Abstract

After fabric relaxation, there is a reduction in wale and course density due to a reduction in loop length and this actually will affect the fabric properties. Then, it is useful to find a relation between loop length and courses and wales per unit length as well as the yarn thickness because wales and courses per unit length can be easily measured at any state while it is difficult to measure the loop length in the knitted fabrics. Therefore, it is required to find an equation, through which the value of loop length can be easily calculated from the measured values of courses and wales per unit length at any state after the knitting process. In this work estimated equations to calculate the knitted loop length for open to normal structure and for normal to compact structure are developed. By comparing the value of the loop length predicted from this work with the other mentioned models, it was found that the calculated values are very near to the L value of the case study; so the developed equations are acceptable. The tightness factor and the porosity of single jersey fabrics were also calculated theoretically.

Keywords

Single jersey; Loop length; Compact; Super compact; Tightness factor; Fabric porosity

1. Introduction

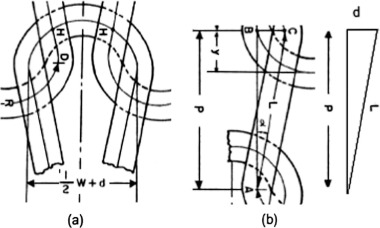

The important loop dimensions are loop length, loop width (wale spacing) and loop height (course spacing). Besides the loop dimensions, which has a great effect on fabric quality and the physical, mechanical and dimensional properties of the cotton single jersey knitted fabric, are the machine gauge, needle type, cam type, yarn feeding system, number of feeders, take down system, cloth rolling or spreading, monitoring and control systems, etc. After fabric relaxation whatever is dry or hot and also after washing there is a reduction in wale and course density due to a reduction in loop length and this actually will affect the other fabric properties. A standard loop shape is shown in Fig. 1 for single jersey structure. The geometrical shape of a standard loop should have same curvature for crown and sinker loop (normally sinker loops are larger than crown). Both the arms of loop should be in the same plane. The bending of crown and sinker loop should be to an equal depth and without twisting or turning. The shape factor, ratio of width to height of the loop should be about 1.3 [1].

|

|

|

Figure 1. Loop shape of jersey knitted fabric by Benltoufa et al. [22]. |

Prakash and Thangamani [2] found that at dry-relaxed state, the values of courses per inch and wales per inch vary with respect to loop length and also any increase or decrease in courses per inch and wales per inch are a reflection of any change in the loop length. Also there was an increase in the initial courses per inch values, while a decrease in wales per inch value was observed during wet relaxation process. They also found that courses per inch values vary with respect to loop length and also a considerable increase in the course per inch after hot washing. Wales per inch values vary with respect to loop length and also decrease after hot washing. It was also found that, loop length values vary before and after wet relaxation and found a minimal change in the loop length after hot washing. Also their results showed that width of fabric values varies with respect to loop length and also a decrease in the width of fabric after hot washing and thickness of fabric values varies with respect to loop length and also an increase in the thickness of fabric after hot washing. Haji [3] concluded that the loop length had a significant effect on the air permeability, bursting strength, dimensional change, crease recovery angle and fabric weight. The loop length had the most significant influence on pilling resistance rating. Marmarali [4] stated that, it was apparent that as the amount of spandex increases loop length values remain nearly the same and the course and wale spacing values decrease.

Kumar and Sampath [5] said that, geometric properties such as course density, stitch density, areal density and tightness factor were found to be inversely proportion to the stitch length at all the relaxation states. Herath and Kang [6] found that, fabric tightness affects significantly the structural behavior of cotton and cotton/spandex structure during relaxation.

