Abstract

Nowadays large part of the time needed to perform a numerical simulation is spent in preprocessing, especially in the geometry cleaning operations and mesh generation. Furthermore, these operations are not easy to automatize because they depend strongly on each geometrical model and they often need human interaction. Many of these operations are needed to obtain a watertight geometry. Even with a clean geometry, classical unstructured meshing methods (like Delaunay or Advancing Front based ones) present critical weak points like the need of a given quality in the boundary mesh or a relatively smooth size transition. These aspects decrease their robustness and imply an extra effort in order to reach the final mesh. Octree based meshers try to relax some of these requirements.

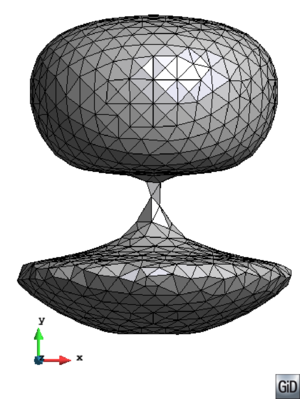

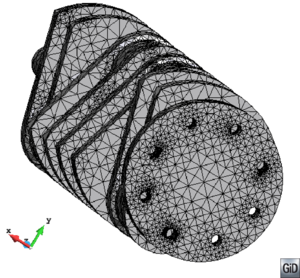

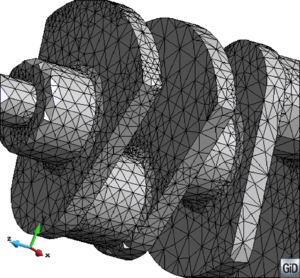

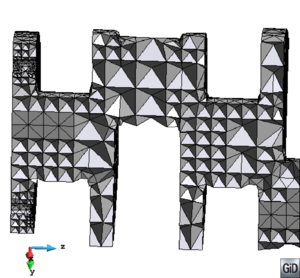

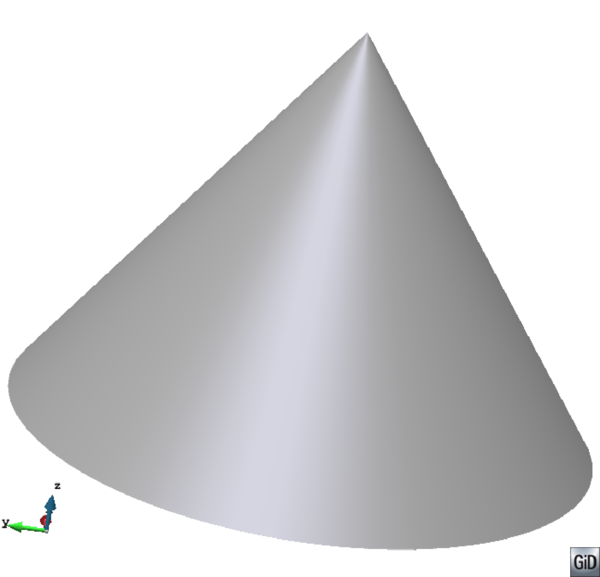

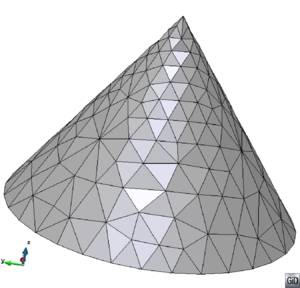

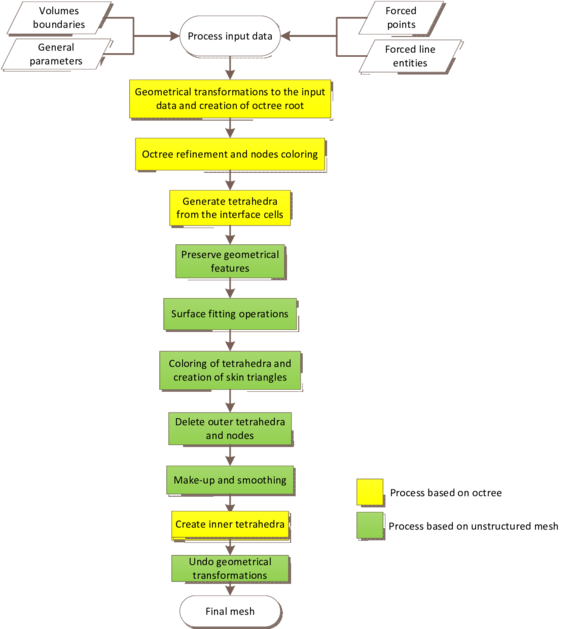

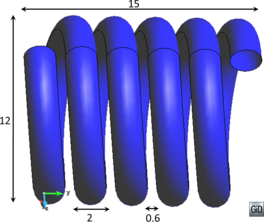

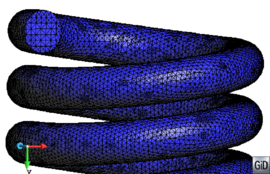

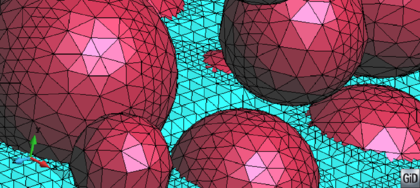

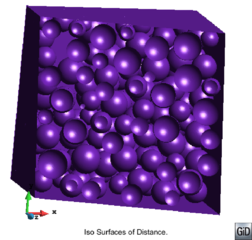

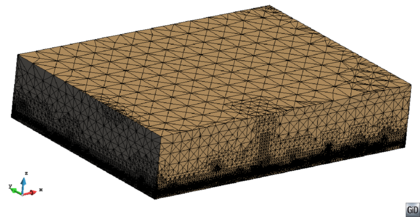

In the present work an octree based mesher for unstructured tetrahedra is presented. The proposed mesher ensures the mesh generation avoiding most of the geometry cleaning operations. It is based in the following steps: fit an octree onto the model, refine it following given criteria, apply a tetrahedra pattern to the octree cells and adapt the tetrahedra close to the contours in order to represent accurately the boundary shape. An important and innovative aspect of the proposed algorithm is it ensures the final mesh preserves the topology and the geometric features of the original model.

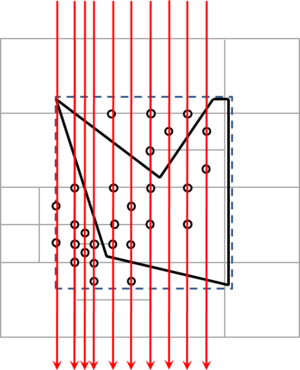

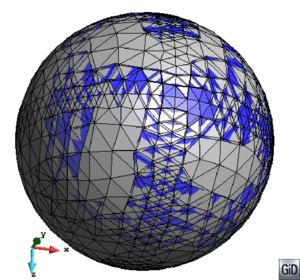

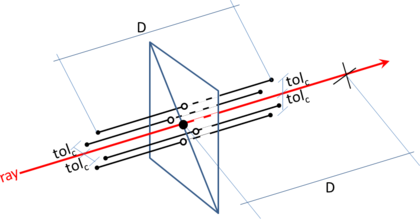

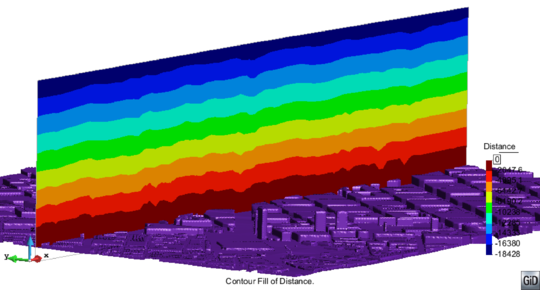

The method uses a Ray Casting based algorithm for the identification of the inner and outer parts of the volumes involved in the model. This technique allows the mesh generation of volumes even with non-watertight boundaries, and also opens the use of the mesher for immersed methods only applying slight modifications to the algorithm.

The main advantages of the presented mesher are: robustness, no need for watertight boundaries, independent on the contour mesh quality, preservation of geometrical features (corners and ridges), original geometric topology guaranteed, accurate representation of the contours, valid for immersed methods, and fast performance. A lot of time in the preprocessing part of the numerical simulation is saved thanks to the robustness of the mesher, which allows skipping most of the geometry cleaning operations.

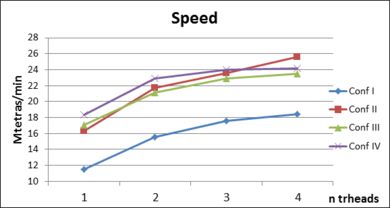

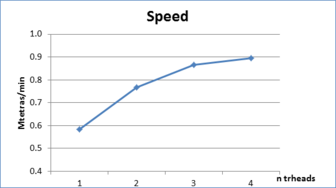

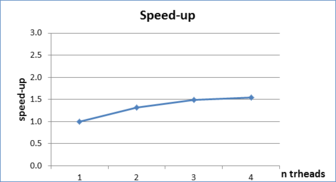

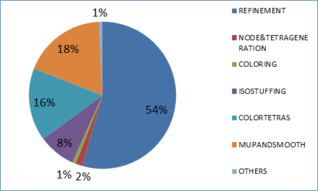

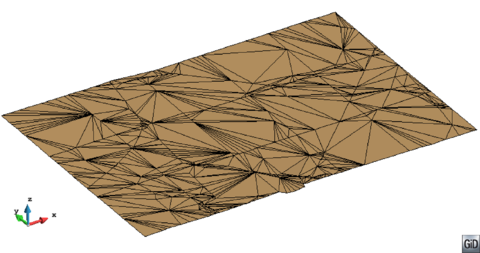

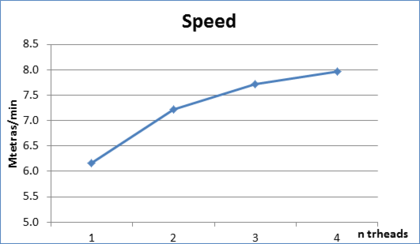

A shared memory parallel implementation of the algorithm has been done. The effectiveness of the algorithm and its implementation has been verified by some validation examples.

Resum

En l'actualitat gran part del temps emprat per córrer una simulació numerica esta dedicat al preprocés, especialment a les operacions de neteja de geometria i generació de malla. A més, aquestes operacions no són facils d'automatitzar degut a la seva forta dependencia del model geometric i sovint necessiten d'interacció humana. Moltes d'aquestes operacions són necessaries per aconseguir una definició topologicament hermetica de la geometria. Inclús amb una geometria neta, els metodes classics de mallat (com els basats en Delaunay o avancament frontal) presenten punts febles crítics com la necessitat d'una certa qualitat de les malles de contorn o una transició de mides relativament suau. Aquests aspectes disminueixen la seva robustesa i impliquen un esforc extra a l'hora d'obtenir la malla final. Els metodes de mallat basats en estructures octree relaxen alguns d'aquests requeriments.

En aquest treball es presenta un mallador basat en octree per tetraedres no estructurats. Un dels aspectes claus d'aquest mallador és que garanteix la generació de malla evitant moltes de les operacions de neteja de geometria. Es basa en els següents passos: encaixar un octree al model, refinar-lo seguint certs criteris, aplicar un patró de tetraedres a les celles de l'octree i adaptar-los a les zones properes als contorns a fi i efecte de representar acuradament la forma del domini. Un aspecte important i innovador de l'algorisme proposat és que manté la topologia del model a la malla final i preserva les seves característiques geometriques.

El metode presentat utilitza un algorisme basat en la tecnica Ray Casting per la identificació de les parts interiors i exteriors dels volums del model. Aquesta tecnica permet la generació de malla de volums inclús amb contorns que no tanquen hermeticament, i també obre l'ús del mallador a metodes immersed aplicant només petites modificacions a l'algorisme.

Els principals avantatges del mallador presentat són: robustesa, no necessitat de definicions hermetiques dels contorns, independent de la qualitat de la malla de contorn, preservació de característiques geometriques (cantonades i arestes abruptes), topologia original de la geometria garantida, representació precisa dels contorns, valid per metodes immersed i rapid rendiment. L'ús del mallador estalvia molt de temps en la part del preprocés de la simulació numerica gracies a la seva robustesa que permet obviar la majoria d'operacions de neteja de geometria.

S'ha dut a terme una implementació parallela amb memoria compartida de l'algorisme. L'efectivitat del mateix i la seva implementació ha estat verificada mitjancant exemples de validació.

1 Introduction

Numerical simulations try to reproduce virtually a physical behavior by solving given equations in a specific domain. They are nowadays essential to understand some complex physical problems in scientific and engineering field. Although experimental setups can be build to study the specific behavior of a given phenomena, sometimes it is hard for these experiments (or even impossible depending on the scale of the tackled problem) to represent it accurately. The increasing advances in terms of computer science technology allow to treat larger and larger problems virtually (in the computer), so each time more and more numerical methods have been developed in the scientific field in order to capture the physics of complex problems.

Together with these developments, the adoption of numerical simulations in industrial processes has became a reality, as it can save a lot of time and effort when evaluating possible solutions for a given problem. The use of numerical simulation tools by the industry requires a software with very high level of robustness, efficiency and performance.

The process to run a numerical simulation involves three main parts: pre-processing, calculation and post-processing. The pre-processing part includes all the operations needed to define and discretize the geometrical domain, assign the required data to it so that the solver can solve the corresponding equations representing a given physical problem (in the calculation part). The post-processing part tries to analyze and visualize the results from the solver in a smart way so that they can be correctly interpreted. This monography is focused on the pre-processing part of the numerical simulations, and specifically on the discretization of the geometrical domain.

The pre-processing operations can be summarized as follows:

- Geometrical definition of the domain. This part of the process is not always performed by the person responsible to run the simulation, and often a third part (a designer) creates the CAD definition of the geometry. Most of the times, this geometry creation does not take into account the requirements of numerical simulation, so a geometry cleaning process is needed in order to be able to perform the discretization of the domain.

- Discretization of the domain. Depending on the nature of the numerical method used for the simulation, different kinds of discretization of the geometrical domain are required. Meshless methods use a collection of points (nodes) as a discretization of the domain. Discrete Element Methods (DEM) use a collection of topologically unconnected objects for this purpose. In many occasions (like in the Finite Element Method (FEM) [1,2], Finite Volumes (FV) or Finite Differences (FD)) the result of the discretization is a mesh: a collection of polygons (in 2D) or polyhedra (in 3D) occupying the space where the domain is. This work focuses on this type of discretization, so in this document the discretization part of the pre-processing operations will be referred as mesh generation.

- Assignation of the data needed to run the simulation. This data can be of different nature depending on the kind of numerical simulation to be run, but most of the times includes the material properties of the different parts of the domain, the initial and boundary conditions for the equations to be solved, and some general parameters for the simulation.

