Abstract

The parametric study of the indoor environment of green buildings focuses on the quantitative and qualitative improvement of residential building construction in China and the achievement of indoor thermal comfort at a low level of energy use. This study examines the effect of the adaptive thermal comfort of indoor environment control in hot summer and cold winter (HSCW) zones. This work is based on a field study of the regional thermal assessment of two typical cases, the results of which are compared with simulated results of various scenarios of “energy efficiency” strategy and “healthy housing” environmental control. First, the simulated results show that the adaptive thermal comfort of indoor environment control is actually balanced in terms of occupancy, comfort, and energy efficiency. Second, adaptive thermal comfort control can save more energy for heating or cooling than other current healthy housing environmental controls in China׳s HSCW zone. Moreover, a large proportion of energy use is based on the subjective thermal comfort demand of occupants in any building type. Third, the building shape coefficient cannot dominate energy savings. The ratio of the superficial area of a building to the actual indoor floor area has a significant positive correlation with and affects the efficiency of building thermal performance.

Keywords

Adaptive thermal comfort ; Building performance ; Low energy residential buildings ; China HSCW zone ; Simulation

1. Introduction

Chinese urbanization has undergone more than three decades of “reform and opening” (Gu et al., 2012 ). The country׳s economic development has stimulated significant growth in rural areas, the physical size, population, and new residential building construction of which have increase. China׳s national development strategy of “green building” was announced in the special planning outline of the country׳s 12th Five-Year Plan (Wu and Xu, 2013 ; Ye et al ., 2013 ). This green building strategy has two main development targets in new building construction: to produce a comfortable building environment and to encourage the efficient use of energy through energy conservation techniques. The most important design strategy of a residential building has previously focused on energy efficiency, and the building criterion of JGJ134-2010 (MHURD-PRC, 2010 ) usually provided the design standard for indoor environmental design or the guideline for building operation. The key guidelines contained in the document “The Technical Essential for Construction of Healthy Housing” published in 2004 (CNERCHS-PRC, 2004 ) clearly defined the norm of comfort in indoor environmental designs. However, such a green building strategy soon moved beyond economic efficiency and also considered the comfort and well-being of local occupants. Knowledge of user perception and satisfaction in green buildings remains lacking (Gou et al., 2013 ). Gou presented a huge difference in satisfaction and comfort in among different green buildings. They further recommended the need to balance the personal comfort of occupants and sustainable levels of energy use.

A green building is defined as one that is energy- and resource-efficient to sustain the life cycle of its operations while being conducive to the health and comfort of its occupants. Green buildings may be considered as a small-scale “ecological footprint” with the following characteristics or effects: minimal energy use; minimal requirement for water, material, and energy resources throughout its life cycle; conducive to occupant health productivity; and minimal waste, pollution, or environmental degradation (Gabay et al., 2014 ). In other words, a green building is characterized by a sustainable design that meets the needs of present users without compromising the ability of future generations to meet their own needs (Roufechaei et al., 2014 ). The green building revolution has proven to be a significant and irreversible event in the building sector and a change that has improved building environments in urban areas and global environments (USEPA ; USGBC ). The intensive study on 40 green projects and hundreds of existing reviews developed by Lawrence Berkeley Laboratory and Capital E Group (Kats et al., 2003 ) show that the cost of occupant comfort, productivity, and health are larger than those spent on construction and operation. The U.S. Green Building Council launched a survey to present a sustainable building design and identify how such a design can positively affect human living; this survey eventually became a significant study on green buildings (Heerwagen, 2000 ; Reeder, 2010 ; Sighn et al ., 2010 ). Two large-scale studies were also launched by the Center for Built Environment of the University of California, Berkeley in North America (Abbazadeh et al ., ; Brager and Baker, ; Leaman and Bordass, 2007 ) and by Building Uses Studies Ltd. in the UK (Leaman and Bordass, 2007 ). These two studies highlighted the limitations of green building performance and occupant comfort and satisfaction (Fu, 2002a ; Fu, 2002b ). Moreover, the indoor environments of “green buildings” became an extension of research on sustainable design, which focused only on natural impact while disregarding occupancy issues. Only a few relevant parametric studies have focused on the indoor thermal environment of green residential buildings in China with consideration of their thermal comfort and energy efficiency. Regional occupant thermal cognition is becoming increasingly important in building designs that follow the “people first” concept.

A cursory review of the literature shows that two different approaches are employed to define thermal comfort, namely, the heat-balance and adaptive approaches (Djongyang et al., 2010 ). The steady-state heat-balance model of thermal comfort is premised on the deterministic logic of physics-physiology-subjective thermal sensation from climate chamber studies. The adaptive approach differs from the theory of stable thermal transfer; consistent conditions of measurement are impossible in field studies under this approach. This method holds that people achieve thermal comfort by flexibly adapting to the overload in the thermal environment to which they are exposed; this idea is also called the “experiential realism” of determining thermal comfort, which in turn promotes the “real” participation of actual occupants (Schiavon and Melikov, 2008 ). Adaptation is a complex process that determines the negative effects of “adaptive feedback” (Yao, 1997 ). The logic of the adaptive PMV (aPMV ) model developed by Yao holds that the full operational details of human adaptation are complicated and can even be partially unknown because such details are based on an individual׳s own physiological, psychological, and behavioral adjustment ( Yao et al., 2009 ). These complicated processes of the “black box” are based on the concept of cybernetics, which considers the influence of social, economic, cultural backgrounds and of the previous thermal experience on behavioral adaptations. The adaptive thermal comfort approach has been used in the environmental assessment of classrooms (Yao et al., 2010 ), offices ( Bouden and Ghrab, 2005 ; Liu et al ., 2012 ), free-running buildings ( Nicol, 2008 ; Nicol and Humphreys, 2002 ), and air-conditioned buildings (Mui and Chan, 2003 ). Some studies that employ adaptive thermal comfort have been specifically conducted in the context of Indian apartments ( Indraganti, 2010 ; Singh et al ., 2011 ). Only very few studies employ this approach in investigating residential buildings with a mixed mode of natural ventilation (NV) and split air-conditioners (SAC) in China. Residential buildings are usually controlled by a mixed mode of ventilation. NV provides fresh air and cools down the indoor air temperature when the environment is uncomfortably warm, but it results in an unwanted waste of energy ( Liu et al ., 2012 ; Yin et al ., 2010 ). Therefore, NV significantly affects the balance of indoor thermal comfort and energy efficiency.