Mikučionienė and Laureckienė [7] found that, plain jersey knitted fabric shrinks in longitudinal direction 3.1%, and in transverse direction – 2.9%. The shrinkage values of plain jersey knitted fabrics after three washing and drying cycles were less than −1%, because in single structure knitted fabrics the zero-shrink-potential is achieved faster than double structure knitted fabrics. Anand et al. [8] stated that, this work demonstrated that changes occurring after laundering were largely due to alterations in the loop shape, rather than yarn or loop length shrinkage. The fabrics had taken up their fully relaxed dimensions after five wash and dry cycles and appropriate conditions for laundering had been applied. Quaynor et al. [9] studied the effects of laundering and laundering temperatures on surface properties and dimensional stability for plain flat knit silk, cotton, and polyester fabrics with varying cover factors. The fabrics were subjected to relaxation processes and an extended series of wash and tumble-dry cycles in laundering baths of various temperatures. The results revealed that the dimensional stability of silk was sensitive to a particular temperature. The highest shrinkage was recorded with slackly knitted cotton at the highest temperature. There was a considerable effect of wet relaxation on dimensional stability as well as on surface properties. Silk’s coefficient of friction was the highest, and the lowest surface friction for cotton higher friction than tightly knitted fabrics. The coefficient of friction had a tendency to decrease with increasing tightness, while the surface roughness showed an opposite tendency. There was a good correlation between stick–slip motion and ribs on the fabrics. Therefore, the loop length can be varied after knitting production i.e. during dry relaxation, wet relaxation, at stretch level, and before and after washing, whatever was cold or hot washing. Then, it was interesting to find a relation between loop length and courses and wales per unit length because wales and courses per unit length can be easily measured at any state while it was difficult to measure the loop length in the knitted fabrics. Therefore, it is required to find an equation, through which the value of loop length can be easily calculated from the measured values of courses and wales per unit length at any state after manufacturing. This theoretical value of loop length will be an equivalent loop length value which is applicable to the measured values of wale and course density.

2. Estimation of loop length of single jersey knitted fabric

Loop length (L) is influenced by yarn input tension, knitted fabric take-down tension, knitting velocity, friction in the knitting zone, machine gauge, machine cam setting, yarn structure, yarn linear density, etc. [10].

A more detailed review of the most noted geometrical knitted loop models, including Leaf and Glaskin’s, Munden’s and Korlinski’s model, is presented elsewhere [11]. In these models, the loop length is defined as the function of parameters other than loop width (1/W) and height (1/C), and yarn thickness.

Peirce [12] presumed that a knitted structure is normal when adjacent yarns within a knitted fabric are joined in contact points only. The projection of the loop onto the fabric plane is composed of the circular needle and sinker arcs connected with straight lines i.e. loop legs. The loop is three-dimensional, which means that the loop arcs and legs lay on the cylinder surface with curvature radius (R) and the axis parallel to the course direction. For a normal structure, loop length (L) depends only on yarn thickness (d) [12]:

|

|

(1) |

The loop length of the open knitted structure (ℓ) defined by Peirce [12] is:

|

|

(2) |

where A = loop width, B = loop height, d = yarn thickness.

Peirce’s loop model was verified through experimental work by Fletcher and Roberts [13], [14] and [15].

According to Dalidovich [16], loop length (L) is a function of loop width (A), loop height (B) and yarn thickness (d). Assuming the simplifications that the loop is planar,

|

|

(3) |

According to Dalidovich, the loop length (L) of a normal structure only depends on yarn thickness (d) and can be calculated with a simple equation:

|

|

(4) |

Vékássy [17] also defined a simplified equation for the loop length of a normal knitted structure in which the needle and sinker arcs are in contact. The loop length (l) of the normal structure is only dependent on yarn thickness (d):

|

|

(5) |

Moreover, Vekassy anticipated the structure being more closed than the normal structure. The loop height of the closed structure is smaller than the height of the normal loop structure.

The loop length (L) of the close knitted structure is as follows:

|

|

(6) |

With the derivation from the original Morooka and Matsumoto and Morooka’s loop model [18] and introduction of loop width (A), loop height (B) and yarn thickness (d), the general equation for the loop length (L) calculation is [19]:

|

|

(7) |

In order to define the mathematical models valid for both, conventional and elasticized single knitted structures, the impact of independent variables to loop length was studied with the multiple linear regressions [20].

