Abstract

An architectural design process is investigated to achieve form flexibility in industrialized building systems (IBS), as IBS constructions do not have sufficient flexibility to develop varied architectural forms. The ethnography method has been used to examine the issues related to “form” flexibility in the design life cycle of IBS constructions by observing the constructions of live experimental models. The major tasks and respective design aspects that facilitate form flexibilities in architectural design have been identified. Furthermore, an integrated life cycle model has been developed to effectively address the interfaces between the design tasks and eventually fulfill the needs of IBS in the design life cycle.

Keywords

Architectural design ; Built environment ; Design management ; Design model ; Design strategy ; Industrialized building system ; Form flexibility

1. Introduction

For achieving sustainable development in Malaysia and transforming the construction industry to be one of the best in the world, the framework of the Malaysian Construction Industry Master Plan fosters the implementation of industrialized building systems (IBS) in building projects (CIDB, 2006 ). However, several construction and engineering aspects related to the IBS are yet to be fully realized in actual practice. One of these aspects is “design flexibility,” which is one key aspect that governs the efficacy of IBS applications. However, this aspect has been largely neglected in both applications as well as literature. As stated by Hamid et al. (2008) , a majority of the current IBS applications—both in design and prefabrication—mainly support conventional building forms (e.g., rectangular and square forms). Such monotonous approaches can hinder an architects ability to develop flexible forms. In particular, prefabricated elements are considered to be inflexible to changes that would be normally required over their life spans (Warszawski, 1999 ; Sarja and Hannus, 1996 ). Simultaneously, architectural designs aimed toward IBS constructions should possess the attributes of manufacturing feasibility and onsite assembly. From the architectural perspective, flexibility can be defined as the ability of a unit to respond to the changes necessitated by the client, design, and manufacturing requirements (Sarja, 1998 ). While architectural design ultimately deals with the configurations, connections, shapes, and orientations of the physical forms, flexibility in architectural design is predominantly related to spatial design and building “forms” (Do and Gross, 2001 ). As such, architects are often inclined to develop varied and unusual architectural forms (Saleh et al., 2003 ). Therefore, further investigation is required to improve the form flexibility in both architectural design practice and construction.

To overcome this barrier, this article presents the results obtained from a research sponsored by the Universiti Putra Malaysia. The issue of achieving form flexibility in IBS constructions during the design stage was investigated based on the premise that “it is extremely important to incorporate system thinking in the architectural design process to foresee and resolve complex issues during the implementation of IBS.” As opposed to concrete and steel constructions, timber construction was investigated in this study since timber is easy to handle and timber elements (used in the experiment) could be easily fabricated. Further, timber comes from a sustainable source; therefore, timber has been fostered by the Construction Industry Development Board (CIDB), Malaysia, as an alternate material for IBS constructions (CIDB, 2003 ). A series of ethnography methods of investigations have been proposed with regard to the construction of live timber houses. Consequently, the most appropriate approach for achieving an integrated system design has been developed. This article describes an integrated system design model that can be used for improving the form flexibility in IBS designs. The proposed model will help architects in understanding the relationship between building systems and their designs, and therefore, incorporate creativity and flexibility in IBS constructions.

1.1. Problems in IBS attributable to design flexibility

In Malaysia, IBS was initially implemented to promote systematic construction processes and minimize the number of foreign workers. However, impediments to achieving this goal have been widely reported in literature. For instance, Hamid et al. (2008) stated that the supply and demand, economic volume, general readiness, and social acceptability were major hurdles. Badir et al. (2002) stated that professionals were not aware of the basics of IBS such as modular coordination as well as volumetric and nonvolumetric construction methods. This argument was supported by many scholars (Gibb, 1999 ; Davidson, 1990 ; Benros and Duarte, 2009 ). Mawdesley and Long (2002) and Jaillon and Poon (2009) argued that future modifications to manufactured building components were not possible as they resulted in less flexibility during the construction phase. Hassim et al. (2009) and Lessing et al. (2005) added that the IBS approach impeded the creation of a customer-oriented design. The coordination between spatial design and dimensioning of elements was poor and was not appropriately incorporated into the designing of spatial and functional space relations (Gibb, 2001 ). The transportation of building components depends largely on the local conditions. For example, to be transportable, the component sizes should be designed in accordance with the carriageway. In addition, incompatible interfaces between manufacturers, poor coordination between the manufacturers and architects during an early design phase, and limited applications of building materials (i.e., mainly using concrete for fabricating precast beams, columns, and panelized wall systems) are some of the pressing problems that mar IBS constructions (Thanoon et al., 2003 ). Tam et al. (2007) suggested a lean construction approach to deliver better standardized products. However, the consequent construction defects were difficult to conceal, possibly leading to structural failures and water leakages. All these impediments adversely impact the design creativity in IBS, resulting in monotonous and aesthetics-deprived buildings.