This study investigates whether the adaptive thermal comfort approach can effectively achieve indoor thermal comfort while saving energy. A parametric simulation is conducted on the basis of data input from field study results. Through the results of the estimations, the actual subjective thermal sensation in local residential buildings is discussed. In particular, we discuss the issue of whether the adaptive thermal comfort approach, including thermal comfort perception and energy performance, improves “green buildings” in a parametric design. This study also extends the investigation on building performance, which used to be defined solely by the “building shape coefficient.”

2. Methodology

2.1. Site and case selection

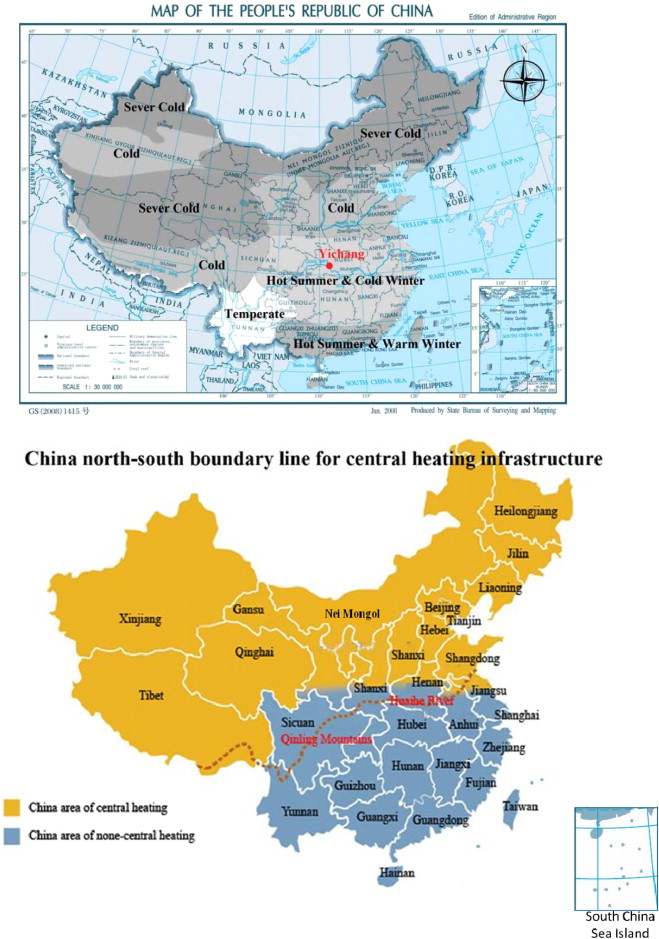

A hot summer and cold winter (HSCW) zone is defined as one of the five thermal design zones that must contend with problems of overheating in hot summers and overcooling in cold winters. The five thermal design zones are defined by thermal design codes (MHURD-PRC, 1993 ; MHURD-PRC, 2011 ) that address building issues under the various weather scenarios in China, which are categorized as “severe cold” (SC), “cold” (C), “moderate” (M), HSCW, and “hot summer and warm winter” (HSWW). Figure 1 shows that a large part of the HSCW zone is located in the middle part of China. A field study was launched in Yichang, which is located in the central part of an HSCW zone in China. The specific classification of the locale is that of a humid subtropical climate under the Koppen climate classification–Cwa (Kottek et al., 2006 ). For historical reasons, no central heating system underpins the design of most indoor thermal environments (see Figure 1 ), and the energy-efficiency standard (JGJ134-2010) for residential buildings recommends that the calculation index of indoor (living room and bedroom) air temperature be set to 18 in winter and 26 in summer. In an NV building, overheating and overcooling are common occurrences. A typical residential apartment in the HSCW zone is designed with NV. However, the indoor thermal environment is actually regulated through mixed control equipped with a SAC and supplemented with a portable electric heater or chiller (NV for fresh air). Consequently, the large amount of electricity used affects the living costs of occupants, particularly in HSCW zones.

|

|

|

Figure 1. Images of China׳s climatic regionalization and heating north–south boundary. (The base map is from the website of the National Administration of Surveying, Mapping and Geoinformation: https://219.238.166.215/mcp/index.asp) |

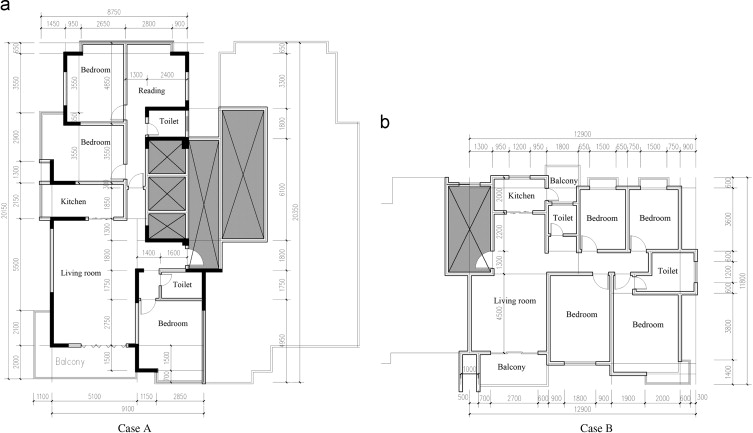

The two selected cases exhibit varying room combinations, as shown in Figure 1 . The majority of external windows follow a north–south orientation. These cases both have four bedrooms and one living room, and only these five rooms are controlled by HVAC installations (involved with thermal calculation). The notation “a” represents case A, which has a longer unit depth than case B. The main building orientation (daylight facade) of case A is perpendicular to the combined direction of the rooms. The notation “b” represents case B, which has the layout of a square unit. The main building orientation of case B is parallel to the combined direction of rooms. These two cases represent a typical apartment design in China׳s residential building market. The apartment designs is this market usually vary in shape, layout, and inner circulation space for corridor direction. This study assesses the functional difference of the inner thermal environment between the two typical cases. The materials used in building construction are nearly similar.

