Abstract

Economic Load Dispatch (ELD) is the process of allocating the required load between the available generation units such that the cost of operation is minimized. The ELD problem is formulated as a nonlinear constrained optimization problem with both equality and inequality constraints. The dual-objective Combined Economic Emission Dispatch (CEED) problem is considering the environmental impacts that accumulated from emission of gaseous pollutants of fossil-fuelled power plants. In this paper, an implementation of Flower Pollination Algorithm (FPA) to solve ELD and CEED problems in power systems is discussed. Results obtained by the proposed FPA are compared with other optimization algorithms for various power systems. The results introduced in this paper show that the proposed FPA outlasts other techniques even for large scale power system considering valve point effect in terms of total cost and computational time.

Abbreviations

ELD , economic load dispatch ; CEED , combined economic emission dispatch ; FPA , flower pollination algorithm ; ED , economic dispatch ; FLC , fuzzy logic control ; ANN , artificial neural network ; EA , evolutionary algorithm ; GA , genetic algorithm ; SA , simulated annealing ; EP , evolutionary programming ; TS , Tabu search ; PSO , particle swarm optimization ; GSA , gravitational search algorithm ; ABC , artificial bee colony ; QP , quadratic programming ; DE , differential evolution ; PPSO , personal best-oriented PSO ; APPSO , adaptive personal-best oriented PSO ; MPSO , modified particle swarm optimization ; ARCGA , adaptive real coded GA ; TSAGA , Taguchi self-adaptive real-coded genetic algorithm ; CCPSO , PSO with both chaotic sequences and crossover operation ; CDE_SQP , combining of chaotic DE and quadratic programming ; EDA/DE , estimation of distribution and differential evolution cooperation ; SOMA , self-organizing migrating strategy ; CSOMA , cultural self-organizing migrating strategy ; DE/BBO , combination of differential evolution and biogeography-based optimization ; DHS , differential harmony search ; BBO , biogeography based optimization ; PSO–SQP , integrating PSO with the sequential quadratic programming ; GA–PS–SQP , hybrid algorithm consisting of GA, pattern search (PS) and SQP ; CPSO , chaotic particle swarm optimization ; CPSO–SQP , hybrid algorithm consisting of CPSO and SQP ; NPSO_LRS , new PSO with local random search ; CDEMD , cultural DE based on measure of populations diversity ; HMAPSO , hybrid multi agent based PSO ; FAPSO-NM , fuzzy adaptive PSO algorithm with Nelder–Mead ; ICA-PSO , improved coordinated aggregation-based PSO ; MODE , multiobjective differential evolution ; NSGA-II , non-dominated sorting genetic algorithm-II ; PDE , Pareto differential evolution ; SPEA-2 , strength Pareto evolutionary algorithm 2 ; ABC_PSO , ABC and PSO ; EMOCA , enhanced multi-objective cultural algorithm ; MABC/D/Cat , modified artificial bee colony with disruptive cat map ; MABC/D/Log , modified artificial bee colony with disruptive logistic map ; CPU , computational time ; NA , not available ; PV , photovoltaic

Keywords

Flower pollination algorithm ; Economic load dispatch ; Combined economic emission dispatch ; Emission constraints ; Valve point loading effect ; Swarm intelligence

Nomenclature

- The total fuel cost of generation in $

- The fuel cost function of generator in $

- The cost coefficients of generator in $/MW2 , $/MW and $ respectively

- The real power generation of generator in MW

d- The number of generators connected in the network

PD- The total load of the system in MW

PL- The transmission losses of the system in MW

, - The real power injections at and buses respectively

, , - The loss-coefficients of transmission loss formula

, - The minimum and maximum values of real power allowed at generator i

ei , fi- The coefficients of generator due to valve point effect in $ and MW−1 respectively

F- The optimal cost of total generation and emission

Fi (Pi ),Ei (Pi ) - The total fuel cost and total emission of generators respectively

a , b , c- The emission coefficients of generators in Kg/MW2 , Kg/MW and Kg respectively

ηi , δi- The emission coefficients of generator in Ton and MW−1 respectively

h- The price penalty factor value in $/Kg

- The pollen i

g * - The current best solution found at the current generation

γ- The scaling factor controlling the step size

Γ(λ ) - The standard gamma function

p- Switch probability

1. Introduction

Economic Dispatch (ED) problem has become a crucial task in the operation and planning of power system [1] . It is very complex to solve because of a nonlinear objective function and a large number of constraints. ED in power system deals with the determination of optimum generation schedule of available generators so that the total cost of generation is minimized within the system constraints [2] and [3] . Well known long-established techniques such as gradient method [4] , lambda iteration method [5] and [6] , linear programming [7] , quadratic programming [8] , Lagrangian multiplier method [9] , and classical technique based on co-ordination equations [10] are applied to solve ELD problems. These conventional methods cannot perform satisfactorily for solving such problems as they are sensitive to initial estimates and converge into local optimal solution in addition to its computational complexity.

During the last decades many researches and techniques had dealt with ELD problems. Fuzzy Logic Control (FLC) has attracted the attention in control applications. In contrast with the conventional techniques, FLC formulates the control action in terms of linguistic rules drawn from the behavior of a human operator rather than in terms of an algorithm synthesized from a model of the system [11] , [12] , [13] and [14] . However, it requests more fine tuning and simulation before operational. Another technique like Artificial Neural Network (ANN) has its own advantages and disadvantages. The characteristics of the system is enhanced by ANN, but the main problem of this technique is the long training time, the selecting number of layers and the number of neurons in each layer [6] , [15] , [16] and [17] .

An alternative approach is to employ Evolutionary Algorithm (EA) techniques. Due to its ability to treat nonlinear objective functions, EA is believed to be very effective to deal with ELD problem. Among the EA techniques, Genetic Algorithm (GA) is introduced in References [18] and [19] , but it requires a very long run time depending on the size of the system under study. Also, it gives rise to repeat revisiting of the same suboptimal solutions. Simulated Annealing (SA) is illustrated in References [20] and [21] , but this technique might fail by getting trapped in one of the local optimal. Evolutionary Programming (EP) is discussed in Reference 22 , but it has a slow convergence rate for large problem. Improved Tabu Search (TS) is introduced in Reference 23 , but the efficiency of this algorithm is reduced by the use of highly epistatic objective functions and the large number of parameters to be optimized. Also, it is a time-consuming method. Ant swarm optimization is presented in Reference 24 , but its theoretical analysis is difficult and probability distribution changes by iteration. Particle Swarm Optimization (PSO) is discussed in References [25] , [26] , [27] and [28] , but it pains from the partial optimism. Moreover, the algorithm cannot work out the problems of scattering and optimization. Gravitational Search Algorithm (GSA) in illustrated in Reference 29 . However, this algorithm appears to be effective for solving ELD problem, it has poor performance at the later search stage due to the lack of agents' diversity in GSA. Artificial Bee Colony (ABC) is developed in Reference 30 to solve the complex non-linear optimization problem, but it is slow to converge and the processes of the exploration and exploitation contradict with each other, so the two abilities should be well balanced for achieving good optimization performance. On the other hand, FPA has only one key parameter p (switch probability) which makes the algorithm easier to implement and faster to reach optimum solution. Moreover, this transferring switch between local and global pollination can guarantee escaping from local minimum solution. Thus, FPA is proposed in this paper to overcome the previous drawbacks. In addition, it is clear from the literature survey that the application of FPA to solve ELD and CEED problems has not been discussed. This encourages us to adopt FPA to deal with these problems.

In this paper, a new approach for solving ELD and CEED problems using FPA methodology is discussed considering the power limits of the generator. The purpose of CEED is to minimize both the operating fuel cost and emission level simultaneously while satisfying load demand and operational constraints. This multi-objective CEED problem is converted into a single objective function using a modified price penalty factor approach. FPA is investigated to determine the optimal loading of generators in power systems. Simulations results for small and large scale power system considering the valve loading effect are implemented to indicate the robustness of FPA.

The remainder of this paper is organized as follows: Section 2 provides a brief description and mathematical formulation of ELD and CEED problems. In section 3 , the concept of FPA is discussed. Section 4 shows the result on three, ten and forty unit thermal test systems. Finally, the conclusion and future work of research are outlined in section 5 .

2. Problem formulation

The CEED problem is to minimize two computing objective functions simultaneously, fuel cost and emission, while satisfying various equality and inequality constraints. Generally the problem is formulated as follows.

2.1. Objective function of ELD

For thermal generating units, the cost of fuel per unit power output varies significantly with the output power of the unit. Fuel costs are usually represented as a quadratic function of output power [31] , as shown in equation (1) .

|

|

( 1) |

Minimize

|

|

( 2) |

The minimization is performed subject to the equality constraint that the total generation must equal to the demand plus the loss thus:

|

|

( 3) |

The total transmission loss using Krons loss formula is given in equation (4)

|

|

( 4) |

It is assumed with little error that these coefficients are constant (as long as operation is near the value where these coefficients are computed).

