1 Introduction

Polyurethanes are a versatile family of polymers which can be employed in a wide range of forms, such as bulk, foams or dispersions, as well as in a variety of applications such as paintings, adhesives, coatings and textiles, among others [1]. In general, polyurethanes are composed by two segments. The soft segment usually provides flexibility to the system and is composed by a low-medium molecular weight polyol, and the hard segment, which generally confers stiffness to the material, is composed by an isocyanate and a diol type chain extender. Considering that both segments are thermodynamically incompatible, they result in a phase separated microstructure where, depending on the chemical structure of reagents, arrange in amorphous or crystalline soft domains and amorphous or ordered hard domains [2]. But those compositions results in hydrophobic polymers, being mainly solventborne systems, and presenting some disadvantages such as inflammability or volatile organic compounds emissions, among other. In this context, the development of waterborne polyurethane (WBPU) systems, by the addition of a covalently bonded internal emulsifier and obtaining stable water dispersions over months, is gaining attention during last years [3]. WBPUs present the advantage of being synthesized by a solvent-free method which implies non-flammability, non-toxicity, reduction of volatile organic compounds emissions, and being environmentally friendly.

Furthermore, the chance to disperse hydrophilic reinforcements in WBPU has focused attention in water dispersible entities, such as cellulose derivatives. Among them, cellulose nanocrystals (CNC) become a suitable candidate for the preparation of nanocomposite materials, considering their unique properties in the nanoscale dimension provided by their high length/diameter aspect ratio and high specific mechanical properties [4,5], but few works consider CNC addition strategy and its effect in the final disposition of CNC in the matrix. Moreover, the use of different processing techniques for obtaining WBPU based systems, results in the formation of different forms of the final material. In this way, electrospinning of dispersions provides the opportunity of obtaining nanoreinforced fibers mats with high porosity and large surface area to volume ratio with tailored fiber diameters [6], which become an attractive alternative to conventional casted coatings in different applications.

Therefore, in this work, a WBPU dispersion was synthesized and WBPU/CNC nanocomposites loaded with different contents of isolated CNC were prepare by the classical mixing by sonication, adding CNC after WBPU synthesis, or the alternative in-situ, adding CNC during the WBPU synthesis, just in the phase inversion step. The obtained dispersions were used in the preparation of films by casting or mats by electrospinning. The effect of CNC addition, as well as the incorporation route has been analyzed in the final properties of casted nanocomposite films and electrospun mats.

2 Experimental

2.1 Materials

CNC were isolated from microcrystalline cellulose via sulfuric acid hydrolysis removing the amorphous regions of cellulose. The isolation was carried out following previously reported method [7].

For the synthesis of WBPU, poly(ε-caprolactone) diol (PCL) (Mw = 2000 g mol-1), purchased from BASF, 1,4 butanediol (BD), supplied by Aldrich, isophorone diisocyanate (IPDI) kindly provided by Covestro and 2,2-bis(hydroxymethyl)propionic acid (DMPA) purchased from Aldrich and used as internal emulsifier, were employed.

2.2 Synthesis of waterborne polyurethane

WBPU with a solid content of 25 wt% and a HS content of about 48 wt% was synthesized by a two step polymerization process following previously published protocol [8], with a PCL:IPDI:DMPA:BD molar composition of 0.5:3.15:0.5:2, considering PCL as SS and IPDI, DMPA and BD as HS.

2.3 Nanocomposites preparation

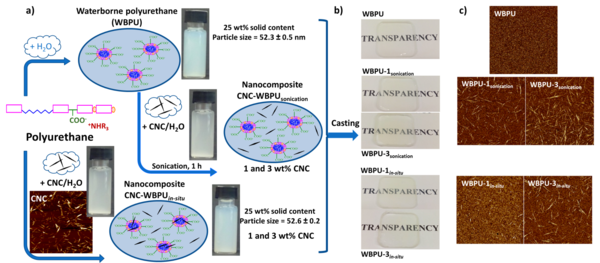

Polyurethane nanocomposites reinforced with 1 and 3 wt% of CNC were prepared by two CNC incorporation routes; mixing

WBPU and CNC by sonication and in-situ during WBPU synthesis. In the first case, the mixture formed by the CNC suspension and the WBPU dispersion was sonicated for 1 h. In the second case, previously sonicated CNC dispersion was incorporated to the polyurethane synthesis in the water addition step. Designation of obtained nanocomposite dispersions is expressed as WBPU-Xsonication and WBPU-Xin-situ for the nanocomposites prepared mixing by sonication and in-situ, respectively, where X denotes CNC weight content in the nanocomposite. A scheme of the WBPU and nanocomposite dispersions prepartion is shown in Figure 1a.

