Abstract

Industrial transformation and green production (ITGP) is a new 10-year international research initiative proposed by the Chinese National Committee for Future Earth. It is also an important theme for adapting and responding to global environmental change. Aiming at a thorough examination of the implementation of ITGP in China, this paper presents its objectives, its three major areas, and their progress so far. It also identifies the key elements of its management and proposes new perspectives on managing green transformation. For instance, we introduce a case study on cement industry that shows the positive policy effects of reducing backward production capacity on PCDD/Fs emissions. Finally, to develop different transformation scenarios for a green future, we propose four strategies: 1) policy integration for promoting green industry, 2) system innovation and a multidisciplinary approach, 3) collaborative governance with all potential stakeholders, and 4) managing uncertainty, risks, and long-time horizons.

Keywords

Industrial transformation; Green industrial policy; Backward production capacity; Cement industry; China

1. Introduction

The increasing danger of catastrophic global environmental change and other aspects of environmental mismanagement have given rise to concerns about economic development exceeding the Earths carrying capacity. In order for the governments environmental objectives to be attained in parallel with positive economic development, a transformation of industry is needed. Many international organizations and developed countries have proposed various ideas and initiatives such as green growth, green economy, green transformation, green structural transformation, sustainable transformation, and green industrial policy (Lütkenhorst et al., 2014, OECD, 2013, UNEP, 2011 and WB, 2012). The term “green structural transformation” refers to a change in the national economy in which carbon-intensive industrial sectors decrease their share of the gross domestic product (GDP) while businesses with low carbon intensity increase their share. Green transformation refers to processes within industries and/or companies that lead to reduced environmental change impact (GA, 2014). Since the 1990s, industrial transformation has been one of the core science projects of the International Human Dimensions Program (IHDP) (Vellinga and Herb, 1999) which has been integrated into the new initiative Future Earth. Significantly, the Fifth IPCC Assessment Report (Working Group III) devotes a whole chapter to Assessing Transformation Pathways that proposes new scenarios based on data from over 1000 new scenarios published since the IPCC Fourth Assessment Report (IPCC, 2014).

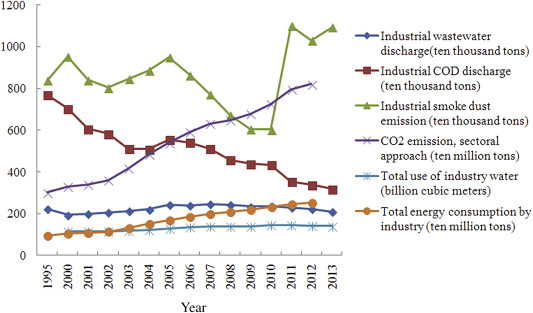

China is struggling to prevent even more environmental pollution and natural disasters that stem, in part, from more than 30 years of unchecked economic growth and industrial development. Though considerable efforts have been made, many environmental problems remain unsolved and yet more new problems have emerged, such as climate change, the loss of biodiversity, overuse of energy and natural resources, environmental risks, and industrial emissions (He et al., 2012, He et al., 2014 and Oosterveer et al., 2006). Consumption of natural resources and utilization of the environment as a sink for emissions still exceed acceptable long-term levels. With the rapid industrialization of the last 20–30 years, the most common industrial emissions, including CO2, industrial smoke dust, have increased continuously in China, while industrial COD discharge has decreased rapidly (Fig. 1). As one of the worlds most fossil-dependent and carbon-intensive economies, China has the highest CO2 emissions of any country.

|

|

|

Fig. 1. Primary industrial emissions and resource use in China from 1995 to 2013. Data sources: OECD/IEA, 2001–2015 and NBSC, 1996, 2001–2014).

|

The challenges of global environmental change and resource restriction call for urgent green transformation for sustainable industry development in China (NDRC, 2007 and UNEP, 2013). The China State Council released the first Industrial Transformation and Upgrading Plan 2011–2015 in 2012. The Plan defined the focus of Chinas industrial development over the next five years as transforming Chinas extensive development practices to a new model driven by technological innovation and domestic demand and consumption, with an emphasis on environmental protection, smart manufacturing, and manufacturing services. Likewise, in a recent flagship report, the National Plan on Global Climate Change (2014–2020), the National Development and Reform Commission (NDRC, 2014) argued that the transition toward a low-carbon, sustainable economic system constitutes a radical transformation involving the radical changes of restructuring the composition and organization of the countrys industries and optimizing the energy structure. The latest Opinions on Accelerating the Construction of Ecological Civilization enacted by the CPC Central Committee and the State Council in April 25, 2015 again emphasized the industrial transformation and greening industries.