Preliminarily, a general linear model with four predictors, i.e. loop width (A), loop height (B), yarn thickness (d) and knitted fabric thickness (t), was obtained for all knitted fabrics, elasticized and conventional Eq. (8).

|

|

(8) |

The model is very good, as it explains more than 99% (R2 adj. = 99.4%) of the variability in loop length (L). For the use of this model, knitted fabric thickness measurements are required.

In order to eliminate the fabric thickness measurements and simplify the calculation, a linear model with three predictors given by Cuden et al. [21], i.e. loop width (A), loop height (B), yarn thickness (d), was developed according to Eqs. (2), (3) and (7). On the basis of this model, it is possible to calculate loop length (L) for all knitted fabrics, elasticized and conventional, as stated hereafter – Eq. (9).

|

|

(9) |

The model is good, as it explains more than 98% (R2 adj. = 98.5%) of the variability in loop length (L).

Again, [21] added that, linear models with three predictors, i.e. loop width (A), loop height (B), yarn thickness (d), were generated.

According to the model, the loop length of conventional samples can be calculated as presented in Eq. (10).

|

|

(10) |

The model explains more than 99% (R2 = 99.8%) of the variability in loop length (L).

The loop length of elasticized samples made from various types of elastomeric yarns can be calculated as presented in Eq. (11).

|

|

(11) |

The new loop model for the elasticized single weft structure is good as it explains more than 98% (R2 adj. = 98.8%) of the variability in loop length (L).

Finally they concluded that, as anticipated, the structures made from conventional yarns without elastane show the best agreement with the studied geometrical loop models for open structures. Elasticized structures cannot be modeled well with the existing geometrical loop models. Therefore, the investigated loop models cannot be generally applied when designing both conventional and elasticized single weft knitted fabrics. For both conventional and elasticized knitted fabric planning, Eq. (9) is the new general loop model, which can be applied. For elasticized single weft knitted structures, Eq. (11) is a new mathematical model, which is proposed.

Estimation for the loop length for both conventional and elastomeric yarn in case of normal, compact and super compact can be derived as follows.

2.1. Estimation of the knitted loop length for open to normal structure

Assume that the knitted loop for open to normal structure has the shape as shown in Fig. 2.

- Loop width = 1/Wales per unit length = 1/w = A

- Loop height = 1/courses per unit length = 1/c = B

|

|

(12) |

|

|

|

Figure 2. Loop shape of single jersey knitted fabric for open to normal structure. |

According to [23] for normal to compact structure A ⩽ 4d, B ⩽ 3.46d.

Therefore by substituting the values of A = 4d and B = 3.46d in Eq. (12) for normal structure the loop length will be 16.63d. So the loop length for open structure will be larger than 16.63d.

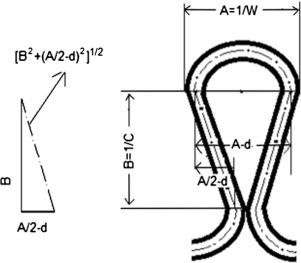

2.2. Estimation of the loop length for normal to compact structure

Assume that the knitted loop has the shape as shown in Fig. 3.

|

|

|

Figure 3. Loop shape for normal to compact single jersey knitted fabric. |

Assumptions

- A is the loop width.

- B is the loop height.

Therefore the loop length can be calculated as follows:

|

|

where

- d = yarn diameter in mm.

- A = 1/Wales per mm = 1/w.

- B = 1/courses per mm = 1/c. Then,

|

|

(13) |

According to [23] for normal to compact structure A ⩽ 4d, B ⩽ 3.46d

|

|

For super compact Single Jersey Knitted Fabric:

|

|

From Eq. (13), L = 5.14d.

