Abstract :This study investigates the anti-erosion mechanisms of a novel graphene-modified tungsten carbide coating under high-speed solid-liquid two-phase flow conditions. A liquid-solid two-phase flow erosion simulation device was employed, and fluid dynamics simulations were conducted using FLUENT software to determine the maximum experimental flow velocity. The influence of flow velocity, sand particle diameter, sand concentration, and fluid temperature on the erosion rate of the coating was systematically analyzed using the control variable method. Experimental results reveal that the erosion rate follows a power-law exponential relationship with flow velocity. When the sand particle diameter is below 0.5 mm, the erosion rate remains relatively stable; however, when the diameter exceeds 0.5 mm, the erosion rate increases significantly with particle size. Furthermore, the erosion rate exhibits a slight increase with higher sand concentrations, while a notable rise in fluid temperature leads to a substantial increase in the erosion rate, with the difference in erosion rates between the 150°C and 200°C coatings becoming more pronounced at elevated temperatures. Scanning electron microscopy (SEM) and numerical simulations were utilized to further elucidate the anti-erosion mechanisms of the coating. The incorporation of tungsten carbide significantly enhances the coating's hardness, while the addition of graphene results in a denser microstructure, effectively reducing porosity and improving the coating's resistance to impact and erosion. The findings demonstrate that the novel graphene-modified tungsten carbide coating exhibits superior erosion resistance, making it highly suitable for enhancing the durability and performance of rigid PDC drill bits in complex downhole environments.

Keywords :graphene, rigid PDC bit, tungsten carbide, erosion, new coating

1 Introduction

In oilfield development, the drill bit is the most critical tool in drilling operations[1,2]. Its performance directly affects the quality, cost, and efficiency of drilling operations[3,4]. The application of rigid PDC bits in special formations has yielded good results; however, the compressive strength of some formations is high. In the drilling process, significant grinding of rigid PDC bits leads to substantial wear of the bit bodies and cutters, thus reducing oil and gas production efficiency, while the cost of rigid PDC bits is high. Therefore, it is necessary to design and optimize the coating of PDC bits[5-7]. Many domestic and foreign scholars have developed PDC bits (Roberts et al., 2005)[8] and personalized bit designs (Clayton et al., 2005; Wells et al., 2008; Sun et al., 2000)[9-11], and optimized tooth arrangement methods have been extensively studied (Ma et al., 2018; Zhang et al., 2024)[12,13]. In deep unconventional oil and gas development, PDC bits often face the danger of erosion by high speed solid-liquid fluids (Zhang et al., 2022)[14]. Therefore, a new graphene-modified tungsten carbide coating (Xuan et al., 2023)[15] was developed to improve the protective performance of PDC bits during solid-liquid erosion. By adopting precoated powder laser coating, researchers mainly use this technique to create protective coatings that extend the service life of mechanical parts. This technology has unique advantages such as low dilution rate, narrow heat-affected zone (HAZ), low thermal shock, a fine coating structure, and good metallurgical combination with the substrate[16,17]. After coating, the surface of the sample is polished, and hardness tests, XRD tests, and microstructure observations are carried out, with the content of WC and graphene being constantly adjusted. Ultimately, the optimal ratio of the new tungsten carbide modified graphene coating has been prepared (Wang et al., 2024)[18]. However, the performance of this new tungsten carbide modified graphene coating under high speed solid-liquid erosion is still unclear, and the erosion prevention mechanism of this coating is also not well understood, so it is urgent to conduct the research presented in this paper.

Many scholars have studied the mechanism of solid-liquid erosion. Marzbali et al. (2023) studied the mechanism of solid-liquid erosion and the impact of low-speed and high speed liquid on solids[19]. Peng et al. (2020) analyzed the wear of different liquid concentrations in solid-liquid two-phase flow[20]. Fujisawa et al. (2019) and Di et al. (2021) studied the influence of surface roughness on liquid impact erosion[21,22], while Fujisawa et al. (2015) examined the influence of material hardness on droplet impact erosion[23]. Hattori et al. (2010) studied fluid velocity and droplet size[24]. Zhao et al. (2020) studied the effects of liquid velocity and temperature on the erosion rate in the solid-liquid two-phase flow process[25]. In the studies mentioned above, the research factors are relatively simple, and all of them were conducted in the absence of coating.

