Abstract

The present paper is part of a research that is developed within the sustainable building design through the revisiting of the traditional construction materials. The results obtained show that the natural stone, enhanced by technological innovations, are often capable of providing excellent performance.

Based on the tests, it was possible to verify and validate the hypothesis that the proposed new system of external vertical opaque enclosure consisting in a panel in dry-assembled and pre-compressed blocks of natural stone through reinforcing steel has good performances when used both in the case of new design and in the case of recovery of modern buildings, when the intervention is being addressed within of an overall building improvement regarding the security, sustainability, functionality and image.

This paper reports the first results obtained by the study of the feasibility of the envelope being tested, through the definition of all the details of links with the existing building structure.

Keywords

Pre-compressed stone panel ; Innovative envelope ; Energy improvement ; Feasibility study

1. Introduction

This paper ties into research aimed at the energy improvement of existing buildings in areas with a Mediterranean climate, mainly those constructed before the emanation of the Law on Energy Saving (L. 737/1976), that provided information on energy efficiency of buildings for the first time. In particular, buildings built after the Second World War, in addition to presenting an alienated relationship towards the area, often were not appropriate for the local climate and show poor durability over time. Therefore, redevelopment strategies should be designed through an integrated approach, in which energy saving is addressed in an overall improvement of the building concerning seismic safety, the quality of life and the esthetic quality. The approach must involve some preponderant elements of the building, such as: the envelope, the facilities and integration with systems that produce energy from renewable sources, taking into consideration the different technological and material characteristics of the existing property on which one operates (Turchini, 2011 ).

In light of these considerations made by the Department of Architecture of the University of Catania, research has been started with the aim of improving the performance of the building envelope from the different points of view: constructive, mechanical and environmental (Lombardo, 2004 ).

The specific object of the study was, in particular a new type of opaque envelope, that in the case of existing buildings with bearing frame, could replace the original vertical envelopes (Lombardo, ; Lombardo and Cicero, 2007 ). These frequently have no thermal insulation and sometimes are in a state of deterioration.

In order to achieve this envelope, a panel has been constructed, by means of dry assembly, with prestressed blocks of natural stone (basalt from Mt. Etna), and thanks to the presence of steel reinforcements located in suitable holes in the blocks (Lombardo, 2007 ).

The research, consisting of several phases, has addressed aspects of the studied panel which allowed for performance evaluations in terms of mechanics and environment.

From a mechanical point of view, the results obtained from the theoretical research confirmed by the experimental phase, through laboratory tests and the creation of a full-scale prototype, show that, due to the high compressive strength, the stone can be made into load-bearing masonry, in dry-assembled and pre-stressed blocks of natural stone, with little thickness, free in space, fixed at the base, without the typical constraints of the masonry with a structural function of box-type, as in the case of the “stone sail” shown in Figure 1 (Lombardo, 2010 ).

|

|

|

Figure 1. Axonometric view, steps of building and section of the stone sail with revealed the system of reinforcements. |

The experiment showed that the state of artificially induced stress to reinforcements located within blocks led the masonry panel to resist what would be otherwise unthinkable stresses, such as flexure and traction, giving this typical behavior of elastic materials, such as structural steel and reinforced concrete (Lombardo, ; Lombardo, 2012b ; Lombardo, ).

From an environmental point of view, the remarkable reduction of the thickness of structural elements made of prestressed masonry, as in the case of the sail that has a thickness of 20 cm and a height of 3.5 m, has as a direct result and a considerable saving of building material.

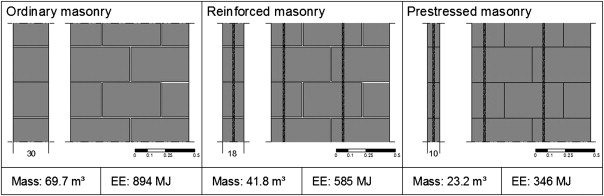

The problems of environmental impact regard both energy consumption in the life cycle of the building for conditioning and maintenance and energy consumption in the construction phase in terms of raw material and embodied energy. The analysis of embodied energy is very interesting because it represents the energy utilized to transform raw materials into building materials. The smaller that value is, the more sustainable the building product (Hammond and Jones, 2011 ). The natural stone, compared with other very widely used construction materials, has a sustainable quotient. From the results obtained by research and shown in Figure 2 , we can note that for a small two-story building in a seismic zone, if constructed with the procedure of prestressed masonry with blocks of natural stone, we get a reduction of mass, measured in terms of volume of used material, equal to 44% compared to reinforced masonry and 67% compared with ordinary masonry; this produces a significant reduction in the structural weight of the entire building (Lombardo, ; Lombardo, 2012b ; Lombardo, ). In terms of environmental impact it has been seen that the reduction of embodied energy is equal to 41% compared to reinforced masonry and 61% compared to ordinary masonry.

