| Abstract

Taking the double-layer water injection well one graded water device could regulate two layers as the design and research goal, the sliding double-layer water injection distributor was designed by using the forward and reverse rotation of the driving motor to control the opening and closing of the two nozzles. The flow field of the two flow channels under different opening was analyzed by FLUENT software. The research shows that when the opening of the nozzle was less than 10mm, the maximum flow rate decreases rapidly, and when the opening exceeds 10mm, it decreases slowly. The mathematical models of flow pressure, flow velocity, and nozzle opening were obtained by data analysis and fitting. Finally, the kinematics simulation was carried out by Adams, and the maximum friction force borne by each seal in the movement process was obtained. The maximum torque borne in the movement process was 120.5N·m, which was less than the rated torque. The supporting motor could meet the design requirements. Keywords : Reservoir water injection, Water distributor, Flow field analysis, Dynamic analysis |

1. Introduction

With the exploitation of the oilfield, the oil content in the formation is decreasing, which leads to a significant reduction in the formation pressure. Therefore, it is necessary to continuously inject water underground to supplement the missing pressure in the formation. In the process of oil production, in case of complex formation structure, layered water injection needs to be used to alleviate the contradiction between layers. The function of packer is to separate each production layer, while the water distributor is to control the water injection between layers and ensure the stability of oil production [1]. Aiming at the existing double-layer water injection wells in the oilfield, a set of single motor-controlled water distributor is designed to achieve the effect of completing two-layer water injection at one time. At present, layered water injection technology has been continuously improved in oilfield production. Wuqi oil production plant adopts the general water injection process, only a few adopt the layered water injection process, and the layered water injection adopts three processes: eccentric water distribution, oil jacket separate injection and concentric separate injection [2]. In 2015, the integrated water distributor of measurement and regulation was designed in Shengli Oilfield, mainly including the accurate down to the oil layer to be injected and the regulation of water injection flow. The conventional concentric adjustable water distributor, large differential pressure concentric adjustable water distributor and non open concentric adjustable water distributor were designed to meet the needs of layered water injection in Shengli Oilfield [3, 4]. The water injection technologies used in Daqing Oilfield mainly include conventional eccentric water injection technology, bridge eccentric layered water injection technology and concentric integral subdivision water injection technology [5]. Although the concentric integrated subdivision water injection process can achieve the purpose of subdivision [6], the application scope of the process is only four layers of water injection layer, and due to the large outer diameter of the water distribution plug, it will be difficult to salvage when the water quality is poor and the scaling is serious. The water distributor and packer not only play the role of stratification, but also play the role of the working cylinder of the integral water separator [7, 8]. In 2019, after years of research and exploration in Shengli Oilfield, the layered water injection process in offshore oilfield is becoming more and more mature and perfect. The supporting tools are applicable to a variety of separate injection process technologies in different reservoirs and well bore structures. In summary, they can be divided into the following types: anchor compensation measurement and adjustment, anti creep measurement and adjustment, concentric double pipes, hydraulic control measurement and adjustment and high inclination new measurement and adjustment [9, 10]. This paper studies and designs a water distributor driven by a single motor to realize double-layer water injection, which is applied to the double-layer water injection well in the oilfield, and further analyzes the performance of the downhole water distributor structure.

2. Structural design of double-layer water injection distributor

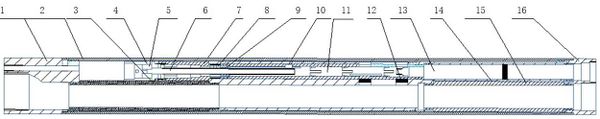

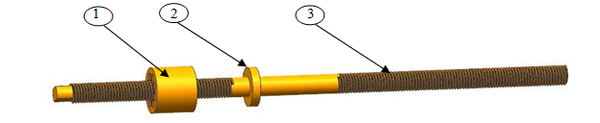

In the design process, considering the sealing conditions between the two water nozzles, set the distance between the two water nozzles, consider the through-hole seal, adopt four seals, and form the sliding rod assembly with the seal and the sliding rod group. The internal main body of the water distributor is designed as shown in Fig. 1 and Fig. 2.