Based on the maximum and minimum power limits of generators the inequality constraint is

|

|

( 5) |

2.2. Effect of valve point on fuel cost objective

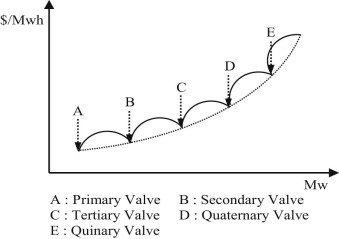

To be more practical, the valve point effect is taken into account in the cost function of generators. The sharp increase in losses due to the wire drawing effects which occur as each steam admission valve starts to open leads to the nonlinear rippled input output curve [32] as shown in Fig. 1 . The obtained cost function based on the rippled curve is more accurate modeling. Thus, the fuel cost function of each fossil fuel generator is given as the sum of a quadratic and a sinusoidal function [33] .

|

|

( 6) |

|

|

|

Fig. 1. Valve point effect. |

2.3. Objective function of CEED

The atmospheric pollutants such as sulfur oxides, nitrogen oxides and carbon dioxide caused by fossil fuel fired generator can be modeled separately [34] , [35] and [36] . However, for comparison purposes, the total emission of these pollutants which is the sum of a quadratic and an exponential function can be expressed as [37] and [38] :

|

|

( 7) |

Optimization of generation cost has been formulated based on classical ELD with emission and line flow constraints. The detailed problem is given as follows [38] .

|

|

( 8) |

The minimum value of the above objective function has to be found out subject to equality and inequality constraints given by equations (3) and (5) . The dual-objective CEED problem is converted into single optimization problem by introducing a price penalty factor h as follows [39] .

|

|

( 9) |

Subject to constraints given by equations (3) and (5) , the price penalty factor h , which is the ratio between the maximum fuel cost and maximum emission of corresponding generator in $/Kg [30] and [33] , blends the emission with fuel cost, then F is the total operating cost in $.

|

|

( 10) |

The following steps are used to find the price penalty factor for a particular load demand:

- Find the ratio between maximum fuel cost and maximum emission of each generator.

- Arrange the values of price penalty factor in ascending order.

- Add the maximum capacity of each unit ( ) one at a time, starting from the smallest hi , until .

- At this point, which associated with the last unit in this process is the approximate price penalty factor value (h ) for the given load.

Hence, a modified price penalty factor (h ) is used to give the exact value for the particular load demand by interpolating the values of (h ), corresponding to their load demand values.

3. Overview of flower pollination algorithm

FPA was developed by Yang in 2012 [40] . It is inspired by the pollination process of flowering plants. Real-world design problems in engineering and industry are usually multiobjective. These multiple objectives often conflict with one another. Also, they have additional challenging issues such as time complexity, inhomogeneity and dimensionality [41] . They are usually more time-consuming. FPA has been adopted in this paper to solve ELD and CEED problems.

3.1. Characteristics of flower pollination

The main purpose of a flower is ultimately reproduction via pollination. Flower pollination is typically correlating with the transfer of pollen, which often associated with pollinators such as birds and insects. Indeed, some flowers and insects have a very specialized flower-pollinator partnership, as some flowers can only attract a specific species of insect or bird for effective pollination. Pollination appears in two major forms: abiotic and biotic. About 90% of flowering plants depend on the biotic pollination process, in which the pollen is transferred by pollinators. About 10% of pollination follows abiotic form that does not require any pollinators [42] . Wind and diffusion help in the pollination process of such flowering plants [43] .

Pollination can be achieved by self-pollination or cross-pollination. Self-pollination is the pollination of one flower from pollen of the same flower. Cross-pollination is the pollination from pollen of a flower of different plants. The objective of flower pollination is the survival of the fittest and the optimal reproduction of plants in terms of numbers as well as the fittest. This can be considered as an optimization process of plant species. All of these factors and processes of flower pollination created optimal reproduction of the flowering plants [43] .

3.2. Flower pollination algorithm

For FPA, the following four steps are used:

Step 1: Global pollination represented in biotic and cross-pollination processes, as pollen-carrying pollinators fly following Lévy flight [44] .

Step 2: Local pollination represented in abiotic and self-pollination as the process does not require any pollinators.

Step 3: Flower constancy which can be developed by insects, which is on a par with a reproduction probability that is proportional to the similarity of two flowers involved.

Step 4: The interaction of local pollination and global pollination is controlled by a switch probability p ∈ [0, 1], lightly biased toward local pollination.

To generate the updating formulas, the above rules have to be converted into proper updating equations. For example at the global pollination step, the pollinators such as insects carry the flower pollen gametes, so the pollen can travel over a long distance because of the ability of these insects to fly and move in much longer ranges. Therefore, global pollination step and flower constancy step can be represented by:

|

|

( 11) |

In fact, L (λ ) is the Lévy flights based step size that corresponds to the strength of the pollination. Since long distances can be covered by insects using various distance steps, a Lévy flight can be used to mimic this behavior efficiently. That is, L > 0 from a Lévy distribution.

|

|

( 12) |

This distribution is valid for large steps s > 0.

For the local pollination, both Step 2 and Step 3 can be represented as

|

|

( 13) |

where and are pollen from different flowers of the same plant species mimicking the flower constancy in a limited neighborhood. For a local random walk, and come from the same species, then ε is drawn from a uniform distribution as [0, 1].

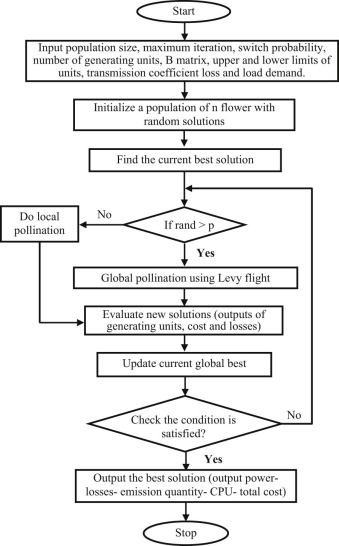

In principle, flower pollination activities can occur at all scales. But in reality, adjacent flower patches are more likely to be pollinated by a local flower pollen than those far away. In order to mimic this, one can effectively use a switch probability (Step 4) to switch between common global pollination to intensive local pollination. To start with, one can use a naive value of p = 0.5. A preliminary parametric showed that p = 0.8 might work better for most applications. The flow chart of FPA is given in Fig. 2 . The data of FPA are shown in Appendix A .

|

|

|

Fig. 2. Flow chart of FPA. |

4. Results and discussion

FPA is employed to solve ELD and CEED problems for different cases to assure its optimization efficiency, where the objective function is limited by the output limits of generation units and transmission losses. The performance of FPA is compared with various optimization algorithms. Simulations were done under the Matlab environment.

4.1. Case study 1

This case considers 40 generators as a large scale power system to confirm the superiority of FPA over other algorithms in reaching optimum solution. Moreover, the effect of valve loading point is taken into account to complete the analysis [45] , [46] , [47] , [48] , [49] , [50] , [51] , [52] , [53] , [54] and [55] . The data of this system are given in Appendix B .

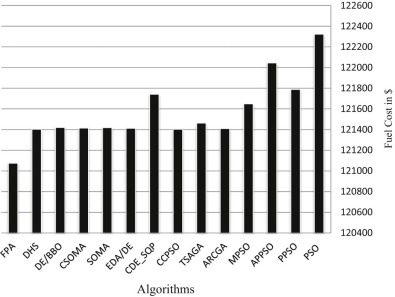

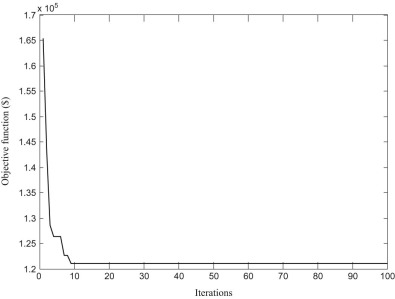

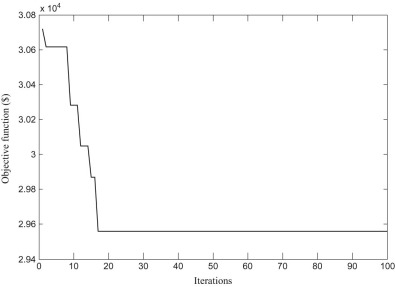

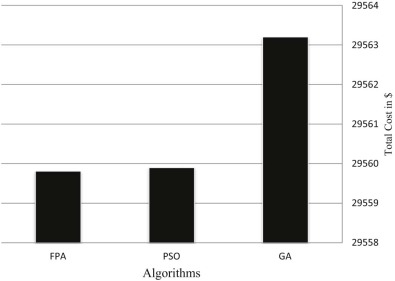

Table 1 outlines the outputs of each unit for 10,500 MW load demand and the cost for each algorithm. It can be noticed that the suggested FPA achieves lower cost compared with other algorithms while achieving the constraints of generations. Therefore, these algorithms have trapped in local minimum solutions. Thus, FPA performs better than these algorithms in terms of fuel cost even for large scale power system with valve loading effect. Also, Table 2 lists the statistical comparison between FPA and different algorithms reported in [47] , [48] , [49] , [50] , [51] , [52] , [53] , [54] , [55] , [56] , [57] , [58] , [59] , [60] , [61] , [62] , [63] and [64] in terms of the best, mean, worst cost and computational (CPU) time through 50 trials. It is clear that the fuel cost obtained by the proposed FPA is better than other algorithms. Fig. 3 shows the total cost for each algorithm. On the other hand, a graph for convergence rate of the objective function is given in Fig. 4 . It can be seen that the objective function is stabilized after 9 iterations. Also, the mean CPU time of FPA is the shortest one.