The presented work proposes a new algorithm for mesh generation: a mesh generator (or simply a mesher). For designing a mesh generator, the basic requirements to be covered must be very clear. Missing the right requirements for the numerical simulation may lead to several limitations in the use of the mesher. There are three basic requirements to be covered by any mesh generator:

- Input data requirements: these requirements fix the characteristics of the input data able to be processed by the mesher. In this sense the input data is understood as the geometrical definition of the domain into which the simulation will be run. Typical requirements of this nature are: allow only a given mathematical definition of the geometry (NURBS, mesh, etc.), a specific topology of the input geometrical entities (watertight geometries, contact entities, etc.) or sizes of input entities inside a given range, among others. Considering the large number of CAD systems available and their different ways for geometrical definition of the domain, these kinds of requirements are in practice really important. Many times the person in charge of the numerical simulation may have no control on the geometrical definition. The situation where the mesher is very restrictive with the quality or the topology of the geometrical definition of the domain, often leads to a considerable increase of the effort in the geometry cleaning operations before the meshing itself. These requirements are not theoretically taken into account to evaluate if a mesher is suitable to generate meshes for given kinds of simulations or not, but in practice they can limit the use of the mesher as the effort dedicated to geometry cleaning operations can grow exponentially when the input geometries become more complex.

- Final mesh requirements: these requirements focus on the specific characteristics of the mesh required by the simulation to be run successfully. Typical requirements of this nature are: uniform elements sizes distribution, control of the mesh sizes in different zones of the domain or precise representation of the contours among others. Each kind of numerical simulation (structural dynamics, computational fluid mechanics (CFD), electromagnetism, etc.) has specific requirements for the mesh to be used. If a numerical simulation has one requirement of this nature for the final mesh and it is not covered by a mesher, this mesh generator is not suitable for the simulation.

- Mesher requirements: these requirements deal with the mesher behavior itself. The mesher can cover the two kinds of requirements presented before in several ways (with different implementations). The use of the mesher in practice often fixes some requirements in terms of speed, usability or memory availability which are also important.

Often, a mesh generator is focused in one type of mesh. Different kinds of meshes can be identified depending on their nature:

- 1D, 2D or 3D; depending on the dimensions of the space used to define the geometry.

- Line, surface or volume meshes; depending on the hierarchy of the geometrical entity to be meshed.

- Structured, semi-structured, unstructured or cartesian; depending on the nature of the topology of the mesh.

- Isotropic or anisotropic; depending on the aspect ratio of the elements to be generated following specific directions.

- Embedded or body-fitted; depending on how they fit or not the boundaries of the domain to be meshed. Body-fitted meshes (used, for instance, in FEM or FV simulations) match perfectly the boundaries of the domain, as embedded ones (used, for instance, in FD, immersed or embedded methods) have faces crossing that boundaries.

- Conformal or non-conformal; depending on the continuity between neighbor elements across edges or faces. In conformal meshes edges and faces match perfectly between neighbor elements, as oposed to non-conformal ones.

- Depending on the element type to be used and the quadratic type of the element (linear or different degrees of quadratic types). Although there are methods using arbitrary polyhedral shapes for the mesh elements [3], it is common to use the same simple polyhedral element for all the domain (triangle, quadrilateral, tetrahedral, etc.).

In this monography 3D unstructured isotropic conformal tetrahedral meshes are considered. Both embedded and body-fitted cases will be covered.

1.1 Motivation

In industrial simulations, the pre-processing operations represent the most time consuming part of the whole process. Among the pre-processing operations, the geometry cleaning and mesh generation parts are the ones which consume more time, due to their specific characteristics:

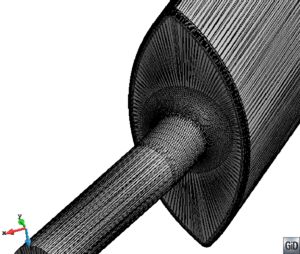

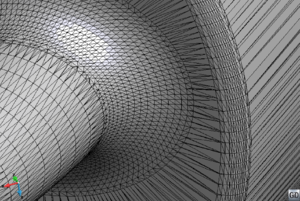

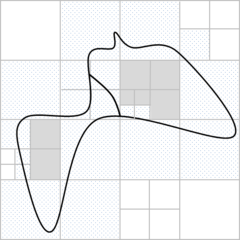

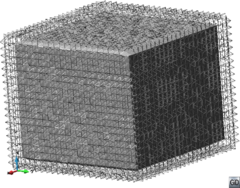

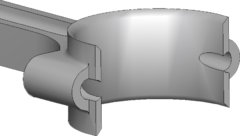

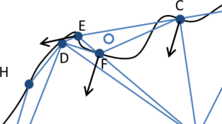

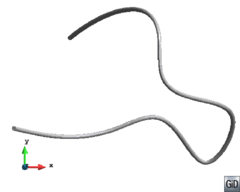

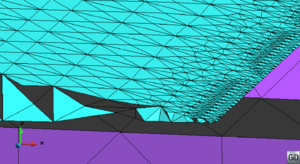

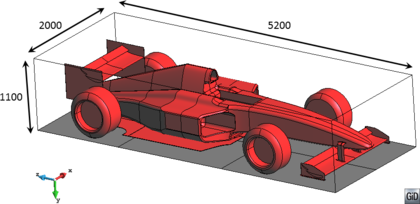

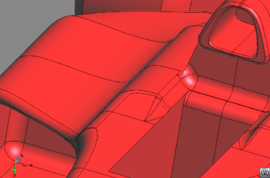

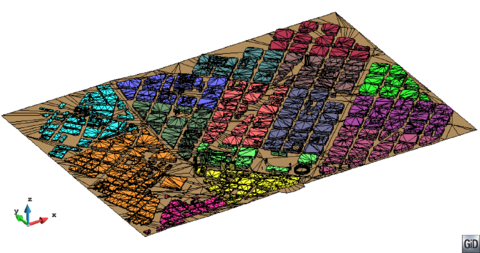

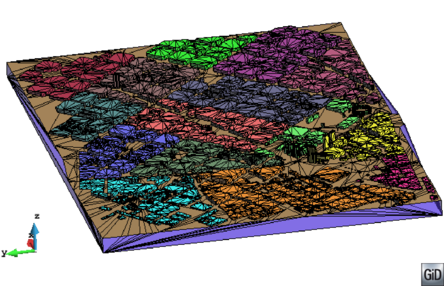

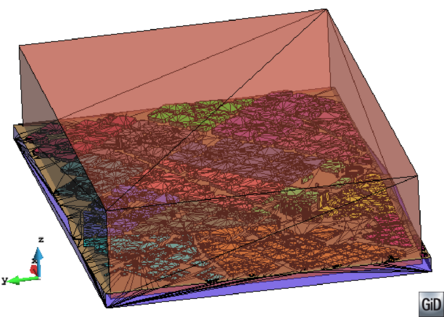

- The geometry cleaning process implies all the operations needed to allow the mesher the correct discretization of the domain. It often needs much human interaction, as it is really difficult to automatize it following general criteria for all kinds of simulations. Most of the meshers need watertight geometries to be able to generate the mesh. In this context, the concept of watertight (for volumes) is used to define a closed collection of surfaces sharing their contour lines. Make watertight an input geometry implies to avoid surface overlapping and gaps in the geometrical definition of the volumes. For many complex 3D geometries (like the one shown in Figure 1), to reach this goal requires a huge effort. Furthermore, classical meshers are not totally independent on the mathematical definition of the geometry. Often the characteristic size of the geometrical entities defining the boundary must be similar to the final mesh size desired for the simulation. This aspect enforces a modification on the definition of the input boundaries depending on the final mesh desired, although it may represent well the shape of the domain.

- Once the geometry is clean enough to generate the mesh, the mesh generation itself can consume a considerable amount of time. Furthermore, the mesh generation process often involves an iterative loop where the person in charge of the simulation defines the desired mesh sizes in the different parts of the domain, and several meshes have to be generated, as the mesher parameters are tuned in order to get an optimum mesh. It also has to be taken into account that nowadays the volume unstructured meshers are not fully robust in the sense that, when dealing with complex geometries, it is not easy to tune its parameters and prepare the input geometry to generate the mesh successfully: often the user must try several configurations (geometry and parameters) until a mesh is generated. This relativizes the speed in the mesh generation, as the mesher itself can be very fast, but the user may need several tries to get a suitable mesh for the simulation.

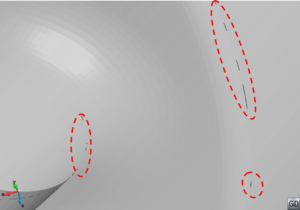

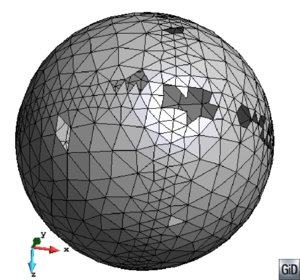

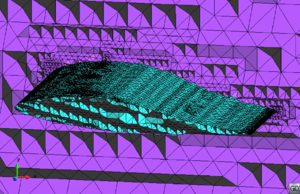

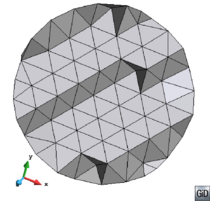

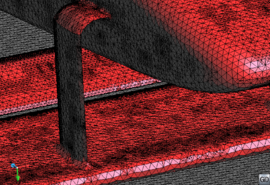

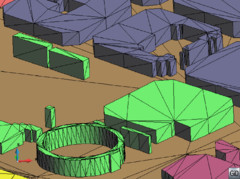

|

| Figure 1: Example of a 3D input boundary (represented with a mesh) where the quality of the triangles is very bad. |

Much effort has to be spent in order to generate a volume mesh of a complex geometry considering the existing meshing algorithms. Some of them are really fast and robust, but they require several geometry cleaning operations. If the time needed for them is added to the total meshing time, they became not so fast in practice. Contribute to reduce this extra effort is the motivation of this monography.

1.2 Objectives

The main objective of this monography is to develop an algorithm for isotropic unstructured volume mesh generation robust enough to be able to generate a mesh from non-cleaned input geometries, using as less input data as possible. This will lead to a drastic reduction of the time consumed in the pre-processing part, and will overcome the actual bottleneck in the whole simulation process.

The mesh generator must be flexible enough in terms of mesh adaptation to the solver requirements considering specific input data. The idea in this work is that the algorithm should be able to generate always a mesh from a given geometrical domain, almost without any specific meshing property assigned to it.

The meshing algorithm presented in this monography has been designed with the following objectives in mind:

- It should be prepared to use the more common geometrical definitions as input data reducing as much as possible its preparation (CAD cleaning operations).

- It must be able to run on a simple PC, but also it should be able to take profit from more complex computer architectures, which enable the use of parallel processing.

- It should be useful for a wide range of application fields. The main characteristics for the mesh to be generated are taken from the requirements for the FEM, but they are general enough to be applied to other numerical methods.

These characteristics lead to a set of requirements to be covered by the meshing algorithm developed in this monography. The main ones are: robust and fast mesh generation, and ability to mesh from non-watertight geometries. The explanation of all the requirements covered by the new mesher is detailed below in Sections 1.2.1, 1.2.2, and 1.2.3.

1.2.1 Mesher requirements

In this section, the requirements of the mesher developed in the monography regarding its behavior are detailed:

- Robustness. This is one of the key objectives and it can also be seen as a requirement for the input data, as this robustness refers to the capability of generating the mesh independently from the input data quality. Some of the existing unstructured volume meshers accomplish all (or almost all) the requirements presented in this work, but they require a very specific tuning of their parameters for successfully generating the mesh. Independently of the sizes assigned by the user, the quality of the input geometrical data or the general parameters chosen, the mesher should be able to generate always a mesh suitable for the simulation. The idea of the new algorithm developed in this monography is that it should generate always a mesh accomplishing the requirements defined in this section without a special training in the use of the mesher.

- Fast mesh generation. One of the key motivations of this work is to reduce the time consumed in the pre-processing operations for a numerical simulation. For this purpose the mesher has to be fast. Moroves, it has to be naturally fast, in the sense that it should imply fast and simple operations. Furthermore, its implementation should take profit from parallel computing strategies.

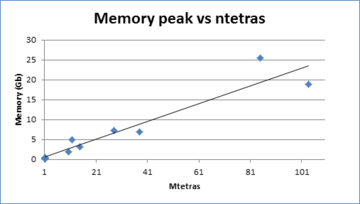

- Prepared to generate really large meshes. As the computer technology is evolving very fast, each time the solvers are capable to solve larger and larger algebraic systems. Thinking about the requirements from different simulations fields for the next years, the mesher should be able to generate billions of tetrahedral elements without problems. This characteristic is really important when deciding some implementation aspects of the algorithm.

1.2.2 Input data requirements

This section focuses on the requirements to be covered by the mesher concerning the input data:

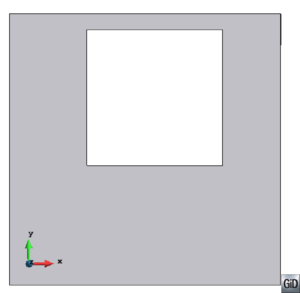

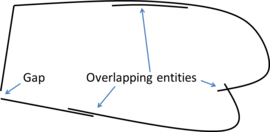

- Accept non-cleaned input geometry. This is another key point of the mesher. The idea is that it should be able to generate the mesh of the model although its geometrical contour comes from a non-cleaned input geometry. In this context, a non-cleaned input geometry is defined as the one containing:

- Non-watertight volumes. This means volumes with contours presenting gaps or overlapping entities.

- Non-coherently oriented contour entities. This means that the contour entities of a volume are not needed to be oriented (all of them) towards the same part of the volume (inner or outer).

