Sagni TEMESGEN1, Girmaye GAREDEW2, Alemayehu FEYISSA3, Emer T. QUEZON4,*

Abstract

The application of industrial wastes, particularly polyisobutylene and ceramic powder, to asphalt has not been investigated. Hence, this study was conducted to determine the influence of these waste materials on the physical and rheological properties of bitumen using both conventional and Superpave tests. In this investigation, a polyisobutylene-ceramic powder was used as a modifier for bitumen with a penetration grade of 60/70 at concentrations of 0.0%, 0.7%, 1.4%, and 2.1% by weight. The results indicated that increasing the content of modifiers resulted in a considerable drop in penetration and a decrease in asphalt ductility. Additionally, the softening point increased as the modifier content also increased. Furthermore, as the modifier concentration increases, the stiffness of the asphalt binder increases at high temperatures, while the complex modulus master curve exhibits a low-frequency response. Similarly, a performance-based asphalt grading system demonstrated that modified bitumen at 0.7% and 1.4% enhanced the PG grades to 64°C and 70°C, respectively. As a result, this represents the increased resistance of modifiers to permanent pavement deformation.

Keywords: Asphalt ductility; Ceramic Powder; Modifiers; Pavement Performance; Softening point; complex modulus; stiffness; Penetration grade<i>

Affiliations:

1Department of Civil Engineering, Institute of Technology, University of Oda Bultum, Chiro, Ethiopia

2Department of Civil Engineering, College of Civil Engineering and Technology, University of Mizan-Tepi, Tepi, Ethiopia

3Department of Civil Engineering, College of Architecture and Civil Engineering, Addis Ababa Science and Technology University, Addis Ababa, Ethiopia

4Cagayan State University, Carig Campus, College of Engineering and Architecture, Civil Engineering Department, Tuguegarao City, Philippines

ORCID: *[0000-0003-0612-500X]

ISSN (Online): (Pending)

1. Introduction

According to Mulatu et al. (2020), by altering the bitumen used in traditional materials, it is possible to enhance the performance of pavement construction while simultaneously extending their service lives. Among other reasons, this is owing to the fact that binding agents behave differently depending on the temperature and traffic loading conditions (SABITA Technical Guideline, 2015), so pavement engineers need to be involved in specific instances to study the performance of the asphalt (Liang et al., 2015).

As the temperature of the pavement increases, the binder undergoes significant volume relaxation, leading to increased flow or plastic deformation. Conversely, when the temperature decreases, the binder undergoes significant volume contraction, resulting in an increase in stiffness (Li et al., 2018). In recent years, various researchers have investigated the benefits of incorporating modifiers into bitumen to enhance its performance, one of which is polyisobutylene. According to the Asphalt Institute, due to its flexibility, polyisobutylene (also known as elastomeric polyisobutylene) is the most popular and successful type of asphalt additive, exhibiting significantly improved ductility compared to the binder at cold temperatures (Shaan et al., 2014; Gama et al., 2016). At low temperatures, it does not crack, but it does melt in the heat (Bressi et al., 2019). It resists permanent deformation by stretching under the load and recovering after removing each load cycle (Zhu et al., 2014).

The rapidly increasing number of vehicles produced each year is primarily due to the large amount of waste tires generated and disposed of without being reused by the industry. It is advantageous to use discarded polyisobutylene waste in paving materials as a modification because it reduces traffic noise, reduces environmental pollution, improves mechanical properties (Zumrawi, MME. 2017; Moreno et al., 2011), increases shear strength and elastic performance (Liu et al., 2017), and has good bonding strength (Zumrawi, MME. 2017). (Sharvin Poovaneshvaran et al., 2019). By nature, due to their black colorability, bitumen and polyisobutylene are sensitive to heat; their contraction on cooling and expansion on heating during thermal cycling must balance to ensurea strong adhesivee bond to another mineral aggregate.