|

|

|

Figure 2. Mass and embodied energy of the ordinary, reinforced and prestressed masonry. |

Sustainability, as well as being considered for the savings in raw material and the thusly incorporated energy, also affects procedure. In fact, the panel built with the dry-assembly procedure allows for reversibility and the ability to recycle components. Also construction flexibility can lead to a broad diversification in the use of the system and to satisfy a wider range of needs in the building (Lombardo, ; Lombardo, 2012b ; Lombardo, ).

When used in building envelopes in areas with a Mediterranean climate, characterized by high thermal shock, the prestressed masonry panel provides excellent thermodynamic performance, along with thermal insulation, compared with other very widespread construction materials, such as brick, wood and concrete, thanks to high thermal inertia even when it has little thickness.

By a thermal point of view, previous research has studied the relation between envelope and energy, relatively to a simple building located in Eastern Sicily, through the connection of thermal mass (in term of heat capacity kJ/m2 K) and thermal insulation (in term of thermal resistance m2 K/W) of the envelopes (Table 1 ) (Lombardo, ; Lombardo and Cicero, ; Lombardo and Cicero, ).

| Heat capacity (kJ/m⊃2; K) | EnRyear (kWh/m⊃2;) | Insulation (0.04 m⊃2;K/W) (cm) | PCM (cm) | Basalt (cm) | Concrete (cm) | Brick (cm) | Wood (cm) |

|---|---|---|---|---|---|---|---|

| 175 | 41.2 | 8 | |||||

| 350 | 40.2 | 8 | |||||

| 1050 | 37.9 | 8 | |||||

| 1750 | 35.3 | 4 | |||||

| 3500 | 29.7 | 4 |

The analyses have been conducted with dynamic calculations thanks to computer simulations (EnergyPlus) of case studies regarding existing modern buildings, built before the emanation of the Law on Energy Saving (1976), in Mediterranean climates.

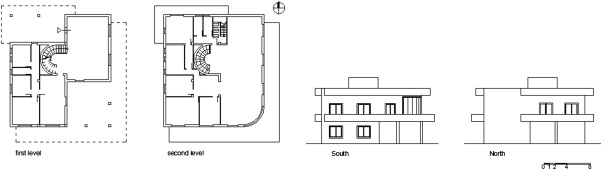

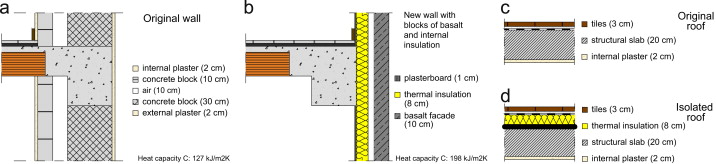

The results have shown that the vertical envelopes consisting of panels of prestressed blocks of natural stone, even with little thickness if combined with a specific value of external insulation, offer excellent performance in regards to comfort level of the rooms and saving energy for summer cooling and winter heating than the original building envelope and to other types of most innovative envelopes based on the use of external insulating and advanced façades (Lombardo, ; Lombardo and Cicero, ; Lombardo and Cicero, ). In particular, an existing two-story residential unit (Figure 3 ) that was built during the second half of the century (1956) in Eastern Sicily was studied, with a unidirectional load bearing frame with external and vertical closures made of concrete blocks (30 cm), air (10 cm) and internal concrete blocks (10 cm) and horizontal closures made of structural slab and tiles (3 cm) (Figure 4 ). For this case study it was designed to replace the original envelope with a new one consisting of internal thermal insulation (8 cm), air (4 cm) and stone panel (10 cm) (Lombardo and Cicero, 2012a ; Lombardo and Cicero, 2012b ). Results obtained are showed in Table 2 .

