Abstract

A simultaneously “nuclear”, permanent, and in-time solution to mankinds energy-related problems would require the relatively rapid manufacture of 10,000–30,000 genuinely sustainable, full-sized (~1 GWe) reactors. This “nuclear renaissance” would have to be implemented with breeder reactors because todays commercial nuclear fuel cycle is unsustainable and based upon a fuel (235U) that is intrinsically expensive and politically problematic. The purpose of this paper is to point out why a simple/cheap “minimal reprocessing” implementation of the European Unions (EUs) molten salt fast reactor (MSFR) concept represents the most promising way to implement that technical fix:

- It would be relatively simple/cheap to both build and operate,

- Its fuel cycle is genuinely sustainable (no fuel shortages “forever”),

- Radwaste management would also be relatively simple and cheap,

- Operation would neither generate nor require huge amounts of transuranic (TRU) elements,

- The consequences of accidents (fuel spills, etc.) would be relatively benign,

- When steady state is achieved, the world would no longer need its uranium enrichment facilities.

Its primary drawback is that it would require virtually everyone currently involved with managing, researching, implementing, regulating, or “helping” the USAs nuclear power industry to embrace a massive paradigm shift.

Introduction

A simultaneously “nuclear”, permanent, and in-time solution to mankinds energy-related problems1 would require the relatively rapid manufacture of 10,000–30,0002 genuinely sustainable, full-sized (~1 GWe), not “modular” (small) reactors. The reasons why such a “nuclear renaissance” would have to be implemented with breeder-type reactors3 were identified by Alvin Weinberg and H. E. Goeller four decades ago [1]; that is, because the fissile consumed by todays “converter” reactors (235U) comprises only ~0.2% of the worlds potential nuclear fuel supply4 and is both expensive and politically problematic to obtain,5 it is too costly to represent a truly sustainable energy (fuel) source for everyone. Two years ago, a book written by the managers of Argonne National Laboratorys (ANLs) “Integral Fast Reactor” (IFR) program reiterated that message and described how the USA had gone about developing/promoting a sustainable nuclear fuel cycle based upon the conversion of 238U to 239Pu [2]. Unfortunately, that/their program was canceled two decades ago and none of the US Department of Energy Office of Nuclear Energys (USDOE-NEs) current research priorities address the development of anything capable of addressing the worlds long-term energy needs.

The rationale6 for why the US-initiated Generation IV International Forum (GIF) program included molten salt reactors (MSRs) among the six (now seven) advanced reactor concepts7 identified for cooperative development included: (1) they can8 be operated in ways that would generate very little long-lived TRU waste; (2) their inventories of fissile materials per unit of energy can be lower than those of other reactors; (3) the dispersible inventory [source term] of radionuclides within them can be less than that of any other reactor; (4) both fuel and operating costs could be very low compared to solid-fuel reactors; and (5) there are large economics-of-scale with the potential to build very large reactors with extremely low per-megawatt capital costs [3]. Unfortunately, despite the fact that virtually all of the research revealing these characteristics had been performed at the USAs Oak Ridge National Laboratory (ORNL)9 several decades earlier, the USA decided to cede GEN–IV MSR development work to its European collaborators in order to attempt another revival of ANLs Liquid Metal-cooled Fast Breeder Reactor (LMFBR, a.k.a., IFR) program. Its latest version would comprise a liquid metal-cooled, metal-fueled, fast-spectrum “burner” reactor (not a breeder – no 238U-containing blanket around the core) fed with TRU “waste” (mostly 239Pu) extracted from spent commercial light water reactor (LWR) fuel via a modified version of the pyrochemical fuel reprocessing/waste treatment system originally developed for the IFR. The resulting “sodium fast reactors” (SFRs) were to have become the USAs chief contribution to the Global Nuclear Energy Partnership (GNEP).

While critical reviews [4] soon led to a drastic downsizing of the USAs GNEP/Advanced Fuel Cycle Initiative NE research and development (R&D) programs [5], its GIF collaborators/partners continued to support/fund theirs, the most promising of which has turned out to be the MSFR concept jointly developed/studied by research teams in seven different counties +EURATOM+Russia. The remainder of this paper will seek to support my contention that it represents the “best” (most practical/cheap/clean/simple/safe) way to realize Weinberg/Geollers technical fix for the consequences of a burgeoning human populations addiction to fossil fuels. That judgment is based upon a comparison of sustainability, cost, and waste management-related considerations.

Evolution of the Molten Salt Breeder Reactor

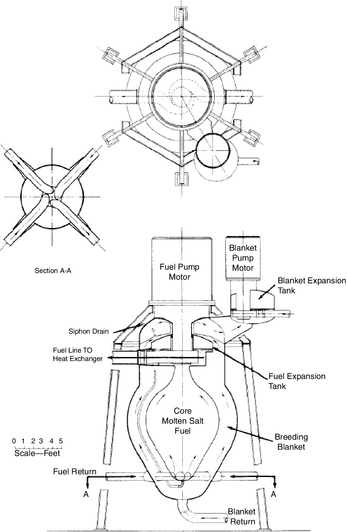

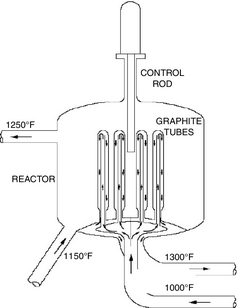

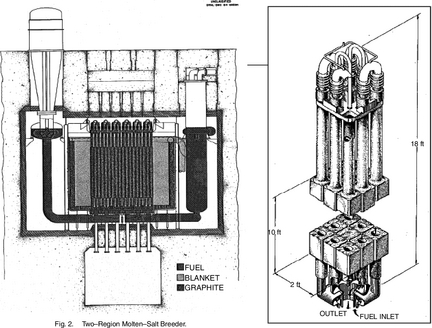

The first research performed to devise a molten salt “power” (electricity-generating) reactor capable of generating as much fissile (233U) as it consumes is summed up in chapters 11–17 of “Fluid Fueled Reactors”[6]. Figure 110 depicts ORNLs “reference reactor” at the time that book was written (1958). It consists of a roughly spherical Hastelloy N “core” (or “reactor”) tank through which the fissile-containing fuel salt stream (primarily 233UF4 in a low-melting solvent comprised of a 2:1 mole-wise mix of 7LiF and BeF2) is pumped, temporarily experiences criticality which generates heat energy which is then transferred to a second nonradioactive molten salt stream via an external heat exchanger. The core tank is situated within a larger “blanket” tank containing a similarly molten blanket salt containing thorium (as ThF4) that absorbs neutrons leaking though the core tanks wall (a.k.a., “barrier”) and is thereby transmuted to 233Pa. The 27-day half-life 233Pa then decays to generate fresh fissile (233U) that is transferred back to the fuel salt stream. In principle, it can operate indefinitely with no fuel other than makeup thorium if it is close coupled to a chemical reprocessing system capable of simultaneously transferring the fissile generated in its blanket salt to the core and preventing excessive fission product (FP) neutron poison11 build up without excessive loss of thorium and 7Li. However, ORNLs calculations indicated that this configuration could not achieve break-even fissile regeneration (isobreeding) with a core tank large enough to generate a worthwhile amount of power (>100 MWe) unless thorium was also present in the fuel-side salt, which, in turn, would raise seemingly insuperable “reprocessing issues” due to its chemical similarities to rare earth element (REE) FP neutron poisons. This, plus the fact that Herbert McPherson, formerly National Carbons foremost graphite expert,12 had assumed management of ORNLs molten salt research program [7], shifted emphasis to the graphite moderated13 two-salt system depicted in Figures 2, 3.

|

|

|

Figure 1. Mid-1950s ORNL unmoderated (no graphite) 2-fluid reactor (from chapter 17 of Ref. 6). |

|

|

|

Figure 2. Mid-1960s ORNL graphite-moderated two-salt reactor, from ORNL 4528. |

|

|

|

Figure 3. Detailed depiction of ORNLs two-salt MSBR. |

In principle, a full-sized (~1 GWe) reactor featuring that concepts complex interlaced graphite pipe core configuration could achieve a CR ≥ 1 utilizing a relatively easy-to-reprocess (meaning thorium-free) fuel salt. Unfortunately, like many “paper reactors”,14 it would have been virtually impossible to either build or operate due to graphites physical characteristics (e.g., highly anisotropic, unweldable, modest strength, poor ductility, etc.) and its propensity to first shrink and then swell upon fast neutron irradiation.

