Abstract

At present, the planning for the conservation or development of Japanese traditional crafts is based on administrative districts or water catchment areas. However, the conservation of Japanese traditions relies not only on the access to relevant natural resources but also on artisans׳ ability to manufacture crafts in specific environments. The perspectives of artisans on their work environments have a significant influence on traditional crafts. In this study, we aimed to investigate the changes in natural resource use in a village recognized for Koishiwara-yaki -style pottery. We employed a questionnaire and conducted interview surveys to collect data on the perceptions of the artisans working in the said village. The findings were as follows. 1) The area commonly regarded by the artisans as their place for pottery was identified. The identification of areas that are significant to local tradition can serve as a vital contribution to spatial planning. 2) The birth place of the local ceramics tradition in a local water catchment area was regarded as critically important in the preservation of the traditions of the village. 3) Several potters emphasized the value of their work environment to ver administrative support because of the historical connection between the place and their traditions. Highlighting this connection can attract historical and cultural tourism to this area.

Keywords

Recognized area ; Cultural landscape ; Modernization ; Traditional craft natural resource

1. Introduction

1.1. Background

The village of Koishiwara is renowned in Japan for its long-standing pottery tradition. Pottery production in this area requires natural resources, such as clay as the primary material, fire wood as fuel, and mountains lopes for constructing climbing kilns. Location is crucial for pottery production of this kind. However, traditional ceramics production areas are being threatened by modernization, including mechanization and the use of external natural resources. As artisans can now practice their craft anywhere, the efficiency of pottery production has markedly improved. Additionally, numerous villages in the study area have merged with neighboring municipalities, and administrative districts have been extended. The production areas are not as clearly demarcated as they used to be.

The current planning for the conservation or development of traditional Japanese crafts with consideration of the importance of cultural and natural landscapes is linked to administrative districts or water catchment areas. However, the preservation and promotion of Japanese crafts relies not only on the access to natural resources but also on artisans׳ ability to produce their crafts in a particular environment. The perspectives of artisans on their work environments are essential factors that influence their work (Yanagi, 1928 ; Risatti, 2007 ). Determining the particular area that is recognized by potters as their pottery site is critical, and the significance that potters attach to such area is essential. The results can contribute to the conservation of the unique local character of the identified area. Therefore, this study aims to identify the boundaries of a pottery heritage area in a village that is recognized by local artisans.

1.2. Literature review

1.2.1. Defining the production area

In primary industries, such as the agriculture and forest industries, the relationship between production and location is relatively easy to define on the basis of the environment. In Europe, the value of a specific location is recognized as terroir , and indicating the geographical location for valuation and preservation purposes is institutionalized. Famous classifications include the Appellationd׳ Origine Controlee in France and the Denominazionedi Origine Controllata in Italy.

However, identifying unique locations related to goods production in secondary industries is considerably complicated because producers tend to move around over time to improve economic efficiency. Traditional crafts go against this trend because location is a crucial factor that influences their production and is typically a major factor that allows traditional crafts to survive through the ages.

Several studies have been conducted in Japan to identify these areas. Researchers have identified such areas as the original locations where artisans lived in and worked, and they have consequently tracked the development of these production areas (Suyama, 1993 ). Tsujimoto et al. (1989) focused on the Japanese textile industry and identified such an areas on the basis of the records of local looms. However, existing studies identified production areas using aggregated points of where artisans worked. In the present work, we aim to identify the production area of traditional potters because it overlaps with the traditional craft production areas identified in previous studies.

1.2.2. Research on area recognition

Since the publication of Lynch׳s The Image of the City in1960 ( Lynch, 1960 ), various methods have been developed to analyze perceptions of certain locations. Nakata and Dohi (1982) examined the differences between urban residents and visitors ‘cognitive styles by evaluating environmental cognition and behavior in urban spaces. Usami et al. (2000) analyzed the relationship between the spatial preferences of visitors to towns and their behavior based on the irrecognition of the space. However, these studies mostly focused on cities.

In the 21st century, the importance of location in traditional craft production has become of value in Japan. Emphasizing the relationships between people and natural environment in rural areas, determining the changes in natural resource usage, and evaluating potters׳ perceptions of the areas they work in were critical for realizing the objectives of the present study.