2.2. Questionnaire survey design

The subjective questionnaire survey aims to find out the occupants׳ mean preference for their indoor thermal sensation that is subjective thermal experience preference which is measured on a seven-point scale based on the thermal sensation Bedford scale or ‘comfort vote’ in ASHRAE standard (Nicol and Humphreys, 2002 ). The questionnaire survey is designed to collect the participants׳ thermal sensation preference of AMV. Following is the survey sample mentioned in ASHRAE 55-2010 informative:

- Interviewee׳s background information, such as age, gender, etc. In the summer time there were 20 participants involved in the on-site measurement and 22 participants in winter seasons. Each voluntary participant took multi-testing in 4–5 working days based on his or her personal schedule. Each testing time usually last one hour and two recording time points of every quarter and three-quarter point, and there are 2–3 times in one day. Consequently, there are 365 recording samples of summer survey collected from case A and 362 samples collected from case B. For winter survey there are 352 samples in case A and 292 samples in case B.

- Interviewee׳s clothes and metabolic rate (real-time activity). The clothing insulation is different during the hot summer and cold winter. The metabolic rate of real-time occupants’ activity refers to ASHRAE 55-2010 normative appendix A and Table B1 and B2 (ASHRAE, 2010 ).

- Interviewee׳s actual thermal experience perception (AMV). The actual thermal sensation preference is based on the ASHRAE seven-point thermal sensation scale that enables the participant to provide a simple description about their personal thermal preference in the testing time.

2.3. On-site measurement

The survey for the on-site measurement comprised two sections. The first section measured and recorded the results of the thermal sensation of participants. The data collection was related to the calculation of the PMV model, which is in turn based on Fanger׳s equation. The data measurement of the PMV calculation was synchronized with the questionnaire for the thermal sensation for a duration of four or five consecutive testing days. Approximately 20 participants were involved in the field study in each extreme season (i.e., overheating in summer and overcooling in winter), with 10 for each prototype case. Participants were required to record their indoor thermal responses two to three times in each testing day. Each time the responses were recorded, they were separated into the first half-time and the middle of the next half-time (i.e., one hour was allotted to each test). This study should be helpful in calculating the “adaptive” coefficient λ for the regional (HSCZ zone) discrepancy between the regularity of the actual subjective thermal sensation AMV and the calculation of the empirical PMV model for residential buildings. The actual PMV model was used to present the regional adaptive coefficient of the HSCW zone for the prototype residential apartment in China.

2.4. Simulation

DesignBuilder, which is a state-of-the-art tool for simulating building energy, CO2 , and lighting and for checking thermal comfort performance, was used as simulation software., This tool can achieve rapid 3-D modeling and includes an innovative dynamic energy simulation engine. DesignBuilder was designed by the British company called “DesignBuilder.” This tool was integrated with the popular simulation engine of EnergyPlus designed by the US Department of Energy. This software has a user-friendly interface for architects, HVAC engineers, energy consultant companies, and university research institutions. DesignBuilder can be used in every step of a building project, and its simulation results provide performance data to evaluate and improve the building throughout its life cycle. The DesignBuilder model in this study was defined by the data input and was organized according to a hierarchy, the default data of which was inherited from the level above in the hierarchy. As an input of the activity schedule, the simulation time-step was based on the questionnaire survey from the field study and was designed on an hourly basis. The output simulation time-step is multi-optional. This tool was designed for the daily study of thermal comfort and monthly study of energy consumption. Table 1 ; Table 2 provide construction/opening design detail of cases׳ modeling inputs for material, thickness and U-value of envelop insulation.

| Components | Material layer | Thickness (m) | U -value (W/m2 -K) |

|---|---|---|---|

| External wall | Cement/plaster/mortar–cement plaster (Outer) | 0.015 | 0.946 |

| EPS expanded polystyrene (lightweight) | 0.02 | ||

| Hollow clay brick | 0.20 | ||

| Cement/plaster/mortar–cement plaster (inner) | 0.015 | ||

| Internal wall: | Plaster (dense) | 0.02 | 2.061 |

| Brick-burned | 0.20 | ||

| Plaster (dense) | 0.02 | ||

| Floor: | Cast concrete | 0.20 | 2.237 |

| Flat roof: | Ceramic floor tiles dry | 0.005 | 0.743 |

| Concrete, cast-lightweight | 0.04 | ||

| Glass fiber quilt | 0.005 | ||

| EPS expanded polystyrene (lightweight) | 0.030 | ||

| Cement/plaster/mortar–cement plaster | 0.020 | ||

| Asphalt mastic roofing | 0.005 | ||

| Cement plaster | 0.020 | ||

| Gypsum plaster, perlite aggregate | 0.005 | ||

| Concrete, cast-dense, reinforced | 0.200 | ||

| Internal door | Solid hardwood door (normally hung) | 0.042 | 2.500 |

| External door | Wooden flush panel hollow core door | 0.042 | 2.557 |

| Components | Material layer | Thickness (m) | U -value (W/m2 -K) |

|---|---|---|---|

| Internal window | UPVC window frame+DblClr 6 mm/6 mm Air | 0.018 | 3.157 |

| External window | UPVC window frame+DblLoE (e 2=0.1) Clr 6 mm/13 mm Air | 0.025 | 1.772 |

| Frame construction | UPVC window frame (Polyvinlychloride) | 0.02 | 3.467 |

The environmental control is composed of the indoor air temperature set-point and the value of the set-back air temperature. The set-point value defines the ideal temperature required for cooling or heating, and the set-back value considers a low level of cooling or heating required at a specific time in the occupancy schedule. Such system creates a real effect of mixed control within residential buildings in HSCW zones in China. Table 3 shows three scenarios of indoor environmental control for simulation work. Scenario 1 was extracted from a series of energy-efficient residential buildings, the design standard of which followed the last version of JGJ134-2010 (MHURD-PRC, 2010 ) (16–18 in winter and 26–28 in summer). Scenario 2 was extracted from China׳s healthy housing technical essentials of construction (CNERCHS-PRC, 2004 ) (18–22 in winter and 24–28 in summer). Scenario 3 included the comfortable air temperature range calculated in a field study with the adaptive thermal comfort model and represented the detailed air temperature range of the two typical cases studies.

