(Tag: Visual edit) |

(Tag: Visual edit) |

||

| Line 5: | Line 5: | ||

An abstract is required for every document; it should succinctly summarize the reason for the work, the main findings, and the conclusions of the study. Abstract is often presented separately from the article, so it must be able to stand alone. For this reason, references and hyperlinks should be avoided. If references are essential, then cite the author(s) and year(s). Also, non-standard or uncommon abbreviations should be avoided, but if essential they must be defined at their first mention in the abstract itself. -->== | An abstract is required for every document; it should succinctly summarize the reason for the work, the main findings, and the conclusions of the study. Abstract is often presented separately from the article, so it must be able to stand alone. For this reason, references and hyperlinks should be avoided. If references are essential, then cite the author(s) and year(s). Also, non-standard or uncommon abbreviations should be avoided, but if essential they must be defined at their first mention in the abstract itself. -->== | ||

| − | '''Evaluation of conventional | + | '''Evaluation of conventional behaviour of bitumen containing PET plastic and HMA pavement response utilizing 3D-Move analysis software''' |

'''Nahusenay Muluken Tessera*'''[1]''', Emer Tucay Quezon'''[2]''', and Thomas Bezabih Bashe'''[3]'''''' | '''Nahusenay Muluken Tessera*'''[1]''', Emer Tucay Quezon'''[2]''', and Thomas Bezabih Bashe'''[3]'''''' | ||

| Line 36: | Line 36: | ||

'''2. Materials and methods''' | '''2. Materials and methods''' | ||

| − | '''Study Area''' | + | <nowiki> </nowiki>'''2.1. Study Area''' |

The study was conducted at the AAiT and AAST university highway laboratory, Addis Ababa, Ethiopia, because of the laboratory equipment's availability to be undertaken for the laboratory tests. Addis Ababa is the capital city of Ethiopia. It is also the largest city in the country by population. | The study was conducted at the AAiT and AAST university highway laboratory, Addis Ababa, Ethiopia, because of the laboratory equipment's availability to be undertaken for the laboratory tests. Addis Ababa is the capital city of Ethiopia. It is also the largest city in the country by population. | ||

| − | '''Materials''' | + | <nowiki> </nowiki>'''2.2. Materials''' |

The raw materials utilized for the laboratory study include Bitumen 60/70 penetration grade and shredded PET plastic. The equipment was also used to evaluate Penetration, Ductility, and Softening point tests and mechanical mixers to produce the modified bitumen to produce homogenous mixtures. | The raw materials utilized for the laboratory study include Bitumen 60/70 penetration grade and shredded PET plastic. The equipment was also used to evaluate Penetration, Ductility, and Softening point tests and mechanical mixers to produce the modified bitumen to produce homogenous mixtures. | ||

| − | '''Research Design''' | + | <nowiki> </nowiki>'''2.3. Research Design''' |

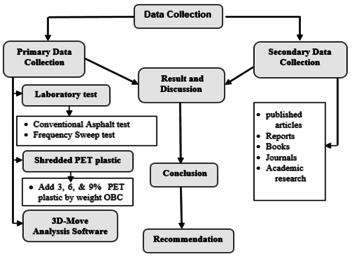

The study used an experimental research method to answer the research question and meet the objectives. The study work follows two phases: - The first phase was sample collection. At this phase, Bitumen 60/70 penetration grade and shredded PET plastic were collected. The second phase was a laboratory test, which followed the ERA, AASHTO, and ASTM procedures. This phase is further classified into two steps. Step-I Quality testing- The quality of the bitumen was tested and compared with the ERA specification and checked that it fulfils the ERA specification. Step-II conventional and Dynamic shear modulus test (DSR)- to determine Penetration, Ductility, and Softening point test values and frequency sweep test data (E*, G*, and phase angle test data) respectively by adding 3, 6, and 9% of shredded PET plastic in the bitumen. The asphalt quality tests are shown in ''Table 1''. In addition, to compare the performance of PET plastic pavement with the normal pavement by considering the effects of loading a moving tire on the pavement by considering dual tire single, dual tire tandem, and Super single tire tandem-axle vehicle loading conditions. The general framework of the study is shown below in ''Figure 1''. | The study used an experimental research method to answer the research question and meet the objectives. The study work follows two phases: - The first phase was sample collection. At this phase, Bitumen 60/70 penetration grade and shredded PET plastic were collected. The second phase was a laboratory test, which followed the ERA, AASHTO, and ASTM procedures. This phase is further classified into two steps. Step-I Quality testing- The quality of the bitumen was tested and compared with the ERA specification and checked that it fulfils the ERA specification. Step-II conventional and Dynamic shear modulus test (DSR)- to determine Penetration, Ductility, and Softening point test values and frequency sweep test data (E*, G*, and phase angle test data) respectively by adding 3, 6, and 9% of shredded PET plastic in the bitumen. The asphalt quality tests are shown in ''Table 1''. In addition, to compare the performance of PET plastic pavement with the normal pavement by considering the effects of loading a moving tire on the pavement by considering dual tire single, dual tire tandem, and Super single tire tandem-axle vehicle loading conditions. The general framework of the study is shown below in ''Figure 1''. | ||

| − | + | [[File:Screenshot 2023-03-02 200827.png|centre|359x359px]] | |

Figure 1 The major framework of the study | Figure 1 The major framework of the study | ||

| Line 83: | Line 83: | ||

|} | |} | ||

| − | '''Mixing of PET plastic with bitumen''' | + | <nowiki> </nowiki>'''2.4. Mixing of PET plastic with bitumen''' |

The shredded PET plastic that is remained after passing through the 4.75mm sieve size used. The wet process is used in the melt-blending technique. Bitumen heated in the oven till fluid condition and shredded plastic slowly added the temperature of 150-160<sup>0</sup>C. The mix continued for 45-60min to produce homogenous mixtures. The Polymer modified asphalt was sealed in containers and stored for further testing. Finally, performance tests were used as Conventional physical tests and DSR (Frequency Sweep test) [16, 17, 18]. | The shredded PET plastic that is remained after passing through the 4.75mm sieve size used. The wet process is used in the melt-blending technique. Bitumen heated in the oven till fluid condition and shredded plastic slowly added the temperature of 150-160<sup>0</sup>C. The mix continued for 45-60min to produce homogenous mixtures. The Polymer modified asphalt was sealed in containers and stored for further testing. Finally, performance tests were used as Conventional physical tests and DSR (Frequency Sweep test) [16, 17, 18]. | ||

| − | '''Conventional Asphalt Binder Physical Tests''' | + | <nowiki> </nowiki>'''2.4.1. Conventional Asphalt Binder Physical Tests''' |

Different tests were performed according to AASHTO test Standards to characterize the properties of bitumen, which mixed with shredded PET plastic a range of 3-9% by the increment of 3% by the weight of the bitumen. The different percent of shredded plastic was added to the bitumen and mixed 45-60min at a temperature 150-160<sup>0</sup>C to ensure good homogeneity; then, various tests were performed. First, the asphalt binder was heated at a temperature of 150<sup>0</sup>C. | Different tests were performed according to AASHTO test Standards to characterize the properties of bitumen, which mixed with shredded PET plastic a range of 3-9% by the increment of 3% by the weight of the bitumen. The different percent of shredded plastic was added to the bitumen and mixed 45-60min at a temperature 150-160<sup>0</sup>C to ensure good homogeneity; then, various tests were performed. First, the asphalt binder was heated at a temperature of 150<sup>0</sup>C. | ||

| − | '''I. Penetration test''' | + | <nowiki> </nowiki>'''I. Penetration test''' |

