1. Introduction

Composite scrap is a source of composite for recycling which can come from end-of-life products or can be generated as production waste during the manufacturing process. The aim of the MC4 project is to find a solution for this waste, in line with the European Union policies that aim to limit the impact of waste in the environment by promoting the use of efficient resources.

This project is divided into multiple working groups, that focus on carbon or glass fiber, on both long and short term. In the scope of this project, FIDAMC is in charge of the recycling of uncured prepreg coming from Automatic Tape Layup processes.

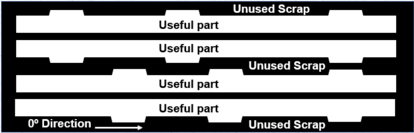

Automatic Tape Layup [1] method allows for a more automated process in the manufacturing of flat (or semi-flat) parts, being a manufacturing process widely used in the aerospace industry. The process consists in a set of rollers that automatically laminate a roll of material (mainly, carbon fiber prepreg) in the needed orientation. Once the whole laminate is completed, an ultrasonic blade cuts the panel to the desired shape, before processing the part in the following manufacturing steps. One disadvantage of this process is that there is a lot of waste material, generated due to the laminate off-cuts, that is not being reused for the manufacturing of other parts. This scrap is characterized for not having a large amount of thickness transitions, besides presenting a predominant orientation (normally 40-50% of 0° fibers).

A typical view of the off cuts generated in this method is represented in Figure 1, where the unused scrap is represented in black. The objective of this line of the MC4 project is the reuse of this scrap material in order to find new applications for this material that nowadays is not more than waste. In order to achieve this target, the material has to be processed until getting a new homogeneous format that can be suitable for the manufacturing., This way, thickness variations and material shape have to be homogenized, trying to take advantage of the fiber orientations. To do that, the material has to be cut into same width strips, and then calendered to reduce its thickness to a constant value for all the strips.

2. Experimental

2.1. Equipment definition

The starting point for evaluating the calender system as a method to reduce the starting thickness and achieve homogenization of the final material was the acquisition of a small equipment representative of the technology (see Figure 2). Selected machine is composed of two rollers (diameter around 30 mm), and a manual lever that generate the movement. The distance between rollers could also be adjusted. As the machine is an R&D acquisition as a proof of concept to validate the concept, width of the rollers is less than 100 mm, not allowing for big chunks of material to be fed. With this machine, an initial calendering of the recycled material could be done, and the performance of the method can be evaluated in order to establish the necessary machine parameters for a possible set-up in production.

Figure 2: Calendering machine

2.2. Starting material

The starting material to evaluate is the scrap generated in the production of aeronautical stiffeners parts.

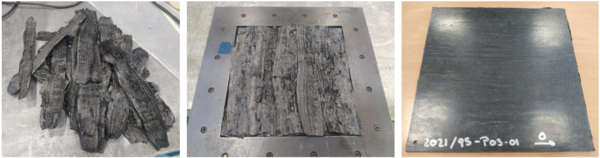

As the material to be used comes from the scrap of production parts, the layers have variable geometry, which makes some kind of size homogenization mandatory to keep up with the process. The “semi-random” geometry is then converted to thin strips like the ones in Figure 3.

2.3. Calendering plan

The test plan for the calendering process consists of three key points:

- Evaluation of the thickness reduction after each step

- Evaluation of the quality/performance depending on the initial thickness

- Effect of different processing temperatures, both on the final result and on the process itself.

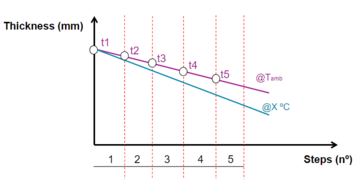

The objecti is to obtain a graph similar to the represented in Figure 4, but with a set of reliable values, to be able to design a new process with a new and more powerful machine.

2.4. Unidirectional scrap calendering

The first tests were performed on pure 0° unidirectional scrap fibers. The results were positive, although some points were made: There is a certain undulation in the calendered section, because of the fiber spreading (there is also no 90° fibers, so the fibers will not be held together, which would help with the thickness reduction).

There is a certain dryness found after calendering, so some resin will be needed to avoid dry areas.

2.5. Multidirectional scrap calendering

After performing the first tests with unidirectional scrap, multidirectional scrap had to be tested. Although the main direction in the ATL panels tends to be 0°, having most of its fibers on that direction, there are still some other orientations that are present in the laminate.

The result of this test was way worse than the unidirectional fibers. 0° plies can be spread parallel to the calendering direction, but 90° plies move back and forth causing wrinkles and inhomogeneity. +-45° plies show an intermediate result between 0 and 90, being the final result not as good as expected (See in Figure 5). Dryness is also higher because of the deconsolidation.

In order to try to reduce the wrinkles that are formed in the calendering process, a second test is performed, but calendering in a perpendicular direction (transversal to ply direction as in figure 6). This significantly improves the results, as the fibers are spread rather than wrinkled.

