by applying strategy 1 again as shown in figure | + | Applying this strategy to the fine-meshed structure (<math>2.5e5</math> elements) yields the approximation shown in figure [[#img-136|136]]. Already without any refinement, the shape of the tubes can be roughly captured (figure [[#img-136|136a]]). The curvature and the sharp edges at the base, however, can not be represented accurately. After the first three refinement steps (figure [[#img-136|136c]]) the hangar approximation converges very well to the original model. Solely the surface of the tube exhibits some edged indentations which can be smoothed by applying strategy 1 again as shown in figure [[#img-136|136c]]. The precise representation of the sharp edges at the base is shown in figure [[#img-136|136d]]. |

<div id='img-136'></div> | <div id='img-136'></div> | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

| Line 6,282: | Line 6,294: | ||

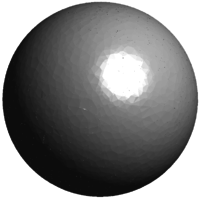

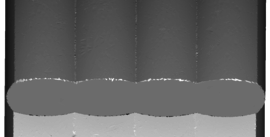

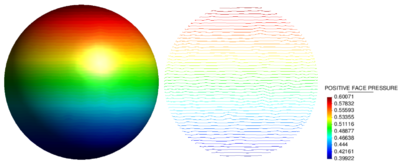

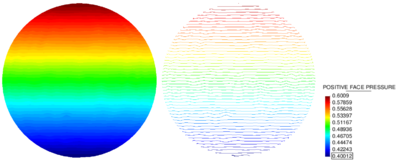

|[[Image:draft_Samper_908356597-monograph-D33_Averaging_results_01.png|400px|]] | |[[Image:draft_Samper_908356597-monograph-D33_Averaging_results_01.png|400px|]] | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

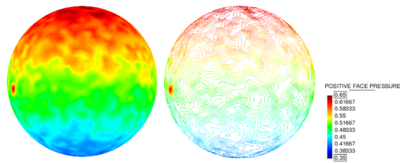

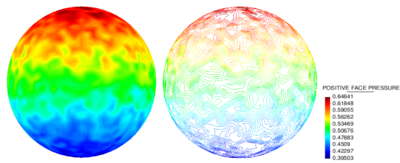

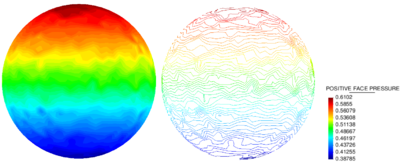

| − | | colspan="1" | (a) elemets/circumference = 14 | + | | colspan="1" | (a) ''elemets/circumference'' = 14 |

|- | |- | ||

|[[Image:draft_Samper_908356597-monograph-D33_Averaging_results_02.png|400px|'''Results of pressure mapping by arithmetic averaging''' - The results are shown for two different levels of refinement of the fluid domain.]] | |[[Image:draft_Samper_908356597-monograph-D33_Averaging_results_02.png|400px|'''Results of pressure mapping by arithmetic averaging''' - The results are shown for two different levels of refinement of the fluid domain.]] | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| − | | colspan="1" | (b) elemets/circumference = 94 | + | | colspan="1" | (b) ''elemets/circumference'' = 94 |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 189:''' '''Results of pressure mapping by arithmetic averaging''' - The results are shown for two different levels of refinement of the fluid domain. | | colspan="1" | '''Figure 189:''' '''Results of pressure mapping by arithmetic averaging''' - The results are shown for two different levels of refinement of the fluid domain. | ||

| Line 6,467: | Line 6,479: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\begin{array}{ccc}\\ \left[~\boldsymbol{x}_I(\boldsymbol{\eta }_I) ~\right]^T \\ \\ \end{array} = \boldsymbol{N}_{local} (\boldsymbol{\eta }_I) | + | | style="text-align: center;" | <math>\begin{array}{ccc}\\ \left[~\boldsymbol{x}_I(\boldsymbol{\eta }_I) ~\right]^T \\ \\ \end{array} = \boldsymbol{N}_{local} (\boldsymbol{\eta }_I) \cdot \left[ \begin{array}{ccc}&&\\ \boldsymbol{x}_1 & \boldsymbol{x}_2 & \boldsymbol{x}_3\\ & &\end{array} \right] \begin{array}{ccc}\\ \end{array} </math> |

| − | + | ||

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (8.25) | | style="width: 5px;text-align: right;white-space: nowrap;" | (8.25) | ||

| Line 6,726: | Line 6,736: | ||

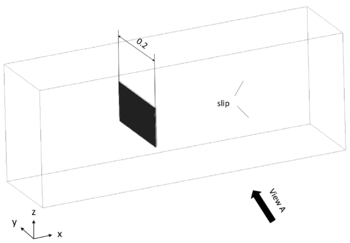

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

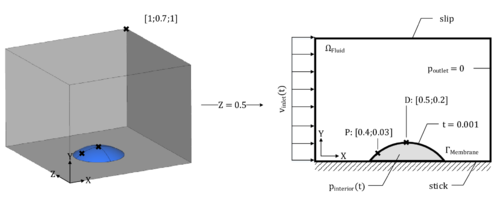

| − | |[[Image:draft_Samper_908356597-monograph-D51_Setup_InflatableMembrane.png| | + | |[[Image:draft_Samper_908356597-monograph-D51_Setup_InflatableMembrane.png|500px|'''Setup of an inflatable membrane in a CFD context''' ]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 208:''' '''Setup of an inflatable membrane in a CFD context''' | | colspan="1" | '''Figure 208:''' '''Setup of an inflatable membrane in a CFD context''' | ||

|} | |} | ||

| − | + | <span id='table-12'></span> | |

| − | {| class="floating_tableSCP wikitable" style="text-align: | + | {| class="floating_tableSCP wikitable" style="text-align: center; margin: 1em auto;min-width:50%;" |

| − | |+ style="font-size: 75%;" | | + | |+ style="font-size: 75%;" |Table. 12 '''Material parameters''' |

| − | |- | + | |- style="border-top: 2px solid;border-bottom: 2px solid;" |

| <math display="inline">\rho _{Membrane}</math> | | <math display="inline">\rho _{Membrane}</math> | ||

| <math>E_{Membrane}</math> | | <math>E_{Membrane}</math> | ||

| Line 6,740: | Line 6,750: | ||

| <math>\rho _{Fluid}</math> | | <math>\rho _{Fluid}</math> | ||

| <math>\mu _{Fluid}</math> | | <math>\mu _{Fluid}</math> | ||

| − | |- | + | |- style="border-top: 2px solid;border-bottom: 2px solid;" |

| <math display="inline">1.1 \cdot 10^3</math> | | <math display="inline">1.1 \cdot 10^3</math> | ||

| <math>1.0 \cdot 10^5</math> | | <math>1.0 \cdot 10^5</math> | ||

| Line 6,760: | Line 6,770: | ||

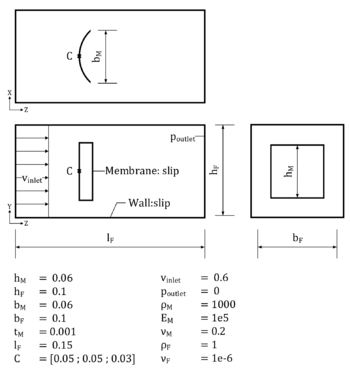

The corresponding boundary conditions can be found in figure [[#img-209|209]]. | The corresponding boundary conditions can be found in figure [[#img-209|209]]. | ||

| − | |||

<div id='img-209'></div> | <div id='img-209'></div> | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

| Line 6,766: | Line 6,775: | ||

|[[Image:draft_Samper_908356597-monograph-D52_inflatableMembrane_p_BC.png|294px|]] | |[[Image:draft_Samper_908356597-monograph-D52_inflatableMembrane_p_BC.png|294px|]] | ||

|[[Image:draft_Samper_908356597-monograph-D52_inflatableMembrane_v_BC.png|294px|'''Prescribed quantities in the simplified hangar scenario''']] | |[[Image:draft_Samper_908356597-monograph-D52_inflatableMembrane_v_BC.png|294px|'''Prescribed quantities in the simplified hangar scenario''']] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" | (a) Prescribed inflatation of the membrane | ||

| + | | colspan="1" | (b) Prescribed flow | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="2" | '''Figure 209:''' '''Prescribed quantities in the simplified hangar scenario''' | | colspan="2" | '''Figure 209:''' '''Prescribed quantities in the simplified hangar scenario''' | ||