1.2.3. Methods

In November and December 2012, we collected data using questionnaires that were distributed to 44 potters belonging to the Koishiwara-yaki pottery cooperative association and by conducting interview surveys. The questionnaire was developed to gather information on the histories of the households involved in the local pottery industry, as well as on their natural resource usage. A total of 41 potters participated in our study. The interview surveys were conducted to identify the views of the participants on the boundaries of the craft heritage area, as well as the spaces they regarded as important.

The steps followed during the interview survey process were as follows. First, we provided a topographical map of the area and indicated the location of the government office, two main national roads, and the participant׳s household. Second, we asked the participants to indicate the area they recognized as part of the pottery village and to draw the boundary lines of the area on the map. Third, we confirmed the boundary lines with the participants. Any errors that were noticed were corrected. In addition, were quested the participants to ensure that the border lines did not cross any mountain ridges. We finally requested the participants to indicate the areas they regarded as important. We used a geographic information system (GIS) to analyze and evaluate the features of the identified areas.

2. Study site and the transformation of crafts

2.1. Location of the village

The Koishiwara village is located in the northern part of the Kyushu Province in the south of Japan. The area is mountainous and far removed from urban areas. Today, the village is renowned for its traditional craft of Koishiwara-yaki. Geographically, the village is separated into two sides. The Koishiwara area formed by a basin occupies one side of the village while the Tuzumi valley area makes up the other side. A river runs through the center of the areas. The Koishiwara area is higher than the Tuzumi area by an elevation difference of approximately 250 m (Koishiwara Village, 2001 ).

Until the early 19th century, the village prospered as a key location and poststation for Syugen-do (a Japanese mountain ascetic practice) practitioners visiting Mount Hiko. Two national roads, Route 211 and Route 500, have recently been improved. The village has three outlets for selling pottery, and a public camping site was established during the 1990s. However, the demand for pottery has significantly decreased. Although the Koishiwara village administratively merged with a neighboring village in 2005, we focused on the Koishiwara village as per the borders of the former district.

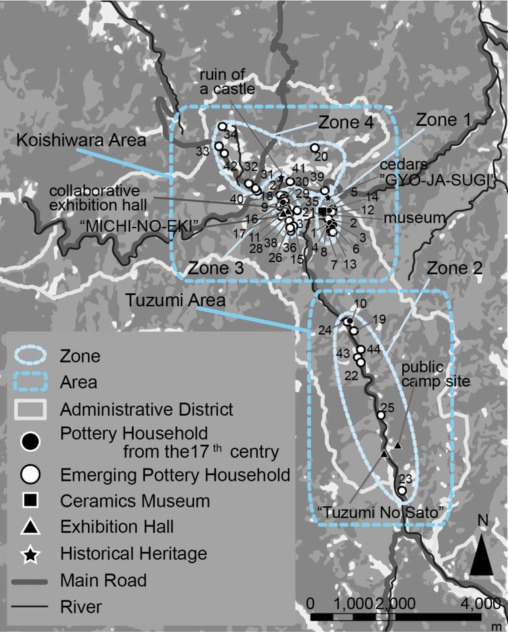

As indicated in Figure 1 , the pottery community is managed by the Koishiwara-yaki pottery cooperative community and is divided into four zones according to their regulations. In this study, we assigned identification numbers to the households and categorized those that formed part of the community according to their residential zone. The zones were numbered as follows: Zone 1 represented Sarayama, Zone 2 represented Tuzumi, Zone 3 represented the area commonly known as Kokudo-suji, and Zone 4 included Hiebata, Okubata, and Haru.