| Outputs | PSO [45] | PPSO [45] | APPSO [45] | MPSO [46] | ARCGA [47] | TSAGA [48] | CCPSO [49] | CDE_SQP [50] | EDA/DE [51] | SOMA [52] | CSOMA [52] | DE/BBO [53] | DHS [54] | ICA-PSO [55] | Proposed FPA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P1 (MW) | 113.116 | 111.601 | 112.579 | 113.9971 | 110.8252 | 114.0000 | 110.7998 | 111.7600 | 111.1110 | 112.8544 | 110.8016 | 110.7998 | 110.7998 | 110.8 | 72.4810 |

| P2 (MW) | 113.010 | 111.781 | 111.553 | 112.6517 | 113.9112 | 111.0400 | 110.7999 | 111.5600 | 110.8299 | 111.7795 | 110.8068 | 110.7998 | 110.7998 | 110.8 | 103.0314 |

| P3 (MW) | 119.702 | 118.613 | 98.751 | 119.4255 | 97.4000 | 97.3000 | 97.3999 | 97.3900 | 97.4122 | 97.4059 | 97.4007 | 97.3999 | 97.3999 | 97.41 | 83.2726 |

| P4 (MW) | 81.647 | 179.819 | 180.384 | 189.0000 | 179.7331 | 179.6000 | 179.7331 | 179.7300 | 179.7443 | 179.7274 | 179.7333 | 179.7331 | 179.7331 | 179.74 | 182.3106 |

| P5 (MW) | 95.062 | 92.443 | 94.389 | 96.8711 | 88.6454 | 90.7210 | 87.7999 | 91.6600 | 88.1510 | 87.9306 | 87.8180 | 87.9576 | 87.7999 | 88.52 | 76.1669 |

| P6 (MW) | 139.209 | 139.846 | 139.943 | 139.2798 | 140.0000 | 140.0000 | 140.0000 | 140.0000 | 139.9959 | 139.9880 | 139.9997 | 140.0000 | 140.0000 | 140.00 | 126.1346 |

| P7 (MW) | 299.127 | 296.703 | 298.937 | 223.5924 | 259.6000 | 260.0600 | 259.5997 | 300.0000 | 259.6065 | 259.7736 | 259.6010 | 259.5997 | 259.5997 | 259.60 | 258.8452 |

| P8 (MW) | 287.491 | 284.566 | 285.827 | 284.5803 | 284.6000 | 285.8700 | 284.5997 | 300.0000 | 284.6045 | 284.6280 | 284.6000 | 284.5997 | 284.5997 | 284.60 | 297.1636 |

| P9 (MW) | 292.316 | 285.164 | 298.381 | 216.4333 | 284.6000 | 284.7700 | 284.5997 | 284.5900 | 284.6149 | 284.7539 | 284.6005 | 284.5997 | 284.5997 | 284.60 | 290.8899 |

| P10 (MW) | 279.273 | 203.859 | 130.212 | 239.3357 | 130.0000 | 130.0000 | 130.0000 | 130.0000 | 130.0002 | 130.0291 | 130.0003 | 130.0000 | 130.0000 | 130.00 | 274.8232 |

| P11 (MW) | 169.766 | 94.283 | 94.385 | 314.8734 | 168.7985 | 94.0000 | 94.0000 | 168.7900 | 168.8029 | 168.7908 | 168.7999 | 168.7998 | 94.0000 | 168.80 | 356.9806 |

| P12 (MW) | 94.344 | 94.090 | 169.583 | 305.0565 | 168.7994 | 168.3800 | 94.0000 | 94.0000 | 94.0000 | 168.8084 | 168.7999 | 94.0000 | 94.0000 | 94.00 | 124.4054 |

| P13 (MW) | 214.871 | 304.830 | 214.617 | 365.5429 | 214.7600 | 214.4500 | 214.7598 | 214.7600 | 214.7591 | 214.7191 | 214.7599 | 214.7598 | 214.7598 | 214.76 | 493.3764 |

| P14 (MW) | 304.790 | 304.173 | 304.886 | 493.3729 | 394.2800 | 394.0100 | 394.2794 | 394.2800 | 394.2716 | 394.2888 | 394.2794 | 394.2794 | 394.2794 | 394.28 | 344.9029 |

| P15 (MW) | 304.563 | 304.467 | 304.547 | 280.4326 | 304.5200 | 394.2700 | 394.2794 | 304.5200 | 304.5206 | 304.5196 | 304.5196 | 394.2794 | 394.2794 | 394.28 | 372.3864 |

| P16 (MW) | 304.302 | 304.177 | 304.584 | 432.0717 | 394.2800 | 304.5700 | 394.2794 | 304.5200 | 394.2834 | 394.2952 | 394.2794 | 394.2794 | 394.2794 | 304.52 | 345.4624 |

| P17 (MW) | 489.173 | 489.544 | 498.452 | 435.2428 | 489.2798 | 489.2800 | 489.2794 | 489.2800 | 489.2912 | 489.2905 | 489.2796 | 489.2794 | 489.2794 | 489.28 | 422.6378 |

| P18 (MW) | 491.336 | 489.773 | 497.472 | 417.6958 | 489.2800 | 489.5600 | 489.2794 | 489.2800 | 489.2877 | 489.2779 | 489.2795 | 489.2794 | 489.2794 | 489.28 | 434.4065 |

| P19 (MW) | 510.880 | 511.280 | 512.816 | 532.1877 | 511.2806 | 511.2900 | 511.2794 | 511.2800 | 511.2977 | 511.2861 | 511.2794 | 511.2794 | 511.2794 | 511.28 | 461.3107 |

| P20 (MW) | 511.474 | 510.904 | 548.992 | 409.2053 | 511.2800 | 511.2700 | 511.2794 | 511.2800 | 511.2791 | 511.2792 | 511.2796 | 511.2794 | 511.2794 | 511.28 | 434.3828 |

| P21 (MW) | 524.814 | 524.092 | 524.652 | 534.0629 | 523.2803 | 523.2300 | 523.2794 | 523.2800 | 523.2958 | 523.2858 | 523.2797 | 523.2794 | 523.2794 | 523.28 | 545.2846 |

| P22 (MW) | 524.775 | 523.121 | 523.399 | 457.0962 | 523.2800 | 523.6300 | 523.2794 | 523.2900 | 523.2849 | 523.2899 | 523.2798 | 523.2794 | 523.2794 | 523.28 | 490.3572 |

| P23 (MW) | 525.563 | 523.242 | 548.895 | 441.3634 | 523.2800 | 523.8200 | 523.2794 | 523.2800 | 523.2856 | 523.2783 | 523.2801 | 523.2794 | 523.2794 | 523.28 | 506.0639 |

| P24 (MW) | 522.712 | 524.260 | 525.871 | 397.3617 | 523.2800 | 523.6200 | 523.2794 | 523.2800 | 523.2979 | 523.3199 | 523.2795 | 523.2794 | 523.2794 | 523.28 | 467.3109 |

| P25 (MW) | 503.211 | 523.283 | 523.814 | 446.4181 | 523.2800 | 523.3300 | 523.2794 | 523.2800 | 523.2799 | 523.2791 | 523.2797 | 523.2794 | 523.2794 | 523.28 | 488.1203 |

| P26 (MW) | 524.199 | 523.074 | 523.565 | 442.1164 | 523.2801 | 523.6800 | 523.2794 | 523.2800 | 523.2910 | 523.3076 | 523.2799 | 523.2794 | 523.2794 | 523.28 | 486.9019 |

| P27 (MW) | 10.082 | 10.800 | 10.575 | 74.8622 | 10.0000 | 10.0000 | 10.0000 | 10.0000 | 10.0064 | 10.0021 | 10.0004 | 10.0000 | 10.0000 | 10.00 | 16.8002 |

| P28 (MW) | 10.663 | 10.742 | 11.177 | 27.5430 | 10.0000 | 10.0000 | 10.0000 | 10.0000 | 10.0018 | 10.0054 | 10.0004 | 10.0000 | 10.0000 | 10.00 | 39.3475 |

| P29 (MW) | 10.418 | 10.799 | 11.210 | 76.8314 | 10.0000 | 10.1600 | 10.0000 | 10.0000 | 10.0000 | 10.0061 | 10.0003 | 10.0000 | 10.0000 | 10.00 | 23.6359 |

| P30 (MW) | 94.244 | 94.475 | 96.178 | 97.0000 | 88.7611 | 87.8700 | 87.8000 | 90.3300 | 96.2132 | 88.8932 | 92.7158 | 97.0000 | 87.7999 | 96.39 | 86.3295 |

| P31 (MW) | 189.377 | 189.245 | 189.999 | 118.3775 | 190.0000 | 190.0000 | 190.0000 | 190.0000 | 189.9996 | 189.9975 | 189.9998 | 190.0000 | 190.0000 | 190.00 | 165.9924 |

| P32 (MW) | 189.796 | 189.995 | 189.924 | 188.7517 | 190.0000 | 190.0000 | 190.0000 | 190.0000 | 189.9998 | 189.9919 | 189.9998 | 190.0000 | 190.0000 | 190.00 | 174.5707 |

| P33 (MW) | 189.813 | 188.081 | 189.714 | 190.0000 | 190.0000 | 190.0000 | 190.0000 | 190.0000 | 189.9981 | 189.9825 | 189.9998 | 190.0000 | 190.0000 | 190.00 | 184.0570 |