In the past, conventional building construction has been adopted in the Malaysian housing sector (IEM, 2003 ). Consequently, the CIDB, Malaysia, has promoted IBS technologies so that prefabricated building components are utilized to the maximum possible extent in the construction industry. As stated by Junid (1986) ; Padrid (1997) ; Trikha (1999) ; Lessing et al. (2005) and Tam et al. (2007) , it is a known fact that IBS integrates the manufacturing and construction processes that involve mass production, where the building components are prefabricated to optimize the majority of onsite construction activities and workmanship, reduce material wastage, reduce the time required, and reduce the overall cost of the project. IBS can also create engineering benefits for the construction industry since it mainly encourages the production of standardized buildings rather than varied ones. Studies have not investigated the manner in which IBS can be incorporated in the development of architectural design to meet contemporary design changes such as “form flexibility” (Howes, 2002 ). On the other hand, architects are unaware of envisioning the incorporation of IBS building components in the architectural design process. The lack of an IBS data repository and inadequate knowledge of IBS among architects has resulted in redundant design flaws during detailed construction documentations, which has further delayed projects (Kamar et al., 2009 ). Moreover, the IBS approach has created a negative perception among the architects and customers because of the following factors: it hinders flexibility; it only allows internal flexibility in the layout; it creates jointing problems; it promotes monotonously manufactured building components; it creates repetition in standardized building components and it does not allow varied forms that can yield creative architectural designs. In spite of these defects, the existing IBS construction practices need to be revitalized in the minds of the designers such that they can efficiently incorporate “system thinking” in the architectural design process. A systematic approach often limits the freedom of designers, notably architects.

Besides the standardization of building components, IBS should be able to develop compatible systems that can integrate building components with the spatial design. In addition, varied forms and efficient design solutions are possible when system thinking is applied at an early phase of the architectural design process (Gann and Senker, 1993 ). In current practices, the industrialized construction, manufacturing, and assembly processes are involved only after the design process is completed (Walch, 2001 ). To improve and enhance the potential outcomes of IBS, an approach involving system thinking, as emphasized by the above mentioned literature, should be integrated with form flexibility during the architectural design process.

2. Research methodology

In this article, we have investigated the issue of creating varied architectural “forms” during the iterative architectural design process. This research adopted the approach of an experimental case study to examine the issues involved in the design life cycle of IBS. For investigating the issues pertaining to manufacturing and assembly, a couple of new timber houses were fabricated as the fabrication of timber materials is often easier than that using other building materials. In addition, timber as a construction material has not been sufficiently investigated with regard to IBS constructions as compared to the other widely used elements that can be prefabricated, such as steel and cast-in-situ and precast concrete (Warszawski, 1999 ). According to a survey conducted by the CIDB, Malaysia, the use of timber in IBS constructions is almost negligible (Majid et al., 2010 ). Therefore, this research can also provide the construction industry with practical standards that can define the use of timber as an alternate sustainable material in IBS constructions.

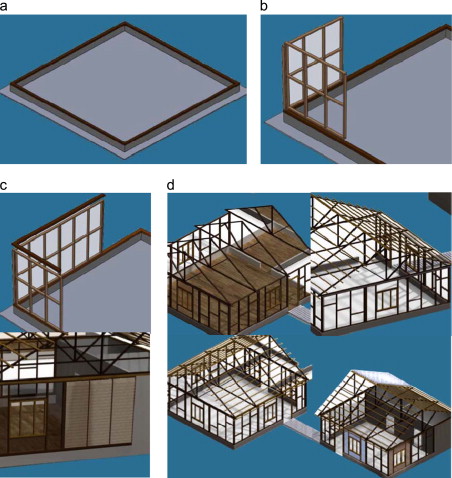

Two units of prefabricated timber houses were designed and constructed at Seremban—situated in the state of Negeri Sembilan, Malaysia—as experimental samples. These houses looked like 'Malay' traditional chalets (see Fig. 1 ) in which an independent square was connected to a semi-covered timber deck. Each square accommodated functional spaces such as a living room, dining room, kitchen, master bedroom, and service facilities. Each unit was designed such that the functional spaces fit in an area of 36 m2 to meet the criteria of modular coordination. Moreover, dimensional coordination was set to follow the aspects of the standardization of components and simplifying prefabrication issues such as the availability of timber sections, transportability, onsite labor involvement, easy assembly to avoid component damage, and maintaining precision in construction. The prefabricated components were also used as infill for nonstructural components. The spatial dimensions were determined according to the size, span, repetitions, and ease of assembly of the building components, regardless of their spatial designations and spatial relations. On the other hand, pyramid roof houses were constructed using bespoke timber elements that were partially assembled onsite.