|

|

|

Figure 1. Locations of pottery households. |

2.2. Historical background of Koishiwara-yaki

2.2.1. Origin and features

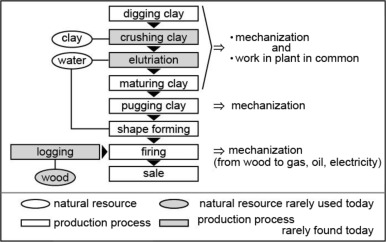

The Koishiwara-yaki ceramics tradition can be traced back to 1682 when the local lord of the region imported artisans from Imari, one of the most renowned porcelain manufacturing areas in Japan. During the 19th century, 10 households were involved in the local pottery industry. Nine of these households were in Sarayama (Zone 1), and the others were based in Tuzumi (Zone 2). The area was semi-agricultural, and its inhabitants worked together. However, the majority of the production was conducted in the households, and skills were transferred from a father to only one of his sons (Moeran, 1984 ). Figure 2 presents this traditional process.

|

|

|

Figure 2. Production using natural resources. |

2.2.2. Japanese folk craft movement and the growing number of kilns

After 1868, toward the end of the Edo period, the potters lost the support of the local lord, and by the end of the Second World War, the pottery industry had stagnated. However, agricultural and forest labor opportunities allowed potters to continue developing their craft as an additional job (Futagami, 1959 ).

The Japanese folk craft movement (Mingeiundo ) gained incredible momentum during the 1920s, causing an upsurge in interest in traditional crafts. The leader of the movement, Muneyoshi Yanagi, and others developed folk craft theory. Specifically, they evaluated the work of numerous artisans according to esthetic value, utility, promotion of traditional skills, and whether the work was based on nature. As a result of this movement, the Koishiwara-yaki ceramics tradition became well known as a prominent traditional folk craft originating from a rural area, and customers started visiting the village ( Yanagi, 1928 ; Yanagi, 1948 ; Nihon Mingei Kyodan, 1971 ).

During this prosperous period from the late 1950s until the 1990s, potters acquired permission to operate independently from master artisans, and consequently, several individual kilns were constructed (Hamada, 1998 ). Although one pottery household gained independence in 1915, our interview survey revealed the possibility of such household being recognized as not conforming to the Koishiwara-yaki style.

Currently, approximately 50 households in the village are involved in pottery production. The increase in the number of pottery households has resulted in the expansion of the production area. Table 1 indicates the years in which new kilns were introduced by these households.

| Zone | Number of kilns constructed | |||||||

|---|---|---|---|---|---|---|---|---|

| 1680s | 1910s | 1950s | 1960s | 1970s | 1980s | 1990s | Total | |

| Zone 1 | 9 | 1 | 2 | 1 | 13 | |||

| Zone 2 | 1 | 1 | 4 | 2 | 8 | |||

| Zone 3 | 1 | 4 | 5 | 4 | 14 | |||

| Zone 4 | 1 | 4 | 4 | 9 | ||||

Two factors are of great importance. First, new kilns were introduced beginning in 1960 in areas that were not traditionally used for pottery production (Zones 3 and 4). Second, most of the new kilns were established along the two national roads. These production sites are regarded as the reason for road improvements that led to the increased number of customers who supported the traditional crafts movement and visited the village by car. Thus, the local pottery production area developed along the main roads.

3. Natural resource use

As Japan modernized, most potters changed the natural resources they used in their work. We studied these changes through a questionnaire. The results are displayed in Table 1 ; Table 2 .

3.1. Clay use

Clay is the most essential raw material used for pottery. In pre-modern times, potters dug for clay in the local mountains and national land areas according to local sustainable usage laws. One potter׳s (ID4) father indicated that an organized group of potters demanded the common use of a nationally owned mountain from the government. Since the establishment of the pottery cooperative association, it has managed the clay refinement processes at the local clay factory, and the potters have been allowed to buy clay from the cooperative (Nakadate and Tomono, 1971 ). Additionally, clay has been imported since the 1940s. Currently, 27 of the 41 potters who participated in the study use a mix of local and imported clay, and all potters are still using local clay, which is never sold to outsiders.

3.2. Water use

Water is used to crush clay and mold it in to shapes. A total of 11 of the traditional potters formerly used water-powered machines known as karausu to crush clay, and most of these artisans worked along the river near Sarayama (Zone 1). The rest did not own akarausu because of either insufficient space or the intense labor involved in carrying clay. However, most of these machines have now been replaced by electrical machines, and only one potter (ID10) still own sakarausu and uses it in the traditional way. Before the clay factory was set up by the pottery cooperative association, potters who did not own akarausu had to buy processed clay from other potters ( Nakadate and Tomono, 1971 ).