Those considerations plus an especially promising breakthrough in reprocessing technology [8] shifted ORNLs attention to the more simply configured, also graphite-moderated, one-salt reactor by the end of the 1960s (Fig. 4).15 This is the “classic MSBR” being investigated when the AEC decided to axe Weinbergs “chemists reactor” program. ORNL operated an ~8 MWt Molten Salt Reactor Experiment (MSRE) pilot plant from 1965 to 1969 to test theories/materials, demonstrate fissile recycle (both 233U and 235U), and determine generic MSR operational characteristics [7]. Due to fiscal constraints, it represented only the MSBRs central core (no surrounding “undermoderated”16 Th-containing blanket zone) and therefore could not “breed”.

The primary weakness of the one-fluid MSBR concept (Fig. 5) is that achieving both the degree and kind17 of reprocessing necessary to achieve break-even fissile regeneration proved to be extremely difficult/expensive – and still would be if attempted today. Another drawback is the fact that the ~300 tons of radiologically contaminated, neutron-damaged graphite within its core would have to be replaced every 3–4 years, which, in the absence of a suitable repository, raises significant waste issues.

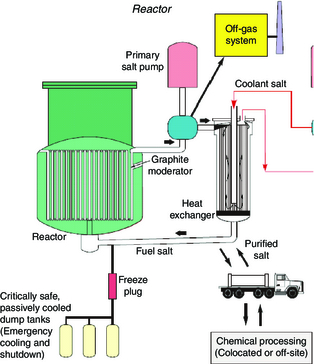

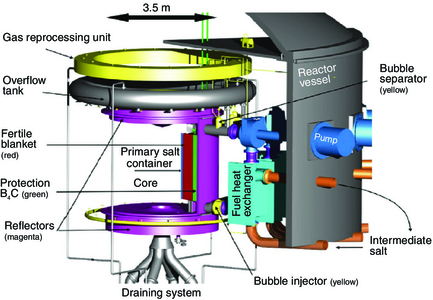

Consistent with GIFs sustainability and safety18 goals [9], ORNLs classic MSBR concept gradually evolved in the direction of unmoderated (no graphite) fast-spectrum systems [10] and eventually (in 2008), the two-fluid (blanket equipped) MSFR (Fig. 6) became the EURATOM Consortiums (EVOLs) “reference” MSR.19 While most of the previous studies of fast-spectrum MSRs had assumed a chloride20 -based solvent salt in order to facilitate Pu breeding [11], fertile-free TRU burning, or U-supported TRU burning [12], EVOLs leadership assumed a somewhat less fast fluoride salt-based system in order to capitalize upon ORNLs extensive materials science and fuel salt chemistry experience [13].

Finally, because it soon became apparent that both CR and reactor durability21 would be improved by surrounding its entire core region with blanket salt rather than just along its sides, recent EVOL papers [14] often describe optimized MSFRs that look much like ORNLs original sphere-within-sphere concept – compare Figures 7 and 1.22

|

|

|

Figure 4. Current depiction of ORNLs graphite-moderated one-salt MSBR (from Ref. 3). |

Everything that the rest of this paper has to say about what could be achieved with the EVOLs reference MSFR would also apply to such an optimized system.

Reasons Why the MSFR is the “Best” Gen IV Reactor

This section only addresses features relevant to its use as a genuinely sustainable thorium-fueled reactor operated to produce cheap, clean, electricity. References [15-17] give more detailed descriptions of both the reactor itself and its characteristics if utilized as a waste treatment technology for LWR-derived TRU.

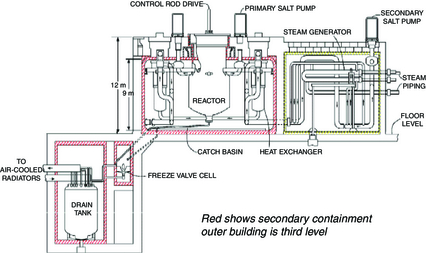

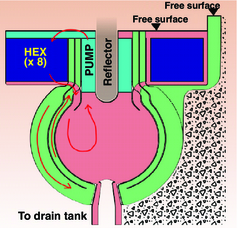

The core of the reference MSFR is a right circular cylinder with diameter equal to height (each 2.17 m), surrounded axially by 1-m thick steel reflectors, and radially by a 50-cm thick fertile blanket salt layer, a boron carbide layer, and a steel neutron reflector. It is filled with the fuel salt with no core internal structures. The fuel circulates out of the core through 16 external loops each of which includes a pump and heat exchanger. A geometrically safe overflow tank accommodates salt expansion/contraction due to temperature changes. A salt draining system connected to the bottom of the core allows core dumping to passively cooled criticality-safe tanks to facilitate maintenance or respond to emergencies. This system includes freeze valves that would melt as soon as electric power is lost or the salt seriously overheats. The entire primary circuit, including the gas reprocessing unit, would be contained within a secondary containment vessel. Figure 5 is a schematic of the primary loops layout and Table 1 summarizes its core parameters.

| Thermal/electric power | 3000 MWt/1500 MWe |

|---|---|

| Core inlet/outlet temperatures | 923/1023 K |

| Fuel salt volume | 18 m3 |

| Fraction of salt inside the core | 50% |

| Number of loops for heat exchange | 16 |

| Flow rate | 4.5 m3/sec |

| Salt velocity in pipes assuming 0.3 m diameter | ~4 m/sec |

| Blanket thickness | 50 cm |

| Blanket salt volume | 7.3 m3 |

| Boron carbide layer thickness | 20 cm |

|

|

|

Figure 5. ORNLs depiction of its one-salt MSBR (early 1970s). |

Its primary fuel salt circuit is connected to two others which serve to keep the salt sufficiently free of the FP “ash” that would otherwise scavenge/absorb too many neutrons. The first of these would be a gas sparging system like that utilized by ORNLs MSRE pilot plant [7]. It would add a small stream of helium bubbles to the salt upstream of the heat exchanger (HX) pump(s) to strip-out both gaseous and nonsoluble FP.23 A 30-second extraction time is generally assumed for both, although, in fact, extraction of nongaseous FPs will take somewhat longer (a noble metal extraction time of several days would have a limited impact on CR [19]). The second clean up circuit is the “reprocessing” system that removes intrinsically soluble (“salt seeking”) FPs (e.g., REE, alkaline earths, alkalis, etc.) from the fuel salt either continuously or batch-wise on a daily basis.

Low reprocessing requirement

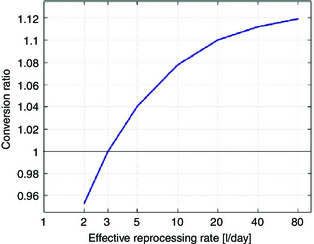

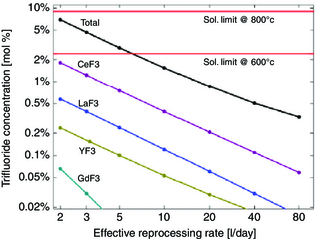

This papers chief technical contribution to the state of the art24 is that it points out that a sustainable (CR ≡ 1) MSFR fuel cycle would require so little salt-seeker removal (see Figs. 8, 9) that doing such reprocessing is unnecessary – everything but the uranium25 (primarily 233U) in the fuel salt requiring that treatment could simply be discarded. The reasons for this include: (1) the value of the nominally costly 7Li and Th in it would be less than the cost of separating/recovering them; (2) discarding TRU rather than recovering/recycling it would minimize the generation of both Pu and minor actinides (MA); (3) the total amount of radwaste generated would be very low; and (4) the resulting much simplified fuel cleanup process would be intrinsically safer to operate and significantly reduce the cost of producing electricity.

|

|

|

Figure 6. Reference MSFR (circa 2009–2013, from Ref. 16). |

|

|

|

Figure 7. “Optimized” MSFR circa 2013 (from Ref. [14]). |

Consequently, satisfying the reprocessing requirements of a MSFR isobreeder would be much simpler, cheaper, and safer than those of either ORNLs classic MSBR or any of the other potentially26 sustainable GEN IV.reactors (SFR/IFR, LFR & GFR). It would also obviate one of the primary drivers for the development of the too-simple “deep burn”-type MSRs that might eventually pose more problematic/costly radioactive waste management issues than does todays nuclear fuel cycle.27