The objective of this paper is to investigate a new tungsten carbide modified graphene coating and examine how different formulations, solid-liquid flow rates, sand diameters, sand concentrations, fluid temperatures, and other factors affect the impact performance of the coating. The maximum flow rate is up to 12 m/s, and the temperature analysis is also increased. The experimental results and numerical simulation results of the stress distribution during the erosion process are combined to reveal the anti-erosion mechanism of this new tungsten carbide modified graphene coating more clearly and accurately.

2 Experimental device and experimental conditions

2.1 High-speed solid-liquid erosion experimental device with nozzle jet

During drilling, the bottom hole experiences a liquid-solid two-phase flow, and the erosion environment is harsh. To clarify the erosion laws and mechanisms, specialized erosion testing equipment must be utilized. Therefore, this project employs a liquid-solid two-phase flow erosion simulation device under nozzle jet conditions to conduct a novel erosion experiment on tungsten carbide coatings.

A physical diagram of the device is shown in Fig. 1. The device mainly consists of a stirring water tank, a high-pressure water pump, an ultrasonic flowmeter, a connecting pipeline, a sample jet test section, and a circuit control system.0

The main technical parameters of the device are as follows:

1) Test pipe diameter: 40mm, material is stainless steel pipe, spray diameter is 9mm;

2)The volume of the liquid storage tank meets the requirements for liquid distribution and experimental quantity, with a volume of 40 L and equipped with an automatic mixing system. The mixing rate is 30 min⁻¹, and the radius of the agitator is 135 mm, which ensures that the liquid is fully stirred. The tank is sealed and easy to clean after the experiment;

3) Flow rate: 0-14m/s;

4) Sand content ratio: 0-2%;

5) Solid particle size: 10-80 mesh;

6) Metal sample size: mm, quantity 1;

7) Working pressure: 0.3MPa;

8) Medium: water, fine sand;

9) Temperature: room temperature - 80℃;

The experimental flow of liquid-solid two-phase flow erosion simulation is as follows:

1) Configure the experimental fluid, mix it with the sand required by the experimental mesh number according to the sand concentration, and pour it into the box for even mixing;

2)Pretreat the surface of the test sample by removing impurities and oxides, weigh the treated sample, fix the sample with a clamp, and adjust the clamp to the erosion angle required by the test (30°);

3)Set experimental conditions in the control system, including flow rate, fluid temperature, and other relevant parameters;

4) Start the erosion experiment, record and analyze the weight loss of the test sample every 2 hours for a total of 12 hours;

5)After the erosion is complete, turn off the power supply of the device, perform an apparent morphology analysis of the experimental sample, and clean the experimental device;

2.2 Experimental samples and erosion rate calculation

As shown in Fig. 2, the holder for fixing the test sample is suitable for a sample size of 43 mm (width) × 13 mm (thickness) × 5 mm. In addition, the clamp and the pointer turntable can adjust the angle between the front of the sample and the direction of the fluid jet, allowing for erosion of the sample at different angles in the range of 0 to 90°. It should be noted that the erosion angle selected for this experiment was 30°.

Based on the development of a new type of tungsten carbide coating and formula, the experimental samples for the erosion experimental study of this project were prepared, as shown in Figure 3 to 6. These samples are mainly divided into three types: 1. Blank sample. This type of sample is mainly used for blank control experiments. 2. A new type of tungsten carbide cladding sample resistant to 150 °C. This type of sample is mainly used to carry out the erosion experiment of the new tungsten carbide coating at 150 °C under different flow rates, sand diameters, and sand concentrations, and is compared with the experimental results of the blank sample. 3. A new type of tungsten carbide cladding sample resistant to 200 °C. This type of sample is mainly used to carry out the erosion experiment of the new tungsten carbide coating at 200 °C under different flow rates, sand diameters, and sand concentrations, and is compared with the experimental results of the blank sample.

In this project, the analysis of erosion results mainly employs the weight loss method to calculate the erosion rate, and surface morphology measurements are used to compare and analyze the changes in the coating surface before and after the erosion.