Clay is shaped using various water sources, such as well water, mountain water, river water, or tap water. Our questionnaire revealed that the use of river water as a power source to crush clay has almost disappeared. However, 24 of 38 potters continue to use natural water to shape clay.

3.3. Wood use

Wood is used to fuel kilns, and ash from woodstoves is used in glazes. The potters used to rely on shrubs from the local mountain or the surrounding national forests for wood. However, since 1940, externally supplied reject wood or left over wood has become available at low prices. Today, all potters use externally sourced wood. Only three of the participants used wood from the local mountain.

Until the 1960s, all potters in the area used wood-fired kilns. Today, gas-fired kilns have become the primary firing method, with only 13 potters still using wood. Nevertheless, independent potters still use wood-fired kilns. They have built small kilns to continue their line of wood-fired products.

4. Areas recognized as the pottery village

We digitalized the pottery production areas identified by the artisans using GI Sand analyzed the forms. We subsequently created a 100 m mesh across all these areas and determined the over lapping areas. A total of 36 potters participated, and 35 questionnaires were completed. One participant was unable to identify the area available to him. The ages of the participants ranged from 33 to 77 years. The average age is 54.7. The participants׳ number of years of residence in the area ranged from 26 to 77 years, and the average is 47.2 years. All the participants were male.

4.1. Types of areas identified

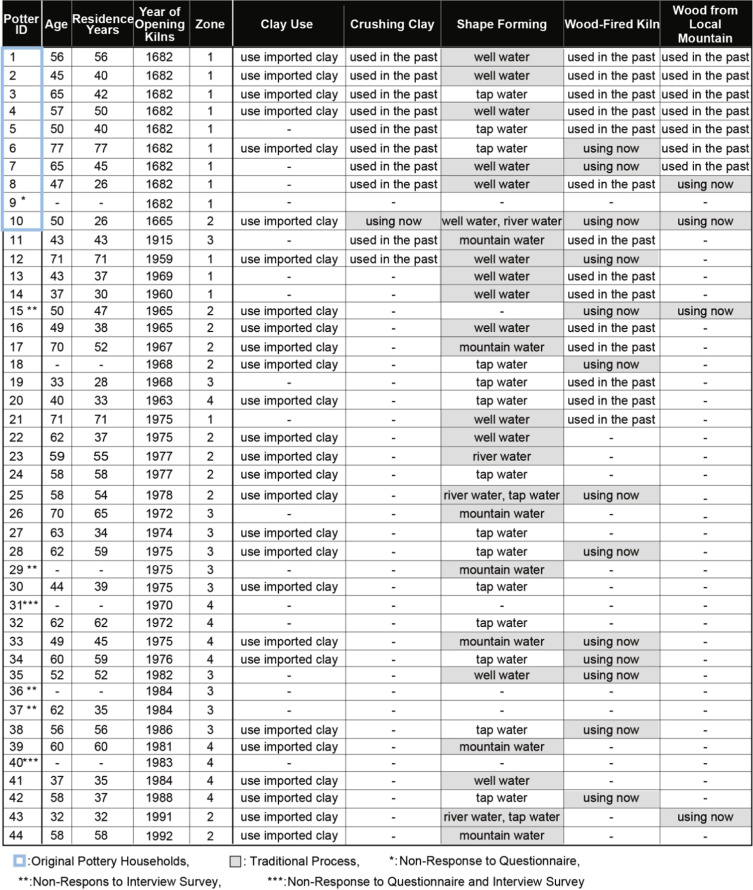

As indicated in Figure 3 , the identified areas could be classified into five types on the basis of variation in spatial coverage.

- Type 1 exclusively comprised Zone 1, which is regarded as the birthplace of the Koishiwara-yaki style of ceramics. Only three potters residing in Zone 1 recognized the importance of this area in the Koishiwara village and regarded it as crucial to their tradition.