Industrial emissions are closely linked with global environmental change. Thus, ITGP came to be established as a priority by the Chinese National Committee for Future Earth (CNC-FE), a new 10-year international research initiative to develop the knowledge to respond effectively to the risks of and opportunities for global environmental change and to support transformation toward global sustainability in the coming decades. The main aim of this study is to provide a thorough examination of the ITGP project in China. It is structured as follows. Section 2 presents three major areas of the project, their objectives and goals. Section 3 describes current progress on industrial transformation with a case study of the cement industry. The conclusions and new perspectives are presented in section 4.

2. Research objectives and major contents

The sustainable transformation of industry will involve a broad spectrum of environmental and social factors, including changes in the production and consumption systems and in the incentive structure that shapes the natural, social, and ecological system. Thus, the goals of the ITGP and this study are as follows.

2.1. Research objectives

The objectives of the ITGP can be summarized as follows:

- To identify the major impacts of global environmental change on industrial development in China.

Because of Chinas vast size and diverse geographic conditions, the impacts of global environmental change in China will vary. However, the main emphasis in environmental change research and policy has been defining the nature of present and future changes in climate and their direct impacts on natural systems (Heltberg et al., 2009) and defining the human-socio-economic system research that can identify and help address the indirect and cumulative effects of environmental stresses and global trends, including industrial development.

- To analyze how industrial emissions influence environmental change in different regions.

Chinese cities and regions have experienced dramatic growth and structural changes, which raises several important questions: To what extent do industrial emissions affect environmental change in different regions? Which areas are the most vulnerable? These are not only scientific questions, but also have implications for preventing and responding to environmental change. In this project, we will delve into the related effects of industrial structure and technical progress on emissions and the impacts of emissions on environmental changes.

- To understand the correlation between industrial production, emissions, and regional environmental change over time.

The combined incremental effects of industrial production—in combination with other human activities—can pose threats to human health and the environment. However, more attention needs to be paid to temporal changes in the regional environment from the perspectives of large-scale industrial production, increase in emissions due to uncertainty of science, and the combined effects of environmental impacts. Interactions among different industries and production processes with regional environments need to be better understood and addressed.

- To develop different scenarios at regional or national levels for industrial transformation towards a green future.

Green processes can support the sustainable development of the manufacturing industry. Green transformation involves not only major technology systems but also systematic social and economic reform. It will thus be necessary to analyze the feasibility of micro-, meso-, and macro-scale scenarios for developing industrial green transformation and their integrated social, economic, and environmental impacts. This will facilitate sustainable development at the regional and national levels in China.

- To introduce an institutional system shaping a new relationship network among consumers, producers, and regulators for green production and sustainability.

To respond to public concerns, it is important that government, industry, and other stakeholders develop a better understanding of where current policy and technology mechanisms are inadequate and where further regulations, commitments, and innovations are needed. It is necessary to strengthen all stakeholders' institutional capacities to work towards a new network system for green production and sustainability.

2.2. Sub-projects and details

The ITGP is organized into three major areas: environmental change and industrial emissions, industrial restructuring and green production processes, and institutional settings for industrial transformation. Its major objectives and contents are presented below.

2.2.1. Environmental change and industrial emissions

The ITGPs objectives for investigating environmental change and industrial emissions are the following:

- To reveal the spatial and temporal coupling relationships between environmental pollution, climate change, and industrial emissions, along with the distribution in air, soil, water, and sediment in different regions.

- To identify pollutant sources in the industrial processes and estimate emissions from industrial and domestic sources in different regions.

- To model and simulate the diffusion and transportation of environmental pollutants in different media at regional or national levels under different scenarios of industrial development.

- To develop an integrated multi-disciplinary approach to mitigation of environmental emissions, including prevention at its source, process efficiency measures, end-of-pipe control, and system innovation.

