Abstract

Flexible supercapacitors, a state-of-the-art material, have emerged with the potential to enable major advances in for cutting-edge electronic applications. Flexible supercapacitors are governed by the fundamentals standard for the conventional capacitors but provide high flexibility, high charge storage and low resistance of electro active materials to achieve high capacitance performance. Conducting polymers (CPs) are among the most potential pseudocapacitor materials for the foundation of flexible supercapacitors, motivating the existing energy storage devices toward the future advanced flexible electronic applications due to their high redox active-specific capacitance and inherent elastic polymeric nature. This review focuses on different types of CPs-based supercapacitor, the relevant fabrication methods and designing concepts. It describes recent developments and remaining challenges in this field, and its impact on the future direction of flexible supercapacitor materials and relevant device fabrications.

Introduction

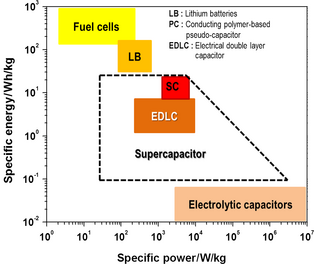

To meet the future demand of the portable and flexible cutting-edge electronics in modern society, it is strongly required to develop next-generation inexpensive, flexible, light-weight, and sustainable energy storage systems with large energy and power density [1-4]. Over the past few years, electrochemical supercapacitors (ESs) have been attracted as a promising energy storage device, due to the higher power density, faster charge-discharge cycles and higher energy storage as compared with the Li-ion batteries [5, 6]. The ESs are ideal electrochemical energy storage devices that possess high energy-storage capacity of conventional battery with the high power supply capability of conventional capacitor, bridging the gap between the traditional capacitor and the battery with long life and the eco-friendly operation, as is evident from the Ragon plot shown in Figure 1.

|

|

|

Figure 1. Ragone plot shows the energy vs. power density comparison of supercapacitors with the other energy storage devices. |

Advances in material science and technology, and the strong consumer market demand for portable, thin and flexible devices, are boosting the rapid development of flexible electronics such as roll-up displays, touch screens, smart electronics, smart textile, wearable sensors. In order to facilitate the growing electronic market, the trend in ES development moves towards the flexible and light-weight electro active materials. Recently, several approaches for flexible supercapacitors have been demonstrated, such as wire-shaped [7], fiber-shaped coaxial supercapacitors [8], carbon nanotubes (CNTs)-based smart textiles, and highly stretchable fiber-shaped supercapacitors [9, 10]. However, the performance of these supercapacitors based on high surface area of carbon nanostructures, usually referred as the electrochemical double-layer capacitors (EDLCs), is limited by their inherent low specific capacitance [11-15]. On the contrary, another group, known as pseudocapacitors, based on transition metal oxides (MOx) [16, 17] and conducting polymers (CPs) [18-21] redox active materials, show very high capacitance behavior. Among the above-mentioned supercapacitor materials, CPs-based pseudocapacitors, with their high-redox active capacitance, high conductivity and, most importantly, high intrinsic flexibility, have promised the most for high performance portable and flexible supercapacitor applications [22-24]. In recent development of CPs-based flexible ES applications, several approaches have been adopted to employ either the CPs alone [25-28] or composites of CPs with carbon materials [29-37] as the electrode materials. Here, in this review, we focus on the recent progress in the development of CPs and their composites for the development of flexible supercapacitors. The highlight of the most recent prototype flexible and bendable supercapacitors is presented in this review with the aim to specify the recent research directions toward the future portable electronic applications.

Materials for Flexible Supercapacitors

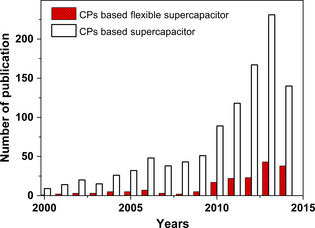

In the last few years, supercapacitors have been extensively studied with three principle types of electrode materials [38], namely carbon-based high surface area materials [39-50], transition metal oxides (MOx) [51-66], and CPs [22, 67-75]. Carbon-based high surface area materials such as activated carbon (AC), CNTs, graphene, graphene oxide (GO), and carbon fibers (CFs) are the common active electrode materials in non-Faradaic EDLCs, while CPs (polyaniline, polypyrrole, and polythiophene) and metal oxides (RuO2, MnO2, V2O5, and Fe2O3, etc.) are frequently and successfully used as the electrode materials for the Faradaic pseudocapacitors. The specific capacitance of EDLCs depends on the exposed surface area and the charge storage capacity of the carbon-based electro active materials. EDLCs show very high power capability due to the rapid sorption and desorption of ions at the solution interface close to the electrode surface. However, the specific capacitance of EDLCs is limited due to the non-Faradaic charge storage mechanism. In contrast, the pseudocapacitors show 10–100 times higher specific capacitance than the EDLCs due to the involvement of Faradaic (redox-reaction) charge storage mechanism taken place in the bulk of the active materials. Interestingly, none of these above-mentioned materials is ideal, and each of them has pros and cons, which has been summarized in Table 1. For instance, carbon-based materials can provide high power density and stability but its low specific capacitance limits its application for high-energy density devices. Metal oxides/hydroxides possess pseudocapacitance, along with the double layer capacitance, wide charge-discharge potential range; however, their application is restricted by limited surface area, low conductivity, high cost, toxicity, and poor stability. CPs have the advantages of high specific capacitance, good conductivity, low cost and ease of fabrication, but relatively low mechanical stability and cycle life constraint their performances. Importantly, among the variety of the materials explored for ES applications, in the last few years, CPs have drawn a greater deal of interest for flexible application, due to their inherent flexible polymeric nature, which is a crucial requirement for the portable flexible electronics. This is clearly illustrated in Figure 2, which shows the recent uprising trend in the number of research publications related to the CPs-based flexible supercapacitor applications, which is quite analogous to the rising demand of the flexible application.

| Physicochemical properties | Carbone materials | Metal oxides | Conducting polymers |

|---|---|---|---|

| |||

| Non faradic capacitance | ☺☺☺☺ | ☺☺ | ☺☺ |

| Faradic capacitance | ☻ | ☺☺☺☺ | ☺☺☺☺ |

| Conductivity | ☺☺☺☺ | ☺ | ☺☺☺☺ |

| Energy density | ☺ | ☺☺☺ | ☺☺ |

| Power density | ☺☺☺ | ☺ | ☺☺ |

| Cost | ☺☺ | ☺☺☺ | ☺☺ |

| Chemical stability | ☺☺☺☺ | ☺ | ☺☺☺ |

| Cycle life | ☺☺☺☺ | ☺☺ | ☺☺ |

| Easy fabrication process | ☺☺ | ☺ | ☺☺☺ |

| Flexibility | ☺☺ | ☻ | ☺☺☺ |

|

|

|

Figure 2. Yearly evolution of the number of publication related to conducting polymer-based supercapacitors and flexible supercapacitors application. Source of the data: Web of Science. |

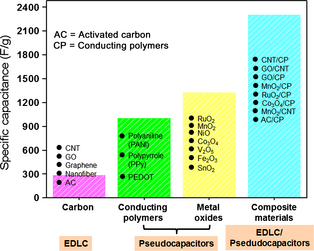

In Figure 3, we have summarized the specific capacitance of the representative EDLCs and pseudocapacitors systems based on various active materials as surveyed from the literature. Carbon materials normally show specific capacitance under 300 F/g, while CPs and MOx can achieve around 1000 F/g. Aside from these three categories of materials, a composite class of materials combining two or more of the abovementioned materials can achieve very high specific capacitance up to 2000 F/g. In the past few years, it has been well demonstrated that the development of binary or ternary nanocomposites of these different capacitive materials become the novel approaches to control and optimize the structures and physical and mechanical properties of electrode materials, in order to achieve the enhanced performance for supercapacitors [76-80]. Various hybrid systems like MOx/CNTs [81-87], CPs/GO [80, 88-92], CPs/CNTs [93-102], and MOx/CPs [103-106] have been developed to improve the specific capacitance, stability, and energy density. However, the properties of composite electrodes depend not only upon the individual active components but also on the morphology and the interfacial characteristics.

|

|

|

Figure 3. Comparison of various materials according to their specific parameter for supercapacitor applications. |

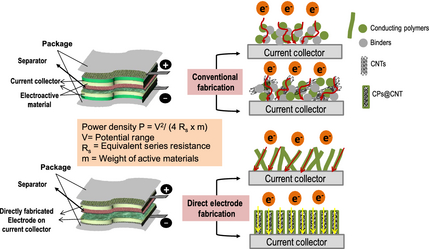

Unlike the traditional capacitors, flexible supercapacitors require the development of flexible components, that is, not only the flexible materials for active electrodes but also the current collector with high mechanical properties (flexibility). Compared to the other common active electrode materials, CPs are most promising due to their inherent flexible polymeric nature suitable for flexible supercapacitor applications. The wet chemical polymerization and electrochemical polymerization (electropolymerization) processes are the most common approaches for the construction of CPs-based supercapacitor. However, the construction of CPs-based flexible supercapacitor by using the traditional slurry-based wet chemical polymerization process is still challenged in terms of practical device fabrication and performance. Conventionally, the slurry-based chemically polymerized CPs are mixed with binders/additives to construct the electrode. Such electrodes suffer from the sluggish rate of ion transport during the redox reaction due to the high interfacial resistances and the inherent resistance of the binder materials, and hence the poor device performance. In order to overcome such a limitation and improve the device performance, the direct growth method has been adopted to construct the CPs directly on the current collectors for supercapacitor applications. This direct growth concept was reported in fuel cell device fabrication in 2005 [107, 108]. Wang et al. [109] have demonstrated that the direct growth of CNTs on carbon cloth (CC) electrode could improve the electron transport and hence the device performances for fuel cell application. Taking advantage of direct growth method, Horng et al. [110] have first demonstrated the polyaniline nanowires (PAn-NWs) on CC synthesized by the electropolymerization technique. This direct electropolymerization method is one of the promising techniques for the binder-free fabrication of CPs or any composite materials on a chosen flexible substrate. Such binder-free active materials directly synthesized on current collectors could achieve very high specific capacitance due to the low interfacial resistance and electron transport, which become a very promising step towards the future development of flexible supercapacitors.