As a heat stabilizer, additive polymer, fine ceramic, and other materials are employed in the modification process to absorb heat and protect the material from thermal stresses. The disadvantage of ceramic is that it is extremely prone to fracture under tension; polyisobutylene, on the other hand, has better elastic deformation and recovery properties under the applied load than both bitumen and ceramic (Gama et al., 2016), owing to the fact that all three of them retain their behavior when mixed together. Ceramic materials are stiff and strong with a high melting point (thermal insulator), high compressive strength, and low heat conductivity (Feng et al., 2013). According to Wan et al. (2016), the temperature stability of asphalt is to some extent related to its softening point. It was emphasized that their test results showed the effect on the softening point of adding fiber (i.e., 1%, 2%, and 3%) by weight, indicating an improvement in temperature stability. The results of the experiment revealed that the penetration of modified asphalt had been significantly reduced, as well as a decrease in the softening point, indicating an improvement in temperature stability. Likely, the ductility of modified asphalt is diminished, which reflects asphalt ri, which results in makes less strain. When the content of modifiers has been increased in bitumen, the penetration value of bitumen is significantly reduced.

The size of the modifier, mixing time, bitumen chemistry, and the nature of the modifier, as well as the modifier's content and the mixing process, are other factors that affect the performance of mixtures (Jeong et al., 2010). On the other hand, Moreno et al. (2011) stated that percentages of fine rubber less than 1% by bitumen's weight show the mixture's best results. Powder polymers are more rapidly dispersed in bitumen than coarse materials (Kalantar, 2012). To improve asphalt modification, rubber fineness particles quickly swell in bitumen at high temperatures than coarse rubber particles, providing a stiffer binder with improved elasticity (Ching and Wing-gun, 2007).

According to previous research (Kalantar, 2012), the optimal mixing process should be carried out at the lowest possible temperature for the shortest possible time to ensure total polymer integration into the bitumen, both economically and to prevent any thermal influence on the polymer. However, to minimize the thermal effect on polyisobutylene during the mixing process, the temperature should be kept below 190˚C. Beyond the limit, rubber burns will negatively impact the pavement performance of mixtures, including increased stiffness, brittleness, and accelerated aging of theumen. SABITA Technical Guideline (2015) indicated that bitumen and crumb rubber are blended at a temperature greater than 180˚C and swell by absorption of some maltenes-fraction of binders in the rubber, which becomes digested by the bitumen. To ensure compatibility between the binder and the rubber, the mixing temperature should be maintained at 180°C for 90 minutes (Moreno et al., 2011) and 160-180°C for the remaining duration (Mashaan et al., 2014). This study aims to investigate and analyze the effect of recycled polyisobutylene and ceramic powder on the mechanical properties of asphalt binders when exposed to high temperatures. The research seekaims to evaluate and investigate the impact of varying percentages of recycled polyisobutylene and ceramic powder on the asphalt's resistance to plastic deformation at elevated temperatures, as well as the influence of aging, using bothndard and Superpave tests.

2. Methodology

Laboratory tests were performed to characterize neat bitumen, modified bitumen, and aging effects. These materials were evaluated as per American Association State Highway and Transportation Officials and American Society of Testing and Materials Standard specifications.

2.1. Materials

Bitumen, waste polyisobutylene, and ceramic waste powder were employed in the experiments. Asphalt cement with a penetration grade of 60/70 is utilized in medium-temperature areas and is not suggested for use in high-temperature areas. Modifiers such as waste polyisobutylene and ceramic materials were mixed together for the laboratory experiment. The materials are taken from the solid waste area, cleaned to remove dirt particles, and dried for one week. A hammer was used to break down the ceramic debris into smaller pieces. The particles were then fed into a crusher machine to achieve the appropriate particle size, which passed the No.200 Sieve. It was collected and processed as filler for the combination of the ingredients.

2.2. Sample preparation

Pretreatment of the modifiers, which included sieving and drying, was performed before their inclusion in the asphalt mixture. Based on the laboratory experiment conducted by Wan et al. (2016), a mixture of Polyisobutylene and ceramic powder, in the same proportion, was prepared with 0.0, 0.7, 1.4, and 2.1% of the asphalt binder, labeled as PCP in the laboratory. The modifiers were slowly and gradually added to heated bitumen and mixed at an average temperature of 180˚C for 90 minutes at 500rpm of mixer speed (Zumrawi, MME. 2017). The mixing continued until a homogenous blend was obtained.