The basic principle of the weight loss method for calculating the erosion rate is as follows:

Before the experiment, the initial weight of the samples was recorded using an electronic balance (see Fig. 7). After the experiment, the test samples were washed with deionized water, and the impurities on the surface of the samples were scraped off with a hard brush and then washed with deionized water for 15 minutes in an ultrasonic cleaner. The washed samples were dried in a 50°C blast drying oven (see Fig. 8) for 0.5 hours and then dried in a dryer for more than 12 hours. After drying, the samples were weighed, and the final weight was recorded.

The weight loss per unit erosion surface area and the unit experimental time is defined as the erosion rate, as shown in Equation (1-1):

| (1-1) |

In the formula, v is the weight loss rate of erosion corrosion, mg/(h·cm²); m1 and m2 represent the weight of the sample before and after the erosion corrosion experiment, g; S is the surface area of the sample, cm²; T is the erosion corrosion time, h.

As shown in Fig. 9, the sample was observed by scanning electron microscopy (SEM) using the LEICA EMUC7FC7 from Germany after high-speed erosion, and was tested after gold spraying.

2.3 Determination of the maximum flow rate in the experiment

Previous studies have shown that flow rate, sand diameter, sand concentration, and other factors impact the erosion rate of the coating, but flow rate is the most significant factor. In order to simulate the jet velocity of the drill bit in the downhole more realistically, and to explore the erosion resistance of the new tungsten carbide coating, determining the maximum jet velocity is very important.

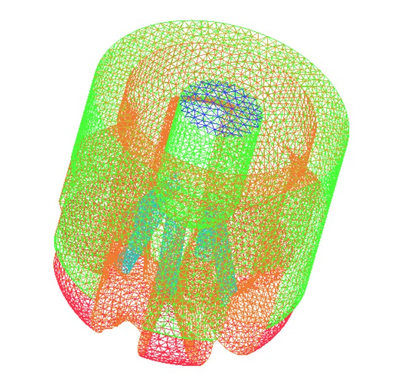

To clarify the flow velocity of the downhole jet near the bit domain under large displacement conditions in the field, a three-dimensional finite element model of a PDC bit with 5 blades and 5 nozzles was constructed, and the model was meshed using an unstructured method (see Fig. 10). The speed was set to a maximum displacement of 32 L/s, and fluid simulation was performed using FLUENT software.

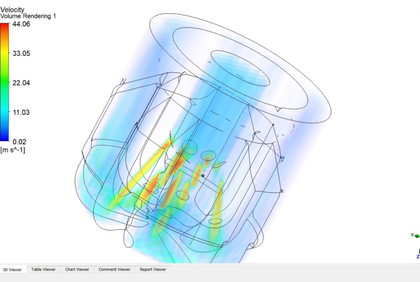

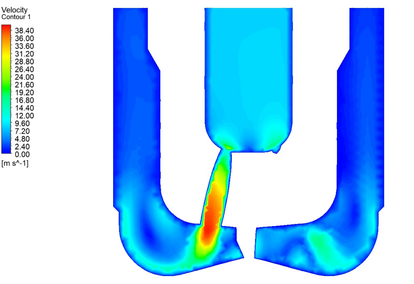

See Fig. 11 for the 3D finite element model of the PDC bit with 5 blades and 5 nozzles. Under the simulation parameters of 32 L/s, the overall 3D flow field at the bottom of the hole has the highest nozzle outlet velocity, which reaches about 38 m/s. As shown in Fig. 12, to further demonstrate the fluid velocity at the bit domain in detail, the two-dimensional flow field simulation results at a single nozzle and blade were obtained. It was found that under the simulated conditions, the maximum flow velocity near the blade of the bit was about 12 m/s, so the maximum jet flow rate of the nozzle simulated by the erosion experiment was set at 12 m/s.