- To present a comprehensive map of major environmental risks and key industrial contributors, as well as policy suggestions for industrial transformation.

2.2.2. Industrial restructuring and green production processes

Another set of objectives focuses on industry and production is as follows:

- To analyze needs for industrial restructuring and green production to address the challenges of global environmental change, increasing energy and input cost, increasing consumer awareness of green products, regulatory pressure, and the need to enhance competitive advantage by differentiation from competitors.

- To develop different scenarios for industrial transformation, including energy efficiency, near-zero emission, resource conservation, and improved productivity at regional or national level.

- To present an industrial structure optimization pathway towards a green future with spatial layout and a phase-by-phase structural adjustment plan for both production processes and major products.

- To develop a science-based action plan to minimize harmful environmental impacts of manufacturing processes at every stage. This includes minimizing emissions, effluents, and accidents; minimizing the use of virgin materials and non-renewable forms of energy; and minimizing the life-cycle cost of products or services.

2.2.3. The institutional setting for industrial transformation

Below are the ITGPs major objectives and contents:

- To identify the major challenges and needs of national or local governments in order to develop an institutional framework to help producers and consumers with the transformation of the industrial system.

- To set up demonstration zones for institutional building of industrial transformation, and then spread the experiences gained in these zones to a national scale. Transformation may well start at local levels, triggered by local initiatives; however, to succeed in the long run as a new way of meeting needs and preferences for a green future, it will have to be accepted and adopted at larger geographic scales.

- To develop a comprehensive mechanism for green transformation with stricter environmental regulations, effective energy conservation and emissions reduction, green technology R&D and application, as well as international cooperation in related industrial sectors.

- To develop pluralistic policy options including efficiency standards, renewable energy portfolio standards, carbon taxes, and the introduction of a system of tradable emission permits for a transformation towards a low-carbon energy economy.

- To formulate a new social interaction network among the major actors (government, producers, and consumers) appropriate for green transformation. This will include promotion of market reform, implementation of governmental strategies and regulations, proactive responses from industry sectors, self-initiative of industrial enterprises, and public participation.

3. The progress so far: A case study of emission reduction in the cement industry

This section presents reduction of pollutant emissions through industrial transformation in the cement industry. Regulations and policies were collected from the governmental documents. The data on production capacity and PCDD/Fs emissions in the cement industry were compiled from the national plans and statistical books. The reported emission factors and estimation methods were applied based on the literature.

3.1. Restructuring regulations and policies

Recently, phase-out of backward production capacity has become the primary measure taken to reform the industrial structure and to conserve energy and reduce pollution discharge in response to global environmental change. In 2007, A General Work Plan for Energy Conservation and Pollution Discharge Reduction (No. 15 of the State Council) first defined the overall goals as well as an implementation plan for eliminating backward production capacity. A Work Plan for Reinforcing the Elimination of Backward Production Capacity (No. 7 of the State Council in 2010) and A Comprehensive Work Plan for Energy Conservation and Pollution Discharge Reduction in the 12th Five-Year (No. 26 of the State Council in 2011) promoted the phase-out of backward production capacity. In December 2011, the Ministry of Industry and Information Technology (MIIT) of China issued the goals and objectives of eliminating backward production capacity for 19 key industries during the 11th Five-Year Plan in China. In 2012, the State Council issued The 12th Five-Year Work Plan for Energy Conservation and Pollution Discharge Reduction (No. 40 of the State Council in 2012), which required 21 industries to phase out backward production capacity, with a focus on eliminating 20 million kilowatts of small thermal power, 48 Mt of iron production capacity, 48 Mt of steel production capacity, 370 Mt of cement production capacity, and 42 Mt of coke production capacity. Correspondingly, the MIIT and the National Energy Administration (NEA) of China have documented a reduction in backward production capacity every year.