| Line 6,774: | Line 6,786: | ||

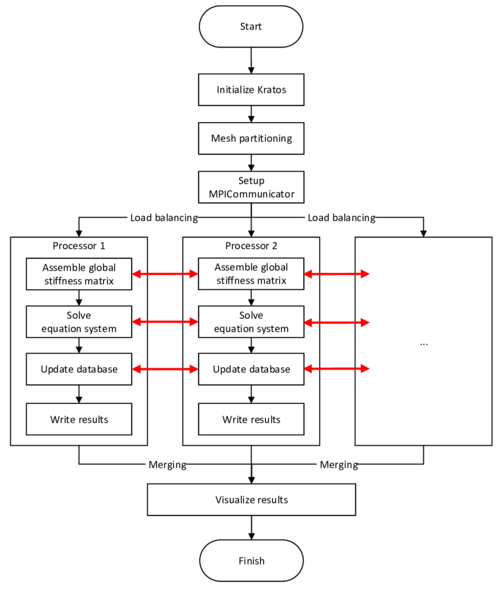

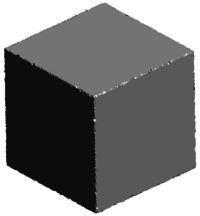

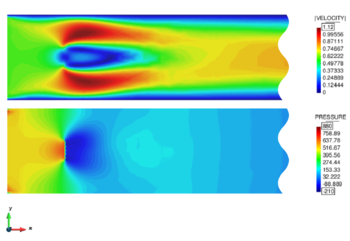

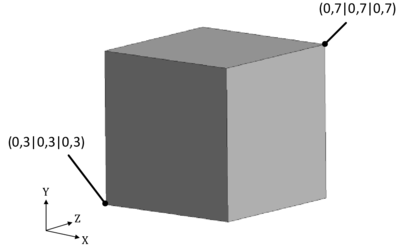

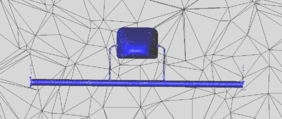

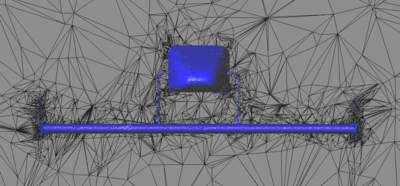

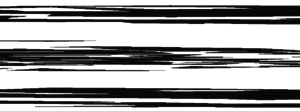

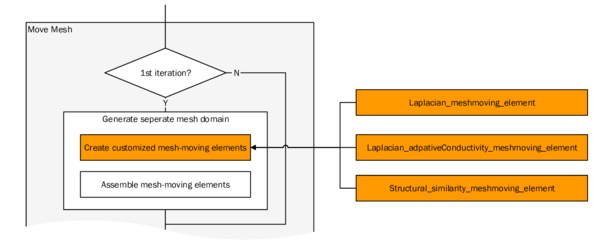

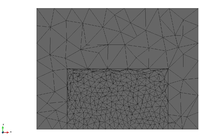

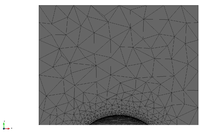

Before discussing the simulation results, however, it is worthwhile to have a look at the different finite element models that needed to be prepared for the intended comparison. The single models are illustrated in figure [[#img-210|210]]. Without having computed anything the first and one of the most convincing advantages becomes already obvious. That is the advantage of a significantly eased pre-processing in the embedded approach. Whereas for the ALE method a detailed and explicit modeling of the interface is necessary, the embedded approach only requires a simple background fluid mesh which may be obtained very quickly by automated meshing routines. Depending on the intended level of accuracy, this may indeed contain areas with different refinement, but creating the latter is still significantly faster than an explicit modeling of the actual interface. In this context it is interesting, that the structure model may be the same in both cases, which means that for the embedded approach given models from earlier simulations may be recycled and do not have to be modeled again. This in fact is an additional advantage regarding the necessary pre-processing which might facilitate a possible change of the solution procedure from the ALE approach to the embedded approach. | Before discussing the simulation results, however, it is worthwhile to have a look at the different finite element models that needed to be prepared for the intended comparison. The single models are illustrated in figure [[#img-210|210]]. Without having computed anything the first and one of the most convincing advantages becomes already obvious. That is the advantage of a significantly eased pre-processing in the embedded approach. Whereas for the ALE method a detailed and explicit modeling of the interface is necessary, the embedded approach only requires a simple background fluid mesh which may be obtained very quickly by automated meshing routines. Depending on the intended level of accuracy, this may indeed contain areas with different refinement, but creating the latter is still significantly faster than an explicit modeling of the actual interface. In this context it is interesting, that the structure model may be the same in both cases, which means that for the embedded approach given models from earlier simulations may be recycled and do not have to be modeled again. This in fact is an additional advantage regarding the necessary pre-processing which might facilitate a possible change of the solution procedure from the ALE approach to the embedded approach. | ||

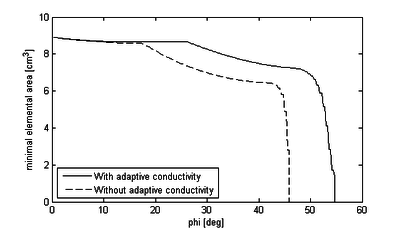

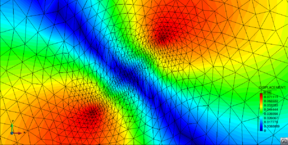

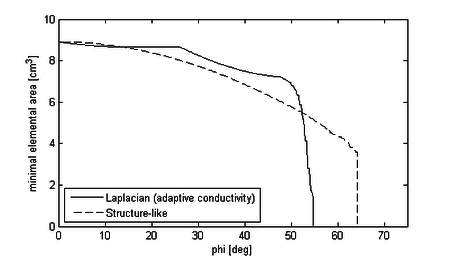

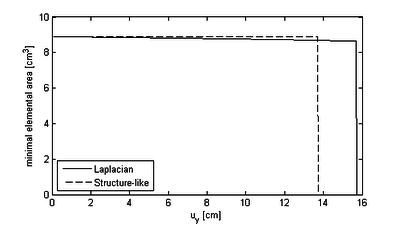

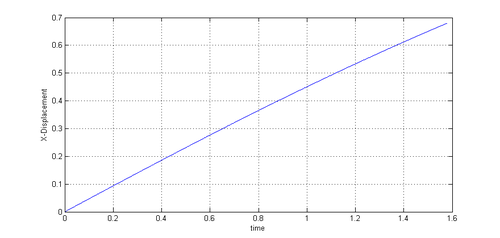

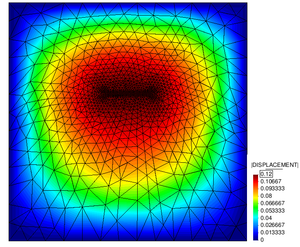

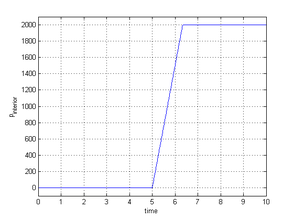

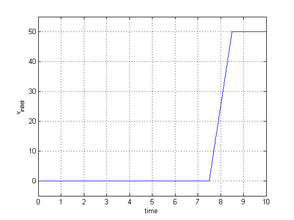

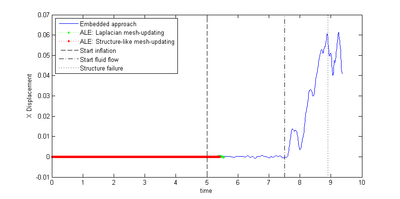

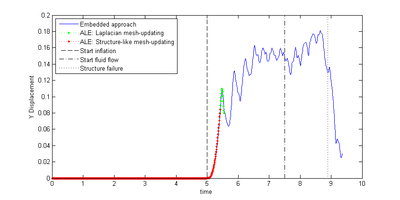

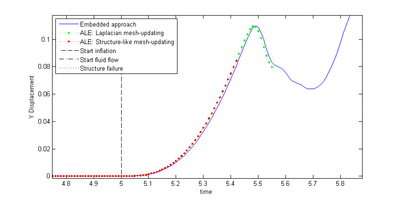

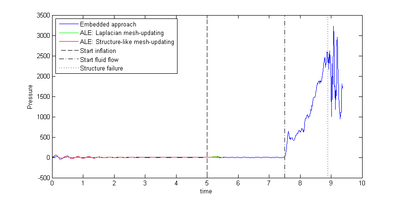

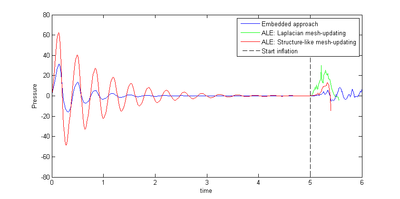

| − | After having modeled the example for both solution approaches it is each simulated for maximum <math display="inline">10s</math>. The simulation is, however, expected to fail earlier due to reasons that we will see later. In the ALE-case we furthermore want to use two different mesh-updating strategies, i.e. the Laplacian mesh-updating with adaptive conductivity and the structure-like alternative. This shall allow us to evaluate the possible improvements in more detail. For the corresponding quantitative evaluation, we are looking at the two distinct nodes that were already given in figure [[#img-208|208]]. To be more precise, we are evaluating the flow-induced displacement at node | + | After having modeled the example for both solution approaches it is each simulated for maximum <math display="inline">10s</math>. The simulation is, however, expected to fail earlier due to reasons that we will see later. In the ALE-case we furthermore want to use two different mesh-updating strategies, i.e. the Laplacian mesh-updating with adaptive conductivity and the structure-like alternative. This shall allow us to evaluate the possible improvements in more detail. For the corresponding quantitative evaluation, we are looking at the two distinct nodes that were already given in figure [[#img-208|208]]. To be more precise, we are evaluating the flow-induced displacement at node "<math display="inline">D</math>" and the resulting pressure evolution at node "<math display="inline">P</math>". Let us first have a look on the displacements of node <math display="inline">D</math> in <math display="inline">X</math> and <math display="inline">Y</math>. The corresponding results are given in figure [[#img-211|211]] and [[#img-212|212]], respectively. |

| − | |||

<div id='img-210'></div> | <div id='img-210'></div> | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_908356597-monograph-D53_Model_Fluid_EM.png| | + | |[[Image:draft_Samper_908356597-monograph-D53_Model_Fluid_EM.png|200px|]] |

| − | |[[Image:draft_Samper_908356597-monograph-D53_Model_Fluid_ALE.png| | + | |[[Image:draft_Samper_908356597-monograph-D53_Model_Fluid_ALE.png|200px|]] |