2.3. Testing program on conventional tests

The easiest and simplest test methods used to examine and predict neat bitumen's rheological behavior are empirical tests such as penetration, ductility, and softening points at one or two temperatures. The results of modified bitumen obtained from these tests may reflect the improvement in physical properties.

2.3.1. Penetration test

Penetration is applied to determine the asphalt consistency concerning time and temperature under the known condition of loading; as per (Drews, 2008a; ASTM-D5, 2006), the bitumen samples were heated until sufficiently fluid to pour, and the heating process was done for not more than 30 minutes by stirring manually to prevent overheating. A standard needle was vertically inserted into the asphalt sample under a load of 100g at 25°C for 5 seconds, and the penetration was measured in increments.1 mm to carry out the test. Bitumen with a low penetration value is highly useful to seas a parameter for binders (Jeffry et al., , while higher penetration values indicate the softening of the asphalt samples (Saoula et al., 2013).

2.3.2. Ductility test

The adhesive or cohesive capability of asphalt is dependent on its ductility. The ductility test measures bitumen's tensile properties, or its stretchability, to characterize cracking at low temperatures (ASTM D5, 2006). Bitumen with a higher ductility value is highly useful (Saoula et al., 2013). According to Limin et al. (2020) and AASHTO T 51 (2009), the bitumen samples were heated and poured into a ductility mold assembly placed on a plate. The ductility device, filled with water at 25˚C, and the asphalt sample were pulled horizontally at 5cm/min acceleration until the bitumen broke. The distance of the bitumen stretch as the spring before the break was recorded.

2.3.3. Softening point test

The softening point is essential because it determines the temperature at which bitumen begins to flow (Saoula et al., 2013) and evaluates the susceptibility of asphalt to temperature changes. The softening point of asphalt is somewhat related to its temperature stability. When it comes to the test results, it is clear that the addition of fiber has a positive influence on the increase in softening point, implying that temperature stability has been improved. In determining the softening point (Drews, A., 2008b; AASHTO T 53, 2009), the bitumen sample was heated for no more than 40 minutes at a temperature of 80˚C to 157˚C. The test was conducted using the ring and two-ball apparatus. The brass ring (weight 3.5 grams), containing a test specimen, was placed in the water bath, where the bath temperature was raised at 5˚C per minute. The temperature of the ball is recorded as it falls into the glass container. This is the temperature at which the steel ball, fixed to the asphalt cylinder, makes contact with the metal bottom, which occurs due to the deformation of the asphalt caused by the temperature change.

2.4. Rheological measurement tests

Sinusoidal tests (Lade Jaya H and Gurindapalli P, 2005), (Estimé M Mukandila et al. 2015) had conducted using dynamic testing by applying oscillating shear strain and shear stress to bitumen specimens mounted between 25mm diameter parallel plates with a 1.0mm gap of the sample's thickness frequency 10 rad/sec at different temperatures.

2.5. Superpave Tests

Superpave tests were conducted for frequency sweep, performance grade determination, and multiple stress creep recovery tests.

2.5.1 Frequency Sweep Test (FST)

During the frequency sweep test, the frequency is varied while the amplitude of the deformation, or alternatively the amplitude of the shear stress, is kept constant. DSR frequency sweep tests are designed to construct master curves of binder complex shear modulus (G*) and phase angle (δ) (Petersen et al., 1994, Anderson et al., 1994). The master curves characterize both the rheological properties of binders over a wide range of temperatures or frequencies

2.5.2 Performance Grading (PG) Determination Test

This test is conducted at high temperatures to categorize the asphalt binder sample into a 60°C incremental performance grading system. A constant frequency of 10 rad/s is used, representing a speed of 80 km/h on the highways. It was believed that the permanent deformation parameter G*/sinδ has a good correlation with rut depth or rutting on the pavement. However, studies indicate a poor relationship between G*/sinδ and rutting depth (Anderson, 2011).