Table 2 compares the MSFR to both of ORNLs graphite-moderated Th-breeders (Figs. 2-5). Note the differences engendered by the shift to a faster neutron spectrum. A point not addressed by Table 2 is that a moderated, one-salt MSBRs 233Pa isolation/hold system creates an almost realistic “proliferation issue”.28 Another is that graphite would likely enhance the corrosion rate of the reactors metallic components [20].

| ORNL 1 GWe 2-salt (ORNL 3791) | ORNL 1 GWe 1-salt “MSBR” (Bettis, NucTech, 1970) | 1.5 GWe MSFR (Florina Ph.D. thesis) | |

|---|---|---|---|

| Reactor characteristics | |||

| Type | C-moderated | C-moderated | “Fast” |

| Moderator | 34 tonnes graphite | 295 tonnes graphite | None |

| Energy density (kW/L) | 91 | 22 | 330 |

| Fuel salt characteristics | |||

| Volume (m3) | 23 | 49 | 18 |

| Content (metric ton): 233U | 0.76 | 2.3 | 5 |

| 7Li | 5.3 | 12.7 | 5.01 |

| Be | 3.1 | 3.6 | N/A |

| Th | N/A | 68 | 41 |

| Processing rate (L/day) | 409 | 26,350 | ~6 |

| Blanket salt characteristics | |||

| (Volume) m3 | 63 | N/A | 7.3 |

| Content (metric ton): Th | 150 | 18 | |

| 7Li | 15 | 1.95 | |

| Processing rate (L/day) | 2860 | ~2 | |

|

|

|

Figure 8. CR versus Reprocessing rate for MSFR Th breeder (JEFF3.1 data base, from Ref. [16]). |

|

|

|

Figure 9. Rare Earth (REE) FP buildup as a function of reprocessing rate (from Ref. [16]). |

Wastes generated by this particular MSFR implementation scenario would consist of: (1) everything in the 6 L29 /day of reprocessed fuel salt except uranium; (2) waste generated by the reactors off gas cleanup and uranium recycling systems; and (3) an occasional “worn out” reactor core and/or blanket salt tank.

The first of these waste streams is simple to characterize because at steady state, the reactors salt cleanup systems must remove FP as fast as it is generated. Since 2 g mol of FP are generated by the fissioning of each mole of fissile, and 3 GWe worth of thermal energy at 200 mev/fission requires the consumption of ~3.13 kg (13.4 g mol) of 233U per day, this corresponds to ~26.8 g mol total FP/day. Since roughly 15% of the FP will consist of inert gases and another 15% will comprise noble metal scum, about 70% or about 20 g mol (about 2 kg) of the FP will accompany the ~1.6 kg of uranium, ~13 kg of thorium, ~1.5 kg of 7Li, and ~7 kg of fluoride in the ~6 L of fuel salt being reprocessed every day. Everything but the uranium in it (about 2 kg) would be fed to a small on-site glass melter along with an iron/aluminum pyrophosphate frit.

That waste would be combined/coprocessed with that generated by the reactors off gas cleanup and uranium recovering/recycling systems because they would all consist of fluoride salts (mole-wise mostly those of the alkali metals) that readily form durable phosphate-based glass/glass ceramic waste form materials [21, 22]. The exact composition of the latter two waste streams is unknown, but since the MSFRs offgas system is similar to that described in ORNL 3791 [23], it is likely to comprise ~8 g mol of miscellaneous FP mixed with roughly 200 g mol of NaF and ~9 mol of MgF2 per day.

Combined, a years worth of those wastes could contain roughly 150,000 g mol of alkali metals, which, because they generally limit the waste loading of radwaste-type glasses,30 correspond to the generation of ~4 m3 of repository-ready glass/glass ceramic waste forms/GWe-year.31 This is far less than the 35–45 m3 of glass-bonded sodalite (a.k.a., “ceramic waste form”) required to immobilize the salt-wastes generated by the pyroprocessing of a GWe-years worth of IFR spent fuel rods [21].

Every 2–4 years those glass/glass ceramic canisters would be accompanied by a roughly half cubic meter metallic waste form generated by hot-pressing the reactors “worn out” super alloy32 core/blanket barrier wall plus the nickel wool FP scum adsorbent into a “brick” like that invoked for the IFRs fuel hull/anode sludge wastes [2].

A key difference between this scenarios waste forms and the raw LWR spent fuel assemblies currently constituting the USAs preferred high-level waste (HLW) waste form is that the former would contain much less long-lived TRU which would significantly simplify their ultimate disposition.

Table 3 compares a GWe-yrs worth of radwaste generated by this MSFR scenario with that generated by the direct disposal of 37 GWd/THM (tonne heavy metal) LWR and 80 GWtd/THM pebble bed-type VHTR (a.k.a., PBMR) reactor fuels.33

| kg waste/GWe-year | |||

|---|---|---|---|

| TRU isotope | MSFR | LWR | PBMR |

| |||

| Np | |||

| 237 | 3.67 | 9.88 | NA |

| 238 | 0.003 | NAa | NA |

| 239 | 4.5E-4 | NA | NA |

| Pu | |||

| 238 | 1.301 | 3.46 | 3.9 |

| 239 | 0.159 | 109.00 | 75.2 |

| 240 | 0.027 | 63.00 | 56.2 |

| 241 | 0.003 | 27.00 | 37.0 |

| 242 | 0.000 | 7.80 | 32.1 |

| Am | |||

| 241 | 0.002 | 0.98 | NA |

| 242 | 1.3E-6 | 0.01 | NA |

| 243 | 7.9E-5 | 1.95 | NA |

| Cm | |||

| 242 | 1.5E-4 | 0.50 | NA |

| 243 | 1.5E-05 | 0.01 | NA |

| 244 | 2.4E-5 | 0.50 | NA |

| Total TRU kg | 5.16 | 224 | 204 |

| Other radwastes | |||

| FP | 762 | 1154 | 952 |

| U | 0 | ~20,000 | ~12,000 |

| “Hot” metallic | ~700 | ~3000 | 0 |

| “Hot” moderator | 0 | 0 | 377,000 |

First, please note that the total amount of TRU-type waste discarded by this MSFR implementation scenario is much less than that in an equivalent amount of spent LWR or VHTR/PBMR fuel34 and that most of its plutonium would be short-lived, nonfissile 238Pu – not the more politically problematic 239Pu. Second, recycling only the uranium in its “reprocessed” fuel rather than all of its actinides virtually eliminates the “higher” minor actinides (Am, Cm, etc.).35 Third, the MSFRs high thermal-to-electrical power conversion efficiency translates to significantly less FP/GWe.36 Finally, it would not generate many tonnes of highly radioactive “spent” moderator per GWe-year as would ORNLs classic MSBR, US/Russian cold-war “production reactors”, gas-cooled, graphite-moderated reactors (acronyms include AVG, HTGR, VHTR, PBMR, NGNP, etc.), the molten salt-cooled, solid-fueled,37 graphite-moderated (FHR or PB-AHTR [24]) reactors that the USA is currently helping China develop [25], or Transatomicpowers (TAPs [26]) zirconium hydride-moderated “Waste-Annihilating Molten Salt Reactor” (WAMSR).38 To date, the worlds graphite-moderated nuclear reactors have generated roughly 250,000 tonnes [27] of radiologically contaminated graphite, most of which lingers in “temporary” storage – any proposed nuclear fuel cycle that would exacerbate this situation simply provides reflexive anti-nukes with another rationale/excuse for not implementing a nuclear renaissance.

There are a host of additional reasons why MSFRs should be relatively cheap. Several are due to the characteristics of their molten salt working fluids:

- Their low viscosity and high heat capacity means that relatively small pumps and heat exchangers are needed.

- Their extremely low vapor pressure at the reactors working temperature means that its pipes, tanks, and heat exchangers would not have to be as strong (heavy/expensive) as those of LWRs or any sort of gas-cooled reactor.