- Type 2 included the Koishiwara area. Six potters from outside Zone 2 recognized the importance of this area. Potters residing in Zones 3 and 4 identified this type as distinct. The results seemed to indicate that the area between Koishiwara and Tuzumi, as well as the strong views about the boundaries of the area, influenced the perspective of the potters.

- Type 3 included both the Koishiwara and Tuzumi areas. One particularly narrow area in Zone 2 was recognized as important, indicating that great importance was attached to the areas along the road that were occupied by households in the pottery industry. Type 3 in turn could be subdivided into two types. Type 3-1 partially covered Zone 2, thus demonstrating that not all potters recognized the importance of these areas. Five potters from each zone supported this type. By contrast, Type 3-2 was recognized by all the participating households and covered the entire area up to the southern end of the village. Eight potters from each zone recognized this type.

- Type 4 included the Koishiwara area, the Tuzumi area, as well as the surrounding mountains. A total of 12 potters from each zone recognized this type, and it was recognized by the largest number of potters. Most of the recognized areas bordered the mountain ridge.

- Type 5 included only one potter׳s worksite, and only one potter (ID10) recognized this type. He still uses natural resources in the traditional way, and most traditional pottery processes are still performed at his site. This result suggested that the area recognized at his site was limited.

|

|

|

Figure 3. Types of areas recognized and number of potters by residential zones. |

All potters, except the one (ID10) who recognized Type 5, recognized additional areas other than their own site and Zone 1.The sizes of the recognized areas varied among potters, and 20 out of 35 potters recognized an area that included all the households involved in the pottery industry. The average age of the potters that recognized Type 4 was the lowest. This result suggested that younger potters tended to recognize a wider area as compared withholder potters.

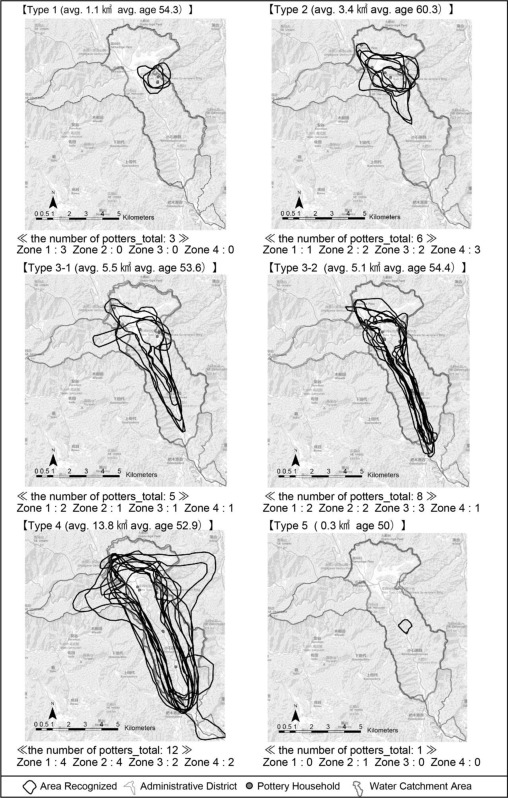

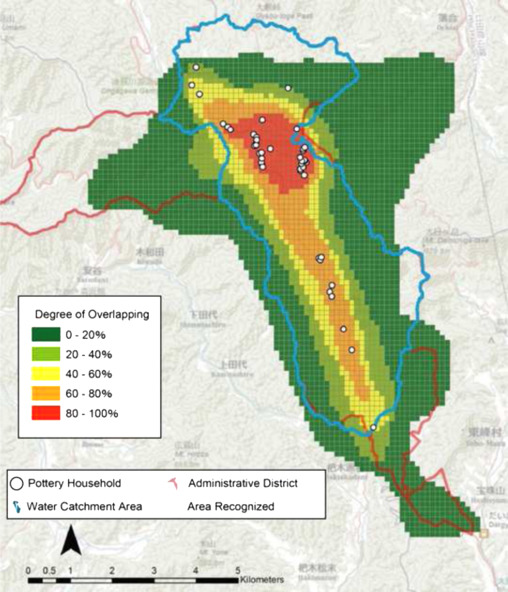

4.2. Overlap of the recognized areas

We identified all overlapping areas with a 100 m mesh. Figure 4 indicates the degree of overlap. Zones 1 and 3 were recognized by over 80% of the participants and formed an area where numerous potters live in close proximity. This area was thus identified as the center of the pottery village. The areas surrounding Zone 1 and those along Route 211 in Zone 2 were recognized by over 60% of the participants. However, the recognized area in Zone 2 was extremely narrow, most likely because the Tuzumi area is a valley. This area may thus be considered an extension of the village, the borders of which vary according to individual perspectives.