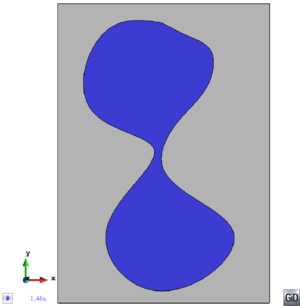

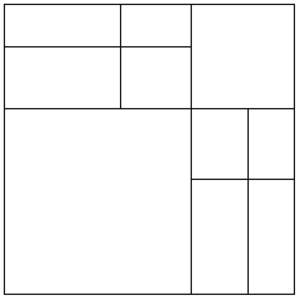

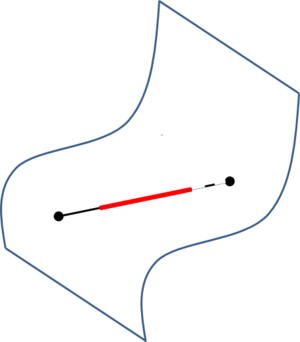

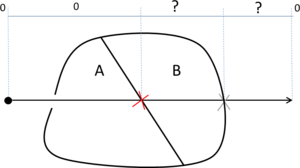

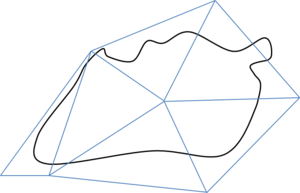

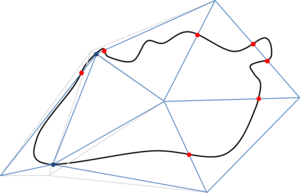

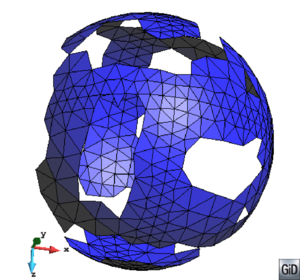

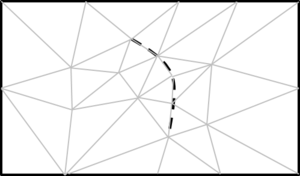

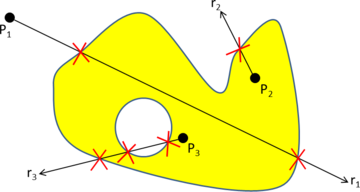

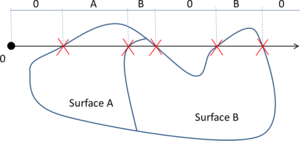

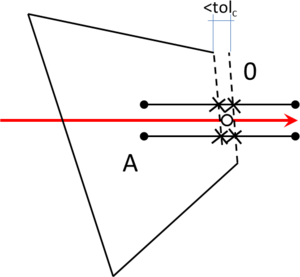

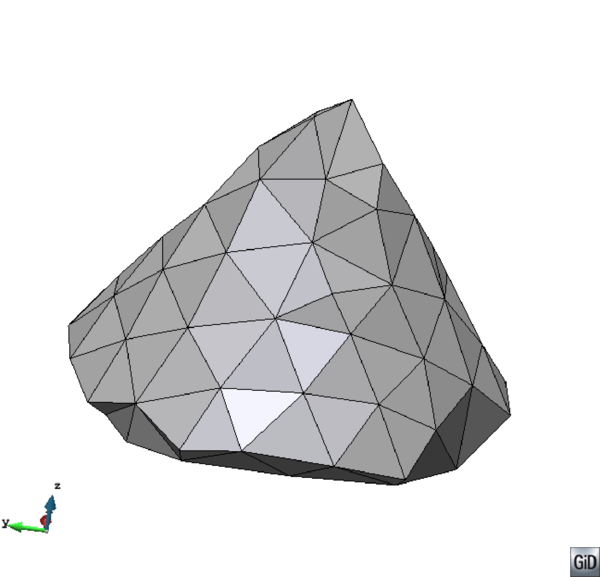

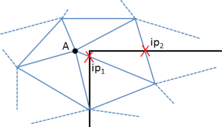

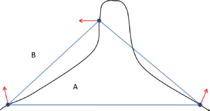

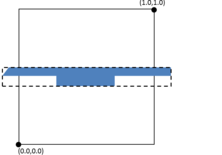

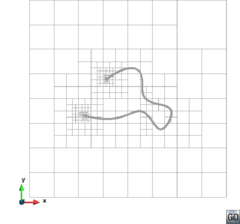

- Low quality definition. The geometrical contour can be defined by geometrical entities (like NURBS) or by a surface mesh. In this context, a geometrical contour with low quality definition means a highly distorted parametrization of the surfaces (in case of geometrical representation), or a mesh containing low quality elements (in case of surface mesh representation). Examples of low quality input geometries and no water-tight domains are shown in Figures 1 and 2. It has to be noted that the algorithm proposed in this document is for 3D volume meshing. However, for sake of simplicity, 2D examples are shown in some figures.

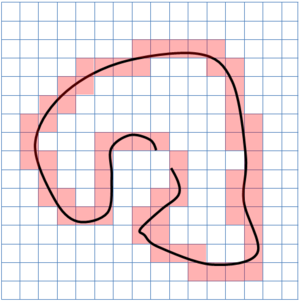

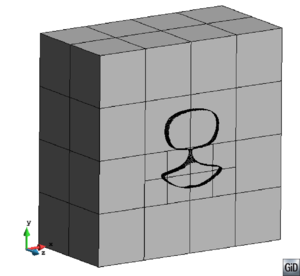

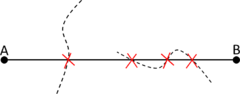

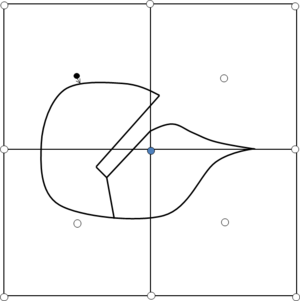

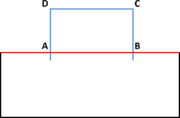

|

| Figure 2: Example of a 2D non watertight input boundary with gaps and overlapping entities. |

- Accept input data in geometry and mesh format. The natural input for a mesher is the geometrical definition of the contours of the model. This geometrical definition can be represented in several ways, but the most common ones are CAD or mesh entities. In this document, when talking about CAD entities, the NURBS surfaces and curves [4] (trimmed or not) will be considered, as they are the most general mathematical representation able to represent all the geometrical shapes.

Although the mesher should generate a mesh from a non-cleaned input geometry, some minimum criteria concerning topology or shape definition may be needed.

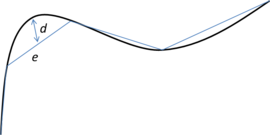

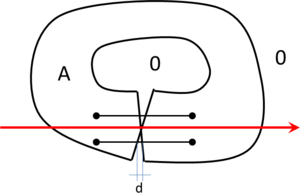

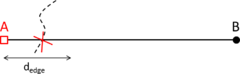

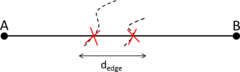

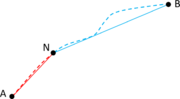

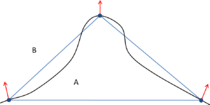

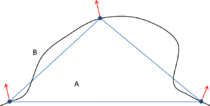

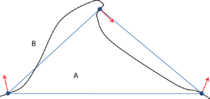

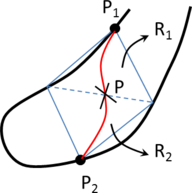

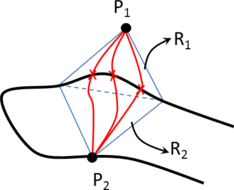

While mesh entities are simpler to be defined, CAD entities are a more precise way of defining a geometry. Meshes often loose continuity in the geometrical definition depending on the smoothness or curvature of the shape to be represented. It also has to be considered that, almost always, the mesh presents a chordal error compared to the smooth original geometry (the chordal error is the distance between a point on the mesh and the original smooth shape the mesh is trying to represent). In the Figure 3 a graphical representation of this chordal error is shown.

The simpler definition and treatment of mesh entities has made them the most common used as input for the existing volume meshers. There are cases where a surface (or a line) cannot be meshed because of its bad parametrization. In these cases, a volume mesher requiring a mesh as input cannot be used. This is the reason why the proposed volume meshing algorithm should be prepared to get as input data mesh entities, as well as NURBS surfaces and curves. Actually, it should be prepared not only to get these kinds of entities as an input, but also to work with them in the geometrical operations needed during the whole meshing process. The methodology presented in this monography is prepared to work either with CAD and mesh entities. Hence, the general form of geometrical entities will be used to refer the input entities defining the contours of the domain. Only if some specific operation is needed for just one of the representations it will be specified if the geometrical entity is a CAD or a mesh one. Following this duality, in this document a single term will be used to refer the different natures of geometrical entities:

- Surface entities for surface mesh elements (especially triangles) and geometrical surfaces (especially NURBS surfaces and patches of connected NURBS surfaces).

- Line entities for line mesh elements and geometrical curves (especially NURBS lines and groups of connected NURBS lines).

- Point entities for nodes of a mesh and geometrical points.

1.2.3 Final mesh requirements

The requirements to be covered by the mesher regarding the final mesh generated are:

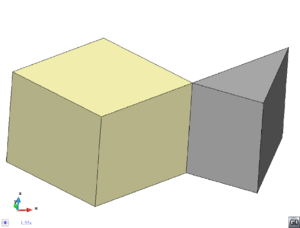

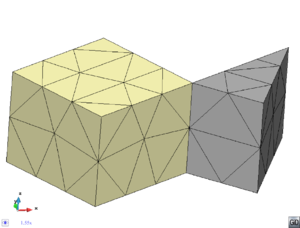

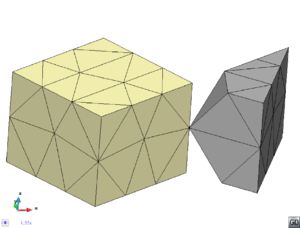

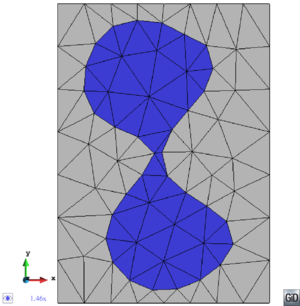

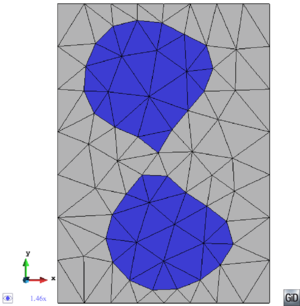

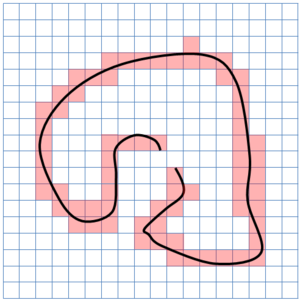

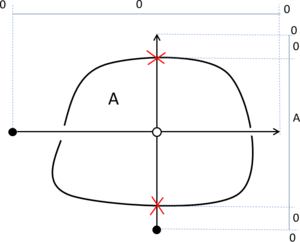

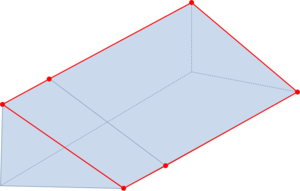

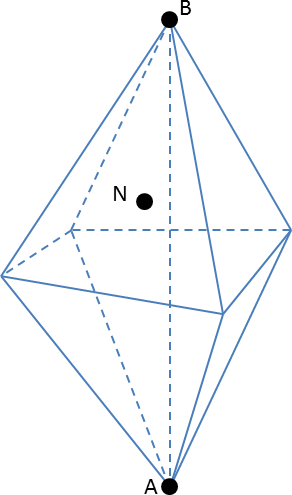

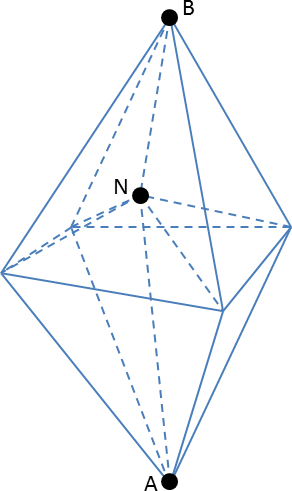

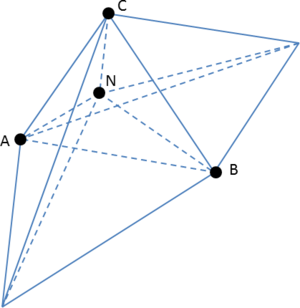

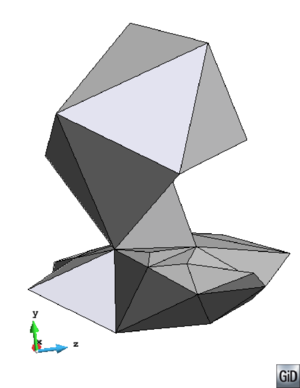

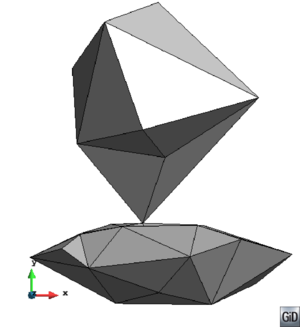

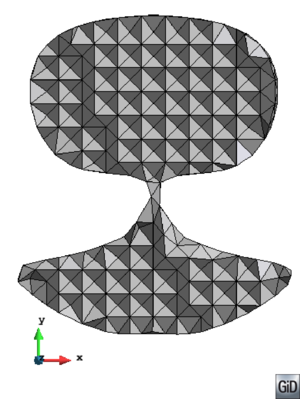

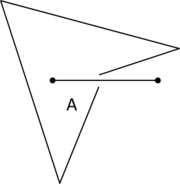

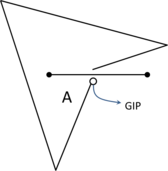

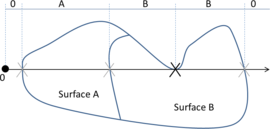

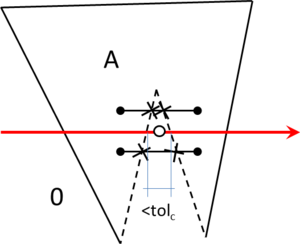

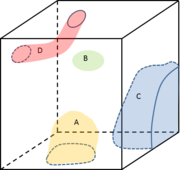

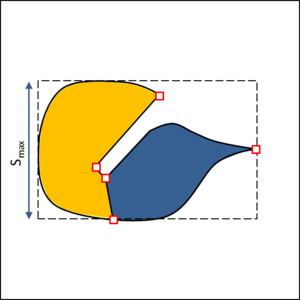

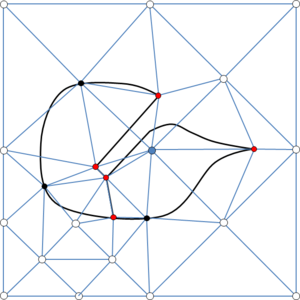

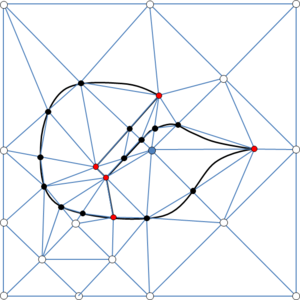

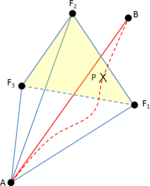

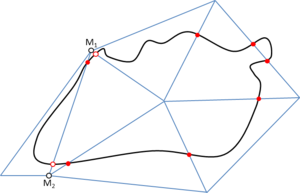

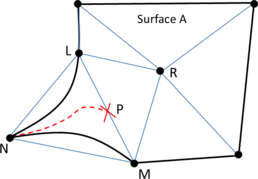

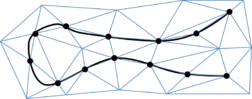

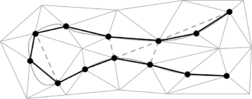

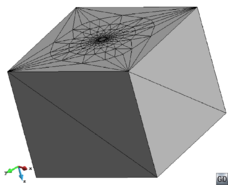

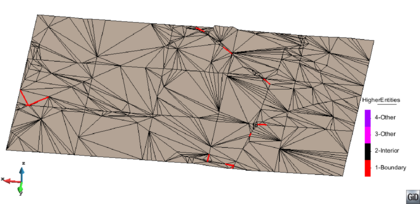

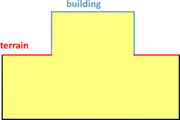

- Maintain volume topology. The topology of the initial domain to be meshed must be preserved in the final mesh. For most meshing algorithms this requirement is automatically satisfied, but it is not automatically guaranteed in all meshing techniques. Considering the final mesh, it has to be possible to identify the volume each tetrahedron belongs to. Then, if getting all the tetrahedra belonging to a given volume, the concept of the mesh of that volume can be defined. The maintenance of the volume topology of the initial domain means that there must be a mesh for each of the initial volumes, and each volume mesh must represent the same relationship between the others. For instance, if two volumes are connected by a line, the meshes of these two volumes must be neighbors sharing line elements. Furthermore, the mesh of a volume itself must represent the topology of the volume (for instance, if the volume has a hole, the mesh must have a hole). In Figure 4 two examples are shown with meshes preserving or not the topology of the original model.

