1 Introduction

The aerospace industry has been resorting to autoclave as the de-facto manufacturing process for composite material based components. Despite its proven reliability, as its possible to manufacture parts with high fibre volume fractions, low void content and considerable repeatability, autoclaves inherently have a high-energy use, which renders the manufactured parts expensive and has an associated environmental impact [1].

Liquid Composite Moulding is a family of Out-of-Autoclave (OoA) processes, which is characterised by the injection of liquid resin into a dry fibrous preform, inside a mould [2]. Resin Transfer Moulding (RTM) is an LCM process, which makes use of a two-sided rigid mould. Using this process, it is possible to compact the fibrous preform to the desired fibre volume fraction, and further inject the catalysed resin at high pressures, if needed. This allows for faster cycle times than the ones obtained traditionally by autoclave, simultaneously being more energy efficient. Despite the advantages cited, achieving process repeatability is still a challenging task in RTM, as the formation of dry zones during resin injection is a common scenario during the iterative phases of the process design.

In RTM, various parameters influence the resin flow behaviour: material parameters such as preform permeability and resin viscosity, as well as process related parameters, such as injection pressure or flow rate, part geometry and the inlet and venting scheme.

The process design needs to take into account all the different parameters, in order to guarantee full impregnation of the fibrous reinforcement. However, disturbances can occur naturally in the process parameters, which may alter the resin flow behaviour, creating dry zones, thus rendering the part defective.

The resin flow behaviour in RTM can be described by Darcy’s law, where the resin superficial velocity u is expressed as a function of the fibrous reinforcement permeability tensor K, the resin viscosity µ and the pressure gradient ∇P.

|

|

(1) |

As one may expect, of the most significant parameters for process modelling is permeability, which reflects the resistance that the fibrous preform exerts to the progression of the resin flow.

The experimental characterization of the permeability of engineering fabrics has been an effort of the worldwide scientific community, which conducted a series of benchmarks between institutions [3,4]. In these exercises it was found that permeability scatter is significant, hence, as stated by Hoes et al. [5], permeability is a material property that should not be characterized by a single value.

Despite the permeability of a fabric can be described by a tensor with averaged components, in a realistic scenario engineering fabrics have inherent distortions due to different reasons such as manufacturing variability, shearing effects and tow waviness [6–9]. These local variations in permeability have an effect on the flow behaviour, which may cause formation of dry zones in the component.

In an effort to achieve a robust process design, local permeability fluctuations should be taken into account in the process modelling approaches. Some studies tried to address this local variability problem by subdividing the domain into unit-cells and assigning uncorrelated random permeability values, following a characteristic probability function [8]. However, this strategy has a sparse physical foundation, which may lead to wrong conclusions [9]. More recent studies try to establish a spatial correlation between local permeability heterogeneities, by determining the correlation length, characteristic probability density functions and first order moments [10,11]. With this data, it is possible to improve stochastic flow simulations, by constructing a random permeability field that reflects the heterogeneity of the textile preform [12].

Besides the preform permeability, the resin flow can be influenced by race-tracking, which is a type of defect that occurs when there is a gap between the preform and the mould walls. This creates a channel with higher permeability than the preform, which modifies flow behaviour, as the resin travels through the gap, instead of permeating the preform. Ultimately, this phenomenon may lead to the formation of dry zones in the composite part. In an effort to understand this type of phenomena, studies aimed to characterize race-tracking experimentally [13,14]. In order to model race-tracking in resin flow simulations, Gokce and Advani [15–17] and Li et al. [14] used the Weibull distribution to represent this parameter.

From the available literature, one can conclude that the process parameters, such as material properties, suffer from a great amount of variability. This reality creates difficulties while modelling the process for numerical simulations, as the use of deterministic variables may lead to wrong conclusions, creating overheads in the process design project. Therefore, a sensitivity analysis framework seems to be appropriate in aiding the design stages, as by taking a statistical approach while modelling the inputs, it is possible to explore the entire space of uncertainty. Hence, using such a framework it is possible to instruct the modeller to the relative importance of the uncertain inputs, in determining the quantity of interest, may it be filling time or unfilled part percentage, for the scope of RTM processing.