This seems a good path to follow, so from this point on, all calendering processes will be done this way, as it is the method that shows the best results.

2.5. Material characterization

In order to validate the process, to see that the properties are somewhat enough for the expected applications, some samples and mechanical testing have to be performed.

The panel was manufactured from the transverse calendered strips, using a hot press tooling, following a curing cycle of 120 min at 185 °C, at 8 bar (Figure 7).

4. Results and discussion

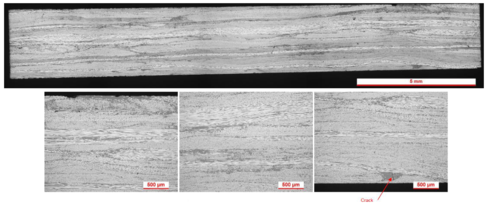

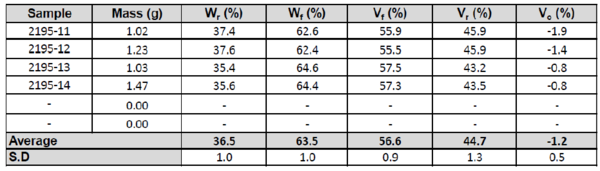

From the panel depicted in Figure 7, a series of tests were performed: tensile (using 15 and 10mm width specimens), micrographs [2] and acid digestion.

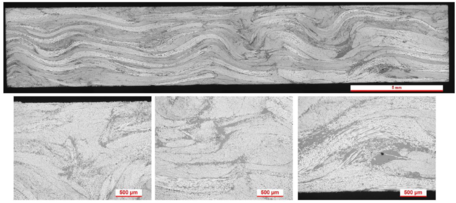

As it can be observed in Figure 8 and Table 1. micrographs and Vh show good results and low porosity, and acid digestion shows almost no voids.

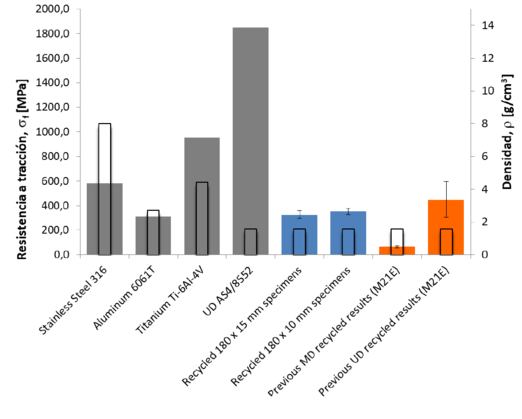

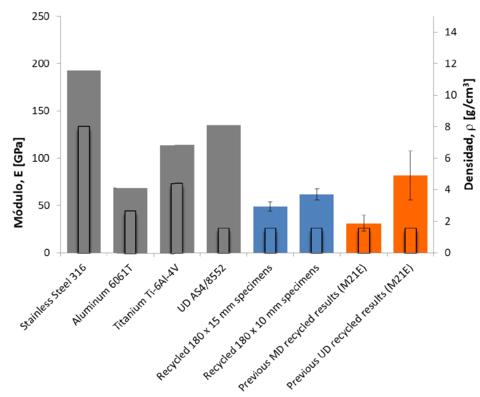

The tensile test results show that the material is promising, as the results are good, compared to other recycled panels performed at fidamc on previous years. The obtained tensile strength is around 330-350 MPa and modulus around 50-60 GPa, which is slightly better than aluminium in tensile strength, but around 75% of its modulus. All results are depicted compared to other materials in Figure 9 and Figure 10.

5. Conclusions

This new process seeks the recycling of the waste material of the ATL panels made for the production of aircraft components. This material will obviously have lower properties than the original one, but the objective is to increase them as much as possible, with the intention of using it for low/medium performance applications, that do not require high performance materials.

The process seems promising; however, some changes have to be made for it to be able to progress. A new automated machine has been acquired with the aim of keeping evaluating and improving the method.

This new machine has a width of 300mm, as well as heated rollers up to 100ºC. It is also electrically operated, making it easier and faster to operate. With this new machine, more in depth tests can be performed to characterize the material to find the most suitable parameters for the calendering process.

Bibliografía

| [1] | C. D. K. X. L. G. P. A.Crosky, Advances in composites manufacturing and process design, 2015. |

| [2] | Sharma, Vipin & Kumar, Dr & Panwar, Ranvir & Pandey, O.. (2012). Microstructural and wear behavior of dual reinforced particle (DRP) aluminum alloy composite. Journal of Materials Science. 47. 6633-6646. 10.1007/s10853-012-6599-4. |

Document information

Published on 15/10/23

Accepted on 28/08/23

Submitted on 20/05/23

Volume 08 - COMUNICACIONES MATCOMP21 (2022) Y MATCOMP23 (2023), Issue Núm. 2 - Fabricación y Aplicaciones Industriales - Sostenibilidad y Reciclaje., 2023

DOI: 10.23967/r.matcomp.2024.02.07

Licence: Other

Share this document

claim authorship

Are you one of the authors of this document?