|

|

|

Figure 3. Studied building. |

|

|

|

Figure 4. Solutions of vertical and horizontal envelopes. |

| Envelope solutions | EnRsum (kWh/m⊃2;) | Tmax (°C) | EnRwin (kWh/m⊃2;) | Tmin (°C) | PEnRyear (kWh/m⊃2;) |

|---|---|---|---|---|---|

| Orginal walls (1.31 W/m⊃2; K) | 8.5 | 32.8 | 42.0 | 5.9 | 57.9 |

| Blocks of stone and internal insulation (0.45 W/m⊃2;K) | 5.7 | 31.9 | 24.0 | 8.3 | 33.9 |

During the entire year, it is possible to observe that the new envelope reduces the primary energy requirement (PEnRyear) of about 40% and the thermal shock of about 4°, which involves a considerable improvement of internal comfort, in comparison with the original state. These values are close to those of a house considered passive.

Further improvements on thermal performances can be obtained studying others elements of the building that have not been studied in this research as for example the glassed envelope (Lombardo and Cicero, 2012a ; Lombardo and Cicero, 2012b ).

In terms of energy requirement and thermal comfort, for an existing residential building in a Mediterranean climate, it is possible to observe that results obtained confirm our expectations. In fact, thermal performances improve very much over hypothesized interventions on the envelope, in respect to the original state.

The studies conducted to date demonstrate that the expectations that have led to the design of the dry-assembled, prestressed stone panel were confirmed with the experimental results.

Based on the tests, described above, it was possible to verify and validate the hypothesis that the stone envelope:

- has good thermal performance,

- has good internal thermal comfort,

- needs less maintenance,

- has a high durability,

- is recyclable,

- can be removed,

- has less embodied energy.

In light of the results obtained, the objective of this work is to study the feasibility of the external vertical opaque enclosure being tested, made by the wall panel in pre-compressed stone and thermal insulation to replace the original one, in the case of the building considered as case study.

In particular, we will study the technical and constructive aspects that allow for easy production of individual components and implementation from the definition of all the details of links with the existing building structure and foundations.

2. The new opaque envelope

The envelope, analyzed here, consists of several sub-components: the first and innermost of which, is a plasterboard panel which is support internally to the finishing of rooms and externally to thermal insulation, and aligned on the edge outside of the structure.

The external sub-components consist of prestressed panels of natural block (basalt from Mt. Etna), suitably connected through elements of dry mechanical fixing it to the bearing structure of the existing building.

The panel transmits its own weight to the ground through a special foundation in reinforced concrete.

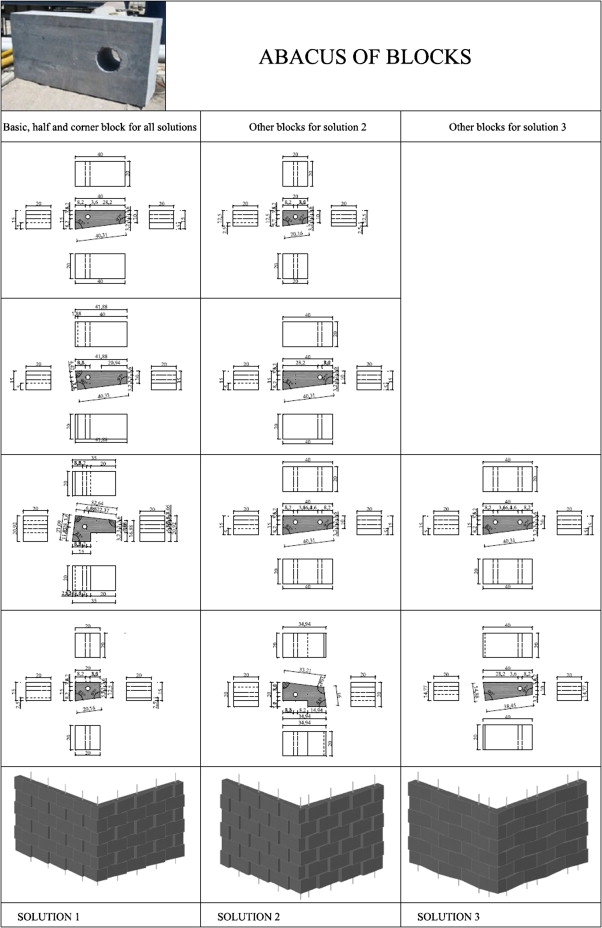

The blocks are designed so that with a very limited number of types could obtain a degree of flexibility and esthetic quality in the design of the panel.