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" | (a) Fluid model in an embedded approach | ||

| + | | colspan="1" | (b) Fluid model in an ALE approach | ||

|- | |- | ||

| colspan="2"|[[Image:draft_Samper_908356597-monograph-D53_Model_Structure.png|294px|'''Possible pre-processing in the embedded and body-fitted approach''']] | | colspan="2"|[[Image:draft_Samper_908356597-monograph-D53_Model_Structure.png|294px|'''Possible pre-processing in the embedded and body-fitted approach''']] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="2" | (c) Common structure model | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="2" | '''Figure 210:''' '''Possible pre-processing in the embedded and body-fitted approach''' | | colspan="2" | '''Figure 210:''' '''Possible pre-processing in the embedded and body-fitted approach''' | ||

| Line 6,791: | Line 6,807: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_908356597-monograph-D54_inflatableMembrane_XDisp.png| | + | |[[Image:draft_Samper_908356597-monograph-D54_inflatableMembrane_XDisp.png|400px|'''Flow induced X-movement of node D from figure [[#img-208|208]]''']] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 211:''' '''Flow induced <math>X</math>-movement of node <math>D</math> from figure [[#img-208|208]]''' | | colspan="1" | '''Figure 211:''' '''Flow induced <math>X</math>-movement of node <math>D</math> from figure [[#img-208|208]]''' | ||

|} | |} | ||

| − | |||

<div id='img-212'></div> | <div id='img-212'></div> | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

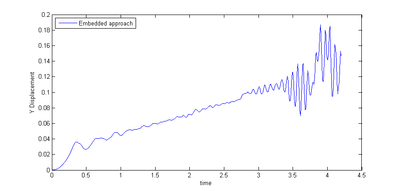

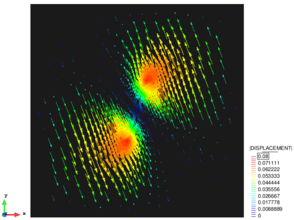

| − | |[[Image:draft_Samper_908356597-monograph-D54_inflatableMembrane_YDisp.png| | + | |[[Image:draft_Samper_908356597-monograph-D54_inflatableMembrane_YDisp.png|400px|]] |

| − | + | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| − | | colspan=" | + | | colspan="1" | (a) Over entire simulation |

| + | |- | ||

| + | |[[Image:draft_Samper_908356597-monograph-D54_inflatableMembrane_YDisp_cutout.png|400px|'''Flow induced Y-movement of node D from figure [[#img-208|208]]''']] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" | (b) Close-up at failure of the ALE solution | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" | '''Figure 212:''' '''Flow induced <math>Y</math>-movement of node <math>D</math> from figure [[#img-208|208]]''' | ||

|} | |} | ||

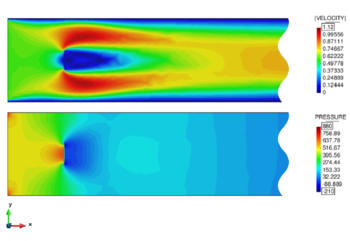

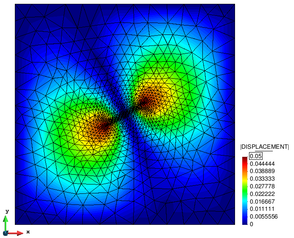

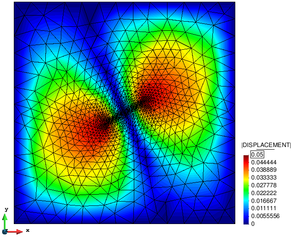

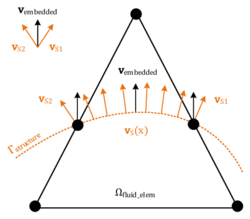

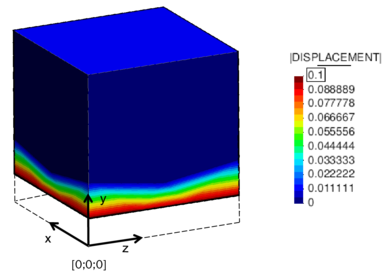

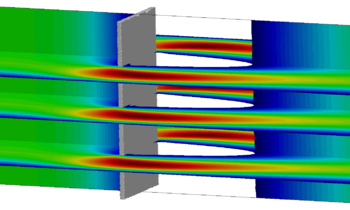

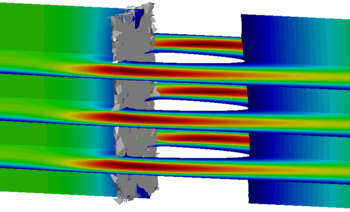

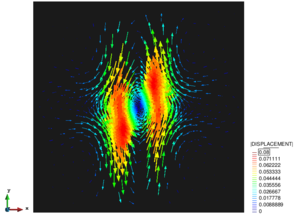

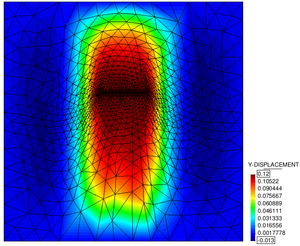

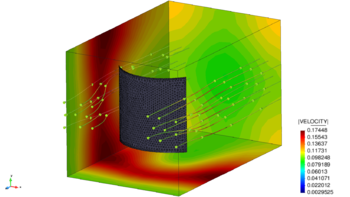

First striking fact seen in both figures is, that with the embedded approach we are able to resolve a significantly wider range of movements compared to the ALE case. In particular it can be seen, that while the ALE-approach already fails<span id="fnc-44"></span>[[#fn-44|<sup>1</sup>]] during the inflation, the embedded approach allows to continue the simulation up to the point of the flow-induced deflection of the inflated membrane. So it is not critically influenced from the complex dynamics of the structure. Figure [[#img-213|213]] and [[#img-214|214]] illustrate the results from the embedded solution for two different instances in time according to the two different load stages. | First striking fact seen in both figures is, that with the embedded approach we are able to resolve a significantly wider range of movements compared to the ALE case. In particular it can be seen, that while the ALE-approach already fails<span id="fnc-44"></span>[[#fn-44|<sup>1</sup>]] during the inflation, the embedded approach allows to continue the simulation up to the point of the flow-induced deflection of the inflated membrane. So it is not critically influenced from the complex dynamics of the structure. Figure [[#img-213|213]] and [[#img-214|214]] illustrate the results from the embedded solution for two different instances in time according to the two different load stages. | ||

| − | |||

<div id='img-213'></div> | <div id='img-213'></div> | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

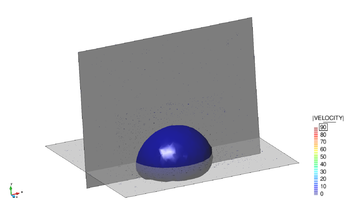

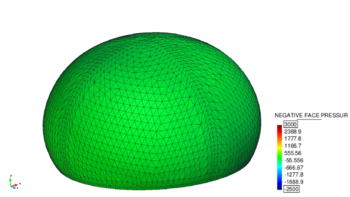

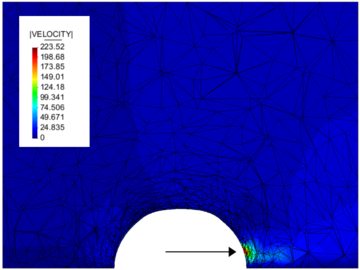

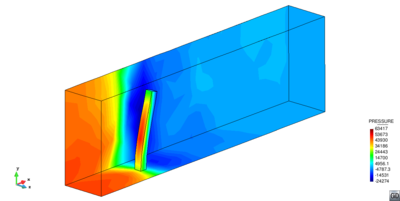

| − | |[[Image:draft_Samper_908356597-monograph-D55_Velocity_NoWind.png| | + | |[[Image:draft_Samper_908356597-monograph-D55_Velocity_NoWind.png|350px|]] |

| − | |[[Image:draft_Samper_908356597-monograph-D55_Pressure_NoWind.png| | + | |- style="text-align: center; font-size: 75%;" |

| − | + | | colspan="1" | (a) Driving velocity field(Fluid model with embedded structure) | |

| − | ]] | + | |- |

| + | |[[Image:draft_Samper_908356597-monograph-D55_Pressure_NoWind.png|350px|'''Inflation of the membrane inside the environmental fluid''' - The figures show a snap-shot at t = 7.5s during the inflation phase]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" | (b) Induced surface pressure (Structure model with mapped pressure) | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| − | | colspan=" | + | | colspan="1" | '''Figure 213:''' '''Inflation of the membrane inside the environmental fluid''' - The figures show a snap-shot at t = 7.5s during the inflation phase |

|} | |} | ||

| − | |||

<div id='img-214'></div> | <div id='img-214'></div> | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