| P34 (MW) | 199.797 | 198.475 | 199.284 | 120.7029 | 164.8000 | 165.2300 | 164.7998 | 200.0000 | 164.9126 | 164.9291 | 164.8014 | 164.7998 | 164.7998 | 164.82 | 193.6668 |

| P35 (MW) | 199.284 | 197.528 | 199.599 | 170.2403 | 164.8000 | 200.0000 | 194.3976 | 200.0000 | 199.9941 | 164.8031 | 164.8015 | 200.0000 | 200.0000 | 200.00 | 191.6152 |

| P36 (MW) | 198.165 | 196.971 | 199.751 | 198.9897 | 164.8054 | 200.0000 | 200.0000 | 200.0000 | 200.0000 | 164.9387 | 164.8051 | 200.0000 | 194.3978 | 200.00 | 196.1763 |

| P37 (MW) | 109.291 | 109.161 | 109.973 | 110.0000 | 110.0000 | 110.0000 | 110.0000 | 110.0000 | 109.9988 | 109.9974 | 109.9998 | 100.0000 | 110.0000 | 110.00 | 90.0101 |

| P38 (MW) | 109.087 | 109.900 | 109.506 | 109.3405 | 110.0000 | 110.0000 | 110.0000 | 110.0000 | 109.9994 | 109.9856 | 109.9998 | 110.0000 | 110.0000 | 110.00 | 37.5421 |

| P39 (MW) | 109.909 | 109.855 | 109.363 | 109.9243 | 110.0000 | 110.0000 | 110.0000 | 110.0000 | 109.9974 | 109.9995 | 109.9996 | 110.0000 | 110.0000 | 110.00 | 89.4239 |

| P40 (MW) | 512.348 | 510.984 | 511.261 | 468.1694 | 511.2800 | 510.9800 | 511.2794 | 511.2800 | 511.2800 | 511.2813 | 511.2797 | 511.2794 | 511.2794 | 511.28 | 471.4405 |

| Fuel cost * 105 $ | 1.22323 | 1.21788 | 1.220446 | 1.216492 | 1.214101 | 1.214630 | 1.214035 | 1.217419 | 1.21412 | 1.214187 | 1.214147 | 1.214208 | 1.214035 | 1.214132 | 1.210745 |

| Algorithm | Best cost ($) | Mean cost ($) | Worst cost ($) | Time (s) |

|---|---|---|---|---|

| ARCGA [47] | 121410.1038 | 121462.1502 | 121536.8745 | 15.67 |

| TSAGA [48] | 121463.07 | 122928.31 | 124296.54 | 696.01 |

| CCPSO [49] | 121403.5362 | 121445.3269 | 121535.4934 | 19.3 |

| CDE_SQP [50] | 121741.9793 | 122295.1278 | 122839.2941 | 14.26 |

| EDA/DE [51] | 121412.50 | 121460.70 | 121517.80 | NA |

| BBO [52] | 121426.66 | 121508.03 | 121688.66 | NA |

| SOMA [52] | 121418.7856 | 121449.8796 | 121508.3757 | NA |

| CSOMA [52] | 121414.6978 | 121415.0479 | 121417.8045 | NA |

| DE/BBO [53] | 121420.89 | 121420.90 | 121420.90 | 60.00 |

| DHS [54] | 121403.5355 | 121410.5967 | 121417.2274 | 1.32 |

| ICA-PSO [55] | 121413.2 | 121428.14 | 121453.56 | 139.92 |

| EP [56] | 122624.35 | 123382.00 | 125740 | 1167.35 |

| EP–SQP [56] | 122323.97 | 122379.63 | NA | 997.73 |

| PSO [56] | 123930.45 | 124154.49 | NA | 933.39 |

| PSO–SQP [56] | 122094.67 | 122245.25 | NA | 733.97 |

| GA–PS–SQP [57] | 121458 | 122039 | NA | 46.98 |

| CPSO [58] | 121865.23 | 122100.87 | NA | 114.65 |

| CPSO–SQP [58] | 121458.54 | 122028.16 | NA | 98.49 |

| NPSO_LRS [59] | 121664.4308 | 122209.3185 | 122981.5913 | 16.81 |

| APSO [60] | 121663.5222 | 122153.6730 | 122912.3958 | 5.05 |

| DE [61] | 121416.29 | 121422.72 | 121431.47 | NA |

| CDEMD [62] | 121423.4013 | 121526.7330 | 121696.9868 | 44.3 |

| HMAPSO [63] | 121586.90 | 121586.90 | 21586.90 | NA |

| FAPSO-NM [64] | 121418.3 | 121418.803 | 121419.8 | 40 |

| FPA | 121074.5 | 121095.7 | 121196.3 | 0.89 |

|

|

|

Fig. 3. Fuel cost for various algorithms for case 1. |

|

|

|

Fig. 4. Objective function for forty unit system. |

4.2. Case study 2

This case studies a 3-unit generating thermal system considering emission impact. The generator cost coefficients, emission coefficients, generation limits and the transmission loss coefficient matrix are given in Appendix B . Table 3 summarizes the results of solving CEED using the proposed FPA compared with GA and PSO [38] . As shown from Table 3 , FPA donates superior result in terms of fuel cost, total cost and CPU compared with other algorithms. Moreover, the equality and inequality constraints are accomplished. The proposed FPA gives better results in terms of minimum total cost and smaller CPU time than other algorithms. Fig. 5 shows the total cost associated with FPA for 400 MW demand. The superiority of the proposed algorithm in decreasing the total cost can be verified as shown in Fig. 6 .

| h | Power outputs | GA [38] | PSO [38] | FPA | |

|---|---|---|---|---|---|

| 400 (MW) | 43.55981 | P1 (MW) | 102.617 | 102.612 | 102.4468 |

| P2 (MW) | 153.825 | 153.809 | 153.8341 | ||

| P3 (MW) | 151.011 | 150.991 | 151.1321 | ||

| (MW) | 7.41324 | 7.41173 | 7.4126 | ||

| Fuel Cost ($) | 20840.1 | 20838.3 | 20838.1 | ||

| Emission (Kg) | 200.256 | 200.221 | 200.2238 | ||

| Total Cost ($) | 29563.2 | 29559.9 | 29559.81 | ||

| CPU (Sec) | 0.282 | 0.235 | 0.175 |

The bold values are obtained using the proposed FPA algorithm.

|

|

|

Fig. 5. Objective function for 3-unit system with demand = 400 MW. |

|

|

|

Fig. 6. Total cost for various algorithms with demand = 400 MW. |

4.3. Case study 3

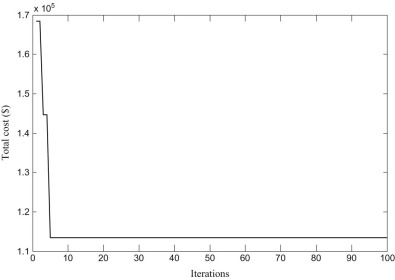

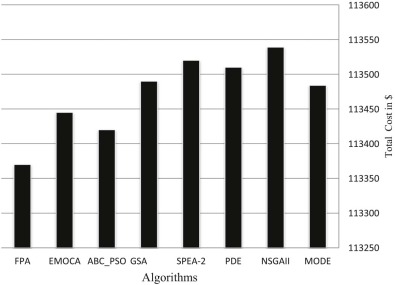

This case involves a ten unit generating thermal system with valve point effects. The fuel cost coefficients, generators constraint, emission coefficients and transmission loss coefficient matrix are shown in Appendix B . Table 4 outlines the results of solving CEED for 2000 MW load demand using FPA and comparing with other algorithms [65] , [66] , [67] and [68] . The result of the suggested algorithm is highlighted here. The suggested FPA yields a lower cost than ABC_PSO, GSA, EMOCA, MODE, PDE, SPEA-2 and NSGA-II by 50$, 120$, 75$, 114$, 140$, 150$ and 169$ respectively while achieving the constraints of system. Also, its emission is also lower than SPEA-2, PDE, GSA, EMOCA, ABC_PSO, MODE and NSGA-II. Thus, FPA succeeds in achieving the global minimum solution. Moreover, the CPU time is smaller than other algorithm. Hence, FPA outperforms and outlasts other algorithms in reducing the net cost with minimum time. In addition, the cost convergence for this demand is given in Fig. 7 . The objective function is convergent after 5 iterations. Finally, the total cost for every algorithm is given in Fig. 8 .