Conducting Polymer-Based Flexible Supercapacitors

CPs are organic polymers that conduct electricity through a conjugated bond system along the polymer chain. In the past two decades, the CPs are extensively explored for ES application due to their reversible Faradaic redox nature, high charge density, and lower cost as compared with the expensive metal oxides [68, 111, 112]. Among all kinds of CPs, polyaniline, polypyrrole, and derivatives of polythiophene have been widely studied as active electrode materials for ESs due to the high electrical conductivity, high pseudocapacitance, and low cost [79, 93, 94, 112-117]. Recently, the CPs are considered to be one of the most promising electrode materials for flexible supercapacitor application due to their high flexibility and ease in fabrication [94]. Morphology of CPs plays an important role in their electrochemical performances. In literature, CPs in various forms, such as bulk powder, nanosheets, nanorods, and nanowalls, along with their versatile availability, have been synthesized and applied successfully. Nanostructured CPs with high surface area and high porosity give the good performances because of their distinctive characteristics of conducting pathways, surface interactions, and high surface-to-volume contribution in nanoscale dimensions. Recent researches demonstrated that the CPs in one-dimensional nanostructures could achieve very high pseudocapacitance compared to its bulk counterpart [20].

Polyaniline

Polyaniline (PAn) is one of the most promising conducting polymer which has been frequently used as a low-cost positive electrode material for ES application due to its variable oxidation state, and excellent doping-dedoping characteristic, which contributes to a very high specific pseudocapacitance [68, 95, 118-129]. Although the protonated emeraldine form of polyaniline has reported to have very poor conductivity, it is one of the most studied CPs due to its high doping level and environmental stability [68, 130]. Theoretically, the maximum doping level of p-type PAn can be achieved to 0.5 (i.e., two monomer units per dopant), and its working potential window can be extended to around 0.7 V, with a maximum theoretical-specific capacitance up to 2000 F/g [131].

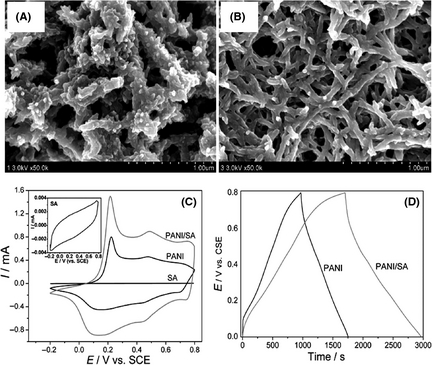

PAn has been synthesized by both chemical and electrochemical oxidation methods using various substrates (i.e., carbon, nickel, stainless steel, and flexible substrates) or blended with a range of materials for ES application. A number of literature reports on PAn-based supercapacitors demonstrate a wide range of specific capacitance from 30 to 3000 F/g. Such deviation is related to various factors like the polymerization process, structural morphology, dopant concentration, and the ionic diffusion length of the electro active material. The perfect requirements for the development of PAn-based pseudocapacitor are the high surface area and the nanoscale architectures that can be achieved in the presence of various dopants in optimized condition. Li et al. [132] have synthesized the nanostructured polyaniline/sodiumalginate (PAn/SA) composite in bulk quantities by a facile solution method, as shown in Figure 4. The electrode of PAn/SA nanofibers, with diameters from 50 to 100 nm, exhibited an excellent electrochemical property (Fig. 4B). It has been observed that electropolymerized PAn had higher specific capacitance (2093 F/g) than the chemically polymerized pure PAn.

|

|

|

Figure 4. (A and B) SEM images of pure PAn and PAn/SA, (C) Cyclic votammograms of SA, pure PAn, and PAn/SA electrodes at a scan rate of 100 mV/s, (D) Galvanostatic charge/discharge curves of pure PAn and PAn/SA nanofiber electrodes at a current density of 1 A/g in 1 mol/L H2SO4. Reproduced with permission [132]. Copyright 2011. American Chemical Society. PAn/SA, nanostructured polyaniline/sodiumalginate; PAn, polyaniline. |

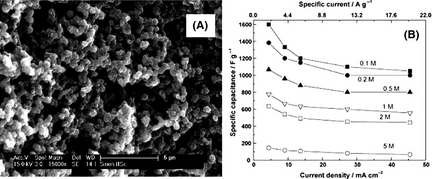

It has been reported that electropolymerized PAn, in presence of Triton X-100 on Ni-electrode, showed very high specific capacitance around 2300 F/g with a consistence charge-discharge cycle stability upto 1000 cycles [133]. In another study, PAn has been deposited on the porous carbon by the potentiodynamic method achieving a very high specific capacitance of 1600 F/g at a current density of 2.2 A/g (Fig. 5). The PAn deposited porous carbon showed fairly adherent, stable electrochemical capacitance over a large number of cycles (~1000) at a high current density (19.8 A/g) [134].

|

|

|

Figure 5. (A) SEM image of PAn/C electrode. (B) Variation of specific capacitance of PAn/C electrode at various charge-discharge current densities. Reproduced with permission [134]. Copyright 2007. Elsevier. PAn, polyaniline. |

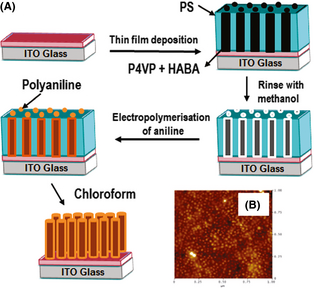

In recent years, fabrication of ordered and aligned nanostructures, including PAn nanostructures, have received significant attention for their superior energy storage application [135-139]. Kulia et al. [140] have demonstrated ordered arrays of vertically aligned PAn nanorods using nanotemplate based on supramolecular assemblies of block copolymer on transparent ITO substrate, as shown in Figure 6. The PAn nanorod arrays with nano-spacing showed super electrochemical property with highest capacitance value achieved around 3407 F/g. However, this ultra-high specific capacitance result for PAn nanorods is contradictory and raises question on the basic understading of PAn-based supercapacitors. Peng et al. [141] have demonstrated that such high specific capacitance value could not be matched with the Faradaic charge storage stoichiometry and existing understanding of electrochemistry of PAn. Additionally, their experimental results and theoretical calculations showed that such ultra-high specific capacitance could only be possible due to the result of an experimental or calculation oversight based on underestimated mass of PAn nanorods. Therefore, for the supercapacitors research based on CPs or other redoxactive materials, high caution is needed to get accurate results.

|

|

|

Figure 6. (A) Schematic presentation of the PAn nanorods synthesis (B) AFM image of PAn nanorods. Reproduced with permission [140]. Copyright 2009. Royal Society of Chemistry. PAn, polyaniline. |

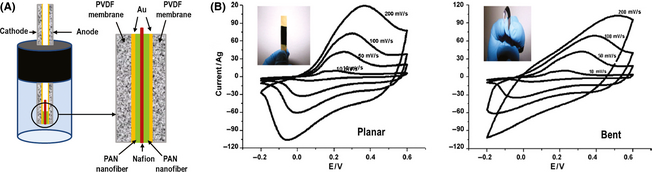

However, the template-based synthesis method is very complex, also unsuitable for the large-scale fabrication. Recently, considerable efforts have been focused on the synthesis of template-free PAn nanostructures. Kim et al. [142] have demonstrated a novel idea of PAn-based highly stable flexible supercapacitor electrode, fabricating a PAn nanofiber electrode on gold-coated polyvinylidene fluoride-co-hexafluropropylene (PVDF). They encapsulated the PAn nanofiber electrode on PVDF in Nafion to demonstrate the highly stable flexible supercapacitor, as shown in Figure 7. Figure 7B shows the performance of a practical flexible-pseudocapacitor of the composite planar and bent electrode. Generally, the PAn-based supercapacitor electrode shows very impressive specific capacitance value although with limited cycle stability. To overcome the stability issue, a range of composite materials and the relevant interface study is required to develop the flexible PAn-based supercapacitors. Recent advanced studies revealed that the incorporation of nanoscale templates, such as CNTs and graphene, has positive influences on the electrochemical properties of the flexible PAn-based supercapacitors [48].

|

|

|

Figure 7. (A) Schematic electrochemical cell of PAn-nanofiber/nafion electrode. (B) Cyclic voltammograms of planar and bent electrode. Reproduced with permission [142]. Copyright 2010. Elsevier. PAn, polyaniline. |

Polypyrrole

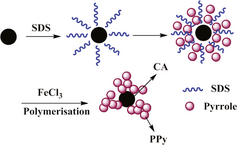

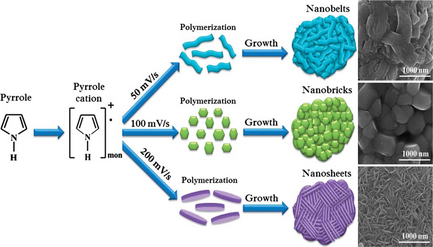

Polypyrrole (PPy) is one of the most promising p-type CPs for the Faradaic pseudocapacitor application due to its unique features such as high conductivity, fast charge-discharge mechanism, good thermal stability, low cost, and high energy density [72, 143-147]. Like PAn, the electrochemical behavior of the PPy-based electrode also depends on the electrode preparation methods and effective surface area of the active electrode. PPy is typically doped with a single-charge and multiple charge anions [148]. It is well reported that the cross-linked PPy has very high capacitance due to high ion diffusivity and porosity of the active material. However, dense and thicker growth of PPy on the current collector reduces the capacitance due to the limited dopants' access to the interior sites of the polymer backbone. In last few years, the CPs-based research has been extensively focused on PPy for the preparation of the pseudocapacitor electrode via either chemical or electrochemical routes. The chemical oxidation-polymerization can synthesize a wide range of PPy nanostructures in presence of excess surfactants but it very difficult to fabricate an electrode for ES application due to the high internal resistance in the presence of binders as mentioned earlier. An et al. [143] have synthesized the PPy/carbon aerogel composite by chemical oxidation polymerization for supercapacitor application, as shown in Figure 8, achieving a specific capacitance of 433 F/g. Recently, Kumar et al. [149] demonstrated that a specific capacitance of 395 F/g could be achieved in p-tolune-sulfonate (pTS)-doped PPy/C composites in Na2SO4 aqueous solution. For direct growth of PPy on the current collector, the electropolymerization process is mostly used for supercapacitor application [150, 151]. In 2012, Dubal et al. [152] have demonstrated various nanostructures of PPy on stainless steel via electropolymerization method for ES application, as shown in Figure 9. Compared to other nanostructures, the PPy nanosheets showed the best specific capacitance (586 F/g). This PPy nanosheet architecture on an appropriate flexible substrate can be an effective approach for the future flexible supercapacitor application. Kim et al. [144] demonstrated a novel approach to prepare a highly stable nafion-doped PPy electrode for ES application.