2.4 Setting of experimental conditions

In order to study the impact of different flow rates, sand diameter, sand concentration, and other factors on the erosion of the new tungsten carbide coating, 32 sets of erosion experiments were conducted under different working conditions, including 2 test samples (the coating formula under 150 °C resistance consists of Ni60A + 60% WC, and the coating formula under 200 °C resistance consists of Ni60A + 60% WC + 0.3% graphene mixed powder), 5 levels of flow rate, 4 levels of sand diameter, 5 levels of sand concentration, and 5 levels of fluid temperature, as summarized in Table 1.

| serial number | test sample | flow velocity

(m/s) |

sand blast finish diameter(mm) | sand concentration

(%) |

flow temperature

(℃) |

| 0 | blank sample | 8 | 0.5 | 1 | 20 |

| 1 | 150°C resistant coating samples | 4 | 0.5 | 1 | 20 |

| 2 | 150°C resistant coating samples | 6 | 0.5 | 1 | 20 |

| 3 | 150°C resistant coating samples | 8 | 0.5 | 1 | 20 |

| 4 | 150°C resistant coating samples | 10 | 0.5 | 1 | 20 |

| 5 | 150°C resistant coating samples | 12 | 0.5 | 1 | 20 |

| 6 | 200°C resistant coating samples | 4 | 0.5 | 1 | 20 |

| 7 | 200°C resistant coating samples | 6 | 0.5 | 1 | 20 |

| 8 | 200°C resistant coating samples | 8 | 0.5 | 1 | 20 |

| serial number | test sample | flow velocity

(m/s) |

sand blast finish diameter(mm) | sand concentration

(%) |

flow temperature

(℃) |

| 9 | 200°C resistant coating samples | 10 | 0.5 | 1 | 20 |

| 10 | 200°C resistant coating samples | 12 | 0.5 | 1 | 20 |

| 11 | 150°C resistant coating samples | 8 | 0.25 | 1 | 20 |

| 12 | 150°C resistant coating samples | 8 | 1 | 1 | 20 |

| 13 | 150°C resistant coating samples | 8 | 2 | 1 | 20 |

| 14 | 200°C resistant coating samples | 8 | 0.25 | 1 | 20 |

| 15 | 200°C resistant coating samples | 8 | 1 | 1 | 20 |

| 16 | 200°C resistant coating samples | 8 | 2 | 1 | 20 |

| 17 | 150°C resistant coating samples | 8 | 0.5 | 0.1 | 20 |

| 18 | 150°C resistant coating samples | 8 | 0.5 | 0.5 | 20 |

| 19 | 150°C resistant coating samples | 8 | 0.5 | 1.5 | 20 |

| 20 | 150°C resistant coating samples | 8 | 0.5 | 2 | 20 |

| 21 | 200°C resistant coating samples | 8 | 0.5 | 0.1 | 20 |

| 22 | 200°C resistant coating samples | 8 | 0.5 | 0.5 | 20 |

| 23 | 200°C resistant coating samples | 8 | 0.5 | 1.5 | 20 |

| 24 | 200°C resistant coating samples | 8 | 0.5 | 2 | 20 |

| 25 | 150°C resistant coating samples | 8 | 0.5 | 1 | 40 |

| 26 | 150°C resistant coating samples | 8 | 0.5 | 1 | 60 |

| 27 | 150°C resistant coating samples | 8 | 0.5 | 1 | 70 |

| serial number | test sample | flow velocity

(m/s) |

sand blast finish diameter(mm) | sand concentration

(%) |

flow temperature

(℃) |

| 28 | 150°C resistant coating samples | 8 | 0.5 | 1 | 80 |

| 29 | 200°C resistant coating samples | 8 | 0.5 | 1 | 40 |

| 30 | 200°C resistant coating samples | 8 | 0.5 | 1 | 60 |

| 31 | 200°C resistant coating samples | 8 | 0.5 | 1 | 70 |

| 32 | 200°C resistant coating samples | 8 | 0.5 | 1 | 80 |

Through the erosion experiments of the 32 groups mentioned above under different working conditions, the influences of flow rate, sand diameter, sand concentration, fluid temperature, and other factors on the erosion of different new tungsten carbide coatings are clarified, which lays the experimental data foundation for further understanding the anti-erosion mechanism of the different coatings.