|

|

|

Fig. 1. Prefabricated Timber House Units constructed at Seremban, Malaysia. |

2.1. Ethnography data collection method

In the experimental case study, the design and construction processes were determined using the ethnography method, because this method has the potential to play a valuable role in design-related research and can effectively delineate the design process. According to Spradley (1979) , ethnography is usually applied in social settings to study peoples behaviors and culture. Since this study primarily involves people and their decision-making attributes during the iterative design process, ethnography is used as a feasible technique to observe the implications of manufacturing and assembly processes involved in the design life cycle of prefabricated timber buildings. Conducting ethnography requires the formulation of a set of open-ended research questions (Atkinson et al., 1999 ). This requires the identification of the nature of the required data, data location, and the informant. As stated by Spradley (1979) , this study revolves around three main components of ethnography: the key informants (KI) as the people , a prefabrication process as the culture , and a prefabricated timber building as the context . Prior to fabricating the model houses, a miniature model house (see Fig. 2 ) was developed to guide the construction of the actual houses. With the aid of these miniature models, the aforesaid three components were represented by a team comprising timber and prefabrication experts who were the KI, five industrial designers (ID) who were the facilitators, and one observer (O) who was present right throughout the project—from the cognitive stage until the construction process. The KI acted as the source whose knowledge and expertise were documented throughout the prefabrication process of the miniature models. The data were obtained through videotaped interviews, archival documents, and photographs. The ethnography data collection method helped the researcher to identify various tasks and aspects involved in the designing, manufacturing, and assembling of the prefabricated timber houses. During the ethnographic data collection, the KI contributed to the construction of the prefabricated timber houses throughout their development process with all suitable technical inputs. Their inputs were incorporated in the following aspects: the design; the selection of timber species; the fabrication and sizing of elements and components; and making decisions regarding the methods of construction, manufacturing, and assembly.

|

|

|

Fig. 2. Key informants (KI), industrial designer (ID) and observer (O) during the ethnography of making the prefabricated timber house miniature. |

In addition, this study revealed certain overlaps that existed when performing various design tasks that require interdependent design decisions. Consequently, these interdependent tasks led to the proposed integrated design model that can assist designers in incorporating IBS in the design process, as discussed later in this article.

3. The implication of design tasks and design aspects in the prefabrication of timber housing

There is no common formula or software tool that can be used to analyze the ethnography data, except transcribing the conversations between the participants and the KI (Gibbs, 2007 ). The ethnography data were analyzed in a qualitative and descriptive manner, where the data collected at various stages of the tasks and subjective design aspects of the prefabrication process were sorted out in a chronological order.

As stated earlier in this article, several engineering factors such as standardization, inflexible joints, logistics, and rigidity, which are unique to IBS building processes and consequently limiting the application of IBS in different types of buildings, were identified during the ethnography data collection process. However, it was observed that form flexibility was one of the major factors that limited the application of IBS in creating varied buildings. Because the IBS building process fosters precision engineering, and therefore, predominantly involves limitations in manufacturing and assembly processes, it was relatively difficult to achieve form flexibility. Initially, the ethnography team was not fully aware of the design tasks and design aspects needed to be considered at the conceptualizing stage. During the course of the ethnography process, it was observed that space planning was critical to achieve the owners requirements in the development of spatial design and form generation. The ethnographer (observer, O) identified this volumetric design of additive and subtractive design processes could not be effectively coordinated with the design of IBS elements and components to conform to their offsite building processes. Volumetric design involves modularizing the space in coordination with building modules, including building elements/components. In addition, the lack of awareness regarding IBS processes required making major alterations in the modules such that they could conform to the prefabrication characteristics and assembly elements/components, thereby facilitating successful offsite construction. These types of iterative adjustments and changes, caused by improper design decisions pertaining to temporal aspects in the design (such as space), had to be investigated to maintain the form.

The temporal aspects of space design included issues such as functional relativity, social factors (comfort and privacy), massing, facade constraints (i.e., windows, shading devices, and protrusions), and building services. These factors were explicitly coordinated mainly with the physical building elements and components. However, during standardization, the temporal aspects of the form generation were represented by dimensions. As per the ethnography, in the IBS building process, dimensional coordination contradicted with the space and modularization of elements/components. An implicit volumetric approach yielded an effective “form” so as to meet the needs of modular coordination. The relationships between spatial (functional space)/temporal aspects and dimensional coordination were revealed at every stage of the prefabrication process throughout the ethnography study.