The design target water injection well diameter is 120mm, the daily water injection volume is 500m3, and the external pressure is 10MPa. In order to meet the structure and size of internal instruments, the position of the central pipe is offset to form an eccentric flow channel. The main dimensions are determined according to the water injection well diameter and process requirements, as shown in Table 1.

| Name | Size | |

| Diameter of outer protective sleeve | 120 mm | |

| First runner diameter | 30 mm | |

| Second runner diameter | 20 mm | |

| Sprue diameter | 45 mm | |

| Nozzle size | long 24 mm | wide 10 mm |

| Nozzle spacing | 50 mm | |

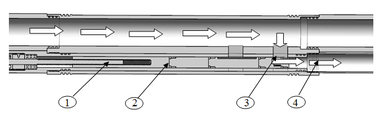

As shown in Figure 3, when the injection liquid is transported from the ground to the main flow channel of the eccentric pipe, the ground control motor drives the motor to drive the lead screw to rotate forward, and the sliding assembly is threaded with the lead screw. In this case, it starts to move to the left along the direction of the lead screw, the first flow channel is slowly opened, the injection liquid enters the first flow channel through the flow channel, and leads to the formation through the connecting pipe of the second flow channel, Complete the first layer of water injection.

As shown in Figure 4, when the motor is reversed, the first-class crossing is closed and the second-class crossing is slowly opened. At this time, the injected liquid enters the second channel pipe from the second channel crossing through the drainage channel, and then leads to the next formation from the second channel connecting pipe to complete water injection. The water nozzle can automatically adjust the opening of the water nozzle according to the change of downhole flow. The pressure difference between the two pressure sensors is used to calculate the water distribution volume and detect and control the downhole flow in real time.

3. Fluent fluid simulation analysis of adjustable nozzle of downhole water distributor

The junction of nozzle and runner is a relatively weak part. Because the fluid flow field at the junction of nozzle and runner will change, it is easy to produce serious scouring phenomenon. Reasonable pipe size design can predict the flow conditions under different pipe diameters [4], so relevant research is carried out.

In the fluid simulation, because the flow channel model is very complex, it is very difficult to divide the mesh as a whole. Therefore, in the mesh division, each part is taken out separately for division, and then imported into fluent for connection to form a complete fluid diagram. The mesh accuracy of each part is controlled above 0.6, and the nozzle position needs special attention, so the mesh accuracy is guaranteed to be above 0.8. According to the actual flow data, it is calculated that the inlet velocity of the flow field is 0.89m/s and the outlet pressure is 10MPa.

In the fluid simulation results, judge whether the fluent analysis converges according to the residual value detected and whether the mass, momentum and energy of the incoming and outgoing fluid are conserved in the flux reports dialog box.

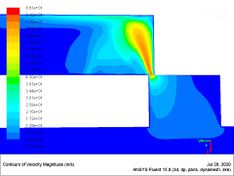

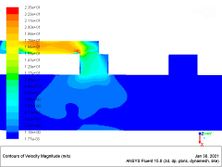

3.1 First runner velocity analysis

For the first flow passage, the fluid enters from the main flow passage pipe, the water nozzle is slowly opened under the drive of the motor, and enters the water injection layer through the external connecting pipe. With the increase of nozzle opening, the maximum velocity at the nozzle decreases. Through the simulation of the internal flow field of the water distributor under different opening degrees, the distribution of the flow velocity in the fluid under the same flow rate is analyzed, and the nozzle size is selected as 2-24mm, with an interval of 2mm for 12 groups of simulation. The simulation results of the first group and the last group are shown in Figure 5, and the overall data are shown in Table 2.