|

|

|

Figure 4. Overlay of area recognized as the pottery village. |

4.3. Relationship with the administrative district and water catchment area

Using GIS, we identified the water catchment area that included all the pottery areas in the village of Koishiwara and compared it with the areas recognized as forming a part of the traditional village and the administrative district.

As indicated in Figure 4 , the area recognized by over 60% of the potters also formed a part of the administrative district. However, the western part of the district was not recognized as part of the pottery village because few households involved in the pottery industry resided there. The water catchment area was smaller than the administrative district and included most of the area recognized by over 60% of the participants. Therefore, the water catchment area more closely matched this area than the district boundaries did.

As indicated in Table 3 , only four of the individually recognized areas were part of the administrative district, and only one fell within the water catchment area. The area recognized as part of the pottery village extended over the mountain ridge in a few places. This result suggested that the extensions of the pottery village were included in the water catchment area but that a number of the individually recognized areas were parts of neither the administrative district nor the water catchment area.

| Type | Number of potters | |||

|---|---|---|---|---|

| Administrative district | Water catchment area | |||

| Included | Run off the edge | Included | Run off the edge | |

| Type 1 | 0 | 3 | 0 | 3 |

| Type 2 | 2 | 4 | 0 | 6 |

| Type 3-1 | 0 | 5 | 0 | 0 |

| Type 3-2 | 1 | 7 | 0 | 8 |

| Type 4 | 0 | 12 | 0 | 12 |

| Type 5 | 1 | 0 | 1 | 0 |

5. Places of importance to potters

We asked the participants to indicate the areas they regarded as important to the pottery village and to provide their reasons for their choices. The participants identified 31 areas and provided 112 reasons. Table 4 indicates the places of importance, their features, and the reasons provided.

| Number of potters | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Important place | Zone | Type of area recognized | Total | ||||||||

| 1 | 2 | 3 | 4 | 1 | 2 | 3-1 | 3-2 | 4 | 5 | ||

| Facilities (Total:26) | |||||||||||

| Koishiwarayaki Ceramics Museum | 4 | 1 | 4 | 3 | 1 | 2 | 2 | 4 | 3 | 0 | 12 |

| Roadside station “Michi-no-eki“ | 2 | 2 | 2 | 2 | 1 | 1 | 0 | 5 | 1 | 0 | 8 |

| Collaborative exhibition hall | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 1 |

| Koishiwara Industry Center “Tuzumi-no-sato“ | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 2 |

| Public camp site | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 |

| Route 211 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 2 |

| Historical sites (Total:17) | |||||||||||

| Stone monument for praying for safety in digging clay | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 |

| Tounose area | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 |

| Ruins of old kilns | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 2 |

| Ruin of a castle | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 1 |

| Cedars planted by practitioners of Shugen-do | 4 | 2 | 0 | 2 | 2 | 1 | 2 | 0 | 3 | 0 | 8 |

| Mount Hiko | 2 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 1 | 3 |

| Kogei-kan | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 |

| Raw materials (Total:13) | |||||||||||

| Rice paddy | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 1 |

| Place with high-quality clay | 2 | 1 | 2 | 4 | 0 | 2 | 1 | 1 | 5 | 0 | 9 |

| Akatani, the place with feldspar | 2 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 3 |

| Nature (Total:10) | |||||||||||

| Ohi River | 0 | 2 | 2 | 0 | 0 | 0 | 2 | 0 | 1 | 1 | 4 |

| Hanazono Fall | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 2 |

| Maple trees in Tuzumi (Zone 2) | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 1 |

| Habitat of fire flies and giant salamanders | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 |

| Surrounding environment | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 |

| View point of Mount Hiko | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 |

