Abstract

Daqing is situated in one of the severely cold regions of China. The living environment in this region is extremely poor because of the harsh climate and the backward economy. The external wall is an important component of the external envelope of buildings, and it greatly contributes to the indoor thermal environment. By taking the external wall as the research object, this study summarizes the characteristics of the external wall structure and analyzes the common materials used in existing rural residences. Specifically, we combine life cycle theory and ecological footprint (EF) theory and introduce the green external wall structure, as well as its application in practice, in accordance with the local ecosystem. Results show that anecological residence offers a better environment and greater economic benefits than a traditional residence. The annual energy consumption, CO2 consumption, and EF of the ecological residence in this study are lower than those of the traditional residence by 69.61%, 17.5 t, and 99.47%, respectively.

Keywords

Life cycle assessment ; Ecological footprint ; Green rural house ; External wall

1. Introduction

1.1. Location and climate

Lindian County, Daqing City, is located in the midwestern part of Heilongjiang Province and is situated between east longitudes 124°18′ to 125°21′ and north latitudes 46°44′ to 47°29′. The west part of the county is contiguous to the Zhalong Nature Reserve, which is home to the world-famous red-crowned crane and to a 3,150,000-acre natural wetland, which is one of the eight wetland reserves in the world. In winter, the mean outdoor wind speed in Lindian County is 3.5 m/s, and the prevailing wind direction is the northwest wind. The mean temperature in the coldest month, the minimum temperature, and the outdoor mean air temperature during heating periods are −19.9 °C, −38.1 °C, and −10.4 °C, respectively. The mean relative humidity is 64%, and the length of the heating period is 182 days. The heating degree day is 5112 °C d, and the maximum depth of frozen land is 205 cm. The winter season in Lindian is long and cold, whereas the summer season is short and cool.

1.2. Materials and structural characteristics of external walls in existing residences

1.2.1. Materials of external walls

On the basis of our investigation into the local rural residences in Daqing, we find that the external walls are predominantly made of 83% homegrown solid clay brick and 7% adobe (Figure 1 ). The adobe wall is constructed by using raw building materials. Therefore, this type of wall is simple and inexpensive to construct. However, the adobe wall has poor durability. Along with the development of construction technology, adobe has been gradually replaced by solid clay brick and red brick. The application of these wall materials significantly improves wall durability. In the last decade, building energy conservation in rural residences has achieved notable progress. New energy-efficient wall materials, including hollow board, hollow brick, and perforated brick, have been applied in practice.

|

|

|

Figure 1. Adobe wall. |

Residences with thermal insulation walls account for 3% of the total number of residences in the research scope. Thermal insulation materials are mainly made of expanded polystyrene (EPS) board. A considerable amount of vegetable-based thermal insulation materials, such as straw board and straw bale (Figure 2 ), are also used.

|

|

|

Figure 2. Straw bale. |

1.2.2. External wall structure

The external wall of local residences in Daqing generally comprises a 490 mm red brick wall and a 400 mm-thick adobe wall. With the application of local energy-saving policies in recent years, walls such as external thermal insulation walls, internal thermal insulation walls, sandwich thermal insulation walls, and straw board walls have been widely applied in practice.

2. Ecological footprint analysis of different structural walls

2.1. Life cycle assessment theory

Life cycle assessment (LCA) is the research on environmental factors and their potential effects on the entire process of a product׳s life cycle (i.e., from the acquisition of raw materials to their production, utilization, and final deposition). LCA emphasizes that at the beginning of a design period of any product or project, the aspects of production, use, waste, and recycling must be considered (Sharma et al., 2011 ). In its practical application, LCA is aimed at reducing environmental impact to the minimum, shortening the design period, and lowering relevant costs. Hence, it brings considerable economic and ecological benefits (Bettles, 1992 ). Construction projects can also be seen as a product of the production process. At the early stages of construction, building design involves decisions on building material types, building material usage, building operation, and eventual disposal of materials. Buildings are special products. Unlike other industrial goods, buildings are large in scale, entail high resource consumption, and operate for long periods. The service life of a residential building is 50–70 years, whereas that of a public building is more than 100 years. The present work focuses on the influence of the external wall of a rural house on the environment. With the aforementioned advantages of LCA, it is deemed suitable for use in the construction industry, as well as in the evaluation of building design plans (Bilec et al., 2010 ).