2 Methodology

2.1 Variance-based sensitivity analysis

In this study, a variance-based sensitivity analysis was conducted, based on the methodology proposed by Saltelli et al. [18].

Taking the ANOVA-HDMR decomposition proposed by Sobol [19]:

|

|

(2) |

By dividing the equation by , one can get:

|

|

(3) |

Therefore, the first order sensitivity indices can be calculated as:

|

|

(4) |

A difficulty arises in determining the n order indices, as the number of terms increases exponentially with the number of input factors, as . Saltelli et al. [18] proposed a more efficient way of determining the total index, by using the total effects. Substituting by , one can effectively condition the expected variance with respect to all factors but one ( ). The calculation of the indices is therefore:

|

|

(5) |

The computational strategy to calculate the conditional variances is as described by Saltelli et al. [18]:

- 1. Generate a (N, 2k) matrix of random numbers, where k is the number of inputs and N is the sample size;

- 2. Define two matrices, each containing half of the sample;

- 3. Define a C matrix, which will be formed by all columns of A, except for the column, which is taken from B;

- 4. Compute the model output for all the input values in the sample matrices A, B and , obtaining three vectors of model outputs of dimension N:

As proposed by Prieur and Tarantola [20], the first order and total order sensitivity indices can be estimated as follows:

|

|

(6) |

|

|

(7) |

Where:

|

|

(8) |

And:

|

|

(9) |

2.2 Random field generation

As the “bulk” permeability values can be represented by a single value, in order to represent the permeability variations throughout the simulation domain in a correlated fashion, a random field generation approach proposed by Dolloff and Doucette [21] was used. Their Fast Sequential Method uses an extension of the sequential generation of a first-order Gauss-Markov process, from a 1D function of time, to a 2D function of horizontal space. This algorithm is orders of magnitude faster than Galerkin-based methods, which is of extreme interest, since the entire simulation framework is based on a Monte-Carlo approach.

As explained in the original paper, the method uses an exponential correlation model for both spatial directions, in an evenly spaced grid. In the third dimension, for each point of the grid domain, one gets a normally distributed (Gaussian) standardized random variable, . The spatial correlation function will be dependent on the values of the grid component-wise differences in both x,y directions of two arbitrary grid points. This correlation function can be written as:

|

|

(10) |

Where are the absolute values of the component-wise differences in the location of two arbitrary points; represent the grid spacing in the directions and represent the spatial correlation distance constants.

The core field generation equation may be written as:

|

|

(11) |

Where:

- correspond to the indexes of each node belonging to the grid;

- (12)

- (13)

- is a random sample of Gaussian white noise

- (14)

- is the desired standard deviation;

3 Numerical simulations

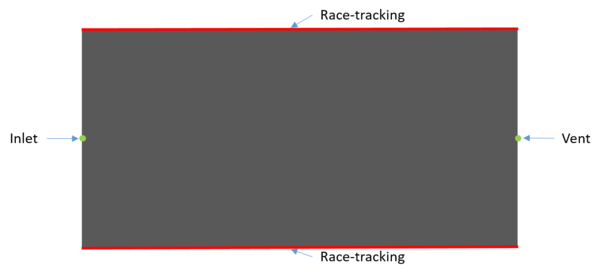

In order to build the initial data matrices that feed the Monte-Carlo framework, preform permeability and race-tracking were considered the process variables, meaning the other process relevant inputs shall be fixed to a constant value.

A random field with a stationary mean was created for each realization, by which the in-plane components of the permeability tensor were assigned. Therefore, the stationary mean value corresponds to the average bulk permeability of the fabric (in a given component) and the local perturbations to a specified correlation distance and standard deviation. There is experimental data available in the literature, capable of feeding the models, therefore the “bulk” permeability values were assigned according to the worldwide permeability benchmark II [4]. For the local permeability perturbations, correlation lengths and standard deviations were taken from the work of Bodaghi et al. [10], whom used the same fabric which was object of study in permeability benchmark II and concluded that the correlation length for the fabric under study was of circa 20mm.