| Pottery households (Total:44) | |||||||||||

| All pottery households | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 2 | 0 | 3 |

| Individual (ID10) | 1 | 4 | 1 | 0 | 0 | 0 | 2 | 0 | 4 | 0 | 6 |

| Individual (ID11) | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 |

| In Sarayama (Zone 1) | 10 | 5 | 8 | 6 | 1 | 5 | 4 | 8 | 11 | 0 | 29 |

| In Tuzumi (Zone 2) | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 |

| Along Route 211 (Zone 3) | 0 | 0 | 3 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 3 |

| In Sarayama and along Route 211 (Zones 1 and 3) | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 |

| Sample number | 12 | 8 | 9 | 7 | 3 | 6 | 5 | 8 | 12 | 1 | 35 |

5.1. Features of the places of importance

The 31 places identified were classified into five groups, namely, facilities, historical sites, raw materials, nature, and households involved in the pottery industry.

The participants indicated that the identified facilities could attract customers to the area and increase sales. All four cooperative marketing places in the village were identified as important. Potters from all zones regarded the Koishiwarayaki Ceramics Museum and the roadside station known as Michi-no-eki as places of importance, with numerous potters specifically identifying them.

Seven sites of historical interest were identified, and the participants indicated that these sites could attract visitors. Three of these places were directly relevant to pottery while three others were linked to Shugen-do. One of these places, Mount Hiko, was far from the village and was not included in any of the areas recognized in this study. Most potters residing in Zone 1 demonstrated interest in these sites. Three types of raw materials were indicated as important to the area, and they were all regarded as highly relevant to the pottery industry. Potters from all the zones regarded high-quality clay as important. Only one potter indicated that the rice paddy where he found the raw material for his glazes was of great importance. The third raw material was mineral feldspar. Potters have traditionally used feldspar in Akatani, the neighboring village of Koishiwara. However, it did not form part of the recognized are as identified in this study.

Six natural resources were identified as important features of the rural area: river, waterfall, trees, animals, and the view. Additionally, the entire natural environment was identified as important. However, very few participants indicated that the natural environment was of great importance.

Seven different households involved in the pottery industry were also identified as important, with individual households regarded by many of the participants as more important than any other feature. Two individual households (ID10 and 11) were noted in particular, and six potters felt particularly strongly about the importance of one household (ID10). This particular home stead dates back to the origin of Zone 2, and the pottery produced in that household remains traditional, as indicated in Table 2 . Four of the six potters who identified it as important reside in Zone 2. A total of 30 of 35 potters identified the households in Zone 1 as important. Zone 1 is the place where the Koishiwara-yaki style originated, and several participants from all zones acknowledged this fact. This result confirmed that Zone 1 is regarded as the center of the pottery village.

5.2. Relationship with the recognized areas

In terms of the recognized area, the Koishiwara Ceramics Museum and the households in Zone 1 were indicated as belonging to all types except Type 5. A significant number of participants indicated that these places were important. The museum is an important tourism base. The households in Zone 1 are also important because they are seen as the birthplace of the local pottery tradition. Zone 1 in particular was indicated as a crucial element of the pottery village. None of the participants indicated that Zone 4 was important. This result may be explained by the fact that the households in this zone are relatively new to the area and are dispersed over a wide area.

None of the Type 1 potters indicated that raw materials or the natural environment were of great importance. Additionally, none of the Type 1 and 2 potters indicated that the natural environment was of great importance or that only pottery was of great importance to the village. On the basis of the particularities of the Type 5 potters, the results demonstrated that if the potters showed an interest in the natural environment, they were likely to recognize a large surface area for the pottery village.

6. Conclusions

After the 1960s, the demand for Koishiwara-yaki- style ceramics rapidly increased, there by unraveling the traditional cooperative and increasing the number of households involved in the pottery industry. During the same period, the modernization of ceramic technologies enabled potters to produce work that did not require local natural resources. Nevertheless, all the artisans in Koishiwara continue to use local clay, and the potters in Sarayama, the birth place of the local ceramics traditions, still use this clay.