2.2. Overview and calculation model of ecological footprint theory

Ecological footprint (EF, which is expressed in terms of global hectare (gha)), represents not only the amount of biologically productive land and sea areas necessary to supply the resources consumed by the human population but also the amount of associated waste (Wackemagel and Rees, 1996 ). Canadian ecologist Rees first presented the concept of EF. Wackemagel later remedied the drawback of EF and consequently optimized it. Wackemagel calculated global EF to be 2.8 ha. The global ecological capacity per people was found to be 2.1 ha, and the ecological deficit per people was calculated at 0.7 ha. The figures indicate the severity of the ecological deficit. Vuuren et al. took seven countries as examples and studied the index division of EF. Their article states that index should be divided into the land use index and CO2 absorbing land index to reduce calculation errors (Vuuren and Smeets, 2001 ). This calculation method is effective in macroscopically analyzing the relationship between a nation׳s trade and ecological environment. Each type of economic or social behavior has its own EF. EF theory, which elaborates the relationship between human development and ecology environment in a new perspective, is simple to calculate and easy to use.

The main factors of the EF calculation model are as follows:

2.2.1. Ecological productive area

The following land types are considered in EF theory: farmland, woodland, grassland, construction land, water area, and energy land. Each land type has its own ecological functions. The ecological productive area represents the areas occupied by different productive lands. It is calculated as follows:

|

|

( 1) |

In the formula,

- Am is the ecological productive area (hm2 ),

- Ci is the resource consumption of item i (kg or m3 ),

- ai is the ecological productive area occupied by item i (hm2 ),

- Pi is the national total output of item i (kg or m3 ).

2.2.2. Influence factor

To unify the measurement unit, all the six land types must be converted by adjusting the influence factor. The influence factor is the ratio of the per unit area yield to the average output of the whole ecological system. It represents the ecological productive capacity of the land.

EF theory is usually applied in macroscopic research. To make this theory suitable for evaluating microcosmic object such as the external wall of a building, the national average ecological productive capacity should be calculated instead of the global average ecological productive capacity (Gu et al., 2005 ). Such approach can improve the accuracy of the research results. Therefore, the unit of EF is national hectare (nha).

The formula of the influence factor is as follows:

|

|

( 2) |

In the formula,

- Qnj is the average productive capacity or waste absorption capacity of the ecological system of a country (kg/hm2 or m3 /hm2 ) and

- Qng is the average productive capacity (kg/hm2 or m3 /hm2 ) of the ecological system at the national level.

2.3. Comprehensive calculation model for life cycle assessment and ecological footprint

LCA is focused on the time-related aspect of a given research object, the index of which is bound to change in different time periods. LCA and EF both evaluate the impact of human activities on the environment but differ in terms of their key points. EF theory establishes a method for calculating the impact of human activity on the ecological environment while LCA theory offers the scientific research boundary of ecological impact. The two theories are both evaluation tools but for different dimensions. As each theory has its own merits, their combination can yield strict and highly scientific research results.

This study combines LCA and EF and considers the effect of the reuse and maintenance of building materials on the EF of residential walls. By using both theories and analyzing the EF of different structural walls, we identify the external wall structure with the least negative effect on the environment.

2.3.1. Recycle factor (RF)

Some recyclable external materials include steel, wood, and brick. Insulation materials such as straw board and rock wool could be reused depending on their condition. However, no authoritative research result can support such idea. Therefore, the RF of an insulation material is assigned the value of 0 (Table 1 ).

| Material | Steel | Brick | Insulation material |

|---|---|---|---|

| RF | 0.5 | 0.6 | 0 |

The energy contained in a building material could be reused in the recycling process. Such energy also represents the value of the EF. However, many EF calculation methods ignore such type of energy. For instance, the energy consumption at the production stage is considerably large, but the recycle ratio is the highest in common building materials. Thus, in this work, the RF is added into the EF. Such adjustment is expected to yield accurate results.

The RF is calculated as follows:

|

|

( 3) |

2.3.2. Maintaining factor (MF)

In LCA, the energy consumption and CO2 emission at the operation stage account for 90% of the gross values (Yan and Ying, 2010 ). Thus, the consumption of energy and resources during the entire usage period represents the main part of the total EF of the external walls of rural houses. If a material of the external wall should be replaced, the EF should be accumulated.

The MF is calculated as follows:

|

|

( 4) |

|

|

( 5) |

2.3.3. Life cycle EF

On the basis of the research on the important factors of life cycle EF, we emphasize the need to incorporate the RF and MF in the traditional calculation of the EF of external wall structures.