For modelling race-tracking, the statistical model proposed by Gokce and Advani [15–17] was used, where the coefficient between race-tracking equivalent permeability and the preform permeability obeys to a Weibull probability distribution.

Both resin viscosity and injection pressure were modelled using a uniform distribution, since this approach allows to establish lower and upper bounds relevant to the process design. Following this idea, the viscosity range was chosen between 0.1 and 0.6 Pa.s, corresponding to the viscosity window of mid to low viscosity epoxies. The injection pressure was chosen to be between 1 and 10 bar, corresponding to the range pressures utilized in light-RTM. Usually, the use of high injection pressures creates other phenomena, such as fibre-washout, that will not be included in this model.

A summary of the values in use can be seen in Table 1.

| Bulk Permeability

(m2) |

Local permeability fluctuations

(m2) |

Race-tracking | Injection pressure (bar) | Resin viscosity

(Pa.s) | |

| Type of distribution | Normal | Normal | Weibull | Uniform | Uniform |

| Mean (x,y) | 8.07e-11; 1.311e-10 | 8.07e-11; 1.311e-10 | |||

| Standard deviation | 1.77e-11; 0.280e-11 | 1.01e-11; 1.390e-11 | |||

| Shape parameter ( ) | 0.5 | ||||

| Location parameter ( ) | 15 | ||||

| Bounds (lower; upper) | 1; 10 | 0.1; 0.6 |

In this study, a rectangle of dimensions 400x200mm served as the basis for the geometrical model of the preform. Shell elements were assigned with a thickness of 2mm, so that the effect of the out-of-plane permeability may be neglected.

The numerical mould filling simulations were conducted using LIMS software, developed at Delaware University [22], while the code necessary to conduct the sensitivity analysis and build the random fields was built in-house using the Python language.

4 Results

First order and total effects sensitivity indices were computed for set of different injection scenarios, where the variables of interest (variables which variance was analysed) were mould filling time and dry spot percentage. Mould filling time was measured by searching for the element in the FEM mesh which control volume was the last one to fill. This can be done by analysing LIMS dump file, where the filling time for each control volume is registered. Dry spot percentage was computed by multiplying the fill factor of each control volume by its respective area. Again, this task can be automatized, since LIMS registers the fill factor of each control volume in the simulation dump file.

Taking the first injection strategy, it can be observed that the process parameter that has the most influence on mould filling time is the injection pressure, followed by the resin viscosity. Indeed the preform permeability and race-tracking seem to have a residual influence. On the other hand, when measuring the first and total effects sensitivity indices for dry spot percentage, it is possible to conclude that race-tracking and permeability have the most influence, respectively.

