1. Introduction

The integration of carbon fiber reinforced polymer (CFRP) composites into aerospace manufacturing is currently the leading strategy for designing and producing structural components. This is largely due to their excellent specific mechanical properties and strong operational performance history.

At AIRBUS, the transition from metallic to composite components has resulted in a significant reduction in greenhouse gas emissions, reaching 63.5 grams of CO2 per passenger-kilometer in 2020. However, maintaining or increasing the use of high-performance composites requires addressing key challenges—most notably, developing technologies that reduce material usage, and that support the reuse and recycling of both structural and auxiliary materials. These efforts are aligned with the sustainability principles known as the "5Rs": Rethink, Refuse, Reduce, Reuse and Recycle [1].

Despite the automation enabled by technologies such as automated fiber placement and tape laying, the widespread use of composites in aerospace has also led to an increase in waste. Beyond the economic costs and value loss associated with incineration, there is an important need to enable a circular economy in the aerospace sector in line with the industry's circularity goals.

Building on our experience with high-performance materials, a Bulk Molding Compound (BMC) process was developed to transform carbon-epoxy prepreg by-products into low performance and non-structural components, promoting a circular economy approach.

This study, led by AIRBUS Spain, aims to assess the feasibility of reusing multilayer prepreg waste. Specifically, it seeks to adapt a validated process—originally developed for single-layer prepreg offcuts (end-of-roll materials)—to multilayer by-products generated prior to curing during the cutting of fresh laminates. The quantities of both waste types generated in production of composite parts are comparable.

To evaluate this new process, demonstrator parts were manufactured, and their mechanical properties were characterized. The goal is to validate the process as a cost-saving and environmentally friendly solution by converting multilayer CFRP prepreg waste into composite non-structural components.

2. Problem Understanding

Global demand for CFRP has increased by 12% since 2010, with expectations that demand will soon outpace supply, leading to an increase in the waste generation. This trend is driven by the extensive use of continuous fiber composites across multiple sectors, including aerospace, marine, and wind energy. Waste generated including End Of Life waste from the aerospace and wind turbine industries alone is projected to exceed 840,000 tons by 2050 [2].

Focusing on non-cured prepreg waste from manufacturing, three main production stages are identified as sources:

- Lay-up: Layers of fresh prepreg are manually or automatically stacked. Depending on the part, this may occur on a tool or flat surface. In some cases, intermediate compaction is required.

- Cutting: The stacked laminate is cut to the required geometry.

- Forming: Conducted automatically under heat (below 90°C) and vacuum, using self-heating presses or infrared-equipped forming tables.

The type of uncured prepreg waste that can be considered as byproducts is defined as follows:

- Multilayer laminates: Result from leftover material during lay-up and represent a significant portion of uncured prepreg waste.

- Single-layer waste: Coming from end of roll or expired prepreg stock.

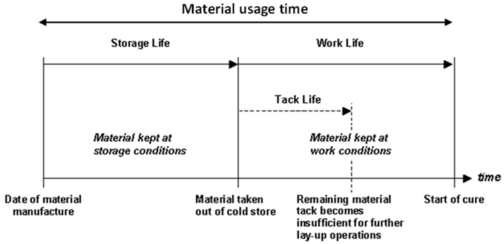

Prepreg waste becomes unusable depending on their material usage (Fig.1) for two main reasons:

First, when their “storage life” has been exceeded. These types of materials are stored under specific conditions, refrigerated at ≤ -18°C to prevent the polymerization of the epoxy resin polymer matrix from progressing. They have a storage life (generally 12 or 24 months), after which they begin to show signs of ageing and become unusable. It should be noted that the term "storage life" covers the period from the time the prepreg is manufactured and stored at -18ºC until it is taken out of the cold storage to be used in the plant.

Second, when its "work life" has been exceeded. This is defined as the maximum time that the material can stay inside clean room conditions until the start of the curing, maintaining its optimum physical, chemical, and mechanical properties. In general, this period is approximately 30 days for carbon prepregs, after which the material ages and its properties deteriorate, rendering it unusable.

3. Reuse Process Description

The main objective is to develop an end-to-end process enabling the reuse of preimpregnated scrap material coming from the manufacturing of composite components, to produce composite parts that can be implemented in the aircraft for different applications.

The process developed for the reuse of multilayer preimpregnated material consists of 5 different steps since the scrap is identified to become a by-product. The process steps are described below:

- 1. BYPRODUCT PREPARATION AND DELIVERY: Unpacking and preparation of the received material, ensuring that it is free of any residual auxiliary materials. This step is crucial and implies a change in the traditional way of working where the scrap was collected with no specific requirements. Proper segregation and flat storage of the byproducts are essential for optimal downstream processing.