| Outputs | MODE [65] | NSGAII [65] | PDE [65] | SPEA-2 [65] | GSA [66] | ABC_PSO [67] | EMOCA [68] | Proposed FPA |

|---|---|---|---|---|---|---|---|---|

| P1 (MW) | 54.9487 | 51.9515 | 54.9853 | 52.9761 | 54.9992 | 55 | 55 | 53.188 |

| P2 (MW) | 74.5821 | 67.2584 | 79.3803 | 72.813 | 79.9586 | 80 | 80 | 79.975 |

| P3 (MW) | 79.4294 | 73.6879 | 83.9842 | 78.1128 | 79.4341 | 81.14 | 83.5594 | 78.105 |

| P4 (MW) | 80.6875 | 91.3554 | 86.5942 | 83.6088 | 85.0000 | 84.216 | 84.6031 | 97.119 |

| P5 (MW) | 136.8551 | 134.0522 | 144.4386 | 137.2432 | 142.1063 | 138.3377 | 146.5632 | 152.74 |

| P6 (MW) | 172.6393 | 174.9504 | 165.7756 | 172.9188 | 166.5670 | 167.5086 | 169.2481 | 163.08 |

| P7 (MW) | 283.8233 | 289.4350 | 283.2122 | 287.2023 | 292.8749 | 296.8338 | 300 | 258.61 |

| P8 (MW) | 316.3407 | 314.0556 | 312.7709 | 326.4023 | 313.2387 | 311.5824 | 317.3496 | 302.22 |

| P9 (MW) | 448.5923 | 455.6978 | 440.1135 | 448.8814 | 441.1775 | 420.3363 | 412.9183 | 433.21 |

| P10 (MW) | 436.4287 | 431.8054 | 432.6783 | 423.9025 | 428.6306 | 449.1598 | 434.3133 | 466.07 |

| Fuel cost * 105 $ | 1.13484 | 1.13539 | 1.1351 | 1.1352 | 1.1349 | 1.1342 | 1.13445 | 1.1337 |

| Emission (Ib) | 4124.9 | 4130.2 | 4111.4 | 4109.1 | 4111.4 | 4120.1 | 4113.98 | 3997.7 |

| Losses (MW) | 84.33 | 84.25 | 83.9 | 84.1 | 83.9869 | 84.1736 | 83.56 | 84.3 |

| CPU (s) | 3.82 | 6.02 | 4.23 | 7.53 | NA | NA | 2.90 | 2.23 |

|

|

|

Fig. 7. Change of objective function with iterations for ten units. |

|

|

|

Fig. 8. Total cost for various algorithms for case 3. |

4.4. Case study 4

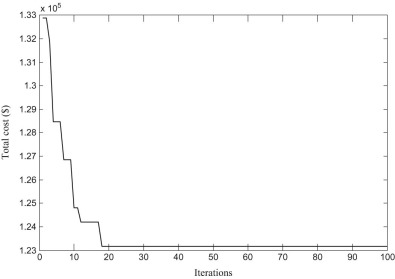

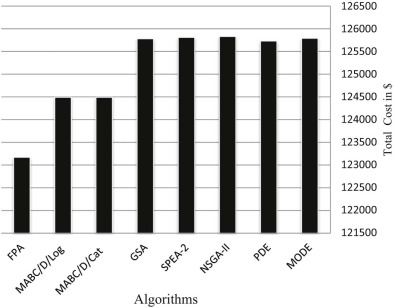

This test system consists of forty generating units with non-smooth fuel cost and emission functions. Unit data and loss coefficients have been found in Appendix B . Table 5 summarizes the results of solving CEED for 10,500 MW load demand using FPA and comparing with MODE, PDE, NSGA-II, SPEA-2 [65] , GSA [66] , MABC/D/Cat [69] and MABC/D/Log [69] . The result of the suggested algorithm yields to a lower fuel cost than others as shown in Table 5 . Therefore, these algorithms have trapped in local minimum solutions. On the other hand, the objective function representing the total cost decreases gradually and converges after 18 iterations as given in Fig. 9 . Moreover, the average CPU time of the proposed FPA is the smallest one compared with other algorithms. The superiority of the proposed FPA in reaching the global minimum cost is detected by examining Fig. 10 .

| Outputs | MODE [65] | PDE [65] | NSGA-II [65] | SPEA-2 [65] | GSA [66] | MABC/D/Cat [69] | MABC/D/Log [69] | Proposed FPA |

|---|---|---|---|---|---|---|---|---|

| P1 (MW) | 113.5295 | 112.1549 | 113.8685 | 113.9694 | 113.9989 | 110.7998 | 110.7998 | 43.405 |

| P2 (MW) | 114 | 113.9431 | 113.6381 | 114 | 113.9896 | 110.7998 | 110.7998 | 113.95 |

| P3 (MW) | 120 | 120 | 120 | 119.8719 | 119.9995 | 97.3999 | 97.3999 | 105.86 |

| P4 (MW) | 179.8015 | 180.2647 | 180.7887 | 179.9284 | 179.7857 | 174.5504 | 174.5486 | 169.65 |

| P5 (MW) | 96.7716 | 97 | 97 | 97 | 97 | 87.7999 | 97 | 96.659 |

| P6 (MW) | 139.2760 | 140 | 140 | 139.2721 | 139.0128 | 105.3999 | 105.3999 | 139.02 |

| P7 (MW) | 300 | 299.8829 | 300 | 300 | 299.9885 | 259.5996 | 259.5996 | 273.28 |

| P8 (MW) | 298.9193 | 300 | 299.0084 | 298.2706 | 300 | 284.5996 | 284.5996 | 285.17 |

| P9 (MW) | 290.7737 | 289.8915 | 288.8890 | 290.5228 | 296.2025 | 284.5996 | 284.5996 | 241.96 |

| P10 (MW) | 130.9025 | 130.5725 | 131.6132 | 131.4832 | 130.3850 | 130 | 130 | 131.26 |

| P11 (MW) | 244.7349 | 244.1003 | 246.5128 | 244.6704 | 245.4775 | 318.1921 | 318.2129 | 312.13 |

| P12 (MW) | 317.8218 | 318.2840 | 318.8748 | 317.2003 | 318.2101 | 243.5996 | 243.5996 | 362.58 |

| P13 (MW) | 395.3846 | 394.7833 | 395.7224 | 394.7357 | 394.6257 | 394.2793 | 394.2793 | 346.24 |

| P14 (MW) | 394.4692 | 394.2187 | 394.1369 | 394.6223 | 395.2016 | 394.2793 | 394.2793 | 306.06 |

| P15 (MW) | 305.8104 | 305.9616 | 305.5781 | 304.7271 | 306.0014 | 394.2793 | 394.2793 | 358.78 |

| P16 (MW) | 394.8229 | 394.1321 | 394.6968 | 394.7289 | 395.1005 | 394.2793 | 394.2793 | 260.68 |

| P17 (MW) | 487.9872 | 489.3040 | 489.4234 | 487.9857 | 489.2569 | 399.5195 | 399.5195 | 415.19 |

| P18 (MW) | 489.1751 | 489.6419 | 488.2701 | 488.5321 | 488.7598 | 399.5195 | 399.5195 | 423.94 |

| P19 (MW) | 500.5265 | 499.9835 | 500.8 | 501.1683 | 499.2320 | 506.1985 | 506.1716 | 549.12 |

| P20 (MW) | 457.0072 | 455.4160 | 455.2006 | 456.4324 | 455.2821 | 506.1985 | 506.2206 | 496.7 |

| P21 (MW) | 434.6068 | 435.2845 | 434.6639 | 434.7887 | 433.4520 | 514.1472 | 514.1105 | 539.17 |

| P22 (MW) | 434.5310 | 433.7311 | 434.15 | 434.3937 | 433.8125 | 514.1455 | 514.1472 | 546.46 |

| P23 (MW) | 444.6732 | 446.2496 | 445.8385 | 445.0772 | 445.5136 | 514.5237 | 514.5664 | 540.06 |

| P24 (MW) | 452.0332 | 451.8828 | 450.7509 | 451.8970 | 452.0547 | 514.5386 | 514.4868 | 514.5 |

| P25 (MW) | 492.7831 | 493.2259 | 491.2745 | 492.3946 | 492.8864 | 433.5196 | 433.5195 | 453.46 |

| P26 (MW) | 436.3347 | 434.7492 | 436.3418 | 436.9926 | 433.3695 | 433.5195 | 433.5196 | 517.31 |

| P27 (MW) | 10 | 11.8064 | 11.2457 | 10.7784 | 10.0026 | 10 | 10 | 14.881 |

| P28 (MW) | 10.3901 | 10.7536 | 10 | 10.2955 | 10.0246 | 10 | 10 | 18.79 |

| P29 (MW) | 12.3149 | 10.3053 | 12.0714 | 13.7018 | 10.0125 | 10 | 10 | 26.611 |

| P30 (MW) | 96.9050 | 97. | 97 | 96.2431 | 96.9125 | 97 | 87.8042 | 59.581 |

| P31 (MW) | 189.7727 | 190.0000 | 189.4826 | 190.0000 | 189.9689 | 159.733 | 159.733 | 183.48 |

| P32 (MW) | 174.2324 | 175.3065 | 174.7971 | 174.2163 | 175 | 159.733 | 159.7331 | 183.39 |

| P33 (MW) | 190 | 190 | 189.2845 | 190 | 189.0181 | 159.733 | 159.733 | 189.02 |

| P34 (MW) | 199.6506 | 200 | 200 | 200 | 200 | 200 | 200 | 198.73 |

| P35 (MW) | 199.8662 | 200 | 199.9138 | 200 | 200 | 200 | 200 | 198.77 |

| P36 (MW) | 200 | 200 | 199.5066 | 200 | 199.9978 | 200 | 200 | 182.23 |

| P37 (MW) | 110 | 109.9412 | 108.3061 | 110 | 109.9969 | 89.1141 | 89.1141 | 39.673 |

| P38 (MW) | 109.9454 | 109.8823 | 110 | 109.6912 | 109.0126 | 89.1141 | 89.1141 | 81.596 |

| P39 (MW) | 108.1786 | 108.9686 | 109.7899 | 108.5560 | 109.4560 | 89.1141 | 89.1141 | 42.96 |

| P40 (MW) | 422.0628 | 421.3778 | 421.5609 | 421.8521 | 421.9987 | 506.1879 | 506.1951 | 537.17 |

| Total cost * 105 $ | 1.2579 | 1.2573 | 1.2583 | 1.2581 | 1.2578 | 1.24490903 | 1.24491161 | 1.23170 |

| Emission * 105 ton | 2.1119 | 2.1177 | 2.1095 | 2.1110 | 2.1093 | 2.56560267 | 2.56560267 | 2.0846 |

| CPU (s) | 5.39 | 6.15 | 7.32 | 8.57 | NA | NA | NA | 4.92 |

|

|

|

Fig. 9. Change of objective function with iterations for forty units. |

|

|

|

Fig. 10. Total cost for various algorithms for case 4. |

4.5. Comparison and discussion

The superiority of the proposed FPA is investigated here by comparison with other optimization algorithms in terms of economic effects and computation efficiency.