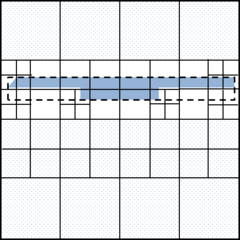

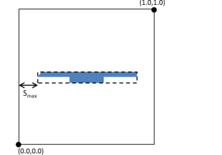

A special case which evidences the importance of maintaining the initial topology is the situation where the domain has very thin parts representing relevant details of it. A 2D case of this kind is shown in Figure 5, where a thin channel-like part can be identified in a surface (Figure 5(a)). Independently on the mesh desired size required by the simulation, the mesher must generate elements small enough not to close this channel-like zone, as the mesh shown in Figure 5(b). The mesh depicted in Figure 5(c) is not acceptable, as it does not preserve the topology of the domain.

| ||||||

| Figure 5: Example of surface mesh preserving or not the topology of the initial domain. (a) 2D geometrical domain formed by two surfaces (colored as blue and gray). (b) Mesh of the surfaces preserving the topology of the initial domain. (c) Mesh of the surfaces not preserving the topology of the initial domain. |

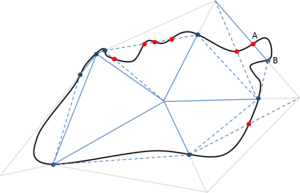

- Maintain a representative lines and surfaces topology. Often it is not required to preserve the topology of all the surface and line entities of the domain to be meshed. As the proposed algorithm is a volume mesher, the surface or line elements in the final mesh are of interest just in order to assign properties to them for the simulation. These properties can be of different nature: material properties, boundary conditions, etc. At the end, the mesher should maintain the topology of some patches of lines and surfaces on user demand, or following some automatic criteria.

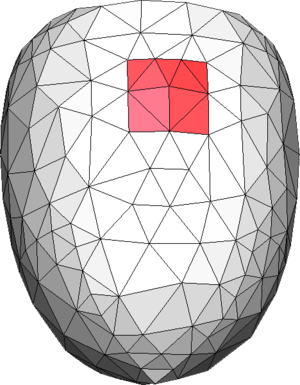

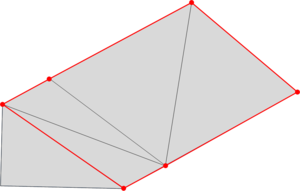

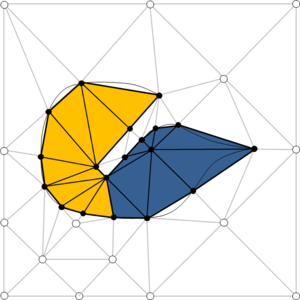

Note that this requirement is not as hard as the typical constrained condition in the boundaries of the domain. Especially when the input data for a mesher is a surface mesh, it is common to require the mesher to be constrained at the boundary. This means that the contour mesh of the final tetrahedral mesh (the triangles representing the skin of the generated tetrahedra) must be topologically identical to the input surface mesh defining the contours of the domain.

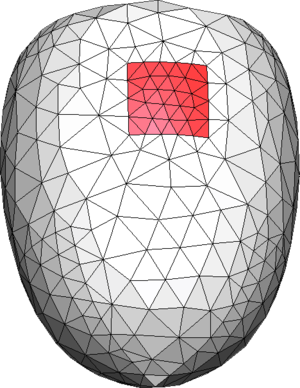

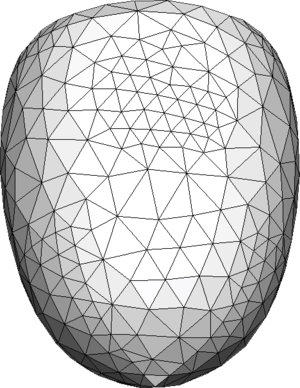

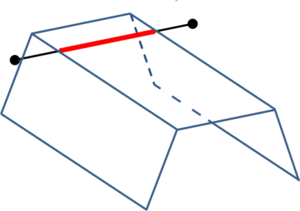

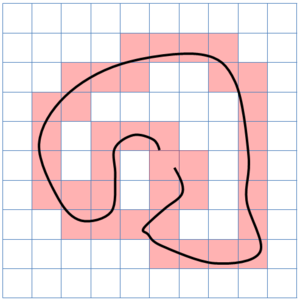

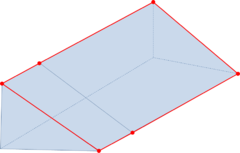

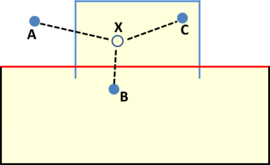

| ||||||

| Figure 6: (a) Contour mesh of a volume with a set of triangles highlighted in red representing the region . (b) A partially constrained tetrahedra mesh generated from the contour mesh shown in (a) where the highlighted set of tetrahedra faces corresponds to the region . (c) A not constrained tetrahedra mesh of the contour mesh shown in (a) (it cannot be identified a set of tetrahedra faces representing the region ). |

In Figure 6(a) an example of the contour of a volume is shown, where a set of surface entities (in this case triangles)are colored in red. Let us call the region represented by those triangles. If the simulation requires a set of triangles representing the region , the mesh generator should provide with a tetrahedral mesh whose skin should have a set of triangles representing that region, but it is not needed for those triangles to be identical as the ones in the input geometry. A tetrahedral mesh accomplishing this criterion is shown in Figure 6(b). A totally unconstrained mesh is depicted in Figure 6(c), where it cannot be identified a set of triangles corresponding to the region . It is obvious that the mesh in Figure 6(b) is not constrained with the input boundary shown in Figure 6(a), as the triangles representing the region are different. However, it can be seen that the requirement of maintaining a representative topology of the surface and line entities of the input data allows a bijective relationship between groups of surface and line entities in the input data and surface and line mesh elements in the final mesh. This requirement is enough to allow an automatic assignment of data from the input boundary geometry to the final mesh entities.

- Generate automatically the contour mesh of the volumes. Although the mesher is thought to generate volume elements (tetrahedra), it should give as an output also the triangular elements corresponding to the contours of the volumes, and the line elements corresponding to the boundaries of certain patches of triangles. This surface and line elements correspond to faces and edges of the final tetrahedral mesh.

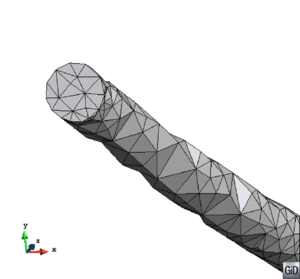

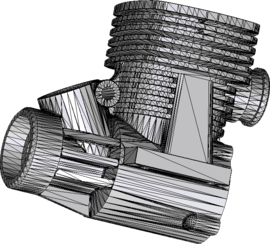

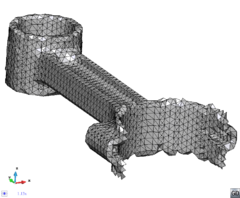

- Preserve geometrical features. This is automatically achieved by the boundary constrained meshers, but it is not guaranteed at all by the types of meshers. This requirement is crucial for the final mesh to represent the shape of the domain precisely. For several kinds of numerical simulations, the presence of sharp edges and corners in the domain affects drastically the results, as they often govern the physical behavior of the process to be simulated. The importance of preserving sharp edges and corners to represent some domains can be appreciated in Figure 7. Part of the contours of a volume are shown in Figure 7(a). The tetrahedral mesh of that volume generated without preserving the sharp edges of the input geometry is shown in Figure 7(b).

|

|

| (a) | (b) |

| Figure 7: (a) View of a part of the contours of a mechanical piece. (b) Tetrahedral mesh of the mechanical part generated without preserving the sharp edges of the input geometry. | |

In terms of the mesher, this requirement means that it should be partially constrained to some line entities from the input geometrical data, and must include fixed nodes in the final mesh (corresponding to specific point entities in the input data). In this context, partially constrained means that if some specific line elements in the input geometrical data must be preserved, a collection of edges from the final mesh should follow the path of those line elements. This is not as restrictive as totally constrained condition.

As it will be explained later on (Section 3.1), the strategy to cover this requirement will be also useful to reach the requirement of maintaining a representative lines and surfaces topology.

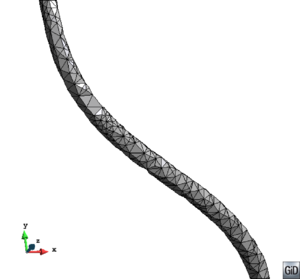

- Allow to skip given details of the domain. This requirement is somehow complementary to the previous one. What it means is that the mesher must be not constrained in some regions. The definition of the geometrical domains includes often very thin or small entities in given parts. The reason for the size of these entities may be the size of the part of the domain represented itself, but the presence of these small entities often responds to the application of a given tangency criteria for the geometrical definition, or they are just the result of some geometrical operation previously done (intersections, Boolean operations, etc.). The basic idea of this requirement is that the sizes of the geometrical entities used to define the contours of the domain are not necessary related to the mesh size needed for the simulation. In the Figure 8, an example is shown where the triangles generated from a patch of surfaces skipping the inner lines between them are much larger than the size of some of the surfaces of the patch. Clearly the simulation should not need such thin triangles in the regions where the surfaces are so thin.

|

|

| (a) | (b) |

| Figure 8: (a) Zoom of a patch of surfaces representing a mechanical part. (b) Triangle mesh of the patch of surfaces shown in (a). | |

Even when the sizes of the input entities are related to the representative size of a specific shape to be represented, the user may desire a bigger mesh size to skip the representation of given details because they are not of interest for the simulation. Instead of forcing the user to modify the input geometry which defines the domain, this requirement makes the mesher skip the detail within the mesh generation process.

The accomplishment of this requirement will let the user to define a desired mesh size distribution in the final mesh just because of the simulation requirements, and not because of the initial way of defining the geometry. In terms of the mesher, this requirement means that it should be able to skip some of the line and point entities from the input geometrical definition of the domain. The entities to be skipped should be defined automatically following some given criterion, or by the user.

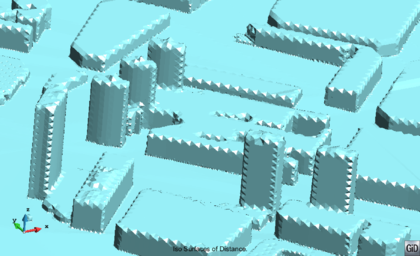

- Precise representation of the contour geometry. This requirement focuses on the need of the nodes of the contours of the final mesh to lay exactly on the geometrical entities defining the contours of the domain. Some mesh generators only approximate the shape of the domain to be meshed, or represent its contours in a staircase manner (specially the meshers based on octree or bin structures). Several numerical methods (specially the FEM) need a precise representation of the contour, as its shape and smoothness may affect drastically the result of the simulation. This is the main reason for this requirement.

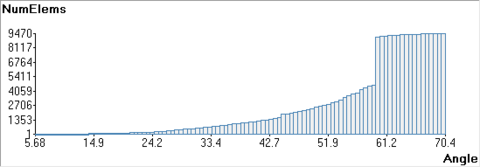

- Final elements quality ensured. The acceptable quality of the mesh elements is a relative parameter, as the different methods used for the numerical simulation are applicable for different ranges of element qualities [5]. Usually, most numerical methods perform better as the shape of the element is closer to the corresponding regular polyhedron, however this cannot be extended to all numerical simulations. This requirement will try to reach a minimum dihedral angle in the final tetrahedra.

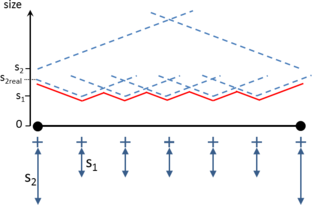

- Allow a 3D spatial size assignment. The use of a non-uniform mesh is crucial for some simulations. In some specific regions of the domain the size of the elements may have an upper bound, but if that size is used in the whole domain the final mesh should have too many elements. Typically, in the regions where there are higher gradients of the variable under study, the simulation needs a finer mesh than in other regions. This requirement is also important in the accurate representation of the shape of the domain, as the curvature of the domain geometry is strongly related with the mesh size needed to accomplish a given chordal error criteria. Just for geometrical purposes, a refined mesh in some regions would be needed.

- Control of sizes transitions. As the final mesh can be non-uniform size distributed, the size of the elements should vary from a region of the domain with a desired size to another. Some numerical simulations do not only require a specific mesh size in some specific zones, but also a given growing law between neighbor elements. The mesher should let the user to control how the element sizes grow (or decrease) from a region of the domain, depending on the distance from the elements to that region.

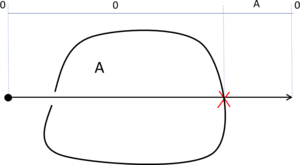

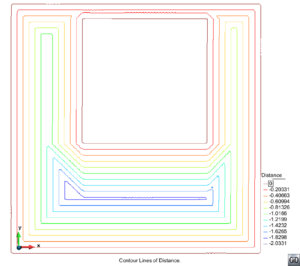

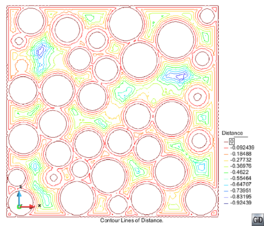

- Applicable for immersed methods. A family of methods for numerical simulations are the so-called immersed methods and embedded methods [6,7]. The main characteristic of these methods is that they do not require a body-fitted mesh to represent the domain. The shape is implicitly introduced by distance from the nodes to the boundaries and a casting process (determine whether a node is inside or outside the domain). In some sense, generating a mesh for a simulation using an immersed method is less restrictive as the geometrical features should not be preserved, but in contrast, the final mesh must have extra information attached. This information is the distance from each node of the mesh to the boundary of the domain.