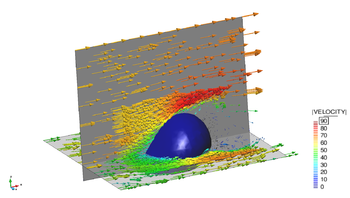

| − | |[[Image:draft_Samper_908356597-monograph-D56_Velocity_InWind.png| | + | |[[Image:draft_Samper_908356597-monograph-D56_Velocity_InWind.png|350px|]] |

| − | |[[Image:draft_Samper_908356597-monograph-D56_Pressure_InWind.png| | + | |- style="text-align: center; font-size: 75%;" |

| + | | colspan="1" | (a) Driving velocity field(Fluid model with embedded structure) | ||

| + | |- | ||

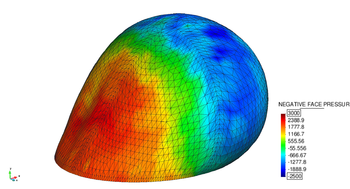

| + | |[[Image:draft_Samper_908356597-monograph-D56_Pressure_InWind.png|350px|'''Flow induced movement of the coupled membrane''' - The figures show a snap-shot of the resulting fluid-structure interaction during the active fluid flow at t = 8.75s]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" | (b) Induced surface pressure (Structure model with mapped pressure) | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="2" | '''Figure 214:''' '''Flow induced movement of the coupled membrane''' - The figures show a snap-shot of the resulting fluid-structure interaction during the active fluid flow at <math>t = 8.75s</math> | | colspan="2" | '''Figure 214:''' '''Flow induced movement of the coupled membrane''' - The figures show a snap-shot of the resulting fluid-structure interaction during the active fluid flow at <math>t = 8.75s</math> | ||

| Line 6,834: | Line 6,860: | ||

Second striking fact when looking at the displacement diagrams is, that changing the mesh-updating strategy in the ALE case only yields comparatively small improvements in terms of possible movements that can be simulated. This means here, that with none of the given mesh-updating strategies we were able to simulate the entire inflation together with the later deflection phase. Only the change to the embedded solution procedure really allows to overcome the respective limitations. Putting this in a more general context, one may realize that with an ALE-solution procedure there will be ''always'' a limit beyond which a proper mesh-update is not possible anymore<span id="fnc-45"></span>[[#fn-45|<sup>2</sup>]]. So having an FSI problem where such a limit is reached, it may be very attractive to choose an embedded solution approach instead of trying various different sophisticated and possibly costly mesh-updating strategies which only allow for a certain shift of the limits instead of really overcoming them. | Second striking fact when looking at the displacement diagrams is, that changing the mesh-updating strategy in the ALE case only yields comparatively small improvements in terms of possible movements that can be simulated. This means here, that with none of the given mesh-updating strategies we were able to simulate the entire inflation together with the later deflection phase. Only the change to the embedded solution procedure really allows to overcome the respective limitations. Putting this in a more general context, one may realize that with an ALE-solution procedure there will be ''always'' a limit beyond which a proper mesh-update is not possible anymore<span id="fnc-45"></span>[[#fn-45|<sup>2</sup>]]. So having an FSI problem where such a limit is reached, it may be very attractive to choose an embedded solution approach instead of trying various different sophisticated and possibly costly mesh-updating strategies which only allow for a certain shift of the limits instead of really overcoming them. | ||

| − | Third, when looking in particular at the <math display="inline">Y</math>-displacement in figure [[#img- | + | Third, when looking in particular at the <math display="inline">Y</math>-displacement in figure [[#img-212|212b]] it can be observed, that there in fact is a quantitative difference in the results. Assuming that the ALE-approach generally is more accurate than the embedded one, this difference may be regarded as true accuracy loss. How this accuracy loss actually influences the principle behavior of the structure and to what extend the system's dynamic is affected by that are still two open questions which could not be answered in the scope of this work. It is nevertheless interesting to note that in this example the simulated principal movement of the membrane up to the point of failure is qualitatively the same with either approach. |

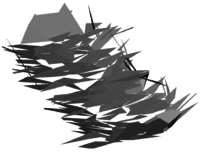

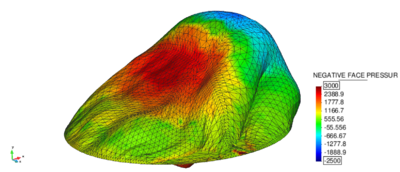

Apart from the movement, also the actual failure situation is interesting. Looking at the results, it can be observed, that the embedded and the ALE approach fail due to two ''different'' reasons. While the ALE approach does not come across an inappropriate mesh-update, which is a numerical problem arising from the explicit modeling of the coupling interface, the embedded approach fails because either of the single partitions, i.e. the fluid model or the structure model, fails, which is not a problem of the coupling but rather more a question of the quality of the single field models. In this example for instance, the embedded FSI approach failed because the structure simulation failed, which in turn is the consequence of invalid element formations that occur due to the fact that we are despite this large movements neglecting physical effects like self contact etc.. Figure [[#img-215|215]] shows the corresponding failure situation of the structure model in the embedded case. The failing mesh-update in the ALE case is illustrated in figure [[#img-216|216]]. | Apart from the movement, also the actual failure situation is interesting. Looking at the results, it can be observed, that the embedded and the ALE approach fail due to two ''different'' reasons. While the ALE approach does not come across an inappropriate mesh-update, which is a numerical problem arising from the explicit modeling of the coupling interface, the embedded approach fails because either of the single partitions, i.e. the fluid model or the structure model, fails, which is not a problem of the coupling but rather more a question of the quality of the single field models. In this example for instance, the embedded FSI approach failed because the structure simulation failed, which in turn is the consequence of invalid element formations that occur due to the fact that we are despite this large movements neglecting physical effects like self contact etc.. Figure [[#img-215|215]] shows the corresponding failure situation of the structure model in the embedded case. The failing mesh-update in the ALE case is illustrated in figure [[#img-216|216]]. | ||

| Line 6,841: | Line 6,867: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_908356597-monograph-D57_Membrane_Failure_01.png| | + | |[[Image:draft_Samper_908356597-monograph-D57_Membrane_Failure_01.png|400px|'''Failure of structure model in the embedded case''' - The picture shows the actual structure model with mapped surface pressure at t = 9.3s. Note the interpenetrating and overlapping elements.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 215:''' '''Failure of structure model in the embedded case''' - The picture shows the actual structure model with mapped surface pressure at <math>t = 9.3s</math>. Note the interpenetrating and overlapping elements. | | colspan="1" | '''Figure 215:''' '''Failure of structure model in the embedded case''' - The picture shows the actual structure model with mapped surface pressure at <math>t = 9.3s</math>. Note the interpenetrating and overlapping elements. | ||

| Line 6,861: | Line 6,887: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_908356597-monograph-D58_inflatableMembrane_p01.png| | + | |[[Image:draft_Samper_908356597-monograph-D58_inflatableMembrane_p01.png|400px|'''Pressure evolution at node P from figure [[#img-208|208]]''']] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 217:''' '''Pressure evolution at node <math>P</math> from figure [[#img-208|208]]''' | | colspan="1" | '''Figure 217:''' '''Pressure evolution at node <math>P</math> from figure [[#img-208|208]]''' | ||

| Line 6,869: | Line 6,895: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_908356597-monograph-D58_inflatableMembrane_p02.png| | + | |[[Image:draft_Samper_908356597-monograph-D58_inflatableMembrane_p02.png|400px|'''Close-up of the pressure evolution at node P from figure [[#img-208|208]]''']] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 218:''' '''Close-up of the pressure evolution at node <math>P</math> from figure [[#img-208|208]]''' | | colspan="1" | '''Figure 218:''' '''Close-up of the pressure evolution at node <math>P</math> from figure [[#img-208|208]]''' | ||

| Line 6,876: | Line 6,902: | ||

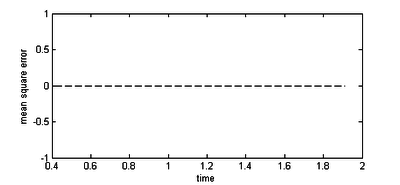

Second interesting fact is revealed when looking a little closer at the pressure gradient in the beginning of the simulation as depicted in figure [[#img-218|218]]. Looking at this close-up we first note that the results in both the different solution approaches actually cannot be significantly compared since the FSI-simulation crashes, too, quickly in case of the ALE approach. A quantitative confrontation of the different solution approaches hence is not possible. Nevertheless what is interesting is the fact that in the embedded approach the flow initialization phase, where we observe a periodic converging pressure gradient, seems to be considerably quicker and also in terms of its magnitude significantly less distinct. It is obvious that this is an effect of the weak imposition of the boundary conditions at the coupling interface in the embedded approach which naturally tends to damp oscillations. This damping may also be regarded as some kind of additional robustness advantage of the embedded approach in contrast to the ALE procedure. It is, however, clear, that this numerical damping at the same time affects the accuracy of the solution. | Second interesting fact is revealed when looking a little closer at the pressure gradient in the beginning of the simulation as depicted in figure [[#img-218|218]]. Looking at this close-up we first note that the results in both the different solution approaches actually cannot be significantly compared since the FSI-simulation crashes, too, quickly in case of the ALE approach. A quantitative confrontation of the different solution approaches hence is not possible. Nevertheless what is interesting is the fact that in the embedded approach the flow initialization phase, where we observe a periodic converging pressure gradient, seems to be considerably quicker and also in terms of its magnitude significantly less distinct. It is obvious that this is an effect of the weak imposition of the boundary conditions at the coupling interface in the embedded approach which naturally tends to damp oscillations. This damping may also be regarded as some kind of additional robustness advantage of the embedded approach in contrast to the ALE procedure. It is, however, clear, that this numerical damping at the same time affects the accuracy of the solution. | ||