|

|

|

Figure 8. Schematic of the synthesis process of PPy/CA composite. Reproduced with permission [143]. Copyright 2010. Elsevier. PPy, polypyrrole. |

|

|

|

Figure 9. Synthesis of PPy nanostructures by electropolymerization. Figures on right show SEM images of the nanobelt, nanobrick and nanosheet architectures of PPy. Reproduced with permission [152]. Copyright 2009. Royal Society of Chemistry. PPy, polypyrrole. |

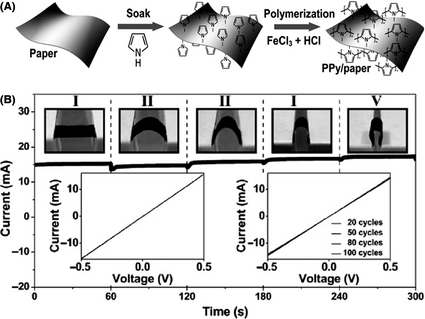

Interestingly, in the recent years, PPy has been extensively focused on the development of the flexible electrode due to its superior flexibility and higher conductivity nature in comparison with the polyaniline and polythiophene. Last year, Yuan et al. [153] have demonstrated a simple “soak and polymerization” method to fabricate PPy-coated paper (Figure 10A). The PPy/paper composite flexible electrodes showed a capacitance of 0.42 F cm−2 with high energy density of 1 mW h cm−3 at a power density of 0.27 W cm−3. In Figure 10B, the conductance stability of the PPy-coated paper at different curvature (bending) state was measured by monitoring the current at a potential of 0.5 V. The conductance of the PPy-coated-paper remained almost constant after 100 cycles of bending. This method is one of the potential low-cost approaches for a large-scale production of conductive paper-based electrode for energy storage applications and flexible electronics and spurred an intense drive to the related fields. However, this material has not been realized with high performances yet; therefore a significant development is needed to reach a very high specific capacitance for a practical application.

|

|

|

Figure 10. (A) Fabrication process of polypyrrole-coated paper (B) Current–time curves of PPy-coated paper bent with different curvatures under a constant voltage. The upper insets reveal the five bending states. The lower insets record the current–voltage curves of PPy-coated paper without bending (left), and after 20, 50, 80, and 100 cycles of bending. Reproduced with permission [153]. Copyright 2009. Royal Society of Chemistry. PPy, polypyrrole. |

Polythiophene and its derivatives

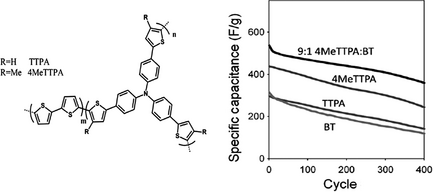

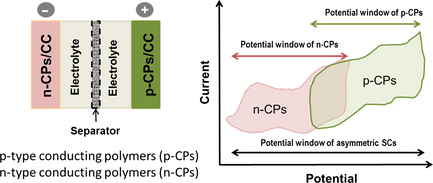

Polythiophene (PTh) and its derivatives can be both p- and n-type CPs. In general, the polythiophene shows poor conductivity but the p-doped polymers are highly stable in air and humidified environment. The specific capacitance of the PTh-based electrode is usually lower as compared with PAn or PPy but the major advantage is that it can work in a comparatively higher potential window (~1.2 V) [154, 155]. This wide negative potential window helps to construct an asymmetric type CPs-based supercapacitor device. Among all the thiophene-based polymers, poly(3,4-ethylenedioxythiophene) (PEDOT), poly(3-(4-flurophenyl)thiphene) (PFPT), poly(3-methyl thiophene) (PMeT) and poly(ditheno(3,4-b:3′,4′d) thiophene) (PDTT) are popular and successfully used for the supercapacitor application. The reported specific capacitance values of these polymers are in the range of 70-200 F/g [154-156]. In the last few years, PEDOT has explored as a most promising pseudocapacitor material due to its high environmental stability [94, 157]. Liu et al. [158] have demonstrated the electropolymerized PEDOT in ionic liquids for potential ES applications. Furthermore, for supercapacitor application, Samui et al. [159] have reported PMeT/C electrode in solid–state gel–polymer electrolyte system. In an extensive research, Kearns et al. have demonstrated that by incorporating suitable, efficient and reversible redox couples in a conventional PTh-based system could enhance the energy and power density of the pseudocapacitor; and furthermore, improve the Faradaic charge storage capacity of the PTh-based polymer by molecular variations [160]. In another approach [161], they have synthesized low-cost thiophene-based copolymer with triarylamine by electro copolymerization process to enhance the charge storage capacity of the PTh supercapacitor. Figure 11 shows the chemical structure of triarylamine-thiophene copolymer and its comparatively higher and stable (400 cycles) specific capacitance as compared with the pure poly(bi-thiophene).

|

|

|

Figure 11. Triarylamine–thiophene copolymer and specific capacitance with various cycles. Reproduced with permission [161]. Copyright 2012. Royal Society of Chemistry. |

In 2009, Robert et al. [162] have reported a new class of dendritic poly(tris(thiophenylphenyl)amine) (pTTPA) conducting polymer. This dendritic pTTPA-based electrode showed high specific capacitance (950 ± 40 F/g) in an organic electrolyte at a potential scan rate of 50 mV/s. This versatile amorphous polymer film opens a new opportunity for the PTh-based ES application. Recently, Österholm et al. [163] have demonstrated the capacitive behavior of PEDOT-films as a flexible supercapacitor electrode in the ionic liquid and organic gel electrolytes. In another approach, Nejati et al. [164] fabricated the ultrathin PTh films within the porous AC nanostructures and increased the specific and volumetric capacitance by 50% and 250%, respectively, as compared with the pure AC. Recently, D'Arcy et al. [165] synthesized nanostructures of the poly(3,4-ethylenedioxythiophene) with large surface areas by vapor phase polymerization for a highly conducting and efficient nanofibrillar electrode which exhibited a specific capacitance of 175 F/g. This novel approach utilizing the vapor phase polymerization method leads to the strong adhesion between the deposited CPs and the current collector, as exhibited by good cycle stability and a low internal resistance. These PTh-based ES researches show a promising step for the future development of the CPs-based flexible energy storage device.

Composite materials-based flexible supercapacitors

CPs are considered as one of the most attractive supercapacitor material due to its inherent flexibility, high charge density, low cost, good environmental stability, and ease-in-synthesis. Unfortunately, the poor cycle stability of CPs greatly restricts its practical utilization. Approaches to the fabrication of composite electrodes combining CPs with carbon materials or metal oxides can offer an effective solution to overcome some of the drawbacks of the CPs-based pseudocapacitors. A number of composite materials based on CPs combined with CNTs [94, 95, 146, 166-170], graphene oxides (GO) [89, 90, 171-178], CC [110, 179, 180], metal oxides (MnO2, CoO3, RuO2) [103, 181-183] have been demonstrated showing highly stable supercapacitive performance, which is mainly attributed to the enhanced conductivity and/or redox behavior of the CPs-composites by CNTs or GO or MOx integration. The composite electrodes have been explored not only to improve the cycle-life and conductivity, also open the possibility of having additional physical properties depending on the individual components and their mutual interactions. Recent development of the flexible CPs-based supercapacitors mainly focus on the carbon-based binary composites than the other oxide-based composites due to high mechanical strength, conductivity and stability of the former, and also because of accessibility of carbon nanostructures in various forms.

Carbon nanotube-based composites

CNTs are well known for their high conductivity and mechanical strength. Both single-wall and multiwall CNTs (viz., SWCNTs and MWCNTs, respectively) have been extensively explored as the EDLCs. It has been well reported that the presence of a thin amorphous defective layer on the outer surface of the CNTs could improve the specific capacitance due to the better charge accumulation [43]. Literature reviews of electrodes made from CPs showed the advantage of possessing very high pseudocapacitance. However, a key weakness of the CPs-based ES electrode is its mechanical instability due to the considerable volume change, repetitive swelling–shrinking, because of ion insertion and release during the repeated charge–discharge cyclic process. Consecutively, the binary composites of CPs with CNTs have been explored extensively, and the studies demonstrated an impressive improvement of mechanical stability and performance of the supercapacitor electrode [184, 185]. In the composite materials, conjugated CPs is effectively attached on the surface of the CNTs via π–π interaction. Significant progress has been made in preparing CNTs/polymer composites in nanostructure or thin film configuration by in situ electropolymerization or chemical oxidative polymerization approaches for ES applications. For instance, Gupta et al. successfully synthesized a PAn/SWCNTs composite electrode and obtained a mass-normalized specific capacitance of 463 F/g of and an area-normalized specific capacitance of 2.7 F/cm2 [186]. Sivakumar et al. [187] synthesized PAn/MWCNTs composite electrode by in situ chemical polymerization, achieving a high initial mass-normalized specific capacitance of 606 F/g. Zhang et al. [116] successfully deposited PAn onto vertically aligned CNTs for preparing supercapacitors, and a high mass-normalized specific capacitance of 1030 F/g was obtained. Other than the oxidative chemical polymerization method, CNTs/polymer nanocomposite can be effectively prepared by an electropolymerization process onto conducting flexible substrates. Hughes et al. [97] have potentiostatically deposited PPy onto the aligned MWCNTs to fabricate the nanocomposite with a large specific capacitance (2.55 F/cm2). In another approach, Li et al. [188] have fabricated a unique CNT/PPy core-shell sponge, and demonstrated its application as a highly compressible supercapacitor electrode with high performance (300 F/g). Fang et al. employed pulsed electrodeposition technique using well-separated short potential pulses, which would allow the pyrrole monomers to diffuse into the carbon materials' pore spaces between the polymerization pulses. A significant improvement in the uniformity of PPy coatings on CNTs has been achieved [189]. Recently, Lin et al. [190] have synthesized aligned PAn/MWCNT composite films with good elasticity via electrochemical route. The flexible composite electrode showed high specific capacitance signifying high stability with bent angle upto 180 degree (Fig. 12).