- 2. CUTTING PROCESS: Using a trimming machine equipped with blades, the material is subjected to a first transversal cut every 25mm, in order to obtain smaller preimpregnated pieces that are easier to handle in the subsequent stages of the process. In a second cutting process, the strips are cut longitudinally every 5 mm to obtain preforms called "chips" with a size of 25 x 5 mm. The separation between layers is done through the shear force introduced in the multilayer by-product during the cutting. The result is a standard monolayer material, similar to what is initially obtained when working with monolayer by-products.

- 3. DOSING: From the monolayers obtained during the cutting process, the optimal amount of material is dosed manually or automatically into a mold, based on the geometric requirements of the final part, to obtain the desired preform.

- 4. PREFORMING: A short consolidation cycle is performed under vacuum and a certain temperature to compact and stabilize the material while maintaining the desired geometry. The optimal pre-forming parameters are 5 minutes under vacuum >450mmHg at 50ºC.

- 5. MOLDING: Using an industry-standard BMC (bulk molding compound) composite molding press, the chips are pressed at 100 bar pressure at 180°C for 30 minutes to mold and cure the resin into the desired shape. Once cooled, the part is removed from the mold, resulting in a part with adequate thickness, surface finish, and flatness.

4. Mechanical Performance

The reuse process described in the previous section involves the cutting of the carbon prepreg into multilayer chips of 25x5mm which negatively impacts mechanical properties due to the length and orientation of the carbon fiber. This length reduction and lack of orientation will have an impact on the mechanical properties of the final composite that were analyzed.

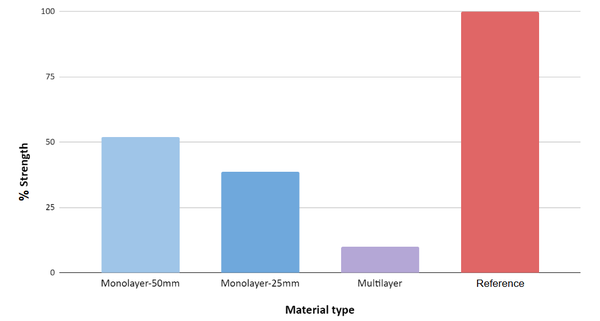

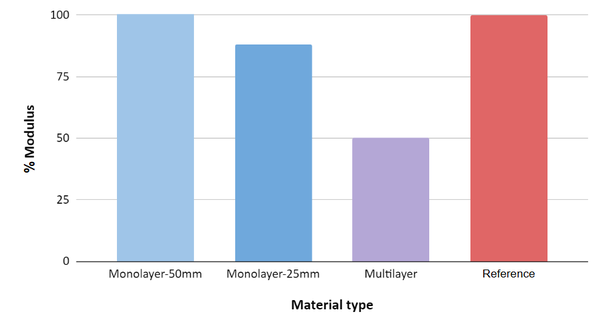

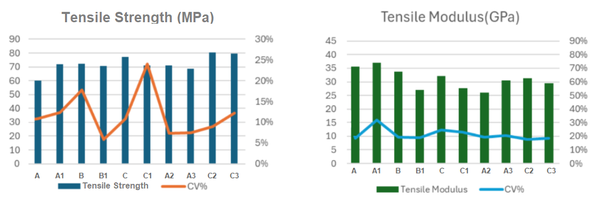

The preliminary assessment performed on the mechanical performance of the multilayer reuse by-product was done testing the tensile strength and modulus. The results were compared with the original material to analyze the properties knockdown when reducing the carbon fiber length, and also compared with preliminary results obtained when monolayer material was used.

Based on the strength results, it can be observed that the multilayer configuration shows a significant decrease of strength properties, about 90% from the reference. It is important to remark that the reference has been obtained from a quasi-isometric lay-up using unidirectional (UD) prepreg, while the panels using monolayer and multilayer has been manufactured by distributing the monolayer uniformly to achieve isotropic behavior, although due to the manufacturing process local areas with different orientation will be presented.

Additionally, an important decrease can be observed when comparing monolayer results for both 50mm and 25mm. This decrease can be explained in how the cutting of the pre-impregnated materials is performed on monolayer versus multilayer. In the monolayer case, the material is perfectly oriented on the 0º being capable of always achieving homogeneous sizes in which the fiber length will be maximum (50mm or 25mm). In the case of the multilayer, the cutting of 25x5mm is performed to a lay-up with different orientations (0º, ±45º and 90º), obtaining the maximum fiber length on the 0º plies, but only 5mm fiber length on the 90º plies and non-homogeneous length on the 45º plies.