Shutting down backward production capacity will not only reduce the emissions of conventional pollutants (e.g. SO2 and COD), but also greatly decrease unintentionally produced persistent organic pollutants in the industrial thermal process, such as polychlorinated dibenzo-p-dioxins (PCDDs), polychlorinated dibenzo furans (PCDFs), Polychlorinated Biphenyls (PCBs), and Hexachlorobenzenes (HCBs). China has become the largest contributor of PCDD/Fs emissions ( Ren, 2010). These emissions are mainly produced by waste incineration, cement production, iron and steel manufacture, non-ferrous metal smelting, electric power generation, heating, and chlorine-containing chemicals (Zheng et al., 2008). Our group has estimated the PCDD/Fs emissions reduction from 2007 to 2009 due to closed backward production capacity in some industries (Geng et al., 2010). Based on that research, this section will evaluate how policies for the phase-out of backward production capacity affect emissions of dioxins in the cement industry in 2006–2013.

3.2. The policy effects of backward production capacity phase-out in the cement industry on PCDD/Fs emissions

From 2006 to 2010, the cement industry actually and cumulatively eliminated 330 million tons of backward cement production capacity (NBSC, 2011). In total, 370 Mt of backward cement capacities (including clinker and mill) are projected to be eliminated during the 12th Five-Year Plan period (2011–2015). Table 1 shows the assigned elimination of cement production capacities by the Chinese government in 2010–2013. On the whole, 3182 companies had to shut down their production lines (MIIT, 2010, MITT, 2011, MITT, 2012a, MITT, 2012b, MITT, 2013a and MITT, 2013b) including clinker production capacity (including vertical shaft kilns, wet process kilns, hollow kilns, etc.) as well as grinding capacity. Furthermore, 659.35 Mt of the cement production (clinker and mill) were eliminated in 2010–2013. The completed elimination of backward production capacity was higher than planned from 2010 to 2013, except for 2012 (MITT and NEA, 2011, MITT and NEA, 2012, MITT and NEA, 2013 and MITT and NEA, 2014). By the end of 2013, the production capacity of new drying process kilns accounted for more than 95% of the total production capacity of kilns, and the ratio of actual operating capacity of a 4000 t per day production line exceeded 60% of the countrys total operating capacity of the new drying process kilns.

| Year | Planned elimination of cement production capacities | Phase-out fulfillment | |||

|---|---|---|---|---|---|

| Clinker (Mt) | Mill (Gt) | Clinker & mill (Mt) | Number of eliminated cement companies | Clinker & mill (Mt) | |

| 2010 | 85.64 | 2.16 | 107.28 | 762 | 140.31 |

| 2011 | 74.39 | 7.89 | 153.28 | 782 | 154.97 |

| 2012 | 84.36 | 19.93 | 283.66 | 1111 | 258.29 |

| 2013 | 75.60 | 1.72 | 92.75 | 527 | 105.78 |

| Total | 319.99 | 31.70 | 636.97 | 3182 | 659.35 |

Note: These data were based on the list of the eliminated companies with backward production capacities from the MIIT. The data from 2006 to 2009 are not available.

The list of eliminated companies in China shows that nearly 90% of the production lines with clinker production capacities were vertical shaft kilns. Emissions of PCDD/Fs from vertical shaft kilns were measured at 0.518 ng TEQ m−3 at a company in Shandong province of China (Price et al., 2011). According to Chinas Handbook of Pollution Discharge Coefficient in the Cement Industry, the flue gas emissions from the cement clinker process is about 3275 m3 t−1 (clinker) for vertical shaft kilns with output of less than 100,000 t per year. To estimate the reduction in PCDD/Fs released into the air by the cement industry due to closure of outdated facilities, the emission factor 1.7 μg I-TEQ t−1 (clinker) using a gas volume of 3275 m3 per ton of clinker and a concentration of 0.518 ng TEQ m−3 were applied.

The clinker capacities of closed facilities in 2006–2013 are given in Table 2. It is estimated that closures due to reductions in backward production capacity in the cement industry reduced airborne emissions of PCDD/Fs by 976.05 g I-TEQ over the past eight years.

| Year | Eliminated clinker production capacity (Mt) | Dioxin emissions (g I-TEQ per year) |

|---|---|---|

| 2006 | 75.00 | 127.50 |

| 2007 | 52.00 | 88.40 |

| 2008 | 53.00 | 90.10 |

| 2009 | 74.16 | 126.07 |

| 2010 | 85.64 | 145.59 |

| 2011 | 74.39 | 126.46 |

| 2012 | 84.36 | 143.41 |

| 2013 | 75.60 | 128.52 |

| Total | 574.15 | 976.05 |

Note: Data on closed clinker capacities from 2006 to 2009 is obtained from Zeng (2011).

