1 Introduction

Additive manufacturing (AM) is one of the most promising areas in the fabrication of components from prototypes to functional structures with complex geometries [1-11]. Compared to conventional methods, AM technologies can shorten the design manufacturing cycle, reduce production costs and increase competitiveness [8-10]. AM technology is a very broad term encompassing numerous methods such as Stereolithography (STL) of a photopolymer liquid, Fused Deposition Modelling (FDM) from polymer filaments, Laminated Object Manufacturing (LOM) from plastic laminations, and Selective Laser Sintering (SLS) from plastic or metal powders [3], [12]. However, the FDM technique is of particular interest due to its relative low cost, low material wastage and ease of use [7]. FDM forms a 3D geometry through the deposition of successive layers of extruded thermoplastic filament, such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), polypropylene (PP) or polyethylene (PE). In addition, engineering thermoplastics with improved mechanical performance, such as polyamide (PA or Nylon), polycarbonate (PC), polyetheretherketone (PEEK), polyetherimide (PEI), polyethersulfone (PES) or polyphenylene sulfide (PPS) are also available [13]. Due to this process, delamination of the component layers can occur resulting in premature failure. Additionally, FDM printed parts typically have lower elastic properties than injection-moulded components of the same thermoplastic [3].

FDM has started to move beyond its initial role as prototyping technology to a process that can build finished parts. However, most of 3D printed polymer products are still used as conceptual prototypes rather than functional components, since pure polymer products built by FDM are lack of strength and functionality as fully functional and load-bearing parts [14-17]. Furthermore, mechanical properties of parts fabricated by conventional FDM are inherently poor because of the thermoplastic resin used, although the optimization of processing parameters, such as build orientation, layer thickness or feed rate, has been investigated for improving the mechanical properties of thermoplastic parts [7], [11], [18-19]. Such drawbacks restrict the wide industrial application of 3D printed thermoplastic polymers, leaving prototyping as the primary application [14].

However, there has been an increasing interest in introducing these technologies in the manufacturing of primary structural parts. 3D printing of polymer composites with enhanced mechanical properties solves the previous limitations by the addition of reinforcements, such as particles, fibres or nanomaterials, into thermoplastic polymers permitting the fabrication of polymer matrix composites, which are characterized by high performance and excellent functionality [8], [10], [20]. However, these composites show poor mechanical properties compared to composites manufactured by conventional methods, because composites reinforced with short fibres or particles are mechanically lower to composites reinforced with continuous fibres. The possibility of employing continuous fibre reinforced thermoplastic composites may lead to product with much higher mechanical performance, which are potentially useful for advanced applications [21]. FDM is a promising alternative of conventional processes for the fabrication of CFRTPCs, such as vacuum forming, filament winding, pultrusion, bladder-assisted moulding or compression, that require expensive facilities and equipment, such as autoclaves or complex rigid moulds for out-of-autoclave processes, hindering the wide application of composites [13], [22-23]. The use of FDM for the manufacturing of CFRTPCs has not been extensively investigated in literature [3], [9-10], [14], [16], [20], [24-26].

FDM is a complex process with a large number of parameters that influence product quality and material properties, and the combination of these parameters is often difficult to understand [7], [11], [27-28]. Different combinations of fibre reinforcements and thermoplastic matrix have been analysed in the literature: continuous carbon, glass or Kevlar® fibre reinforcements embedded in PLA, ABS or nylon thermoplastic composites [8-10]. The results of the previous studies have shown an increase in mechanical strength of continuous fibre reinforced 3D printed composite structures compared to pure thermoplastic 3D printed structures. However, the level of increase in strength was moderated upon continued increase in fibre content due to weak bonding between the fibre/matrix layers as well as the presence of increased levels of air voids (porosity) with fibre content. Since mechanical properties are crucial for functional parts, it is essential to examine the influence of process parameters on mechanical performance [9], [29].

In this study, the characterization and assessment of the effect of build orientation, layer thickness and fibre volume content on the mechanical properties of 3D printed continuous fibre reinforced composites components manufactured by FDM technique are examined. In addition, SEM images of fractured surfaces of tensile samples are evaluated to determine the effects of process parameters on failure modes. Finally, the practicality of the previous results is assessed further by testing a functionally static load-bearing assembly as a case example.