- Their ability to solubilize both fissile and fertile materials means that they obviate virtually all of the costs (manufacture, shipping, loading, “shuffling”, unloading, storage, dissolution, separation, refabrication, more shipping, etc.) incurred with the solid fuels invoked for all of the other GIF reactor candidates.

Another reason for a relatively low cost is that the MSFRs active core region is so small (3 m3/GWt) that it should be possible to design an optimized version in which components subject to especially high neutron flux (primarily the tank wall(s) separating the blanket and fuel salt streams) would be relatively simple to replace (this should be a primary goal of future MSFR development work). Because a 2-cm thick, 9 m3, spherical core tank would weigh roughly 4 tonnes and the real-world price of the super alloy [28] it is apt to be made of is roughly $5/kg,39 its cost should be quite low.40 This is a vitally important point because a systems durability and affordability is as much determined by its maintainability as by its frequency of failure.

Issues, Arguments, Quibbles, and Excuses

The “proliferation” problem

“Your scenario is impossible because its fissile isn't denatured.”

This assertion makes about as much sense as claiming that it would be impossible to revive the USAs space exploration program because its current leadership would prefer that any “new” technical initiative be powered with wind turbines and conservation. First, since it tacitly assumes that new reactors would be similar to todays reactors (and therefore subject to the same set of arbitrary, and apparently politically immutable, man-made rules), it also tacitly assumes that our descendants will always need the uranium enrichment facilities that represent a far more realistic proliferation threat than does the fissile material within nuclear reactors. Second, diluting/denaturing the 233U in the MSFRs salt stream(s) with ~8 times as much 238U would: (1) render its fuel cycle unsustainable (CR < 1) and therefore defeat one of the key reasons for implementing a nuclear renaissance with them; (2) greatly complicate operation rendering them more difficult/dangerous to run and increase their electricitys cost; and (3) turn them into just another large-scale TRU-type radwaste generator. The fact remains that the US federal government – a signatory and vociferous proponent of the Nuclear Non-Proliferation Treaty – has been operating many HEU (Highly Enriched Uranium)-fueled (mostly naval) reactors for decades and is likely to continue to do so. There have been no “diversions” of their fissile by terrorists and it is unrealistic to assume that the fissile within nuclear reactors sited in any “First World” country would be either. Like war, proliferation is a political issue and its solution, if there is one, will be found in that arena. It has nothing to do with civilian reactor designs, which means that attempts to leverage it to claim superiority for a particular GEN IV technology do no favor to either nuclear power or humanitys future prospects.

“Your scenario is impossible because it discards ~1 kg of isotopically pure 7Li per GWe-day and the USA doesn't possess lithium isotope separation capability.”

This argument ignores the fact that the USA generated the ~half-tonne of “pure” 7Li required to operate ORNL'S MSRE over fifty years ago. The reason why it has lost that capability is that the process employed at that time was “dirty” and it therefore became more convenient to outsource the production of both 6Li and 7Li to other countries.41 Today, the USA possesses roughly twice as many tax/ratepayers as it did then and could now take advantage of the fact that Chinas entrepreneurs could quickly supply whatever is needed. To them 7Li would probably be considered the byproduct because the more valuable isotope would go to making better (lighter) Li-ion batteries for the millions of Chinese-made electric cars rendered practical by a cheap nuclear renaissance.

“The nickel–based alloys required to build your reactor are damaged by neutrons, which means that we must wait until someone discovers something better (unobtanium?).”

This is just another excuse for more foot-dragging because the primary reason that the nuclear industry is concerned about nickel embrittlement is that it weakens thick-walled SS pipes/tanks that are supposed to withstand 1000–2200 psi pressure differentials for several decades. In a MSFR, those pressure differentials would be far lower,42 which means that the reason for using nickel is that it renders metallic surfaces inert to fluoride/fluorine-induced corrosion. Since corrosion is a surface phenomenon, it would be reasonable to make the bulk of the core/blanket barrier wall out of a probably cheaper, low nickel alloy and plate its surfaces with a thin layer of pure Ni [29]. Another comforting fact is that the ~15% nickel D9 stainless steel-clad fuel utilized by ANLs exhaustively studied IFR pilot plant (EBR II) experienced similar neutron fluxes while safely achieving burn ups of over 170 GWd/MTHM Ref. [[[#ese359-bib-0002|[2]]], Table 6–1]. Additionally, since a properly designed MSFRs core tank wall could be replaced as often as wished, it is unreasonable to assert that its durability constitutes a show stopper. In any case, definitive answers to such questions can only be generated by open minds willing to suggest/authorize/perform realistic tests.

“Molten salts are too corrosive/reactive/dangerous, etc.”

Dry fluoride ion-based salts (not hydrofluoric acid or fluorine gas) are only corrosive to materials that are more electropositive (reactive to fluorine) than are the metals (in this case lithium and thorium) from which the cations accompanying that fluoride were derived. Since most of the materials used in/around nuclear reactors (steel, concrete, etc.) are less electropositive (reactive) than is either elemental thorium or lithium, there is little/no driving force for corrosion or any other sort of reaction if/when such contact occurs. Spilled molten salt could cause a “burn” in the same sense that hot cooking oil can but cannot actually burn (or explode) as would an IFR/SFRs molten sodium if it were to contact air, water, or human sweat.43

“Since the startup of each new MSFR would require about 5 tonnes of fissile, wouldn't it be impossibly expensive to get a significant number of them built?”

Before describing several ways to address this question,44 I should point out that the startup fuel of any of the nuclear industrys proposed full-sized (not “modular”), GEN III LWRs would also contain/require ~5 tonnes of “new” fissile (235U).

The first scenario is that assumed by most of the western worlds NE R&D experts for any sort of fast reactor; that is, that it/they would be both started up and run with TRU “pyroprocessed” from spent LWR reactor fuel (e.g., GNEP). While that proposal is theoretically feasible and serves a political purpose,45 such fuel would be far more expensive and dangerous to use than is “fresh” 235UF4 and thereby apt to stifle a US nuclear renaissance.46 Consequently, I will not attempt to assign numbers to it.

My second scenario assumes that MSFRs would be started with 235U (as ≥80% 235UF4) generated by a 20% increase in the USAs current investment in the uranium enrichment “separative work units” (SWUs) utilized to produce fuel for its ~100 existing LWRs. Since the nuclear power industrys spokespersons contend that its total fuel costs (roughly 25% of which goes for enrichment) are “low”,47 a temporary 20% increase in the USAs total commitment to enrichment should also constitute a “low” cost. If we also consider that each MSFR is apt to generate somewhat more fissile than it consumes (I've assumed 4.5%, see Fig. 8), this scenario would double the USAs total nuclear power generating capacity (to ~200 GWe) in 24 years and nearly quintuple it (to 487 GWe) by the end of this century.

My third scenario is similar but assumes that rather than continue to keep the current LWR fleet running indefinitely, five of them (oldest first) would be shut down during each of the first 20 years and the SWUs devoted to feeding them applied to generating additional MSFR start up fuel instead. After that, all of the SWUs currently used to feed the USAs LWRs (~1.25E+7/year) would be applied to MSFR start up. This scheme would treble the USAs nuclear power generating capacity in 19 years and raise it to ~1985 GWe by the end of the century.

Fourth, since the USA purportedly still possesses ~600 tonnes of cold war-generated, weapons grade HEU, (http://www.pogo.org/blog/2014/08/20140825-no-more-excuses-for-failing-to-downblend.html), lets assume that its decision makers decide to devote 500 tonnes of it to MSFR startup over the next ten years48 (build 10 MSFRs per year) while decommissioning an equal number of LWRs applying their SWUs to producing additional MSFR startup fuel. This scheme would double the USAs nuclear power generating capacity within 9 years and raise it to 2017 GWe by 2100 AD.

Finally, during the cold war, the USAs production reactors generated roughly 100 tonnes of bomb-grade plutonium (>90% 239Pu), much of which is currently being stored in vaults at the Savannah River National Laboratory. Such plutonium is a much better fissile (fuel) than is the mix of TRU isotopes in spent LWR fuel and available in a form (pure PuO2) that can be easily/cheaply converted to PuF3. Utilizing it to start a small fleet of MSFRs (~20) could simultaneously kick-start a USA nuclear renaissance while rendering it useless for weapons manufacture.49. For example, if the USA were to start five MSFRs with that Pu and shut down five of its oldest LWRs for each of four years and then continue to shut down another five LWRs per year during the next fifteen utilizing their enrichment capacity to make more MSFR startup fuel, its nuclear power generating capacity would double in ~19 years and reach ~1673 GWe by 2100 AD – all accomplished with the same enrichment capacity used to generate todays 100 GWes worth of LWR power.

