Abstract

Three types of low-carbon vehicle technologies in China are reviewed. Potential effects are listed for those integrated energy-saving technologies for conventional vehicles. Low carbon transitions, including alternative vehicle power train systems and fuels, are discussed on their development status and trends, including life cycle primary fossil energy use and greenhouse gas emissions of each pathway. To further support the low-carbon vehicle technologies development, integrated policies should seek to: (1) employ those integrated energy-saving technologies, (2) apply hybrid electric technology, (3) commercialize electric vehicles through battery technology innovation, (4) support fuel cell vehicles and hydrogen technology R&D for future potential applications, (5) boost the R&D of second generation biofuel technology, and (6) conduct further research on applying low-carbon technologies including CO2 capture and storage technology to coal-based transportation solutions.

Keywords

low carbon ; vehicle technology ; greenhouse gas

1. Introduction

According to the World Energy Outlook 2008 edited by the International Energy Agency (IEA), oil accounted for 96% of the total energy consumption in China’s Transport Sector in 2005 and the oil consumption in the Transport Sector accounted for 35% of the total oil consumption in the whole country for that year, and the latter rate will rise to 55% in 2030. For CO2 emissions, the Transport Sector accounted for about 8% of the total emission in China in 2005 and this proportion will rise to 11% in 2030. With the rapid growth of vehicle population, passenger and freight traffic in China’s road transport, the pressure of both fuel shortages and greenhouse gas (GHG) emissions is increasing. A cluster of technology and policy tools are essential to control the vehicle population, reduce the average distance travelled, improve the level of fuel economy and decrease emissions [ Xu et al., 2009 ]. The in-depth study on the status quo and development trend of low-carbon vehicle technology will be helpful for policy-making regarding the energy-saving of Transport Sector in China [ Yan and Crookes, 2009 ].

2. Categories of low-carbon vehicle technology

As to the supplies of transport energy, there is a unanimous view that oil will play dominant roles in transport energy until 2030, while hydrogen or electric energy will replace oil ultimately in the future (later than 2030). There is an inevitable energy diversification trend in the transition period [ Wang and Ouyang, 2007 ].

Like developed countries, China is taking three categories of measures including comprehensive energy-saving vehicle technologies application, vehicle power electrification and vehicle energy diversification to reduce car traffic energy consumption [ NEO and CATARC, 2008 ]. Accordingly, the low-carbon vehicle technologies are sorted into three categories — integrated energy-saving technologies, vehicle power electrification technologies, and low-carbon vehicle alternative fuels (VAF) technologies [ AERT, 2007 ].

3. Contents of integrated energy-saving technologies for conventional vehicles

There are four kinds of technologies for those integrated energy-saving vehicle [ NEO and CATARC, 2008 ], energy-efficient technologies for conventional gasoline engine, advanced diesel engine technology, vehicle power train energy-saving technologies, and other comprehensive vehicle energy-saving technologies.

Firstly, conventional gasoline engine can get energy-saving merit if they have the following elements, low-friction, high compression ratio, multi-valve, variable air-fuel mixture ratio, fuel direct injection, and light-weight. The fuel economy can be improved by 3%–5%, 1%–3% and 10%–20% with the multi-valve technology, the variable valve timing technology, and the fuel direct injection technology employed respectively. Secondly, compared to the spark ignition gasoline vehicle, the same type diesel vehicle becomes 30% more fuel-efficient on average and this figure will be 30%–40% if it is an advanced diesel vehicle. Thirdly, fuel consumption can be cut with the multiple and continuously variable gear-shift ratios application. For example, the fuel economy can be improved by 2%–3% with one more gear-shift ratio added in the transmission system. Lastly, it represents an important energy-saving solution to cut down the overall vehicle weight — the fuel economy can be improved by 6%–8% if 10% of the overall vehicle weight is cut off.

4. Low-carbon development of vehicle power train systems

In the broad definition, electric vehicles include pure electric vehicles (EVs), hybrid electric vehicles (HEVs), and fuel cell electric vehicles (FCEVs) [ Edwards, 2006 ]. They are low carbon electrification power train systems and do not only use the conventional compression-ignition and spark-ignition internal-combustion engine (ICE).