2.5.3 Multiple Stress Creep Loading and Recovery (MSCR) Test

The MSCR test is conducted to evaluate the binder's potential for permanent deformation. It is the latest improvement on Superpave Performance Graded (PG) asphalt binder specifications. It is conducted after performing the PG test and estimates the rutting parameter of asphalt binders, which typically occur at higher service temperatures. A one-second creep load is applied to the asphalt binder sample. After the 1-second load is removed, the sample is allowed to recover for 9 seconds. Typically, the test begins with applying a low stress of 0.1kPa for 10 creep/recovery cycles; then, the stress is increased to 3.2kPa and repeated for an additional 10 cycles. In the MSCR test, higher levels of stress and strain are applied to the binder, better representing what occurs in an actual pavement. TThs new high-temperature test for asphalt binders was developed under the NCHRP ito address concerns related to the testing of polymer-modified asphalt binders and field performance issues (J. hang et al., 2015; Bahia et al., 2001).

3. Results and Discussion

3.1 Effects of Polyisobutylene-ceramic powder on Penetration

The effect of varying content modifiers on the penetrating properties of base asphalt during the After Rolling Thin Film Oven Test (ARTFOT) and the unaged or Before Thin Film Oven Test (BRTFOT) of the binder is depicted in Figure 1. It is observed that the addition of modifiers to the base asphalt binder reduces its Penetration slightly. As shown in the plot below, the laboratory results indicate that the addition of polyisobutylene and ceramic powder to the asphalt binder leads to a decrease in the penetration value, which is indicative of an increase in the asphalt's hardness at moderate temperatures (25℃). It means an increase in the binder's ha, which ties the consistency, making the control material (bitumen) stiff. Hence, the aged bitumen penetration grade classification was changed from 60/70 to 40/50 penetration grade, with 1.4 and 2.1% by weight of PCP, respectively. It is essential to do this because the stiffness of the Polyisobutylene-ceramic powder bitumen material improves dispersion within the bitumen matrix. This would decrease penetration and incrthe softening point; the result obtained has been an increase is been rutting resistance (Porto M et al.,;2019, Ahmed A et al., 2021).

3.2 Effects of Polyisobutylene-ceramic powder on ductility

The adhesive capability of asphalt is dependent on bitumen stretch. Ductility (ASTM D113-99 1999) , 199 1999) test measures the tensile properties of bitumen, or the ability to stretch (expressed as percent of elongation), to characterize temperatures. Bitumen with a higher ductility value is very useful. Figure 2 shows that base bithe base bitumen's ductility decreases as the percent content of modifiers' polyisobutylene-ceramic powder increases. A decrease in ductility property value indicatessa loss of base asphalt flexibility and low adhesive properties of bitumen, implying an adverse effect of the modifierresence of several heteroatoms and the polarity of modifiethe modifiedt binder, thereby improving the adhesion of bitumen toward the aggregate. On the contrary, the result of this study revealed the ductiat the ductility of modified asphalt had increathe content of modifiers increased. It was because ceramic contais contain high percentages of silicon dioxide (SiO2h reduces the adhesiveness of bitumen toward aggregate (Sagni and Avinash, 2021).

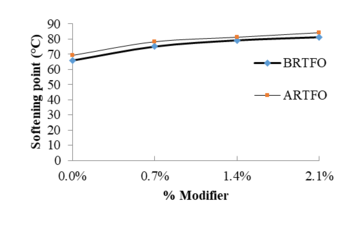

3.3. Effects of Polyisobutylene-ceramic powder on softening

The increment of softening point can be used as a good indicator to measure the hardening level of the mixed materials during aging. Figure 3 shows the effect of polyisobutylene and ceramic powder modified asphalt binder on softening point changes after rolling thin film oven test (RTFOT) aging. An increase in the softening point indicates a decrease in the sensitasphalt's sensitivity to high temperatures, which in turn leads to an increase in crack resistance at low temperatures and a reduction in permanent deformationsgh temperatures (Asim Hassan Ali et al., 2013). The improvement in the softening point of the asphalt due t, achieved by adding polyisobutylene and ceramic powder, can reduce the asphalt's susceptibility to high temperatures. Tans the possibility of using modified asphalt with both modifiers in areas with high traffic loads and high temperatures.