2.3.1 Films preparation by casting

WBPU and nanocomposite films were prepared by casting. Dispersions were cast in Teflon molds allowing to dry in a climatic chamber at 25 ºC and 50% of relative humidity during 7 days, and finally in a vacuum oven. The WBPU and nanocomposite films were stored in a desiccator for 1 week before their characterization.

2.3.2 Mats preparation by electrospinning

Dispersions for the electrospinning process were prepared by adding 4 wt% of PEO respect to total water content in the previously prepared WBPU and nanocomposite dispersions. The dispersions were charged in a 18-gage blunt-end needle which was mounted on a syringe pump (Cole-Parmer). Randomly oriented fibers were electrospun by applying a voltage between 12 and 14 kV to the needle using a Spellman CZE1000R high voltage supply, with a low current output. The ground plate (stainless steel sheet on a screen) was placed at 30 cm from the needle tip. The syringe pump delivered the polymer dispersion at a controlled flow rate of 0.5 mL h−1. The resulting fibers were collected (for 1 h) on the screen in order to produce a sheet of nonwoven fabric.

2.4 Characterization

Dynamic light scattering (DLS) was used for the measurement of dispersions particle size and distribution employing a BI-200SM goniometer, from Brookhaven, measuring the dispersed light (He–Ne laser) intensity at 90º with a detector (BI-APD) placed on a rotary arm. The concentration of sulfate groups anchored to CNC surface was determined by elemental analysis (EA) using a Euro EA3000 Elemental Analyzer of Eurovector. Rheological measurements of the polymer dispersions were performed in a Haake Rheostress stress-controlled rotational viscoelastometer at 25 ± 2 ºC using a cone-plate geometry (ϕ = 40 mm, angle of 2º). Fourier transform infrared spectroscopy (FTIR) analysis of the casted films and electrospun mats was performed in a Nicolet 6700 spectrometer. Spectra were collected at a resolution of 8 cm−1 by accumulating 64 scans. Morphology of casted films and electrospun mats surface was analyzed by atomic force microscopy (AFM) using a Bruker Dimension Icon equipment with an integrated force generated by cantilever/silicon probes, applying a resonance frequency of about 180 kHz. The cantilevers were 125 μm long, with a tip radius of 5–10 nm. Electrospun mats morphology was also analyzed using a Hitachi S-2700 Scanning Electron Microscope (SEM) at 15 kV accelerating voltage. Samples were sputter-coated with a Pt/Au layer. The hydrophilicity of the mats were measured by dynamic water contact angle (WCA) using a Dataphysics OCA20 equipment. Deionized water drop of 3 μL was deposited in the surface of the mats and the drop volume was increased, in advancing WCA, and reduced, in receding WCA, during the test at a constant flow of 0.5 μL.

3 Results and discussion

A CNC suspension with a solid content of about 0.5 wt% and a sulfur content of 1,28% was obtained. The rod-like isolated CNC showed a diameter (D) about 5.4 ± 1.5 nm and length (L) around 167 ± 31 nm, leading to a L/D aspect ratio of 31. The particle size and distribution of the synthesised WBPU and the nanocomposite prepared in-situ with 1 wt% of CNC were determined by DLS, resulting in similar particle size and polydispersity, 52.3 ± 0.2 nm and 0.08 ± 0.05 and 52.6 ± 0.2 nm and 0.06 ±0.02, respectively, suggesting that CNC do not affect particle formation. The small particle size and narrow distribution contribute to the stability of dispersions over months.