The rest of the paper is organized as follows. First, the experimental methodology carried out in this study is briefly summarized with particular emphasis on specimen preparation, 3D printing process and the experimental set-up. Thereafter, the key results of the investigation are summarized, and the effects of the different process parameters are highlighted. Finally, conclusions and extensions of this work are outlined.

2 Experimental methodology

2.1 Materials, 3D printer and specimen preparation

The goal of this study is to analyse the mechanical performance of 3D printed CFRTPCs samples. Nylon filament (matrix) was supplied by Markforged® with a diameter of 1.75 mm. Prior to use, this thermoplastic polymer was store in a Pelican® 1430 modified dry box to minimize moisture absorption in the same way as the manufactured specimens prior to testing [7]. The reinforced fibres, such as glass, carbon and Kevlar®, were also supplied by Markforged®. The fibre filaments consisted on a mixture of a bundle of long fibres and a polymer resin (nylon), forming a preimpregnated-like material. The fibre volume fraction of the fibre bundles has been studied and it turned out to be an average value of 34.5%. This value is in good agreement with the results of Klift et at [24] and Justo et al [16]. The blinder is a polymer resin (nylon) that melts in the print head and ensures that the fibres will adhere to the previous layers.

The basic stiffness and strength properties of nylon and continuous fibres used in this study are depicted in Table 1 [30].

| Properties | Nylon | Carbon | Glass | Kevlar |

| Tensile Strength (MPa) | 54 | 700 | 590 | 610 |

| Tensile Modulus (MPa) | 940 | 54000 | 21000 | 27000 |

| Tensile strain at Break (%) | 260 | 1.5 | 3.8 | 2.7 |

| Flexural Strength (MPa) | 32 | 470 | 210 | 190 |

| Flexural Modulus (MPa) | 840 | 51000 | 22000 | 26000 |

| Izod Impact notched (J/m) | 1015 | 958 | 2603 | 1873 |

| Density (g/cm3) | 1.1 | 1.4 | 1.5 | 1.2 |

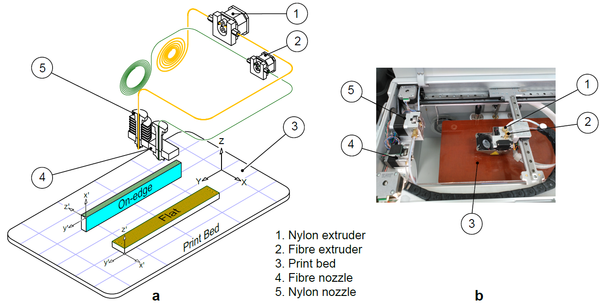

3D printed CFRTPCs samples were manufactured using a MarkForged® MarkTwo desktop 3D printer. This system can print two kind of materials independently and, hence, it has two extruders and two print heads (Figure 1). One of the print heads is used to extrude nylon (matrix) and the other one is used to print fibre reinforcement. The nylon and fibre layers are printed with a hot end temperature of 273 ºC and 232 ºC, respectively, on a non-heated print bed. Carbon fibre was printed in layers of 0.125 mm and Kevlar® and glass fibres were printed in layers of 0.1 mm. The design of the 3D printer allows continuous fibre reinforcement to be placed as required. It allows specifying the fibre orientation on the layer-by-layer deposition process. MarkTwo uses its own software designated as Eiger®. This software allows to import .STL and .OBJ models.