| Thermal environment control | Scenario 1 | Scenario 2 | Scenario 3 | |

|---|---|---|---|---|

| Both | Both | Case A | Case B | |

| Heating set-point | 18 | 22 | 21.4 | 22.6 |

| Heating set-back | 16 | 18 | 15.4 | 16.8 |

| Cooling set-point | 26 | 24 | 21.4 | 22.6 |

| Cooling set-back | 28 | 28 | 27.4 | 28.3 |

| HVAC supply heating | 20 | 24 | 23.4 | 24.6 |

| HVAC supply cooling | 24 | 22 | 19.4 | 20.6 |

| Natural ventilation cooling | 16 | 18 | 15.4 | 16.8 |

| Max in-out Delta'''T | −50 | −50 | −50 | −50 |

The HVAC supply temperatures are defined as higher than the set-point temperature (neutral point) for heating and lower than that for cooling. Consequently, the heating or cooling supply is designed according to a deviation of 2 °C from the set-point value. In this study, the NV temperature was equal to the set-back temperature that prevents any overcooling in indoor environments that may be caused by NV. The NV simulation is set to the “scheduled” option in DesignBuilder according to the minimum fresh air required per person (30 m3 /h-per person is equal to approximately 8.3 l/s-per person) (CNERCHS-PRC, 2004 ; MHURD-PRC, 2010 ). The scheduled NV option is activated when the indoor air temperature is higher than the NV cooling set-point temperature (see Table 3 ), and the difference between the indoor and outdoor air temperature is less than the maximum value of the inside–outside delta temperature setting (−50 means the NV is unrestricted by the inside–outside delta temperature setting in DesignBuilder).

3. Field study results

Yao et al. (2009) used the least square method to calculate the value of the adaptive coefficient λ . The results of PMV calculation and AMV records are defined as pairs of inputs (x , y ). The (x , y ) function curve is deviated by the least square method to fit each pair of data points. The mathematical formula of the relationship among aPMV , PMV , and λ is as follows:

|

|

( 1) |

In the field study for summer, 31 daily sets of data (PMV calculation and AMV records) were used for case A and 28 for case B. In the field study for winter, 43 daily sets of data were used for case A and 36 for case B. The adaptive coefficients for the two prototype cases in summer and winter can be calculated using Eq. (1) . These values are substituted into the adaptive coefficient formula Eqs. (2) , (3) , (4) ; (5) as listed below.

|

|

( 2) |

|

|

( 3) |

|

|

( 4) |

|

|

( 5) |

The aPMV model equations above show that the PMV values are corrected versus those of the aPMV data set with the subjective adaptive coefficient effect. The use of linear regression analysis enables the relationship between the aPMV values and indoor air temperature to be summarized by the two equations for the two selected cases (for both warm and cold indoor situations).

|

|

( 6) |

|

|

( 7) |

Eqs. (6) ; (7) give an acceptable range of 0 to −1 for 15.4 °C to 21.4 °C, respectively, in cold conditions in case A and a range of 0–1 for 21.4 °C to 27.4 °C, respectively, in hot conditions (i.e., 21.4 °C is the neutral temperature for case A). The equations give a range of 16.8–22.6 °C for case B in cold conditions and 22.6–28.3 °C in hot conditions (i.e., 22.6 °C is the neutral temperature for case B). The temperature at which the air is considered neutral is used as the set-point. The lower limit is the heating set-back point, whereas the upper limit is designed as the cooling set-back point. Table 3 shows three scenarios of simulation input; Scenarios 1 and 2 are respectively based on China׳s current building environment design code of energy efficiency strategy (low level) and healthy housing technical essentials (high level), whereas scenario 3 is based on the above mentioned field study on adaptive thermal comfort strategy (Figure 2 ).

|

|

|

Figure 2. Layout of cases (a) A and (b) B. |

4. Simulation results and discussion

4.1. Indoor thermal comfort perception

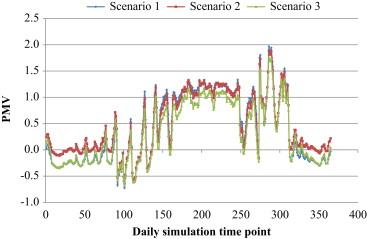

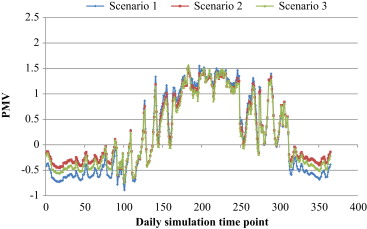

This study assessed building performance using the subjective perception of the thermal environment and Fanger PMV simulated results, which are presented in Figure 3 ; Figure 4 on the basis of the annual values of cases A and B. According to the perception values in case A (see Figure 3 ), nearly all cooling perception assessments are slightly higher than −0.5, which is the midpoint between the neutral point of a comfortable 0 and a slightly cool −1. The warming perception assessment is partly higher than 1.0 (slightly warm), and some of the assessments even reach approximately 2.0 (warm) in late summer. Scenario 3 of the adaptive thermal comfort shows a significant tendency toward a cooler perception in cold winter and hot summer than that scenario 2 of China׳s “healthy housing” environment control. Moreover, scenario 3 shows that the PMV simulated values are close to the thermal neutral point 0. In case B, the three scenarios exhibit a cool feeling in cold winter, during which all the PMV simulated vales are lower than −0.5. Scenario 2 yielded cooler perceptions than scenario 3 in cold winter but warmer perceptions than scenario 1. In hot summer, the perception values are almost the same across all three scenarios and are partly over the comfort range (0–1.0), even reaching a value between 1.0 and 1.5. In case A, the scenario of adaptive thermal comfort displays a similar sensation as that in cold winter and a cooler sensation in hot summer than that simulated by the scenario of the energy-efficient strategy design. In case B, the scenario of adaptive thermal comfort displays a warm sensation in cold winter and similar simulated results in hot summer. Therefore, the adaptive thermal comfort presents a balanced cognition in current green residential buildings in HSCW zones in China. Although various building layouts exhibit varying thermal comfort demand, the adaptive thermal comfort model has a relatively lower thermal comfort demand than the current control using the “healthy housing” technical essential (CNERCHS-PRC, 2004 ) but higher than that controlled using the energy-efficient strategy design (MHURD-PRC, 2010 ).