4.5.1. Economic effects

As seen in Fig. 3 , Fig. 6 , Fig. 8 and Fig. 10 , the proposed FPA can get the best solution among other algorithms in the literatures. From Table 2 , it is obvious that the mean cost value obtained by the proposed FPA is comparatively less compared with other algorithms. Therefore, the proposed FPA can result in better economic effects than other algorithms. Moreover, it leads to higher quality solution than other algorithms.

4.5.2. Convergence property and computation efficiency

From Fig. 4 , Fig. 5 , Fig. 7 and Fig. 9 , one can get that the descending speeds at the beginning are high; this indicates the high convergence of the proposed algorithm based on evolution search. FPA can be convergent quickly and get the optimum results in very small iteration numbers. It is confirmed to have a good convergence property. As seen in Table 1 , Table 2 , Table 3 , Table 4 and Table 5 , CPU times of the proposed FPA are smaller than other algorithms since FPA has only one key parameter. Thus, it can get better computation efficiency than other algorithms.

5. Conclusions

In this paper, FPA has been developed to solve ELD and CEED problems in power systems. The performance of the FPA was tested for various test cases and compared with the reported cases in recent literatures. The superiority of FPA over other algorithms for settling ELD and CEED problems even for large scale power system with valve point effect is confirmed. Moreover, the economic effect, computation efficiency and convergence property of FPA are demonstrated. Therefore FPA optimization is a promising technique for solving complicated problems in power systems. Applications of the proposed algorithm to multi-area power system integrated with wind farms and PV system are the future scope of this work.

Appendix A

- Parameters of FPA for case 40 generators: Maximum number of iterations = 500, population size = 20, probability switch = 0.8.

- Parameters of FPA for case 3, 10 generators: Maximum number of iterations = 500, population size = 25, probability switch = 0.75.

Appendix B

See Table B1 , Table B2 and Table B3 and the transmission line losses coefficient.

| Unit | γ $/MW2 h | β $/MWh | α $/h | a (Kg/MW2 h) | b (Kg/MWh) | c (Kg/h) | (MW) | (MW) |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.03546 | 38.30553 | 1243.5311 | 0.00683 | −0.54551 | 40.2669 | 35 | 210 |

| 2 | 0.02111 | 36.32782 | 1658.5696 | 0.00461 | −0.5116 | 42.89553 | 130 | 325 |

| 3 | 0.01799 | 38.27041 | 1356.6592 | 0.00461 | −0.5116 | 42.89553 | 125 | 315 |

The transmission line losses coefficient of three units system.

.

| Unit | γ $/MW2 h | β ($/MWh) | α ($/h) | e ($/h) | f (rad/MW) | (MW) | (MW) | a (Ib/MW2 h) | b (Ib/MWh) | c (Ib/h) | η (Ib/h) | δ (1/MW) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P1 | 0.12951 | 40.5407 | 1000.403 | 33 | 0.0174 | 10 | 55 | 0.04702 | −3.9864 | 360.0012 | 0.25475 | 0.01234 |

| P2 | 0.10908 | 39.5804 | 950.606 | 25 | 0.0178 | 20 | 80 | 0.04652 | −3.9524 | 350.0056 | 0.25475 | 0.01234 |

| P3 | 0.12511 | 36.5104 | 900.705 | 32 | 0.0162 | 47 | 120 | 0.04652 | −3.9023 | 330.0056 | 0.25163 | 0.01215 |

| P4 | 0.12111 | 39.5104 | 800.705 | 30 | 0.0168 | 20 | 130 | 0.04652 | −3.9023 | 330.0056 | 0.25163 | 0.01215 |

| P5 | 0.15247 | 38.539 | 756.799 | 30 | 0.0148 | 50 | 160 | 0.0042 | 0.3277 | 13.8593 | 0.2497 | 0.012 |

| P6 | 0.10587 | 46.1592 | 451.325 | 20 | 0.0163 | 70 | 240 | 0.0042 | 0.3277 | 13.8593 | 0.2497 | 0.012 |

| P7 | 0.03546 | 38.3055 | 1243.531 | 20 | 0.0152 | 60 | 300 | 0.0068 | −0.5455 | 40.2669 | 0.248 | 0.0129 |

| P8 | 0.02803 | 40.3965 | 1049.998 | 30 | 0.0128 | 70 | 340 | 0.0068 | −0.5455 | 40.2669 | 0.2499 | 0.01203 |

| P9 | 0.02111 | 36.3278 | 1658.569 | 60 | 0.0136 | 135 | 470 | 0.0046 | −0.5112 | 42.8955 | 0.2547 | 0.01234 |

| P10 | 0.01799 | 38.2704 | 1356.659 | 40 | 0.0141 | 150 | 470 | 0.0046 | −0.5112 | 42.8955 | 0.2547 | 0.01234 |

The transmission line losses coefficient of ten units system.

.

| e ($/h) | f (rad/MW) | c (Ib/h) | b (Ib/MWh) | a (Ib/MW2 h) | η (Ib/h) | δ (1/MW) | Unit | (MW) | (MW) | α $/h | β $/MWh | γ $/MW2 h |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P1 | 36 | 114 | 94.705 | 6.73 | 0.00690 | 100 | 0.084 | 60 | −2.22 | 0.0480 | 1.3100 | 0.05690 |