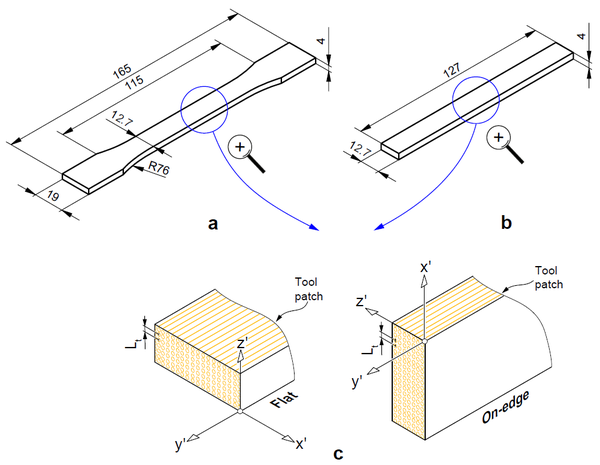

There are no standard test methods for determining tensile and flexural properties of CFRTPCs parts manufactured using FDM. In this study, the ASTM D3039 [31 and D790 [32] methods were applied for testing tensile and flexural specimens, respectively. The geometry of the 3D printed specimens were modelled using SolidWorks®, exported as an STL file and imported to the 3D printing software. Two types of fibre pattern can be selected in the MarkForged® MarkTwo desktop 3D printer: concentric and isotropic. In this study, isotropic fibre patterns were analysed. The term “isotropic” does not define the mechanical properties of the test specimens. Isotropic fill is in this case resulted in an unidirectional anisotropic specimen. Furthermore, the isotropic pattern was observed to yield higher tensile strength and stiffness than concentric pattern [14]. The main dimensions and details of layer thickness and build orientation (Flat and On-edge) of the 3D printed specimens are shown in Figure 2.

2.2 Process parameters

The mechanical properties of parts fabricated using FDM technologies depend on the selection of process parameters [7], [10], [33]. Two types of specimens have been considered: unreinforced and continuous reinforced nylon specimens. Two build orientations were assessed: Flat and On-edge, where the fused filament deposition and reinforcements were positioned in the direction of the longest dimension of the 3D printed specimen. Two different layer thickness were used for continuous reinforced specimens: Lt = 0.125 mm for carbon fibres and Lt = 0.1 mm for glass and Kevlar® fibres. The usual minimum layer thickness found in the literature was Lt = 0.1 mm [3]. Furthermore, different fibre volume contents were considered: partially and fully reinforced specimens. At least two nylon layers must be added in each specimen (roof and floor layers). For ease of reference purposes, partially reinforced specimens are labelled as Types A and B and fully reinforced specimens are labelled as Type C.

Table 2 outlines the fibre volume content of partially reinforced samples (Type A and Type B) and fully reinforced samples (Type C) of the different type of fibre reinforcements (Carbon, Kevlar and Glass fibres) as a function of the build orientations (Flat and On-edge orientations).Types A and B were selected with similar fibre volume content in both build orientations (Flat and On-edge) for comparative purposes. Type C depicts different fibre volume content for Flat and On-edge orientations due to different internal structure of the 3D printed nylon specimens as a function of the build orientation. Flat and On-edge samples show different fixed nylon volume content because of their different internal structure, and, hence, different maximum fibre volume content could be achieved. These fibre volume contents helped to assess the effect of the fibre content (fibre layers) on the mechanical performance and gained an insight into the failure modes bonding response of fibre-fibre and fibre-matrix interfaces.

| Fibre volume content (%) | Type A | Type B | Type C |

| Carbon fibre | |||

| Flat | 1.88 | 15.07 | 26.38 |

| On-edge | 2.03 | 15.06 | 19.96 |

| Kevlar fibre | |||

| Flat | 3.01 | 15.07 | 27.13 |

| On-edge | 2.93 | 14.99 | 20.04 |

| Glass fibre | |||

| Flat | 3.01 | 15.07 | 27.13 |

| On-edge | 2.93 | 14.99 | 20.04 |

Certain parameters, such as temperature, feed rate, fill density and pattern of the thermoplastic matrix (nylon) and fibre angle or fibre fill type (isotropic) were fixed for all the samples in order to focus on the influence of the previous parameters.

3 Results and discussion

Average and standard deviation of the test results of the maximum strength (σt, σf) and stiffness (Et, Ef) for the 3D printed composites samples are tabulated for reinforced nylon samples in Tables 3 and 4.