The life cycle EF is calculated as follows:

|

|

( 6) |

2.4. Calculation of the life cycle and ecological footprint of external walls

(Table 2 shows the boundary conditions of the accounting model.)

| Floor area (m2 ) | Breadth (m) | Depth (m) | Clear height (m) | Orientation |

|---|---|---|---|---|

| 64.48 | 10.4 | 6.2 | 2.5 | Due South |

2.4.1. Calculation of the EF of typical external walls

On the basis of the results of the analysis, we determine six types of typical external wall structures. The structural patterns of these structures are shown in Table 3 .

| Model no. | Structure | Material thickness (mm) | EF (nha) |

| a | Solid clay brick | 490 | 1835.67 |

| b | Perforated brick | 240 | 5.15 |

| EPS plate | 100 | ||

| c | Nonsolid clay brick | 240 | 5.23 |

| EPS plate | 100 | ||

| d | Nonsolid clay brick | 240 | 5.04 |

| Straw board | 240 | ||

| Nonsolid clay brick | 120 | ||

| e | Straw bale | 500 | 4.41 |

| f | Straw board | 60 | 5.07 |

| Rock wool | 20 | ||

| Straw board | 60 |

According to the aforementioned formula for calculating life cycle EF, formula 6 can be used to evaluate the EF of the different external wall structures of rural houses.

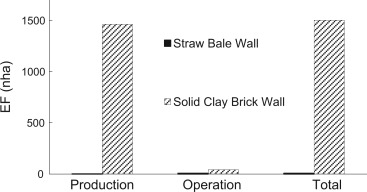

The results are presented as follows. The solid clay brick wall has the greatest EF at 1835.67 nha (Table 3 ), which is 416 times more than that of model e (straw-bale wall) and 362 times more than that of model f (straw board sandwich wall).

2.4.2. Calculation of the EF of energy-efficient external walls

On the basis of the Energy-Efficient Design Standard of Rural Residences (GB/T 50824-2013), we define the heat transfer coefficient of an external wall as 0.5 W/(m2 K) in the accounting model.

By comparing the accounting results (Table 4 ), we find that the EF of the solid clay brick wall is large and is higher than that of other structures by several orders of magnitude. Specifically, the EF of the solid clay brick wall is 235,053 times higher than that of the straw-bale wall. The structures of models 2–6 are considered as energy-efficient wall structures, whose EF is only the mantissa of that of the traditional solid brick wall. The comparison results show that the solid clay brick wall has the most significant effect on ecology among all the types of wall structures.

| No. | Structure | Material thickness (mm) | EF (nha) |

| 1 | Solid clay brick | 1250 | 1175.265 |

| 2 | Perforated brick | 240 | 0.219 |

| EPS plate | 53 | ||

| 3 | Nonsolid clay brick | 240 | 0.226 |

| EPS plate | 53 | ||

| 4 | Nonsolid clay brick | 240 | 0.025 |

| Straw board | 120 | ||

| Nonsolid clay brick | 120 | ||

| 5 | Straw bale | 500 | 0.005 |

| 6 | Straw board | 60 | 0.033 |

| Rock wool | 20 | ||

| Straw board | 60 |

2.5. Analysis of the calculation results

The analysis of the obtained EFs of the different wall structures is as follows.

2.5.1. Effect of materials on the EF

- The life cycle and EF of the vegetable-based thermal insulation wall are significantly lower than those of other walls.

Models 1 to 6 contain almost all of the commonly used external wall structure patterns of rural residences in cold regions. Model 1 yields the highest EF, which is about tens of thousand times greater than that of other models. The total EF of walls with straw bale or straw board as their thermal insulation material is lower than that of walls with EPS plate. This finding suggests that walls with vegetable-based thermal insulation have the least ecological appropriation.

- The life cycle and EF of perforated brick are lower than those of solid brick with the same wall structure.

From the perspective of life cycle, the proportion of EF in the construction stage is higher than that in the production stage. The heat conductivity coefficient of perforated brick (0.51 W/m–0.682 W/m K) is lower than that of solid brick. Thus, the heat transfer coefficient of model b is lower than that of model c. Given that the operation energy consumption and EF of walls are determined by their heat transfer coefficient, the life cycle and EF of model b are lower than that of model c. Therefore, perforated brick is superior to solid brick in terms of EF.

2.5.2. Effect of structures on the EF

- The total life cycle and EF are highly correlated with the heat transfer coefficient of walls.