According to AASHTO T 49, a 100g sample of asphalt binder with 3%, 6%, and 9% by weight of sample shredded plastic was heated in an oven for enough time to soften entirely and uniformly mixed. Then it was transferred into a penetration test cup and allowed to cool to room temperature for 1 hour. The sample was then placed in water with a temperature controller set to 25<sup>0</sup>C and allowed to condition for about 1 hour. It was then removed, dried the water quickly, and placed under the needle of the penetrometer. Then three readings were taken for a single penetration cup after placing the tip of the penetrometer needle precisely at the surface of the cup before the instrument was started. The average of the three sample values was recorded [19, 20] | According to AASHTO T 49, a 100g sample of asphalt binder with 3%, 6%, and 9% by weight of sample shredded plastic was heated in an oven for enough time to soften entirely and uniformly mixed. Then it was transferred into a penetration test cup and allowed to cool to room temperature for 1 hour. The sample was then placed in water with a temperature controller set to 25<sup>0</sup>C and allowed to condition for about 1 hour. It was then removed, dried the water quickly, and placed under the needle of the penetrometer. Then three readings were taken for a single penetration cup after placing the tip of the penetrometer needle precisely at the surface of the cup before the instrument was started. The average of the three sample values was recorded [19, 20] | ||

| − | '''II. Ductility test''' | + | <nowiki> </nowiki>'''II. Ductility test''' |

According to AASHTO T 51, the asphalt binder mixed with 3%, 6%, and 9% by weight of sample shredded plastic was heated and poured in the mold assembly placed on a plate. The samples were cooled in the air at room temperature for about 30min and then put in a water bath at 27°C temperature. The mold has removed on both sides and hooked on the machine; then, the assembly-contained sample was kept in a water bath of the ductility machine range of 80-90 minutes, and the machine was operated. Finally, measured a ductility value, the distance from the point up to break off the thread, and recorded in cm [21]. | According to AASHTO T 51, the asphalt binder mixed with 3%, 6%, and 9% by weight of sample shredded plastic was heated and poured in the mold assembly placed on a plate. The samples were cooled in the air at room temperature for about 30min and then put in a water bath at 27°C temperature. The mold has removed on both sides and hooked on the machine; then, the assembly-contained sample was kept in a water bath of the ductility machine range of 80-90 minutes, and the machine was operated. Finally, measured a ductility value, the distance from the point up to break off the thread, and recorded in cm [21]. | ||

| − | '''III. Softening Point test''' | + | <nowiki> </nowiki>'''III. Softening Point test''' |

AASTO T 53 stated that asphalt binder mixed with 0, 3, 6, and 9% PET shredded plastic by weight of binder should be heated and poured into two small brass rings and allowed to cool. A heated knife blade was used to trim the surface of the samples to the level of the brass rings. The prepared samples were then conditioned in a temperature controller at 4°C for at least 30 minutes before the test. A steel 3.55gm ball-bearing was centered on each specimen and placed in a glass jar. An electric heater and thermometer were fitted into the beaker filled with clean, distilled water. The temperature when each of the balls and samples touches the bottom plate of support was recorded as softening point value. The average of two read values was taken and rounded to the nearest whole degree [19, 22]. | AASTO T 53 stated that asphalt binder mixed with 0, 3, 6, and 9% PET shredded plastic by weight of binder should be heated and poured into two small brass rings and allowed to cool. A heated knife blade was used to trim the surface of the samples to the level of the brass rings. The prepared samples were then conditioned in a temperature controller at 4°C for at least 30 minutes before the test. A steel 3.55gm ball-bearing was centered on each specimen and placed in a glass jar. An electric heater and thermometer were fitted into the beaker filled with clean, distilled water. The temperature when each of the balls and samples touches the bottom plate of support was recorded as softening point value. The average of two read values was taken and rounded to the nearest whole degree [19, 22]. | ||

| − | '''Rolling Thin-film Oven test (RTFO)''' | + | <nowiki> </nowiki>'''IV. Rolling Thin-film Oven test (RTFO)''' |

According to AASHTO T 240, a rolling thin film oven test (RTFO) follows aging asphalt binders' basic steps. The RTFO simulates the asphalt binder aging (hardening) during the production and construction of HMA pavement [23]. It exposes the fresh binder to heat and airflow during rolling. It takes only 85min to perform the test, then provides an aged asphalt binder for further testing by the DSR and conventional asphalt test. The amount of volatile loss indicates the total aging that may occur during HMA production and construction [24]. | According to AASHTO T 240, a rolling thin film oven test (RTFO) follows aging asphalt binders' basic steps. The RTFO simulates the asphalt binder aging (hardening) during the production and construction of HMA pavement [23]. It exposes the fresh binder to heat and airflow during rolling. It takes only 85min to perform the test, then provides an aged asphalt binder for further testing by the DSR and conventional asphalt test. The amount of volatile loss indicates the total aging that may occur during HMA production and construction [24]. | ||

| − | '''Dynamic Shear Modulus test''' | + | <nowiki> </nowiki>'''V. Dynamic Shear Modulus test''' |

Frequency sweep tests:- were also performed to determine the dynamic shear modulus G* and phase angle δ on the temperatures at 21.1, 37.8, and 54.4<sup>0</sup>C with 0, 3, 6, and 9% shredded PET plastic mixed with bitumen. The shear strain was applied for all the samples, and the frequency range used was 0.1Hz to 25Hz [25, 26]. | Frequency sweep tests:- were also performed to determine the dynamic shear modulus G* and phase angle δ on the temperatures at 21.1, 37.8, and 54.4<sup>0</sup>C with 0, 3, 6, and 9% shredded PET plastic mixed with bitumen. The shear strain was applied for all the samples, and the frequency range used was 0.1Hz to 25Hz [25, 26]. | ||

| − | '''3D-Move Analysis Software''' | + | <nowiki> </nowiki>'''2.5. 3D-Move Analysis Software''' |