Any of the last three MSFR startup scenarios would obviate the USAs need/rationale/excuses for uranium enrichment after ~2100 AD.

“Why not just build “advanced” LWRs instead? (corollary: don't we have enough uranium to just keep doing what we're familiar with?).”

This question tacitly assumes that our political leadership will not choose to address climate change and the consequences of fossil fuel depletion with nuclear power; that is, that only a few new reactors will be built during the next several decades.50 If that is the case then there is indeed “plenty of uranium.” (Another drawback is that it would be “burning our descendants seed corn”; that is, when they finally do decide to switch to a sustainable nuclear fuel cycle, the world won't contain as much “cheap” fissile to start it with.) However, if our leaders do decide to face up to those problems, their fix will have to be implemented with breeder-type reactors. The following ball-park calculation demonstrates the reason for this:

- Current EIA estimates peg the worlds total current energy use at ˜500E+18 J/a

- Since a 1 GWe LWR has an thermal-to-electrical energy conversion efficiency of about 33% and uses about 200 metric tonnes (t) of raw uranium per year…

- Jheat energy/t U = 1/0.33 × 1E + 9 J/s × 3600 sec/h ×24 h/d × 365 y/a/200 tU = 4.73E + 14

- The uranium industrys latest Redbook (http://www.world-nuclear-news.org/ENF-U…07127.html) states that “total identified U resources at a ‘reasonable’ (currently <$260/kg) price” is 7,096,600 tU.

- If the worlds total current energy needs were to be met with todays reactors fueled with “reasonably priced” uranium, how long would it last?

- Since tonnes U/a = 500E + 18/4.73E + 14 = 1.06E + 6

Time ‘til gone = 7.096E + 6/1.06E + 6 = 6.71 years.

If the same Redbooks 10,400,500 tU of “undiscovered resources” (expected to exist based on existing geological knowledge but requiring significant exploration to confirm and define them) were to be found/used too, it could fuel that scenarios clean/green LWR-powered world for another ~9.8 years.

The same report goes on to say that, “The increase in the resource base is the result of concerted exploration and development efforts. Some $2 billion was spent on uranium exploration and mine development in 2010, a 22% increase on 2008 figures…” This means that even with todays still relatively concentrated uranium ores (certainly with respect to seawaters ~3 ppb U), extending that industrys “resource base” is currently costing its customers a great deal of money.51

“Why is this/your MSFR implementation scenario especially ‘sustainable’?”

The answer is that “it represents a permanent solution to humanitys energy problems”. The following ball-park calculation supports this contention52 :

- @ ˜2.7 g/cc, the mass of the Earths crustal landmass (not under its oceans) to 1 km depth (i.e., “readily accessible rock”) ≈4.2E + 17 tonnes

- Total fossil fuel (CHx) = ∑coal + shale kerogen + petroleum + natural gas) reserves ≈1638E +9 tonnes (843 + 500 + 170 + 125 gigatonnes - recent EIA estimates) – consequently, weight fraction CHx in readily accessible rock is ≈3.9 ppm (1638E+9/4.2E+17)

- The combustion of one gram of “average” CHx generates ˜37,000 joules of heat energy plus about 3 grams of CO2

- Mankinds current fossil fuel consumption rate (˜500 exajoules/a) represents about 1% (or 500E+18/(1638E+9*1E+6*37000)) of its total CHx reserves

- @ 12 ppm, thorium in the Earths crustal landmass ≈4655 gigatonnes53

- @ 200 Mev/atom, the fission of one gram of 233U via MSFR produces 8.3E+10 Joules of heat energy and'no'“greenhouse” gases

- Since this scenario would discard ˜80% of the Th,

- MSFR energy/fossil energy ≈1.3E+6 (1-0.8)*(4655/1638)*(8.3E+10/3.7E+4)

- Therefore, @ humanitys current total energy demand, “readily accessible” thorium could power us for ˜1.3E+8 years (1.3E+6*1/about 1%)

.

By circa 1.3E+8 AD, the FP accompanying the discarded thorium in most of this scenarios waste forms would have decayed thereby converting their repository to an extremely rich (~24% Th and 3% 7Li) ore body that could go on powering our descendants for another half-billion years. After that has been consumed, they could then begin to extract thorium from the next kilometer-thick layer of the Earths crustal landmass.

Conclusions

To summarize, a properly designed (readily maintainable) MSFR isobreeder represents todays “best” Gen IV option because:

- Its compact size and simplicity relative to alternatives invoking solid fuels and/or moderators (all of the other GIF candidates) means that it should be relatively cheap to both build and operate (less metal needed to fabricate/maintain and no initial fuel fabrication, handling, durability, shuffling, transport, reprocessing, or fuel refabrication costs).

- Its fuel cycle is genuinely sustainable – no fuel shortages “forever”.

- Radwaste management should be relatively simple/cheap.

- Operation would neither generate nor require huge amounts of TRU.

- Its ˜700°C operating temperature and high heat capacity working fluid translates to higher electricity generation efficiencies and more direct process heat applications.

- Its nonreactive, high-boiling, working fluid reduces both the probability and consequences of accidents (spills, etc.).

- When steady state is attained (˜100 years) they would obviate the need/rationale for either uranium enrichment or uranium mining.

- Fueling them would generate far less environmental impact (e.g., mine tailings, etc.) than would any of the nonbreeder Gen IV reactor concepts.

This scenarios primary drawback is that it would require virtually everyone involved with researching, implementing, regulating, or “helping” the USAs nuclear power industry to embrace a massive paradigm shift. The reasons for this include:

- The nuclear industrys current business model is already profitable, firmly established, and primarily cost-plus54 which means that most of its leadership resists change.55

- The USAs political system strongly caters to established (moneyed) interests and has become virtually incapable of addressing any politically sensitive and/or nonimmediate national problem (e.g., climate change) regardless of how important it might be from a “technical” point of view.56

- Its leadership has supported (via earmarks) a series of long-winded, multi $billion, boondoggles (e.g., the Savannah River Sites MOx plant, LLNLs “National Ignition Facility”, SANDIA et. al.s Yucca Mountain studies, Hanfords “Waste Treatment Plant”, the Idaho National Laboratorys “steam reformer”, etc.) that have served to convince many people that any sort of US nuclear renaissance is apt to be risky, environmentally impactful, and prohibitively expensive.

- The leadership of the USAs national laboratories is no longer able to make tough decisions57 or authorize the sorts of “messy” real-world experimentation required to develop an unfamiliar reactor concept and then demonstrate its viability (currently, if a proposed project can't be almost 100% proven/completed with “paper studies”, it won't be undertaken). The Nuclear Regulatory Commission possesses the same mindset.

- The leadership of most of the worlds environmental organizations does not realize that a properly implemented nuclear renaissance represents the most reasonable way to serve their cause and therefore continue to resist anything that might lead to one.

The most sensible way to implement a US nuclear renaissance would be to build clusters of MSFRs (a total of 1500–3000 GWes worth) both where todays LWRs are located and at US DOEs already radiologically compromised nuclear facilities. These “power parks” would include a centralized reprocessing/waste treatment facility to recover useful materials (e.g., 99Mo,58 rhodium, and palladium) from radwastes before they are vitrified. They would be surrounded by energy intensive manufacturing facilities (e.g., water desalination,59 aluminum, steel, fertilizer/synthetic fuel (most of which could be ammonia, http://nh3fuelassociation.org/), titanium, lithium, rare earths, cement plants…) which would provide millions of high-quality jobs and thereby address other problems generated by the USAs post-Vietnam War policy shifts.