1.2.4 Surface meshing

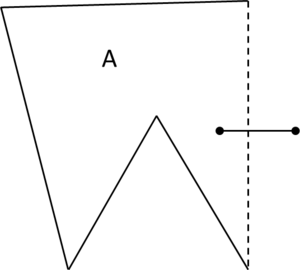

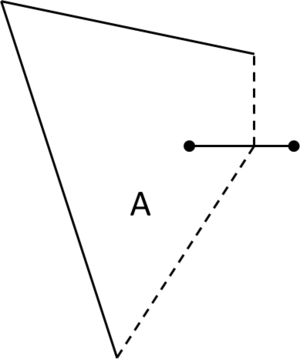

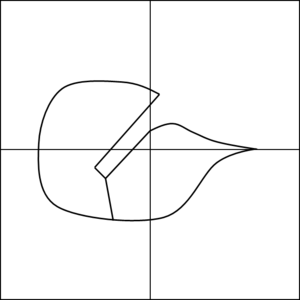

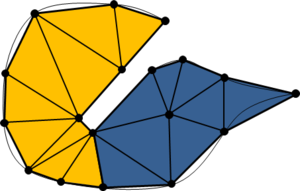

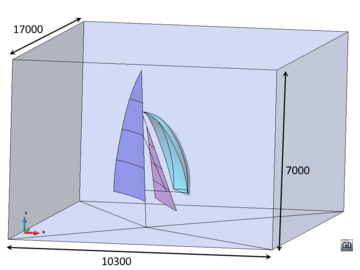

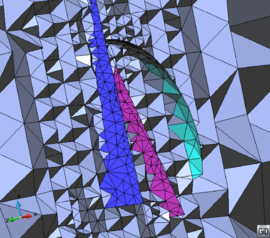

Although the main objectives of the monography are related to volume meshing, there is a secondary objective for the new mesher, which is to be able to mesh 3D surfaces and lines which are not boundary of any volume accomplishing the requirements defined above. This capability would give several advantages to the method:

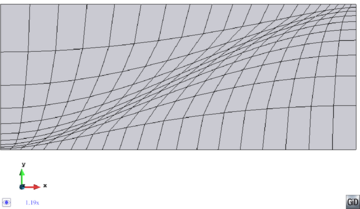

- Generate conformal meshes of volumes containing inner surfaces or lines. These are entities totally inside the volume, but not belonging topologically to the boundaries of the volume. An example of this case could be the representation of a sail (3D surface) into a control volume in order to perform a CFD simulation. The sail is totally inner to the control volume, and the mesh of it must be conformal with the tetrahedra representing the control volume. A 2D example of this case is shown in Figure 9. In this example a surface (bounded by solid black lines) has an inner line (dotted black curve), and the mesh of the surface (in gray) is conformal with this line.

|

| Figure 9: 2D example of a surface mesh (gray lines) conformal with an inner line of the surface (dotted line). |

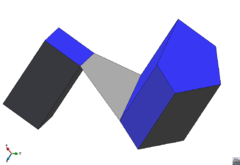

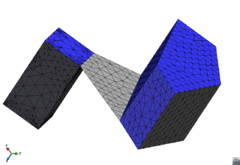

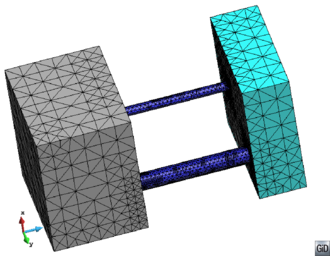

- Mesh in a conformal way a model with volumes and surfaces or lines connected to them. A case of two volumes connected by a surface is depicted in Figure 10. The mesh of the volumes and the surface must be conformal in the contact lines between them. This case can be also meshed by generating separately the volume meshes with the octree mesher, and afterwards mesh the surface using other meshing algorithms. This would not take profit on the advantages of meshing the whole model at once.

|

|

| (a) | (b) |

| Figure 10: (a) Example of a model containing two volumes (in blue) and a surface (in grey) connecting them. (b) A conformal mesh of the model considering the volumes and the surface mesh. | |

- Mesh patches of surface entities together preserving features, but skipping the inner line entities between them if needed. The entities to be skipped could be detected automatically following a given smoothness criteria, or under user demand. Figure 8 shows an example of triangle mesh representing a collection of surface entities, but skipping the inner line entities.

- If the patches of surfaces are not topologically connected, the proposed method could act as a CAD cleaning tool, as it could extract a continuous manifold surface mesh from a collection of surface entities with gaps or overlaps. The extraction of surface skin meshes from a volume discretization has been used in [8] and [9], and it is interesting for CAD cleaning, as well as for boolean operations involving non-watertight geometries. The preservation of geometrical features is essential for these purposes.

1.3 Structure of the monography

The monography is structured in the following chapters:

- Chapter 1: Introduction. This chapter focuses on introducing the context of the presented work. Its motivation is explained (Section 1.1), and its objectives are detailed (Section 1.2).

- Chapter 2: State of the art on mesh generation. In this chapter the different mesh types are presented (Section 2.1) as well as the state of the art of different meshing techniques (Sections 2.2, 2.3, 2.4 and 2.5). The advantages and drawbacks of each meshing method is studied, and the proposed solution for the meshing algorithm is justified (Section 2.6).

- Chapter 3: Basic concepts of the new mesher. Several concepts and some auxiliary algorithms are defined in order to allow a better understanding of the meshing algorithm presented. Its main parts are:

- Definition of the input data for the presented meshing algorithm and a proposal of how the mesher can interact with CAD data, integrated within a pre-processing system (Section 3.1).

- Octree structure characteristics (Sections 3.2 and 3.3). The definition and main characteristics of the octree structure (which plays a key role in the presented work) are presented. Special interest is given to its specific properties for the meshing process. The notation is defined which will be referred to in the following chapters.

- Geometrical intersections (Section 3.4). As the geometrical intersections are crucial for some of the algorithms presented, this section analyzes them deeply and studies the pathological configurations that may occur.

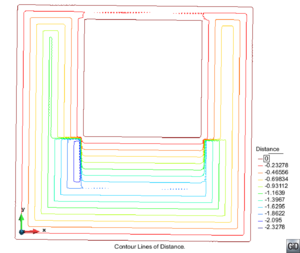

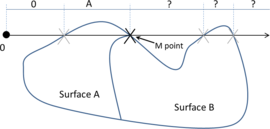

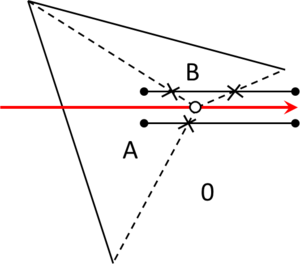

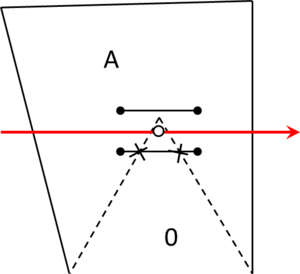

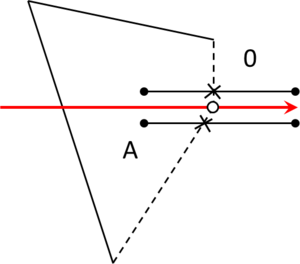

- Chapter 4: Coloring algorithm. The coloring process determines where a point in space is topologically: it determines if it is outside the domain, inside a given volume, or onto an interface between volumes. This is one of the main operations involved in the presented mesher and can be understood as an auxiliary algorithm for the meshing itself, so a whole chapter is devoted to it. In this chapter different approaches to solve the coloring problem are studied (Section 4.1), and a new algorithm based in the ray casting technique is exposed (Section 4.2). The implementation of this algorithm is presented in Section 4.3.

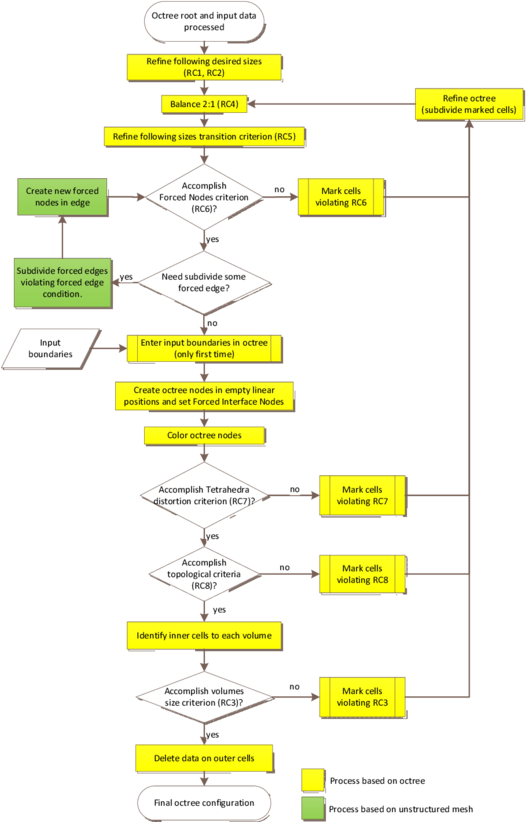

- Chapter 5: Octree based mesher. This chapter focuses on the new meshing algorithm itself. After an introduction, where its main idea is highlighted (Section 5.1), the algorithm for embedded (Section 5.2) and body-fitted (Section 5.3) meshes is detailed.

- Chapter 6: Implementation aspects. In this chapter all the implementation details for the meshing algorithm developed are explained. After some general aspects of the implementation (Section 6.1), the implementation of the octree structure is analyzed (Section 6.2). Sections 6.3, 6.4, and 6.5 focus on the implementation of specific parts of the meshing algorithm itself. Some considerations on the parallel implementation of the mesher are pointed out in Section 6.6. A list of the values of the parameters relevant for the mesher used in the presented implementation of the algorithm is detailed in Section 6.7.

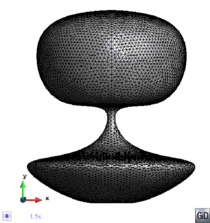

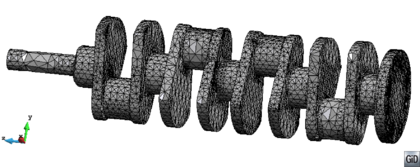

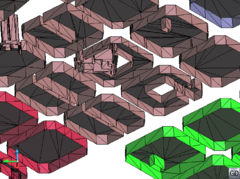

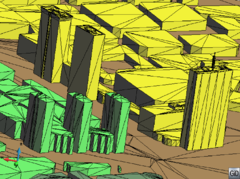

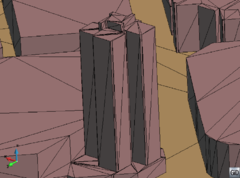

- Chapter 7: Examples. In this chapter the results of some validation examples highlighting specific characteristics of the presented mesher are shown (Section 7.1). Sections 7.2 and 7.3 analyze the results of the meshing algorithm applied to real complex geometries under different configurations.

- Chapter 8: Conclusions and future research lines. This chapter lists the conclusions of the presented work (Section 8.1) and proposes some futures lines of research (Section 8.2).

- Appendix A: Profiling tables and complete data of examples. In this appendix, tables with all the profiling data concerning times and memory for the whole configurations used in the examples run to validate the meshing algorithm are provided.

It is highlighted that, although the meshing algorithms presented are directly applied to volume meshing, most of the geometrical operations are applicable (with slight modifications) to surface meshing in 2D cases. Taking into account that some concepts are much more clear to understand from a 2D scheme (especially when dealing with geometry), in this monography 2D examples are used sometimes to illustrate some of the concepts explained.

2 State of the art on mesh generation

In this monography isotropic volume meshers are considered. Isotropic meshers can be defined as the ones trying to generate elements as much regular as possible, understanding a regular element as the one whose edges have the same length.

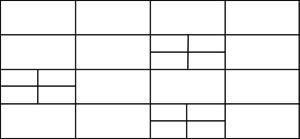

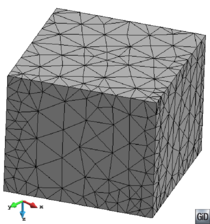

2.1 Mesh types

There are two main families of meshers depending on the kind of mesh they generate: structured and unstructured [10]. Actually, a third kind of meshers can be classified as semi-structured ones. A structured mesh is defined as a mesh which all inner nodes have the same degree (the degree of a node is the number of elements owning it), while the nodes of an unstructured mesh have different degrees. Semi-structured meshes can only be applied to topologically prismatic geometries, and they basically repeat the structure of an unstructured mesh (in the tops of the prismatic shape) in different layers following the structured direction. An example of this kinds of mesh is shown in Figure 11.

Unstructured meshers [11,5,12] can be divided in three main families: advancing front, Delaunay and space decomposition methods.

In the following sections, the main characteristics of these methods as well as their main advantages and drawbacks are detailed, focusing on the requirements defined in section 1.2. The aim of this chapter is to highlight which of those requirements are covered by each meshing method, so the algorithms are not deeply detailed and only their main characteristics are pointed out.

| ||||||

| Figure 11: Examples of different types of mesh(a) Structured triangle mesh. (b) Unstructured triangle mesh. (b) Semi-structured prism mesh. |

2.2 Structured meshers

Structured and semi-structured meshers often get as input data the position of the nodes in the contours of the domain, and generate the inner nodes positions from a given interpolation [10,12,4]. The quality of the final mesh obtained is directly related to the kind of interpolation used and the degree of distortion of the contours of the domain, so a minimum level of element quality cannot be guaranteed for arbitrary domains. However, for good shaped volumes and uniform sizes distributions these methods provide with very good quality meshes.

The main advantages of structured meshers are:

- Fast and robust. As they are based on a given predefined interpolation, they are really fast and robust.

- Parallelizable. Apart from being fast, these kind of meshers are very parallelizable.