<nowiki> 3D-Move analysis software is a continuum-based finite-layer approach to analyze asphalt pavement responses under various moving traffic load, traffic velocity, axle configurations, and tire contact areas to a pavement structure. The Asphalt Research Consortium developed the software. Which is a group of five organizations; Texas A&M University, Western Research Institute, University of Nevada-Reno (UNR), University of Wisconsin-Madison, and Advanced Asphalt Technologies and available at http://www.arc.unr.edu/Index.html. Moreover, 3D Move Analysis Software entering the frequency sweep test data (E* and G* test data) of asphalt mixes in the analysis. It was taken into account the properties of the viscoelastic material in the study. Furthermore, 3D Move Analysis software utilized stresses and strains due to loading to predict rutting depths, top-down and bottom-up cracking due to loading of asphalt pavement [14], [15]. The main screen of 3D-Move Analysis software Ver 2.1 in </nowiki>''Figure 2.'' | <nowiki> 3D-Move analysis software is a continuum-based finite-layer approach to analyze asphalt pavement responses under various moving traffic load, traffic velocity, axle configurations, and tire contact areas to a pavement structure. The Asphalt Research Consortium developed the software. Which is a group of five organizations; Texas A&M University, Western Research Institute, University of Nevada-Reno (UNR), University of Wisconsin-Madison, and Advanced Asphalt Technologies and available at http://www.arc.unr.edu/Index.html. Moreover, 3D Move Analysis Software entering the frequency sweep test data (E* and G* test data) of asphalt mixes in the analysis. It was taken into account the properties of the viscoelastic material in the study. Furthermore, 3D Move Analysis software utilized stresses and strains due to loading to predict rutting depths, top-down and bottom-up cracking due to loading of asphalt pavement [14], [15]. The main screen of 3D-Move Analysis software Ver 2.1 in </nowiki>''Figure 2.'' | ||

| Line 118: | Line 118: | ||

Figure 2 Screen Shoot of Main Screen of 3D Move Analysis software | Figure 2 Screen Shoot of Main Screen of 3D Move Analysis software | ||

| − | '''3D-Move Analysis of software selection criteria''' | + | <nowiki> </nowiki>'''2.5.1. 3D-Move Analysis of software selection criteria''' |

Most mechanistic procedures used to compute pavement responses are simpler; the tire-pavement interface's stress distributions are modeled as static, uniform, and stationary circular loads. For example, ELSYM5, WESLEA 3.0, BISAR 3.0, CIRCLY 7.0, KENLAYER, ILLI-PAVE, MICH-PAVE [13]. Therefore, compare 3D-Move Analysis software with others based on different conditions. These are:- | Most mechanistic procedures used to compute pavement responses are simpler; the tire-pavement interface's stress distributions are modeled as static, uniform, and stationary circular loads. For example, ELSYM5, WESLEA 3.0, BISAR 3.0, CIRCLY 7.0, KENLAYER, ILLI-PAVE, MICH-PAVE [13]. Therefore, compare 3D-Move Analysis software with others based on different conditions. These are:- | ||

| − | '''1. Model Approach''' | + | <nowiki> </nowiki>'''1. Model Approach''' |

The 3D-Move model has been recognized as an efficient tool to simulate moving loads compared to the other software because the 3D-Move program uses a finite layer approach and Fourier Transform Technique for estimating pavement responses. This Fourier series expansion decomposes the loads into harmonic components in space (x and y directions). The total response at a given location is then calculated by adding the individual responses from each harmonic component [27, 28]. It can handle any number of layers with complex loading at the surface and any number of response evaluation points. The 3D-Move model is ideally suited for pavement response evaluations since only a few critical responses are needed for pavement performance evaluations. Therefore, 3D-Move performs much more computationally efficient than the moving load models based on the finite element method such as KENLAYER, ILLI-PAVE, and MICH-PAVE [29]. | The 3D-Move model has been recognized as an efficient tool to simulate moving loads compared to the other software because the 3D-Move program uses a finite layer approach and Fourier Transform Technique for estimating pavement responses. This Fourier series expansion decomposes the loads into harmonic components in space (x and y directions). The total response at a given location is then calculated by adding the individual responses from each harmonic component [27, 28]. It can handle any number of layers with complex loading at the surface and any number of response evaluation points. The 3D-Move model is ideally suited for pavement response evaluations since only a few critical responses are needed for pavement performance evaluations. Therefore, 3D-Move performs much more computationally efficient than the moving load models based on the finite element method such as KENLAYER, ILLI-PAVE, and MICH-PAVE [29]. | ||

| − | '''2. Tire-Pavement Interaction''' | + | <nowiki> </nowiki>'''2. Tire-Pavement Interaction''' |

3D-Move uses tire-pavement interaction-induced loading to model pavement responses. This is a critical factor considering that the noncircular loaded area and non-uniform contact stress induced from the tires can significantly affect pavement response computation. In addition, the tire-induced load varies with the vehicle's speed as it travels through the pavement. To ensure the success of mechanistic modeling, tire-pavement interaction, loading characteristics, and material behavior need to be incorporated realistically. However, Conventional multi-layer programs such as BISAR, ELSYM, and WESLEA software are simple to use. Still, they do not accurately consider the mechanisms associated with moving tire-induced loading on the pavement. Most of them are limited to defining static uniform circular loads. Moreover, the software developed based on Burimister’s layered theory solves for an elastic multilayered system under stationary single or multiple circular loaded areas with uniform normal contact pressure [30]. | 3D-Move uses tire-pavement interaction-induced loading to model pavement responses. This is a critical factor considering that the noncircular loaded area and non-uniform contact stress induced from the tires can significantly affect pavement response computation. In addition, the tire-induced load varies with the vehicle's speed as it travels through the pavement. To ensure the success of mechanistic modeling, tire-pavement interaction, loading characteristics, and material behavior need to be incorporated realistically. However, Conventional multi-layer programs such as BISAR, ELSYM, and WESLEA software are simple to use. Still, they do not accurately consider the mechanisms associated with moving tire-induced loading on the pavement. Most of them are limited to defining static uniform circular loads. Moreover, the software developed based on Burimister’s layered theory solves for an elastic multilayered system under stationary single or multiple circular loaded areas with uniform normal contact pressure [30]. | ||

| − | '''3. Defining Loading Characteristics''' | + | <nowiki> </nowiki>'''3. Defining Loading Characteristics''' |

The load applied by a moving vehicle varies with its traveling speed and pavement surface characteristics. Conventional response analysis tools typically ignore this variation in the moving load. However, 3D-Move analysis is considered loading characteristics with different traveling speeds because vehicle speed influences pavement response computation such as strain and deflection. | The load applied by a moving vehicle varies with its traveling speed and pavement surface characteristics. Conventional response analysis tools typically ignore this variation in the moving load. However, 3D-Move analysis is considered loading characteristics with different traveling speeds because vehicle speed influences pavement response computation such as strain and deflection. | ||

| − | '''4. Axle Configuration and Contact Pressure Distribution''' | + | <nowiki> </nowiki>'''4. Axle Configuration and Contact Pressure Distribution''' |

In 3D-Move Analysis, the pavement contact stress distribution is input data and assumes simple contact stress distributions such as circular or elliptical loaded areas with uniform vertical stress. However, in reality, the pavement contact stress distributions are non-uniform and more complex. The 3D-Move Analysis considers six loading conditions and is classified into an option; each option has been predefined in different load cases. These are: - Option A: Pre-defined load cases, Option B: User selected Pre-defined Axle/ Tire Configuration (Uniform pressure), Option C: User selected Tire Configuration and Contact Pressure Distribution from Database, Option D: Semi-Trailer Truck Including Vehicle Dynamics, Option E: Special Non-Highway Vehicles, and Options F: User-Input Tire Configuration and Contact Pressure Distribution [31]. | In 3D-Move Analysis, the pavement contact stress distribution is input data and assumes simple contact stress distributions such as circular or elliptical loaded areas with uniform vertical stress. However, in reality, the pavement contact stress distributions are non-uniform and more complex. The 3D-Move Analysis considers six loading conditions and is classified into an option; each option has been predefined in different load cases. These are: - Option A: Pre-defined load cases, Option B: User selected Pre-defined Axle/ Tire Configuration (Uniform pressure), Option C: User selected Tire Configuration and Contact Pressure Distribution from Database, Option D: Semi-Trailer Truck Including Vehicle Dynamics, Option E: Special Non-Highway Vehicles, and Options F: User-Input Tire Configuration and Contact Pressure Distribution [31]. | ||

| − | '''5. Characterization of Asphalt Materials''' | + | <nowiki> </nowiki>'''5. Characterization of Asphalt Materials''' |