The USA currently spends about 300 times as much to “maintain its nuclear deterrence” as it does on the “Advanced Reactor Concept” R&D which could address the root causes of conflict.60 At this point in time the MSFR is just an especially reasonable paper reactor that wasn't “discovered” by the USA and is therefore unknown to its political leadership and most of its nuclear engineers. However, since the EU has demonstrated that a nuclear renaissance implemented with them could likely address both climate change and the otherwise inevitable social/economic consequences of fossil fuel depletion in a uniquely affordable and environmentally correct fashion, the people responsible for implementing the USAs NE R&D programs should be encouraged/enabled to do the scientific research, design work, and pilot plant testing necessary to turn it into a practical (both maintainable and affordable) reactor.

Acknowledgments

I thank Kirk Sorensen, whose “energy from thorium” blogsite reminded me of why I had decided to become a scientist in the first place, and then provided the technical information/tools required to pursue whats become my retirement hobby. Second, I thank Professor MaryLou Dunzik-Gougar (NE ISU), who paid my registration fee at the conference (GLOBAL 2013) where I first learned about MSFR. Finally, I thank Carlo Fiorina, whose presentations at that conference revealed that the European Unions EVOL program had finally addressed the chief weakness of Weinbergs “chemists reactor” and then volunteered to perform the calculations which “proved” it.

Conflict of Interest

None declared.

Notes

- 1 Global warming/climate change, ocean acidification, air pollution, biofuel-driven food cost escalation, water shortages/pollution, relentless cost of living increases, widespread poverty, and political impasses up to and including outright war (see http://www.cna.org/sites/default/files/MAB_2014.pdf).

- 2 The USAs ~5% of the worlds population uses ~20% (~100 exajoules/year) of its total energy: 100 exajoules/year corresponds to the thermal energy output of ~1000 1 GWe nuclear reactors (or 5555 of B&W‘s currently front-running “mPower” small modular reactor (SMR) concept - see http://en.wikipedia.org/wiki/B%26W_mPower).

- 3 Conversion ratio (CR) ≡ fissile generated/fissile consumed: if CR < 1 the reactor is a “converter” (and also unsustainable); if CR ≡ 1.00, its an “isobreeder”; if CR > 1.00, its a “breeder”.

- 4 235U/(all U+Th) ≈ 0.002.

- 5 Witness the perpetual brouhaha generated by Irans uranium enrichment facility.

- 6 Unstated reasons include the fact that molten salt breeder reactors (MSBRs) are much better suited to “burning” thorium than is any solid-fueled reactor. This is important because the earths crust contains ~4 times as much thorium as uranium and its “combustion” generates far less long-lived TRU waste.

- 7 The original six GIF candidates included three fast reactors (gas-cooled [GFR], sodium cooled [SFR], and lead cooled [LFR]) and three thermal reactors (graphite moderated/molten salt [MSR], gas cooled/graphite moderated/very high temperature [VHTR], and supercritical water-cooled/moderated [SCWR]). The seventh added later is the subject of this paper, the molten salt fast reactor (MSFR). See https://www.gen-4.org/gif/upload/docs/application/pdf/2014-06/gif_2013_annual_report-final.pdf.

- 8 “Cans” and “coulds” are italicized because there are many ways to implement MSRs, only some of which exhibit the characteristic in question (see D. Holcomb et. al., “Fast Spectrum Molten Salt Reactor Options”, ORNL/TM 2011/105 R (July 2011).

- 9 ORNLs MSR/MSBR program cancellation in 1973 was accompanied by the downsizing of its long-time Director, Alvin Weinberg (see Ref. [1]). The reason stated for the AECs actions was that the USA “could no longer afford” to support two breeder reactor programs (this is ironic because in 1972, ANLs LMFBR development work had cost taxpayers 26 times as much ($123.2M/$4.8M) as had ORNLs MSBR program – see L. Cohens “The Technology Pork Barrel”, Brooking Institution Press, 1991, p. 234). Overall, total US LMFBR R&D spending has been ~150 times that devoted to MSR-related work.

- 10 “Two-fluid” rather than “two-salt” because most of ORNLs MSBR modeling work assumed that the reactors fuel salt would contain thorium as well as fissile. Such systems are now generally called “1½ salt” reactors. “Two-salt” is now generally reserved for reactor concepts in which 100% of the thorium (and therefore fissile generation) is in the surrounding blanket.

- 11 “Poisons” are materials that scavenge/absorb neutrons that would otherwise serve a useful purpose.

- 12 Dr. McPhersons development of boron-free graphite (boron is a powerful neutron poison) had previously rendered Hanfords war-winning 239Pu production reactors possible.

- 13 The technical reason for moderating a MSRs core (with graphite, zirconium hydride or BeO) is that doing so would increase fission cross sections thereby allowing it to operate with a smaller fissile inventory – a characteristic deemed to be of paramount importance when ORNL was pursuing its MSR studies. One of the downsides of moderation is the fact that parasitic neutron absorption cross sections become much higher which means that far more “reprocessing” (greater degree of FP removal) is required to achieve break-even fissile regeneration.

- 14 http://www.ecolo.org/documents/documents_in_english/Rickover.pdf.

- 15 That breakthrough invoked a ~20 stage countercurrent extraction/back extraction system utilizing a molten bismuth solvent containing an electrochemically generated metallic reductant (lithium and/or thorium) to selectively recover key species (U, Th, REE, and Pa) from a molten salt slipstream [8].

- 16 The periphery of the MSBRs core possessed larger salt channels than did its center (less graphite/cc) which would have simultaneously suppressed fission and enhanced conversion (breeding) therein.

- 17 “Degree” because a great deal of reprocessing (>1200 L/day) would have been required to achieve break-even fissile generation: “kind” because that system would have to be able to remove 233 Pa (a readily transmuted neutron poison), store it ex situ until it had decayed to 233U, and then return it to the fuel salt loop. Two-fluid MSRs can isobreed without a 233Pa isolation/hold system.

- 18 “Safer” because EVOLs studies indicate that a MSFR would possess much larger negative temperature and void reactivity coefficients than would the classic MSBR.

- 19 The basic concept was described over 50 years ago when US physicists realized that an unmoderated MSBR would likely be simpler to both build and operate. See L.G. Alexander, “MSFRs”, Proceedings of Breeding Large Fast Reactors, ANL-6792 (1963). Unfortunately, it was subsequently essentially forgotten until the EVOLs MSR researchers decided to resurrect it.

- 20 All else being equal, a chloride-based MSR is “faster” than its fluoride analog because the halide atoms comprising ~two-thirds of those present in either of their salt streams are heavier.

- 21 “Durability” because the blanket salt would intercept the fast-moving neutrons that would eventually damage the reference MSFRs axial reflectors.

- 22 The key difference between the MSFR and the 8-ft core diameter, two-fluid reference reactor described in Chapter 14 of Ref. [6], is that ORNLs modelers chose to limit the latters maximum fuel-side salts thorium concentration to 7 mole % because (to them) its fissile inventory would become “excessive” above that figure (that was before todays centrifuges rendered HEU relatively “cheap”). The addition of thorium to a MSRs fuel salt “hardens” its core’s neutron spectrum rendering it “faster”.

- 23 Xenon and krypton (roughly 16 wt% of all FP) comprise the majority of inert gas FP. Nonsoluble FP comprise elements (e.g., Pd, Ru, Re, Te, Ag, and Mo) too “noble” to exist as cations in its redox-controlled fuel salt stream and which therefore tend to accumulate as a metallic scum at the gas/liquid interface within the sparge gas disengaging system where they could be adsorbed onto nickel “wool”.

- 24 Descriptions of MSFR reprocessing systems still invariably invoke >20 stage counter current liquid-–liquid extraction systems like those assumed for ORNLs MSBR; for example, see slide 50 of Ref. [15].

- 25 Uranium separation/recycling is the best-proven of the technologies proposed/investigated for MSR salt clean-up [7]: elemental fluorine bubbled through the molten salt – either blanket or fuel – selectively oxidizes its uranium to gaseous UF6 that is then adsorbed upon a cool filter comprised of NaF salt granules. It would then be transferred to a second molten fuel salt slip stream by heating that filter and bubbling the re-evaporated UF6 through it along with sufficient hydrogen gas to convert (reduce) it back to salt-soluble UF4.

- 26 “Potentially” because solid-fuel reprocessing/recycling schemes for the LFR and GFR haven't been worked out yet and that proposed for the IFR is apt to be too expensive (see p. 124 of http://www.pdfdrive.net/fast-reactor-development-in-the-united-states-e2611848.html.)