There remains the bottleneck for driving power and battery life of EVs though they have been put in use for decades and have a simple structure. However, EVs achieve actual zero-emission during their traveling, and have very low energy consumption per kilometer driven, and their fuel economy is considered to be 300% more than for gasoline vehicles in the same period [ Zhang et al. , 2008 ]. According to the calculation of Ou et al. [2010], the EVs which are currently showcased in China consume 150 kW h per 100 km and the fuel economy is 300% of the baseline diesel vehicles which use 45 liter diesel when running the same distance. From the life cycle analysis (LCA) covering all the stages of energy resource extraction, transportation, fuel conversion, distribution and storage, EVs can save 27% of the total primary fossil energy and reduce 10% of GHG emissions. With battery technology improvements, the advantage of energy-saving and GHG emissions reduction will be more obvious, and it is estimated that EVs can save about 50% of energy and reduce about 35% of GHG emissions in 2012 during the LCA of passenger EVs [ Ou et al., 2009a ].

Furthermore, the GHG emissions reduction merit of EVs will be expanded when employing CO2 capture and storage (CCS) technologies for the coal-fired power plants [ IPCC, 2005 ; NDRC, 2007 ]. It is assumed that CCS technology reduces the conversion efficiency of coal-to-electricity to 32%, but captures 80% of CO2 produced in power plants. The LCA impacts for EVs are dramatic. Although energy use increases slightly compared to the original scenario, GHG emissions are reduced by 73% when compared to a conventional vehicle [ Ou et al., 2009a ].

Recently, the R&D (research and development) and industrialization of HEVs, including passenger cars and commercial vehicles, are becoming the focuses in the development of energy efficient vehicles in China. A number of pilot HEVs have been developed and demonstrated in some cities with the energy-saving rate of 15%–30% [ NEO and CATARC, 2008 ]. Moreover, according to Zhang et al. [2008], it is estimated that the energy-saving rate for HEVs in 2020 will reach 35%–45%, close to the current level of the United States.

FCEVs supply power for power train through the chemical reactions of hydrogen and air. The energy efficiency is much higher than for the ICE vehicles though lower than that of pure EVs.

According to the calculation of Ou et al. [2010], the FCEVs during demonstration travelling consumed 10.76 kg hydrogen per 100 km which is produced from natural gas (NG) and the fuel economy is 124% of the same size diesel vehicles which consumed 45 liter diesel when running the same distance. In LCA, FCEVs increase 10% of the total primary fossil energy but reduce 10% of GHG emissions. With the technology improvement of fuel cell and hydrogen production and storage, FCEVs will get the advantages of energy-saving and GHG emissions reduction. The fuel economy of FCEVs can be 130% more than that of advanced gasoline vehicle in 2020 which is estimated by Zhang et al. [2008].

5. Low-carbon transitions of alternative vehicle fuel pathways

Besides the electricity and hydrogen pathways, gaseous fuel such as compressed NG (CNG) and liquefied petroleum gas (LPG), liquid fuel derived from coal and biomass are all important VAF pathways.

5.1. Technology pathways commercialized or on large-scale demonstration

As shown in Table 1 , those VAF pathways commercialized or demonstrated on large-scale in China have different performances regarding technology maturity status, energy use and GHG emission.

| Pathway | Fuel production technology status[ Zhang et al., 2008 ] | Vehicle use technology status [ Zhang et al., 2008 ] | Vehicle powertrain system [ AERT, 2007 ] | Vehicle energy efficiency being used (to baseline) [ NEO and CATARC, 2008 ] | Life cycle fossil energy use ratio relative to baseline [ Ou et al ., 2010 ; Ou et al ., 2009b ] | Life cycle GHG emissions ratio relative to baseline [ Ou et al ., 2010 ; Ou et al ., 2009b ] | Other issues [ NEO and CATARC, 2008 ] |

|---|---|---|---|---|---|---|---|

| CNG | Mature | Application maturely in the feedstock abundant district | CNG engine | Equivalent to gasoline vehicle | 0.86 (to gasoline) | 0.72 (to gasoline) | Inadequate supply network, storage difficulties |

| LPG | Mature | Application maturely in the feedstock abundant district | Modified gasoline engine | Equivalent to gasoline vehicle | 0.84 (to gasoline) | 0.78 (to gasoline) | Inadequate supply network, storage difficulties |

| Coal-based methanol | Mature | Demonstration in certain districts | Modified gasoline engine | Equivalent to gasoline vehicle | 1.18 (to gasoline) | 2.12 (to gasoline) | Potentially toxic, not strong power |