|

|

|

Figure 12. (A) SEM of the PAn/MWCNT composite (inset photograph showing that the supercapacitor is transparent and flexible). (B) Specific capacitance for a supercapacitor based on the PAn/MWCNT measured at various bent angles, Reproduced with permission [190]. Copyright 2013. Nature Publishing Group. MWCNT, multiwall carbon nanotube; PAn, polyaniline. |

Graphene/graphene oxide-based composites

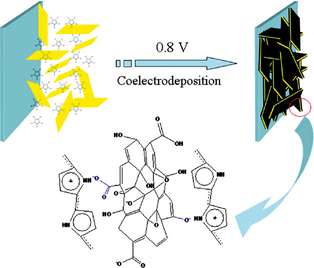

Graphene has wide potential applications in energy-related systems, mainly because of its unique one atom-thick 2D structure, high electric or thermal conductivity, great mechanical strength, inherent flexibility, and huge specific surface area. In recent years, there arises an intensive trend to mix CPs with graphene materials to form composites to fabricate flexible ES electrodes [191]. The porous layer structures of graphene not only facilitate the transport of electrolyte ions within the electrodes hence improve the specific capacitance, but also control the morphology of CPs in the graphene/polymer composite. The first graphene/CPs composite was reported in 2010 [192], in which PAn nanostructures have vertically grown on the graphene surface by electrodeposition method, achieving a significantly high specific capacitance (550 F/g). Thereafter, both covalent and noncovalent strategies have been adapted to preparing the graphene/polymer composites for development of flexible supercapacitors. Zhou et al. [175] have synthesized GO/PPy nanocomposite films by a one-step co-electrodeposition method, as shown in Figure 13. Here, the relatively large anionic GO served as a weak electrolyte and was entrapped in the PPy nanocomposites during the electrochemical polymerization, and also acted as an effective charge-balancing dopant within the PPy.

|

|

|

Figure 13. A typical a one-step co-electrodeposition method for the synthesis of GO/PPy nanocomposites. Reproduced with permission [175]. Copyright 2012. Royal Society of Chemistry. PPy, polypyrrole; GO, graphene oxide. |

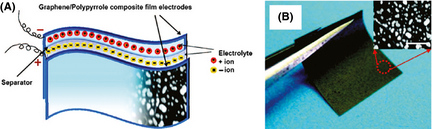

Further, Davies et al. [174] have developed flexible, uniform graphene/PPy composite films using a pulsed electropolymerization for supercapacitor electrodes (Fig. 14). This flexible supercapacitor film could achieve high energy and power densities, due to the favorable nucleation of the PPy chains at defects sites in the graphene surface.

|

|

|

Figure 14. (A) Schematic diagram of the Graphene/PPy composite based flexible supercapacitors, (B) SEM image of the G/PPy. Reproduced with permission [174]. Copyright 2011. American Chemical Society. PPy, polypyrrole. |

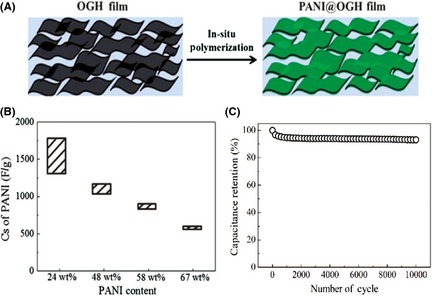

Recently, Zhang et al. [176] have demonstrated a flexible composite membrane of reduced graphene oxide and polypyrrole nanowire (RGO–PPy) via in situ reduction of GO in presence of PPy nanowires (PPy-NWs). A symmetric supercapacitor has been fabricated by direct coupling of two membrane electrodes, without the use of any binder or conductive additive. The supercapacitor achieved a large areal capacitance (175 mF/cm2) and excellent cycling stability. The in situ reduction of GO in the composite dispersion with PPy-NWs renders the formation of the RGO–PPy composite foam via self-assembly, as shown in Figure 15. A recent study by Wang et al. [193] on oriented graphene hydrogel (OGH)/PAn composite film suggested that if PAn nanostructure is properly engineered, PAn could provide a combination of high capacitance and long cycling stability. In the PAn/OGH composite, as the PAn content increased from 24 to 67 wt%, the specific capacitance drastically decreased from 1739 to 574 F/g, as shown in Figure 16B. Furthermore, the composite shows a very high stability upto 10,000 cycles (Fig. 16C). Interestingly, this is a promising approach towards the development of the high performance flexible supercapacitors.

|

|

|

Figure 15. Formation processes of RGO–PPy foam and RGO/PPy membrane [176]. Copyright 2013. Royal Society of Chemistry. RGO, reduced graphene oxide; PPy, polypyrrole. |

|

|

|

Figure 16. (A) Schematic preparation of a PAn/OGH film, (B) specific capacitance of PAn vs. its own weight at the current density of 10 A/g, (C) Capacitance retention of PAn (48 wt%)/OGH film at a current density of 100 A/g for 10,000 cycles. Reproduced with permission [193]. Copyright 2013. Royal Society of Chemistry. OGH, oriented graphene hydrogel. |

CC-based flexible composites

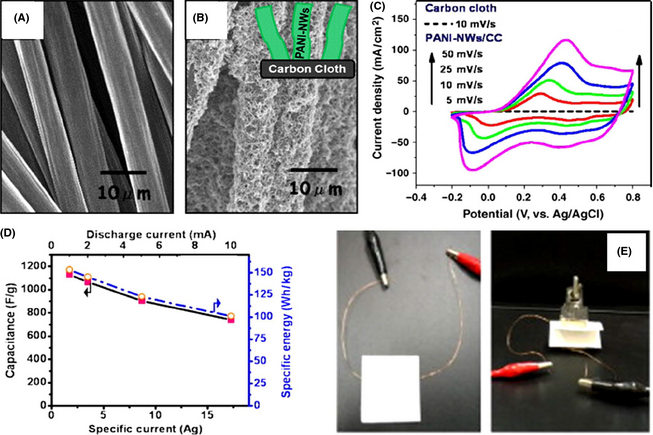

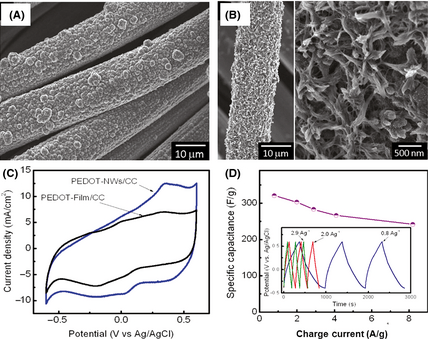

Among all the carbon-based substrates, CC is a potential low cost material as a current collector for supercapacitor device owing to their unique 3-D structure, high surface area, remarkable chemical stability, electrical conductivity and flexibility. Therefore, uniting the flexible natures of CC with CPs can be a preferable approach for soft portable electronic equipments, such as roll-up display, electric paper and wearable systems for personal multimedia. Hong et al. [110] have first demonstrated direct-growth of PAn-NWs on CC by electrochemical polymerization, and achieved a high specific capacitance (1079 F/g). Figure 17A and B show the SEM images of a bare CC surface and the PAn-NWs modified CC. A symmetric flexible supercapacitor made of PAn-NWs directly grown on CC with cellulose film as separator by sandwiching two PAn-NWs/CC electrodes and 1 mol/L H2SO4 as the electrolyte has been demonstrated using a two-electrode system. In the Figure 17E, optical photograph (left: flat and right: bent ES cells) shows the mechanical flexibility of PAn-NWs/CC capacitors. In 2011, Cheng et al. [179] have explored electro-etched carbon-fiber cloth as an electrode for supercapacitors by coating PAn-NWs, which could achieve a mass-normalized specific capacitance of 673 F/g and an area-normalized-specific capacitance of 3.5 F/cm2. It has been observed that the shape and size distribution of the CPs on the CC substrate as well the character of the electrolyte would be the major considering factors for the improvement of these composites-based capacitors. Hence, the influence of nanostructure active materials can also be expected, as discussed in previous sections. Besides these factors, the working potential window is another important factor. PEDOT has a larger reversible oxidation–potential window than other CPs. Consequently, the operating potential window, hence the specific power density of supercapacitor could be increased by using PEDOT-based electrode. Recently, Hsu et al. [180] have developed PEDOT-NWs/CC electrodes by electrochemical polymerization. Figure 18 represents the morphologies of PEDOT-Film/CC and PEDOT-NWs/CC electrodes, and their corresponding capacitive performances. Furthermore, the current research on the polymer/CC suggests the great potential of large-scale application of CPs-based flexible supercapacitors.

|

|

|

Figure 17. SEM images of (A) carbon cloth (CC), (B) PAn-NWs/CC electrodes. (C) cyclic voltammetry of PAn-NWs/CC and CC electrode at different scan rates. (D) Gravimetric capacitance and specific energy as functions of charge–discharge current density of the PAn-NWs/CC. (E) Photographs demonstrating mechanical flexibility of PAn capacitors, flat sheet (left), and curvature (bent) ES cells (right). Reproduced with permission [110]. Copyright 2010. Elsevier. PEDOT, poly(3,4-ethylenedioxythiophene); CC, carbon cloth. |

|

|

|

Figure 18. FESEM of (A) PEDOT-Film/CC and (B) PEDOT-NWs/CC electrodes. (C) Comparison of PEDOT-Film/CC and PEDOT-NWs/CC electrodes. (D) Specific capacitance of PEDOT-NWs/CC electrode with different current density; inset is the galvanostatic charge/discharge of PEDOT-NWs/CC at various current densities. Reproduced with permission [180]. Copyright 2013. Elsevier. PEDOT, poly(3,4-ethylenedioxythiophene); CC, carbon cloth. |