The asphalt layer can be characterized as a linear elastic material or as a viscoelastic material. The dynamic modulus is required for the viscoelastic analysis. Therefore, 3D Move Analysis Software allows the analysis to input the frequency sweep test data (E*, G*, and phase angle δ data) of asphalt mixes. It was taken into account the viscoelastic material properties in the analysis and can be input in three different ways, but the other software is not considered [14, 15]. | The asphalt layer can be characterized as a linear elastic material or as a viscoelastic material. The dynamic modulus is required for the viscoelastic analysis. Therefore, 3D Move Analysis Software allows the analysis to input the frequency sweep test data (E*, G*, and phase angle δ data) of asphalt mixes. It was taken into account the viscoelastic material properties in the analysis and can be input in three different ways, but the other software is not considered [14, 15]. | ||

| − | '''6. Performance Models''' | + | <nowiki> </nowiki>'''6. Performance Models''' |

The current version of 3D-Move analysis software is equipped with two pavement prediction models: NCHRP 137A and VESYS performance models. These models primarily have cracking and rutting distress modes. However, the software listed above is not considered such a type of condition. | The current version of 3D-Move analysis software is equipped with two pavement prediction models: NCHRP 137A and VESYS performance models. These models primarily have cracking and rutting distress modes. However, the software listed above is not considered such a type of condition. | ||

| Line 168: | Line 168: | ||

'''3. Results and discussion''' | '''3. Results and discussion''' | ||

| − | '''The Effect of PET on conventional properties of Unaged Asphalt binder''' | + | <nowiki> </nowiki>'''3.1. The Effect of PET on conventional properties of Unaged Asphalt binder''' |

| − | <nowiki> </nowiki>'''The Effect of PET plastic on the Penetration Test''' | + | <nowiki> </nowiki> 3.1.1. '''The Effect of PET plastic on the Penetration Test''' |

The test results of the asphalt binder 60/70 grade prepared at the various percentage of PET plastic 0, 3, 6, and 9% by total weight of asphalt binder. ''Figure 4'' represents the effect of variable concentrations of PET plastic on the penetration properties of asphalt binder and presented that decreased penetration grade values by 10.2%, 25.8%, and 31.5% with an increase in the concentration of PET plastic by addition of 3%, 6%, and 9% of PET, respectively, as compared to the original bitumen. This shows the increase in stiffness and consistency of bitumen. The stiffness of the bitumen can be advantageous as it increases the stiffness of the material and improves the rutting resistance of the mix. The 3% PET modified bitumen penetration grade value is not a significant change from the original bitumen grade range. However, When 6% and 9% PET by weight of bitumen mixed, the penetration result become 49.3mm and 45.5mm, respectively, which is closer to bitumen grade 40/50. This mix can be suitably used in hotter climatic conditions, especially in regions with a substantially higher temperature differential. ''Figure 4'' shows the linearity equation (PT= -2.4488%PET + 66.253) indicate that one percent of PET plastic adding decreased 2.4488 unit value of penetration grade from the original asphalt binder. | The test results of the asphalt binder 60/70 grade prepared at the various percentage of PET plastic 0, 3, 6, and 9% by total weight of asphalt binder. ''Figure 4'' represents the effect of variable concentrations of PET plastic on the penetration properties of asphalt binder and presented that decreased penetration grade values by 10.2%, 25.8%, and 31.5% with an increase in the concentration of PET plastic by addition of 3%, 6%, and 9% of PET, respectively, as compared to the original bitumen. This shows the increase in stiffness and consistency of bitumen. The stiffness of the bitumen can be advantageous as it increases the stiffness of the material and improves the rutting resistance of the mix. The 3% PET modified bitumen penetration grade value is not a significant change from the original bitumen grade range. However, When 6% and 9% PET by weight of bitumen mixed, the penetration result become 49.3mm and 45.5mm, respectively, which is closer to bitumen grade 40/50. This mix can be suitably used in hotter climatic conditions, especially in regions with a substantially higher temperature differential. ''Figure 4'' shows the linearity equation (PT= -2.4488%PET + 66.253) indicate that one percent of PET plastic adding decreased 2.4488 unit value of penetration grade from the original asphalt binder. | ||

| Line 176: | Line 176: | ||

Figure 4 Penetration test result with different PET | Figure 4 Penetration test result with different PET | ||

| − | <nowiki> </nowiki>'''The Effect of PET plastic on the Ductility Test''' | + | <nowiki> </nowiki> 3.1.2 '''The Effect of PET plastic on the Ductility Test''' |

<nowiki> </nowiki>''Figure 5'' shows the effect of various percentages of bitumen modified PET plastic on the ductility value of bitumen. The Ductility of the original bitumen value showed slightly reduced by 5.6% with 3% PET plastic and gradually decreased with the addition of a different percentage of PET plastic reduced by 31.6% with 6%. At 9% PET plastic, the ductility value is highly reduced by 40.1% compared with the original bitumen. But still, now, the value is satisfied with the ERA specification. This shows that the adhesive property of the modified binder decrease with an increase in the concentration of PET due to low interlocking between excessive polymer molecules with bitumen and makes bitumen stiffer. Therefore, the optimum percentage of this PET plastic is necessary for the desired value of Ductility of bitumen needed for construction work. ''Figure 5'' shows the linearity equation (DT= -6.9%PET + 145.63) indicate that one percent of PET plastic adding decreased 6.9 unit value of ductility value from the original asphalt binder. | <nowiki> </nowiki>''Figure 5'' shows the effect of various percentages of bitumen modified PET plastic on the ductility value of bitumen. The Ductility of the original bitumen value showed slightly reduced by 5.6% with 3% PET plastic and gradually decreased with the addition of a different percentage of PET plastic reduced by 31.6% with 6%. At 9% PET plastic, the ductility value is highly reduced by 40.1% compared with the original bitumen. But still, now, the value is satisfied with the ERA specification. This shows that the adhesive property of the modified binder decrease with an increase in the concentration of PET due to low interlocking between excessive polymer molecules with bitumen and makes bitumen stiffer. Therefore, the optimum percentage of this PET plastic is necessary for the desired value of Ductility of bitumen needed for construction work. ''Figure 5'' shows the linearity equation (DT= -6.9%PET + 145.63) indicate that one percent of PET plastic adding decreased 6.9 unit value of ductility value from the original asphalt binder. | ||

| Line 182: | Line 182: | ||

Figure 5 Ductility test result with different PET | Figure 5 Ductility test result with different PET | ||

| − | '''The Effect of PET plastic on the Softening point Test''' | + | <nowiki> </nowiki>'''3.1.3. The Effect of PET plastic on the Softening point Test''' |