| Coal-based DME | Mature | R&D and demonstration | Modified diesel engine | Equivalent to diesel vehicle | 1.28 (to gasoline) | 2.17 (to gasoline) | High transportation and storage cost |

| Bio-ethanol | Mature | Demonstration and deployment in certain districts | Gasoline engine (blended) | Equivalent to diesel vehicle | 0.49–1.09 (to gasoline) | 0.66–1.40(to gasoline) | Energy use and GHG emissions closely related with feedstock type |

| Bio-diesel | R&D and demonstration | Easy to use due to its similar traits to diesel | Diesel engine (blended) | Slightly better than diesel vehicle | 0.38–0.78 (to diesel) | 0.51–1.08(to diesel) | Energy use and GHG emissions closely related with feedstock type |

According to LCA calculation [ Ou et al., 2010 ], CNG vehicles use 14% less fossil energy and emit 28% less GHG than baseline diesel vehicles. LPG vehicles have similar dual merits to CNG vehicles. As to coal-based fuel vehicles, they emit 110%–120% more GHG and use 20%–30% more fossil fuel (primarily coal) than those diesel-fueled vehicles.

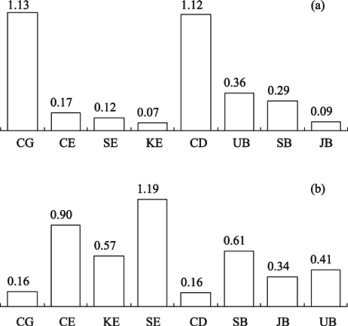

For biofuel vehicles, the LCA of energy use and GHG emissions vary dramatically due to different feedstock [ Ou et al., 2009b ]. The biofuel pathways of corn-derived ethanol (CE), sweet sorghum-derived ethanol (SE) and soybean-derived biodiesel (SB) have negative NEV (the result of the energy contained in the fuel minus its LCA primary energy consumption) which is similar to conventional gasoline (CG) and conventional diesel (CD) baselines. But the pathways of cassava-derived ethanol (KB), jatropha fruit-derived biodiesel (JB) and used cooking oil-derived biodiesel (UB) have positive NEV. Ranked by their low to high NER (the ratio of the energy contained in the fuel to the LCA fossil fuel consumption), the pathways are SE, CG, CD, CE, SB, UB, KE and JB. When 1 MJ fuel is obtained and utilized, SE and CE pathways lead to significant increase in GHG emissions up to 26.43% and 39.91% respectively, but KE, JB and UB indicate significant GHG emissions reduction of 33.96%, 49.34% and 21.54% respectively (Fig. 1 ).

|

|

|

Figure 1. Life-cycle petrol energy and coal energy inputs of biofuel pathways [ Ou et al., 2009b ], (a) petrol energy input (MJ per MJ fuel), (b) coal energy input (MJ per MJ fuel) |

5.2. Technology pathways on small-scale demonstration or being in the process of R&D

There are mainly two kinds of VAF pathways being promising but still on small-scale demonstration or being in the process of R&D in China.

Although they are in the R&D stage and need technology leapfrog now cellulosic ethanol and biomass to liquid are expected to get obvious energy-saving and GHG emissions reduction merits. According to Chai [2008] , fossil energy consumption of LCA in 2020 for cellulose ethanol will decline to a very low level and the corresponding GHG emissions will be low, and combination with HEVs technology and E85 which is blended with this kind of ethanol and gasoline in a ratio of 85:15 by volume can emit only 25% GHG which are of that of conventional gasoline car.

Coal-to-liquid (CTL) pathways including both direct and indirect conversion technologies from coal to oil are in the small-scale demonstration phase. CTL products have high compatibility and can be directly applied to diesel vehicles and this VAF pathway has superior energy efficiency performances to a certain degree. Large-scale coal-based hydrogen production technologies are also being pilot technologies in the industry. But if low carbon technologies such as clean coal and CCS technology are not employed, both energy consumption and GHG emissions in LCA will be still at high levels for the future coal-based fuel. According to the CATARC and GM [2007] , it is estimated that the GHG emissions of coal-based fuel in LCA will be 50%–150% more than that of gasoline in 2015. With the help of CCS and HEVs technologies, coal-based fuel can get GHG emissions reduction merit and use equivalent fossil fuel for LCA when taking the convention petroleum as a baseline in 2020 in China [ Zhang et al., 2008 ].