- 27 A typical “deep burn” MSR scenario (e.g., ORNL/TM- 7207, available gratis at http://energyfromthorium.com/ornl-document-repository/) invokes a huge (~320 tonnes of fuel salt containing both thorium and 238U-denatured fissile in a BeF2/7LiF solvent moderated with ~1200 ton of graphite) one-fluid reactor that is to be operated for thirty years with no reprocessing other than gas sparging and noble metal scum removal. Fresh fissile (typically 20% 235U enriched uranium) is periodically added to compensate for the fact that although it exhibits “high” conversion (~0.8), it can't generate enough of its own fissile (233U and 239Pu) to continue operating without it. At the end of thirty years, everything including the graphite is to be “reprocessed” by whoever owns it at that time. Other than “simplicity”, the chief driver/rationale for this concept is greater proliferation resistance: imaginary terrorists who have managed to “divert” some of its intensely radioactive fuel salt would have to chemically isolate the uranium and/or plutonium in it and implement an equally surreptitious/successful isotopic separation process in order to generate bomb-grade fissile (some decision makers and most anti-nukes seem to take such ridiculous scenarios very seriously).

- 28 The reason for this is that the fissile generated in its 233Pa isolation/hold tank would contain insufficient 232U to discourage imaginary terrorists.

- 29 The assumed 6 liter/day reprocessing/discard rate is determined by the fuel salts REE FP solubility limit (Fig. 9), not achieving a CR of exactly 1.000 (see Fig. 6). Because there is still some uncertainty in 233Us fast neutron fission-to-capture ratio, a reprocessing/discard rate of up to 9–10 L/per day might eventually prove to be necessary.

- 30 Alkali metals generate “non bonded” oxygen atoms in glasses which lower their water leach resistance.

- 31 This figure assumes recycle of most of the fluorine as makeup ThF47LiF, NaF, etc., see Ref. [22].

- 32 The most promising super metal candidates tested to date are Hastelloy EM 721 and HN80MTY.

- 33 This scenarios MSFR TRU-waste generation figures were calculated by Carlo Fiorina using an “extended-EQL3D” program and the JEFF3.1 nuclear data base. LWR TRU-waste figures are based upon a recent analysis of 37 GWd/MTU Fukishima fuel rods (ORNL TM2010/286 http://info.ornl.gov/sites/publications/files/Pub27046.pdf). HTGR Pu-waste/GWe figures were calculated from the data in Julian Lebenhafts MS thesis (MIT 2001) http://hdl.handle.net/1721.1/28288 which source did not mention/discuss the minor actinides (MA).

- 34 And also less TRU waste than that apt to be generated by a sustainable version of the SFR (IFR). The reason for this is that any U/Pu based, solid-fueled breeder would build up a huge inventory of TRU (typically 5–15 tonnes/GWe) which, in that case, would be contained within ~100,000 steel-clad, sodium-containing, fuel pins all of which would have to be repeatedly dissolved/reprocessed/refabricated via an intrinsically “arty” batch-type pyrochemical process. The low TRU loss figures (typically <0.1%) usually attributed to the IFR (by far the most exhaustively studied of GIFs proposed fast reactor fuel cycles) ignores the fact that such low losses have never actually been achieved: see slide 16 of http://energy.gov/sites/prod/files/NEAC_Rev5.pdf.

- 35 Actinide discard eliminates most MA precursors and most of that which is produced would be burned to FP by this scenarios combination of ~3000 day in-core residence time and extremely high neutron flux (the MSFR is also a “deep burn” reactor).

- 36 The reasons for the MSFRs superior heat-to-electrical conversion efficiency are that it operates at a higher temperature than do either LWRs (~300°C) or LMFBRs (~500°C) and would also likely be coupled to more efficient turbines (supercritical CO2/Brayton instead of steam/Rankine).

- 37 It is almost impossible (too expensive, difficult, and “dirty”) to reprocess graphite-based solid reactor fuels, which means that it is almost impossible to implement a genuinely sustainable nuclear renaissance with reactors that require them.

- 38 Analysis of the numbers revealed by Ref. [26] suggests that WAMSRs core will contain about 47 tonnes of zirconium hydride encased within metallic cladding subject to the same conditions that a MSFRs core tank wall would experience. If it also lasts for 4 years, this translates to generating ~22 tonnes of a probably pyrophoric metallic radwaste/GWe-years worth of WAMSR power.

- 39 GOOGLE “Hastelloy N” and peruse ALIBABAs price quotes for “large lots.”

- 40 that is, probably under $50,000 worth of super metal/replacement. To put this into perspective, at 6 cents per kWhr, the electricity generated by the reference MSFR each day would be worth $2.16 million.

- 41 The USAs LWRs currently consume ~1000 kg of 7LiOH per year, 100% of which is imported. There is also currently very little demand for the pure 6Li that some of its fusion bomb warhead designs call for. Mole-wise, lithium is as common as chlorine in the Earths crust and most of it is 7Li.

- 42 Peak pressure anywhere within a MSFRs fuel salt system would be <100 psi (6.8E5 Pa) [16].

- 43 Most of chapter 6 of James Mahaffeys latest book, “Atomic Accidents”, is devoted to the “events” –mostly sodium leaks and fires – that have plagued most of the worlds sodium cooled reactors.

- 44 Assumptions: (a) all scenarios begin immediately (2014); (b) each LWR consumes 0.685 tonne of 235U per year (CR~0.4); (c) MSFR CR = 1.045; (d) all of the reactors generate ~3 GWt (consume ~3.13 kg fissile/day); and, (e) enrichment of natural uranium to 80% 235U rather than to 4.5% requires ~50% more SWUs (see http://www.wise-uranium.org/nfcue.html).

- 45 The dry-cask storage of todays huge backlog of spent LWR fuel is a fully developed, genuinely safe, and affordable technology. On the other hand, implementing a HLW repository for it (disposal) constitutes a “transcientific” (political) problem which means that NE R&D scientists/engineers can (and do) only “study” proposed solutions such as GIFs waste-burning reactor scenarios.

- 46 Since cost-related risk dominates decision making in the “Free World”, its electrical utility CEOs will be reluctant to employ reactors that would commit them to utilizing a fabulously expensive, tough-to-handle, low-quality fuel obtained via the “pyroprocessing” (by whom?) of spent LWR fuel, and then continuously separating/partially recombining/partially discarding everything (7Li, TRU, U, 233Pa, Th, and misc. FP) in that fuel in order to operate them. As had happened during the course of the USAs “Clinch River” LMFBR boondoggle, they are apt to believe that the adoption of an unnecessarily complex nuclear fuel cycle is unlikely to benefit them or their customers.

- 47 At $142/SWU, the enrichment cost of the fuel currently feeding the USAs LWRs adds ~$1.8 billion per year to its citizens’ utility bills (http://www.eia.gov/uranium/marketing/).

- 48 DOEs current management plan for that HEU is to down blend it with natural or depleted uranium to render it less attractive to the horde of imaginary terrorists seeking to “divert” fissile from the USAs civilian reactors. Its implementation would waste an already-made $5 billion SWU investment.

- 49 DOEs current management plan for that plutonium is to substitute it for 235U in “mixed oxide fuel” (MOX) destined for use by the USAs civilian LWRs (http://www.huffingtonpost.com/project-on-government-oversight/budget-for-mox-program-cu_b_2662552.html). That progam is currently 300% over budget (expenditures to date, ~$7.7 billion), a decade behind schedule, and has sparked zero interest from its proposed customers (MOX is far more radioactive than is their usual fuel and would therefore require extensive changes).

- 50 It also tacitly assumes that the USA will neither choose to reindustrialize itself (windmills and solar panels are too unreliable to power modern factories) nor address the root cause of climate change in time to head off probable disaster (i.e., by circa 2100 AD, see http://www.worldbank.org/en/topic/climatechange/publication/turn-down-the-heat.)

- 51 To get some idea of what the uranium industrys definition of “reasonable” could become if the whole world were to try to power itself with “advanced” LWRs, see… http://www.foe.org.au/anti-nuclear/issues/oz/u/cartel.

- 52 Readers are encouraged to GOOGLE the figures used in my examples and repeat the calculations with whatever they come up with - any reasonable set of different inputs will support the contentions.