3 Experimental results and rule analysis of solid-liquid erosion of new coating under different factors

3.1 Comparative analysis of erosion rate of different coating samples

The erosion rate calculation method in Formula 1-1 was used to calculate and compare the erosion rates of blank samples, 150°C coated samples, and 200°C coated samples under the conditions of flow rate of 8 m/s, sand diameter of 0.5 mm, sand concentration of 1%, and fluid temperature of 20°C (i.e., conditions 0, 3, and 8). The results are shown in Fig. 13. From the diagram, it can be seen that the erosion rate of the blank sample is the highest among the samples tested, reaching 1.558 mg/(h·cm²), while the erosion rates of the 150°C coating sample and the 200°C coating sample are 0.805 mg/(h·cm²) and 0.753 mg/(h·cm²), respectively, both of which have decreased compared to the blank sample. It can be seen that the two new tungsten carbide coatings have stronger erosion resistance. The reason for the improvement of erosion resistance is that after the addition of WC, new phases WC, W₂C, WSi₂, W, and C appear in the coating, which makes the hardness of the coating significantly improved, so the erosion resistance is improved. At room temperature, the hardness of the 150°C-resistant coating sample and the 200°C-resistant coating is 1075 HV and 1101 HV, respectively, and the erosion rate under this experimental condition is not significantly different.

On this basis, the surface morphology of the blank sample and the 150°C coated sample after erosion was analyzed. The results are shown in Fig. 14. It can be seen from the figure that the surface of the 150°C coated sample is relatively flat, and the traces of damage after erosion wear are relatively shallow, with only a few minor scratches. This is due to the plasticity of the coating compared to Q235 steel, which greatly dissipates the kinetic energy of the particles when they impact the sample, and can alleviate the impact of sand-containing fluid on the steel PDC bit material to some extent.

3.2 Comparative analysis of erosion rate of coating samples at different flow rates

The erosion rates of 150°C resistance coating samples and 200°C resistance coating samples under different flow rates were calculated and compared. The results are shown in Fig. 15. It can be seen from the diagram that the higher the flow rate, the greater the erosion rate of the two coating samples.

In addition, through further fitting analysis, it was found that the erosion rate obtained in the experiment has an approximate exponential relationship with the flow rate (also referred to as erosion velocity) (as shown in Fig. 16), with the correlation reaching 0.98 and 0.96, respectively, which is generally consistent with the conclusions obtained in the existing research. Therefore, under the condition of large displacement, special attention should be paid to monitoring the erosion damage of the drill bit.

3.3.Comparative analysis of erosion rate of coating samples with different sand diameter

The erosion rates of 150℃ resistance coating samples and 200℃ resistance coating samples under different sand particle diameters were calculated and compared, and the results are shown in Figure 17. As can be seen from the figure, when the sand diameter is less than 0.5 mm, the erosion rate has little difference; when the sand diameter is greater than 0.5 mm, the erosion rate of the two coating samples increases with the sand diameter. This trend indicates that there is a threshold value for the sand particle diameter in the process of solid-liquid erosion, and when it is less than this threshold, the erosion rate basically remains unchanged. Therefore, in the process of drilling and rock breaking, we should try to ensure that the diameter of the rock debris broken at the bottom of the hole is at a small level, which is not only conducive to keeping the hole clean but also helps reduce the erosion damage of the bit.

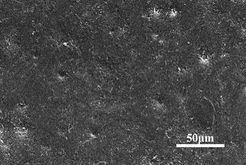

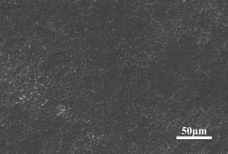

In addition, the surface morphology of the 150℃ resistance coating sample was further compared after erosion at 0.5 mm and 2 mm, and the results are shown in Figure 18. It can be seen from the figure that under conditions of large diameter sand erosion, the surface microstructure of the new type of tungsten carbide coating is rougher, and more numerous and deeper scratches appear on the surface. It can be seen that under conditions of large diameter sand erosion, the surface of the coating is cut more extensively, resulting in more serious erosion.

|

|

3.4.Comparative analysis of erosion rate of coating samples under different sand concentrations

The erosion rates of 150°C resistance coating samples and 200°C resistance coating samples under different sand concentrations were calculated and compared. The results are shown in Fig. 19. It can be seen from the figure that as the sand concentration increases, the erosion rate increases slightly. This is because as the sand concentration increases, the number of solid particles impacting and cutting the surface of the coating during the same erosion time increases, resulting in a slight increase in the erosion rate.