Based on the design iteration, the ethnographer (observer, O) observed and derived a series of design tasks, as shown in Table 1 . These tasks included the selection of an appropriate building system, constructability, manufacturing, and assembly. The process of prefabrication, as observed through the ethnographic study, was considered to be a significant source that enabled better decisions in the architectural design.

| Design tasks | Design aspects | Effect on Form |

|---|---|---|

| Selection of appropriate building system |

|

Need to foresee coordination between functional space in connection with spatial and dimensional relationships to represent the design system |

| Constructability |

|

Design must incorporate modularization to ease constructability |

| Manufacturing |

|

The manufacturing process of the elements must involve instructions from manufacturers in order to achieve flawless production. |

| Assembly |

|

Assembly of prefabricated timber components consequently led to changes during the assembly. |

Analyses of the ethnography data led to the identification of the most significant linkages between the design tasks and subjective design aspects for creating flexible “forms” in designing timber IBS buildings. One of the critical issues observed during the architectural design process was achieving flexible “forms” during an early design phase and continually maintaining the same form throughout the fabrication process. In accordance with the requirements of prefabrication, the dimensions should be standardized. Further, when changes occur, these dimensions should be continually controlled in connection with the design of architectural elements such as functional spaces, designs of openings (i.e., windows and doors), structural elements, roofing, and aesthetics. The morphological expressions of such detailing can be labeled as “form.”

In the early design phase, the KI emphasized that “the prime focus of prefabrication should be the consideration of the dimensional coordination among the spatial and building elements.” The coordination should evolve whilst considering adaptable design changes pertaining to the spatial relations and architectural elements (i.e., spaces, openings for light and ventilation, service shafts, projective and recessive elements in the façade, and structural and construction detailing). Simultaneously, it should enable the prediction of standardizations during the iterative design process. Therefore, to enable the architects to exhibit their creativity and morphing abilities, they must preconceive the constraints pertaining to the design life cycle of IBS.

Within this context, most of the buildings designed for prefabrication might have impeded product manufacturing, logistic supply, and assembly process; this, in turn, would have required iterative revisions in the architectural design, and therefore, delayed the coordination process to meet the necessary standardizable dimensions. For instance, the recurring changes/flaws recognized during the manufacturing process would eventually affect the elements connected during their assembly. For instance, certain variations in the design of a wall panel can affect the roof dimensions. The significance of the design iterations is to foresee design-induced flaws and avoid them before beginning the manufacturing and assembly processes. During the study, iterative design revisions were made in the architectural detailing such that the design elements could conform to the desirable form with customizable flexibility. During the initial stage of the prefabrication process, the design tasks need to be synchronized with the relevant design knowledge.

3.1. Selection of appropriate building system

For addressing the design task of the “selection of an appropriate building system,” the investigation team—comprising the aforesaid KI, ID, and O—brainstormed; subsequently, from the ethnographic study, the pertinence of building systems and their types in designing prefabricated buildings were determined. The dimensional aspects of each space should be ascertained in connection with the design of various elements and components of the buildings. Therefore, the concept of spatial design is closely linked to “form” as it yields appropriate design decisions with regard to building elements and components. The major constraints, as revealed by the experimental model, when addressing the issues of building systems in an architectural design include the following aspects:

- The dimensions of the prefabricated elements and components should be designed such that they conform to the spatial layout. For example, a multitude of spatial connections between the spaces and their orientations should meet the standardizable dimensions. The space constraints should be volumetrically designed (i.e., symmetry, dimensional proportions, and dimensional gradation) to meet the standardization requirements.

- Dimensional coordination is nothing but a modular system in which the functions are designed with certain limitations. This is applied not only to the horizontal elements but also to all the vertical and volumetric elements/components of the building (e.g., the toilet pod). Therefore, the design approach should be volumetric (e.g., form) rather than only spatial.

3.2. Constructability

The design aspects related to “constructability” were identified when a set of prefabricated elements and components were developed for manufacturing and assembly. To facilitate constructability, the KI emphasized “repetitions” in the design of the building elements/components. Subsequently, both the experimental miniature model and the actual building model proved the need for designing repetitive elements/components and their influences on the dimensional coordination between the spatial spaces and vertical elements were demonstrated. Therefore, constructability warrants the need to integrate the designs of spaces and elements for achieving a desirable “form.” It was also observed that constructability influences the design decisions in relation to architectural design features. A fragmented design process causes variations in the elements due to the lack of inputs from the manufacturing and assembly processes. In addition, the design separation between the spaces and elements/components does not meet the requirements of the manufacturer. The process of designing elements and components should not be finalized until the prefabrication aspects meet the manufacturing requirements, such as the availability of timber of the required size, strength, durability, treatability, and other working properties (i.e., ease of planning; ease of boring and boring finish; ease of turning and turning finish; and convenient nailing, application, and jointing systems). These properties are designed in conjunction with the manufacturing indices.

In particular, the following design constraints hindered the constructability aspect:

- The size of cross sections (timber sizes) needed to be fixed in accordance with the design and manufacturability of the elements and components.

- Uniformity in the size of the elements/components should be improved proportionately such that standardization and repetition can be facilitated, and therefore, wastages can be reduced.

- Aesthetic design (design style) with varied dimensions having repetition, symmetry, and rhythm should abide by the principle of proportion to maintain dimensional relativity. The volumetric design approach should involve space modularization.