On the other hand, these meshers have some important drawbacks:

- Need of specific topology for the input data. The main problem of this kind of meshers remains in a requirement for the input data: they need a specific topology for the geometrical definition of the contours of the domain. As an example, to generate a structured mesh of hexahedra, the input geometry must be topologically an hexahedra. This means it has to be a volume with 6 contour surfaces, and each one of their must have 4 contour lines. This requirement makes impossible to use this kind of meshers for arbitrary geometries with complex topology. A family of methods has been proposed that are able to skip this problem [13]. They are basically based in decomposing the original domain to be meshed into different parts which do accomplish with the topology demanded by the mesher. Then, each of these parts can be meshed in a structured manner, so they are often referred as structured by blocks or multi-block meshers. Several implementations of these methods have been carried out [11,10], but in practice they are meaningful for very specific domains only. Depending on the topology required by the mesher, some geometries are impossible to be decomposed in such this way, and even when this decomposition is possible, from complex original geometries is not obvious to generate this decomposition automatically. This often implies an extra pre-processing operation before using the mesher, which is the splitting (manually) of the domain in different parts.

|

| Figure 12: Example of a 2D structured quadrilateral mesh with a non-uniform size distribution. A high level of element distortion can be appreciated. |

- High distortion in non-uniform meshes. As the nodes of structured meshes have the same degree, a predefined topology of the mesh is forced. It generally tends to generate uniform meshes. Structured meshers can relatively distort the elements in some region in order to provide with a non-uniform mesh, but the fixed topology of the mesh does not allow a sharp sizes transition without an excessive distortion in the elements. A 2D example illustrating this problem is depicted in Figure 12.

2.3 Advancing front method

The advancing front method [14,15,16,17] is a common technique for generating unstructured meshes. It gets a closed and oriented mesh of the boundary of the domain as input and mesh its inner part. The surface elements of this mesh are the ones in the active front, and the algorithm can be summarized with the following points:

- From each element in the front (face) a new volume element is generated. An optimal position of the node needed to build the element is obtained and the nodes and faces of the active front close to it are considered. The new element is build using a new node in the optimal position or an existing close node, depending on the resulting configuration: the new element should not intersect any one of the close already existing faces.

- The active front is updated adding the new faces created, and removing the ones already shared by two elements.

- These two steps are repeated until there are no faces in the active front. Then all the domain has been filled with volume elements.

Although the advancing front is mainly used for generation of tetrahedral (or triangle in 2D) elements, some adaptations of the method have been done to generate other types of elements [18], and even for generating particles for DEM simulations [19]. The present work is focused in tetrahedra mesh generation. There are several possible implementations of the advancing front method [11] depending on the way of creating the new elements from a face of the front, the way of considering the mesh desired size in the inner part of the domain, or the order in which the faces of the front are processed, among others. In special, much work have been done in order to improve the efficiency in evaluating the desired mesh size in a specific region of the domain, and control a smooth size transition in the final mesh. This is one of the strong points of advancing front techniques, as the creation of each element can fit very well the desired mesh requirements. Different approaches use a background grid to set the mesh desired size [16,15,20,21], or sources from which the desired mesh size vary following a given function [22], which provides with a very smooth transition between element sizes. A combination of different methods can be used in order to improve accuracy and reach an efficient implementation of the method [23]. However, independent of the implementation, one can identify some general advantages and disadvantages of advancing front based techniques. The main advantages are:

- Good quality meshes. In the advancing front method, each new element is created connecting a face of the active front with a new node or an existing one. This choice is done based on an optimal position for this new node in order to get the best element (in terms of quality) taking into account the desired size of the mesh in that region. This methodology for creating the elements gives high quality elements in the final mesh, even before any smoothing process.

- Automatic preservation of topology. The advancing front method is naturally constrained, as each element of the surface mesh of the contours of the domain to be meshed will become a face of the final tetrahedra.

- Good control on the size transitions. As explained before, each new element is created from an existing face and an optimal position of the node to create the element from the face. Considering the desired size for the final mesh in the region where the face is, and the size of the face itself, the size transitions from one part of the mesh to another is totally controlled.

- Parallelizable. The creation of each new element using the advancing front method is clearly local. The geometrical and topological checks needed to create the new element only take into account the nodes and faces inside a specific radius of influence of the face the new element is created from. This aspect makes totally independent the creation of an element from the creation of another element which is far enough. Although it is not obvious to implement an efficient parallel version of the advancing front method, at least the element generation method is local enough to make the implementation affordable. [24] proposed a first octree subdivision of the domain, and then apply the advancing front technique in each of the cells of the octree, seaming afterwards the interface parts between cells.

The main drawbacks of the advancing front method are:

- Strong dependency on the contour mesh quality. Considering that the surface elements of the initial contour mesh will be faces of the final volume elements, the quality of these contour elements is totally related with the quality of the tetrahedra in contact with them: if a triangle of the contour of the domain has a very small angle in some of its nodes, the resulting tetrahedron from it will have a very small dihedral angle. This implies a great effort in the mesh generation of the contours of the volumes to be meshed. Often this effort takes most of the part of time in the pre-processing operations of the whole simulation when using the advancing front technique.

- Requires watertight input geometry. The reason for this is that the initial surface mesh representing the boundary of the domain will be the skin of the tetrahedra in the final mesh.

- Not very robust. Theoretically, the advancing front is a robust method. However, the locality of the element creation process and the checks needed to evaluate if the new element created intersects or not the active front require some tolerances. These tolerances must be tuned precisely in order not only to avoid the crossing of the active front, but also to avoid different parts of the front to get very close. This situation can lead to geometrical configurations of the active front which make almost impossible the creation of a new element. The tuning of these tolerances and other parameters can be done as general as possible, but as the active front evolves during the meshing process, these geometrical configurations are not under control, and cannot be predicted. This aspect, together with the hard dependency on the contour mesh quality makes the advancing front method not so robust in practice.

- Not very fast. Every candidate new element to be created needs to be checked in order to verify if the active front is intersected by some of its faces and edges. This involves the use of several geometrical intersections operations in the whole meshing process. This aspect, together with other characteristics of the advancing front method, makes it not very fast in comparison with other meshing algorithms.

2.4 Delaunay method

A Delaunay mesh is defined as a mesh which elements accomplish the Delaunay condition: the circumcircle (in 2D case) or the circumscribed sphere (in 3D case) of any element has no node from the mesh inside [10]. Given a cloud of points, a Delaunay triangulation can always be created from their Dirichlet tesselation connecting them with a set of triangles (in 2D) or tetrahedra (in 3D) without adding any extra node [10].

The Delaunay meshing methods [12,25,5,11] depart from the contour of the domain and generate the Delaunay triangulation of its nodes. This mesh is the convex hull of the domain to be meshed. Although it is already a mesh, its elements may have a low quality, or may not fit with the desired mesh size in that region of the domain: these are the bad elements. The following strategy is applied recursively to all the bad elements:

- A node is created in the centroid of the element. Some strategies allow the creation of the new node at the edges or faces of the elements [26] in order to improve the quality of the elements respecting the contours of the domain.

- All the elements of the mesh which circumscribed sphere (or circumcircle in 2D) includes the new node are deleted. Note that a void region is created containing the new node inside.

- A Delaunay triangulation is created with the new node and the contour nodes of this void region.

This procedure leads to a Delaunay mesh (accomplishing the Delaunay condition), but this does not guarantee a given level of quality by itself. Often, some elements can present very low quality (especially in 3D cases). These elements may have null volume and are called slivers. Even if its volume is equal to zero, they can accomplish the Delaunay condition. For this reason, it is common to relax the Delaunay condition in some regions in order to avoid quality problems [27].

The main advantages of this method are:

- Robust. Mathematically, we can always obtain a Delaunay mesh from a cloud of points. However, sometimes the modifications of the method to cover the requirements of the simulation make it not so robust.

- Fast. Although it depends strongly on the implementation, it can be said that Delaunay methods are naturally faster than the advancing front ones.

The main drawbacks of the Delaunay method are:

- Naturally not constrained. Delaunay methods use the representation of the contour of the domain as an initial configuration for the insertion of nodes procedure, but the final mesh boundaries are not guaranteed to be constrained with that contour. Some strategies can be applied [28,29,30] in order to guarantee that the nodes in the initial contours will lay on the contour of the final mesh, or even a constrained condition in the faces of the initial contour, but these modifications reduce the performance and robustness of the method. Furthermore, if there are huge different mesh desired sizes in the domain, these strategies are not very robust.

- Requires watertight input geometry. As in the advancing front method, the contours of the domain are required to be watertight. Actually, a strategy could be followed to treat non-watertight geometries. It is based on generating the first mesh (the convex hull in the traditional Delaunay methods) using only the nodes of the contours, with an automatic recognition of the boundaries: the so called alpha-shape method [31]. This would indeed generate a volume mesh from a non-watertight geometry, but there is no enough control in the boundaries recognition to ensure that mesh correctly represents the topology of the domain.

- Not naturally parallelizable. The check of the Delaunay condition of an element requires taking into account all the mesh entities participating in the circumscribed sphere of the element. As its radius depends on the position of the nodes of the element (cannot be bounded a priori), the treatment of one element can involve the whole mesh in some configurations. This implies a hard dependency ranging from an element to the whole mesh, so a parallel implementation of the method is not obvious. However, some parallel implementations (mainly for shared memory paradigm) of the Delaunay method have been carried out, [32] or [33].

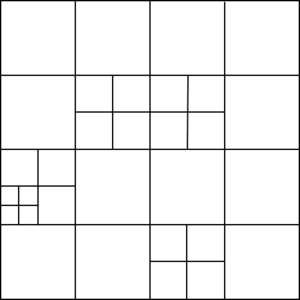

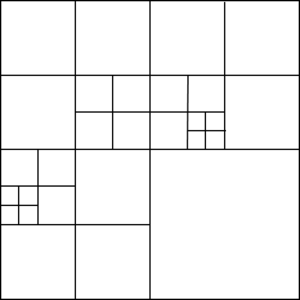

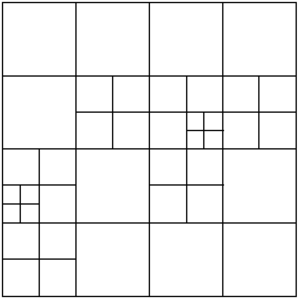

2.5 Space decomposition methods

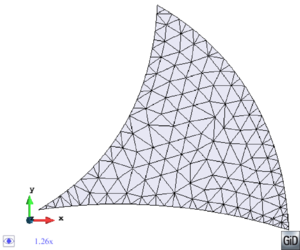

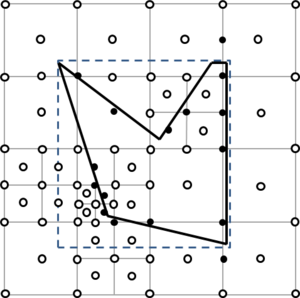

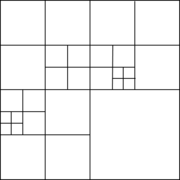

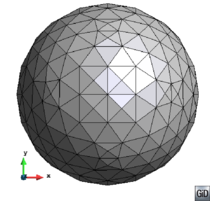

Space decomposition-based methods follow a different philosophy than the methods explained before. To generate the mesh, they basically subdivide the space into cells providing with a spacial decomposition covering the space where the domain is (overlapping the domain). These cells can be thought in a general way, but it is common to use one of the following main structures which govern their configuration:

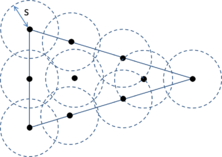

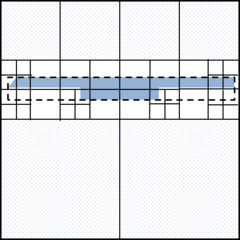

- Bin: a bin structure provides with an homogeneous grid as the space decomposition formed by regular cells (squares in 2D or cubes in 3D). A graphical view of a 2D bin is shown in Figure 13(a).

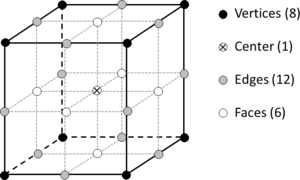

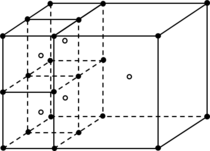

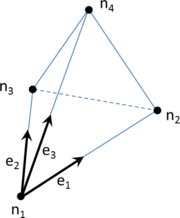

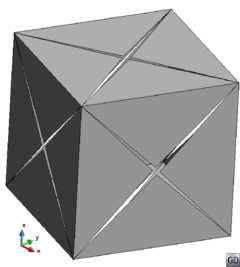

- Octree: an octree (quadtree for the 2D case) is basically a hierarchical spatial structure that partitions the 3D space into regular cells [34]. These cells can be refined in given zones of the domain. A graphical view of a quadtree is shown in Figure 13(b). A more detailed definition of the octree structure is given in Section 3.2.

|

|

| (a) | (b) |

| Figure 13: 2D examples of typical structures used in space decomposition based meshing algorithms. (a) Bin. (b) Quadtree. | |

The bin structure is suitable for homogeneous discretizations. It is common to use an octree structure as the regular grid (which gives the name of the family of methods), because it is more flexible for mesh generation purposes, as domains to be meshed and desired mesh sizes are commonly non-homogeneous. Octree-based meshers were pioneered by Yerry and Shephard in [35] and, since then, several approaches have been proposed [36,37,38,39,40,41,42].

The octree structure was thought for the first time for space searching purposes [34], and the specific topology of the spatial decomposition it represents (detailed in Section 3.2) gives several advantages for mesh generation. Somehow, an octree can be considered a mesh itself (it can be thought as a non-conformal hexahedra mesh), so it is really natural to build a mesh from it.

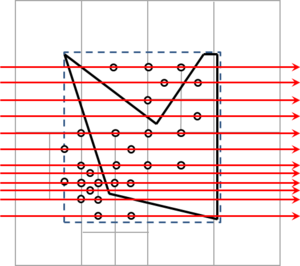

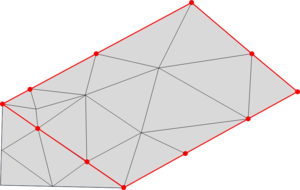

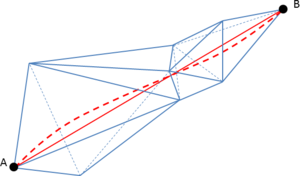

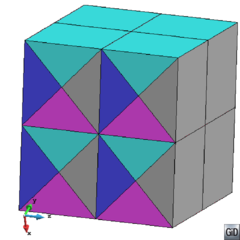

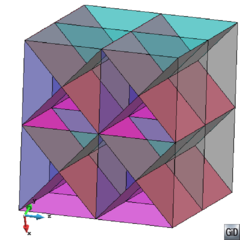

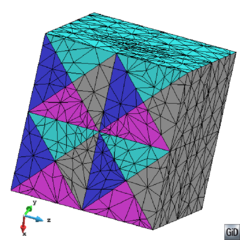

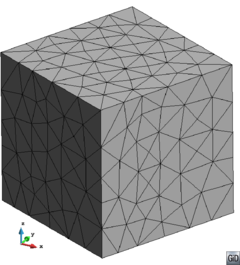

Although several algorithms have been proposed parting from the octree-based family of methods, almost all of them follow three main steps:

- Generate the regular grid for the space decomposition.