Metal oxides-based composites

Metal oxides (MOx) are considered one of the most promising materials for the next generation of ES [51, 53, 57, 59], providing higher pseudocapacitance through bulk redox reactions compared with surface charge storage of carbonaceous materials. However, the large volume variation induced structural change limits the stability of these electrode materials, causing the rapid capacity loss during the repeated charge/discharge processes. Additionally, due to the poor electrical conductivity, MOx also suffers from low capacitive behaviors. On the contrary, CPs provides the good electrical conductivity with additional flexible polymeric nature. Therefore, significant synergistic effects are expected between MOx and CPs when combined at the molecular scale, and these may lead to novel flexible supercapacitors with improved capacitive properties superior to those of each individual material [103-105]. The aim is to maximize the practical use of the combined advantages of both CPs and MOx as active ES materials to improve the electrochemical energy storage and solve the current ES electrode problems experienced by those of pure CPs or MOx as active materials. In a composite, CPs provide polymeric flexibility and high electrical conductivity to allow easy processing of MOx in the composite for high performance and improved cycle stability of flexible supercapacitors application. The MOx component mainly provides high specific capacity depending on its redox properties and structural morphologies. The resultant MOx/CPs composite is not merely the sum of the individual components, but rather a new supercapacitor material with new functionalities and properties. Several CPs/MOx composites materials [61, 77, 183, 194, 195] are proposed based on various MOx like RuO2, MnO2, TiO2, Fe2O3, Co3O4 etc. with PAn, PPy, PEDOTs CPs. In 2008, Zhang et al. [194] have developed a simple, template free approach to grow a well-aligned large-scale cone shaped nanostructures of RuO2/PPy of specific capacitance ~15.1 mF/cm2 (∼302 F/g) at current density of 0.5 mA/cm2 with a potential range of −0.2 to 0.7 V. Overall, this electrode material exhibited very high stability and promising supercapacitor performances. Among all the MOx, the RuO2 with the highest theoretical specific capacitance was explored widely in the ES energy storage research, but these electrode materials suffer from the extremely high production cost. Therefore, it is necessary to explore another low cost and highly redox MOx for a low cost commercial energy storage electrochemical application. Thereafter several research works based on inexpensive MnO2 with a variety of nanostructures were explored for the high specific capacitance and rate stability [104, 196]. More or less, the overall drawback of MnO2 regarding poor electrical conductivity is remaining the same as the other MOx. For effective and promising supercapacitor applications, a range of MnO2-based binary phase hybrids are demonstrated with CPs [195, 197]. Hou et al. [77] have demonstrated MnO2/CNT/CP ternary nanostructures exhibiting high specific capacitance 427 F/g with high cycle stability. Zhou et al. [183] have claimed an impressive 2223 F/g for a composite with 3D CoO with PPy nanowire. In their work, the aqueous asymmetric supercapacitor device with a maximum potential window of 1.8 V was demonstrated with a very high energy density (∼43.5 Wh/kg), high power density (∼5500 W/kg at 11.8 Wh/kg) and outstanding cycleability. Reports also show that the core-shell or hybrid nanostructure composite has been potential for improved flexible supercapacitor applications. Recently, Li et al. [198] have demonstrated the core-shell CNT@PPy@MnO2 ternary composite electrode for ES application. In their work, the synergistic effects from respective PPy and MnO2, in addition of the porous conductive CNT framework, were attributed for the superior electrochemical performance of the hybrid electrode. In another work, Wang et al. have prepared MnO2-PPy hybrid nanofilm directly on the CC for high voltage symmetric ES application [199]. We believe that these binary and ternary MOx composites with CPs can open a new avenue for a flexible energy storage device.

Challenges

From the above section, it can be clearly understood that different C-based and metal oxide materials (CNTs, CFs, RGO, GOs and MOx) composites with CPs can impel the future of CPs-based nanohybrids, and flexible electrode engineering provide an important way to optimize the CPs-based high performance flexible supercapacitors. Research studies also claim that the composite formation can affect the overall electrochemical Faradaic charge transfer process, and the final supercapacitive performance and stability of the electroactive materials. A summary of some important works involving CPs for flexible supercapacitors application is presented in Table 2. From the table, we can clearly observe that in the last 5 years how the CPs-based flexible supercapacitor materials improved from the binary to ternary compositions. In addition, it is also found that, in the majority of the researches, CPs-based composites were the best performing flexible supercapacitors when directly fabricated on the flexible current collector.

| Electrode materials | Specific capacitance | Energy density and power density | Stability | Year/Ref. |

|---|---|---|---|---|

| ||||

| G-PAn paper | 233 F/g at 2 mV/s in 1 mol/L H2SO4 | – | No loss after 1500 cycles | 2009 [200] |

| PAn NW/CC | 1079 F/g at 1.73 A/g in 1 mol/L H2SO4 | 100.9 Wh/kg and 12.1 kW/kg | 14% loss after 2100 cycles | 2010 [110] |

| GN/PAn-NF | 210 F/g at 0.3 A/g in 1 mol/L H2SO4 | – | 29% loss after 800 cycles | 2010 [171] |

| Cloth-SWCNT-PAn | 410 F/g at 0.5 A/g in 1 mol/L H2SO4 | – | 10% loss after 3000 cycles | 2011 [201] |

| G/PPy | 237 F/g at 0.01 V/s in 1 mol/L KCl | 33 Wh/kg and 1184 W/kg | – | 2011 [174] |

| GN-PPy/CNT | 211 F/g and 122 F/cm3 at 0.2 A/g in 1 mol/L KCl | – | 5% loss after 3000 cycles | 2012 [202] |

| MnO2/PEDOT:PSS-SS-PET | 1670 mF/cm2 at 0.5 mA/cm2 in 0.5 mol/L Na2SO4 | 1.80 mWh/cm3 | 0.5% loss after 4000 cycles | 2013 [105] |

| PEDOT-NWs/CC | 256 F/g at 0.8 A/g in 1 mol/L Na2SO4 | 182.1 Wh/kg and 13.1 kW/kg | 30% loss after 1000 cycles | 2013 [180] |

| G-PAn paper | 763 F/g at 1 A/g in 1 mol/L H2SO4 | – | 18% loss after 1000 cycles | 2013 [203] |

| PAn/eCFC | 1035 F/g at 1 A/g in 1 mol/L H2SO4 | 22.9 Wh/kg and 36.5 kW/kg | 18% loss after 1000 cycles | 2013 [204] |

| 3D RGO/PAn | 385 F/g at 0.5 A/g in 1 mol/L H2SO4 | – | 12% loss after 5000 cycles | 2013 [205] |

| PPy/MnO2/CF | 69.3 F/cm3 at 0.1 A/cm3 in PVA/H3PO4 | 6.16 mWh/cm3 and 0.04 W/cm3 | 13.3% loss after 1000 cycles | 2013 [206] |

| MWCNT/PAn Film on PET | 233 F/g at 1 A/g in H3PO4-PVA | – | No loss after 1000 cycles | 2013 [190] |

| RGO/PPy | 175 mF/cm2 at 10 mV/s in 2 mol/L KCl | – | 7% loss after 5000 cycles | 2013 [176] |

| PANI/OGH film | 1104 F/g at 10 A/g in 1 mol/L H2SO4 | – | 7% loss after 10,000 cycles | 2013 [193] |

| PPy-coated paper | 0.42 F/cm2 at 1 mA/cm2 in PVA/H3PO4 | 1.0 mWh/cm3 and 0.27 W/cm3 | 25.4% loss after 10,000 cycles | 2013 [153] |

| PPy hydrogel-CC | 400 F/g at 1 A/g in 1 mol/L H2SO4 | – | 7% loss after 2100 cycles | 2014 [207] |

| PAn/Buckey-paper | 430 F/g at 10 A/g in 0.5 mol/L H2SO4 | – | 20% loss after 1000 cycles | 2014 [208] |

| BC-MWCNTs/PAn | 656 F/g at 1 A/g in 1 mol/L H2SO4 | – | 0.5% loss after 1000 cycles | 2014 [209] |

| RGO/PAn/eCFC | 1145 F/g at 1 A/g in 1 mol/L H2SO4 | 25.4 Wh/kg and 92.2 kW/kg | 6% loss after 5000 cycles | 2014 [210] |

| CNT/PPy/MnO2 sponge | 305.9 F/g at 2 mV/s in 2 mol/L KCl | 8.6 Wh/kg and 16.5 kW/kg | 9.8% loss after 1000 cycles | 2014 [198] |

| CSA-PAn/RGO | 431 F/g at 0.45 F/g in 1 mol/L H2SO4 | – | 26% loss after 500 cycles | 2014 [211] |

| (PPy/LGS)-coated cotton | 304 F/g at 0.1 A/g in 2 mol/L NaCl | – | – | 2014 [212] |

However, it should be noted that, although the CPs-based composites show very high specific capacitance but their device performances like power density, energy density and cycle stability are very far from the practical industrial applications. Also, most of the research works have mainly focused on the high performance of the supercapacitor materials, but the optimization of the supercapacitor cell fabrication and their effect on device performance, such as power density, energy density and stability, were less discussed. Thus, to delve into the power density and energy density study of the complete capacitor cell and more advance characterizations of the interfacial resistance should be focused carefully in this field because it would be very instructive for real and commercial energy storage device applications. Lastly, it is necessary to put some effort on defining the industrial standards for the commercialization of ES [79]. Although, in the current market, the carbon-based ES (basically EDLCs kinds) becomes commercially available, there is lacked of any industrial standards for ES (for both EDLCs and pseudocapacitors) at this moment. Therefore, it is necessary to establish some general industrial standards, such as performance, electrode structural and dimensional parameters, and so on, depending on the kinds of ES and its applications.

Present Efforts and Future Developments

The CPs-based redox materials are bringing a revolution in the flexible pseudocapacitor applications. The future of the CPs-based flexible energy storage devices hold even greater promise for a novel low cost, light-weight and highly flexible devices. These CPs-based supercapacitors are expected to take a tremendous amount of market-share of the existing Li-ion batteries in next 10 years to fulfill the huge demand of the flexible electronic devices. The distinctive features of CPs-based supercapacitors are high Faradaic capacitance, high flexibility, high conductivity and ease-in-fabrication for thin and wearable electronic devices. Owing to these unique advantages, the CPs-based flexible supercapacitors can be directly mounted or integrated into the clothing that can be stretchable or rolled up and plugged into an electrical storage device.

Although recent developments in CPs-based flexible supercapacitors appear extremely promising, there remain several challenges restricting their real applications, as described in previous section. Several potential resolutions have attempted focusing on how to achieve the following: (1) improved mechanical stability utilizing highly flexible current collectors; (2) improved cycle stability of the CPs-based flexible supercapacitors using composites with carbon nanomaterials or self-healing ionic polymers; (3) adaptability of nanoscale active materials with high power characteristics and solid/gel-type or ionic or organic electrolyte systems ensuring the safety and improving the power density; (4) improved charge/ionic transport, reducing the interfacial and/or internal resistance, by direct synthesis of active materials on the current collector without any binders involved; and last but not least (5) hybrid asymmetric flexible supercapacitors based on p-type and n-type CPs. Although, in current scenario, n-type CPs-derivatives are found to be much poor in quality compared to their p-type counterparts.