The trend of the EF of external walls in the operation stage is consistent with their heat transfer coefficients. This result suggests that a wall with good heat insulation has correspondingly low EF in the operation stage; that is, the EF of a wall with thermal insulation is lower than that of a wall without thermal insulation.

- The EF of the sandwich thermal insulation wall is lower than that of the external thermal insulation wall with the same thermal insulation thickness.

To compare the effects of the two types of external wall structures on EF, we use the same value for the thermal insulation thickness. The structure of the sandwich thermal insulation wall is as follows: 120 mm brick wall+100 mm EPS plate+240 mm brick wall. By comparison, the structure of the external thermal insulation wall is as follows: 240 mm brick wall+100 mm EPS board. The total EFs of these two structures are 3.82 and 3.61 nha (Table 5 ), respectively, with a gap of 0.214 nha. The total annual EF of the EPS external thermal insulation wall is 0.07 nha. Given that the EF of the house equipped with EPS external thermal insulation wall for three years is 214 nha, the ecological performance of the sandwich thermal insulation wall is superior to that of the external thermal insulation wall.

| EF of materials | EF of operation | Total EF | |

|---|---|---|---|

| External thermal insulation wall | 0.40 | 3.42 | 3.82 |

| Sandwich thermal insulation wall | 0.26 | 3.35 | 3.61 |

3. External wall structural design of green residences

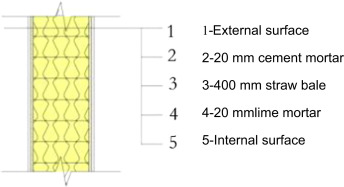

On the basis of the above results, we select the straw-bale wall as the external wall of green residences. The specific structure design is as follows.

3.1. Framework and padding of the straw-bale wall

The bearing structure of the green residence is reinforced concrete frame, and the weight of the roof is supported by the ring beam with column. The main thermal insulation material is straw bale (Figure 3 ).

|

|

|

Figure 3. Straw-bale wall. |

Straw bales are padding filled in the framework. Straw bale serves only as thermal insulators and enclosure shelter but not as load-bearing components (Figure 3 ). The plastering layer on the surface of the straw-bale wall is composite mortar mixed with fiber or hay, which can enhance the toughness of the mortar and avoid surface cracking resulting from different shrinkages (Figure 4 ). To keep the surface of the straw bale smooth, protruding straws should be trimmed before plastering, and gaps should be plugged by cob.

|

|

|

Figure 4. Structure of straw-bale wall. |

3.2. Joints between straw bale and load-bearing framework

The connection between the straw bale and the load-bearing framework is important. The joints between the straw bale, ring beam, load-bearing column, and foundation beam should be fixed by a No. 14 wire or nylon cord (interval of 500 mm) and covered by a metal net after connection. This metal net not only fixes the straw bales but also strengthens the plaster surface in case of cracking.

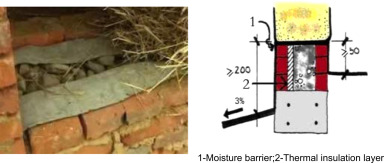

3.3. Fireproof and moisture-proof straw-bale wall

After the special combustion test, the compact straw bales demonstrate good flame resistance, which completely meets the requirements of fire burning time for common residences. The wire across the straw-bale wall must be protected by a sheath, and a certain degree of isolation should be provided between the stove and heated brick bed. In addition, contact between the straw-bale wall and the heated brick bed should be strictly avoided.

The humidity of the straw-bale wall has a great effect on its thermal insulation performance. When the wall is damp and not treated in time, mildew could form and cause rotting in serious cases. Therefore, strengthening the moistureproofing measures of the straw-bale wall is important.

Two aspects should be considered in moistureproofing the straw-bale wall: the vertical and horizontal surfaces of the wall. The moistureproofing method for the vertical surface is completed by overhanging eaves and plaster. By contrast, the moistureproofing method for the horizontal surface is completed by laying the moistureproofing layer on top of the wall. Linoleum and asphalt can be used as moistureproofing materials. The surface of the wall foundation should be protected from moisture and placed 200 mm above the indoor floor. As shown in Figure 5 , an outward apron should be placed outside the wall foundation.

|

|

|

Figure 5. Moistureproofing method for straw-bale wall at the foundation. |

4. Ecological assessment of the external residential wall

4.1. Ecological assessment

The EF of the external wall can be divided into the following parts: the EF of the material production stage and the EF of the construction stage. We assume that the life cycle of residences is 50 years. Suppose that the traditional residence has the same mass as that of an ecological residence. The accounting results are shown in Table 6 .