- Generate the elements of the final mesh directly using given patterns from the cells of the regular grid.

- Fit somehow the boundaries of the domain.

Concerning the first step, as it has been pointed out before, the octree is the most common structure used for the space decomposition. From the theoretical point of view, all octrees are similar, but depending on the way the octree will be used, different implementations have been proposed by several authors [43,34] in order to improve the efficiency of the octree, the performance for searching processes, the optimization considering the memory needed to store it, etc... More details on the implementation of the octree are presented in Section 6.2.

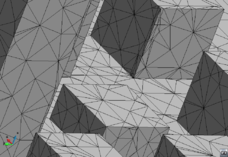

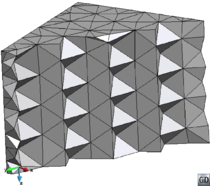

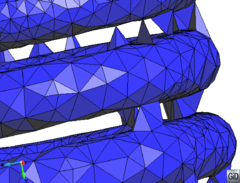

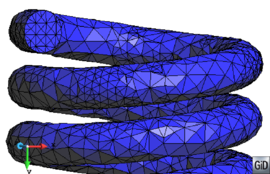

The generation of the elements of the final mesh from the octree is a simple process. It is based in creating the mesh elements directly from the octree cells (the definition of octree cell, as well as other octree related basic concepts are explained in detail in Section 3.2). Some of the existing methods apply different splitting patterns from the cells to get tetrahedra [35,44,37]. Other methods can get directly the cells of the octree as hexahedra elements of the final mesh (in cases where the final mesh is not needed to be conformal), or create transition elements when two neighbors present hanging nodes [42]. [40] proposes a different approach: create special cells where the octree is refined (where the neighbor elements are not conformal) and build the dual of the octree. The cells of it are directly the elements of the final mesh. With this approach a final mesh of conformal hexahedra is obtained automatically.

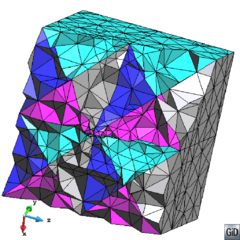

The key difference of each method remains in the third step, which is the most complex one. As the octree is a regular space decomposition, their cells do not fit exactly the contours of the domain to be meshed. Getting only the elements coming from the cells which are in the inner part of the domain (or even the ones intersecting its boundaries), the contours of the final mesh are staircase-like, so they are not able to represent smooth shapes with a given curvature.

Considering the inner cells (the ones totally inside a volume) and the interface ones (the ones colliding with the contours of a volume), different strategies have been proposed to fit the contours:

- Get only the inner cells and fill somehow the empty space between them and the real contour of the domain. This family of methods profits from the main advantages of octree-based methods for the inner part of the domains, but presents the same limitations near the contours as the methods used to fill those empty spaces.

- Project onto the contour of the domain the boundary nodes of the elements created from the inner cells using different techniques [36,39]. This strategy warps the nodes coming from the octree, so the shape of the octree changes, but its topology remains the same. [42] proposes a pillowing technique near the contours to avoid bad shaped elements (hexahedra) after mapping the nodes.

- Move some nodes and split the elements intersecting the contours of the domain in order to represent it precisely [37].

Although these methods achieve the smooth representation of the contours, they have to follow specific strategies to preserve the geometrical features (corners or sharp edges). [41] proposes a re-tetrahedralization of the octants of the octree containing sharp edges using advancing front or Delaunay technique, taking into account the intersection points between the sharp edges and the octree cells. [40] follows a strategy based on detecting which triangle from the input boundary the final nodes lay onto, and assuming that if two nodes lie onto two triangles connected by a sharp edge, there should be a sharp edge between those nodes of the final mesh. This strategy is not so robust, as it assumes that the sizes of the final elements is quite similar to the sizes of the triangles of the contour, so the triangles where two neighbor nodes of the final mesh lie onto are supposed to be neighbors connected by an edge. This is not a general situation.

As it has been explained, several approaches have been proposed departing from the octree-based family of methods. Although each approach has its own characteristics, some common advantages can be detected:

- Robust. The operations involved in most common octree-based methods are designed to be robust independently on the tuning of their control parameters. This is applicable to the operations dealing with the octree itself, but some processes dealing with the mesh generated (especially for body-fitted meshes) may not be so robust.

- Fast. As mentioned above, the octree is a structure used to make faster the searching algorithms in space. Indeed, almost all the meshing algorithms use an octree as a tool for searching purposes. In this case, this structure is also the base of the mesh generation itself, so the algorithm takes profit from it to improve its performance. Furthermore, the inner elements of the mesh are created directly based on a division pattern of the octree cells, which is really fast in comparison with other methods which have to take care on geometrical aspects when generating each element.

- Naturally parallelizable. The octree itself is a partition of the space, so it is really easy to identify the parts of the domain affected when some part of the mesh is modified or generated. Furthermore, typical operations involved in an octree-based mesher are performed at octree cell level, and most of them are independent from one cell to another, so the parallelization of some parts of the algorithm is almost automatic. Several parallel implementations of the octree structure have been carried out taking advantage on these features [TU:2005:SPO:1105760.1105769,CamataCoutinho].

- Good quality meshes. As the mesh elements in these methods come from a predefined pattern of decomposition of an octree cell, all the inner elements are in a range of qualities known a priori. However, the elements in the contour of the domain are typically more distorted (depending on the method used).

- Allow not cleaned geometry as input. Most octree-based methods only take care on the position in space of the boundaries of the domain rather than a topological relationship between the contour entities. This is a key point to allow some of the octree-based meshers to work with non-watertight input geometries. This property also makes octree-based meshers independent from the quality of the contour meshes used as input.

The main drawbacks of octree-based methods are:

- Naturally not constrained. The space decomposition of the octree does not respect the topology of the model. Octree-based methods are often not constrained, and the topology preservation is usually linked to the sizes of the octree cells used. This ends with a need for the user of the mesher to assign properly the desired sizes of the mesh, taking into account some kind of characteristic size of the model in specific regions of the domain.

- Hard to preserve geometric features. This drawback is strongly linked with the previous one: as the mesher is not constrained, it is hard to preserve sharp edges or corner points from the input data in the final mesh. Furthermore, cases where the sharp edges involve a small dihedral angle are very unfavorable for these methods, as the octree cells are very regular by its nature: it is hard to represent a small angle parting from a regular shape.

- Predefined size transitions. As most elements come from a direct pattern from the octree cells, the size of an element in comparison with the size of its neighbor is strongly related with the sizes ratio between neighbor cells in the octree. This link makes quite stiff the possibility of applying a smooth size transition in the final mesh. For some simulation methods, the meshes obtained by octree-based meshers present (locally) too sharp variations in the sizes of neighbor elements.

- Alignment of edges in a preferred direction. Because of the regular partition of space the elements come from, these meshes tend to generate meshes aligned with it. This alignment may influence the solution of the numerical simulation depending on the method used.

- Creation of too refined meshes. Octree-based meshers tend to generate a large number of elements, specially when the model has sharp features. This is because these methods often try to guarantee a minimum element quality by refining the octree near them.

2.6 Proposed solution

The strategy chosen in this work to cover all the requirements described in Section 1.2 is to develop an octree-based mesher. The election of an octree-based mesher in this work has been made taking into account the main advantages and disadvantages of the different methods:

- Structured and semi-structured meshers have been disregarded because the requirement for the input geometry to present a given topology is so restrictive that it makes them non applicable for many complex cases.

- Advancing front like methods have not been taken into account because the hard dependency they have on the quality of the input mesh for being successful in the mesh generation. Furthermore, they are directly not applicable if the input geometry is not watertight, unless some geometry repairing process is applied prior to the meshing itself.

- Delaunay methods have not been taken into account because they are not naturally constrained, and the proposals for them to be constrained blur some of its advantages. Furthermore, Delaunay methods are not naturally parallelizable, and they often generate localized bad quality elements.

- Octree-based methods are fast, robust and lead to very good quality meshes. Their main disadvantage are the inability to preserve the input topology, and their not constrained nature. However, the advantages of this family of methods, together with the ideas presented in this monography to overcome these drawbacks have tipped the balance to these methods.

As explained in Section 1.2.4, although the main objective of this work is to develop a new volume mesher, the methodology proposed is applicable to generate meshes of 3D surfaces and lines not belonging to any volume. The case of lines is automatically solved with the special treatment of line elements in the volume mesher (Section 5.3.1), and some adaptations are maid to the volume mesher in order to mesh surfaces as it is explained on Section 5.3.10.

3 Basic concepts of the new mesher

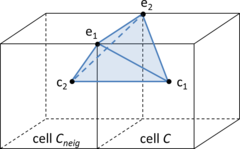

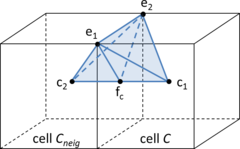

This chapter focuses on defining the different concepts involved in the proposed meshing algorithm, as well as some auxiliary algorithms needed to understand it. The following concepts will be described:

- Input data (Section 3.1). The input data needed for the mesher is defined, as well as the way of interaction of the mesher with a CAD system.

- Octree structure (Section 3.2). As the octree is the base structure for the mesher, an introduction to it is carried out in this section, highlighting its main characteristics.

- Octree properties for mesh generation (Section 3.3). Some specific properties of the octree are used in the meshing algorithm. A detailed explanation of them, as well as the key notation is introduced.

- Geometrical intersections (Section 3.4). The way the new algorithm deals with the geometrical intersections is presented. Also, the notation of pathological intersection types is introduced. This issues will be referred to in other parts of the work.

3.1 Definition of input data

The essential input for the mesher is the geometrical definition of the boundaries of each volume of the domain. As indicated in Section 1.2.2, this definition can be carried out using CAD or mesh entities. In this document the general concepts of surface, line and point entities will be used for both representations.

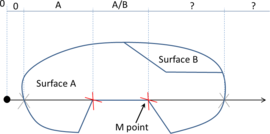

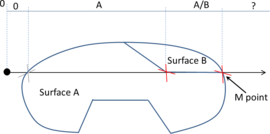

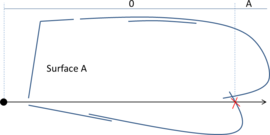

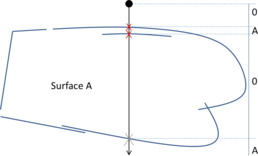

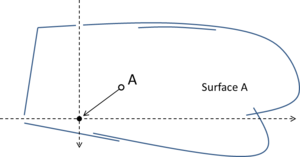

At this point, it has to be commented that the mesher considers the outer part of the domain as another volume to be meshed. It takes the name of outer volume, or volume number zero. Of course, the outer volume extends until infinite and it has no sense to consider it as a closed volume, so it is treated in a special manner. Later on it will be explained in more detail how the mesher deals with it.

Together with the surface entities an extra information is needed: the identification of the volumes each surface entity is interfacing. Note that considering the outer part of the domain as a virtual volume, all the surface entities defining the domain are interfacing two volumes. It may have sense for a surface entity to interface more than two volumes, but this would imply overlapping definitions of the 3D space (parts of space belonging to more than one volume). These kinds of topology are not considered in the present work.

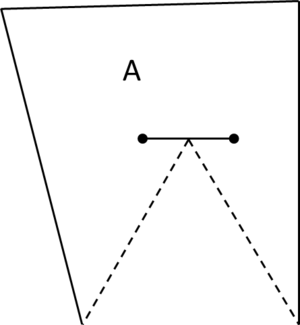

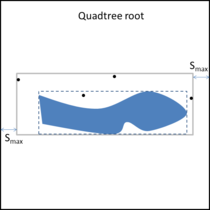

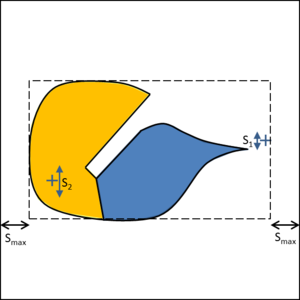

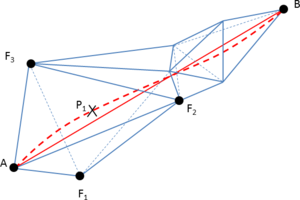

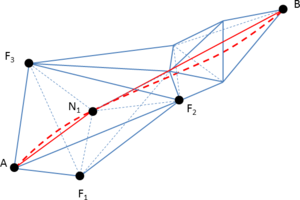

Apart from the geometrical definition of the boundaries of each volume of the domain, extra information can be given to the mesher in order to specify some characteristics of the final mesh. It is important to note that this extra information is optional, as the mesher should generate the mesh of the domain with or without it. This information is given by the mesh size entities, the forced point entities, the forced line entities and the general parameters. Hereafter the characteristics of these data are detailed:

- Mesh size entities. The mesh size entities are geometrical entities used to provide the mesher with the desired size of the mesh in different regions of the 3D space. These geometrical entities can be point, line, surface or volume entities (both in mesh or CAD form), and they have a desired mesh size associated to them. These entities can be part of the input boundaries or not. If a desired mesh size is needed to be assigned to a volume, it can be provided just with the identification of the volume, without the need of creating the corresponding geometrical entities (volume entities in this case).

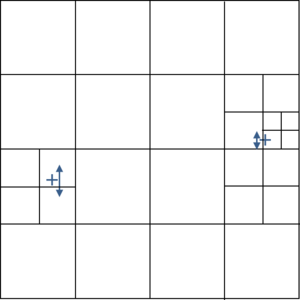

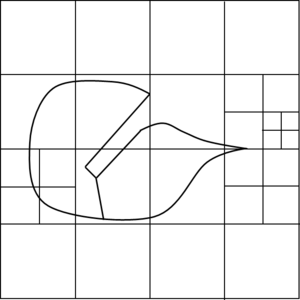

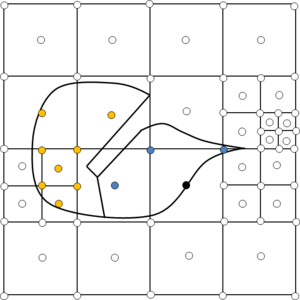

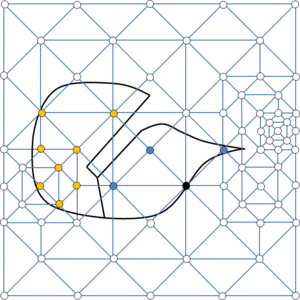

- Forced point entities. These are positions in space where the final mesh is forced to have nodes. They can be part of the input boundaries or not.