4. Conclusions and recommendations

The green industrial transformation is a project involving high levels of ambition, uncertainty, and complexity. At the core of this necessary transformation towards sustainable practice is a profound renovation of economic structures, technologies, and institutions. Successful transformation requires greening at various levels, from peoples norms and values to changes in political institutions, from innovations at the level of households, firms, and value chains to changes in mechanisms of local, national and global governance. Understanding how such co-evolution unfolds and who and what drives it or obstructs it is the basis for accelerating change towards the sustainability of the industrial transformation.

The ITGP is a new 10-year international research initiative proposed by the CNC-FE. The research theme can support transformation of the industrial system by exploring various transformation scenarios. Such research should take a multi-disciplinary approach and should focus on the industrial system as a whole, including production, consumption, and the incentive structure that shapes the interaction between the two.

As the case study showed that the industrial sectors were important sources of environmental emissions such as PCDD/Fs in China. Through policies such as closure or phase-out of industry companies with backward production capacity, energy consumption and emissions of environmental pollutants will be reduced. For example, from 2006 to 2013, the cement industry eliminated 574 Mt of cement clinker and reduced approximately 976.05 g I-TEQ of airborne PCDD/Fs emissions. It should be noted that PCDD/Fs are unintentionally generated by industrial thermal production processes and can be released into air, water, land, products, and residues. This paper only estimates the reduction of PCDD/Fs emissions to air. Eliminating backward production capacities can reduce PCDD/Fs emissions to each medium. Therefore, reductions in PCDD/Fs emissions due to elimination of backward production capacities will be much greater than the preceding estimates.

Based on the preceding analysis, we recommend four policy measures to promote the green transformation of industries in China.

Firstly, to promote policy integration.

In all cases of successful transformation, the state has played a proactive role (Lütkenhorst et al., 2014). However, this is not to say that such successes all follow a uniform model. On the contrary, they encompass a variety of different institutional arrangements and policies. Environmental policy and industrial policy are the most relevant areas to the industrial transformation. Green industrial policy is an economic policy that reduces the environmental burden of industrial production by reducing the size of the most polluting sectors (inter-sectoral structural change) (Jacob et al., 2004). It requires a shift not only in environmental and innovation policies but also in the economic and regional policies of a country. There are three reasons why strong integration with other policies and programs is needed: first, the need for external incentives for the programs; second, the need for different approaches for leaders and followers; and third, the need to change the dominant regulatory system (de Bruijin and Norberg-Bohm, 2005).

Developing countries, including China, which are especially vulnerable to climate instability, will need to design green industry policies that have a long-term focus; are closely connected to other policy domains; and have mechanisms in place to address, and possibly even compensate, those who experience setbacks due to structural change. This will ensure not only economic and social objectives, but also enhance climate resilience.

Secondly, to adopt a system of innovation thinking and a multi-disciplinary approach.

Responding to the climate imperative will require not a new, synthesized one-size-fits-all model but a system of innovative thinking and a multiplicity of economic development paths. System innovations are not merely about changes in technical products, but also about policy, user practices, infrastructure, industry structures and symbolic meaning. For sustainable industrial transformation, we should take a systems approach that is multi-disciplinary in scope and interdisciplinary in nature and that integrates the natural and social sciences for policy making.

System innovations are complex and uncertain, and involve multiple social groups. Several strands in the literature address important questions about how to develop and accelerate learning and innovation, and the role of capabilities in shaping industry structural transformation. Kemp and Loorbach (2005) identified the key elements of transition management: a long-term approach, backcasting, multi-domain and multi-level thinking, a focus on practical learning philosophy, and an orientation towards system innovation or an integral and dynamic innovation system (Morioka et al., 2006). How do system innovations for industrial transformation come about? They need a so-called multi-level perspective: micro-level, meso-level, and macro-level. The micro-level is formed by technological niches, the locus for radical innovations. The meso-level is formed by socio-technical regimes. The macro-level is formed by the socio-technical landscape, which encompasses phenomena in the wider exogenous environment affecting socio-technical development, such as globalization, environmental problems, and cultural changes.

Thirdly, to practice collaborative governance.