|

|

|

Figure 3. PMV simulation results of case A under three scenarios. |

|

|

|

Figure 4. PMV simulation results of case B under three scenarios. |

As the field study of the aPMV equations for cases A and B, the slopes of Eqs. (6) ; (7) indicate that the adaptive thermal sensitivity of occupants changes along with the indoor air temperature. This relation indicates that if the indoor air temperature changes by 1 °C, then the adaptive thermal sensation changes in values equal to thermal sensation. The value of the slope can then be defined as the thermal sensitivity of occupants toward the ambient environment (Yao et al., 2009 ). A change in the air temperature by nearly 6 °C results in a per unit change in thermal sensation in case A and 5.7 difference in case B per unit of thermal sensation change. Therefore, the differences of the PMV simulation results (see Figure 3 ; Figure 4 ) show different thermal sensitivity values under specific indoor environmental controls. Although the maximum difference between cases A and B is approximately 0.5, the air temperature of the indoor thermal environment may have a difference of 2–3. Such difference causes more energy use demand for heating up or cooling down on the basis of the adaptive thermal comfort of occupants.

4.2. Energy consumption performance

The simulation of energy consumption performance in this study considered only lighting and energy for heating and cooling. Table 4 ; Table 5 respectively present the monthly and annual energy consumption for heating and cooling alongside the various scenario inputs. The peak value of energy use typically occurs in extreme seasons (summer or winter) under different scenarios. A thermal comfort demand for indoor heating also occurs in March and April (out of local winter time) and a cooling demand in September and October (out of local summer time). The monthly energy breakdown for heating and cooling indicates that the scenario of the energy-efficient strategy design results in the lowest energy use for heating. The scenario of “healthy housing” results in the highest energy use, whereas that of the adaptive thermal comfort results in a middle level of energy consumption. As regards energy use for cooling down in hot summer, the highest energy cost is caused by the scenario of adaptive thermal comfort, the lowest by the scenario of energy-efficient strategy design, and the middle range by the scenario of “healthy housing.” This finding indicates that the current green housing design standard for energy efficiency in China underestimates the energy use for warming a house in cold winter. The “healthy housing” technical guide overestimates the energy use for heating more than the scenario of adaptive thermal comfort does. However, as regards cooling energy use, the two scenarios of energy-efficient strategy and “healthy housing” both underestimate energy use more than the scenario of adaptive thermal comfort does.