In this specific case a single type of basis block and relative half block has been thought, this one could be used in correspondence of the end portions of the panels.

For the corners of the building elements of a special format have been adapted (Figure 5 ).

|

|

|

Figure 5. Abacus of blocks for three different solutions. |

The square blocks, made from basalt from Mt. Etna, were made with a precision cut made by numerically controlled machines.

The base block has a height equal to 20 cm and a length of 40 cm and a thickness ranging from 10 cm to 15 cm. The variable thickness obtained by a sloped cutting on the front of the blocks, stems from a specific desire to give a pleasing esthetic impact-formal on façade based on the chiaroscuro effect (Figure 6 ).

|

|

|

Figure 6. Examples of different esthetic solutions (3 and 2) for stone façade. |

The block, designed in order to create a self-shading element for the façade, is obtained by optimization of the geometry of the external surface, in such a way that it contributes to attenuate the absorption of heat through the larger development of the dispersant surface.

The block in fact has an external surface higher than that of a parallelepiped block.

Moreover, the type of working can be carried out in two directions (horizontal and vertical), both to adapt to different esthetic needs and to ensure the protection from solar radiation in different conditions of orientation.

Other types of working may be performed to obtain different effects on the façade.

A cylindrical hole with a diameter of 36 mm has been made in the blocks in order to make room for the reinforcements.

The size of the blocks and the hole was studied in order to guarantee the staggered joints and alignment of the hole where the prestressed steel rod is placed through all the layers, for different formal configurations of the façade.

3. Structural testing

The procedures for calculating the prestressing, required to ensure the stability of the panel, are made according to the methodology already applied to the “stone sail” (Lombardo, ; Lombardo, 2012b ; Lombardo, ).

The prestressing load which was calculated takes into account the characteristics of the building and of the site where the work will be done, the geometric data and the weight of the panel, the stresses due to wind and earthquakes, and the strength of the basalt, which is higher than 100 MPa. For the case study, it was determined that the use of threaded bars in galvanized steel, with a diameter equal to 16 mm, placed, inside the hole, from each other at a distance of 40 cm, which corresponds to the size of the block.

For the protection of reinforcements, a waterproof membrane has been prepared.

4. Link system between the panel and the existing building

From a mechanical point of view, the panel is designed to be independent of the existing bearing structure, with regard to the vertical component of the loads because the weight is transmitted to the ground through an independent foundation, specially made.

The panel is connected to the bearing structure of the building, in correspondence with the beams to the quota of each slab through a system of suitable junctions in order not to transmit vertical loads to the structure itself.

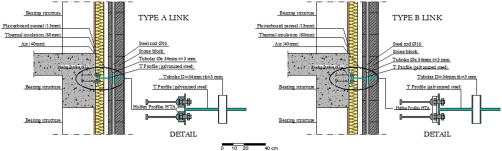

The creation of the junctions is within the ordinary types of existing links. In particular, these are made with standard Halfen profiles, bolts and galvanized steel plates (Figure 7 ).

|

|

|

Figure 7. Link types A and B. |

The HALFEN profile anchored at the level of each slab, to the perimeter beams of the bearing structure of the building, through the grouting of steel bolts, allows you to connect this structure to the panel through nuts and bolts and two steel plates welded to a T. The core of the T is inserted within the thickness of the panel and is integral with this due to a hollow tubular welded to it which fits inside the hole of the block of stone, where to independently goes the prestressing steel rod.

With regard to the load acting horizontally, one can make different choices that influence the resolution of the connection node of the panel to the existing building, in light of the fact that the panel due to its high slenderness offers minimal resistance to actions out of plane and high resistance to actions in its plane.

In a first case, it may confer to the panel, the behavior of bracing of the existing structure. In this case the structure and the panel must be constrained to actions along the plane of the panel itself and not constrained for actions agents out of plane (link type A).

In a second case you can make the choice not to influence the static behavior of the building, making the panel structurally independent from the existing structure. In this case the structure and the panel may not be constrained to actions agents both longitudinally and transversally to the plane of the panel itself (link type B).