6. Policy suggestions

Integrated policies should be implemented to promote forward-thinking solutions to China’s transportation energy and GHG emissions problems.

These low carbon policies might include: (1) employing those integrated energy-saving technologies; (2) promoting HEVs technology; (3) commercializing EVs through battery technology innovation; (4) supporting FCEVs and hydrogen technology R&D for future potential applications; (5) boosting the R&D of second generation biofuel technology; and (6) conducting further research on applying low-carbon technologies including CCS technology to coal-based transportation solutions.

Acknowledgements

The project is co-supported by the China National Social Science Foundation (09&ZD029), MOE Project of Key Research Institute of Humanities and Social Sciences at Universities in China (2009JJD790029), Doctoral Thesis Fund of Beijing Municipal Science and Technology Commission (zz200923) and the CAERC program (Tsinghua/ GM/SAIC-China). The authors would like to thank the reviewers, Dr. Kristin. B. Zimmerman of GM and Mr. Benny Zhang of GM-China for their generous help.

Received 9 June 2010; revised 14 July 2010; accepted 21 July 2010

References

- AERT, 2007 AERT (Alternative Energy Research Team of NDRC, China); China alternative energy research report (in Chinese). (7 June 2007) Accessed http://www.drcnet.com.cn/DRCnet.Common.web/DocViewSummary.aspx?LeafID=14130&DocID=1516667

- CATARC (China Automotive Technology and Research Center) and GM (General Motors), 2007 CATARC (China Automotive Technology and Research Center), GM (General Motors); Well-to-Wheels analysis of energy consumption and GHG emissions of multiple vehicle fuel pathway in future China, CATARC (2007), p. 83

- Chai, 2008 Q. Chai; Research on the Biomass-derived Automotive Alternative Energy Industry (in Chinese), Tsinghua University (2008), p. 222

- Edwards, 2006 R. Edwards; Well-to-Wheels analysis of future automotive fuels and powertrain, EUCAR, CONCAVE, JRC/IEC (2006)

- IPCC, 2005 IPCC (Intergovernmental Panel on Climate Change); B. Mertz (Ed.), et al. , Carbon Dioxide Capture and Storage: IPCC Special Report, Cambridge University Press (2005), p. 431

- NDRC, 2007 NDRC (National Development and Reform Commission of China); China’s national climate change program (in Chinese) (2007) Accessed http://news.xinhuanet.com/politics/2007-06/04/content_6196300.htm

- NEO and CATARC, 2008 NEO (National Energy Office), CATARC (China Automotive Technology and Research Center); Research report of vehicle traffic energy consumption and energy-saving trends in China (in Chinese), NEO (2008), p. 57

- Ou et al., 2010 X. Ou, S. Chang, X. Zhang; Alternative fuel buses currently in use in China: life-cycle fossil energy use, GHG emissions and policy recommendations; Energy Policy, 38 (2010), pp. 406–418

- Ou et al., 2009a X. Ou, Y. Qin, S. Chang, et al.; Life-cycle analysis of energy consumption and GHG emissions of electric vehicle in China in future; Automobiles and Parts (in Chinese), 770 (2009), pp. 40–41

- Ou et al., 2009b X. Ou, X. Zhang, S. Chang, et al.; Energy consumption and GHG emissions of six biofuel pathways by LCA in (the) People’s Republic of China; Applied Energy, 86 (2009), pp. S197–S208

- Wang and Ouyang, 2007 H. Wang, M. Ouyang; Transition strategy of the transportation energy and powertrain in China; Energy Policy, 35 (2007), pp. 2313–2319

- Xu et al., 2009 G. Xu, J. Zou, B. Yang, et al.; Technology options and policy package for controlling the fuel consumption & GHGs emission of vehicle transportation in China; Advances in Climate Change Research (in Chinese), 5 (3) (2009), pp. 167–173

- Yan and Crookes, 2009 X. Yan, R.J. Crookes; Reduction potentials of energy demand and GHG emissions in China’s road transport sector; Energy Policy, 37 (2009), pp. 658–668

- Zhang et al., 2008 A. Zhang, W. Shen, W. Han, et al.; Life Cycle Analysis of Automotive Alternative Energy (in Chinese), Tsinghua University Press (2008), p. 220

Document information

Published on 15/05/17

Submitted on 15/05/17

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?