The areas recognized by the participants varied individually, but these areas could be classified into five groups according to surface area. The study results revealed one common area recognized by all the participants. This area is centrally located and is known as Sarayama. In this area, pottery is still produced according to traditional methods, and it is home to a ceramics museum for tourists. Therefore, this area should be considered as the primary locus of the Koishiwara-yaki tradition, and all conservation and development efforts toward the pottery village should revolve around this space.

This commonly recognized area falls within the local water catchment area, and most of the individually recognized are as extend beyond the mountain ridge. Identifying areas of importance to the people who preserve this national heritage can serve as a vital contribution to efficient spatial planning, as well as to the conservation and development of pottery traditions.

The main difference in the participants׳ identification of areas of importance to their tradition depended upon whether they were aware of the existence of the natural environment. The use of natural resources in the Koishiwara-yaki style has decreased over time; hence, few people recognize its importance. However, some people have started to notice the crucial relationship between traditional crafts and natural environment in Japan. Planners should take certain steps and consider the influence of the natural environment on the quality of artisans׳ work.

Several participants placed greater value on their location than on the administrative district because of its historical connections. These connections may serve as a basis for the development of a thriving tourist site steeped in culture and history.

Acknowledgments

The authors appreciate the cooperation of the potters of the Koishiwara-yaki pottery cooperative society. The authors also thank the Ministry of Education, Culture, Sports, Science and Technology , MEXT for supporting the research through the Strategic Support for Research Project by Private Universities (Project no. S1203007 ).

References

- Futagami, 1959 Futagami,H., 1959. A Geographical study of the traditional industries in Japan, (1st Report) the structure of production of the Koishiwara pottery industry in Kyushu. In: Proceedings of the Fukuoka Gakugei University, 9 (2), 57–66.

- Hamada, 1998 T Hamada; Santi No Henyou To Dentou No Jikaku; Jpn. J. Hum. Geogr., 55 (6) (1998), pp. 606–621

- Koishiwara Village, 2001 Koishiwara Village, 2001. KoishiwaraSonshi. Koishiwra Village, Fukuoka.

- Lynch, 1960 K. Lynch; The Image of the City; The MIT Press, Massachusetts (1960)

- Moeran, 1984 B. Moeran; LostInnocence: Folk Craft Potters of Onta, Japan; University of California Press, California (1984)

- Nakadate and Tomono, 1971 K. Nakadate, H. Tomono; Sangyo Kouzou No Henkaku To Zairai Sangyo No Henyo–Koishiwara Minyo-gyo Wo Tyushin To Shite; Sangyo Roudo Kenkyu Shoho, 55 (1971), pp. 91–107

- Nakata and Dohi, 1982 H. Nakata, H Dohi; Comparison between urban resident׳s and visitor׳s cognitive style; Trans. Archit. Inst. Jpn., 320 (1982), pp. 116–125

- Nihon Mingei Kyodan, 1971 Nihon Mingei Kyodan, 1971. Koishiwara-yaki No Keizai Kozou Jittai Tyousa. Nihon Kogei Kan, Osaka.

- Risatti, 2007 H. Risatti; A Theory of Craft; The University of North Carolina Press, Carolina (2007)

- Suyama, 1993 S Suyama; Regional expansion of the Shikki production area in Wajima City. Ishikawa Prefecture; Geogr. Rev. Jpn. Ser. A, 66 (A-10) (1993), pp. 597–618

- Tsujimoto et al., 1989 Tsujimoto,S. Kitamura, Y. and Ueno,K.,1989. Industrial Structure of the Textile Industrial Region in the West Kanto District. Taimeido, Tokyo.

- Usami et al., 2000 T. Usami, et al.; The structure of town attachment from the aspect of town visitors׳ behavior sphere and preference sphere; J. Jpn. Inst. Landsc. Archit., 63 (5) (2000), pp. 809–814

- Yanagi, 1928 Yanagi, M., 1928. KogeiNoMichi. Guroriasosaete, Kobe.

- Yanagi, 1948 Yanagi, M.,1948. TeshigotoNoNihon. Seibunsha, Tokyo.

Document information

Published on 12/05/17

Submitted on 12/05/17

Licence: Other

Share this document

claim authorship

Are you one of the authors of this document?