In last two decades, the transformation in governance has usually been described in terms of three trends (Héritier, 2002). In environmental and natural resource arenas, collaborative governance is becoming a trend. Collaborative governance comprises “the processes and structures of public-policy decision-making and management that engage people constructively across the boundaries of public agencies, levels of government, and/or the public, private, and civic spheres in order to carry out a public purpose that could not otherwise be accomplished’’ (Ansell and Gash, 2008 and Emerson et al., 2012). Four common dimensions of capacity within collaborative governance regimes are structural arrangements, leadership, knowledge and learning, and resources (Emerson and Gerlak, 2014).

Systematic changes are required that go beyond the domain of individual sectors and include chains of production and consumption, including distribution and disposal activities. In order to develop different transformation scenarios towards a green future, all possible stakeholders should participate in shaping a new relationship network among consumers, producers, and regulators. In charting the course towards a green transformation, some particularly important elements need to be highlighted, including broad social consensus on the direction of change and related long-term objectives, multi-stakeholder change alliances, complemented openness to systematic policy learning, and a transparent policy process (Lütkenhorst et al., 2014). Creative new ways of collaborative public-private policy making and enforcement are required, following the principle of involving public agencies in market processes, combined with autonomy in decision-making to avoid political capture.

Fourthly, to manage uncertainty, risk, and long-time goals.

Almost everything is at stake in this effort to transform in industry. The industrial transition management framework should address these critical problems through multi-disciplinary and practical efforts. However, while these may generate reliable knowledge in isolation, the variability of projections increases with the level of multi-disciplinary involvement, the size of the system, and the time horizon being considered. Industrial transformation and green industrial policy has always been faced with the perils of uncertainty and the need to explore assessments and judgments that attempt to anticipate and shape desired future scenarios. Transition processes are beset with structural uncertainties of different kinds (Lecuyer and Quirion, 2013). Limited information and risk-prone simulation of future scenarios have challenged any industrial policy put into practice, thus leading to uncertainty about the effectiveness of macro-management (Lütkenhorst et al., 2014).

Envisioning and implementing a process for sustainable industrial transformation, which requires looking ahead one or two generations, requires insight and imagination. Shortsightedness, the orientation towards shareholder value, and short cycles also present obstacles to innovation in the business sector. The long-term visions of sustainability can function as a guide for formulating programs and policies and setting short-term and long-term objectives. These visions must be as appealing and imaginative to be supported by a broad range of actors. Only during the course of the transition process will the most innovative, promising, and feasible transition visions and images be chosen. The practical management of a desired transition proceeds by repetitively executing a cycle of four steps (Loorbach and Rotmans, 2006). Indeed, in conceptualizing green industrial policy, we also need long-term perspectives for developing new technologies, promoting their diffusion, and changing consumer behavior and acceptance of new technologies.

In terms of the different patterns of economic development, current industrial structure, management level, and solutions for green transformation are place specific and will require a high degree of contextualization. In some cases, the economic opportunities associated with the emerging green economy/markets will trigger the build-up of new orders and sources of competitiveness for the industrial market and provide new foundations for green industrial transformation. In other words, new technological options may exert a strong pull and lead to changes in industrial structure and development levels. In many cases, norms and values may change first, and then drive industrial policy and technology innovations. The scientific community should therefore perform in-depth case studies on industrial transformations in specific sectors, on the success, failure and challenges of environmental and industrial policies, paying attention to changing state-society relations and contributions from different levels of Chinese government to international environmental regimes and vice versa. We conclude, therefore that there is no single way to stimulate the fundamental innovations necessary for industrial transformation: Policy and economic systems as a whole must respond to this enormous challenge. The implementation of ITGP will contribute greatly to this process.

Acknowledgement

This study is funded by the Chinese Academy of Sciences (KZZD-EW-TZ-12), National Natural Science Foundation of China (414201040045 and 41371488), and Natural Science Foundation of Hainan Province (413129).