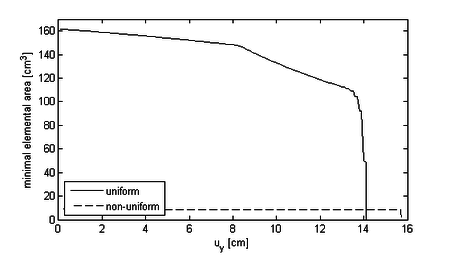

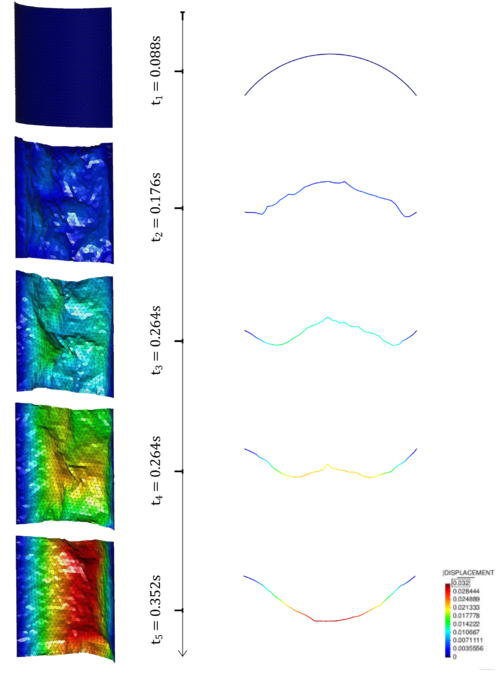

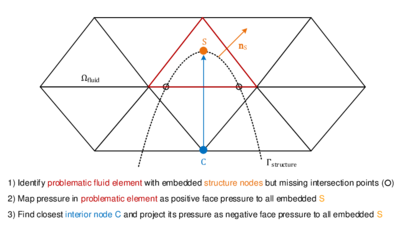

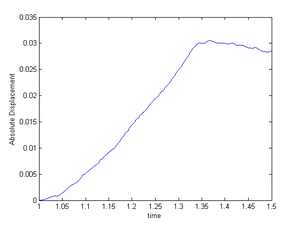

| − | Having now seen a few of the major advantages of the embedded approach, an important negative effect, that was encountered during the above analysis, shall be mentioned. To this end we have a look at the vertical displacement of node <math display="inline">D</math> when the above membrane is inflated comparatively slowly. The corresponding displacement curve is depicted in figure [[#img-219|219]]. Due to the very slow inflation of the membrane we in the beginning do not get this oscillating movement as we saw it in figure | + | Having now seen a few of the major advantages of the embedded approach, an important negative effect, that was encountered during the above analysis, shall be mentioned. To this end we have a look at the vertical displacement of node <math display="inline">D</math> when the above membrane is inflated comparatively slowly. The corresponding displacement curve is depicted in figure [[#img-219|219]]. Due to the very slow inflation of the membrane we in the beginning do not get this oscillating movement as we saw it in figure [[#img-211|211a]] but rather more a steadily growing membrane after a short transient phase. Actually this is what we physically expected from a slowly inflated membrane. Nevertheless, when continuing the simulation, at around <math display="inline">t = 2.75s</math>, suddenly a highly dynamic behavior forms out, which continues to grow more and more as the structure keeps inflating. |

The reason for this unexpected dynamic behavior was found to be the mapping problem described in chapter [[#8.3.2 Persisting problems with pressure mapping|8.3.2]]. Due to the curved shape of the membrane locally bad intersection patterns formed out. At the corresponding spots then the actual pressure conditions could not be resolved properly which eventually influenced the system dynamics critically. This observation emphasizes the demand for a powerful ''and'' robust mapping technique since possible limitations might not necessarily lead to a crashing simulation, where we are technically able to observe a problem free of doubt. Instead they can just initiate or change the dynamic behavior which is much more subtle and hence significantly more difficult to encounter. | The reason for this unexpected dynamic behavior was found to be the mapping problem described in chapter [[#8.3.2 Persisting problems with pressure mapping|8.3.2]]. Due to the curved shape of the membrane locally bad intersection patterns formed out. At the corresponding spots then the actual pressure conditions could not be resolved properly which eventually influenced the system dynamics critically. This observation emphasizes the demand for a powerful ''and'' robust mapping technique since possible limitations might not necessarily lead to a crashing simulation, where we are technically able to observe a problem free of doubt. Instead they can just initiate or change the dynamic behavior which is much more subtle and hence significantly more difficult to encounter. | ||

| Line 6,883: | Line 6,909: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_908356597-monograph-D59_inflatableMembrane_problem.png| | + | |[[Image:draft_Samper_908356597-monograph-D59_inflatableMembrane_problem.png|400px|'''Artificial dynamic behavior during inflation due to mapping problems.''' - The figure shows the vertical displacement of the membrane during a comparatively slow inflation. Note that the simulation did not numerically fail but was finished intentionally.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 219:''' '''Artificial dynamic behavior during inflation due to mapping problems.''' - The figure shows the vertical displacement of the membrane during a comparatively slow inflation. Note that the simulation did not numerically fail but was finished intentionally. | | colspan="1" | '''Figure 219:''' '''Artificial dynamic behavior during inflation due to mapping problems.''' - The figure shows the vertical displacement of the membrane during a comparatively slow inflation. Note that the simulation did not numerically fail but was finished intentionally. | ||

| Line 6,907: | Line 6,933: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

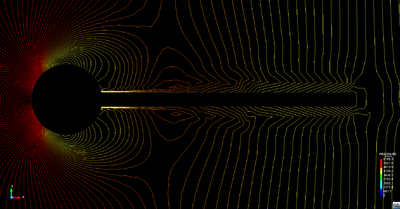

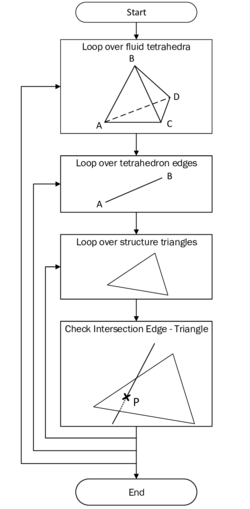

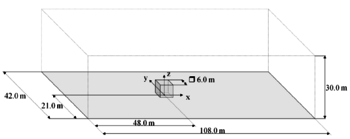

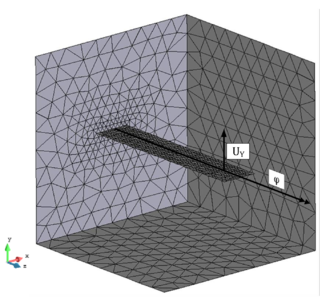

| − | |[[Image:draft_Samper_908356597-monograph-D61_bucklingMembraneSetup.png| | + | |[[Image:draft_Samper_908356597-monograph-D61_bucklingMembraneSetup.png|350px|'''3D setup of the flow-induced buckling of a membrane''']] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 220:''' '''3D setup of the flow-induced buckling of a membrane''' | | colspan="1" | '''Figure 220:''' '''3D setup of the flow-induced buckling of a membrane''' | ||

| Line 6,915: | Line 6,941: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

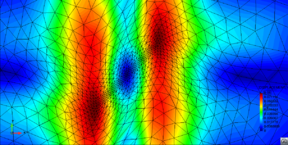

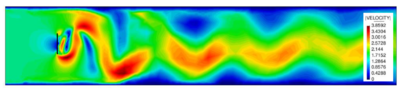

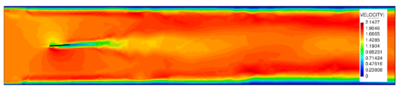

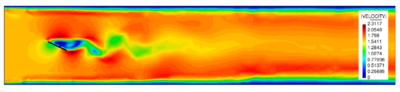

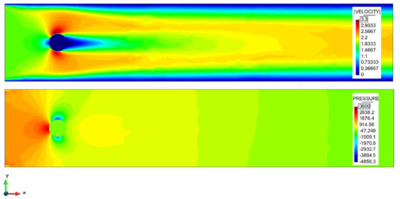

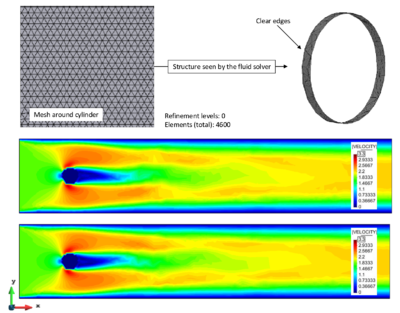

| − | |[[Image:draft_Samper_908356597-monograph-D62_BucklingMembrane_Velocity.png| | + | |[[Image:draft_Samper_908356597-monograph-D62_BucklingMembrane_Velocity.png|350px|'''3D model of the flow-induced buckling of a membrane''']] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 221:''' '''3D model of the flow-induced buckling of a membrane''' | | colspan="1" | '''Figure 221:''' '''3D model of the flow-induced buckling of a membrane''' | ||

| Line 6,925: | Line 6,951: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

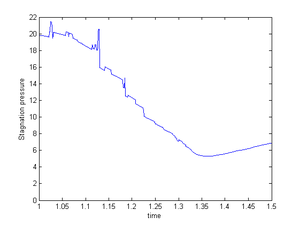

| − | |[[Image:draft_Samper_908356597-monograph-D63_BuckMembrane_P.png| | + | |[[Image:draft_Samper_908356597-monograph-D63_BuckMembrane_P.png|300px|'''Gradient of stagnation pressure at point C from figure [[#img-220|220]]''']] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 222:''' '''Gradient of stagnation pressure at point <math>C</math> from figure [[#img-220|220]]''' | | colspan="1" | '''Figure 222:''' '''Gradient of stagnation pressure at point <math>C</math> from figure [[#img-220|220]]''' | ||

| Line 6,933: | Line 6,959: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_908356597-monograph-D63_BuckMembrane_D.png| | + | |[[Image:draft_Samper_908356597-monograph-D63_BuckMembrane_D.png|300px|'''Gradient of absolute displacement at point C from figure [[#img-220|220]]''']] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 223:''' '''Gradient of absolute displacement at point <math>C</math> from figure [[#img-220|220]]''' | | colspan="1" | '''Figure 223:''' '''Gradient of absolute displacement at point <math>C</math> from figure [[#img-220|220]]''' | ||