A normal to open structure converts to a compact or a very compact structure after the dry or dry and wet relaxation. The values of the loop width (A) for open, normal, compact and super compact are larger than 4, equal to 4, from 2 to 4, less than 2 respectively. The values of the loop height (B) are larger than 3.46 for open, equal to 3.46 for normal, from 3 to 3.46 for compact and from 1 to 3 for super compact [23]. However, [23] approaches the ideal lengthwise-normal structure (B = 3.46). The loose knitted fabrics made from yarns without the elastane core are lengthwise loose, as in most cases B > 3.46. The ideal linear loop module is δ = 16.6 −17.3. Therefore by substituting the values of A and B, for loose to super compact knitted fabric, in the developed equations of the loop length, the ideal linear loop module will be larger than 16.63 for open, equal to 16.63 for normal, from 16.63 to 5.14 for compact, less than 5.14 for super compact.

Case study:

The values of the four predictors from an experiment were as follows:

- W = 36 Wales per inch.

- C = 48 courses per inch.

- d = 0.176 mm.

- L = 2.8 mm.

A comparison between the values of loop length obtained from the different mentioned models and the models from this work is shown in Table 1.

| Model name | Estimated loop length (mm) |

|---|---|

| Peirce model Eq. (1) | 2.93 |

| Peirce Eq. (2) | 2.98 |

| Dalidovich model Eq. (3) | 2.718 |

| Dalidovich Eq. (4) | 2.92 |

| Vekassy model Eq. (5) | 3.05 |

| Vekassy Eq. (6) | 2.35 |

| Morooka Eq. (7) | 2.517 |

| Eq. (8) | 2.86 |

| Eq. (9) | 2.9 |

| Eq. (10) | 2.67 |

| Eq. (11) | 3.37 |

| Loop length from this work Eq. (12) | 2.776 |

| Loop length from this work Eq. (13) | 2.779 |

By comparing the value of the loop lengths predicted from this work from Eqs. (12) and (13) with the other models mentioned before, it is clear that the calculated values are very near to the L value in this case study, which means that the developed equations are acceptable and the loop model is also very near to the actual value.

3. Estimation of tightness factor of the knitted fabric

Generally the tightness factor of the knitted fabric is given [21] as follows:

|

|

(14) |

where L = loop length in mm.

The above equation is true if the loop length is constant at any state after knitted fabric manufacturing but it is not the case because the loop length contracted during fabric finishing and during washing whatever cold or hot washing at end-use. Therefore, if we substitute the values of loop length in conjunction with the value of Wales and courses at the two mentioned equations of loop length, the tightness factor will be as follows:

|

|

(15) |

|

|

(16) |

where Eq. (15) by using estimated loop length from Eqs. (12) and (16) by using estimated loop length from Eq. (13).

Also if we considered that the tightness factor is the ratio of the area covered by the fabrics to the total area then:

|

|

(17) |

where d = 0.044 in mm.

To simplify the Eq. (17) by ignoring the area repeated by the yarn (4d2), the Eq. (17) will be the following:

Loop length ∗ yarn diameter ∗ Wales/unit length ∗ courses/unit length

|

|

(18) |

Case study:

By comparing the values of Tightness factor calculated from Eqs. (15), (16), (17), (18), (19) and (20) by the other which was calculated from Eq. (14), it is obvious that the results of Eqs. (14) and (15) are very near to the result of the normal equation of tightness factor, and this confirms that the equations of loop length proposed in this work are acceptable (Table 2).