The choice is motivated by reasons related to the configuration of the building from an architectural and structural point of view, taking into account the possibility of using mixed solutions as in the case study considered here, for example, where the building, with unidirectional frames, presents considerably different rigidities in the two directions.

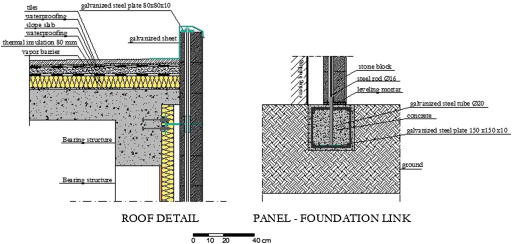

The top closure system, at the last layer of blocks, is constituted by a plate, also made of galvanized steel (80×10 mm). The rod is linked to the head block through the top plate and a steel nut (M16 quality 8.8). For each nut a specific value of tightening has been applied to give the required prestressing obtained from structural tests of the panel (Figure 8 ).

|

|

|

Figure 8. Link panels – roof and panel – foundation. |

The water protection between the panel and the roof of the building is created through laying of a shaped plate.

5. Link system between the panel and the foundation

The link system between the panel and the foundation, in reinforced concrete (h =30 cm, s =30 cm) is made up of several elements: one plate, in galvanized steel (150×150×10 mm), anchored to the steel reinforcing of the foundation, and a hollow cylindrical element, always made of galvanized steel, consisting of a tubular (F25 M16 l=350 mm), threaded inside and welded to the plate (Figure 8 ).

The plate is completely embedded within the foundation and the tubular comes out from the top of the foundation (5 cm), so as to allow the tightening between the foundation and steel threaded rods. In cases where it is not possible to create the concrete foundation one may employ less invasive systems based on the use of micropiles.

6. Assembly procedure

In the foundation, once the steel reinforcement was prepared, bottom plates with threaded cylinder (located at a distance of 40 cm from each other) were put in place and welded to the bottom reinforcement. The concrete casting to a height of 30 cm was performed, taking care to protect the top of the threaded cylinder. Once foundations were finished, the first layer of blocks was placed by putting a layer of leveling to improve the adherence between the foundation and the blocks. The threaded rods were then clamped to each cylinder.

After putting all the steel bars into their housing, we proceeded with the laying of each block.

Up to a height of 2 m, the building of the sail which takes place by sliding the block along the steel rod, can be done fairly quickly and easily by a single worker, being the weight of the block below that permitted by ergonomic regulation.

For the case study, in addition to isolating the flat roof, it is expected to remove the original vertical envelope, to put the thermal insulation with its internal support and finally to realize the stone panel.

In this case, the building of the panel can be divided in stages (two for each floor).

At the last layer, the rod is linked to the block of head through the top plate and a steel nut to which is applied a specific value of tightening.

7. Conclusions

This research is developed within a sustainable building design through the revisiting of the traditional construction materials. The results obtained show that the natural stone, enhanced by technological innovations, are often capable of providing excellent performance.

The proposed new system of panel in dry-assembled and pre-stressed blocks of natural stone through reinforcing steel was designed to be used both in the case of new projects in the case of recovery of existing buildings, with bearing frame when the intervention is being addressed within an overall building improvement regarding the security, sustainability, functionality, and image.

The external vertical closure being tested is a variant in what is called advanced façade.

The advanced façade, characterized by fine elements, is an element constructed essentially as a more external stratification to the vertical closing walls of a building, to protect the insulating coat, because both the air curtain and the building façade have a low thermal insulation capacity.

The vertical closure analyzed, consisting of the stone and prestressed panel, has performance capabilities, such as to constitute the vertical closing of a building, as seen from the experiments conducted to date, due to the excellent physical–chemical characteristics of the stone. In addition to functioning as a protective element of insulation, it itself has excellent thermal performances, as well as mechanical, esthetic, functional, and energetic, qualities.

The vertical opaque envelope thus made, becomes a single element of function and image.

Function and image are obtained with a single element and with a low cost in the buildings life cycle, according to the parameters of industrial types, through optimization of passive and active contribution of the sun, the benefits produced by the stone panel, the dry-assembling, the reduction of maintenance, the high durability and recyclability of components.

In terms of environmental impact, from a point of view of durability, the stone façade is preferable in the life cycle of the building, compared to widespread solutions, for example external insulation and plaster. In fact, the stone façade has a higher construction cost but lower cost in the life cycle because it needs less maintenance.