| Scenario 1 | Scenario 2 | Scenario 3 | ||||

|---|---|---|---|---|---|---|

| Heating | Cooling | Heating | Cooling | Heating | Cooling | |

| (kWh) | (kWh) | (kWh) | (kWh) | (kWh) | (kWh) | |

| January | 478.25 | 0 | 618.79 | 0 | 474.76 | 0 |

| February | 344.02 | 0 | 469.71 | 0 | 342.94 | 0 |

| March | 185.39 | 0 | 302.68 | 0.69 | 207.09 | 1.56 |

| April | 0.06 | 6.68 | 18.75 | 17.22 | 15.92 | 47.04 |

| May | 0 | 130.76 | 2.76 | 170.21 | 2.48 | 229.74 |

| June | 0 | 478.5 | 0 | 488.49 | 0 | 540.77 |

| July | 0 | 832.63 | 0 | 794.54 | 0 | 818.77 |

| August | 0 | 819.83 | 0 | 787.49 | 0 | 813.04 |

| September | 0 | 266.42 | 0.16 | 293.44 | 0.17 | 347.97 |

| October | 0 | 18.26 | 14.21 | 41.6 | 12.34 | 82.79 |

| November | 83.04 | 3 | 186.56 | 7.35 | 116.85 | 16.59 |

| December | 295.93 | 0 | 433.77 | 0 | 303.37 | 0 |

| Annual | 1386.69 | 2556.08 | 2047.4 | 2601.04 | 1475.92 | 2898.28 |

| Scenario 1 | Scenario 2 | Scenario 3 | ||||

|---|---|---|---|---|---|---|

| Heating | Cooling | Heating | Cooling | Heating | Cooling | |

| (kWh) | (kWh) | (kWh) | (kWh) | (kWh) | (kWh) | |

| January | 372.6 | 0 | 474.47 | 0 | 417.91 | 0 |

| February | 272.36 | 0 | 363.01 | 0 | 316.35 | 0 |

| March | 154.08 | 0 | 241.44 | 0.51 | 207.3 | 0.39 |

| April | 0.22 | 0.05 | 20.58 | 4.77 | 25.95 | 10.41 |

| May | 0 | 26.39 | 1.84 | 67.54 | 4.11 | 90.24 |

| June | 0 | 209.26 | 0 | 251.91 | 0.01 | 253.6 |

| July | 0 | 409.82 | 0 | 437.6 | 0 | 507.94 |

| August | 0 | 405.9 | 0 | 428.91 | 0 | 500.04 |

| September | 0 | 105.69 | 0.05 | 146.93 | 0.29 | 161.61 |

| October | 0.01 | 2.9 | 10.5 | 11.03 | 16.87 | 24.7 |

| November | 74.52 | 0.28 | 153.91 | 0.6 | 127.51 | 3.22 |

| December | 238.5 | 0 | 338.01 | 0 | 291.29 | 0 |

| Annual | 1112.29 | 1160.29 | 1603.81 | 1349.8 | 1407.58 | 1552.13 |

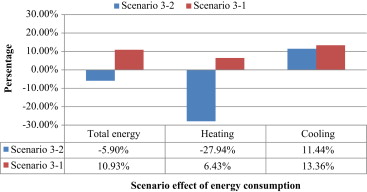

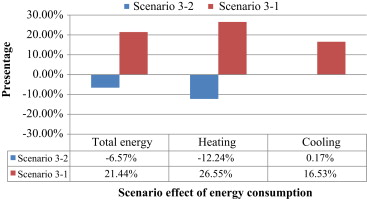

Figure 5 ; Figure 6 present the comparative results of the energy use per unit of flooring area for heating and cooling and the total consumption of energy in each case study. For the energy consumption study of the simulation, case A displays higher energy conservation of nearly 28% for heating under the scenario of adaptive thermal comfort than the “healthy housing” technical control does. This value is also higher by approximately 6.5% of that of the energy-efficient strategy. The scenario of the adaptive thermal comfort model uses more energy for cooling than the other two scenarios. The rates of over-percentage are approximately 12–13%. Moreover, the total changing rates of the adaptive thermal comfort model is 6.0% lower than that of the “healthy housing” scenario but approximately 11% higher than that of the energy-efficient strategy. In case B, the energy use for heating is higher than that of the adaptive thermal comfort and energy-efficient scenarios by approximately 26.5%. However, the value is lower than that of the “healthy housing” scenario by approximately 12%. The adaptive thermal comfort scenario also uses more energy for cooling than the other two. The rates of increasing percentage is 16.5% of that of the energy-efficient strategy and nearly equal to that of the “healthy housing” scenario. The total increasing rate of energy use is approximately 21.5% for the deviation between the adaptive thermal comfort model and energy-efficient strategy. The decreasing rate of energy use is approximately 6.5% of the adaptive thermal comfort model and “healthy housing” level. The scenario of adaptive thermal comfort thus saves more energy consumption than the current “healthy housing” scenario in HSCW zones in China. However, based on the subjective thermal comfort demand, a high level of energy use persists in whichever building type the occupant stays in.

|

|

|

Figure 5. Comparison of energy consumption per unit floor area for heating and cooling in case A under different scenarios of environment control. |

|

|

|

Figure 6. Comparison of energy consumption per unit floor area for heating and cooling in case B under different scenarios of environment control. |

4.3. Building shape coefficient query for building performance

The building shape coefficient is usually emphasized in regional building design standards in China (JGJ134-2010 for HSCW zones). A review of the relevant studies conducted in China (Cao et al ., 2005 ; Fu, 2002a ; Fu, 2002b ; Liu and Ding, 2006 ; Xiao, 2004 ) shows that the building shape coefficient is generally considered as a significant factor in a building׳s energy saving. For architectural research, this coefficient is defined as the ratio of a building׳s outer surface area (i.e., in contact with the external ambience) to its inclusive volume. Often considered to save more energy, a small building coefficient indicates a small outer surface area with low heating loss. That is, the building shape coefficient should be controlled within limitations. For example, the limitations for HSCW zones (MHURD-PRC, 2010 ) are 0.55 (3 floors), 0.4 (4–11 floors), and 0.35 (12 floors). Since 1974, the first energy conservation design standard and evaluation criterion has been used for buildings (NBSIR 74-452) (Heldenbrand, 1974 ) and in related research published in the UK (CIBSE, 2006 ). Such criterion does not emphasize the index of building shape as an effective method for assessing energy use in buildings. However, in the current building design standard of China, the building shape coefficient is mandatory for inspecting building energy conservation.

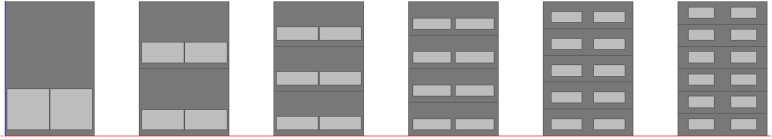

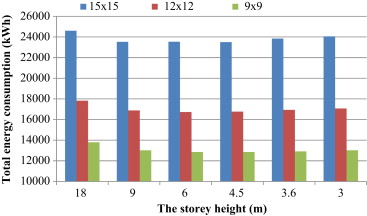

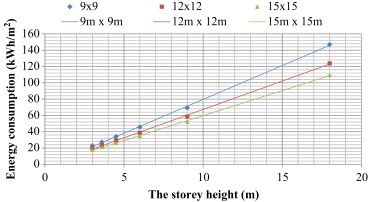

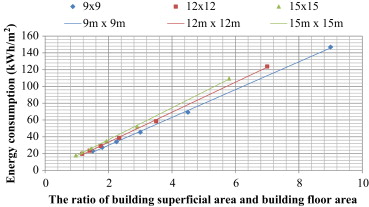

Simulation software provides an easy method for examining the relationship between energy consumption and building shape coefficient. According to related studies on China׳s building shape coefficient, the lowest building shape coefficient is the square. Consequently, the simulation shape is defined as a square with the following dimensions: 9 m×9 m, 12 m×12 m, and 15 m×15 m square block models for the prototype study of small, medium, and large apartments, respectively. The total height of the modeling block is 18 m, which is approximately equal to a six-floor building (i.e., a common type of Chinese low-rise residential building). Figure 7 shows that the floor-to-floor height change is from 3 m to 18 m (63 m, 5 storeys, 3.6 m, 4 storeys, 4.5 m, 3 storeys, 6 m, 2 storeys, 9 m, 1 storey, 18 m). Thus, the number of floor levels is accordingly altered from six floors to one. It is defined as a changing variable for various energy performances. The external window area is designed with a constant setting of 30% glazing on the external wall. The output indicates the relationship between energy use and height of the building storeys, as well as that between the energy use per unit of indoor floor area and the storey height.

|

|

|

Figure 7. Simulation work for energy consumption under a constant building shape coefficient. |