It is broadly accepted that the efficiency of the CPs-based supercapacitor highly depends on the interaction of the active electrode materials with the current collector. Number of materials was employed as current collectors, among which CC, CFs, porous carbon paper, porous GOs composites are quite promising for the future flexible ES applications. Stability of the CPs-based supercapacitor is one of the most critical issues for the commercial applications. Making composites with C-based nanomaterials (CNTs, graphene, GOs) is a common strategy to enhance the stability of electro active materials. Besides, the development of copolymers composite with self-healing ionic polymers and other suitable CPs can be another promising way to produce mechanically stable polymer composites for flexible supercapacitor applications. In both cases, the self-healing ionic polymers or carbon nanostructures could protect the CPs structures from the mechanical rupture during the electrochemical charge/discharge process and improve the cycle stability of the supercapacitors.

According to the electrode designing aspects, besides the proper choice of active electrode materials, appropriate choice of electrolytes is also important to improve the ES performance. It is well accepted that the enhancement of the working potential window is the most effective way to increase both the energy and power density of the supercapacitors. In any electrochemical process, the safe or withstanding working potential window is limited due to the electrochemical stability of the electrolytes and the generation of gaseous products at cathode and anodes (positive or negative electrodes) during the voltammetric measurements. According to the advanced supercapacitor electrolyte research, organic (acetonitrile, propylene carbonate, linear sulfones etc.) and ionic liquid (imidazolium, pyrrolidium etc.)-based electrolytes [213] could improve the working potential window almost 1.5–2 times than that of acid-based aqueous electrolytes, although suffer from poor ionic conductivity (by a factor of 1/2) than the aqueous type.

Meanwhile, extensive researches have been focused on the development of nanostructured active electrode materials, for which the ES performance benefits via the enhancement in the electrode/electrolyte interface areas and the decrease in cationic diffusion length within the active materials. In recent years, several approaches to fabricate CPs in nanostructures have been attempted in order to improve its electrochemical capacitance performance. However, the exact mechanism of charge storage and delivery for a supercapacitor is very complex, because the shape, the connectivity and the size distribution of CPs, as well as the nature of electrolyte and substrate-polymer interface, all have to be considered.

Another important issue is the equivalent series resistance (ESR) of the electrodes, to which the maximum power density of a supercapacitor is inversely proportional. Accordingly, lowering both the internal resistance of the active materials (CPs) and the contact (interfacial) resistance between the CPs and the current collector would be the important key to improve the charge/ionic transport and hence achieve the high power density. Recently, several approaches have been attempted to overcome the abovementioned issue by developing the core-shell-type CPs/C or CPs/MOx composites on the current collector, via growing C-based nanostructures or MOx nanostructures directly onto the current collector [38] and subsequent coating of CPs on carbon or MOx nanostructures. The overall process has been demonstrated schematically in the Figure 19. Unlike the supercapacitors made of powder-type active materials, the direct electrode-design approach can improve the high power performance by reducing the ESR with low contact resistance between the CPs-collector and between the components of CPs/C or CPs/MOx composites and due to the absence of insulating binders.

|

|

|

Figure 19. Schematic diagram of the CPs-based flexible electrode fabrication process. CPs, conducting polymers. |

Generally, the CPs are classified in to p-type and n-type CPs depending on their doping process. These two types CPs also work into different potential ranges depending on their electronic characteristics. Owing to these characteristics, it is possible to design an asymmetric hybrid supercapacitor, as illustrated schematically in Figure 20. Utilizing the positive potential window of p-type polymers with a comparatively negative potential window of n-type derivatives, the maximum withstanding voltage-limits (cell working potential window) of the supercapacitor would be improved and enhanced the specific power density. In fact, there are several challenges remain even though, based on the recent development in the CPs-based flexible supercapacitor research, a substantial progress can be highly anticipated in the near future.

|

|

|

Figure 20. Schematic diagram of asymmetric supercapacitors based on conducting polymers. |

Summary

The research and developments of the CPs-based flexible supercapacitors have been progressed rapidly in the last several years. Numerous efforts have been directed toward such CPs-based supercapacitor as a new platform for flexible energy storage device. This review has briefly discussed the recent development, covering some of the successful and promising research works achieving high specific capacitance based on CPs-based flexible supercapacitors. Interestingly, it has been observed that the direct growth of the CPs nanostructures by electropolymerization process onto a flexible substrate would be one of the most promising ways to achieve a flexible supercapacitor with high specific capacitance. We hope that this review will serve as a stimulant for new thoughts in the quest of rational designs for more efficient CPs-based pseudocapacitors for flexible devices. However, it is obvious that there are several issues that remain to be overcome to achieve the device performances, like power density, energy density and cycle stability, apposite for the practical industrial applications. Further advances are needed to achieve a high specific power and energy density taking advantage of the higher working potential window in the eco-friendly ionic liquid electrolyte system. Additional efforts are also needed to promote the large-scale commercial electronics applications. A better and mature understanding must be developed through long-term research efforts to elucidate the effects of in-situ doping and polymer architecture on these pristine and hybrids conducting polymeric materials, and the way those findings can be used to guide the future synthesis efforts.

Acknowledgments

We thank the Ministry of Science and Technology (MOST), Academia Sinica, National Taiwan University and Ministry of Education (MOE), Taiwan and AOARD of AFOSR for financial support.

Conflict of Interest

None declared.

References

- Tarascon, J. M., and M. Armand. 2001. Issues and challenges facing rechargeable lithium batteries. Nature414:359–367.

- Nishide, H., and K. Oyaizu. 2008. Toward flexible batteries. Science319:737–738.

- Rogers, J. A., T. Someya, and Y. Huang. 2010. Materials and mechanics for stretchable electronics. Science327:1603–1607.

- Lipomi, D. J., and Z. Bao. 2011. Stretchable, elastic materials and devices for solar energy conversion. Energy Environ. Sci.4:3314–3328.

- Miller, J. R., and P. Simon. 2008. Electrochemical capacitors for energy management. Science321:651–652.

- Jennings, A., S. Hise, B. Kiedrowski, and C. Krouse. 2009. Urban battery litter. J. Environ. Eng.135:46–57.

- Lee, J. A., M. K. Shin, S. H. Kim, H. U. Cho, G. M. Spinks, G. G. Wallace, et al. 2013. Ultrafast charge and discharge biscrolled yarn supercapacitors for textiles and microdevices. Nat. Commun.4:1970. doi:10.1038/ncomms2970

- Le, V. T., H. Kim, A. Ghosh, J. Kim, J. Chang, Q. A. Vu, et al. 2013. Coaxial fiber supercapacitor using all-carbon material electrodes. ACS Nano7:5940–5947.

- Jost, K., C. R. Perez, J. K. McDonough, V. Presser, M. Heon, G. Dion, et al. 2011. Carbon coated textiles for flexible energy storage. Energy Environ. Sci.4:5060–5067.

- Yang, Z., J. Deng, X. Chen, J. Ren, and H. Peng. 2013. A highly stretchable, fiber-shaped supercapacitor. Angew. Chem. Int. Ed.52:13453–13457.

- Pandolfo, A. G., and A. F. Hollenkamp. 2006. Carbon properties and their role in supercapacitors. J. Power Sources157:11–27.

- Frackowiak, E., and F. Béguin. 2001. Carbon materials for the electrochemical storage of energy in capacitors. Carbon39:937–950.

- Wu, T.-H., C.-T. Hsu, C.-C. Hu, and L. J. Hardwick. 2013. Important parameters affecting the cell voltage of aqueous electrical double-layer capacitors. J. Power Sources242:289–298.

- Jiang, H., P. S. Lee, and C. Li. 2013. 3D carbon based nanostructures for advanced supercapacitors. Energy Environ. Sci.6:41–53.

- Amali, A. J., J.-K. Sun, and Q. Xu. 2014. From assembled metal-organic framework nanoparticles to hierarchically porous carbon for electrochemical energy storage. Chem. Commun.50:1519–1522.

- Sassin, M. B., C. N. Chervin, D. R. Rolison, and J. W. Long. 2013. Redox deposition of nanoscale metal oxides on carbon for next-generation electrochemical capacitors. Acc. Chem. Res.46:1062–1074.

- Zhi, M., C. Xiang, J. Li, M. Li, and N. Wu. 2013. Nanostructured carbon-metal oxide composite electrodes for supercapacitors: a review. Nanoscale5:72–88.

- Prasad, K. R., K. Koga, and N. Miura. 2004. Electrochemical deposition of nanostructured indium oxide: high-performance electrode material for redox supercapacitors. Chem. Mater.16:1845–1847.

- Kalaji, M., P. J. Murphy, and G. O. Williams. 1999. The study of conducting polymers for use as redox supercapacitors. Synth. Met.102:1360–1361.

- Wang, K., H. Wu, Y. Meng, and Z. Wei. 2014. Conducting polymer nanowire arrays for high performance supercapacitors. Small10:14–31.

- Liu, T., L. Finn, M. Yu, H. Wang, T. Zhai, X. Lu, et al. 2014. Polyaniline and polypyrrole pseudocapacitor electrodes with excellent cycling stability. Nano Lett.14:2522–2527.

- Snook, G. A., P. Kao, and A. S. Best. 2011. Conducting-polymer-based supercapacitor devices and electrodes. J. Power Sources196:1–12.

- Mike, J. F., and J. L. Lutkenhaus. 2013. Recent advances in conjugated polymer energy storage. J. Polym. Sci. Part B: Polym. Phys.51:468–480.

- Ramya, R., R. Sivasubramanian, and M. V. Sangaranarayanan. 2013. Conducting polymers-based electrochemical supercapacitors – progress and prospects. Electrochim. Acta101:109–129.

- Amarnath, C. A., J. H. Chang, D. Kim, R. S. Mane, S.-H. Han, and D. Sohn. 2009. Electrochemical supercapacitor application of electroless surface polymerization of polyaniline nanostructures. Mater. Chem. Phys.113:14–17.

- Zhang, H., Q. Zhao, S. Zhou, N. Liu, X. Wang, J. Li, et al. 2011. Aqueous dispersed conducting polyaniline nanofibers: promising high specific capacity electrode materials for supercapacitor. J. Power Sources196:10484–10489.

- Park, J. H., and O. O. Park. 2002. Hybrid electrochemical capacitors based on polyaniline and activated carbon electrodes. J. Power Sources111:185–190.