| EF | Straw-bale wall | Solid clay wall |

|---|---|---|

| Production stage | 0.09 | 1460 |

| Delivery stage | 0 | 0 |

| Construction stage | 0.03 | 0.10 |

| Operation stage | 7.57 | 42.86 |

| Total | 7.69 | 1502.96 |

4.1.1. Amount of EF

Figure 6 shows that the EF of the ecological residence is significantly lower than that of the traditional residence for both the production and operation stages. The EFs of the ecological residence during production and operation are only 0.6‰ and 17.66% of those of the traditional residence, respectively. Therefore, the external wall of the ecological residence has minimal negative effect on the ecosystem and can be classified as an environmentally friendly wall.

|

|

|

Figure 6. Comparison of the EFs of straw-bale wall and solid clay brick wall. |

4.1.2. Evaluation of ecological deficit/surplus

Given the bio-capacity of the building lot in Heilongjiang Province (i.e., 9719.31 nha), the annual bio-capacity of the ecological residence is 0.684 nha. The construction cycle is 1 year, and the operation cycle is 50 years. The life cycle bio-capacity of the ecological residence is 34.88 nha if the bio-capacity during the period remains unchanged. The life cycle EF of the straw-bale wall is 7.66 nha. Therefore, the straw-bale wall has an ecological surplus.

4.1.3. Accounting of the EF index (EFI)

The EFI is the percentage of the difference between bio-capacity and the EF in bio-capacity. When the EFI is between 0.5 and 1, the evaluated object is in the state of strong sustainability. By parity of reasoning, an EFI of less than 0.5 represents weak sustainability, an EFI between 0 and −1 represents unsustainability, and an EFI less than −1 represents serious unsustainability (Vuuren and Smeets, 2001 ). The EFI of the straw-bale wall is 0.78, which suggests that it is in the state of strong sustainability.

4.1.4. Analysis of environmental benefit and economy

- EF

The above data show that the total reduction of the EF ofthe ecological residence is 1494 nha, which is 99.47% lower than that of the traditional residence. The EFs of the ecological residence during production, construction, and operation are lower than those of the traditional residence by 99.99%, 70%, and 82.34%, respectively.

- Ecological cost

The total cost of the external wall of the ecological residence is 12,409 RMB, whereas that of the traditional residence is 19,245 RMB. The cost of the external wall of the ecological residence is 7395 RMB lower than that of the traditional residence. In addition, the cost per square meter of the former is 37 RMB lower than that of the latter.

The performance of the ecological residence is outstanding from the environmental and economic perspective because of its low cost and minimal effect on the ecosystem during its life cycle.

4.2. Evaluation of the operation effect

To examine the practical effects of the project, we tested the building thermal performance in the winter of 2012. The results of the heat transfer coefficient of the building envelope are shown in Table 7 . The heat transfer coefficient of the external wall is significantly lower than the requirement of the Rural Residential Energy-Saving Design Standard (GB/T 50824-2013).

| Location | Heat transfer coefficient [W/(m2 K)] |

|---|---|

| Roof | 0.40 |

| External wall | 0.37 |

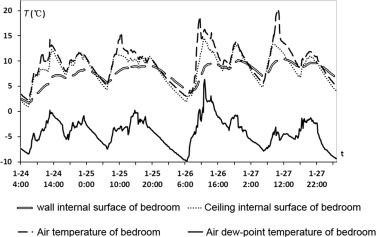

4.2.1. Surface temperature of the external wall

The surface temperature of the external wall remains higher than the air dew point temperature (Figure 7 ). This finding denotes that condensation will not occur on the inner surface of the external wall.

|

|

|

Figure 7. Inner surface temperature of bedroom envelope. |

The temperature curves of the inner surface of the roof overlap the air temperature curves in the bedroom, and the average difference between the temperatures of the inner surface of the external wall and air is 2.1 °C. Therefore, cold radiation is significantly avoided in the structure.