| Filling time | Dry spot percentage | |

| Permeability | 0.005 | 0.207 |

| Race-tracking | 0.035 | 0.552 |

| Resin viscosity | 0.279 | 0.068 |

| Injection pressure | 0.574 | 0.023 |

| Filling time | Dry spot percentage | |

| Permeability | 0.019 | 0.301 |

| Race-tracking | 0.076 | 0.977 |

| Resin viscosity | 0.388 | 0.221 |

| Injection pressure | 0.734 | 0.208 |

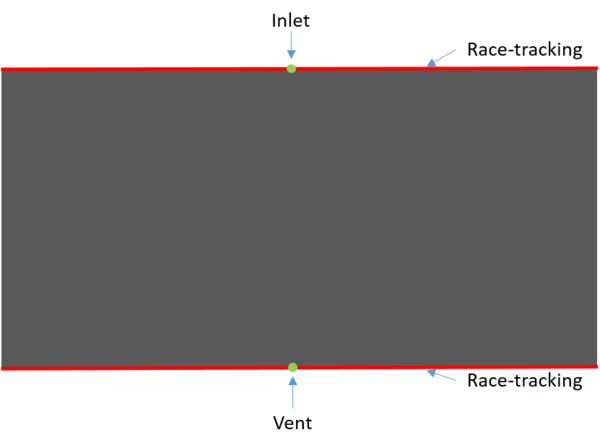

From the second injection strategy, one may observe that the influence of all design variables, related to dry spot percentage have decreased to a null value. Indeed, due to the injection strategy used in this design iteration, the effect of race-tracking and permeability on dry spot percentage was eliminated. In terms of filling time, it can be seen that pressure and race-tracking are the most influential parameters, followed by resin viscosity.

| Filling time | Dry spot percentage | |

| Permeability | -4e-5 | ≈0 |

| Race-tracking | 0.387 | ≈0 |

| Resin viscosity | 0.137 | ≈0 |

| Injection pressure | 0.362 | ≈0 |

| Filling time | Dry spot percentage | |

| Permeability | 0.002 | ≈0 |

| Race-tracking | 0.639 | ≈0 |

| Resin viscosity | 0.290 | ≈0 |

| Injection pressure | 0.625 | ≈0 |

5 Conclusions

This framework allows one to compute the sensitivity indices for each variable of interest, therefore allowing a deeper understating of how each design variable will influence the final result, may it be filling time, dry spot formation, etc.. Injection pressure and resin viscosity were identified as the most influential parameters in terms of mould filling time, whereas race-tracking was identified as the most influential parameter in terms of dry spot formation. Nevertheless, it is essential to view each process design as an individual case of study, as generalizations about the process variables influence, may lead to wrong conclusions.

In this study, it was demonstrated that an optimized position of the inlet gates and vents, minimizes the influence of variables such as race-tracking. Such approach foments an increase in the process reliability, as the system is less sensitive to undesired flow behaviours created by a defective positioning of the fabric layers. A strategy towards robust process design is therefore presented.

Nevertheless, in the literature it was found that permeability may play a more important role than the one attributed in this model, even for rectangular geometries. Since this model does not consider out-of-plane permeability (as the geometry is a rectangular shell with 2mm thickness), an important component may have been omitted, especially in the case of thicker lay-ups. Thus, a three-dimensional model may have to be considered in order to reflect the resin flow mechanics with more accuracy. Furthermore, the permeability fluctuations considered in the model, do not reflect the case of more aggravated cases of fibre distortions, such as draping effects or fibre washout, where it is possible to have highly discrepant permeabilities.

6 References

[1] R. A. Witik, F. Gaille, R. Teuscher, H. Ringwald, V. Michaud, and I. Works, “Assessing the economic and environmental potential of out of autoclave processing,” 18th Int. Conf. Compos. Mater., pp. 1–6, (2011).

[2] C. D. Rudd, A. C. Long, K. N. Kendall, and C. G. E. Mangin, Liquid Moulding Technologies, 1st ed. Woodhead Publishing Ltd, (1997).

[3] R. Arbter et al., “Experimental determination of the permeability of textiles: A benchmark exercise,” Compos. Part A Appl. Sci. Manuf., vol. 42, no. 9, pp. 1157–1168, (2011).

[4] N. Vernet et al., “Experimental determination of the permeability of engineering textiles: Benchmark II,” Compos. Part A Appl. Sci. Manuf., vol. 61, pp. 172–184, (2014).

[5] K. Hoes et al., “New set-up for measurement of permeability properties of fibrous reinforcements for RTM,” Compos. - Part A Appl. Sci. Manuf., vol. 33, no. 7, pp. 959–969, (2002).

[6] C. C. Wong and A. C. Long, “Modelling variation of textile fabric permeability at mesoscopic scale,” Plast. Rubber Compos., vol. 35, no. 3, pp. 101–111, (2006).

[7] M. Louis and U. Huber, “Investigation of shearing effects on the permeability of woven fabrics and implementation into LCM simulation,” vol. 63, pp. 2081–2088, (2003).