3.5.Comparative analysis of erosion rate of coating samples at different fluid temperatures

The erosion rates of 150°C resistance coating samples and 200°C resistance coating samples under different sand concentrations were calculated and compared. The results are shown in Figs. 20 and 21. It can be seen from the diagram that the erosion rate increases significantly with the increase in fluid temperature, and the difference in erosion rate between the 150°C coating sample and the 200°C coating sample becomes more pronounced with the increase in temperature. This is because, as the temperature increases, the 200°C resistance coating contains graphene with better thermal conductivity. The appropriate amount of graphene enhances the heat dispersion ability of the 200°C resistance coating sample under high temperature fluid erosion, and the hardness of the 200°C resistance coating decreases as the temperature rises. However, the decrease in hardness will be smaller than that of the 150°C resistance coating, resulting in a larger difference in erosion rate between the two.

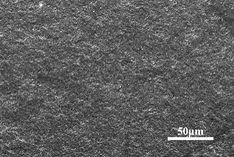

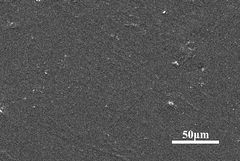

In addition, the surface morphology of the coating samples after erosion at 150°C and 200°C during erosion at 80°C was further compared. The results are shown in Fig. 22. It can be seen from the figure that under high temperature conditions, micro erosion pits appeared on the surface of the 150°C resistance coating. This is because heat is concentrated on the surface of the coating sample under high temperature erosion, and the heat dispersion ability of the 150°C coating is less effective than that of the 200°C coating, which aggravates the damage to the coating structure under impact and forms micro-erosion pits. Compared with the blank sample and the 150°C resistance coating sample, no obvious erosion pits were found on the surface of the 200°C resistance coating under high-temperature, high-speed solid-liquid two-phase fluid erosion, and a relatively smooth surface was maintained. In summary: if the coating layer with 200°C resistance is applied to the steel PDC bit, the bit will have higher erosion resistance and anti-balling ability, which will help to improve the stability and lifespan of the bit in the complex downhole working environment.

|

|

|

(1) 150°C resistant coating sample (b) 200°C resistant coating sample

4 Simulation of stress distribution of different structures under impact

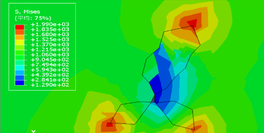

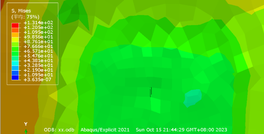

In order to determine the impact resistance performance of the coating with finer structure, the finite element model of two materials with different surface structures was created using ABAQUS software. The surface structure of one material contains an irregular coarse branched structure to simulate the surface structure of the coating with 150°C resistance, while the surface structure of the other material contains a tiny granular structure to simulate coatings resistant to 200°C. As shown in Figure 23, the model size is 80mm × 100mm, and the thickness is 1mm. The model is further meshed, and the stress distribution under impact is simulated by applying the impact load.

|

|

| (a)Materials with rough structure | (b)Materials with fine structure |

The stress distribution results under the impact are shown in Figure 24. It can be observed that the material with rough structure exhibits significant deformation under the impact load, and stress concentration occurs in several areas (red area in the figure). The occurrence of stress concentration negatively affects the impact resistance of the 150°C coating, while the material with fine structure does not exhibit stress concentration under impact. This is due to the addition of graphene, which makes the structure of the 200°C-resistant coating finer, reducing uneven slipping of the coating after impact and exhibiting strong resistance to deformation and displacement, thus effectively dispersing the stress concentration formed during the impact process. This demonstrates that graphene can significantly improve the impact resistance of the composite coating.

|

|

| (a)Materials with rough structure | (b)material with a fine structure |

Fig.24 Comparison of stress distribution simulation results of two different structural materials under impact

5 Erosion prevention mechanism of novel tungsten carbide modified graphene coating

Based on indoor erosion experiments and numerical simulations of material surface impact for the new tungsten carbide coating, the influence of various factors on the erosion resistance of the coating was analyzed. The changes in surface morphology of different coatings after erosion were compared, and the surface stress distribution of coarse and fine materials under impact was clarified. The anti-erosion mechanism of the new tungsten carbide coating is summarized.