In this simulation study, all the building blocks have a height of 18 m. Figure 8 shows that the total energy consumption of the building block has a decreasing tendency from a 1-storey to a 2-storey block, and an increasing tendency from a 3-storey to a 6-storey block. A large size of modeling block has a relatively low building shape coefficient and consumes more energy than a small size of modeling block. Figure 9 shows the energy use per unit of indoor flooring across various designs of buildings based on their storey height. All of their relationships are linear, and the under same volume of building block (with the same shape coefficient), the building with more storeys always has consumes less energy per unit of floor area in each modeling block than a building with less storeys. Moreover, the modeling block that has a larger cross-section area consumes less energy than a modeling block with a smaller cross-section area. Figure 10 shows the relationship between energy consumption per unit of floor area and the ratio of the superficial area and actual floor area. All of their relationships are linear, and all modeling blocks that have a high ratio consume a great amount of energy per unit of floor area. According to the same ratio, the larger the cross-section area of a block, the more energy it consumes.

|

|

|

Figure 8. Relationship between total energy consumption and building storey height under different model sizes. |

|

|

|

Figure 9. Relationship between energy consumption per unit floor area and storey height. |

|

|

|

Figure 10. Relationship between energy consumption per unit floor area and the ratio of building superficial area to building floor area. |

Consequently, the building shape coefficient is a rough concept of the parametric design of a building׳s energy conservation issues. Moreover, indoor space design with different storey-height has a strong relationship with indoor floor area, which affects the level of demand for indoor energy consumption and a building׳s energy use performance. The total energy consumption tends to be parabolic as the indoor floor area increases (i.e., the total height of a building remains constant with different indoor storey level designs). A building׳s energy consumption per unit of flooring has a linear relationship with storey height, ratio of a building׳s superficial area, and the actual indoor floor area. Moreover, when the block height is constant, a larger cross-section area results in lower building energy performance. When the ratio of the building׳s superficial area and building floor area is constant, a larger cross-section area results in higher building energy performance. In China, the current climate׳s regional standard for residential building design neglects the limitations of building shape design for energy conservation. Indoor environmental design has a strong relationship with the requirements of thermal environment comfort; however, current Chinese building shape coefficients consider only the success of energy conservation in a simple building design. More indoor environmental designs, such as spatial objective or subjective evaluation, and more energy cognition should be considered. Occupancy is always related to indoor floor area; the amount of energy consumed per unit of floor area is necessary to understand a building׳s performance in restoring thermal comfort.

5. Conclusions

This study used the intelligent software called DesignBuilder, which employs the powerful and comprehensive energy simulation engine EnergyPlus, to simulate indoor thermal comfort and energy issues. Three scenarios of the indoor environment were used in the simulations to demonstrate the performance of the adaptive thermal comfort approach under various climatic situations in HSCW zones in China. The following conclusions can be drawn:

- The adaptive thermal comfort model shows that the current residential building design standard in HSCW zones and the healthy housing construction technical essentials do not achieve a balance between indoor thermal comfort and energy saving demand. The adaptive thermal comfort model is premised on the principle of “occupants first” for indoor environment design. Field studies on adaptive thermal comfort and subjective thermal assessment research on real green residential building design provide examples of actual human adaptation.

- The current residential building design standard for energy efficiency in HSCW zones in China underestimates the energy use for warming a house in cold winter. Moreover, the “healthy housing” technical guide overestimates the energy use for heating more than the scenario of adaptive thermal comfort does. In hot summer, these two scenarios of residential building both underestimate energy use more than the adaptive thermal comfort scenario does.

- The simulation work for the parametric analysis shows that the relationship between building shape coefficient and energy saving is a vague concept in relation to a building׳s energy consumption. Therefore, a low building shape coefficient does not always ensure low energy consumption. The building shape coefficient usually has a negative effect on architectural esthetics, and indoor space design with different storey heights has a strong relationship with indoor floor area. The ratio of a building׳s superficial area and actual indoor floor area is significant to practical projects that deal with energy-efficiency research and building dynamic monitoring work in the post-construction step.

References

- Abbazadeh et al., Abbazadeh, S., Zagreus, L., Lehrer, D., and C., H., 2006. Occupant satisfaction with indoor environmental quality in green buildings. In: Proceedings of Healthy Buildings, pp. 365–370.

- ASHRAE, 2010 ASHRAE; ASHRAE Standard 55-2010: Thermal Environmental Conditions for Human Occupancy; American Society of Heating Regrigeration and Air- Conditioning Engineers, Atlanta, GA (2010)

- Bouden and Ghrab, 2005 C. Bouden, N. Ghrab; An adaptive thermal comfort model for the Tunisian context: a field study results; EnergyBuild, 37 (9) (2005), pp. 952–963

- Brager and Baker, Brager, G.S., and Baker, L., 2008. Occupant satisfaction in mixed-mode buildings. In: Proceedings of Air Conditioning and the Low Carbon Cooling Challenge.

- Cao et al., 2005 Y. Cao, S. Lu, H. Fan, Z. Bu, D. Li; Discussion on relationship between building shape coefficient and energy saving; Hous. Sci., 2005 (4) (2005), pp. 26–28

- CIBSE CIBSE, 2006. Environmental design. CIBSE Guide A, Chartered Institution of Building Services Engineers.

- CNERCHS-PRC, 2004 CNERCHS-PRC; The Technical Essentials for Construction of Healthy Housing; China Building Press, China National Engineering Research Center for Human Settlements, Beijing (2004)

- Djongyang et al., 2010 N. Djongyang, R. Tchinda, D. Njomo; Thermal comfort: a review paper; Renew. Sustain. Energy Rev., 14 (9) (2010), pp. 2626–2640

- Fu, 2002a X. Fu; Calculating method of residential energy consumption and program implement in hot summer and cold winter region; J. Southeast Univ. (Nat. Sci. Ed.), 132 (12) (2002)

- Fu, 2002b X. Fu; Technology for Energy Efficiency of Buildings in Hot Summer and Cold Winter Zone; China Architecture and Building Press, Beijing (2002)

- Gabay et al., 2014 H. Gabay, I.A. Meir, M. Schwartz, E. Werzberger; Cost-benefit analysis of green buildings: an Israeli office buildings case study; Energy Build., 76 (2014), pp. 558–564

- Gou et al., 2013 Z. Gou, D. Prasad, S. Siu-Yu Lau; Are Green Buildings More Satisfactory and Comfortable?; 39, Habitat International (2013), pp. 156–161

- Gu et al., 2012 C. Gu, L. Wu, C. Ian; Progress in research on Chinese urbanization; Front Archit. Res, 1 (2) (2012), pp. 101–149

- Heerwagen, 2000 J. Heerwagen; Green buildings, organizational success, and occupant productivity; Build. Res. Inf., 28 (2000), pp. 353–367

- Heldenbrand, 1974 Heldenbrand, J.L., 1974. Design and Evaluation Criteria for Energy Conservation in New Buildings. NBSIR 74-452, National Bureau of Standards (NBS), Washington, D.C. (USA).