| a. Velocity chart of opening 2 mm | b. Velocity chart of opening 24 mm |

| Fig.5 First runner velocity chart | |

| Opening | Maximum velocity | Eddy current velocity | Outlet velocity |

| 2 mm | 86.1 m/s | 17.2 m/s | 4.3 m/s |

| 4 mm | 48.7 m/s | 12.18 m/s | 3.825 m/s |

| 6 mm | 34.2 m/s | 5.12 m/s | 3.418 m/s |

| 8 mm | 25.6 m/s | 3.84 m/s | 5.12 m/s |

| 10 mm | 20.5 m/s | 3.07 m/s | 5.12 m/s |

| 12 mm | 20.49 m/s | 3.07 m/s | 5.12 m/s |

| 14 mm | 14.5 m/s | 2.16 m/s | 5.05 m/s |

| 16 mm | 12.1 m/s | 2.13 m/s | 4.83 m/s |

| 18 mm | 10.6 m/s | 2.12 m/s | 4.78 m/s |

| 20 mm | 10.1 m/s | 2.02 m/s | 4.54 m/s |

| 22 mm | 8.99 m/s | 1.34 m/s | 4.49 m/s |

| 24 mm | 8.64 m/s | 0.86 m/s | 4.31 m/s |

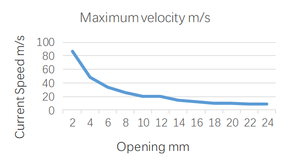

It can be seen from the simulation data in the table that the flow velocity at the vortex on the right is much less than the inlet flow velocity, which has little impact on the overall kinetic energy, so it has little impact on the fluid simulation results. According to the simulation data, draw the curve under the change of maximum flow velocity with opening, as shown in Fig. 6.

The simulation data are fitted by Origin software, and the change law is shown in formula (1).

…………………………………………………………………………………… (1)

Where, v represents flow velocity, m/ s; x represents opening, mm.

3.2 Second runner velocity analysis

For the second channel, similar to the first channel, the nozzle is slowly opened by motor drive. The internal flow field of water distributor under different opening is simulated, and the internal velocity distribution under the same flow and different opening is analyzed, as shown in Table 3. The analysis results of 6mm and 16mm opening are shown in Figure 7.

|

|

|

| a. Velocity chart of opening 6 mm | b. Velocity chart of opening16 mm |

| Fig.7 Second runner velocity chart | |

| Opening | Maximum velocity | Eddy current velocity | Outlet velocity |

| 2 mm | 94.3m/s | 80.121 m/s | 18.9 m/s |

| 4 mm | 50.7 m/s | 46.508 m/s | 10.3 m/s |

| 6 mm | 34.7 m/s | 33.111 m/s | 9.2 m/s |

| 8 mm | 30.4 m/s | 28.9 m/s | 7.6 m/s |

| 10 mm | 27.2 m/s | 25.729 m/s | 6.81 m/s |

| 12 mm | 25.2 m/s | 23.929 m/s | 6.36 m/s |

| 14 mm | 24.3 m/s | 23.542 m/s | 6.22 m/s |

| 16 mm | 23.96 m/s | 22.312 m/s | 5.97 m/s |

| 18 mm | 23.5 m/s | 22.155 m/s | 5.68 m/s |

| 20 mm | 23.23 m/s | 21.521 m/s | 5.15 m/s |

| 22 mm | 22.86 m/s | 21.426 m/s | 5.02 m/s |

| 24 mm | 22.55 m/s | 21.32 m/s | 4.13 m/s |

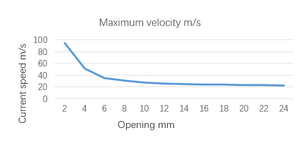

According to the 12 groups of simulation results, with the increase of opening, the maximum flow drops rapidly before 10mm, and when the opening exceeds 10mm, the flow drops slowly. Draw the flow change curve under different opening degrees, as shown in Figure 8.

Similarly, the curve equation is fitted to obtain the change law between the opening of the second channel and the flow rate, as shown in equation (2).

………………………………………………………………………………………(2)

Compared with the first flow channel, because the design outlet of the second flow channel is small and the fluid needs to pass through the drainage channel, the overall flow rate is higher than that of the first flow channel. Because the flow layer and pressure are different, the deeper the water injection well, the greater the pressure. Therefore, it is suitable for water injection in the middle and deep layers of double layers.