3.4 Effects of Polyisobutylene-ceramic powder on the flashpoint

The variation of flash point values for both unaged and aged bitumen at different percentages of polyisobutylene-ceramic powder added to the asphalt binder is presented in Figure 4. A significant change in flashpoint was observed with the addition of modifiers to the aged or After Rolling Thin Film Oven Test binder, and to the unaged or Before Thin Film Oven Test binder. The increment of asphalt modified flash point values is observed as the modifier's content increases compared with the base material (pure asphalt binder PEN 80/100).

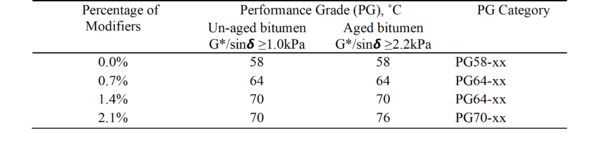

3.5 Performance Grade Determination

(G*/sin )test result

Using the indicator (G*/sin), the Superpave specification limits for resistance to rutting were determined by managing bitumen stiffness. The bitumen was evaluated to assess its suitability for use in the warmest location. The PG temperature indicates the maximum temperature at which the original asphalt binder exhibits G*/sinδ ≥ 1.0 kPa and the aged binder exhibits G*/sinδ ≥ 2.2 kPa. This requirement should be satisfied if the bitumeihas expected to serve in a hot climate (ASTM 2004; Sutanto et al., 2018)This means that the asphalt binder's stiffness will have sufficient resistance to permanent deformationce (Tadele and Quezon, 2021).

Table 1 presents the maximum temperature of PG for both pure and aged binders. The PG temperatures presented are based only on maximum temperature to represent the asphalt binder being placed in hot climates, especially in desert areas. The data analysis revealed that adding polyisobutylene-ceramic powder increased the maximum temperatures at which the pure binder exhibited G*/sin𝞭 ≥ 1.0kPa and the aged binder exhibited G*/sin𝞭 ≥ 2.2kPa, as evidenced by the recorded PG values. It is worth noting that at low temperatures, the modified asphalt exhibits different values for the G*/sin (δ) parameter. However, with the addition of 0.7% and 1.4% polyisobutylene, the performance grade of ceramic powder has been improved from PG58˚C to PG64˚C and from PG64˚C to PG70˚C. The PG's increment indicates that the rheological parameters of complex modulus, G*, increase as the modifiers' content increases. The other observation from Figure 6 and Table 1 is that the modifier in amounts of 0.7% and 1.4% has a minimal effect on permanent deformation based on the parameter G*/sin𝞭 of aged bitumen from 64˚C and 70˚C which remains softer after aging. Hence, it is an indication of not being susceptible to hardening.

Figure 5 below depicted the values of G* elaborated uniformly increased in the temperature range of 52˚C to 70˚C as a polyisobutylene-ceramic powder content increased and gradually decreased in-between temperature 64˚C to 70˚C with the same G* value except for the slope of G* for 2.1% for unmodified bitumen. This situation revealed the temperature susceptibility of bitumen at high temperatures.

Figure 6 displayed the G* values of neat and modified binders are smaller values before aged than after aged. In the temperature range of 52˚C to 70˚C, base bitumen plotted a sharp increase in G* slope show a gradual reduction of G* value as the temperature increases, representing improved bitumen stiffness and lower temperature susceptibility of they bitumen.

3.6 Frequency sweep test result

Plotting the master curves at several temperatures and frequencies utilizes the time-temperature superposition principle, a fundamental concept in the study of viscoelastic materials. In doing so, the asphalt binders were assumed to be thermo-rheological simple materials, and their structural properties were considered not to change within the test temperature range. The binder shear modulus master curves were developed using the generalized logistic function. A different form of the generalized logistic function was used for the binder phase angle master curves. The Williams-Landel-Ferry (WLF) relation was used to describe the shift factors. The binder master curve at a reference temperature of 21.1°C is shown in Figure 7.