4.2.2. Indoor temperature

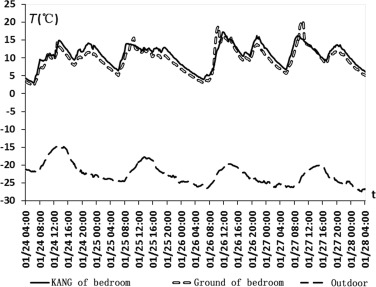

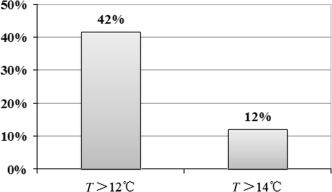

The average outdoor temperature during the test is −22.55 °C. The outdoor temperature decreases rapidly (Figure 8 ). Approximately 45 kg of straw is burned as fuel twice every day at 4 a.m. and 5 p.m. Data show that more than 42% of the collection points in the bedroom have a temperature of more than 12 °C, and more than 12% have a temperature of more than 14 °C (Figure 9 ). The lowest temperature is observed at about 4 a.m. every day. Therefore, compared with the traditional rural residence, the ecological residence not only reduces fuel consumption significantly but also improves the indoor thermal environment.

|

|

|

Figure 8. Indoor air temperature in a bedroom. |

|

|

|

Figure 9. Distribution of indoor air temperature in a bedroom. |

4.2.3. Energy-saving effect

The heat consumption index of the traditional rural residence is 68.33 W/m2 , whereas that of the ecological residence is 20.76 W/m2 . The comparison shows that the energy-saving rate of the ecological residence is 69.61%.

4.2.4. CO2 emission

The coal consumption index of the traditional rural residence is 74.68 kg/m2 . Assuming that the floor area of the traditional rural residence is the same as that of the ecological residence (i.e., 104.84 m2 ), the coal consumption of the traditional rural residence is 7.83 tec. The cumulative coal consumption of the traditional rural residence for 50 years is 391.47 tec.

The coal consumption index of the ecological residence is 13.15 kg/m2 , and its cumulative coal consumption for 50 years is 68.93 tec. The reduction of CO2 emission of the straw-bale wall residence for 50 years is 876.15 t, which is a reduction of 17.5 t per year.

5. Conclusion

By combining LCA and EF theories, we are able to analyze and quantify the effect of the materials and structures of external walls on ecology and apply the research results in practice. The results of the comprehensive assessment of operation performance suggest that the eco-sustainability of the ecological residence is superior to that of the traditional residence. Compared with that of the traditional residence, the indoor thermal environment of the ecological residence is improved significantly, thus fulfilling the goal of low energy and low EF. In addition, the ecological residence has lower construction cost compared with the traditional residence. Thus, the ecological residence achieves good performance in terms of ecological, economic, and social benefits.

Acknowledgments

This research is supported by the Key Projects of the National Science and Technology Pillar Program during the 12th Five-Year Plan Period (No. 2011BAJ08B01-01 ) and by the Specialized Research Fund for the Doctoral Program of Higher Education (No. 20122302110041 ).

References

- Bettles, 1992 Bettles I. (1992), Design for Manufacture & Assembly (DFMA) – The Boothroyd & Dewhurst Approach [M]. In: Proceedings of IEE Conference Publication, (359):316–321.

- Bilec et al., 2010 Melissa M. Bilec, Robert J. Ries, H. Scott Matthews; Life-cycle assessment modeling of construction processes for buildings; J. Infrastruct. Syst., 16 (3) (2010), pp. 199–205

- Gu et al., 2005 Xiaowei Gu, Qing Wang, Jianxing Liu, et al.; A new method of ecological footprint base on national hectare; J. Northeastern Univ., 26 (4) (2005), pp. 295–298

- Mathis Wackemagel, 1996 William E Rees. Mathis Wackemagel; Our Ecological Footprint. Reducing Human Impact on the Earth; New Society Publishers, Canada: Gabriola Island, B.C. (1996)

- Sharma et al., 2011 Aashish Sharma, Abhishek Saxena, Muneesh Sethi, et al.; Life cycle assessment of buildings: a review; Renew. Sustain. Energy Rev., 15 (1) (2011), pp. 871–875

- van Vuuren and Smeets, 2001 D.P van Vuuren, E.M.W. Smeets; Ecological footprints of Benin, Bhutan, Costa Rica and the Netherlands; Ecol. Econ., 34 (1) (2001), pp. 115–130

- Yan and Ying, 2010 Zhu Yan, Chen Ying; Case of residential building life cycle energy consumption and environmental emissions; J. Tsinghua Univ., 50 (3) (2010), pp. 330–334

- Zhao et al., 2004 Ping Zhao, Jifeng Tong, Juanrong Ma; The research on system of the building material environment load index and evaluate; Chin. Build. Mater. Sci. Technol. (6) (2004), pp. 1–7

Document information

Published on 12/05/17

Submitted on 12/05/17

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?