3.3. Manufacturing

Although the manufacturing process is not part of the design process, significant issues were identified that could be used for anticipating design-induced flaws during onsite assembly and their impact on prefabricated elements/components. In particular, certain issues pertaining to the methods involved in timber procurement, transportation, packaging, and onsite assembly were considered, consequently leading to iterative modifications in the design. The iterative design process yielded the manufacturing specifications required to make assemble-able elements and components. The specifications include the following:

- Awareness regarding the wood species to be used for various prefabricated elements/components is critical. The working properties offered by various species including ease of planning, ease of boring and boring finish, ease of turning and turning finish, and ease of nailing should be considered. This will assist architects in distinguishing between their structural and nonstructural applications (for example, floor, wall, roof, and other structural applications). If the species selection is not considered in the early design phase, the resultant manufacturing imprecision can damage the joints of the elements/components and result in disparate forms and sizes.

- The utilization of composite techniques regarding mixing and matching materials (for example, jointing interfaces between steel and timber) is critical for fabricating flexible joints. In addition, inappropriate manufacturing detailing (including tolerance) and the lack of knowledge in manufacturing can lead to structural failures.

- As much as possible, lightweight elements/components should be designed such that jointing can be flexibly achieved and the material can be easily handled, which can expedite both transportation and onsite assembly.

By using the aforesaid aspects, modular systems suitable for fabricating standardized jointing, demountable systems, and standardized assemblies can be developed. By applying these aspects along with the other tasks can yield damage-free elements and components. These aspects are beneficial to improve the constructability of IBS buildings and they also play a vital role in form flexibility.

3.4. Assembly

As stated in the literature, the significance of the prefabrication process lies in the reduction in a majority of onsite construction activities that can lead to time optimization, labor reduction, cost-saving, and reduction in construction wastages. Assembly activities play a major role in designing trimmed elements, and therefore, reduce the required onsite construction works. A smart jointing system using cranes and related technical know-how should be considered in the design. Understanding the onsite assembly process during the experimental modeling (including the floors, walls, and roofs) can enable the anticipation of assembly detailing including element plumpness, concealing and fastening the finished materials, as well as mechanical and electrical requirements such as cladding, paneling, calking, trimming, and sheathing. The same should be considered during the design process to effectively conceive the assembly process. Fig. 3 shows the sequential assembly activities undertaken for each layer of the elements/components of the timber building.

|

|

|

Fig. 3. The assembly method adopted in the miniature model of the prefabricated timber house. |

Design variations in terms of dimensional incompatibility caused problems in the upcoming layers involved in the assembly sequence and element/component detailing. The design was iteratively amended during the onsite assembly as the technical know-how of the assembly process was not adequately included in the design process. Such subjective and intricate assembly changes were minutely investigated during the experimental modeling and the following aspects were formulated:

- The selection of appropriate species and cross section for achieving assemblable construction is highly critical.

- Leveling for tolerance and tangential movements should be considered.

- The building service requirements (including mechanical and electrical) should be easily concealable for smoothly installing and maintaining the building services.

- Weight is the most critical factor as it determines the manual or automated applications in the assembly process. The lifting process should be hassle-free and should involve lesser number of scaffoldings.

- The quality of the factory-produced trimmed products should be retained, because it promotes damage-free elements and enhances their aesthetics.

- The design must afford adequate flexibility, easy jointing systems, and assembly sequences (i.e., connectors, hinges, rebates, interlocker, sliding tracks, calking, and clips/anchors for installations) to carry out the assembly process safely and quickly.

The aforesaid tasks and respective aspects (constraints) were derived from the ethnography of the experimental model. The designers—besides their conventional design wisdom—should consider these tasks when developing prefabricated building elements/components for IBS buildings.

4. Integrated design tasks for improving forms in IBS

In design practice, the evolution of the “building form” is an iterative process such that all the aspects of the design requirements are entirely met in the architectural design process. As documented in the ethnography data, this research identified various tasks and aspects that are interdependent on each other. To avoid recurring changes and amendments, the concept of manufacturing and assembly should be inculcated in the early design phase. This is one of the feasible solutions that this research has proposed in designing flexible forms.

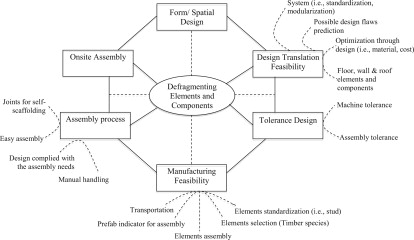

The ethnography of the experimental model was the key source of data required in developing the proposed model of the design life cycle for IBS, which focuses mainly on “defragmentation” of the elements/components. The life cycle tasks derived from the experimental model included the following: feasible translation of design into prefabrication, design of building elements and components, design of the dynamics and tolerance of the embedded joints, manufacturing/production design aspects for elements and components, and various design aspects of the assembly process. The purpose of this model is to bridge the gap between the design developments and construction documentation in which the manufacturing aspects, construction logistics, assembly aspects, and selection of material properties can be adopted. The integration of these tasks and aspects facilitates resolving the manufacturing problems and optimizing the design. The life cycle tasks and other constraints that should be predicted along the process of design development are shown in Fig. 4 . In addition, the proposed model facilitates the interdependency between the tasks, eventually enabling the fulfillment of the requirements of IBS in the design life cycle.