(1) With the addition of tungsten carbide, the hardness of the new tungsten carbide coating has significantly improved, and the coating with high hardness favors resistance to deformation and displacement;

(2) The addition of graphene makes the microstructure of the coating denser, effectively reduces the porosity of the coating, improves coating toughness, and enhances the ability to resist erosion. When microcracks are generated by impact, the fine-grained structure also hinders crack propagation and alters the propagation direction, thus increasing the energy of penetrating crack formation and the impact work required for the fracture of the cladding layer.

(3) The fine structure can reduce uneven slipping of the cladding after impact, thereby effectively reducing stress concentration and improving erosion resistance.

6 Conclusion

(1) The erosion rate of the blank sample is the highest, while the erosion rates of the 150℃ resistant coating sample and the 200℃ resistant coating sample are significantly decreased.

(2) The higher the flow rate, the higher the erosion rate. When the sand diameter is greater than 0.5 mm, the erosion rates of the two types of coating samples increase with increasing sand diameter. With increasing sand concentration, the erosion rate increases slightly. The erosion rate increases significantly with increasing fluid temperature, and the difference between the erosion rates of the 150℃ coated samples and the 200℃ coated samples becomes more pronounced with increasing temperature.

(3) Due to the addition of WC, the hardness of the new tungsten carbide coating has significantly improved. Due to the addition of graphene, the microstructure of the coating is finer, the porosity of the coating is effectively reduced, and the toughness of the 200℃ coating has improved, enhancing its ability to resist erosion.

(4) The fine structure hinders crack propagation and changes the direction of propagation, thereby increasing the energy required for crack formation and increasing the impact work required for the fracture of the cladding layer. Additionally, it can effectively disperse the stress concentration formed by the cladding during the impact process and improve erosion resistance.

Acknowledgments

This work was supported by the Open Fund of State Key Laboratory of Shale Oil and Gas Enrichment Mechanisms and Effective Development,the Postgraduate Research & Practice Innovation Program of jiangsu Province (KYCX24 3248),and the Postgraduate Research & Practice Innovation Program of Jiangsu Province (KYCX24 3242).

Declaration of interest statement

The authors declare no conflict of interest.

Author contribution

Jiangshuai Wang:Conceptualization and Methodology.

Zixiao Song:Writing Original Draft and Writing Review & Editing.

Song Deng:Supervision.

Qianyu Ren:Investigation and Formal Analysis.

Bohan Zheng:Investigation and Validation.

Data will be provided upon request

Reference

[1] Cardoe J, Nygaard G, Lane C, et al. Oil and gas drill bit technology and drilling application engineering saves 77 drilling days on the world’s deepest engineered geothermal systems EGS wells[C]//SPE/IADC Drilling Conference and Exhibition. SPE, 2021: D021S002R002.

[2] Borash A R, Nurshakhanova L K, Arshidinova M T, et al. Improving the efficiency of PDC bits in oil and gas drilling[J]. International Multidisciplinary Scientific GeoConference: SGEM, 2023, 23(1.1): 705-710.

[3] SUN, M. G. (2001). Design and application of the PDC bit suited for multi-interbedded formation. Acta Petrolei Sinica, 22(5), 95.

[4] Hanna C, Douglas C, Asr H, et al. Application specific steel body PDC bit technology reduces drilling costs in unconventional North America shale plays[C]//SPE Annual Technical Conference and Exhibition?. SPE, 2011: SPE-144456-MS.

[5] Chen C, Feng A, Wei Y, et al. Effects of WC particles on microstructure and wear behavior of laser cladding Ni60 composite coatings[J]. Optics & Laser Technology, 2023, 163: 109425.

[6] Wang Q, Chen F Q, Li Q, et al. Microstructure and properties of Ni60 alloy coating prepared by electromagnetic compound field assisted laser cladding[J]. Materials Chemistry and Physics, 2022, 291: 126678.

[7] Xu S, Cai Q, Li G, et al. Effect of scanning speed on microstructure and properties of TiC/Ni60 composite coatings on Ti6Al4V alloy by laser cladding[J]. Optics & Laser Technology, 2022, 154: 108309.