References

- Ansell and Gash, 2008 C. Ansell, A. Gash; Collaborative governance in theory and practice; J. Public Adm. Res. Theory, 18 (4) (2008), pp. 543–571

- de Bruijin and Norberg-Bohm, 2005 T. de Bruijin, V. Norberg-Bohm; Industrial Transformation: Environmental Policy Innovation in the United and Europe; The MIT Press, Cambridge (2005)

- Emerson and Gerlak, 2014 K. Emerson, A. Gerlak; Adaptation in collaborative governance regimes; Environ. Manage, 54 (2014), pp. 768–781

- Emerson et al., 2012 K. Emerson, T. Nabatchi, S. Balogh; An integrated framework for collaborative governance; J. Public Adm. Res. Theory, 22 (1) (2012), pp. 1–29

- Geng et al., 2010 J. Geng, Y. Lu, T. Wang, et al.; Effects of energy conservation in major energy-intensive industrial sectors on emissions of polychlorinated dibenzo-p-dioxins and polychlorinated dibenzofurans in China; Energy Policy, 38 (2010), pp. 2346–2356

- GA, 2014 GA (Growth Analysis); Prerequisites for a Green Structural Transformation of Swedish Industry – Synthesis Report; Report 2014, 01 The Swedish Agency for Growth Policy Analysis, Östersund (2014)

- He et al., 2012 G.-Z. He, Y.-L. Lü, A.P.J. Mol, et al.; Changes and challenges: Chinas environmental management in transition; Environ. Dev., 3 (2012), pp. 25–38

- He et al., 2014 G.-Z. He, L. Zhang, A.P.J. Mol, et al.; Why small and medium chemical companies continue to pose severe environmental risks in rural China; Environ. Pollut., 185C (2014), pp. 158–167

- Heltberg et al., 2009 R. Heltberg, P.B. Siegel, S.L. Jorgensen; Addressing human vulnerability to climate change: toward a ‘no-regrets’ approach; Glob. Environ. Change, 19 (2009), pp. 89–99

- Héritier, 2002 A. Héritier; Common Goods: Reinventing European and International Governance; Rowman & Littlefield, Lanham (2002)

- IPCC, 2014 IPCC; Climate Change 2014: Mitigation of Climate Change. IPCC Working Group III Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press, Cambridge and New York (2014)

- Jacob et al., 2004 K. Jacob, M. Binder, A. Wieczorek; Governance for industrial transformation; Proceedings of the 2003 Berlin Conference on the Human Dimensions of Global Environmental Change, Environmental Policy Research Centre, Berlin (2004)

- Kemp and Loorbach, 2005 R. Kemp, D. Loorbach; Dutch policies to manage the transition to sustainable energy; F. Beckenbach, U. Hampicke, C. Leipert (Eds.), et al., Jahrbuch Ökologische Ökonomik: Innovationen Und Transformation. Band 4 (2005) (Metropolis, Marburg)

- Lecuyer and Quirion, 2013 O. Lecuyer, P. Quirion; Can uncertainty justify overlapping policy instruments to mitigate emissions?; Ecol. Econ., 93 (2013), pp. 177–191

- Loorbach and Rotmans, 2006 D. Loorbach, J. Rotmans; Managing transitions for sustainable development; X. Olshoorn, A.J. Wieczorek (Eds.), Understanding Industrial Transformation: Views from Different Disciplines, Springer, Amsterdam (2006)

- Lütkenhorst et al., 2014 W. Lütkenhorst, T. Altenburg, A. Pegels, et al.; Green industrial Policy-managing Transformation under Uncertainty; Discussion Paper Deutsches Institut für Entwicklungspolitik, Bonn (2014)

- MIIT, 2010 MIIT (Ministry of Industry and Information Technology of China); A Proposed Announcement of a List of Backward Enterprises to Be Closed in 2010 (Ref. No. 111); (2010) (in Chinese)

- MITT, 2011 MITT; A Proposed Announcement of a List of Backward Enterprises to Be Closed in 2011 (Ref. No. 161); (2011) (in Chinese)

- MITT, 2012a MITT; A Proposed Announcement of a List of Backward Enterprises in 19 Industrial Sectors to Be Closed in 2012–First List (Ref. No. 26); (2012) (in Chinese)

- MITT, 2012b MITT; A Proposed Announcement of a List of Backward Enterprises to Be Closed in 2012–Second List (Ref. No. 39); (2012) (in Chinese)

- MITT, 2013a MITT; A Proposed Announcement of a List of Backward Enterprises to Be Closed in 2013–First List (Ref. No. 35); (2013) (in Chinese)