- Indraganti, 2010 M. Indraganti; Adaptive use of natural ventilation for thermal comfort in Indian apartments; Build. Environ., 45 (6) (2010), pp. 1490–1507

- Kats et al., 2003 Kats, G., Alevantis, L., Berman, A., Mills, E., and Perlman, J., 2003. The Costs and Financial Benefits of Green Buildings. United States Green Building Council (USGBC).

- Kottek et al., 2006 M. Kottek, J. Grieser, C. Beck, B. Rudolf, F. Rubel; World map of the Köppen–Geiger climate classification updated; Meteorol. Z., 15 (3) (2006), pp. 259–263

- Leaman and Bordass, 2007 A. Leaman, B. Bordass; Are users more tolerant of ‘green’ buildings?; Build. Res. Inf., 35 (2007), pp. 662–673

- Liu et al., 2012 J. Liu, R. Yao, J. Wang, B. Li; Occupants׳ behavioural adaptation in workplaces with non-central heating and cooling systems; Appl. Therm. Eng., 35 (2012), pp. 40–54

- Liu and Ding, 2006 X. Liu, L. Ding; Analysis on the effect of building shape coefficient for energy saving; J. Hunan Univ. Sci. Technol. (Nat. Sci. Ed.), 21 (2) (2006), pp. 25–28

- MHURD-PRC, 2010 MHURD-PRC; Design Standard for Energy Efficiency of Residential Buildings in Hot Summer and Cold Winter Zone, China Architecture and Building Press, Beijing, China (2010)

- MHURD-PRC, 1993 GAQSIQ-PRC MHURD-PRC; Thermal Design Code for Civil Building; China Plan Press, Beijing, China (1993) (GB 50178-93)

- MHURD-PRC, 2011 GAQSIQ-PRC MHURD-PRC; Design Code for Residential Buildings (GB50096-2011), Ministry of Housing and Urban–Rural Development of the PRC, General Administration of Quality Supervision, Inspection and Quarantine of the PRC, China architecture and building press, Beijing (2011)

- Mui and Chan, 2003 K.W.H. Mui, W.T.D. Chan; Adaptive comfort temperature model of air-conditioned building in Hong Kong; Build. Environ., 38 (6) (2003), pp. 837–852

- Nicol, 2008 J.F. Nicol; Adaptive Thermal Comfort and Carbon Saving in Buildings. Change to Survive; Oxford Brookes University (2008)

- Nicol and Humphreys, 2002 J.F. Nicol, M.A. Humphreys; Adaptive thermal comfort and sustainable thermal standards for buildings; Energy Build., 34 (6) (2002), pp. 563–572

- Reeder, 2010 L. Reeder; Guide to Green Building Rating Systems: Understanding LEED, Green Globes, Energy Stars, the National Green Building standard, and More; Wiley, Hoboken, NJ, USA (2010)

- Roufechaei et al., 2014 K.M. Roufechaei, A. Hassan Abu Bakar, A.A. Tabassi; Energy-efficient design for sustainable housing development; J. Clean. Prod., 65 (2014), pp. 380–388

- Schiavon and Melikov, 2008 S. Schiavon, A.K. Melikov; Energy saving and improved comfort by increased air movement; Energy Build., 40 (10) (2008), pp. 1954–1960

- Sighn et al., 2010 A. Sighn, M. Syal, S.C. Grady, S. Korkmaz; Effects of green building on employees health and productivity; Am. J. Pub. Health, 100 (2010), pp. 1665–1668

- Singh et al., 2011 M.K. Singh, S. Mahapatra, S.K. Atreya; Adaptive thermal comfort model for different climatic zones of North-East India; Appl. Energy, 88 (7) (2011), pp. 2420–2428

- USEPA USEPA, 2009. Definition of Green Building. United States Environmental Protection Agency (USEPA).

- USGBC USGBC, 2009. Green Building and LEED Core Concepts. United States Green Building Council (USGBC).

- Wu and Xu, 2013 Y. Wu, R. Xu; Green building development in China-based on heat pump demonstration projects; Renew. Energy, 53 (2013), pp. 211–219

- Xiao, 2004 W. Xiao; Study on economical design of residential house; J. Xi׳an Univ. Archit. Technol. (Nat. Sci. Ed.), 2004 (36) (2004), pp. 303–305

- Yao, 1997 R. Yao; Study on Indoor Climate Simulation and Thermal Comfort (Ph.D. thesis); Chongqing Jianzhu University, Chongqing, China (1997)

- Yao et al., 2009 R. Yao, B. Li, J. Liu; A theoretical adaptive model of thermal comfort—adaptive Predicted Mean Vote (aPMV); Build. Environ., 44 (10) (2009), pp. 2089–2096

- Yao et al., 2010 R. Yao, J. Liu, B. Li; Occupants׳ adaptive responses and perception of thermal environment in naturally conditioned university classrooms; Appl. Energy, 87 (3) (2010), pp. 1015–1022

- Ye et al., 2013 L. Ye, Z. Cheng, Q. Wang, W. Lin, F. Ren; Overview on Green Building Label in China; Renew. Energy, 53 (2013), pp. 220–229

- Yin et al., 2010 W. Yin, G. Zhang, W. Yang, X. Wang; Natural ventilation potential model considering solution multiplicity, window opening percentage, air velocity and humidity in China; Build. Environ., 45 (2) (2010), pp. 338–344

Document information

Published on 12/05/17

Submitted on 12/05/17

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?