| Line 6,945: | Line 6,971: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

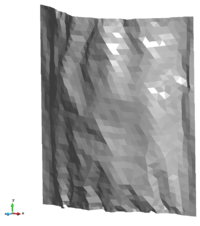

| − | |[[Image:draft_Samper_908356597-monograph-D64_BuckMembrane_Contours.png| | + | |[[Image:draft_Samper_908356597-monograph-D64_BuckMembrane_Contours.png|500px|'''Flow-induced buckling of a membrane''' - The left sequence plots the displacements as contours whereas the right sequence shows a lateral cut through the membrane at y = 0.05 for the different time instances.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 224:''' '''Flow-induced buckling of a membrane''' - The left sequence plots the displacements as contours whereas the right sequence shows a lateral cut through the membrane at <math>y = 0.05</math> for the different time instances. | | colspan="1" | '''Figure 224:''' '''Flow-induced buckling of a membrane''' - The left sequence plots the displacements as contours whereas the right sequence shows a lateral cut through the membrane at <math>y = 0.05</math> for the different time instances. | ||

| Line 6,952: | Line 6,978: | ||

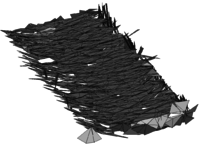

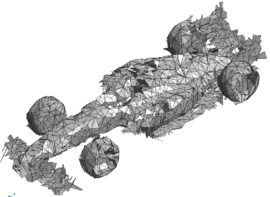

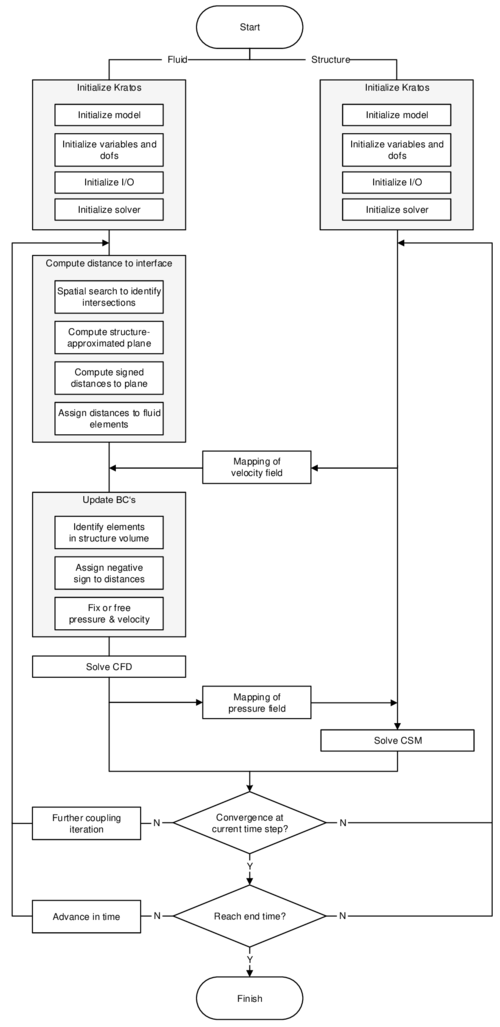

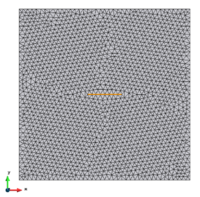

Looking at the herein depicted deformation pattern, one can see that in fact the embedded approach handles the massively occurring wrinkles without any problems. So despite the complex mesh configuration of the structure, the FSI simulation remains stable without any additional loss of accuracy. Obviously, when using a body-fitted approach, this would not be the case, since a mesh-updating procedure would most probably fail at a certain instance in particular at highly transient spots with local peaks and valleys such as they appear in the middle of the membrane. One typical remedy in the latter case certainly might be a complete re-meshing. But since the wrinkles are occurring during the entire simulation a re-meshing would have to be performed in each step causing an explosion of the computational costs. Moreover, even with a re-meshing there is no guarantee that all the elements in the fluid are properly distributed. So in fact we observe a superior robustness of the embedded approach when comparing it to any body-fitted method, such as the ALE approach. | Looking at the herein depicted deformation pattern, one can see that in fact the embedded approach handles the massively occurring wrinkles without any problems. So despite the complex mesh configuration of the structure, the FSI simulation remains stable without any additional loss of accuracy. Obviously, when using a body-fitted approach, this would not be the case, since a mesh-updating procedure would most probably fail at a certain instance in particular at highly transient spots with local peaks and valleys such as they appear in the middle of the membrane. One typical remedy in the latter case certainly might be a complete re-meshing. But since the wrinkles are occurring during the entire simulation a re-meshing would have to be performed in each step causing an explosion of the computational costs. Moreover, even with a re-meshing there is no guarantee that all the elements in the fluid are properly distributed. So in fact we observe a superior robustness of the embedded approach when comparing it to any body-fitted method, such as the ALE approach. | ||

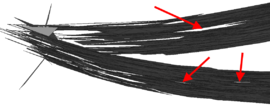

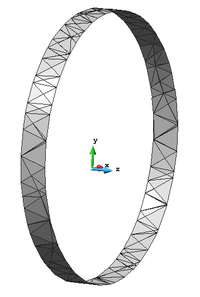

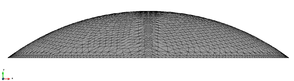

| − | At this point it is worthwhile to recap also from the other chapters, that the herein presented embedded method poses a particularly robust method for fluid-structure interaction analysis because of three facts: Firstly there is no technical link between the different discretizations involved, which is why any mesh-update generally becomes obsolete. Nevertheless, there exists of course a coupling. Here, however, the velocities are applied in a weak sense which yields a second robustness benefit. Third and last reason is based on the fact that an embedded approach introduces implicitly a certain length-scale below which no structural detail can be resolved. The length-scale is thereby defined by the background fluid mesh. So every detail of an embedded structure which is smaller than the corresponding size of the background fluid element will not be captured. This implicitly filters problematic local effects such as wrinkles. For an impression see figure [[#img-225|225]]. It is the last reason that mainly affects the accuracy of the solution, which is why for this simulation again the earlier presented refinement strategy was applied. So in the present simulation the structure is seen by the embedded solver as shown in figure [[#img- | + | At this point it is worthwhile to recap also from the other chapters, that the herein presented embedded method poses a particularly robust method for fluid-structure interaction analysis because of three facts: Firstly there is no technical link between the different discretizations involved, which is why any mesh-update generally becomes obsolete. Nevertheless, there exists of course a coupling. Here, however, the velocities are applied in a weak sense which yields a second robustness benefit. Third and last reason is based on the fact that an embedded approach introduces implicitly a certain length-scale below which no structural detail can be resolved. The length-scale is thereby defined by the background fluid mesh. So every detail of an embedded structure which is smaller than the corresponding size of the background fluid element will not be captured. This implicitly filters problematic local effects such as wrinkles. For an impression see figure [[#img-225|225]]. It is the last reason that mainly affects the accuracy of the solution, which is why for this simulation again the earlier presented refinement strategy was applied. So in the present simulation the structure is seen by the embedded solver as shown in figure [[#img-225|225c]]. |

| − | |||

<div id='img-225'></div> | <div id='img-225'></div> | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_908356597-monograph-D64_SkinMesh_01.png| | + | | colspan="2" |[[Image:draft_Samper_908356597-monograph-D64_SkinMesh_01.png|200px|]] |

| − | | | + | |- style="text-align: center; font-size: 75%;" |

| + | | colspan="2" | (a) Structure mesh | ||

|- | |- | ||

| − | | | + | |[[Image:draft_Samper_908356597-monograph-D64_SkinMesh_03.png|200px|]] |

| + | |[[Image:draft_Samper_908356597-monograph-D64_SkinMesh_02.png|200px|'''Structure mesh and its embedded representation at t = 0.15s''']] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" | (b) Coarse representation within the fluid (35000 fluid elements) | ||

| + | | colspan="1" | (c) Refined representation within the fluid (250000 fluid elemenets) | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="2" | '''Figure 225:''' '''Structure mesh and its embedded representation at <math>t = 0.15s</math>''' | | colspan="2" | '''Figure 225:''' '''Structure mesh and its embedded representation at <math>t = 0.15s</math>''' | ||