<nowiki> </nowiki>''Figure 6'' show that softening point value increases with increasing PET plastic content. This phenomenon depicts that the resistance of the binder to the effect of heat is increased and reduced its tendency to soften at high temperature. Thus, with the addition of PET, the modified binder becomes less susceptible to temperature changes. Consequently, by using PET plastic waste in a bituminous mix, the rate of Rutting decreases due to the increase in softening point. ''Figure 6'' shows the linearity equation (SF= 1.533%PET + 47.65) indicate that one percent of PET plastic adding increased by 1.533 units of softening value from the original asphalt binder. | <nowiki> </nowiki>''Figure 6'' show that softening point value increases with increasing PET plastic content. This phenomenon depicts that the resistance of the binder to the effect of heat is increased and reduced its tendency to soften at high temperature. Thus, with the addition of PET, the modified binder becomes less susceptible to temperature changes. Consequently, by using PET plastic waste in a bituminous mix, the rate of Rutting decreases due to the increase in softening point. ''Figure 6'' shows the linearity equation (SF= 1.533%PET + 47.65) indicate that one percent of PET plastic adding increased by 1.533 units of softening value from the original asphalt binder. | ||

| Line 188: | Line 188: | ||

Figure 6 Softening Point test result with different PET | Figure 6 Softening Point test result with different PET | ||

| − | '''The Aging Effect of Bitumen on the conventional tests using RTFO''' | + | <nowiki> </nowiki>'''3.1.4. The Aging Effect of Bitumen on the conventional tests using RTFO''' |

After aging the modified bitumen, Penetration, Ductility, and softening point tests were conducted for each percentage of mixes for the 0%, 3%, 6%, and 9% PET plastic. After aging, the result of penetration, Ductility, and softening point value decreased because of both air oxidation, polymerization (molecules combined and form large molecule), and loss of more volatile components. ''Figure 7, Figure 8'', and ''Figure 9'' Showed that the gap between the aged and unaged value of penetration, Ductility, and softening point decreased with increased concentration of PET plastic. This shows that the original asphalt binder becomes highly aged when exposed to air and heat compared with modified asphalt binder and decreased the aging character because the plastic concentration reduced the amount of asphalt binder content and decreased the oxidation and loss of volatile components. | After aging the modified bitumen, Penetration, Ductility, and softening point tests were conducted for each percentage of mixes for the 0%, 3%, 6%, and 9% PET plastic. After aging, the result of penetration, Ductility, and softening point value decreased because of both air oxidation, polymerization (molecules combined and form large molecule), and loss of more volatile components. ''Figure 7, Figure 8'', and ''Figure 9'' Showed that the gap between the aged and unaged value of penetration, Ductility, and softening point decreased with increased concentration of PET plastic. This shows that the original asphalt binder becomes highly aged when exposed to air and heat compared with modified asphalt binder and decreased the aging character because the plastic concentration reduced the amount of asphalt binder content and decreased the oxidation and loss of volatile components. | ||

| Line 198: | Line 198: | ||

Figure 9 Comparison between Softing Point for aged and unaged binder | Figure 9 Comparison between Softing Point for aged and unaged binder | ||

| − | '''The Numerical Results of Pavement Response with and without PET plastic''' | + | <nowiki> </nowiki>'''3.2. The Numerical Results of Pavement Response with and without PET plastic''' |

In this section, to compare the performance of plastic pavement with the normal pavement by considering the effects of loading a moving tire on the pavement by a recreation of dual tire single, dual tire tandem, and Super single tire tandem-axle vehicle loading conditions with 3 million repetitions during the design period of 20 years. A typical 4-layer flexible pavement structure was used in the analysis, consisting of a 5cm AC layer, 25cm base course, 30cm Sub-base, and subgrade. | In this section, to compare the performance of plastic pavement with the normal pavement by considering the effects of loading a moving tire on the pavement by a recreation of dual tire single, dual tire tandem, and Super single tire tandem-axle vehicle loading conditions with 3 million repetitions during the design period of 20 years. A typical 4-layer flexible pavement structure was used in the analysis, consisting of a 5cm AC layer, 25cm base course, 30cm Sub-base, and subgrade. | ||

Revision as of 18:22, 2 March 2023

1 Title, abstract and keywords

Evaluation of conventional behaviour of bitumen containing PET plastic and HMA pavement response utilizing 3D-Move analysis software

'Nahusenay Muluken Tessera*[1], Emer Tucay Quezon[2], and Thomas Bezabih Bashe[3]'

*Corresponding author’s e-mail: nahutesera@gmail.com

ABSTRACT

A well-developed road network provides good services for road consumers. Most roads in the world are flexible types of pavement. Bitumen is viscous-elastic properties and is very sensitive to temperature; it plays a vital role in the production of hot mix asphalt and influences the performance of HMA pavement. Flexible pavements are linked to extreme high-temperature causing rutting and fatigue cracking. Pavement distress shortens service life and increases maintenance costs. This research focused on improving pavement resistance to distresses by modifying the conventional properties of bitumen using alternative materials such as shredded PET plastic. In this study, two stages were applied. The first stage was collecting samples, and the second determined the conventional properties of bitumen by adding 3%, 6%, and 9% of shredded PET plastic in the bitumen. Penetration, Ductility, and Softening point tests were conducted to analyze the conventional behavior of bitumen. Finally, for evaluating rutting damage, top-down, and bottom-up crack, utilizing 3D-Move analysis software by considering moving vehicles under various loads and speeds. From the conventional bitumen test, at 3% PET plastic add to the bitumen has no significant effect on the penetration grade, Ductility, and softening point. However, when 6% and 9% PET by weight of bitumen mixed, the penetration grade, ductility, and softening result become 49.3mm, 45.5mm, 97mm, 85mm, and 57mm and 62oC, respectively compared with the penetration grade, ductility, and softening point value of unmodified bitumen (66.5mm, 142cm, and 48.9oC). Besides, the 3D-Move Analysis software results that asphalt binders with higher PET plastic content have the best performance to resist the rutting damage, top-down and bottom cracks.

Keywords: Hot mix asphalt, Rutting and fatigue cracking, Polyethylene terephthalate, Maintenance costs, 3D-Move analysis.

[1] *1 Rond ad Transport Engineering Stream, Department of Civil Engineering, School of Civil Engineering and Built Environment, Hawassa Institute of Technology, Hawassa University, Hawassa, Ethiopia.

[2] 2 Professor (Associate)-Cagayan State University-Carig Campus, College of Engineering & Architecture, Civil Engineering Department, Tuguegarao City 3500, Cagayan Valley Region-Region 02, PHILIPPINES.

[3] 3Lecturer, Highway Engineering in Civil Engineering Department, School of Civil Engineering and Built Environment Hawassa University, Institute of Technology, Hawassa University, Hawassa, Ethiopia.