| Build orientation | Type A

σt (MPa) |

Type B

σt (MPa) |

Type C

σt (MPa) |

| Carbon fibre | |||

| Flat | 96.6(1.3) | 239.8(14.9) | 436.7(6.2) |

| On-edge | 63.9(0.5) | 177.2(7.9) | 341.2(10.2) |

| Kevlar fibre | |||

| Flat | 97.1(2.1) | 211.7(4.9) | 305.2(36.2) |

| On-edge | 55.8(1.9) | 127.5(7.1) | 235.6(2.1) |

| Glass fibre | |||

| Flat | 113.4(2.5) | 235.9(11.0) | 381.2(28.1) |

| On-edge | 66.8(2.3) | 146.2(8.1) | 295.2(23.5) |

| Build orientation | Type A

σf (MPa) |

Type B

σf (MPa) |

Type C

σf (MPa) |

| Carbon fibre | |||

| Flat | 80.7(6.7) | 355.6(35.1) | 423.5(10.3) |

| On-edge | 38.1(0.4) | 122.3(8.4) | 157.1(5.5) |

| Kevlar fibre | |||

| Flat | 85.3(11.3) | 162.1(3.2) | 189.8(2.5) |

| On-edge | 37.9(1.6) | 61.7(1.2) | 73.8(2.1) |

| Glass fibre | |||

| Flat | 121.1(21.5) | 170.7(23.8) | 205.1(6.4) |

| On-edge | 37.5(3.4) | 71.2(2.6) | 97.9(4.6) |

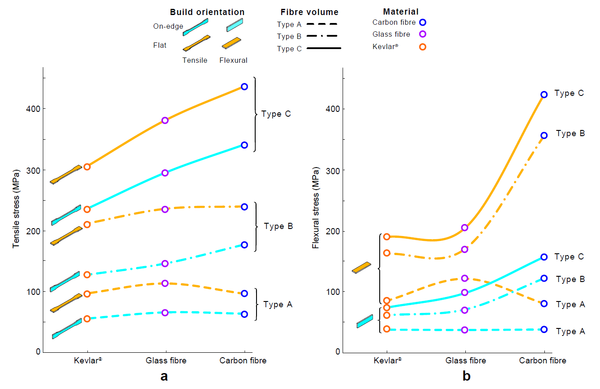

In order to clarify the results for a better understand of the correlation between the different ranges of process parameters on mechanical performance, the graphical representation of these results is shown in Figure 3. These figure shows the average maximum tensile and flexural strengths as a function of layer thickness and fibre volume content, respectively.

The bonding performance of the interface between fibres and matrix is a main factor for the mechanical performance of 3D printed composite structures. The maximum achievable strength of 3D printed fibre reinforced composites is limited by the fibre-matrix interaction in porous areas [10], [14], [23], [25]. The role of type of fibre reinforcement (carbon, glass or Kevlar®), build orientation and fibre volume fraction on the mechanical strength and stiffness of 3D printed composite samples were analysed. It is important to note that, during the printing procedure, no pressure was applied after a layer was laid up. It is well known that pressure plays a fundamental role on the manufacturing of laminated parts from both thermoset and thermoplastic-based composites. The absence of pressure in highly viscous matrices is directly related to the presence of defects (pores or matrix-dominated areas) [14], [16], [25,26,34].

Tables 3 and 4 and Figure 3 depict the average and standard deviation of the maximum strength and stiffness for the 3D printed reinforced nylon samples. The results reveal that the type of fibre reinforcement, build orientation and fibre volume content significantly affected the mechanical performance of the 3D printed composite samples. The differences on mechanical properties of 3D printed composite samples due to the type of fibre reinforcement can be explained by the differences on mechanical properties of the individual continuous fibres. Table 1 depicts the mechanical performance of the nylon matrix and the individual continuous fibres. More specifically, it is observed that carbon fibre showed the best performance in terms of tensile and flexural strength and stiffness, while glass and Kevlar® fibres resulted in lower ones with similar values. Carbon fibres are known for their high stiffness-to-weight ratio but are expensive and, hence they are mainly used in industries such as automotive or aerospace industry. On the other hand, glass and Kevlar® fibres are relatively inexpensive, and exhibit fairly good mechanical properties and they are suitable for parts that are less stringent on weight and strength, so that parts can be manufactured at lower cost. In addition, Kevlar® fibres are well known for its enhanced impact properties. These observations were in good accordance with the results of 3D printed reinforced samples depicted in Tables 4 and 5. The advantage of using carbon fibre to reinforce a 3D printed part was further evident from the flexural results, as the stiffness of the samples reinforced with carbon fibre are twice that of Kevlar® and three times that achieved using glass fibre. For example, an increase in tensile and flexural strength was observed from nylon samples to Type C flat composite samples for the three fibre reinforcements, increasing by 1313% and 1888% for carbon fibre, 887% and 791% for Kevlar® fibre and 1133% and 863% for glass fibre samples. These improvements in mechanical performance are even higher in terms of stiffness. Tensile and flexural testing demonstrated strengths of up to 436 MPa for tensile and 423.5 MPa for flexural loading with Type C, which are higher that the reported results of some non-ferrous metal alloys, such as Aluminium 6061-T6 [14].