- 53 This figure is ~190,000 times greater than that of the 235U in the earths oceans.

- 54 Electrical utilities are natural monopolies regulated in a way that guarantees a “reasonable” profit. The US Federal Governments employees (both direct and contractor) enjoy a similar monopoly on NE R&D research requiring the use and/or generation of other than trace levels of radionuclides and/or radiation.

- 55 “…nuclear engineering is to engineering as modern Islam is to religion”, (James Mahaffey, “Atomic Awakening: A New Look at the History and Future of Nuclear Power,” Pegasus Books, June 2009, p. XVI). This cultural characteristic plus a tight technical/academic job market inhibits innovation by lower level employees.

- 56 For example, it is incapable of siting a HLW repository anywhere within~640 million acres of federal land some of which (e.g., the Nevada Test Site) is both otherwise useless and already contaminated.

- 57 In contrast, Admiral Rickover had an unambiguous mission combined with both the will and technical talent required to make the decisions required to keep his project on track. He could not have succeeded if he had been either technically clueless or forced to embrace “all of the above” (unfocused).

- 58 Any one of the MSFRs in those parks could supply 100% of the worlds 99Mo requirement (its the radioisotope in the “cows” milked to generate the 99Tc used for medical imaging). Because its production has been outsourced to other countries, it now costs US consumers ~$350 million/year.

- 59 Two 1.5 GWe MSFRs coupled to a reverse osmosis-based seawater desalination plant could generate the ~5 million acre ft/year of water required to revive Californias already climate change impacted agriculture industry. A few more of them might be able to save Texas’ cattle industry.

- 60 https://www.armscontrol.org/act/2012_06/Resolving_the_Ambiguity_of_Nuclear_Weapons_Costs points out that DOE/NNSA currently spends ~$6.9 billion/a to maintain the USAs stockpile of nuclear weapons & that total (DOD+DOE) nuclear weapons-related expenditures are $20–40 billion/a. In 2014, total expenditures for “advanced nuclear reactor concept R&D” were $0.12 billion.

References

- Goeller, H. E., and A. M. Weinberg. 1976. The age of substitutability. Science191: 683–689, also available as OSTI 5045860

- Till, C., and Y. I. L. Yang. 2011. Plentiful energy: the story of the integral fast reactor. Create Space182–188.

- Forsberg, C. A., P. F. Peterson, and H. H. Zhao. 2004. An advanced molten salt reactor using high technology. ICAPP 04, Pittsburg, PA, Je13-17.

- 2008. Review of DOEs nuclear energy research and development program. Appendix A, NAP Press.

- Akerlund, I., and J. Freed. Nuclear energy renaissance set to move on without US. Third Way, Available at http://content.thirdway.org/publications/851/Third_Way_Report_-_Nuclear_Energy_Renaissance_Set_to_Move_Ahead_Without_U.S..pdf (A comprehensive description of what has been happening with USAs NE R&D programs) (accessed 14 August 2014).

- James, Lane (AEC). Fluid fuel reactors. Addison-Wesley (1958) (this book can be accessed gratis at http://energyfromthorium.com/ornl-document-repository/)

- MacPherson, H. G. 1985. Molten salt reactor adventure. Nucl. Sci. Eng.90: 374–380.

- Whatley, M. E., L. E., McNeese, W. L., Carter, L. M., Ferris, and E. L., Nicholson.1970. Engineering development of the MSBR fuel cycle. Nucl. Appl. Technol.8: 170–178. (can be accessed gratis at http://energyfromthorium.com/ornl-document-repository/)

- Mathieu, L., D. Heuer, R. Brissot, C. Garzenne, C. Le Brun, Lecarpentier, et al. 2009. Possible configurations for the TMSR and advantages of the fast non moderated version. Nucl. Sci. Eng.161:78–89.

- Mathieu, L., D. Heuer, E. Merle-Lucotte, R. Brissot, C. Le Brun, E. Liatard, et al. 2006. The thorium molten salt reactor: moving on from the MSBR. Prog. Nucl. Energy48:664–679.

- Mourogov, A., and P. M. Bokov. 2006. Potentialities of the fast spectrum molten salt reactor concept: REBUS-3700. Energy Convers. Manage.47:2761–2771.

- Ignatiev, V., O. Feynberg, I. Gnidoi, A. Merzlyakov, V. Smirnov, A. Surenkov, et al. 2007. Progress in development of Li,Be,Na/F Molten SaltActinide Recycler & Transmuter Concept. Proc. ICAPP 2007, May 13–18, Nice, France.

- EVOL Project. 2012. Evaluation and viability of liquid fuel fast reactor systems. Available at: http://www.li2c.upmc.fr/.

- Aufiero, M., and O. Geoffrey. 2013. A few comments on the MSFR safety and design optimization. EVOL Meeting, Grenoble, France 26–28 June 2013.

- E Merle-Lucotte. Introduction to the Physics of the MSFR. Thorium Energy Conference 2013 (ThEC13) – Cern, Geneva, Available at http://indico.cern.ch/getFile.py/access?contribId=36%26sessionId=9%26resId=1%26materialId=slides%26confId=222140 (accessed 9 Jan 2015).

- Aufiero, M., et al. 2013. An extended version of the SERPENT-2 Code to investigate fuel burnup and core evolution in the molten salt fast reactor. J. Nucl. Mater.441:473–486.

- Fiorina, C. The molten salt fast reactor as a fast-spectrum candidate for thorium implementation. Doctoral dissertation, POLITECNICO DI MILANO, 2013, Available at https://www.politesi.polimi.it/bitstream/10589/74324/1/2013_03_PhD_Fiorina.pdf (accessed 9 Jan 2015).

- Merle-Lucotte, E., D. Heuer, M. Allibert, M. Brovchenko, N. Capellan, and V. Ghetta. 2011. Launching the thorium fuel cycle with the molten salt fast reactor. Proc. ICAPP 2011, May 2–5, Nice, France.

- Merle-Lucotte, E., D. Heuer, M. Allibert, V. Ghetta, and C. Le Brun. 2008. Introduction to the physics of molten salt reactors. Materials issues for generation IV systems. NATO Sci. Peace Security Ser. B Phys. Biophys.2008:501–521.

- Olson, L. C. Materials corrosion in molten LiF-NaF-KF eutectic salt. Section 2–8, Ph.D. Dissertation, UWM, 2009, Available at http://allen.neep.wisc.edu/docs/dissertation-olson-luke.pdf.

- Siemer, D.. 2012. Improving the integral fast reactors proposed salt waste management system. Nucl. Technol.178:341–352.

- Siemer, D.. 2014. Molten salt breeder reactor (MSBR) waste management. Nucl. Technol.185:101–108.

- Scott, C. D., and W. L. Carter. Preliminary design study of a continuous fluorination-vacuum distillation system for regenerating fuel and fertile streams in a molten salt breeder reactor. ORNL-3791, UC-80-ReactRt Technology, TID-4500, 1966

- Forsberg, C. W., P. F. Peterson, and R. A. Kochendarfer. Design options for the advanced high temperature reactor. Proceedings of ICAPP ‘08, Anaheim CA, Je 8-12, 2008.

- Thorium-Fueled Molten Salt Reactors Weinberg Foundation Je2013 p. 14, http://www.the-weinberg-foundation.org/wp-content/uploads/2013/06/Thorium-Fuelled-Molten-Salt-Reactors-Weinberg-Foundation.pdf

- TRANSATOMICPOWER. Technical white paper, V 1.01. Available at http://transatomicpower.com/white_papers/TAP_White_Paper.pdf (accessed March 2014).

- Progress in radioactive graphite waste management. IAEA TECDOC 1647, 2010 http://www-pub.iaea.org/MTCD/Publications/PDF/te_1647_web.pdf

- Serp, J., and H. Boussier. Molten salt reactor system 2009–2012 status. Available at http://www.iaea.org/NuclearPower/Downloadable/Meetings/2013/2013-02-28-03-01-INPRO-GIF/11.anzieu1.pdf (accessed 9 Jan 2015).

- Olson, L. C. Materials Corrosion. (Ref 20, Section 4–8).

Document information

Published on 01/06/17

Submitted on 01/06/17

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?