The case study, analyzed in this paper, has highlighted that the new building envelope (vertical and horizontal) implies a reduction of Primary energy requirement equal to about 40% and a significant improvement in inside comfort, compared to the original enclosure.

With a limited working and variance of type of blocks, which simplifies production, you can get different effects of chiaroscuro on the façade, with a pleasant impact.

Each element has been designed thinking about its possible assembly and the ease with which this should be done, in such a way as to minimize the work of precision in building.

The new enclosure system, coupled with control and working systems over individual blocks, of next generation, gives the possibility to create high performance building elements.

Cutting, done with these machines is much more precise, giving to the block a perfect square with regular faces, promoting a better adhesion between these which involves an excellent water resistance of the panel and also a more uniform transmission of the prestressing load in blocks.

At present, research has shown success in the application of the new type of panel, using assembly procedures in place for morphologically simple buildings with a limited number of floors.

These results allow us to go beyond research to define the possible application of the studied innovative stone envelopes to more complex buildings also thanks to the creation of a prototype.

References

- Hammond and Jones, Hammond G., Jones G., 2011. Inventory of Carbon & Energy (ICE). Version 2.0, Department of Mechanical Engineering, University of Bath, UK

- Lombardo, 2004 Lombardo G., 2004. La modernità del basalto dell'Etna Innovazione e sperimentazione, Il Lunario, Enna.

- Lombardo and Cicero, 2007 Lombardo G., Cicero C., 2007. Verso un'edilizia sostenibile: caratteristiche termofisiche e prestazioni energetiche degli involucri massivi. In: L'involucro edilizio una progettazione complessa. Ancona, 21–23.11.2007, vol. 3.1, pp. 377–386, FIRENZE: Alinea Editrice, ISBN: 978-88-6055-223-5 .

- Lombardo, 2007 Lombardo G., 2007. The return of the stone in architectural composition. In: Atti del Terzo congresso internazionale Ar.Tec. “L'involucro edilizio. Una progettazione complessa”, Ancona. 21–23 novembre. FIRENZE: Alinea editrice, Italy.

- Lombardo, 2010 Lombardo G., 2010. Built architecture with natural stone. In: Atti del convegno internazionale: 37th IAHS World Congress on Housing “DESIGN, TECHNOLOGY, REFURBISHMENT AND MANAGEMENT OF BUILDINGS” Santander, Spain, 26–29 October 2010. International Journal for Housing Science and Its Applications 35(2), 2011.

- Lombardo, Lombardo G., (2012a). Architectural Vanguard Stone. FRONTIERS OF ARCHITECTURAL RESEARCH, issue 1, p. 244–252, ISSN: 2095-2635, 10.1016/j.foar.2012.05.001

- Lombardo, 2012b Lombardo G., 2012b. Natural stone between shape and structure. In: Atti del convegno internazionale: Visions for the Future of Housing Mega Cities. Istanbul, Tecnical University, 16–19 April, pp. 857–864. ISBN: 978-975-561-418-2.

- Lombardo, Lombardo G., 2012c. Weightiness and lightweight for a temporary architecture sustainable. Journal of Civil Engineering and Architecture 1.

- Lombardo and Cicero, Lombardo G., Cicero C., 2011a. Building envelope and energy. Journal of Civil Engineering and Architecture 11.

- Lombardo and Cicero, Lombardo G., Cicero C., 2011b. Materiali ed energia nella progettazione dell'involucro edilizio, Il Progetto Sostenibile, n. 30.

- Lombardo and Cicero, 2012a Lombardo G., Cicero C., 2012a. Sustainable building envelopes. In: Atti del convegno internazionale: Visions for the Future of Housing Mega Cities, Istanbul, Technical University, 16–19 April, pp. 865–870. ISBN: 978-975-561-418-2.

- Lombardo and Cicero, 2012b Lombardo G., Cicero C., 2012b. Aesthetic and energetic performances of sustainable envelopes. In: Acts of 12th International Docomomo Conference: The Survival of Modern, Espoo, Finland, 7–10 August.

- Turchini, Turchini G., 2011. New research for the restoration, Arketipo n. 57, ottobre.

Document information

Published on 12/05/17

Submitted on 12/05/17

Licence: Other

Share this document

claim authorship

Are you one of the authors of this document?