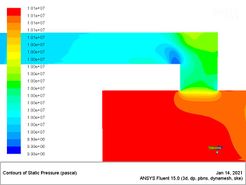

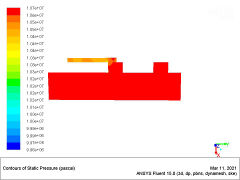

3.3 Fluid pressure distribution in the first channel

Under the same inlet velocity, the internal flow field under different nozzle openings is simulated, and 12 groups of flow pressure analysis results are obtained, as shown in Table 4. The simulation results of 2mm and 24mm openings are shown in Figure 9..

|

|

| |||||||||||||||||||||||||||||||||||||||

| a. Opening 2 mm flow pressure diagram | b. Opening 24mm flow pressure diagram | |||||||||||||||||||||||||||||||||||||||

| Fig.9 First channel flow pressure diagram

Table.4 flow pressure simulation results of a channel with different openings

| ||||||||||||||||||||||||||||||||||||||||

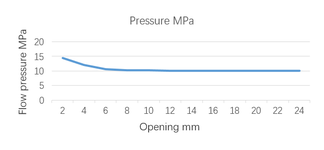

According to table 4, it can be seen that the flow pressure decreases with the increase of opening. The change curve of flow rate under different opening conditions is drawn according to the data, as shown in Figure 10

According to the curve, the flow pressure drops rapidly before the opening is 6mm, and tends to be flat after it exceeds 6mm. The equation fitting is carried out with the simulation data of Origin software, and the change law is shown in equation (3).

…………………………………………………………………………………………………(3)

Where, p represents flow pressure, MPa; x represents opening, mm

The fluid simulation analysis of the first flow channel is carried out, and the functional relationship between the flow pressure and the opening under different opening degrees is obtained. It can adjust different opening degrees through the pressure sensor, so as to achieve the required pressure of the water distributor, carry out real-time control and adjust the opening of the water nozzle, realize the water flow adjustment under different pressures, and complete balanced water injection

3.3 Fluid pressure distribution in the second channel

Use the same method to simulate the second flow channel and observe the pressure distribution of the fluid in the pipeline. The calculation results are shown in Table 5, and the analysis results of 10mm and 14mm openings are shown in Figure 11.

| a. Opening 10mm flow pressure diagram | b. Opening 14mm flow pressure diagram |

| Fig.11 Second channel flow pressure diagram | |

| Opening | Maximum flow pressure | Outlet flow pressure |

| 2mm | 15.8MPa | 10.104MPa |

| 4mm | 11.7MPa | 10.080MPa |

| 6mm | 11.2MPa | 10.058MPa |

| 8mm | 11.0MPa | 10.049MPa |

| 10mm | 10.82MPa | 10.033MPa |

| 12mm | 10.8MPa | 10.039MPa |

| 14mm | 10.7MPa | 10.021MPa |

| 16mm | 10.625MPa | 10.015MPa |

| 18mm | 10.537MPa | 10.014MPa |

| 20mm | 10.51MPa | 10.013MPa |

| 22mm | 10.492MPa | 10.021MPa |

| 24mm | 10.41MPa | 10.011MPa |

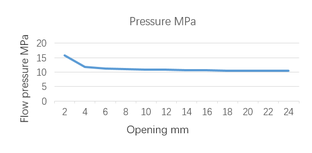

With the increase of the nozzle opening, the pressure of the fluid in the pipe at the same position decreases continuously, and the internal flow pressure of the second channel is higher than that of the first channel. Since the outlet pipe diameter of the second channel is smaller than that of the first channel, and the second channel must pass through the drainage channel, the flow pressure change curve under different openings is drawn according to the data, as shown in Figure 12.

It can be seen from the flow pressure curve that the opening is within 4mm. With the increase of opening, the pressure drop is fast. After exceeding 4mm, the flow pressure drops slowly. The simulation data of Origin software is used for fitting, and the change law is shown in equation (4).

…………………………………………………………………………………………… (4)

The fluid simulation analysis of each channel is carried out, and the mathematical models between flow velocity, flow pressure and opening under different opening are obtained. According to each model, the operation status of the water distributor can be judged in the work, and the conditions for subsequent Adams dynamic simulation are provided.

4. dynamic simulation analysis of water distributor

During the opening adjustment of the water distributor, friction force will be generated between the seal and the sliding sleeve. The motion process is simulated by ADAMS to analyze the torque to be overcome by the motor, complete the motor selection and verify the rationality of the structural design.