| Fed loop length (mm) | Yarn count (Tex) | Wales per inch | Courses per inch | Yarn diameter (mm) | Tightness factor from Eq. (14) | Tightness factor from Eq. (15) | Tightness factor from Eq. (17) | Tightness factor from Eq. (18) |

|---|---|---|---|---|---|---|---|---|

| 2.6 | 14.75 | 30.48 | 60.96 | 0.160 | 1.47 | 1.42 | 1.17 | 1.24 |

| 2.7 | 16.4 | 38 | 56 | 0.176 | 1.49 | 1.57 | 1.15 | 1.49 |

| 2.8 | 16.4 | 36 | 48 | 0.176 | 1.44 | 1.45 | 0.98 | 1.3 |

4. Estimation of knitted fabric porosity

Porosity is one of the main physical parameters that have a great influence on comfort properties. Porosity of knitted fabric can be defined as [1 − the ratio between the volume of the fibers in the cell to the volume of the unit cell of knitted fabric].

Therefore

|

|

where L, loop length in mm and tex/106 is the weight of yarn per mm

|

|

where (t) is the Fabric Thickness, which is 2d for Single Jersey i.e.,

- t = 2d.

- d = 0.044 in mm.

|

|

|

|

(19) |

where

- C = Courses/mm.

- W = Wales/mm.

- L, loop length in mm.

- fiber density in gm/mm3.

To simplifying the above equation the Volume of the yarn can be calculated from another way as follows:

|

|

If the yarn is assumed theoretically to be circular in cross section

|

|

Therefore

|

|

|

|

(20) |

Benltoufa et al. [22] found that the porosity can be calculated as follows

|

|

- t: sample’s thickness (cm);

- L: elementary loop length (cm);

- d: yarn diameter (cm);

- C: number of courses per cm;

- W: number of Wales per cm.

Case study:

The porosity of Single Jersey cotton knitted fabrics was calculated from Eq. (19) as shown in Table 3.

| Measured loop length (mm) | Yarn count (Tex) | Wales per inch | Courses per inch | Tightness factor from Eq. (14) | Porosity from Eq. (19) (%) |

|---|---|---|---|---|---|

| 2.3 | 20 | 47 | 85 | 1.9 | 52 |

| 2.5 | 20 | 46 | 66 | 1.78 | 60 |

| 2.8 | 16.4 | 36 | 48 | 1.44 | 77 |

If the fabric porosity is calculated from the Eq. (20) the value will be smaller than the calculated value in Table 3 because the yarn diameter was assumed to be circular and it is not the case in knitted fabrics because the yarn twist has low value.

5. Conclusion

In this work, an attempt has been carried out to develop a geometrical theoretical model for the determination of the loop length of single jersey knitted fabrics: a defined simplified equations for the loop length for open to normal knitted structure and for normal to compact structure in which the wales and courses are adjacent to each other and after knitting become highly close in contact. By comparing the predicted values of the loop lengths from this work by Eqs. (12) and (13) with the other researcher’s models, it was found that the calculated loop length values are very near to the actual fed loop length.

From the developed equations of the loop length, we found that, the ideal linear loop module will be larger than 16.63 for open single jersey structure, equal to 16.63 for normal, from 16.63 to 5.14 for compact, and less than 5.14 for super compact structures.

Also, theoretically the tightness factor and the porosity of single jersey knitted fabrics were calculated by substituting the developed loop length equations and the results agree closely with the normal equation of tightness factor.

References

- [1] S.C. Anand, K.S.M. Brown, L.G. Higgins, D.A. Holmes, M.E. Hall, D. Conrad; Effect of laundering on the dimensional stability and distortion of knitted fabrics; AUTEX Res. J., 2 (2) (2002)

- [2] C. Prakash, K. Thangamani; Establishing the effect of loop length on dimensional stability of single jersey knitted fabric made from cotton/lycra core spun yarn; Indian J. Sci. Technol., 3 (3) (2010)

- [3] M.A. Mona Haji; Physical and mechanical properties of cotton/spandex fabrics; Pak. Text. J., 62 (1) (2013), pp. 52–55

- [4] A. Bayazit Marmarali; Dimensional and physical properties of cotton/spandex single jersey fabrics; Text. Res. J., 73 (1) (2003), pp. 11–14