Concerning modulus behaviour, multilayer material shows a 50% decrease from the reference. This stiffness loss can be associated with the different fiber orientation presented on the multilayer due to fiber orientation observed in the multilayer configuration as the random distribution made on the panels manufacturing.

5. Ageing influence

Additionally, to the characterization of the mechanical behavior, the second main parameter that was analyzed was the influence of ageing on the mechanical properties and manufacturability.

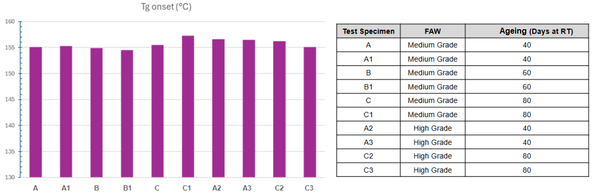

As explained in Section 2 of this paper, the most common worklife of the aeronautic carbon fiber pre-impregnated materials is 30 days. In order to not be constrained to the multilayer scrap generated inside the 30 days of worklife and to be capable of reusing expired material, different ageing time was analyzed. The ageing time analyzed were 40, 60, and 80 days, and the glass transition temperature after curing, tensile strength, tensile modulus, and manufacturability were analyzed to determine the potential impact of ageing on the process.

The analysis made on the effect of ageing on the glass transition temperature shows that no difference has been observed between 40, 60 or 80 days of ageing.

No influence on Tg ((glass trasition temperature) has been seen neither between different fiber areal weight (FAW) grades. It shall be noted that low Tg values by DMA were obtained due to a short curing cycle (30 min at 180ºC) applied during the press molding process. The expected Tg value in this epoxy resin is approximately 180ºC, while the Tg values obtained were in the range of 155ºC. To corroborate this hypothesis, a post-curing cycle of 180ºC for 1h was performed and the Tg was measured again. After the post-curing, the Tg increases from 154ºC to 184ºC, indicating that the press curing cycle of 30min at 180ºC does not achieve a high degree of cure on the parts.

Regarding mechanical performance, no major differences have been observed between different ageing times, which are characteristic of high variability in the properties due to the non-homogeneous distribution and orientation of the fiber on the laminate.

6. Manufacturing Trials

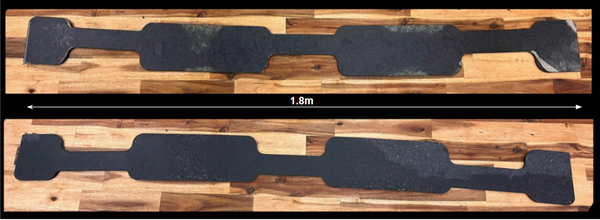

Several representative aeronautical parts were manufactured with reused multilayer scrap to demonstrate the feasibility of the process described. As can be seen in the picture below, parts of 1.8 meters and a thickness of 4mm were manufactured with the different ageing times of 40, 60 and 80 days.

Material with an ageing of 80 days allows easier layers separation and more simplicity during the cutting process. However, the material flow during the press cycle decreases and may originate dry areas on the part. Low part thickness can generate problems during manufacturing due to the lack of mass flow during the press process resulting in uneven thickness of the produced part (due to inadequate mould filling).

7. Conclusion

The main conclusions that can be extracted from this work can be summarized as follows:

- Multilayer reuse scrap shows a 90% decrease in tensile strength and 50% in tensile modulus. This decrease is inherent to the cutting process effect on the fiber orientation and length, in which a maximum length of 25mm on the 0º plies, but lower on the 45º and 90º, and.

- Ageing time above 30 days up to 80 days does not impact mechanical properties or the cured part glass transition temperature.

- BMC press process of 30 minutes at 180ºC does not reach a high degree of curing on the material, being necessary a post cure cycle of 1 hour at 180ºC to reach the expected Tg.

- High ageing of the multilayer prepreg will improve and simplify the cutting process due to the drier state in which the material will be. However, this may lead to dry areas on the final part due to the lack of resin flow during curing.

- Higher part thickness produces a more significant load gradient which leads to more freedom for the mass flow to be distributed homogeneously.

8. Acknowledgments

This work was supported by the project TED2021-131102B-C21, funded by MCIN/AEI/10.13039/501100011033 and the European Union “NextGenerationEU”/PRTR; and the

project PID2022-138496OB-I00 from Agencia Estatal de Investigación of Spanish Government and

AIRBUS OPERATIONS S.L.

9. Bibliography

[1] Meshram, K.K. The circular economy, 5R framework, and green organic practices: pillars of sustainable development and zero-waste living. Discov Environ 2, 147 (2024). https://doi.org/10.1007/s44274-024-00177-4

[2] Libro blanco de sostenibilidad en los materiales compuestos, 2025, AEMAC.

Document information

Accepted on 07/07/25

Submitted on 12/04/25

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?