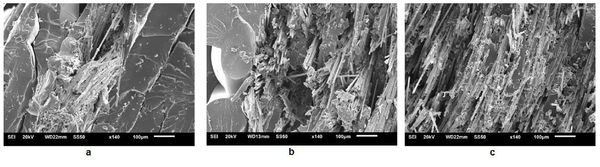

In addition, Figure 4 shows SEM images with the details of the tensile fractured surfaces of flat oriented carbon fibre reinforced samples as a function of the type of the fibre volume content. For example, an increase of fibre content from Type A flat samples to Type C flat samples tended to promote higher tensile and flexural strength (352% and 424.7%, respectively). In the case of Kevlar® and glass fibres, increasing fibre content from Type A to Type C depicted an increasing trend of tensile and flexural strength, but to a lesser extent than carbon fibre reinforced samples (214% and 122% for Kevlar® and 236% and 125% for glass fibres samples). In addition, Type A glass fibre reinforced samples showed a more efficient mechanical performance than carbon and Kevlar® reinforced samples, with higher strength and stiffness. However, the level of increase in strength and stiffness for the different fibre reinforcements was moderated from Type B to Type C upon continued increase in fibre volume content. This effect was more remarkable in the case of Kevlar® and glass fibre reinforced samples. The addition of fibres had two opposite effects. On one hand, it could prevent crack propagation efficiently, which contributed to the improvement of the strength and stiffness of the reinforced samples. On the other hand, the increase of fibre content could increase the defect density due to weak bonding between the fibre/matrix layers as well as the presence of increased levels of air voids (porosity) with fibre content. In addition, fibre reinforced samples showed poor wettability of bundles by the nylon and, hence, weaker bonding between fibres and matrix (nylon). These results were in agreement with previous findings [14], [34].

4 Conclusions

The mechanical performance of 3D printed continuous fibre reinforced thermoplastic composites was studied. Continuous glass, carbon and Kevlar® reinforced nylon composites were manufactured by FDM technology. Tensile and three-point bending tests were carried out to determine the mechanical response of the printed specimens following the ASTM standard recommendations. Different ranges of three main process parameters were analysed: layer thickness of unreinforced samples (Lt = {0.1, 0.125, 0.2} mm), build orientation (flat and on-edge) and fibre volume content (Types A, B and C). The practicality of the results was assessed by testing an evaluation structure.

It has shown that the effect of layer thickness on the mechanical performance of nylon specimens was marginally significant. It was observed that flat orientation showed the highest values for maximum tensile and flexural strength and stiffness in most cases.

Moreover, the effects of build orientation, the type of reinforcement and fibre volume content on the mechanical performance of reinforced nylon specimens were of particular significance. Flat samples exhibited higher values of strength and stiffness than on-edge samples. Furthermore, carbon fibre reinforced composites exhibited the best tensile and flexural strength performance with higher stiffness. On the other hand, Kevlar® fibre reinforced composites had the lowest mechanical performance. By reason of the anisotropic nature of Kevlar® fibre, the compressive strength was much lower than that of glass and carbon fibres. Thus, its composite easily failed due to the failure of fibres under compression (and hence flexural performance was also lower). Extensively fibre pull-out and minor fibre breakage was observed for the fibre reinforcement. The extensive pull-out indicated improper coating of nylon matrix onto the fibre surface during the manufacturing of composite filament and poor interfacial bonding between matrix and fibres.

Finally, the results have shown that strength and stiffness increased as fibre volume content increased, depending on build orientation. Nevertheless, the level of increase in mechanical performance was moderate with continued increase in fibre content, particularly in the case of Kevlar® and glass fibres. This was in part due to weak bonding between the fibre/nylon layers as well as the presence of increased levels of defects. Hence, in the light of the previous conclusions, a logical recommendation was to print flat in order to save time and money, with improved mechanical performance.

The results have shown that it is still a challenge to increase the mechanical performance of 3D printed continuous fibre reinforced composite materials with respect to the autoclave manufacturing of common prepreg materials. A compaction stage after the deposition of the filament would be desirable to reduce porosity. FDM composite parts have lower fibre volume fractions than the pre-pregs materials used as reference [16]. These were the main causes for the differences found in tensile and flexural properties. Nevertheless, the properties obtained by 3D printed continuous reinforced composites by FDM are significantly higher than the usual 3D FDM thermoplastics.