[8] A. Endruweit, A. C. Long, F. Robitaille, and C. D. Rudd, “Influence of stochastic fibre angle variations on the permeability of bi-directional textile fabrics,” Compos. Part A Appl. Sci. Manuf., vol. 37, no. 1, pp. 122–132, (2006).

[9] M. Bodaghi, S. V Lomov, P. Simacek, N. C. Correia, and S. G. Advani, “On the variability of permeability induced by reinforcement distortions and dual scale fl ow in liquid composite moulding : A review,” Compos. Part A, vol. 120, no. October 2018, pp. 188–210, (2019).

[10] M. Bodaghi, A. Vanaerschot, S. V Lomov, and N. C. Correia, “Composites : Part A On the variability of mesoscale permeability of a 2 / 2 twill carbon fabric induced by variability of the internal geometry l,” Compos. Part A, vol. 101, no. 101, pp. 394–407, (2017).

[11] M. Yun, T. Carella, P. Simacek, and S. Advani, “Stochastic modeling of through the thickness permeability variation in a fabric and its effect on void formation during Vacuum Assisted Resin Transfer Molding,” Compos. Sci. Technol., vol. 149, pp. 100–107, (2017).

[12] M. Yun, P. Simacek, C. Binetruy, and S. Advani, “Random field generation of stochastically varying through the thickness permeability of a plain woven fabric,” Compos. Sci. Technol., vol. 159, pp. 199–207, (2018).

[13] S. Bickerton and S. G. Advani, “Characterization and modeling of race-tracking in liquid composite molding processes,” Compos. Sci. Technol., vol. 59, pp. 2215–2229, (1999).

[14] J. Li, C. Zhang, R. Liang, and B. Wang, “Statistical characterization and robust design of RTM processes,” Compos. Part A Appl. Sci. Manuf., vol. 36, no. 5, pp. 564–580, (2005).

[15] A. Gokce and S. G. Advani, “Vent Location Optimization Using Map-Based Exhaustive Search in Liquid Composite Molding Processes Map-Based Exhaustive Search in Liquid Composite,” Mater. Manuf. Process., vol. 19, no. 3, (2004).

[16] A. Gokce and S. Advani, “Combinatorial Search to Optimize Vent Locations in the Presence of Disturbances in Liquid Composite Molding Processes Combinatorial Search to Optimize Vent Locations,” Mater. Manuf. Process., vol. 18, (2003).

[17] A. Gokce and S. G. Advani, “Simultaneous gate and vent location optimization in liquid composite molding processes,” Compos. Part A, vol. 35, pp. 1419–1432, (2004).

[18] A. Saltelli et al., Global Sensitivity Analysis: The Primer. (2008).

[19] I. M. Sobol, “Global sensitivity indices for nonlinear mathematical models and their Monte Carlo estimates,” Math. Comput. Simul., vol. 55, pp. 271–280, (2001).

[20] C. Prieur and S. Tarantola, “Variance-Based Sensitivity Analysis : Theory and Estimation Algorithms,” in Handbook of Uncertainty Quantification, (2015), pp. 1–23.

[21] J. Dolloff and P. Doucette, “The Sequential Generation of Gaussian Random Fields for Applications in the Geospatial Sciences,” ISPRS Int. J. Geo-Information, vol. 3, pp. 817–852, (2014).

[22] M. V. Bruschke and S. G. Advani, “A finite element/control volume approach to mold filling in anisotropic porous media,” Polym. Compos., vol. 11, no. 6, pp. 398–405, (1990).

Document information

Published on 23/06/22

Accepted on 23/06/22

Submitted on 23/06/22

Volume 04 - Comunicaciones Matcomp19 (2020), Issue Núm. 2 - Procesos de Fabricación y Técnicas de Unión, 2022

DOI: 10.23967/r.matcomp.2022.06.038

Licence: Other

Share this document

claim authorship

Are you one of the authors of this document?