The individual isotherm curves were shifted horizontally along the frequency axis to form a master curve at the reference temperature. The Figure displayed that as the reduced frequency decreases, the shear modulus decreases continuously, reflecting the reduction in shear deformation's resistance, resulting in reduced elasticity or ability to store energy. On the contrary, as modifiers' content increases, the stiffness of the asphalt binder increases, resulting in increased resistance to permanent deformation. At lower temperatures and higher reduced frequency, the asphalt binder exhibited different stiffness.

3.7 Multiple stress creep recovery (MSCR) test results

Figures 8 & 9 show the relationships between non-recoverable creep compliance (Jnr values) and percent of modifiers and selected temperature tested at 0.1 kPa and 3.2 kPa shear stress levels. Asphalt binder with a higher Jnr value typically measures lower stiffness and vice versa.

In Figure 8, the increase in the percent of modifiers enhances the asphalt binder's stiffness properties, resulting in better recovery of strain at maximum temperature with lower non-recoverable creep compliance (Jnr values) and a stiffer binder. Simultaneously, the temperature increased the asphalt binder's stiffness properties due to the modifiers' content, as shown in Figure 9, because in a desert area, hot temperature asphalt binder is easily affected by the combined effect of heavy traffic load and temperature. Due to strain recovery, these early signs of permanent deformations under heavy traffic load have been improved as polyisobutylene and ceramic powder contents increased when used in asphalt mixture design. A slightly higher Jnr(3.2kpa) value was obtained for a given test temperature than the overall Jnr values. The stress-temperature dependency and the elastic recovery properties of the asphalt binders were sufficiently characterized using the MSCR test. The AASHTO M 332 comparison with computed Jnr (3.2kPa) depends on the traffic level and load rate. At 2.1% PCP, the modified bitumen showed lower Jnr values in Figures 8 & 9, indicating a stiff binder and improving elastic performance. This represents modifiers that will enhance resistance to permanent deformation.

4. Conclusion and Recommendation

The elastomeric modifiers and aging of the asphalt binder significantly influence the bitumen's physical and rheological properties. A significant decrease in Penetration and an increase in softening points have been observed as the modifier's content increases. Results indicated a substantial reduction in the elastic properties of modified bitumen or ductility at 25˚C. Bitumen is brittle, and it is a problem for pavement service performance. As the modifiers' content increases, the stiffness of the asphalt binder increases at high temperatures, and low frequency was observed from the complex modulus master curve.

Besides, a performance-based asphalt grading system demonstrated 0.7% and 1.4% modified bitumen improved PG at 64˚C and 70˚C, respectively. The PG's increment showed that the rheological parameters of complex modulus Gthe complex modulus G* increased with the content of the modifiersdicated that the modifiers improved the permanent deformation resistance. As per AASHTO M-33ccording to AASHTO M-332, a 2.1% polyisobutylene-ceramic powder modifier exhibiterable creep compliance (Jnr values). It means the binder performance at service temperature is indicated up to 70˚C of high temperature. Thus, using recycled polyisobutylene-ceramic powder as a modifier is acceptable.

Acknowledgment:

The authors acknowledge the Addis Ababa Science and Technology University (AASTU) and the Civil Engineering Department staff for their advice and encouragement during the conduct of this research undertaking, as well as the Cagayan State University (CSU) in the Philippines.

Funding:

The authors received no direct funding for this research.

Conflict of Interest:

The authors declare that there is no conflict of interest.

References

AASHTO T 51, 2009 Edition, 2009 - Standard Method of Test for Ductility of Asphalt Materials.

Asim A., Nuha S. M., and Mohamed R. K. (2013). Investigations of Physical and Rheological Properties of Aged Rubberized Bitumen. Journal of Advances in Materials Science and Engineering. 1-7. https://doi.org/10.1155/2013/239036

Ahmed A. H, Ramadhansyah P. J, Haryati Y, Norhidayah A.H, Salam R. O, Aletba, G. F. H, Ekarizan Sh & Mohd R. M. H, (2021). Physical, chemical and morphology characterization of nano ceramic powder as Bitumen modification, International Journal of Pavement Engineering. 22:7, 858-871, DOI: 10.1080/10298436.2019.1650277

ASTM (2004). ASTM D 2872-12e1. Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). (C), 1–6. https://doi.org/10.1520/D2872.