Latest revision as of 13:22, 6 June 2019

Abstract

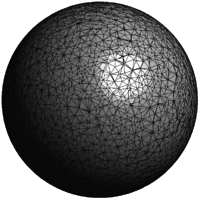

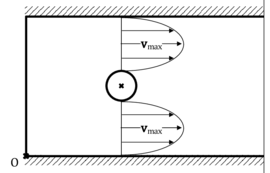

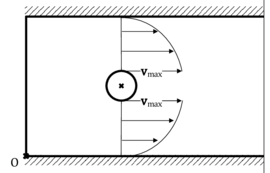

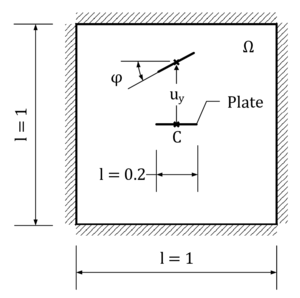

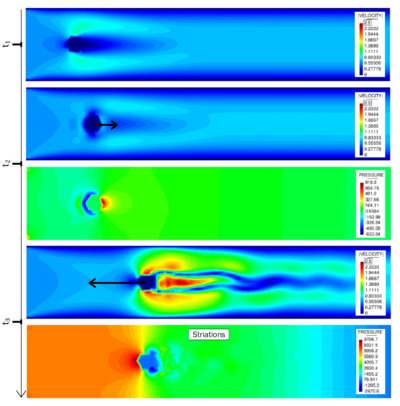

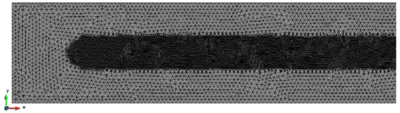

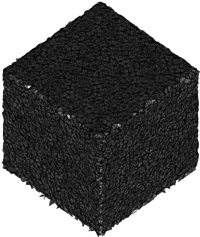

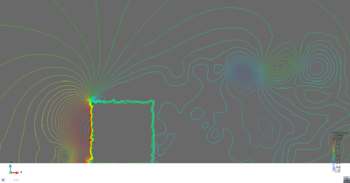

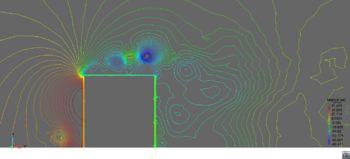

Designing large ultra-lightweight structures within a fluid flow, such as inflatable hangars in an atmospheric environment, requires an analysis of the naturally occurring fluid-structure interaction (FSI). To this end multidisciplinary simulation techniques may be used. The latter, though, have to be capable of dealing with complex shapes and large deformations as well as challenging phenomena like wrinkling or folding of the structure. To overcome such problems the method of embedded domains may be used. In this work we discuss a new solution procedure for FSI analyses based on the method of embedded domains. In doing so, we are in particular answering the questions: How to track the interface in the embedded approach, how does the subsequent solution procedure look like and how does both compare to the well-known Arbitrary Lagrangian-Eulerian (ALE) approach? In this context a level set technique as well as different mapping and mesh-updating strategies are developed and evaluated. Furthermore the solution procedure of a completely embedded FSI analysis is established and tested using different small- and large-scale examples. All results are finally compared to results from an ALE approach. It is shown that the embedded approach offers a powerful and robust alternative in terms of the FSI analysis of ultra-lightweight structures with complex shapes and large deformations. With regard to the solution accuracy, however, clear restrictions are elaborated.

Acknowledgements

This monograph was written at the International Center for Numerical Methods in Engineering (CIMNE, Barcelona) based on a joint research project with the Technical University Munich (TUM) during the period from May to December 2013. During that time, we gained vast experience in numerical methods, software development and their practical application to solve complex engineering problems within a dynamic and innovative research team. The project, however, would not have been possible without the tremendous support of Riccardo Rossi (CIMNE) and Roland Wüchner (TUM). Both of them contributed decisively to the success of this work and are responsible for a challenging but exciting topic branching into the world of FSI simulations.

Roland Wüchner dedicated himself to the subject with a lot of interest that he showed during the numerous intercontinental sessions where he often sacrificed his valuable evenings for an in-depth discussion. He reserved many hours to shape the subject in detail in order to guarantee a benefit for all the contributors. Moreover, he constantly motivated us by guiding and refining all our ideas. The same is true for Riccardo Rossi. He offered a fantastic technical and personal support in all questions that arose. Many of the here presented ideas were driven by his support or on his initiative. We thank you both a lot!

Furthermore, we want to thank Pooyan Dadvand and Jordi Cotela who provided us with the implementation of many functionalities in Kratos. For any kind of problem with Kratos they patiently did intensive investigations until the problem was solved. In general, we acknowledge the support of every single person of the Kratos and the GiD team.

Finally, all the authors wish to thank the ERC for the support under the projects uLites FP7-SME-2012 GA n.314891 and NUMEXAS FP7-ICT-611636.

1 Introduction

Objects of interest within the scope of this work are inflatable mobile light-weight hangars for the application in aerospace industry (See figure 1). Purpose of such a hangar is to cover aircrafts ranging from smaller propeller machines up to large scale passenger aircraft both from civil and military services. The advantage of such a structure is obvious: It offers the possibility to flexibly and quickly build up and position a hangar without occupying expensive and rare space permanently. This allows a fast reaction to current needs such as the protection of single aircraft from weather influences or the setup of a provisional operating base while being protected from external surveillance.

] ]

|

| Figure 1: Example of an inflatable hangar - Adopted from [1] |

In order to ensure functionality and safety, prior tests regarding the structure's behavior within the environmental fluid, i.e. an air flow, are essential. Here the investigation of the respective fluid-structure-interaction is of particular importance due to the lightweight concept being strongly affected by e.g. wind loads. Physical tests in this regards are, however, very costly since the lightweight concept does typically not allow for any scaling of the model to smaller sizes. This means, that a physical test always requires a very cost-intensive full-scale model. That is the reason why people are particularly interested in the powerful as well as resource- and cost-efficient virtual design analysis, which in this case means a computational analysis of the fluid-structure interaction (FSI).

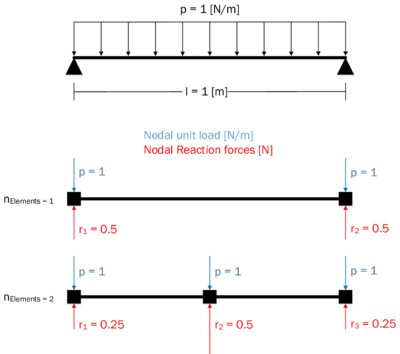

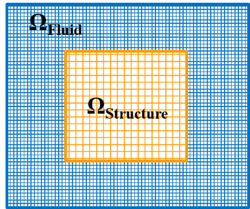

Requirement for the corresponding coupled simulation, though, is the ability to deal with large deformations, wrinkling or folding, respectively. To this end a simulation technology based on the method of embedded domains1 is developed at the International Center of Numerical Methods in Engineering (CIMNE). The method of embedded domains is an alternative methodology for the computation of partial differential equations and as such offers the interesting advantage of efficiently dealing with complex boundaries and large deformations where a body-fitted technique like the Arbitrary Lagrangian-Eulerian method (ALE) for examples uses an often expensive moving domain discretization (“Moving Mesh”). Particularly in the scope of fluid-structure interaction analysis, the embedded methods allows to separately handle the different physical entities without having to account for a specific interface model. Instead different overlapping discretizations ("embedded meshes") are used. See figure 2 for an illustration of the different approaches.

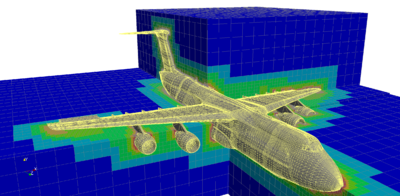

In this context, the goal of the present monograph is 1) the further development of the at CIMNE developed method of embedded domains such that it may be used for large-scale CFD and FSI problems and 2) the evaluation of the method compared to the well-known ALE approach. In doing so the tasks were split into two key topics: first the interface tracking in the embedded case and second the setup and comparison of the FSI solution procedure in both cases. For the interface tracking in the embedded method, level set techniques were to be implemented and verified. In terms of the solution procedures the goal was to develop and implement different mesh-updating strategies in the ALE-case as well as mapping techniques for the embedded method. Hence different test scenarios of coupled fluid-structure problems were to be developed, set up and simulated in order to finally compare the methods. For the sake of software modularity focus was here set on partitioned solution techniques. Furthermore in order to keep the computational costs of the coupled analyses as low as possible, parallelization techniques ought to be applied throughout the entire implementation phase.

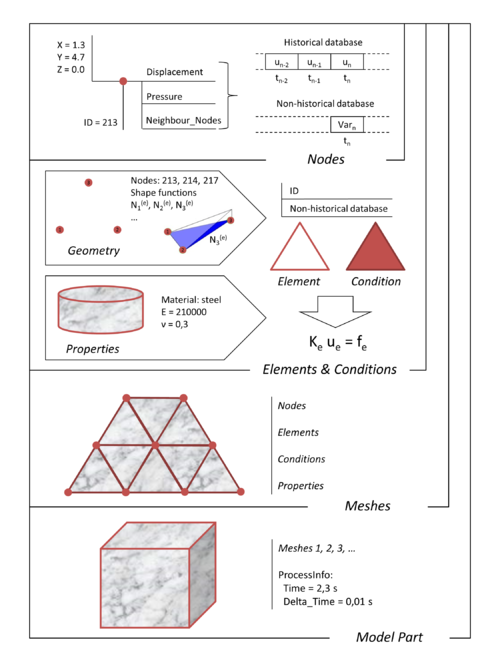

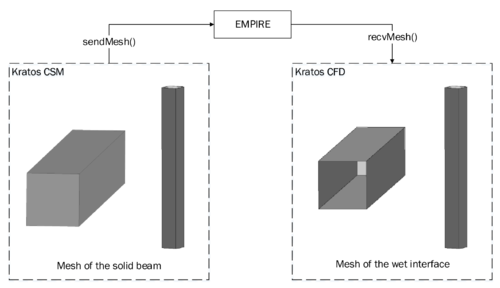

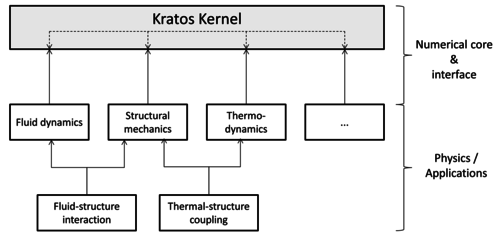

The software environment was generally given by the CIMNE in-house multiphysics finite element solver “Kratos”. For the partitioned analysis furthermore the simulation environment EMPIRE (“Enhanced Multi Physics Interface Research Engine”, Technical University Munich) was to be used. So an additional specification arising from this context required the set up of an interface between both software frameworks in order to be able to use the full functionality of EMPIRE together with all features in Kratos. Perspectively the goal is to use Kratos via EMPIRE together with the at the Technical University Munich (TUM) developed structural solver “Carat++” in a common partitioned FSI-environment. This shall allow to combine and consolidate capabilities of either software package and hence the knowledge of either of the related research groups.