|

|

|

Fig. 4. Integrated design life cycle of IBS. |

4.1. Design translation feasibility

The design translation feasibility is a knowledge-based assessment system used to achieve constructability in IBS constructions. This assists in anticipating recurrent design modifications, and subsequently, making better decisions on appropriate “building systems.” It also helps in translating the implicit design decisions into defragmented elements/components for prefabrication, while considering other aspects that are interdependent in the early design phase such as those in the manufacturing and assembly processes. The following aspects should be considered in achieving the feasibility of design translation and reducing the recurrence of design revisions that is normally required in the construction of IBS buildings.

- Modularization should be achieved by handling issues such as space, form features (geometry), dimensions, and building elements/components. Modular coordination should consider manufacturing and assembly requirements, availability of material, transportability, and constructability. As there is no single and perfect prescribed modular application, an appropriate system can be achieved only by following the “mix and match” method with regard to space and building standards by deploying ratio/divisibility, proportion, and standardization. Finally, the resultant set proportions and set standardization can form the benchmarks in the form of modules that should be adopted throughout the building development process.

- The standards will contribute toward defragmenting various building elements/components including the floors, walls, and roofs so that they are manufacturable and assemble-able (for example, panel walls and standardized bespoke elements, modular roof trusses, modular rafters, and purlins).

- Repetition should also be featured in standardization so that flexible architectural forms can be designed having different architectural styles, patterns, rhythms, and harmonies. For example, featured repetitions in timber IBS constructions include window/panel wall awnings, projections, sunshades, balconies, as well as decorative protrusions in the floors, walls, and roofs.

The ethnography results from the models designed by Junid (1986) ; Trikha (1999) ; Lessing et al. (2005) and Tam et al. (2007) demonstrated the importance of the feasibility of design translation and demonstrated the use of the architectural design process to resolve issues related to the manufacturing and assembly processes. Task interdependencies unveil and curtail abrupt design changes, which are normal occurrences during manufacturing and onsite assembly of building elements/components. Besides, this approach results in balanced composition (i.e., symmetry) and modular designs.

4.2. Defragmenting building elements/components

Defragmentation yields an adequate number of element details that should be matched with the manufacturing requirements. They are normally expressed in terms of modularity, symmetry, proportional ratio, and identifiable pattern. Defragmentation examines the feasibility of using design features to fully achieve the manufacturing and assembly requirements. It synergizes task interdependency and fuses design development with construction documentation to obtain comprehensive jointing and assembly methods for various building elements and components. The defragmentation process developed during the ethnography of the timber model yielded exclusive construction documentation that supported flawless manufacturing and assembly processes. In implementing the defragmentation process, the following aspects should be considered:

- Modularization should be incorporated both in the spatial design and elements/components.

- Support the evolution of modularized design patterns in spatial designs in relation to architectural features (i.e., symmetry).

- The elements/components that can be defragmented should be designed for various jointing systems, which will simplify both onsite assembly and deconstruction.

- IBS design standards should be used to achieve element/component defragmentation, and therefore, support manufacturing and mobility.

4.3. Tolerance

Tolerance refers to the behavior of material under changes and structural reactions. In assembly elements, tolerance can be used to control joint damages such as leakages, fissures, and failure to withstand expansions and contractions. Prior consideration of tolerances can help reducing manufacturing errors and simplify jointing requirements, and therefore, assist in the structures response to tangential movements induced by weather, wind, and structural dynamics. The tolerance design should be addressed in conjunction with the other interdependent tasks such as manufacturing so that manufacturing flaws can be avoided during the later stages. The following aspects should be applied in tolerance design for both jointing and making systemic patterns for the façade.

- Identify and design suitable jointing systems with recommended tolerances (for instance, from 3 mm to 5 mm).

- Fabricate grooves and inlays in the joints and create architectural design patterns to improve the façade (for instance, joints between panel walls, floors and walls, and marking sills should be provided with such grooves).

The inclusion of the aforesaid aspects of tolerance in the design process can yield flexible jointing systems and improve the façades aesthetics with higher precision.

4.4. Manufacturing physical elements/components

It is a transition phase between the design and assembly processes, where the manufacturing aspects are applied to manufacture building elements and components off the site. The inclusion of manufacturing issues into the design life cycle of IBS can help in predicting design-induced construction problems prior to production and onsite assembly. The manufacturing issues include cutting types, fastening methods (boring and nailing), durable assembly, selection of permissible cross sections (dimensions), and assembly properties (location and edges). The following design aspects related to issues including sequence, onsite assembly markings, and transportability should be considered.