In conclusion, 3D printing of continuous fibre-reinforced parts complements the existing composite manufacturing processes by taking advantage of the complexity that FDM enables in the design of composite parts. Hence, it seems to be a very promising procedure for the manufacturing of 3D printed continuous fibre-reinforced composite parts once some of the current disadvantages are overcome. It is a relatively new technique and there is a lack of experimental data on the mechanical performance of structures manufactured by this process, underscoring the need for further research to improve our understanding of the mechanical behaviour of 3D printed composites. In addition, further work is required for the characterization of complex parts made with this technology and the study of a treatment to reduce the porosity and low interlayer bonding strength of the parts and maybe including a compaction stage.

Acknowledgements

This research was supported by the Spanish Ministerio de Economía y Competitividad (Plan Nacional de I+D+i), under research grants DPI2016-77715-R and DPI2015-65472-R, co-financed by the ERDF (European Regional Development Fund) and Grants no. GI20163590 and GI20174156 financed by University of Castilla-la Mancha. I García-Moreno would like to acknowledge the financial support of the Castilla-La Mancha Government (JCCM) and the ERDF (SBPLY/16/180501/000041). J.M. Reverte also would like to acknowledge the financial support of Spanish Ministerio de Economía y Competitividad (Plan Nacional de I+D+i) under research grant BES-2016-076639.

References

[1] B. M. Tymrak, M. Kreiger, J. M. Pearce, Mechanical properties of components fabricated with open-source 3D printers under realistic environmental conditions. Materials and Design 58 (2014) 242-246.

[2] M. Sugavaneswaran, G. Arumaikkannu. Analytical and experimental investigation on elastic modulus or reinforced additive manufactured structure. Materials and Design 66 (2015) 29-36.

[3] G. W. Melenka, B. K. O. Cheung, J. S. Schofield, M. R. Dawson, J. P. Carey. Evaluation and prediction of the tensile properties of continuous fiber-reinforced 3D printed structures. Composite Structures 153 (2016) 866-875.

[4] M. Domingo, J. M. Puigriol, A. A. Garcia, J. Lluma, S. Borros, G. Reyes. Mechanical property characterization and simulation of fused deposition modeling polycarbonate parts. Materials and Design 83 (2015) 670-677.

[5] C. Casavola, A. Cazzato, V. Moramarco, C. Pappalettere. Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory. Materials and Design 90 (2016) 453-458.

[6] B. Rankouhi, S. Javadpour, F. Delfanian, T. Letcher. Failure analysis and mechanical characterization of 3D printed ABS respect to later thickness and orientation. Journal of Failure Analysis and Prevention 16 (2016) 467-481.

[7] J. M. Chacón, M. A. Caminero, E. García-Plaza, P. J. Nuñez. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Materials and Design 124 (2017) 143-157.

[8] T. Hofstatter, D. B. Pedersen, G. Tosello, H. N. Hansen. State-of-the-art of fiber-reinforced polymers in additive manufacturing technologies. Journal of Reinforced Plastics Composites 36 (2017) 1061-1073.

[9] P. Parandoush, D. Lin. A review on additive manufacturing of polymer-fiber composites. Composite Structures 182 (2017) 36-53.

[10] X. Wang, M. Jiang, Z. Zhou, J. Gou, D. Hui. 3D printing of polymer matrix: A review and prospective. Composites: Part B 110 (2017) 442-458.

[11] Y. Song, Y. Li, W. Song, K. Y. Lee, V. L. Tagarielli. Measurements of the mechanical response of unidirectional 3D-printed PLA. Materials and Design 123 (2017) 154-164.

[12] J. Kotlinski. Mechanical properties of commercial rapid prototyping materials. Rapid prototyping Journal 20 (2014) 499-510.

[13] S. S. Yao, F. L. Jin, K. Y. Rhee, D. Hui, S. J. Park. Recent advances in carbon fiber-reinforced thermoplastic composites: A review. Composites: Part B 142 (2018) 241-250.

[14] A. N. Dickson, J. N. Barry, K. A. McDonnell, D. P. Dowling. Fabrication of continuous carbon, glass and kevlar fibre reinforced polymer composites using additive manufacturing. Additive Manufacturing 16 (2017) 146-152.

[15] Y. Nakagawa, K. I. Mori, T. Maeno. 3D printing of carbon fibre-reinforced plastic parts. The International Journal of Advanced Manufacturing Technology 91 (2017) 2811-2817.

[16] J. Justo, K. Tavara, L. Garcia-Guzman, F. Paris. Characterization of 3D printed long fibre reinforced composites. Composite Structures 185 (2018) 537-548.