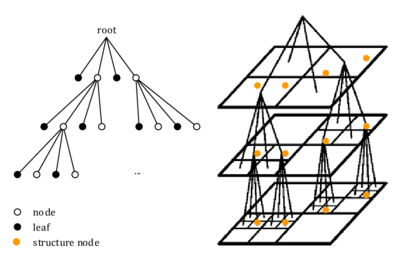

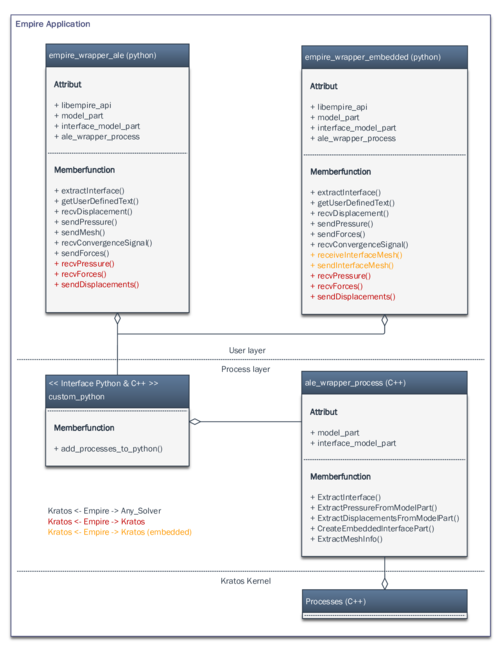

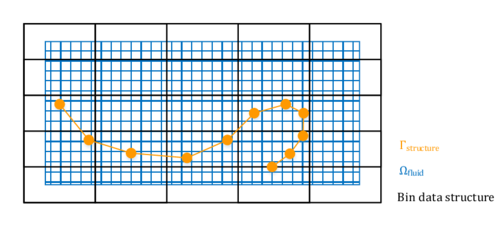

Based on all the aforementioned goals, the present monograph is organized as follows: In the first section (chapter 2 to 4) the theoretical background regarding the analysis of coupled fluid-structure problems is given. Here it starts with a discussion of the single field problems which subsequently is extended and merged to the fundamentals of coupled fluid-structure analyses. In both cases the above stated and newly in Kratos implemented method of embedded domains is introduced in detail. Part of the theoretical framework is also a discussion of how in both approaches the computational efficiency may be improved. This includes the presentation of parallelization techniques as well as spatial search algorithms specifically applied in case of the embedded method.

In the second section then (chapter 5 to 6) the different applied software packages as well as the corresponding software interface are described. Here the contents are presented in a very application oriented way in order to provide a documentation for future users.

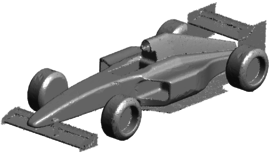

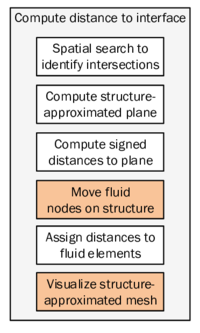

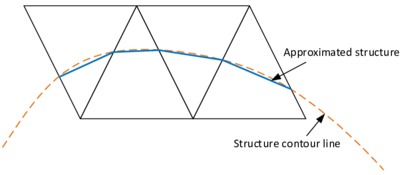

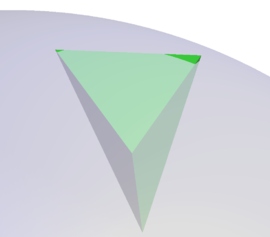

In the third section (chapter 7) the first key topic of the present monograph is elaborated, i.e. the interface tracking in the scope of the embedded method. Here we answer the questions regarding how to track the interface with two overlapping meshes and how does this affect the corresponding solution quality. Therefore different geometry examples, from a generic structure to a large scale Formula One car, are investigated. Furthermore in this context, different fluid problems are simulated with the embedded method and subsequently evaluated.

Having discussed how to track the interface in the embedded case and knowing about the situation in a body-fitted approach, the fourth section (chapter 8) is dedicated to the second key topic of this monograph, i.e. the actual solution procedure with fluid-structure simulations using either of the aforementioned methods. Here the different developed process steps are elaborated and evaluated in detail giving finally a complete overview of the entire solution process in both cases. With all the implementations then at hand, two solution examples of fully coupled problems are presented which eventually allows for a comparison of the two different approaches.

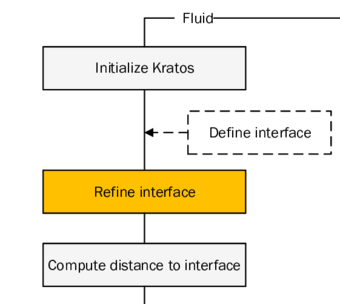

Finally all the results are briefly summarized and contrasted to the above stated goals.

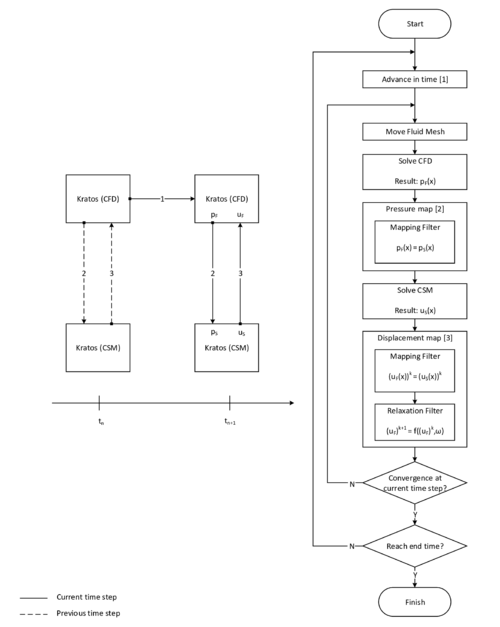

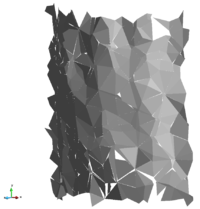

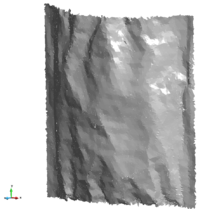

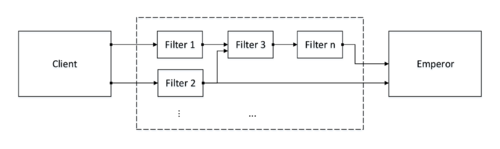

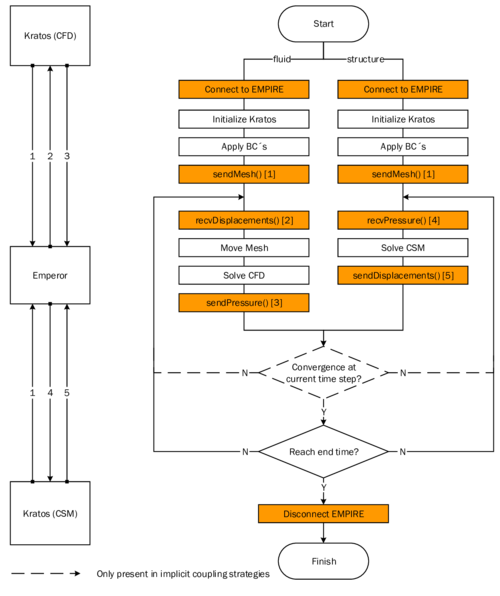

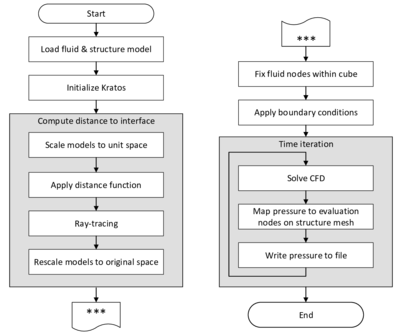

In order to facilitate the understanding of the later presented developments, the two process flows corresponding to the two different solution approaches as they were established in Kratos, shall be outlined here in advance (3, 4)2. For now, they shall just give an idea about the necessary steps to establish a coupled fluid-structure simulation using one of the above mentioned approaches. In the later course of this monograph then, whenever a feature is discussed or developed, its integration into the overall process is illustrated by means of these two charts. This allows to see importance and impact of single developments in a more general context.

|

| Figure 3: Partitioned FSI simulation using the ALE approach |

|

| Figure 4: Partitioned FSI simulation using the embedded approach |

(1) In literature also called “immersed” or “fix-grid” methods

(2) Note that both of the depicted processes show a partitioned analysis

2 Fluid and structure as uncoupled fields

In the following the mechanical fundamentals of fluids and structures shall be discussed together with their numerical treatment, i.e. their spatial discretization via FEM, their time discretization using different time integration schemes and their solution by some selected procedures. Both fluid and structure will be regarded as a continuum. Consequently their formulation will be similar and based on classical continuum mechanics. Given this assumption, the chapter will start with a brief introduction into the general description of motion according to basic continuum mechanics. Actual differences between structures and fluids from the point of view of their mechanical description will be elaborated in the later course of the chapter. Afterwards the method of embedded domains will be introduced into the context of classical fluid mechanics. Particularly the relevant element formulation will be of interest here. A discussion of how to impose corresponding boundary conditions will finally close the chapter.