2 The main text

1. Introduction

Transport has become a significant economic sector globally, and most roads in the world are flexible types of pavement [1]. A well-developed road network facilitates the transportation and marketing of farm products, while bad roads are delaying the movement of goods and services from producers to consumers and farm products from the rural areas to urban centers, which leads to vehicle damage and affects the socio-economic activity of the society [2]. Most roads in Ethiopia are also flexible pavement types [3].

Bitumen is the raw material in the construction of HMA pavement. It is a visco-elastic material at a moderate temperature. It is susceptible to the temperature that stiffens when low and softens when the temperature becomes high. At high temperatures, it fails by Rutting because it is soft, and at low temperatures, it fails by thermal cracking [4]. These failers are the most predominant distress types in the hot mix asphalt pavements [5]. This distress declines the service life of the pavement, develops higher surface roughness, leads to vehicle damage and reduced comfort of passengers, and increases the cost of maintenance [6, 7]. There are different solutions to reduce pavement distresses. The method to improve the quality of bitumen by modification like Polymers, crumb rubber, and fiber modification helped enhance the performance of asphalt pavements by increasing the fatigue life and maximizing the resistance cracking and permanent deformation [8]. The Properties of asphalt can be improved by controlling the refines process are very difficult to achieve. Therefore, the most favored method to enhance the quality of asphalt by modification with Polymer is to enhance the hot mix asphalt pavement performance [6, 9]. Nowadays, many types of research have been conducting on using Polymer in road construction, such as Plastic roads, because it has two benefits and more available. One is used as a modifier in the hot mix asphalt pavement, and the other is better to protect the environment from pollution [10].

Improvement of road performance is necessary because there are several traffic factor-like heavier loads, higher traffic volume, and higher tire pressure. [5, 11]. [12] explain that the shredded PET plastic added to hot aggregates forms a fine plastic coat over the aggregate. The coated aggregates mix with asphalt is found to have higher strength and resistance to Rutting and satisfactory performance over the life of the pavement.

The current procedures used to compute pavement responses are much simpler; the stress distributions at the tire-pavement interface are modeled as static, dynamic, uniform and non-uniform, and stationary circular loads [13]. Moreover, 3D Move Analysis Software entering the frequency sweep test data (E* and G* test data) of asphalt mixes in the analysis. It was taken into account the properties of the viscoelastic material in the investigation. Furthermore, 3D Move Analysis software is utilized stresses and strains due to loading to predict rutting depths, top-down and bottom-up cracking due to loading of asphalt pavement [14, 15].

2. Materials and methods

2.1. Study Area

The study was conducted at the AAiT and AAST university highway laboratory, Addis Ababa, Ethiopia, because of the laboratory equipment's availability to be undertaken for the laboratory tests. Addis Ababa is the capital city of Ethiopia. It is also the largest city in the country by population.

2.2. Materials

The raw materials utilized for the laboratory study include Bitumen 60/70 penetration grade and shredded PET plastic. The equipment was also used to evaluate Penetration, Ductility, and Softening point tests and mechanical mixers to produce the modified bitumen to produce homogenous mixtures.

2.3. Research Design

The study used an experimental research method to answer the research question and meet the objectives. The study work follows two phases: - The first phase was sample collection. At this phase, Bitumen 60/70 penetration grade and shredded PET plastic were collected. The second phase was a laboratory test, which followed the ERA, AASHTO, and ASTM procedures. This phase is further classified into two steps. Step-I Quality testing- The quality of the bitumen was tested and compared with the ERA specification and checked that it fulfils the ERA specification. Step-II conventional and Dynamic shear modulus test (DSR)- to determine Penetration, Ductility, and Softening point test values and frequency sweep test data (E*, G*, and phase angle test data) respectively by adding 3, 6, and 9% of shredded PET plastic in the bitumen. The asphalt quality tests are shown in Table 1. In addition, to compare the performance of PET plastic pavement with the normal pavement by considering the effects of loading a moving tire on the pavement by considering dual tire single, dual tire tandem, and Super single tire tandem-axle vehicle loading conditions. The general framework of the study is shown below in Figure 1.

Figure 1 The major framework of the study

Table 1 Asphalt quality tests

|

Conventional Asphalt physical test |

Test Method |

|

Penetration Grade test |

AASHTO T 49 |

|

Ductility test |

AASHTO T 51-94 |

|

Softening point test |

AASHTO T53-06 |

2.4. Mixing of PET plastic with bitumen

The shredded PET plastic that is remained after passing through the 4.75mm sieve size used. The wet process is used in the melt-blending technique. Bitumen heated in the oven till fluid condition and shredded plastic slowly added the temperature of 150-1600C. The mix continued for 45-60min to produce homogenous mixtures. The Polymer modified asphalt was sealed in containers and stored for further testing. Finally, performance tests were used as Conventional physical tests and DSR (Frequency Sweep test) [16, 17, 18].

2.4.1. Conventional Asphalt Binder Physical Tests

Different tests were performed according to AASHTO test Standards to characterize the properties of bitumen, which mixed with shredded PET plastic a range of 3-9% by the increment of 3% by the weight of the bitumen. The different percent of shredded plastic was added to the bitumen and mixed 45-60min at a temperature 150-1600C to ensure good homogeneity; then, various tests were performed. First, the asphalt binder was heated at a temperature of 1500C.

I. Penetration test

According to AASHTO T 49, a 100g sample of asphalt binder with 3%, 6%, and 9% by weight of sample shredded plastic was heated in an oven for enough time to soften entirely and uniformly mixed. Then it was transferred into a penetration test cup and allowed to cool to room temperature for 1 hour. The sample was then placed in water with a temperature controller set to 250C and allowed to condition for about 1 hour. It was then removed, dried the water quickly, and placed under the needle of the penetrometer. Then three readings were taken for a single penetration cup after placing the tip of the penetrometer needle precisely at the surface of the cup before the instrument was started. The average of the three sample values was recorded [19, 20]

II. Ductility test

According to AASHTO T 51, the asphalt binder mixed with 3%, 6%, and 9% by weight of sample shredded plastic was heated and poured in the mold assembly placed on a plate. The samples were cooled in the air at room temperature for about 30min and then put in a water bath at 27°C temperature. The mold has removed on both sides and hooked on the machine; then, the assembly-contained sample was kept in a water bath of the ductility machine range of 80-90 minutes, and the machine was operated. Finally, measured a ductility value, the distance from the point up to break off the thread, and recorded in cm [21].

III. Softening Point test

AASTO T 53 stated that asphalt binder mixed with 0, 3, 6, and 9% PET shredded plastic by weight of binder should be heated and poured into two small brass rings and allowed to cool. A heated knife blade was used to trim the surface of the samples to the level of the brass rings. The prepared samples were then conditioned in a temperature controller at 4°C for at least 30 minutes before the test. A steel 3.55gm ball-bearing was centered on each specimen and placed in a glass jar. An electric heater and thermometer were fitted into the beaker filled with clean, distilled water. The temperature when each of the balls and samples touches the bottom plate of support was recorded as softening point value. The average of two read values was taken and rounded to the nearest whole degree [19, 22].