| P2 | 36 | 114 | 94.705 | 6.73 | 0.00690 | 100 | 0.084 | 60 | −2.22 | 0.0480 | 1.3100 | 0.05690 |

| P3 | 60 | 120 | 309.540 | 7.07 | 0.02028 | 100 | 0.084 | 100 | −2.36 | 0.0762 | 1.3100 | 0.05690 |

| P4 | 80 | 190 | 369.030 | 8.18 | 0.00942 | 150 | 0.063 | 120 | −3.14 | 0.0540 | 0.9142 | 0.04540 |

| P5 | 47 | 97 | 148.890 | 5.35 | 0.01140 | 120 | 0.077 | 50 | −1.89 | 0.0850 | 0.9936 | 0.04060 |

| P6 | 68 | 140 | 222.330 | 8.05 | 0.01142 | 100 | 0.084 | 80 | −3.08 | 0.0854 | 1.3100 | 0.05690 |

| P7 | 110 | 300 | 287.710 | 8.03 | 0.00357 | 200 | 0.042 | 100 | −3.06 | 0.0242 | 0.6550 | 0.02846 |

| P8 | 135 | 300 | 391.980 | 6.99 | 0.00492 | 200 | 0.042 | 130 | −2.32 | 0.0310 | 0.6550 | 0.02846 |

| P9 | 135 | 300 | 455.760 | 6.60 | 0.00573 | 200 | 0.042 | 150 | −2.11 | 0.0335 | 0.6550 | 0.02846 |

| P10 | 130 | 300 | 722.820 | 12.9 | 0.00605 | 200 | 0.042 | 280 | −4.34 | 0.4250 | 0.6550 | 0.02846 |

| P11 | 94 | 375 | 635.200 | 12.9 | 0.00515 | 200 | 0.042 | 220 | −4.34 | 0.0322 | 0.6550 | 0.02846 |

| P12 | 94 | 375 | 654.690 | 12.8 | 0.00569 | 200 | 0.042 | 225 | −4.28 | 0.0338 | 0.6550 | 0.02846 |

| P13 | 125 | 500 | 913.400 | 12.5 | 0.00421 | 300 | 0.035 | 300 | −4.18 | 0.0296 | 0.5035 | 0.02075 |

| P14 | 125 | 500 | 1760.400 | 8.84 | 0.00752 | 300 | 0.035 | 520 | −3.34 | 0.0512 | 0.5035 | 0.02075 |

| P15 | 125 | 500 | 1760.400 | 8.84 | 0.00752 | 300 | 0.035 | 510 | −3.55 | 0.0496 | 0.5035 | 0.02075 |

| P16 | 125 | 500 | 1760.400 | 8.84 | 0.00752 | 300 | 0.035 | 510 | −3.55 | 0.0496 | 0.5035 | 0.02075 |

| P17 | 220 | 500 | 647.850 | 7.97 | 0.00313 | 300 | 0.035 | 220 | −2.68 | 0.0151 | 0.5035 | 0.02075 |

| P18 | 220 | 500 | 649.690 | 7.95 | 0.00313 | 300 | 0.035 | 222 | −2.66 | 0.0151 | 0.5035 | 0.02075 |

| P19 | 242 | 550 | 647.830 | 7.97 | 0.00313 | 300 | 0.035 | 220 | −2.68 | 0.0151 | 0.5035 | 0.02075 |

| P20 | 242 | 550 | 647.810 | 7.97 | 0.00313 | 300 | 0.035 | 220 | −2.68 | 0.0151 | 0.5035 | 0.02075 |

| P21 | 254 | 550 | 785.960 | 6.63 | 0.00298 | 300 | 0.035 | 290 | −2.22 | 0.0145 | 0.5035 | 0.02075 |

| P22 | 254 | 550 | 785.960 | 6.63 | 0.00298 | 300 | 0.035 | 285 | −2.22 | 0.0145 | 0.5035 | 0.02075 |

| P23 | 254 | 550 | 794.530 | 6.66 | 0.00284 | 300 | 0.035 | 295 | −2.26 | 0.0138 | 0.5035 | 0.02075 |

| P24 | 254 | 550 | 794.530 | 6.66 | 0.00284 | 300 | 0.035 | 295 | −2.26 | 0.0138 | 0.5035 | 0.02075 |

| P25 | 254 | 550 | 801.320 | 7.10 | 0.00277 | 300 | 0.035 | 310 | −2.42 | 0.0132 | 0.5035 | 0.02075 |

| P26 | 254 | 550 | 801.320 | 7.10 | 0.00277 | 300 | 0.035 | 310 | −2.42 | 0.0132 | 0.5035 | 0.02075 |

| P27 | 10 | 150 | 1055.100 | 3.33 | 0.52124 | 120 | 0.077 | 360 | −1.11 | 1.8420 | 0.9936 | 0.04060 |

| P28 | 10 | 150 | 1055.100 | 3.33 | 0.52124 | 120 | 0.077 | 360 | −1.11 | 1.8420 | 0.9936 | 0.04060 |

| P29 | 10 | 150 | 1055.100 | 3.33 | 0.52124 | 120 | 0.077 | 360 | −1.11 | 1.8420 | 0.9936 | 0.04060 |

| P30 | 47 | 97 | 148.890 | 5.35 | 0.01140 | 120 | 0.077 | 50 | −1.89 | 0.0850 | 0.9936 | 0.04060 |

| P31 | 60 | 190 | 222.920 | 6.43 | 0.00160 | 150 | 0.063 | 80 | −2.08 | 0.0121 | 0.9142 | 0.04540 |

| P32 | 60 | 190 | 222.920 | 6.43 | 0.00160 | 150 | 0.063 | 80 | −2.08 | 0.0121 | 0.9142 | 0.04540 |

| P33 | 60 | 190 | 222.920 | 6.43 | 0.00160 | 150 | 0.063 | 80 | −2.08 | 0.0121 | 0.9142 | 0.04540 |

| P34 | 90 | 200 | 107.870 | 8.95 | 0.00010 | 200 | 0.042 | 65 | −3.48 | 0.0012 | 0.6550 | 0.02846 |

| P35 | 90 | 200 | 116.580 | 8.62 | 0.00010 | 200 | 0.042 | 70 | −3.24 | 0.0012 | 0.6550 | 0.02846 |

| P36 | 90 | 200 | 116.580 | 8.62 | 0.00010 | 200 | 0.042 | 70 | −3.24 | 0.0012 | 0.6550 | 0.02846 |

| P37 | 25 | 110 | 307.450 | 5.88 | 0.01610 | 80 | 0.098 | 100 | −1.98 | 0.0950 | 1.4200 | 0.06770 |

| P38 | 25 | 110 | 307.450 | 5.88 | 0.01610 | 80 | 0.098 | 100 | −1.98 | 0.0950 | 1.4200 | 0.06770 |

| P39 | 25 | 110 | 307.450 | 5.88 | 0.01610 | 80 | 0.098 | 100 | −1.98 | 0.0950 | 1.4200 | 0.06770 |

| P40 | 242 | 550 | 647.830 | 7.97 | 0.00313 | 300 | 0.035 | 220 | −2.68 | 0.0151 | 0.5035 | 0.02075 |

References

- [1] A. Chakrabarti, S. Halder; Power System Analysis: Operation and Control; Prentice-Hall of India, New Delhi (2006)

- [2] D.P. Kothari, J.S. Dhillon; Power System Optimization; (2nd ed.)PHI Learning Pvt. Ltd, New Delhi (2006)

- [3] G. Aydin; Modeling of energy consumption based on economic and demographic factors: the case of Turkey with projections; Renew. Sustain. Energy Rev, 35 (2014), pp. 382–389

- [4] J.C. Dodu, P. Martin, A. Merlin, J. Pouget; An optimal formulation and solution of short-range operating problems for a power system with flow constraints; Proc. IEEE, 60 (1) (1972), pp. 54–63

- [5] C.L. Chen, S.C. Wang; Branch and bound scheduling for thermal generating units; IEEE Trans. Energy Convers, 8 (2) (1993), pp. 184–189

- [6] P. Aravindhababu, K.R. Nayar; Economic dispatch based on optimal lambda using radial basis function network; Int. J. Electr. Power Energy Syst, 24 (7) (2002), pp. 551–556

- [7] J. Parikh, D. Chattopadhyay; A multi-area linear programming approach for analysis of economic operation of the Indian power system; IEEE Trans. Power Syst, 11 (1) (1996), pp. 52–58

- [8] J.Y. Fan, L. Zhang; Real-time economic dispatch with line flow and emission constraints using quadratic programming; IEEE Trans. Power Syst, 13 (2) (1998), pp. 320–325

- [9] J. Nanda, L. Hari, M.L. Kothari; Economic emission dispatch with line flow constraints using a classical technique; IEE Proc. Gener. Trans. Distrib, 141 (1) (1994), pp. 1–10

- [10] A.A. El-Keib, H. Ma, J.L. Hart; Environmentally constrained economic dispatch using the Lagrangian relaxation method; IEEE Trans. Power Syst, 9 (4) (1994), pp. 1723–1729

- [11] Y.S. Brar, J.S. Dhillon, D.P. Kothari; Multiobjective load dispatch by fuzzy logic searching weightage pattern; Electr. Power Syst. Res, 63 (2002), pp. 149–160

- [12] C.A. Roa-Sepulveda, M. Herrera, B. Pavez-Lazo, U.G. Knight, A.H. Coonick; Economic dispatch using fuzzy decision trees; Electr. Power Syst. Res, 66 (2) (2003), pp. 115–122

- [13] P. Attaviriyanupap, H. Kita, E. Tanaka, J. Hasegawa; A fuzzy-optimization approach to dynamic economic dispatch considering uncertainties; IEEE Trans. Power Syst, 19 (3) (2004), pp. 1299–1307

- [14] L. Singh, J.S. Dhillon; Fuzzy satisfying multiobjective thermal power dispatch based on surrogate worth trade-off method; Electr. Power Components Syst, 36 (1) (2008), pp. 93–108

- [15] C.T. Su, C.T. Lin; New approach with a Hopfield modeling framework to economic dispatch; IEEE Trans. Power Syst, 15 (2) (2000), pp. 541–545

- [16] A.Y. Abdelaziz, S.F. Mekhamer, M.A.L. Badr, M.Z. Kamh; Economic dispatch using an enhanced Hopfield neural network; Electr. Power Components Syst, 36 (7) (2008), pp. 719–732

- [17] P. Surekha, S. Sumathi; A self-adaptive fuzzy c-means based radial basis function network to solve economic load dispatch problems; Int. J. Comput. Appl, 25 (4) (2011), pp. 50–59

- [18] M.A. Abido; A novel multiobjective evolutionary algorithm for environmental economic power dispatch; Electr. Power Syst. Res, 65 (1) (2003), pp. 71–81

- [19] H. Bouzeboudja, A. Chaker, A. Alali, B. Naama; Economic dispatch solution using a real coded genetic algorithm; Acta Electrotechnica Informatica, 5 (4) (2005), pp. 1–5

- [20] K.P. Wong, Y.W. Wong; Genetic and genetic/simulated – annealing approaches to economic dispatch; IEE Proc. Gener. Transm. Distrib, 141 (5) (1994), pp. 507–513

- [21] K.P. Wong, C.C. Fong; Simulated annealing based economic dispatch algorithm; IEE Proc. C (Gener. Transm. Distrib.), 140 (6) (1993), pp. 509–515

- [22] N. Sinha, R. Chakrabarti, P.K. Chattopadhyay; Evolutionary programming techniques for economic load dispatch; IEEE Trans. Evol. Comput, 7 (1) (2003), pp. 83–94

- [23] W.M. Lin, F.S. Cheng, M.T. Tsay; An improved Tabu search for economic dispatch with multiple minima; IEEE Trans. Power Syst, 17 (1) (2002), pp. 108–112

- [24] J. Cai, X. Ma, L. Li, Y. Yang, H. Peng, X. Wang; Chaotic ant swarm optimization to economic dispatch; Electr. Power Syst. Res, 77 (10) (2007), pp. 1373–1380

- [25] J.B. Park, K. Lee, J. Shin, K.Y. Lee; A particle swarm optimization for economic dispatch with nonsmooth cost functions; IEEE Trans. Power Syst, 20 (1) (2005), pp. 34–42

- [26] M.R. Alrashidi, M.E. El-Hawary; A survey of particle swarm optimization applications in power system operations; Electr. Power Components Syst, 34 (12) (2006), pp. 1349–1357