ASTM D5-06, Standard Test Method for Penetration of Bituminous Materials, ASTM International, West Conshohocken, PA, 2006,[http:// www.astm.org www.astm.org]

Bressi, S., Fiorentini, N., Huang, J., & Losa, M. (2019). Crumb Rubber Modifier in Road Asphalt Pavements: State of the Art and Statistics. The Coatings, 9, 384. https://doi.org/10.3390/coatings9060384

Ching, W.C., Wing-gun, W. (2007). Effect of crumb rubber modifiers on high-temperature susceptibility of wearing course mixtures. 21, 1741–1745. https://doi.org/10.1016/j.conbuildmat.2006.05.020.

Drews, A. (2008a). Standard Test Method for Penetration of Bituminous Materials. Manual on Hydrocarbon Analysis, 6(i), 47-47–3. [https:doi.org/ https:doi.org/]10.1520/mnl10829m.

Drews, A. (2008b). Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). Manual on Hydrocarbon Analysis. 6(1-c), 50-50–4. https://doi.org/10.1520/mnl10830m.

Estimé, M M. et al. (2015). Principle of Dynamic Shear Rheometer Testing of Non-Standard Samples for Cohesion and Adhesion of Bituminous Road Seal Materials. Conference paper CAPSA pp. 1-8

Feng, D., Yi, J., Wang, D. ( 2013). Performance and thermal evaluation of incorporating waste ceramic aggregates in wearing a layer of asphalt pavement. Journal of Materials in Civil Engineering. 25(7), 857–863. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000788.

Gama, D.A., Rosa, J.M., De Melo, T.J.A., Rodrigues, J.K.G. (2016). Rheological studies of asphalt modified with Elastomeric polymer. Construction and Building Materials. 106, 290–295. https://doi.org/10.1016/j.conbuildmat.2015.12.142.

Jeffry, S.N.A., Jaya, R.P., Hassan, N.A., Yaacob, H., Mirza, J., Drahman, S.H. ( 2018). Effects of nano-charcoal coconut-shell ash on the physical and rheological properties of Bitumen. Construction and Building Materials. 158, 1–10. https://doi.org/10.1016/j.conbuildmat.2017.10.019.

Jeong, K., Lee, S., Amirkhanian, S.N., Kim, K.W. (2010). Interaction effects of crumb rubber modified asphalt binders. Construction and Building Materials. 24(5), 824–831. https://doi.org/10.1016/j.conbuildmat.2009.10.024.

Kalantar, Z. (2012). Properties of bituminous mix and binder modified with waste polyethylene terephthalate. Master thesis. University of Malaya, Kuala Lumpur, Malaysia.

Li, Q., Qiu, Y., Rahman, A., Ding, H. (2005). Application of steel slag powder to enhance the low-temperature fracture properties of asphalt mastic and its corresponding mechanism. Journal of Cleaner Production. 184, 21–31. https://doi.org/10.1016/j.jclepro.2018.02.245.

Lade Jaya H., Gurindapalli., P. (2005). Correction of sinusoidal sweep test to field random vibrations. Master thesis. Blekinge Institute of Technology, Karlskrona, sweden.

Liang, M., Xin, X., Fan, W., Luo, H., Wang, X., Xing, B. (2015). Investigation of the rheological properties and storage stability of CR/SBS modified asphalt. Construction and Building Materials. 74, 235–240. https://doi.org/10.1016/j.conbuildmat.2014.10.022.