IV. Rolling Thin-film Oven test (RTFO)

According to AASHTO T 240, a rolling thin film oven test (RTFO) follows aging asphalt binders' basic steps. The RTFO simulates the asphalt binder aging (hardening) during the production and construction of HMA pavement [23]. It exposes the fresh binder to heat and airflow during rolling. It takes only 85min to perform the test, then provides an aged asphalt binder for further testing by the DSR and conventional asphalt test. The amount of volatile loss indicates the total aging that may occur during HMA production and construction [24].

V. Dynamic Shear Modulus test

Frequency sweep tests:- were also performed to determine the dynamic shear modulus G* and phase angle δ on the temperatures at 21.1, 37.8, and 54.40C with 0, 3, 6, and 9% shredded PET plastic mixed with bitumen. The shear strain was applied for all the samples, and the frequency range used was 0.1Hz to 25Hz [25, 26].

2.5. 3D-Move Analysis Software

3D-Move analysis software is a continuum-based finite-layer approach to analyze asphalt pavement responses under various moving traffic load, traffic velocity, axle configurations, and tire contact areas to a pavement structure. The Asphalt Research Consortium developed the software. Which is a group of five organizations; Texas A&M University, Western Research Institute, University of Nevada-Reno (UNR), University of Wisconsin-Madison, and Advanced Asphalt Technologies and available at http://www.arc.unr.edu/Index.html. Moreover, 3D Move Analysis Software entering the frequency sweep test data (E* and G* test data) of asphalt mixes in the analysis. It was taken into account the properties of the viscoelastic material in the study. Furthermore, 3D Move Analysis software utilized stresses and strains due to loading to predict rutting depths, top-down and bottom-up cracking due to loading of asphalt pavement [14], [15]. The main screen of 3D-Move Analysis software Ver 2.1 in Figure 2.

Figure 2 Screen Shoot of Main Screen of 3D Move Analysis software

2.5.1. 3D-Move Analysis of software selection criteria

Most mechanistic procedures used to compute pavement responses are simpler; the tire-pavement interface's stress distributions are modeled as static, uniform, and stationary circular loads. For example, ELSYM5, WESLEA 3.0, BISAR 3.0, CIRCLY 7.0, KENLAYER, ILLI-PAVE, MICH-PAVE [13]. Therefore, compare 3D-Move Analysis software with others based on different conditions. These are:-

1. Model Approach

The 3D-Move model has been recognized as an efficient tool to simulate moving loads compared to the other software because the 3D-Move program uses a finite layer approach and Fourier Transform Technique for estimating pavement responses. This Fourier series expansion decomposes the loads into harmonic components in space (x and y directions). The total response at a given location is then calculated by adding the individual responses from each harmonic component [27, 28]. It can handle any number of layers with complex loading at the surface and any number of response evaluation points. The 3D-Move model is ideally suited for pavement response evaluations since only a few critical responses are needed for pavement performance evaluations. Therefore, 3D-Move performs much more computationally efficient than the moving load models based on the finite element method such as KENLAYER, ILLI-PAVE, and MICH-PAVE [29].

2. Tire-Pavement Interaction

3D-Move uses tire-pavement interaction-induced loading to model pavement responses. This is a critical factor considering that the noncircular loaded area and non-uniform contact stress induced from the tires can significantly affect pavement response computation. In addition, the tire-induced load varies with the vehicle's speed as it travels through the pavement. To ensure the success of mechanistic modeling, tire-pavement interaction, loading characteristics, and material behavior need to be incorporated realistically. However, Conventional multi-layer programs such as BISAR, ELSYM, and WESLEA software are simple to use. Still, they do not accurately consider the mechanisms associated with moving tire-induced loading on the pavement. Most of them are limited to defining static uniform circular loads. Moreover, the software developed based on Burimister’s layered theory solves for an elastic multilayered system under stationary single or multiple circular loaded areas with uniform normal contact pressure [30].

3. Defining Loading Characteristics

The load applied by a moving vehicle varies with its traveling speed and pavement surface characteristics. Conventional response analysis tools typically ignore this variation in the moving load. However, 3D-Move analysis is considered loading characteristics with different traveling speeds because vehicle speed influences pavement response computation such as strain and deflection.

4. Axle Configuration and Contact Pressure Distribution

In 3D-Move Analysis, the pavement contact stress distribution is input data and assumes simple contact stress distributions such as circular or elliptical loaded areas with uniform vertical stress. However, in reality, the pavement contact stress distributions are non-uniform and more complex. The 3D-Move Analysis considers six loading conditions and is classified into an option; each option has been predefined in different load cases. These are: - Option A: Pre-defined load cases, Option B: User selected Pre-defined Axle/ Tire Configuration (Uniform pressure), Option C: User selected Tire Configuration and Contact Pressure Distribution from Database, Option D: Semi-Trailer Truck Including Vehicle Dynamics, Option E: Special Non-Highway Vehicles, and Options F: User-Input Tire Configuration and Contact Pressure Distribution [31].

5. Characterization of Asphalt Materials

The asphalt layer can be characterized as a linear elastic material or as a viscoelastic material. The dynamic modulus is required for the viscoelastic analysis. Therefore, 3D Move Analysis Software allows the analysis to input the frequency sweep test data (E*, G*, and phase angle δ data) of asphalt mixes. It was taken into account the viscoelastic material properties in the analysis and can be input in three different ways, but the other software is not considered [14, 15].

6. Performance Models

The current version of 3D-Move analysis software is equipped with two pavement prediction models: NCHRP 137A and VESYS performance models. These models primarily have cracking and rutting distress modes. However, the software listed above is not considered such a type of condition.

NCHRP 1-37A performance prediction model consists of six distress modes:

· AC Top-down & Bottom-up cracking

· AC (Asphalt Concrete) Rutting

· Base Rutting

· Subbase Rutting and

· Subgrade Rutting.

VESYS Model:- is a well-documented probabilistic and mechanistic flexible pavement analysis computer program series [32]. This model also has been incorporated into 3D-Move Analysis software to predict the structural responses and the integrity of flexible pavements. VESYS model for flexible pavements consists of a primary response model and a damage model. The primary response model is the time-dependent state of stress, strain, or deformation in the pavement. The direct response model represents the pavement system by an n-layer semi-infinite continuum such that the upper n-1 layers are finite in thickness.

All layers are infinite to a horizontal extent. In contrast, the bottom layer is infinite in extent. The materials in each layer are assumed to be isotropic and homogeneous. While the damage model in the VESYS model consists of three independent models to predict the accumulation of pavement cracking, Rutting, and roughness within a given design period [31].

Under such circumstances, 3D-Move performs much more efficiently than the other moving load models based on the finite element method.

Figure 3 General Procedure of 3D-Move Analysis Software

3. Results and discussion

3.1. The Effect of PET on conventional properties of Unaged Asphalt binder

3.1.1. The Effect of PET plastic on the Penetration Test

The test results of the asphalt binder 60/70 grade prepared at the various percentage of PET plastic 0, 3, 6, and 9% by total weight of asphalt binder. Figure 4 represents the effect of variable concentrations of PET plastic on the penetration properties of asphalt binder and presented that decreased penetration grade values by 10.2%, 25.8%, and 31.5% with an increase in the concentration of PET plastic by addition of 3%, 6%, and 9% of PET, respectively, as compared to the original bitumen. This shows the increase in stiffness and consistency of bitumen. The stiffness of the bitumen can be advantageous as it increases the stiffness of the material and improves the rutting resistance of the mix. The 3% PET modified bitumen penetration grade value is not a significant change from the original bitumen grade range. However, When 6% and 9% PET by weight of bitumen mixed, the penetration result become 49.3mm and 45.5mm, respectively, which is closer to bitumen grade 40/50. This mix can be suitably used in hotter climatic conditions, especially in regions with a substantially higher temperature differential. Figure 4 shows the linearity equation (PT= -2.4488%PET + 66.253) indicate that one percent of PET plastic adding decreased 2.4488 unit value of penetration grade from the original asphalt binder.