- MITT, 2013b MITT; A Proposed Announcement of a List of Backward Enterprises to Be Closed in 2013–Third List (Ref. No. 46); (2013) (in Chinese)

- MITT and NEA, 2011 MITT, NEA (National Energy Administration of China); The Accomplishment of Elimination Backward Production Capacities in 2010 (Ref. No. 36); (2011) (in Chinese)

- MITT and NEA, 2012 MITT, NEA; The Accomplishment of Elimination Backward Production Capacities in 2011 (Ref. No. 62); (2012) (in Chinese)

- MITT and NEA, 2013 MITT, NEA; The Accomplishment of Elimination Backward Production Capacities in 2012 (Ref. No. 57); (2013) (in Chinese)

- MITT and NEA, 2014 MITT, NEA; The Accomplishment of Elimination Backward Production Capacities in 2013 (Ref. No. 75); (2014) (in Chinese)

- Morioka et al., 2006 T. Morioka, O. Saito, H. Yabar; The pathway to a sustainable industrial society – initiative of the Research Institute for Sustainability Science (RISS) at Osaka University; Sustain. Sci., 1 (2006), pp. 65–82

- NBSC, 1996 NBSC (National Bureau of Statistics of China); 2001–2014. China Statistical Yearbook; China Statistics Press, Beijing (1996) (in Chinese)

- NBSC, 2011 NBSC (National Bureau of Statistics of China); Chinas Progress on Economic Restructuring-economic and Social Development Achievement Report; (2011) (in Chinese)

- NDRC, 2007 NDRC (National Development and Reform Commission); Chinas National Climate Change Programme; (2007) (in Chinese)

- NDRC, 2014 NDRC; National Plan on Global Change (2014–2020); (2014) (in Chinese)

- OECD, 2013 OECD; Putting Green Growth at the HEART of Development. OECD Green Growth Studies; OECD Publishing, Paris (2013)

- OECD/IEA, 2001–2015 OECD/IEA; CO2 Emissions from Fuel Combustion 2000–2014; OECD/IEA, Paris (2001–2015)

- Oosterveer et al., 2006 P. Oosterveer, S. Kamolsiripichaiporn, R. Rasiah; The ‘greening’ of industry and development in southeast Asia: perspectives on industrial transformation and environmental regulation; introduction; Environ. Dev. Sustain, 8 (2006), pp. 217–227

- Price et al., 2011 L. Price, A. Hasanbeigi, N. Zhou, et al.; Increasing Energy Efficiency and Reducing Emissions from Chinas Cement Kilns: Audit Report of Two Cement Plants in Shandong Province, China (LBNL-5583E); Ernest Orlando Lawrence Berkeley National Laboratory (2011)

- Ren, 2010 Z.-Y. Ren; Statistical Analysis on the Categorical Dioxins Emissions and Ambient Air Monitoring on Dioxins Pollution in Typical Industrial Areas of a Metropolis; PhD Dissertation The Graduate School of Chinese Academy of Sciences, Beijing (2010) (in Chinese)

- UNEP, 2011 UNEP; Towards a Green Economy: Pathways to Sustainable Development and Poverty Eradication; UNEP, Geneva (2011)

- UNEP, 2013 UNEP; Chinas Green Long March; UNEP, Nairobi (2013)

- Vellinga and Herb, 1999 P. Vellinga, N. Herb; Industrial Transformation it Science Plan; IHDP Report No. 12 IHDP, Amsterdam (1999)

- WB, 2012 WB (World Bank); Inclusive Green Growth: The Pathway to Sustainable Development; World Bank, Washington, DC (2012)

- Zeng, 2011 X. Zeng; Chinas cement industry-review the 11th Five-Year Plan and look forward to the 12th Five-Year Plan; China Cem., 7 (2011), pp. 73–77 (in Chinese)

- Zheng et al., 2008 M. Zheng, Y. Sun, W. Liu; Dioins and Furan Emission Inventories in China; China Environmental Science Press, Beijing (2008) (in Chinese)

Document information

Published on 19/07/16

Licence: CC BY-NC-SA license

Share this document

Keywords

claim authorship

Are you one of the authors of this document?