- [27] L. Coelho, C. Lee; Solving economic load dispatch problems in power systems using chaotic and Gaussian particle swarm optimization approaches; Int. J. Electr. Power Energy Syst, 30 (5) (2008), pp. 297–307

- [28] D.C. Secui, I. Felea, S. Dzitac, L. Popper; A swarm intelligence approach to the power dispatch problem; Int. J. Comput. Commun. Contr, 5 (3) (2010), pp. 375–384

- [29] H.M. Dubey, M. Pandit, B.K. Panigrahi, M. Udgir; Economic load dispatch by hybrid swarm intelligence based gravitational search algorithm; Int. J. Intell. Syst. Appl, 5 (8) (2013), pp. 21–32

- [30] D.G. Prasad, D.H. Mohan, P. Manjree, B.K. Panigrahi; Economic load dispatch using artificial bee colony optimization; Int. J. Adv. Electron. Eng, 1 (1) (2011), pp. 119–124

- [31] A.J. Wood, B.F. Wollenberg; Power Generation Operation and Control; (2nd ed.)John Wiley and Sons, New York (1996)

- [32] D.C. Walters, G.B. Sheble; Genetic algorithm solution of economic dispatch with valve point loading; IEEE Trans. Power Syst, 8 (3) (1993), pp. 1325–1332

- [33] K. Senthil, K. Manikandan; Economic thermal power dispatch with emission constraint and valve point effect loading using improved Tabu search algorithm; Int. J. Comput. Appl, 3 (9) (2010), pp. 6–11

- [34] J.G. Vlachogiannis; On the profitability of load dispatch in power systems; Int. Rev. Electr. Eng, 8 (2) (2013), pp. 810–819

- [35] G. Aydin; The modeling of coal related CO2 emissions and projections into future planning; Energy Sources Part A Recovery Util. Environ. Eff, 36 (2) (2014), pp. 191–201

- [36] G. Aydin; The development and validation of regression models to predict energy-related CO2 emissions in Turkey; Energy Sources Part B Econ. Plann. Policy, 10 (2) (2015), pp. 176–182

- [37] M.A. Abido; Environmental/economic power dispatch using multiobjective evolutionary algorithms; IEEE Trans. Power Syst, 18 (4) (2003), pp. 1529–1537

- [38] A.L. Devi, O.V. Krishna; Combined economic and emission dispatch using evolutionary algorithms – a case study; ARPN J. Eng. Appl. Sci, 3 (6) (2008), pp. 28–35

- [39] P. Venkatesh, R. Gnanadass, N.P. Padhy; Comparison and application of evolutionary programming techniques to combined economic emission dispatch with line flow constraints; IEEE Trans. Power Syst, 18 (2) (2003), pp. 688–697

- [40] X.S. Yang; Flower pollination algorithm for global optimization, unconventional computation and natural computation; Lect. Notes Comput. Sci, 7445 (2012), pp. 240–249

- [41] X.S. Yang, M. Karamanoglu, X. He; Multi-objective flower algorithm for optimization; Procedia Comput. Sci, 18 (2013), pp. 61–68

- [42] A. Ochoa, S. Gonzalez, L. Margain, T. Padilla, O. Castillo, P. Melin; Implementing Flower Multi-Objective Algorithm for Selection of University Academic Credits; NaBIC (2014), pp. 7–11

- [43] S. Łukasik, P.A. Kowalski; Study of Flower Pollination Algorithm for Continuous Optimization; Advances in Intelligent Systems and Computing, vol. 322, Springer International Publishing, Warsaw, Poland (2015), pp. 451–459

- [44] A.Y. Abdelaziz, E.S. Ali; Static VAR compensator damping controller design based on flower pollination algorithm for a multi-machine power system; Electr. Power Components Syst, 43 (11) (2015), pp. 1268–1277

- [45] C.H. Chen, S.N. Yeh; Particle Swarm Optimization for Economic Power Dispatch with Valve-Point Effects; IEEE PES Transmission and Distribution Conference and Exposition Latin America, Venezuela (2006), pp. 1–5

- [46] Hardiansyah; A modified particle swarm optimization technique for economic load dispatch with valve-point effect; Int. J. Intell. Syst. Appl, 7 (2013), pp. 32–41

- [47] N. Amjady, H.N. Rad; Solution of nonconvex and nonsmooth economic dispatch by a new adaptive real coded genetic algorithm; Expert Syst. Appl, 37 (7) (2010), pp. 5239–5245

- [48] P. Subbaraj, R. Rengaraj, S. Salivahanan; Enhancement of self-adaptive real coded genetic algorithm using Taguchi method for economic dispatch problem; Appl. Soft Comput, 11 (1) (2011), pp. 83–92

- [49] J.B. Park, Y.W. Jeong, J.R. Shin, K.Y. Lee; An improved particle swarm optimization for nonconvex economic dispatch problems; IEEE Trans. Power Syst, 25 (1) (2010), pp. 156–166

- [50] L.D.S. Coelho, V.C. Mariani; Combining of chaotic differential evolution and quadratic programming for economic dispatch optimization with valve-point effect; IEEE Trans. Power Syst, 21 (2) (2006), pp. 989–996

- [51] Y. Wang, B. Li, T. Weise; Estimation of distribution and differential evolution cooperation for large scale economic load dispatch optimization of power systems; Inf. Sci. (Ny), 180 (12) (2010), pp. 2405–2420

- [52] L.D.S. Coelho, V.C. Mariani; An efficient cultural self-organizing migrating strategy for economic dispatch optimization with valve-point effect; Int. J. Energy Convers. Manag, 51 (12) (2010), pp. 2580–2587

- [53] A. Bhattacharya, P.K. Chattopadhyay; Hybrid differential evolution with biogeography-based optimization for solution of economic load dispatch; IEEE Trans. Power Syst, 25 (4) (2010), pp. 1955–1964

- [54] L. Wang, L.P. Li; An effective differential harmony search algorithm for the solving non-convex economic load dispatch problems; Int. J. Electr. Power Energy Syst, 44 (2013), pp. 832–843

- [55] J.G. Vlachogiannis, K.Y. Lee; Economic load dispatch – a comparative study on heuristic optimization techniques with an improved coordinated aggregation-based PSO; IEEE Trans. Power Syst, 24 (2) (2009), pp. 991–1001

- [56] T.A.A. Victoire, A.E. Jeyakumar; Hybrid PSO–SQP for economic dispatch with valve-point effect; Electr. Power Syst. Res, 71 (1) (2004), pp. 51–59

- [57] J.S. Alsumait, J.K. Sykulski, A.K. Al-Othman; A hybrid GA–PS–SQP method to solve power system valve-point economic dispatch problems; Appl. Energy, 87 (5) (2010), pp. 1773–1781

- [58] C. Jiejin, L. Qiong, L. Lixiang, P. Haipeng, Y. Yixian; A hybrid CPSO–SQP method for economic dispatch considering the valve-point effects; Int. J. Energy Convers. Manag, 53 (1) (2012), pp. 175–181

- [59] A.I. Selvakumar, K. Thanushkodi; A new particle swarm optimization solution to nonconvex economic dispatch problems; IEEE Trans. Power Syst, 22 (1) (2007), pp. 42–51

- [60] A.I. Selvakumar, K. Thanushkodi; Anti-predatory particle swarm optimization: solution to nonconvex economic dispatch problems; Electr. Power Syst. Res, 78 (1) (2008), pp. 2–10

- [61] N. Noman, H. Iba; Differential evolution for economic load dispatch problems; Electr. Power Syst. Res, 78 (8) (2008), pp. 1322–1331

- [62] L.D.S. Coelho, R.C.T. Souza, V.C. Mariani; Improved differential evolution approach based on cultural algorithm and diversity measure applied to solve economic load dispatch problems; Math. Comput. Simul, 79 (10) (2009), pp. 3136–3147

- [63] R. Kumar, D. Sharma, A. Sadu; A hybrid multi-agent based particle swarm optimization algorithm for economic power dispatch; Int. J. Electr. Power Energy Syst, 33 (1) (2011), pp. 115–123

- [64] T. Niknam; A new fuzzy adaptive hybrid particle swarm optimization algorithm for non-linear, non-smooth and non-convex economic dispatch problem; Appl. Energy, 87 (1) (2010), pp. 327–339

- [65] M. Basu; Economic environmental dispatch using multi-objective differential evolution; Int. J. Appl. Soft Comput, 11 (2011), pp. 2845–2853

- [66] U. Güvenç, Y. Sonmez, S. Duman, N. Yorükeren; Combined economic and emission dispatch solution using gravitational search algorithm; Sci. Iran. D Comput. Sci. Eng. Electr. Eng, 19 (6) (2012), pp. 1754–1762

- [67] E.D. Manteaw, N.A. Odero; Combined economic and emission dispatch solution using ABC_PSO hybrid algorithm with valve point loading effect; Int. J. Sci. Res. Publ, 2 (12) (2012), pp. 1–9

- [68] R. Zhang, J. Zhou, L. Mo, S. Ouyang, X. Liao; Economic environmental dispatch using an enhanced multi-objective cultural algorithm; Electr. Power Syst. Res, 99 (2013), pp. 18–29

- [69] D.C. Secui; A new modified artificial bee colony algorithm for the economic dispatch problem; Int. J. Energy Convers. Manag, 89 (2015), pp. 43–62

Document information

Published on 10/04/17

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?