Dispersions obtained for both methods were used for the preparation of nanocomposite films by casting. As can be observed (Figure 1b), transparent WBPU and nanocomposite films were obtained. In addition, samples were completely soluble in THF and DMF. Morphology of WBPU and nanocomposite films was analyzed by AFM (Figure 1c). In the AFM phase image of WBPU matrix, light and dark regions are appreciated associated with the polyurethane crystalline and amorphous domains, respectively. Analyzing nanocomposites, it can be observed a homogeneous distribution of CNCs in the WBPU matrix. However, some differences can be distinguished comparing both nanocomposite images. In the case of nanocomposites obtained from dispersions prepared by sonication, CNCs in all of its length and dispersed homogeneously in the matrix are observed. In nanocomposites obtained from in-situ prepared dispersions instead, CNCs seem to be shorter despite possessing the same aspect ratio. So, this fact would imply that CNCs are partially embedded in the matrix due to the greater intercalation among WBPU particles when were added during such particles formation.

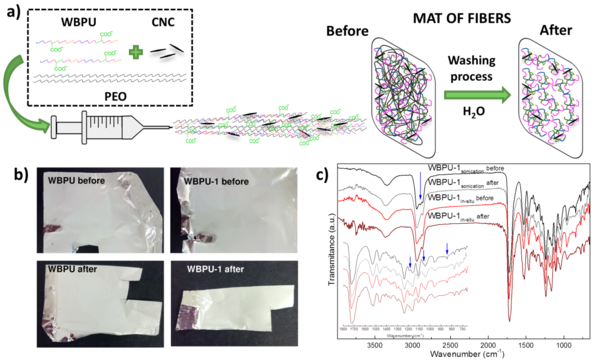

Electrospinning is a suitable technique for obtaining mats of fibers in the nano and micrometer diameter range from a polymer solution induced by an electric field applied between the syringe tip, where the polymer solution droplet is formed, and the grounded collector, where the fibers mat is deposited (Figure 2a). The proper formation of fibers depends on several parameters related with solution and processing variables, as well as environment conditions. Previously synthesized WBPU and WBPU/CNC nanocomposites prepared by sonication and in-situ were used as polymer solution. It was seen that the dispersability of WBPU is not good enough for the packaging of chains by entanglements in order to form a continuous fiber [9]. Thereby, low contents of water-soluble high molecular weight PEO were used as template polymer. Mixtures of PEO and dispersions prepared by sonication method presented lower viscosity values, due to the diluting effect by the additional water employed for the addition of CNC. Instead, in the case of in-situ method, an increase was observed by the interactions generated by CNC addition. It was seen that all mixtures presented good spinability (Figure 2b). The PEO, as auxiliary polymer for electrospinning, was removed from electrospun fibers by water extraction and verified by Fourier transform infrared spectroscopy by the reduction or disappearance of some peaks after the treatment (Figure 2c).

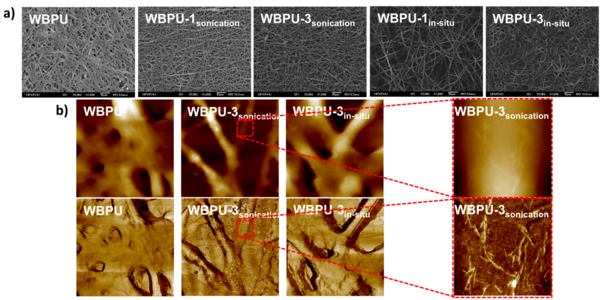

The morphology of WBPU and nanocomposite mats before washing treatment was analyzed by SEM (Figure 3a). It was observed that nanocomposites showed more defined fiber morphology comparing with the matrix. This fact indicates that CNC favored the spinnability of the dispersions. The sulfate groups anchored in their surface induce CNC to act as polyelectrolytes, increasing ionic strength in the system and facilitating the ejection of fibers, except in the case of 3 wt% of CNC incorporated by in-situ method, which would be attributed to the higher viscosity. Comparing both methods, it was observed that in the case of sonication thinner fibers were obtained, which would be related with the disposition of CNC in the matrix. In this case, they would tend to locate in the surface of fibers, being the effect more remarkable comparing with in-situ method, where CNC would remain embedded in the matrix. Mats were also analyzed by AFM after the washing treatment (Figure 3b). Comparing both methods, the sonication route resulted in thinner fibers. In this case, also CNCs were appreciated in the surface, whereas by in-situ method CNCs were not discerned.