- Prasad, K. R., and N. Munichandraiah. 2002. Fabrication and evaluation of 450 F electrochemical redox supercapacitors using inexpensive and high-performance, polyaniline coated, stainless-steel electrodes. J. Power Sources112:443–451.

- Nyström, G., A. Razaq, M. Strømme, L. Nyholm, and A. Mihranyan. 2009. Ultrafast all-polymer paper-based batteries. Nano Lett.9:3635–3639.

- Song, H. K., and G. T. R. Palmore. 2006. Redox-active polypyrrole: toward polymer-based batteries. Adv. Mater.18:1764–1768.

- Nyström, G., A. Mihranyan, A. Razaq, T. Lindström, L. Nyholm, and M. Strømme. 2010. A nanocellulose polypyrrole composite based on microfibrillated cellulose from wood. J. Phys. Chem. B114:4178–4182.

- Mihranyan, A., L. Nyholm, A. E. G. Bennett, and M. Strømme. 2008. A novel high specific surface area conducting paper material composed of polypyrrole and cladophora cellulose. J. Phys. Chem. B112:12249–12255.

- Khomenko, V., E. Raymundo-Piñero, E. Frackowiak, and F. Béguin. 2006. High-voltage asymmetric supercapacitors operating in aqueous electrolyte. Appl. Phys. A82:567–573.

- Shown, I., T. Imae, and S. Motojima. 2012. Fabrication of carbon microcoil/polyaniline composite by microemulsion polymerization for electrochemical functional enhancement. Chem. Eng. J.187:380–384.

- Wang, K., Q. Meng, Y. Zhang, Z. Wei, and M. Miao. 2013. High-performance two-ply yarn supercapacitors based on carbon nanotubes and polyaniline nanowire arrays. Adv. Mater.25:1494–1498.

- Zhou, H., G. Han, Y. Xiao, Y. Chang, and H.-J. Zhai. 2014. Facile preparation of polypyrrole/graphene oxide nanocomposites with large areal capacitance using electrochemical codeposition for supercapacitors. J. Power Sources263:259–267.

- Liu, M., S. He, W. Fan, Y.-E. Miao, and T. Liu. 2014. Filter paper-derived carbon fiber/polyaniline composite paper for high energy storage applications. Compos. Sci. Technol.101:152–158.

- Simon, P., and Y. Gogotsi. 2008. Materials for electrochemical capacitors. Nat. Mater.7:845–854.

- Hsu, H. C., C. H. Wang, S. K. Nataraj, H. C. Huang, H. Y. Du, S. T. Chang, et al. 2012. Stand-up structure of graphene-like carbon nanowalls on CNT directly grown on polyacrylonitrile-based carbon fiber paper as supercapacitor. Diam. Relat. Mater.25:176–179.

- Yang, S.-Y., K.-H. Chang, H.-W. Tien, Y.-F. Lee, S.-M. Li, Y.-S. Wang, et al. 2011. Design and tailoring of a hierarchical graphene-carbon nanotube architecture for supercapacitors. J. Mater. Chem.21:2374–2380.

- Naoi, K., W. Naoi, S. Aoyagi, J.-I. Miyamoto, and T. Kamino. 2012. New generation “nanohybrid supercapacitor”. Acc. Chem. Res.46:1075–1083.

- Naoi, K., S. Ishimoto, J.-I. Miyamoto, and W. Naoi. 2012. Second generation ‘nanohybrid supercapacitor': evolution of capacitive energy storage devices. Energy Environ. Sci.5:9363–9373.

- Ghosh, A., and Y. H. Lee. 2012. Carbon-based electrochemical capacitors. Chemsuschem5:480–499.

- Zhang, H., G. Cao, Y. Yang, and Z. Gu. 2008. Comparison between electrochemical properties of aligned carbon nanotube array and entangled carbon nanotube electrodes. J. Electrochem. Soc.155:K19–K22.

- Niu, Z., W. Zhou, J. Chen, G. Feng, H. Li, W. Ma, et al. 2011. Compact-designed supercapacitors using free-standing single-walled carbon nanotube films. Energy Environ. Sci.4:1440–1446.

- Izadi-Najafabadi, A., S. Yasuda, K. Kobashi, T. Yamada, D. N. Futaba, H. Hatori, et al. 2010. Extracting the full potential of single-walled carbon nanotubes as durable supercapacitor electrodes operable at 4 V with high power and energy density. Adv. Mater.22:E235–E241.

- Niu, C., E. K. Sichel, R. Hoch, D. Moy, and H. Tennent. 1997. High power electrochemical capacitors based on carbon nanotube electrodes. Appl. Phys. Lett.70:1480–1482.

- Dai, L., D. W. Chang, J.-B. Baek, and W. Lu. 2012. Carbon nanomaterials for advanced energy conversion and storage. Small8:1130–1166.

- Chen, W., R. B. Rakhi, M. N. Hedhili, and H. N. Alshareef. 2014. Shape-controlled porous nanocarbons for high performance supercapacitors. J. Mater. Chem. A2:5236–5243.

- Ma, X., L. Gan, M. Liu, P. K. Tripathi, Y. Zhao, Z. Xu, et al. 2014. Mesoporous size controllable carbon microspheres and their electrochemical performances for supercapacitor electrodes. J. Mater. Chem. A2:8407–8415.

- Huang, H.-S., K.-H. Chang, N. Suzuki, Y. Yamauchi, C.-C. Hu, and K. C. W. Wu. 2013. Evaporation-induced coating of hydrous ruthenium oxide on mesoporous silica nanoparticles to develop high-performance supercapacitors. Small9:2520–2526.

- Lin, K.-M., K.-H. Chang, C.-C. Hu, and Y.-Y. Li. 2009. Mesoporous RuO2 for the next generation supercapacitors with an ultrahigh power density. Electrochim. Acta54:4574–4581.

- Li, S.-M., Y.-S. Wang, S.-Y. Yang, C.-H. Liu, K.-H. Chang, H.-W. Tien, et al. 2013. Electrochemical deposition of nanostructured manganese oxide on hierarchically porous graphene–carbon nanotube structure for ultrahigh-performance electrochemical capacitors. J. Power Sources225:347–355.

- Hu, C.-C., C.-W. Wang, T.-H. Wu, and K.-H. Chang. 2012. Anodic composite deposition of hydrous RuO2–TiO2 nanocomposites for electrochemical capacitors. Electrochim. Acta85:90–98.

- Hu, C.-C., C.-Y. Hung, K.-H. Chang, and Y.-L. Yang. 2011. A hierarchical nanostructure consisting of amorphous MnO2, Mn3O4 nanocrystallites, and single-crystalline MnOOH nanowires for supercapacitors. J. Power Sources196:847–850.

- Chang, K.-H., C.-C. Hu, C.-M. Huang, Y.-L. Liu, and C.-I. Chang. 2011. Microwave-assisted hydrothermal synthesis of crystalline WO3–WO3·0.5H2O mixtures for pseudocapacitors of the asymmetric type. J. Power Sources196:2387–2392.

- Hsu, C.-T., and C.-C. Hu. 2013. Synthesis and characterization of mesoporous spinel NiCo2O4 using surfactant-assembled dispersion for asymmetric supercapacitors. J. Power Sources242:662–671.

- Hu, C.-C., H.-Y. Guo, K.-H. Chang, and C.-C. Huang. 2009. Anodic composite deposition of RuO2·xH2O–TiO2 for electrochemical supercapacitors. Electrochem. Commun.11:1631–1634.

- Chen, Y.-C., Y.-K. Hsu, Y.-G. Lin, Y.-K. Lin, Y.-Y. Horng, L.-C. Chen, et al. 2011. Highly flexible supercapacitors with manganese oxide nanosheet/carbon cloth electrode. Electrochim. Acta56:7124–7130.

- Zheng, J. P., P. J. Cygan, and T. R. Jow. 1995. Hydrous ruthenium oxide as an electrode material for electrochemical capacitors. J. Electrochem. Soc.142:2699–2703.

- Wu, N.-L.2002. Nanocrystalline oxide supercapacitors. Mater. Chem. Phys.75:6–11.

- Liu, T. C., W. G. Pell, and B. E. Conway. 1999. Stages in the development of thick cobalt oxide films exhibiting reversible redox behavior and pseudocapacitance. Electrochim. Acta44:2829–2842.

- Srinivasan, V., and J. W. Weidner. 2000. Studies on the capacitance of nickel oxide films: effect of heating temperature and electrolyte concentration. J. Electrochem. Soc.147:880–885.

- Cottineau, T., M. Toupin, T. Delahaye, T. Brousse, and D. Bélanger. 2006. Nanostructured transition metal oxides for aqueous hybrid electrochemical supercapacitors. Appl. Phys. A82:599–606.

- Zhai, T., F. Wang, M. Yu, S. Xie, C. Liang, C. Li, et al. 2013. 3D MnO2-graphene composites with large areal capacitance for high-performance asymmetric supercapacitors. Nanoscale5:6790–6796.

- Yang, P., Y. Li, Z. Lin, Y. Ding, S. Yue, C. P. Wong, et al. 2014. Worm-like amorphous MnO2 nanowires grown on textiles for high-performance flexible supercapacitors. J. Mater. Chem. A2:595–599.

- Hu, C.-C., and J.-Y. Lin. 2002. Effects of the loading and polymerization temperature on the capacitive performance of polyaniline in NaNO3. Electrochim. Acta47:4055–4067.

- Ryu, K. S., K. M. Kim, N.-G. Park, Y. J. Park, and S. H. Chang. 2002. Symmetric redox supercapacitor with conducting polyaniline electrodes. J. Power Sources103:305–309.

- Ryu, K. S., Y. Lee, K.-S. Han, Y. J. Park, M. G. Kang, N.-G. Park, et al. 2004. Electrochemical supercapacitor based on polyaniline doped with lithium salt and active carbon electrodes. Solid State Ionics175:765–768.

- Chang, K.-W., Z.-Y. Lim, F.-Y. Du, Y.-L. Yang, C.-H. Chang, C.-C. Hu, et al. 2009. Synthesis of mesoporous carbon by using polymer blend as template for the high power supercapacitor. Diam. Relat. Mater.18:448–451.

- Xu, Y., J. Wang, W. Sun, and S. Wang. 2006. Capacitance properties of poly(3,4-ethylenedioxythiophene)/polypyrrole composites. J. Power Sources159:370–373.