[17] H. A. Albadi, H. T. Thai, V. Paton-Cole, V. I. Patel. Elastic properties of 3D printed fibre reinforced structures. Composite Structures 193 (2018) 8-18.

[18] N. Aliheidari, R. Tripuranenia, A. Ameli, S. Nadimpalli. Fracture resistance measurement of fused deposition modeling 3D printed polymers. Polymer Testing 60 (2017) 94-101.

[19] W. Gao, Y. Zhang, D. Ramanujan, K. Ramani, Y. Chen, C. B. Williams, C. C. L. Wang, Y. C. Shin, S. Zhang, P. D. Zavattieri. The status, challenges, and future of additive manufacturing in engineering. Computer-Aided Design 69 (2015) 65-89.

[20] R. Matsuzaki, M. Ueda, M. Namiki, K. Joeong, H. Asahara, K. Horiguchi, T. Nakamura, A. Todoroki, Y. Hirano. Three dimensional printing of continuous fibre composites by in-nozzle impregnation. Scientific Reports 6 (2016) 23058.

[21] P. Bettini, G. Alitta, G. Sala, L. D. Landro. Fused deposition technique for continuous fiber reinforced thermoplastic. Journal of Materials Engineering and Performance 26 (2017) 843-848.

[22] X. Tian, T. Liu, C. Yang, Q. Wang, D. Li. Interface and performance of 3D printed continuous carbon fiber reinforce of PLA composites. Composites: Part A 88 (2016) 198-205.

[23] C. Yang, X. Tian, T. Liu, Y. Cao, D. Li. 3D printing for continuous fiber reinforced thermoplastic composites: mechanism and performance. Rapid Prototyping Journal 23 (2017) 209-215.

[24] F. van der Klift, Y. Koga, A. Todoroki, M. Ueda, Y. Hirano, R. Matsuzaki. 3D printing of continuous carbon fibre reinforced thermo-plastic CFRTP tensile test specimens. Open journal of composite materials 6 (2016) 18-27.

[25] M. A. Caminero, J. M. Chacón, I. Garcia-Moreno, J.M. Reverte. Interlaminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Polymer Testing 68 (2018) 415-423.

[26] M. A. Caminero, J. M. Chacón, I. Garcia-Moreno, G. P. Rodriguez. Impact damage resistance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Composites Part B 148 (2018) 93-103.

[27] R. J. Zaldivar, D. B. Witkin, T. McLouth, D. N. Patel, K. Schmitt, J. P. Nokes. Influence of processing and orientation print effects on the mechanical and thermal behaviour of 3D-printed ULTEM 9085 material. Additive Manufacturing 13 (2017) 71-80.

[28] J. R. C. Dizon, A. H. Espera, Q. Chen, R. C. Advincula. Mechanical characterization of 3D-printed polymers. Additive Manufacturing 20 (2018) 44-67.

[29] D.-A. Türk, F. Brenni, M. Zogg, M. Meboldt, Mechanical characterization of 3D printed polymers for fiber reinforced polymers processing, Mater. Des. 118 (2017) 256–265.

[30] MarkForged, MarkForged MarkTwo, Https://Markforged.Com/. (2018).

[31] D3039/D3039M. ASTM standard test method for tensile properties of polymer matrix composite materials. Annual book of ASTM standards 15 (2012) 1-10.

[32] D790. ASTM standard test method for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. Annual book of ASTM standards 10 (2010) 1-11.

[33] M. Fernandez-Vicente, W. Calle, S. Ferrandiz, A. Conejero. Effect of infill parameters on tensile mechanical behaviour in desktop 3D printing. 3D printing and Additive Manufacturing 3 (2016) 183-192.

[34] G.D. Goh, V. Dikshit, A.P. Nagalingam, G.L. Goh, S. Agarwala, S.L. Sing, J. Wei, W.Y. Yeong, Characterization of mechanical properties and fracture mode of additively manufactured carbon fiber and glass fiber reinforced thermoplastics, Mater. Des. 137 (2018) 79–89.

Document information

Published on 21/06/22

Accepted on 21/06/22

Submitted on 21/06/22

Volume 05 - Comunicaciones Matcomp19 (2021), Issue Núm. 3 - Procesos de Fabricación – Materiales Funcionales., 2022

DOI: 10.23967/r.matcomp.2022.06.032

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?