- [5] V. Kumar, V.R. Sampath; Investigation on the physical and dimensional properties of single jersey fabrics made from cotton sheath – elastomeric core spun; Fibres Text. East. Eur.; 21, 3 (99) (2013), pp. 73–75

- [6] C.N. Herath, B. Choon Kang; Effect of washing cycles on behavior of core spun cotton/spandex interlock structures; Fibers Polym., 10 (2) (2009), pp. 209–216

- [7] D. Mikučionienė, G. Laureckienė; The influence of drying conditions on dimensional stability of cotton weft knitted fabrics; Mater. Sci. (Medžiagotyra), 15 (1) (2009) ISSN: 1392–1320

- [8] S.C. Anand, K.S.M. Brown, L.G. Higgins, D.A. Holmes, M.E. Hall, D. Conrad; Effect of laundering on the dimensional stability and distortion of knitted fabrics; AUTEX Res. J., 2 (2) (2002)

- [9] L. Quaynor, M. Takahash, M. Nakajima; Effects of laundering on the surface properties and dimensional stability of plain knitted fabrics; Text. Res. J., 70 (1) (2000), pp. 28–35

- [10] A. Pavko-Cuden; Study of the Weft Knitted Loop; Doctoral Thesis University of Ljubljana, Ljubljana (2005)

- [11] A. Pavko-Cuden; Parameters of compact single weft knitted structure, Part 1: loop modules and Munden constants – state of research; Tekstilec, 53 (2010), pp. 205–214

- [12] F.T. Peirce; Geometrical principles applicable to the design of functional fabrics; Text. Res. J., 17 (1947), pp. 123–147

- [13] H.M. Fletcher, S.H. Roberts; The geometry of plain and rib knit cotton fabrics and its relation to shrinkage in laundering; Text. Res. J., 22 (1952), pp. 84–88

- [14] H.M. Fletcher, S.H. Roberts; The geometry of knit fabrics made of staple rayon and nylon and its relationship to shrinkage in laundering; Text. Res. J., 22 (1952), pp. 466–471

- [15] H.M. Fletcher, S.H. Roberts; Relationship of the geometry of plain knit cotton fabric to its dimensional change and elastic properties; Text. Res. J., 24 (1954), pp. 729–737

- [16] A.S. Dalidovich; Basics of knitting technology; Legkaya Industriya, Moscow (1970), p. 296 In Russian

- [17] A. Vékássy; Examination of the cover-factor and specific weight of weft-knitted or looped basis texture based on the exact value of the loop length; Acta Tech., 31 (1960), pp. 69–102

- [18] Hi. Morooka, Y. Matsumoto, H. Morooka; A geometric analysis of the stitch form of a circular plain knit fabric inserted over a cylinder; Text. Res. J., 68 (1998), pp. 930–936

- [19] A. Cuden; Geometrical models of weft knitted loop: open, normal and compact structure; Tekstilec, 53 (2010), pp. 113–138

- [20] M. Bona; Statistical Methods for the Textile Industry; Biella, Biella (1993)

- [21] A. Cuden, A. Hladnik, F. Sluga; Loop length of plain single weft knitted structure with elastane; J. Eng. Fibers Fabr., 8 (2) (2013), pp. 110–120

- [22] S. Benltoufa, F. Fayala, M. Cheikhrouhou, S. Ben Nasrallah; Porosity determination of jersey structure; AUTEX Res. J., 7 (1) (2007)

- [23] A. Cuden; Parameters of compact single weft knitted structure (Part 2): loop modules and munden constants – compact and supercompact structure; Tekstilec, 53 (2010), pp. 259–272

Document information

Published on 12/04/17

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?

![Loop shape of jersey knitted fabric by Benltoufa et al. [22].](/wd/images/9/9e/Draft_Content_264605278-1-s2.0-S1110016816000594-gr1.jpg)