Figure 4 Penetration test result with different PET

3.1.2 The Effect of PET plastic on the Ductility Test

Figure 5 shows the effect of various percentages of bitumen modified PET plastic on the ductility value of bitumen. The Ductility of the original bitumen value showed slightly reduced by 5.6% with 3% PET plastic and gradually decreased with the addition of a different percentage of PET plastic reduced by 31.6% with 6%. At 9% PET plastic, the ductility value is highly reduced by 40.1% compared with the original bitumen. But still, now, the value is satisfied with the ERA specification. This shows that the adhesive property of the modified binder decrease with an increase in the concentration of PET due to low interlocking between excessive polymer molecules with bitumen and makes bitumen stiffer. Therefore, the optimum percentage of this PET plastic is necessary for the desired value of Ductility of bitumen needed for construction work. Figure 5 shows the linearity equation (DT= -6.9%PET + 145.63) indicate that one percent of PET plastic adding decreased 6.9 unit value of ductility value from the original asphalt binder.

Figure 5 Ductility test result with different PET

3.1.3. The Effect of PET plastic on the Softening point Test

Figure 6 show that softening point value increases with increasing PET plastic content. This phenomenon depicts that the resistance of the binder to the effect of heat is increased and reduced its tendency to soften at high temperature. Thus, with the addition of PET, the modified binder becomes less susceptible to temperature changes. Consequently, by using PET plastic waste in a bituminous mix, the rate of Rutting decreases due to the increase in softening point. Figure 6 shows the linearity equation (SF= 1.533%PET + 47.65) indicate that one percent of PET plastic adding increased by 1.533 units of softening value from the original asphalt binder.

Figure 6 Softening Point test result with different PET

3.1.4. The Aging Effect of Bitumen on the conventional tests using RTFO

After aging the modified bitumen, Penetration, Ductility, and softening point tests were conducted for each percentage of mixes for the 0%, 3%, 6%, and 9% PET plastic. After aging, the result of penetration, Ductility, and softening point value decreased because of both air oxidation, polymerization (molecules combined and form large molecule), and loss of more volatile components. Figure 7, Figure 8, and Figure 9 Showed that the gap between the aged and unaged value of penetration, Ductility, and softening point decreased with increased concentration of PET plastic. This shows that the original asphalt binder becomes highly aged when exposed to air and heat compared with modified asphalt binder and decreased the aging character because the plastic concentration reduced the amount of asphalt binder content and decreased the oxidation and loss of volatile components.

Figure 7 Comparison between penetration for aged and unaged binder

Figure 8 Comparison between Ductility for aged and unaged binder

Figure 9 Comparison between Softing Point for aged and unaged binder

3.2. The Numerical Results of Pavement Response with and without PET plastic

In this section, to compare the performance of plastic pavement with the normal pavement by considering the effects of loading a moving tire on the pavement by a recreation of dual tire single, dual tire tandem, and Super single tire tandem-axle vehicle loading conditions with 3 million repetitions during the design period of 20 years. A typical 4-layer flexible pavement structure was used in the analysis, consisting of a 5cm AC layer, 25cm base course, 30cm Sub-base, and subgrade.

Results showed that AC Rutting, top-down, and bottom-up cracking decrease with increased PET contents. Figure 10 shows that the rutting depths in the asphalt concrete layer decreased with PET plastic content. At 0 and 3%, plastic content has no significant variation, while at 6 and 9% PET content, the rutting failer decreases with increased PET. Furthermore, Dual tire single axle load has more significant pavement damage than another load case because the load is concentrated and higher load effect on the pavement. In contrast, super single tire tandem axle load has a lower impact than others because it has more than two axles and a single broader tire base. Due to this, a higher contact surface area leads to the distribution of the load uniformly and decreases the pressure. In addition to this, the rutting resistance of a modified binder is better than a conventional binder.

Figure 11 also shows that the top-down cracking results followed the same trend as Rutting, at 3%PET plastic has slightly higher than the conventional binder. However, at 6 and 9%, PET plastic content have a lower top-down value and best performance. It indicates that the PET plastic modifier binder has better resistance to top-down cracking at the top of the pavement by decreasing High surface horizontal tensile stresses due to truck tires, age hardening of the asphalt binder resulting in high thermal stresses in the HMA, and modify the stiffness of the upper layer caused by high surface temperatures. Figure 12 indicate that HMA pavement has a better resistance of bottom-up cracking when the PET content increase. It means that the modified binder of HMA pavement has a better resistance of tensile bending stresses at the bottom of the HMA layer and then progresses up to the pavement's surface. Super single tire tandem axle load has a lower value than others. Overall results of the analysis showed that asphalt binders with higher PET plastic content have the best performance since the stiffness of the asphalt mixes would increase with the addition of PET plastic. Thus, making asphalt mixes perform better and its resistance to distresses higher.

Figure 10 Effect of PET content on Rutting of asphalt concrete layer

Figure 11 Effect of PET content on the top-down cracking of asphalt concrete layer

Figure 12 Effect of PET content on the bottom-up cracking of asphalt concrete layer

4. Conclusions

This study tries to evaluate bitumen-containing PET plastic's conventional behavior and the pavement response using 3D-Move analysis software. Based on the results obtained from this study, the following conclusions can be made:

The addition of PET plastic changes the bitumen properties by decrease the penetration and ductility value with an increased softening point as the PET plastic content increased. At 3% PET modified bitumen is not a significant change from the original bitumen grade range. However, when 6% and 9% PET by weight of bitumen mixed, the penetration result become 49.3mm and 45.5mm, respectively, which is closer to bitumen grade 40/50. And also, at 3% PET, plastic add to the bitumen has no significant effect on the ductility value of the original bitumen. However, gradually decrease with the increase in the addition of PET plastic.

After aging, penetration, Ductility, and softening point value decreased because of both air oxidation and loss of more volatile components, making it stiffer for all the mixes and decreasing the value.

The results showed that asphalt binders with higher PET plastic content have the best performance to resist the rutting damage, top-down, and bottom crack. At 0 and 3%, plastic content has no significant variation, while at 6 and 9% PET content, the rutting failure decrease with an increase in the PET content. Top-down cracking at 3%PET plastic has slightly higher than the conventional binder. However, at 6 and 9%, PET plastic content have a lower top-down value. Super single tire tandem axle load has a lower value than others.

3 Bibliography

4 Acknowledgments

5 References

Document information

Published on 27/04/25

Submitted on 21/03/23

Volume 1, Issue Issue-1, June, 2025

DOI: https://doi.org/10.5281/zenodo.17597618

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?