The hydrophylicity of mats before and after whasing treatment was analyzed by dynamic water contact angle (Figure 4). Before the washing treatment, it was observed that the matrix presented angle values around 70º. Instead, in general, nanocomposites presented values between 80 and 90º, presenting more hydrophobic character, despite containing hydrophylic cellulose nanocrystals. This fact is related to the finer and more defined fibers as observed by SEM, favored by the incorporation of CNC. Regarding the effect of CNC incorporation route, in the case of sonication method, the more exposed CNC resulted in lower values as CNC content increases. However, by in-situ method, tended to maintain similar values. This can be related with CNC disposition, since in the case of incorporated in- situ, CNC result embedded in the matrix. After the washing treatment, the matrix became more hydrophobic, the water contact angle values increase around 80-90º, due to the removal of water soluble PEO, whereas nanocomposites tended to became more hydrophilic. Water contact angle values decrease from around 80-90º to 60-70º, due to the greater cellulose nanocrystals exposure, more specifically in the case of incorporated by sonication, which can even reorient toward water drop.

4 Conclusions

CNC-WBPU nanocomposite dispersions containig 1 and 3 wt% of CNC were prepare by mixing by sonication and in-situ, and were employed for the preparation of nanocomposite films by casting and nanocomposite mats by electrospinning. AFM images of nanocomposite films showed a good CNC dispersion in WBPU resulting in different CNC dispositions in the matrix depending on CNC incorporation route. Continuous fiber mats were obtained from all dispersions. Moreover, CNC addition promoted the spinnability of thinner fibers comparing with the matrix. AFM images revealed that in the case of mixing by sonication route, CNC tended to be located in the surface of fibers, whereas by in-situ method, resulted embedded in the matrix. The different CNC disposition in the matrix modulated the surface behavior of electrospun mats.

Acknowledgments

Financial support from the Basque Government (IT-776-13 and KK-2016/00043) and Spanish Ministry of Economy and Competitiveness (MINECO) (MAT2016-76294R) is gratefully acknowledged. We also wish to acknowledge the “Macrobehaviour-Mesostructure-Nanotechnology” SGIker unit from the University of the Basque Country, for their technical support.

Referencias

[() ] J.O. Akindoyo, M.D.H. Beg, S. Ghazali, M.R. Islam, N. Jeyaratnam, A.R. Yuvaraj, RSC Advances 6, 114453–114482 (2016).

[2] I. Yilgör, E. Yilgör, G.L. Wilkes, Polymer 58 , A1–A36 (2015).

[3] K. Matsunaga, K. Nakagawa, S. Sawai, O. Sonoda, M. Tajima, Y. Yoshida, Journal of Applied Polymer Science 98, 2144-2148 (2005).

[4] S.J. Eichhorn, Soft Matter 7, 303–315 (2011).

[5] M.A.S. Azizi Samir, F. Alloin, A. Dufresne, Biomacromolecules 6, 612–626 (2005).

[6] S. Torres-Giner, R. Pérez-Masiá, J.M. Lagaron, Polymer Engineeringand Science 56, 500–527 (2016).

[7] A. Santamaria-Echart, L. Ugarte,C. García-Astrain, A. Arbelaiz, M.A. Corcuera, A. Eceiza, Carbohydrate Polymers 151,1203–1209 (2016).

[8] A. Santamaria-Echart, A. Arbelaiz, A. Saralegi, B. Fernández-d’Arlas, A. Eceiza, M.A. Corcuera, Colloids and Surfaces A: Physicochemical and Engineering Aspects 482, 554–561 (2015).

[9] L. Buruaga, H. Sardon, L. Irusta,A. González, M.J. Fernández-Berridi, J.J. Iruin, Journal of Applied Polymer Science 115, 1176–1179 (2010).