- The designers must coordinate with the manufacturers to have an appreciation and understanding of the manufacturing process prior to the completion of the design.

- Manufacturers’ inputs in deriving the design specifications for the elements/components should be sought for achieving standardization, onsite assembly, and transportability.

- Suitable jointing systems—addressing both mountable and demountable issues—should be developed.

4.5. Assembly

Assembly relates to the design of architectonic entities in which the jointing systems are fabricated for assembling the building elements/components. The requirements of the assembly process that should be considered during the design process include the following: easy transportability and simplified man-handling, easy assembly using the least number of scaffoldings, requirement of minimal final finishing and trimming touches, and aesthetics of the element/components. The aspects required to achieve workability (i.e., feasibility) and improved performance (i.e., time and speed) in assembly design should include the following:

- The design of the building elements/components should incorporate the features required for onsite assembly.

- The joints should be designed to simplify the assembly process, deconstruction, and transportation.

- To enjoy engineering optimization, the design should consider to incorporate the use of construction equipments on the site.

- Trimming and finishing touches are the most critical tasks that should be considered in the jointing system so that the aesthetics of the building can be improved and the joints can be devoid of leakages and failures.

The aforesaid aspects should be addressed in conjunction with the other interdependent tasks to meet the strategic requirements of the assembly process. Applying these aspects in the early design phase improves form flexibility.

5. Limitation of the model

The integrated life cycle design for IBS constructions was developed using tropical timber material. Although most of the design tasks and the respective strategies were derived from the case study of live timber construction pursued in Seremban (Malaysia), they could be applied in the case of concrete and steel materials, too. However, the application of this model using other materials such as concrete and steel requires further investigations. Consequently, besides some additions and omissions, certain additional tasks and aspects might evolve. The findings of the integrated design life cycle model, including the process interdependencies, should be further validated before they are widely applied. As a result of this model, the architectonic aspects of several assembly joints were developed. The architectonic forms were specifically designed and developed for timber and were later patented; these patents are pending with the World Intellectual Patent Office (WIPO), European Patent Office (EPO), Australian Patent Office (APO), and Malaysian Patent Office (MYPO).

6. Conclusion

Conducting research on the use of timber in IBS constructions is the first of its kind in Malaysia. Literature review has shown that few scholarly works have investigated the incorporation of manufacturability that facilitates creativity in design. The ethnography of the Seremban timber house model significantly contributed toward formulating various tasks and aspects that enunciate the integration of IBS into the design life cycle. The ethnography process led to the generation of documentation for the entire model development process, and subsequently, the construction process, which led to the categorization of tasks and respective aspects. It also led to the identification of both explicit and implicit processes during prefabrication. The integrated model, as described in this article, focuses on the core task of defragmentation and other interdependent tasks; this model exhibited improved form flexibility. The interfaces of all the stakeholders involved in the design showed improved communication and better design outcomes, thereby achieving the core benefits of the IBS. The findings of the integrated design life cycle model including the process interdependencies should be further validated before they are widely applied using other construction material including concrete and steel.

Acknowledgement

This research was partly sponsored by Universiti Putra Malaysia . The authors acknowledge the significant contributions received from the Centre for Real Estate Studies, Universiti Teknologi Malaysia, in successfully completing this article. Gratitude is also expressed toward Ms. Daniele Rambaldini, whose constructive suggestions greatly contributed to develop the ethnography model.

References

- Atkinson et al., 1999 P. Atkinson, A. Coffey, S. Delamont; Ethnography: post, past and present; Journal of Contemporary Ethnography, 28 (5) (1999), pp. 460–471

- Badir et al., 2002 Y.F. Badir, M.R.A. Kadir, A.H. Hashim; Industrialized building systems construction in Malaysia; Journal of Architectural Engineering, 8 (2002), pp. 19–23

- Benros and Duarte, 2009 D. Benros, J.P. Duarte; An integrated system for providing mass customized housing; Automation in Construction., 8 (1) (2009), pp. 310–320

- CIDB, 2006 CIDB, 2006. Construction industry master plan Malaysia 2006–2015. Kuala Lumpur, Malaysia: Construction Industry Development Board (CIDB).

- CIDB, 2003 CIDB, 2003. IBS Survey 2003. Kuala Lumpur, Malaysia: CIDB.

- Davidson, 1990 Davidson, C.H., 1990. Open industrialization: a technical and organizational prerequisite. Paper Presented at Open Industrialization: A Solution for Building Modernization, Stuttgart.