[8] Roberts T S, Schen A E, Wise J L. Optimization of PDC drill bit performance utilizing high-speed, real-time downhole data acquired under a cooperative research and development agreement[C]//SPE/IADC Drilling Conference and Exhibition. SPE, 2005: SPE-91782-MS.

[9] Clayton R, Chen S, Lefort G. New bit design, cutter technology extend PDC applications to hard rock drilling[C]//SPE/IADC Drilling Conference and Exhibition. SPE, 2005: SPE-91840-MS.

[10] Wells M, Marvel T, Beuershausen C. Bit balling mitigation in PDC bit design[C]//IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition?. SPE, 2008: SPE-114673-MS.

[11] Sun M, Zhang Y, Yang Y, et al. New cutting structure design improves the performance of the PDC bit[C]//SPE Western Regional Meeting. SPE, 2000: SPE-62858-MS.

[12] Ma Y, Huang Z, Li Q, et al. Cutter layout optimization for reduction of lateral force on PDC bit using Kriging and particle swarm optimization methods[J]. Journal of Petroleum Science and Engineering, 2018, 163: 359-370.

[13] Zhang F, Lu Y, Zhu H, et al. COMPARATIVE ANALYSIS OF STRUCTURE PERFORMANCE OF PDC CUTTER TOOTH SURFACE AND INTERFACE MATCHING PAIR[J]. Journal of Theoretical & Applied Mechanics (14292955), 2024, 62(1).

[14] Zhang F, Lu Y, **e D, et al. Experimental study on the impact resistance of interface structure to PDC cutting tooth[J]. Engineering Failure Analysis, 2022, 140: 106503.

[15] Xuan L, Wang J. A new type of high hardness coating for improving drill bit stability in unconventional oil and gas development[J]. Frontiers in Energy Research, 2023, 11: 1277648.

[16] Riveiro A, Mejías A, Lusquiños F, et al. Laser cladding of aluminium on AISI 304 stainless steel with high-power diode lasers[J]. Surface and Coatings Technology, 2014, 253: 214-220.

[17] D'Amato, C., Betts, J. C., & Buhagiar, J. (2014). Laser surface alloying of an A356 aluminium alloy using nickel and Ni-Ti-C: A corrosion study. Surface and Coatings Technology, 244, 194-202.

[18] Wang M, Xuan L, Wang L, et al. Performance and Formula Optimization of Graphene-Modified Tungsten Carbide Coating to Improve Adaptability to High-Speed Fluid Flow in Wellbore[J]. Processes, 2024, 12(4): 714.

[19] Marzbali M, Yeganehdoust F, Ibrahim M E, et al. Liquid–solid impact mechanism, liquid im**ement erosion, and erosion-resistant surface engineering: A review[J]. Coatings, 2023, 13(3): 577.

[20] Peng G, Huang X, Zhou L, et al. Solid-liquid two-phase flow and wear analysis in a large-scale centrifugal slurry pump[J]. Engineering Failure Analysis, 2020, 114: 104602.

[21] Fujisawa K, Ohki M, Fujisawa N. Influence of surface roughness on liquid droplet im**ement erosion[J]. Wear, 2019, 432: 202955.

[22] Di J, Wang S, Yan X, et al. Experimental investigation on effect of surface strengthening process and roughness on water droplet erosion behavior in turbomachinery[J]. Tribology International, 2021, 153: 106647.

[23] Fujisawa N, Yamagata T, Takano S, et al. The influence of material hardness on liquid droplet im**ement erosion[J]. Nuclear Engineering and Design, 2015, 288: 27-34.

[24] Hattori S. Effects of impact velocity and droplet size on liquid im**ement erosion[C]//International Symposium on the Ageing Management & Maintenance of Nuclear Power Plants. 2010, 58: 71.

[25] Zhao Y L, Ye F X, Zhang G, et al. Investigation of erosion-corrosion behavior of Q235B steel in liquid-solid flows[J]. Petroleum Science, 2022, 19(5): 2358-2373.

Document information

Published on 17/11/25

Submitted on 09/11/25

Licence: CC BY-NC-SA license

Share this document

Keywords

claim authorship

Are you one of the authors of this document?