ADAMS software provides a variety of definition methods of motion pairs, which can truly simulate the motion process of mechanical system. This system involves 12 components. In order to achieve the required motion, the added motion pairs are shown in Table 6.

| Component 1 | Component 2 | Constraint relation |

| Sliding sleeve | earth | Fixed pair |

| Key | earth | Fixed pair |

| Screw | earth | Rotating pair |

| Slide bar | Sliding sleeve | Moving pair |

| Screw | Slide bar | Screw pair |

| Screw | earth | Cylindrical pair |

| Sealing element | Slide bar | Hu Ke pair |

| Sealing element | Sliding sleeve | Moving pair |

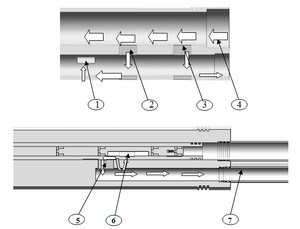

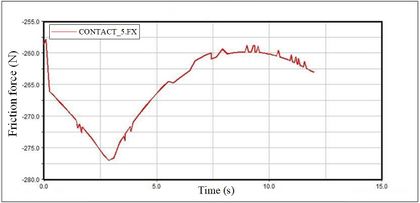

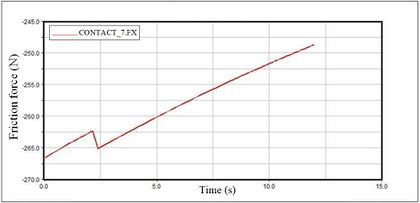

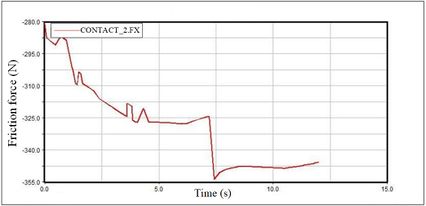

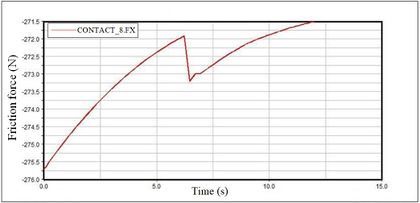

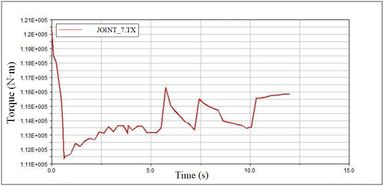

Since the motor needs sealing protection, there is a sealing design between the lead screw and the motor. As shown in Figure 13, a compression plate is designed on the lead screw to compress the sealing sleeve, and the sealing sleeve and the lead screw are isolated from the contact between the fluid and the motor. ADAMS simulation analysis is carried out on a flow channel, and the friction between each seal and the sliding sleeve is obtained through simulation, as shown in Figures 14 and 15, It can be seen from the figure that with the movement of the sliding assembly, the friction between the seal and the sliding sleeve changes continuously in one cycle. The relevant data are sorted out as shown in Table 7 and table 8.

| Seal No | Maximum | Minimum | average value |

| 1 | 280N | 223N | 250N |

| 2 | 276N | 257N | 265N |

| 3 | 266N | 248N | 258N |

| 4 | 230N | 200N | 212N |

| Table.8 Friction value of large seal | |||

| Seal No | Maximum | Minimum | average value |

| 1 | 354N | 280N | 325N |

| 2 | 360N | 322N | 335N |

| 3 | 317N | 301N | 310N |

| 4 | 275N | 271N | 273N |

From the above data analysis, it can be seen that the friction generated by the seal changes with the pressure and the contact surface. As the time when the four seals generate the maximum friction is different during the movement of the seal, considering the extreme working conditions, the maximum friction generated by each seal is combined as the basis for selecting the motor. The sum of the dynamic friction calculated according to tables 7 and 8 is 3306 N, The maximum friction obtained is substituted into Adams components as a known condition, and the external load is re established to simulate the torque required by the motor, as shown in Figure 16.

As shown in the figure, the maximum torque is 120.5N•m. according to the torque power function, the power of the motor is about 1.5kW, which is less than the rated power of the selected motor 2kW, meeting the design requirements.