Limin Li, Zhaoyang Guo, Longfei Ran, and Jiewen Zhang (2020). Study on Low-Temperature Cracking Performance of Asphalt under Heat and Light Together Conditions. Materials 2020, 13, 1541; 1-14. https://doi.org/10.3390/ma13071541

Liu, H., Fu, L., Jiao, Y., Tao, J., Wang, X. (2017). Short-term aging effect on properties of sustainable pavement asphalts modified by waste rubber and diatomite. Sustainability (Switzerland). 9(6). https://doi.org/10.3390/su9060996

Mashaan, N.S., Ali, A.H., Karim, M.R., Abdelaziz, M. (2014). A Review on Using Crumb Rubber in Reinforcement of Asphalt Pavement. The Scientific World Journal. Volume 2014, Article ID 214612, 1-2. http://dx.doi.org/10.1155/2014/214612

Moreno, F., Rubio, M.C., Martinez-Echevarria, M.J. (2011). Analysis of digestion time and the crumb rubber percentage in dry-process crumb rubber modified hot bituminous mixes. Construction and Building Materials. 25(5), 2323–2334. https://doi.org/10.1016/j.conbuildmat.2010.11.029

Mulatu, A., Quezon, E.T., Gudina, O. (2020). Evaluation of the HMA performance using the combined effects of marble waste dust filler and Superpave aggregate gradation. Australian Journal of Civil Engineering. 12(1), 1-11. https://doi.org/10.1080/14488353.2020.1854942

Olkeba, S. T. ., & Potdar, A. M. (2021). Effects of waste ceramic dust and butyl rubber on rheological properties of asphalt binder. ASEAN Engineering Journal, 11(2), 51-63. Https://doi.org/10.11113/aej.v11.16678

Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Oliviero Rossi, C. Bitumen and Bitumen Modification: A Review on Latest Advances. Appl. Sci. 2019, 9, 742. https://doi.org/10.3390/app9040742

SABITA Technical Guideline (2015). The Use of Modified Bituminous Binder in Road Construction. Southern African Bitumen Association. TG 1 3rd Edition. 1-115

Saoula, S., Soudani, K., Haddadi, S., Munoz, M.E., Santamaria, A. (2013). Analysis of the Rheological Behavior of Aging Bitumen and Predicting the Risk of Permanent Deformation of Asphalt. Materials Sciences and Applications. 04(05): 312–318.

Sharvin Poovaneshvaran, Mohd Rosli Mohd Hasan, Ramahansyah Putra jaya (2019). Impacts of recycled crumb rubber powder and natural rubber latex on the modified asphalt rheological behavior, bonding, and resistance to shear. Construction and Building Materials. 234:117357. https://doi.org/10.1016/j.conbuildmat.2019.117357.

Sutanto, M., Bala, N., Al Chodri, F., Sunarjono, S. (2018). Effect of Hydrated Lime and Portland Cement on Asphalt Binders using DSR. MATEC Web of Conferences. 203, 1–8. https://doi.org/10.1051/matecconf/201820305006

Tadele, B., Quezon, E.T. (2021). Evaluation of Waste Engine Oil Rejuvenation for Highly Short Term Aged Asphalt Binder. Australian Journal of Civil Engineering. 12(1), 1-11. https://doi.org/10.1080/14488353.2021.1896124

Wan, J., Wu, S., Xiao, Y., Liu, Q., Schlangen, E. (2016). Characteristics of ceramic fiber modified asphalt mortar. Materials. 9(9), 1–12. https://doi.org/10.3390/ma9090788.

Zhu, J., Birgisson, B., Kringos, N. ( 2014). Postprint Polymer Modification of Bitumen: Advances and Challenges. European Polymer Journal. 54, 18–38. http://dx.doi.org/10.1016/j.eurpolymj.2014.02.005

Zumrawi, MME. (2017). Effect of Crumb Rubber Modifiers (CRM) on Characteristics of Asphalt Binders in Sudan. International Journal of Materials Science and Applications. Special Issue: 2D Materials and Van Der Waals Heterostructures. Vol. 6, No. 2-1, 2017, pp. 1-6. https://doi.org/10.11648/j.ijmsa.s.2017060201.11

Document information

Published on 01/10/25

Submitted on 27/09/25

Volume 1, Issue Issue-2, December, 2025

DOI: https://doi.org/10.5281/zenodo.17558906

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?