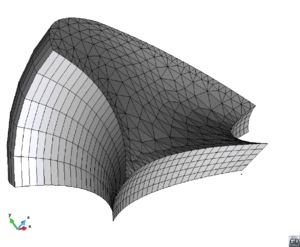

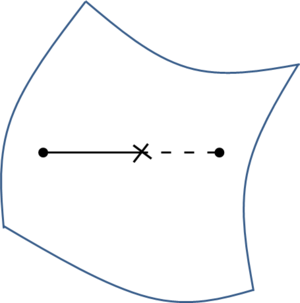

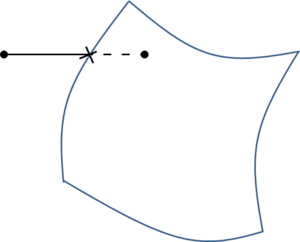

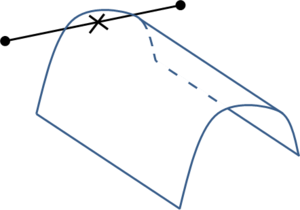

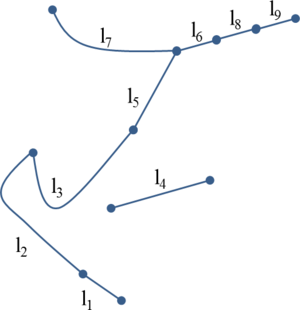

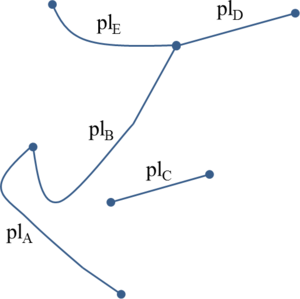

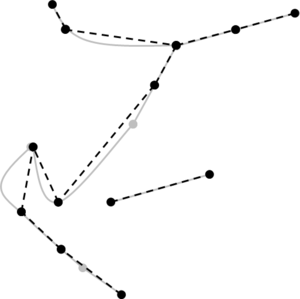

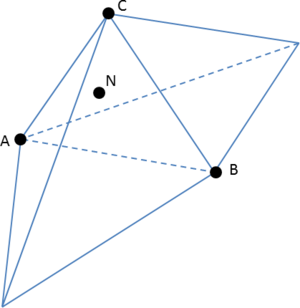

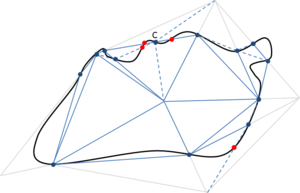

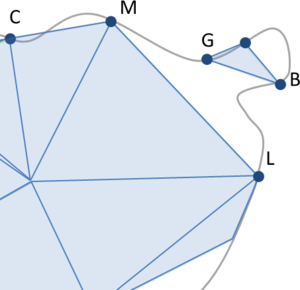

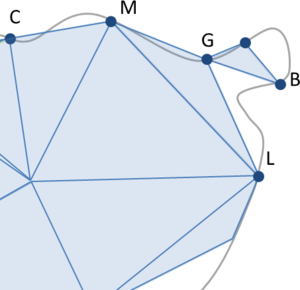

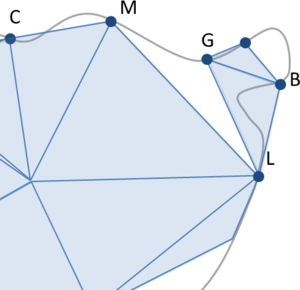

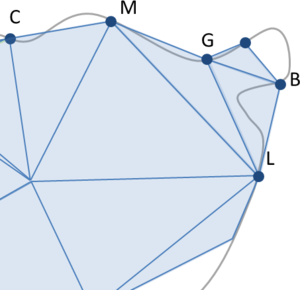

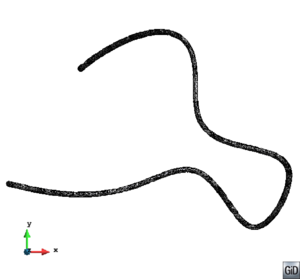

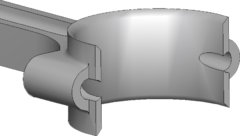

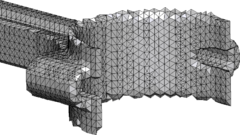

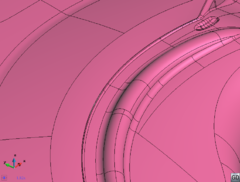

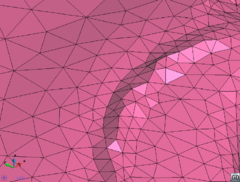

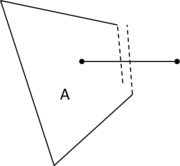

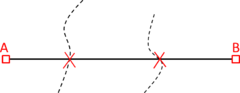

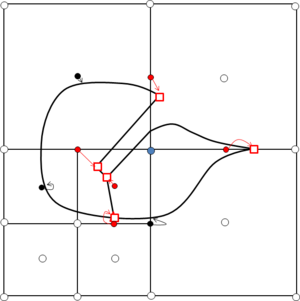

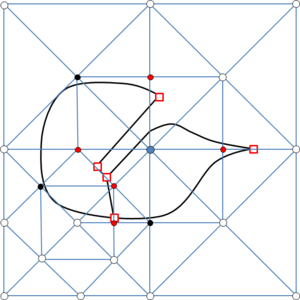

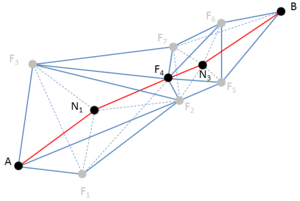

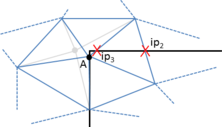

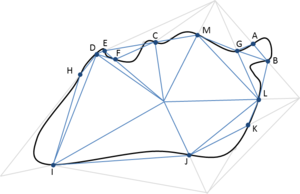

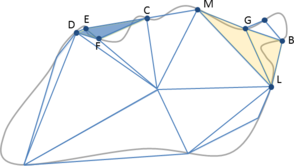

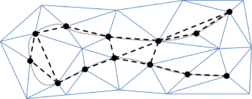

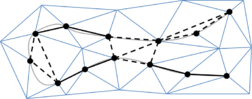

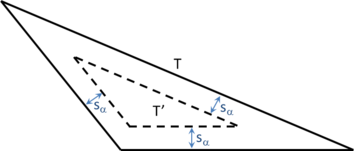

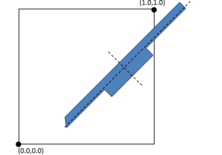

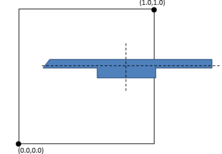

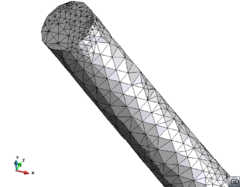

- Forced line entities. These are line entities to be preserved in the final mesh. This means that the final tetrahedra mesh will have a connected path of edges identifiable as a linear mesh of each forced line entity. As an example, the line entities in Figure 14(a) can be considered as forced line entities, as a path of connected edges representing it can be identified in the mesh shown in Figure 14(b). Forced line entities can be part of the input boundaries or not.

|

|

| (a) | (b) |

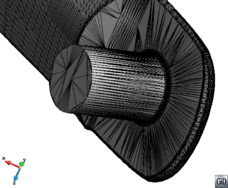

| Figure 14: (a) Contours of a volume highlighting some of its forced line entities. (b) View of the tetrahedra mesh of the volume highlighting the sharp edges corresponding to the forced line entities in (a). | |

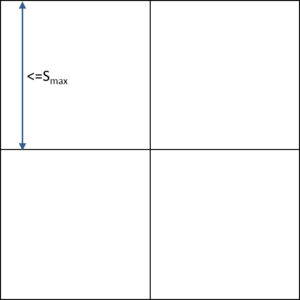

- General parameters. These are some global parameters which govern the behavior of the mesher and are not attached to geometrical entities. These parameters are optional, as the mesher should work without them, but they can help to fit the final mesh into the requirements of the simulation. Hereafter there is a list of these parameters:

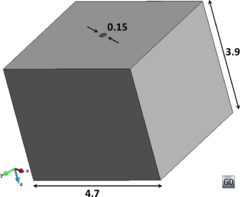

- General mesh size. This is the mesh size desired in the regions of the domain where there are no mesh size entities. If this parameter is not entered, the general mesh size is taken as the size of the bounding box of the domain.

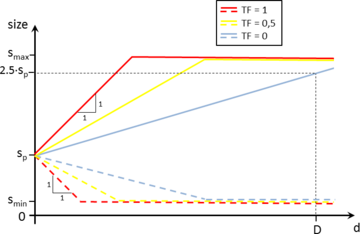

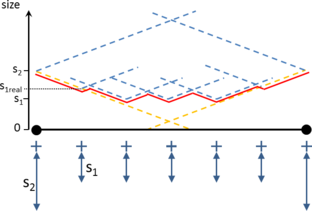

- Size transition factor. It controls the behavior of the size transition function. The definition and use of this function is explained in Section 5.2.2, and it basically determines if the size of the elements grows faster or slower from the areas where the mesh size is smaller to the ones where it is larger.

- Maximum angle for sharp edges. This is the dihedral angle below which an edge of the input geometry is considered to be preserved in the final mesh.

- Maximum chordal error. Two values may be needed: a relative and an absolute limit for the chordal error allowed for the mesh to be generated.

- Maximum distance between overlapping boundaries. This parameter is named . It is only applicable in case of non watertight geometries. It represents an estimation of the maximum distance between overlapping surfaces interfacing the same volumes. The definition and use of this parameter is explained in Section 3.4.

Apart from all these data, extra information can be attached to the entities defining the input boundaries: the external data. The external data can be of any nature and it has no relevance for the meshing process, but the mesher will transfer it to the corresponding entities of the final mesh. As an example, if a surface entity defining part of the boundary of a volume has some external information, the nodes of the final mesh placed on that surface entity, or the faces of the tetrahedra with all its nodes onto it will have the same external data attached to them.

3.1.1 Integration with CAD data

To prepare all the data needed for a numerical simulation it is common to use a software tool: the pre-processor. As explained in Chapter 1, part of these data is the mesh representing the geometry of the domain. As the geometry of the domain is often provided in a CAD format, pre-processors typically are forced to work with CAD data and generate the meshes for the simulation. This is the reason why pre-processors are often CAD systems, and they include several meshers inside.

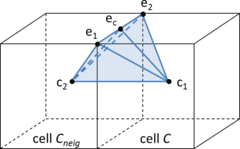

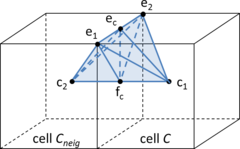

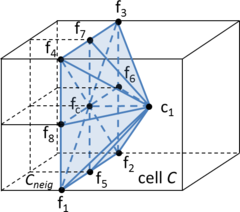

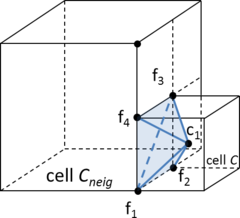

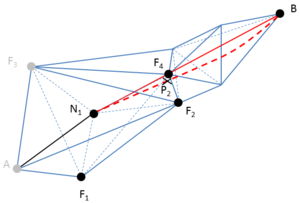

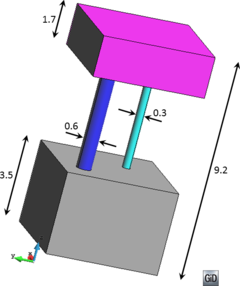

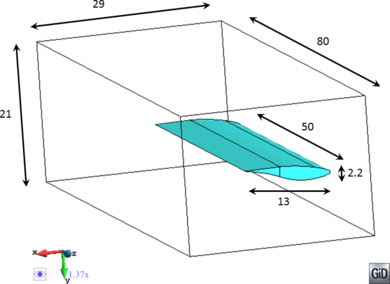

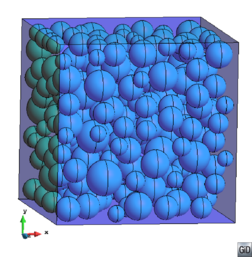

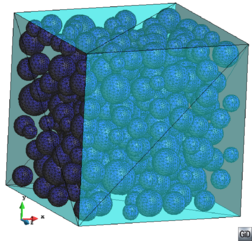

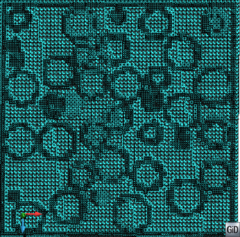

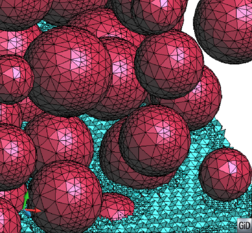

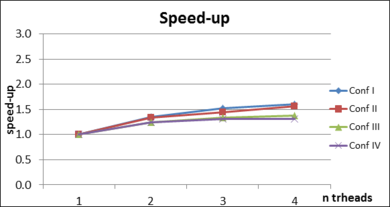

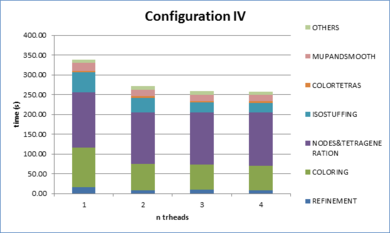

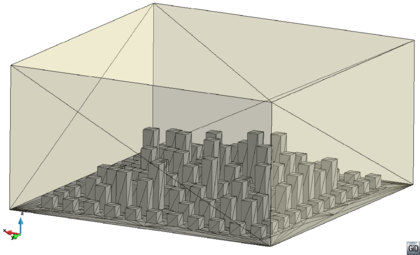

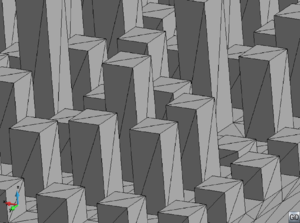

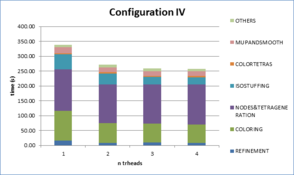

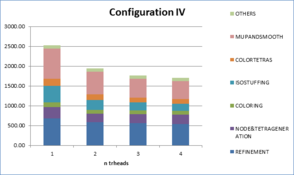

From the point of view of a general pre-processor or a CAD system willing to use the presented mesher, there are some interesting aspects to be considered. Typically the geometrical entities inside these systems have several information attached related with the simulation data (boundary conditions, material properties, etc...) or to the CAD system structures (layers grouping the entities, topological information, etc...). This information must be transferred to the generated mesh, which implies the following requirement for the mesher: it should return specific meshes representing given geometrical entities (not only volumes, but also curves and surfaces).