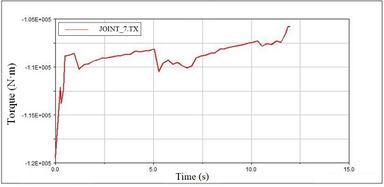

The ADAMS simulation analysis of the two flow channels is carried out in the same way. Through the simulation analysis, the friction between each seal and the sliding sleeve is obtained, and the relevant data are extracted to calculate that the sum of dynamic friction is 2966N.

By using the same method, as shown in Figure 17, the maximum torque of the reverse motor is 120N•m, and the corresponding required power is about 1.5kW, which is less than the rated power 2kW, meeting the production requirements of the oilfield.

5 Conclusion

Aiming at the design and research goal of two-layer water injection well and one graded water distributor, a set of single motor-driven water distributor is designed to realize underground two-layer water injection, and the key structures of the water distributor are simulated by fluid and dynamics. The main research conclusions are as follows:

1. For the double-layer water injection well with a diameter of 120mm and an injection volume of 500 cubic meters per day, a double-layer water injection well is designed, which uses the forward and reverse rotation of the motor to control the opening and closing of the two water nozzles. The design water nozzle size is 24mm, the spacing between the two water nozzles is 50mm, four seals are adopted, and the diameters of the two flow channels are 30mm and 20mm respectively. According to the limitation of water injection well and the size of accessories, the eccentric pipe string is used to complete the overall structural design of water distributor.

2. Fluent software is used to simulate the flow field of the two flow channels under different nozzle opening. The analysis shows that when the nozzle opening is less than 10mm, the maximum flow rate decreases rapidly, and then decreases slowly after exceeding 10mm. The mathematical model between flow pressure, flow velocity and nozzle opening is obtained by fitting, which provides a basis for subsequent research.

3. The kinematics simulation is carried out by using ADAMS software. The analysis shows that the sliding rod drives the seal to slide in the sliding sleeve. The friction force of each seal is 120.5N•m, the maximum torque limit is 120.5N•m, and the motor power required by the corresponding motor is 1.5kW, which is less than the rated power 2kW, meeting the design requirements.

Acknowledgement

This research is supported by China University of Petroleum (East China).

References

[1]Chen Haojie Simulation and structural optimization of packer for layered water injection [D] China University of Petroleum (East China), 2017.

[2]Wang Changwei Analysis on present situation of layered water injection process in Wuqi oil production plant [J] China Petroleum and chemical industry standards and quality, 2018,38 (24): 160-161.

[3]Li Changyou New progress of layered water injection technology integrating measurement and regulation in Shengli Oilfield [J] Petroleum machinery, 2015,43 (6): 66-70.

[4]Wang Zenglin Research and practice of layered water injection technology in Shengli Oilfield [j] Oil and gas geology and recovery factor, 2018,25 (06): 1-6 Doi:10.13673/j.cnki Cn37-1359/te June 1, 2018.

[5]Dang Lanlan Research on downhole multifunctional water injection tool [J] Sino foreign energy, 2018,23 (04): 54-57.

[6]Xu Wenlin Practical application analysis of layered water injection technology in Oilfield [J] Chemical engineering and equipment, 2019 (04): 86 + 49.

[7]Han Wenchao, Xu Wanli Design of a new downhole layered water injection tool [J] Inner Mongolia petrochemical industry, 2014,40 (04): 81 + 89.

[8]Zhu Zhenkun Research on bridge eccentric integrated water injection technology [D] Daqing Petroleum Institute, 2008.

[9]Mu Jihua Present situation and Prospect of layered water injection technology in Shengli Offshore Oilfield [j] Neijiang technology, 2019,40 (05): 34-35 .

[10]Ju Yafeng, Wang Zhiguo, Ma Hongxing, Chen Wei, jinxiaohong, gongxuemei Test and evaluation of intelligent testing and allocation technology for layered water injection wells [j] Oil and gas well test, 2006 (06): 51-52+56+74-75.

Document information

Published on 15/11/22

Accepted on 03/11/22

Submitted on 08/06/22

Volume 38, Issue 4, 2022

DOI: 10.23967/j.rimni.2022.11.002

Licence: CC BY-NC-SA license

Share this document

claim authorship

Are you one of the authors of this document?