- Do and Gross, 2001 E.Y.-L. Do, M.D. Gross; Thinking with diagrams in architectural design; Artificial Intelligence Review, 15 (2001), pp. 135–149

- Gann and Senker, 1993 D. Gann, P. Senker; International trends in construction technologies and the future of house building; Futures, 25 (1993), pp. 53–65

- Gibb, 1999 A.G. Gibb; Off-site fabrication: pre-assembly, prefabrication and modularization; Whittles Publishing Services, Caithness (1999)

- Gibb, 2001 A.G. Gibb; Standardization and pre-assembly-distinguishing myth from reality using case study research; Construction Management and Economics, 19 (2001), p. 307

- Gibbs, 2007 G.R. Gibbs; Analysing Qualitative Data, vol. 6, Sage Publications Limited, London (2007)

- Hamid et al., 2008 Z. Hamid, K.A.M. Kamar, M. Zain, K. Ghani, A.H.A. Rahim; Industrialized building systems (IBS) in Malaysia: the current state and R&D initiatives; Malaysian Construction Research Journal, 2 (2008), pp. 1–13

- Hassim et al., 2009 S. Hassim, M.S. Jaafar, S.A. Sazalli; The contractor perception towers industrialised building system risk in construction projects in Malaysia; American Journal of Applied Sciences, 6 (2009), pp. 937–942

- Howes, 2002 R. Howes; Industrialized housing construction—the UK experience; Advances in Building Technology, 1 (2002), pp. 383–390

- IEM, 2003 IEM, 2003. A need for new building technologies. In: Proceedings of the International Conference on Industrialized Building Systems, Malaysia, 10–11 September, 2003.

- Jaillon and Poon, 2009 L. Jaillon, C.S. Poon; The evolution of prefabricated residential building systems in Hong Kong: a review of the public and the private sector; Automation in Construction, 18 (2009), pp. 239–248

- Junid, 1986 Junid, S.M.S., 1986. Industrialized building systems. In: Proceedings of UNESCO/FEISEAP Regional Workshop, UPM, Serdang, Selangor.

- Kamar et al., 2009 Kamar, K.A.M., Alshawi, M., Hamid, Z., 2009. Barriers to industrialized building systems: the case of Malaysia, In: Proceedings of the BuHu 9th International Postgraduate Research Conference (IPGRC 2009), University of Salford, Salford, UK, 29–30 January, 2009.

- Lessing et al., 2005 Lessing, J., Stehn, L., Ekholm, A., 2005. Industrialised housing: definition and categorization of the concept. In: Proceedings of IGLC-13, Sydney, Australia.

- Majid et al., 2010 Majid, T.A., Azman, M.N.A., Zakaria, S.A.S., Zaini, S.S., Yahya, A.S., Ahamad, M.S.S., Hanafi, M.H., 2010. The industrialized building system (IBS) survey report 2008—educating the Malaysian construction industry. In: Proceedings of the Computer Research and Development, 2010s International Conference on IEEE. pp. 615–619

- Mawdesley and Long, 2002 Mawdesley. M.J., Long, G., 2002. Prefabrication for lean building service distribution. Paper Presented at Proceedings IGLC, Gramado, Brazil.

- Padrid, 1997 Padrid, W., 1997. Global trends in research, development and construction. In: Proceedings of the International Conference on Industrialized Building System, CIDB, Malaysia.

- Saleh et al., 2003 J.H. Saleh, D.E. Hastings, D.J. Newman; Flexibility in system design and implications for aerospace systems; Acta Astronautica, 53 (2003), pp. 927–944

- Sarja and Hannus, 1996 A. Sarja, M. Hannus; Modular systematics for the industrialized building; Technical Research Center of Finland, VTT Publications, Espoo (1996)

- Sarja, 1998 A. Sarja; Open and Industrialised Building, vol. 2, E. & F.N. Spon, London, United Kingdom (1998)

- Spradley, 1979 J.P. Spradley; The Ethnographic Interview; Harcourt Brace Jovanovich College Publishers, Orlando, Florida (1979)

- Trikha, 1999 Trikha, D.N., 1999. Industrialized building system: prospect in Malaysia. In: Proceeding of World Engineering Congress, Kuala Lumpur.

- Tam et al., 2007 V.W. Tam, C.M. Tam, S.X. Zeng, W.C. Ng; Towards adoption of prefabrication in construction; Building and Environment, 42 (2007), pp. 3642–3654

- Thanoon et al., 2003 Thanoon, W.A., Peng, L.W., Kadir, M.R.A., Jaafar, M.S., Salit, M.S., 2003. The essential characteristics of industrialized building system. In: Proceedings of the International Conference on Industrialized Building Systems, Malaysia, 10 September 2003. p. 89–96.

- Walch, 2001 Walch, Karin, D.I., 2001. Industrial prefabrication: Buildings mass-produced or made to measure. Paper Presented at 6th E3 Building Workshop, Vienna.

- Warszawski, 1999 A. Warszawski; Industrialized and Automated Building Systems: A Managerial Approach; E. & F.N. Spon, London, United Kingdom (1999)

Document information

Published on 12/05/17

Submitted on 12/05/17

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?