- Fan, L.-Z., and J. Maier. 2006. High-performance polypyrrole electrode materials for redox supercapacitors. Electrochem. Commun.8:937–940.

- Hussain, A. M. P., and A. Kumar. 2006. Enhanced electrochemical stability of all-polymer redox supercapacitors with modified polypyrrole electrodes. J. Power Sources161:1486–1492.

- Muthulakshmi, B., D. Kalpana, S. Pitchumani, and N. G. Renganathan. 2006. Electrochemical deposition of polypyrrole for symmetric supercapacitors. J. Power Sources158:1533–1537.

- Noh, K. A., D.-W. Kim, C.-S. Jin, K.-H. Shin, J. H. Kim, and J. M. Ko. 2003. Synthesis and pseudo-capacitance of chemically-prepared polypyrrole powder. J. Power Sources124:593–595.

- Yu, G., L. Hu, N. Liu, H. Wang, M. Vosgueritchian, Y. Yang, et al. 2011. Enhancing the supercapacitor performance of graphene/MnO2 nanostructured electrodes by conductive wrapping. Nano Lett.11:4438–4442.

- Hou, Y., Y. Cheng, T. Hobson, and J. Liu. 2010. Design and synthesis of hierarchical MnO2 nanospheres/carbon nanotubes/conducting polymer ternary composite for high performance electrochemical electrodes. Nano Lett.10:2727–2733.

- Li, Q., J. Liu, J. Zou, A. Chunder, Y. Chen, and L. Zhai. 2011. Synthesis and electrochemical performance of multi-walled carbon nanotube/polyaniline/MnO2 ternary coaxial nanostructures for supercapacitors. J. Power Sources196:565–572.

- Wang, G., L. Zhang, and J. Zhang. 2012. A review of electrode materials for electrochemical supercapacitors. Chem. Soc. Rev.41:797–828.

- Dong, L., Z. Chen, D. Yang, and H. Lu. 2013. Hierarchically structured graphene-based supercapacitor electrodes. RSC Adv.3:21183–21191.

- Chou, S.-L., J.-Z. Wang, S.-Y. Chew, H.-K. Liu, and S.-X. Dou. 2008. Electrodeposition of MnO2 nanowires on carbon nanotube paper as free-standing, flexible electrode for supercapacitors. Electrochem. Commun.10:1724–1727.

- Fan, Z., J. Chen, B. Zhang, B. Liu, X. Zhong, and Y. Kuang. 2008. High dispersion of γ-MnO2 on well-aligned carbon nanotube arrays and its application in supercapacitors. Diam. Relat. Mater.17:1943–1948.

- Zhao, X., C. Johnston, and P. S. Grant. 2009. A novel hybrid supercapacitor with a carbon nanotube cathode and an iron oxide/carbon nanotube composite anode. J. Mater. Chem.19:8755–8760.

- Qin, X., S. Durbach, and G. T. Wu. 2004. Electrochemical characterization on RuO2.xH2O/carbon nanotubes composite electrodes for high energy density supercapacitors. Carbon42:451–453.

- Lee, J.-K., H. M. Pathan, K.-D. Jung, and O.-S. Joo. 2006. Electrochemical capacitance of nanocomposite films formed by loading carbon nanotubes with ruthenium oxide. J. Power Sources159:1527–1531.

- Wang, W., S. Guo, I. Lee, K. Ahmed, J. Zhong, Z. Favors, et al. 2014. Hydrous ruthenium oxide nanoparticles anchored to graphene and carbon nanotube hybrid foam for supercapacitors. Sci. Rep.4:4452. doi:4410.1038/srep04452

- Jiang, Y., P. Wang, X. Zang, Y. Yang, A. Kozinda, and L. Lin. 2013. Uniformly embedded metal oxide nanoparticles in vertically aligned carbon nanotube forests as pseudocapacitor electrodes for enhanced energy storage. Nano Lett.13:3524–3530.

- Hung, P.-J., K.-H. Chang, Y.-F. Lee, C.-C. Hu, and K.-M. Lin. 2010. Ideal asymmetric supercapacitors consisting of polyaniline nanofibers and graphene nanosheets with proper complementary potential windows. Electrochim. Acta55:6015–6021.

- Wang, H., Q. Hao, X. Yang, L. Lu, and X. Wang. 2009. Graphene oxide doped polyaniline for supercapacitors. Electrochem. Commun.11:1158–1161.

- Yan, J., T. Wei, B. Shao, Z. Fan, W. Qian, M. Zhang, et al. 2010. Preparation of a graphene nanosheet/polyaniline composite with high specific capacitance. Carbon48:487–493.

- Yan, J., T. Wei, Z. Fan, W. Qian, M. Zhang, X. Shen, et al. 2010. Preparation of graphene nanosheet/carbon nanotube/polyaniline composite as electrode material for supercapacitors. J. Power Sources195:3041–3045.

- Diggikar, R. S., D. J. Late, and B. B. Kale. 2014. Unusual morphologies of reduced graphene oxide and polyaniline nanofibers-reduced graphene oxide composites for high performance supercapacitor applications. RSC Adv.4:22551–22560.

- Frackowiak, E., V. Khomenko, K. Jurewicz, K. Lota, and F. Béguin. 2006. Supercapacitors based on conducting polymers/nanotubes composites. J. Power Sources153:413–418.

- Lota, K., V. Khomenko, and E. Frackowiak. 2004. Capacitance properties of poly(3,4-ethylenedioxythiophene)/carbon nanotubes composites. J. Phys. Chem. Solids65:295–301.

- Khomenko, V., E. Frackowiak, and F. Béguin. 2005. Determination of the specific capacitance of conducting polymer/nanotubes composite electrodes using different cell configurations. Electrochim. Acta50:2499–2506.

- Gupta, V., and N. Miura. 2006. Polyaniline/single-wall carbon nanotube (PANI/SWCNT) composites for high performance supercapacitors. Electrochim. Acta52:1721–1726.

- Hughes, M., M. S. P. Shaffer, A. C. Renouf, C. Singh, G. Z. Chen, D. J. Fray, et al. 2002. Electrochemical capacitance of nanocomposite films formed by coating aligned arrays of carbon nanotubes with polypyrrole. Adv. Mater.14:382–385.

- Peng, C., S. Zhang, X. Zhou, and G. Z. Chen. 2010. Unequalisation of electrode capacitances for enhanced energy capacity in asymmetrical supercapacitors. Energy Environ. Sci.3:1499–1502.

- Meng, C., C. Liu, and S. Fan. 2009. Flexible carbon nanotube/polyaniline paper-like films and their enhanced electrochemical properties. Electrochem. Commun.11:186–189.

- Lachman, N., H. Xu, Y. Zhou, M. Ghaffari, M. Lin, D. Bhattacharyya, et al. 2014. Tailoring thickness of conformal conducting polymer decorated aligned carbon nanotube electrodes for energy storage. Adv. Mater. Interfaces1:1400076. doi: 10.1002/admi.201400076

- Zhou, Y., N. Lachman, M. Ghaffari, H. Xu, D. Bhattacharya, P. Fattahi, et al. 2014. A high performance hybrid asymmetric supercapacitor via nano-scale morphology control of graphene, conducting polymer, and carbon nanotube electrodes. J. Mater. Chem. A2:9964–9969.

- Fu, H., Z.-J. Du, W. Zou, H.-Q. Li, and C. Zhang. 2013. Carbon nanotube reinforced polypyrrole nanowire network as a high-performance supercapacitor electrode. J. Mater. Chem. A1:14943–14950.

- Sharma, R. K., A. C. Rastogi, and S. B. Desu. 2008. Manganese oxide embedded polypyrrole nanocomposites for electrochemical supercapacitor. Electrochim. Acta53:7690–7695.

- Sivakkumar, S. R., J. M. Ko, D. Y. Kim, B. C. Kim, and G. G. Wallace. 2007. Performance evaluation of CNT/polypyrrole/MnO2 composite electrodes for electrochemical capacitors. Electrochim. Acta52:7377–7385.

- Su, Z., C. Yang, C. Xu, H. Wu, Z. Zhang, T. Liu, et al. 2013. Co-electro-deposition of the MnO2-PEDOT:PSS nanostructured composite for high areal mass, flexible asymmetric supercapacitor devices. J. Mater. Chem. A1:12432–12440.

- Rodriguez-Moreno, J., E. Navarrete-Astorga, E. A. Dalchiele, R. Schrebler, J. R. Ramos-Barrado, and F. Martin. 2014. Vertically aligned ZnO@CuS@PEDOT core@shell nanorod arrays decorated with MnO2 nanoparticles for a high-performance and semi-transparent supercapacitor electrode. Chem. Commun.50:5652–5655.

- Sun, C.-L., L.-C. Chen, M.-C. Su, L.-S. Hong, O. Chyan, C.-Y. Hsu, et al. 2005. Ultrafine platinum nanoparticles uniformly dispersed on arrayed CNx nanotubes with high electrochemical activity. Chem. Mater.17:3749–3753.

- Chen, L. C., C. Y. Wen, C. H. Liang, W. K. Hong, K. J. Chen, H. C. Cheng, et al. 2002. Controlling steps during early stages of the aligned growth of carbon nanotubes using microwave plasma enhanced chemical vapor deposition. Adv. Funct. Mater.12:687–692.

- Wang, C. H., H. Y. Du, Y. T. Tsai, C. P. Chen, C. J. Huang, L. C. Chen, et al. 2007. High performance of low electrocatalysts loading on CNT directly grown on carbon cloth for DMFC. J. Power Sources171:55–62.

- Horng, Y.-Y., Y.-C. Lu, Y.-K. Hsu, C.-C. Chen, L.-C. Chen, and K.-H. Chen. 2010. Flexible supercapacitor based on polyaniline nanowires/carbon cloth with both high gravimetric and area-normalized capacitance. J. Power Sources195:4418–4422.

- Rudge, A., I. Raistrick, S. Gottesfeld, and J. P. Ferraris. 1994. A study of the electrochemical properties of conducting polymers for application in electrochemical capacitors. Electrochim. Acta39:273–287.

- Burke, A.2007. R&D considerations for the performance and application of electrochemical capacitors. Electrochim. Acta53:1083–1091.

- Girija, T. C., and M. V. Sangaranarayanan. 2006. Analysis of polyaniline-based nickel electrodes for electrochemical supercapacitors. J. Power Sources156:705–711.