| (47 intermediate revisions by 3 users not shown) | |||

| Line 3: | Line 3: | ||

In this research, the free surface of micro film of hexyl alcohol on a partially submerged rotating drum has been predicted using CFD (computational fluid dynamics) and compared with experimental data and analytical solution. The trend of has been found very comparable with experimental and analytical solution. A Matlab code was used to model the flow and film dynamics. Computationally it was an unsteady state problem and semi-steady state was achieved. No surfactant was present on the surface. The speed of the moving rotating drum was set a ''rpm''. With the increase of rotating drum, the minimum film thickness increases with ''rpm'' (for <math display="inline">\alpha _o </math> = 47<math>^{0}</math> and for <math display="inline">\alpha _o </math>= 58<math>^{0}</math>). | In this research, the free surface of micro film of hexyl alcohol on a partially submerged rotating drum has been predicted using CFD (computational fluid dynamics) and compared with experimental data and analytical solution. The trend of has been found very comparable with experimental and analytical solution. A Matlab code was used to model the flow and film dynamics. Computationally it was an unsteady state problem and semi-steady state was achieved. No surfactant was present on the surface. The speed of the moving rotating drum was set a ''rpm''. With the increase of rotating drum, the minimum film thickness increases with ''rpm'' (for <math display="inline">\alpha _o </math> = 47<math>^{0}</math> and for <math display="inline">\alpha _o </math>= 58<math>^{0}</math>). | ||

| − | '''Keywords''': | + | '''Keywords''': Liquid film, cfd, vof, moving surface, hexyl alcohol |

==1. Introduction== | ==1. Introduction== | ||

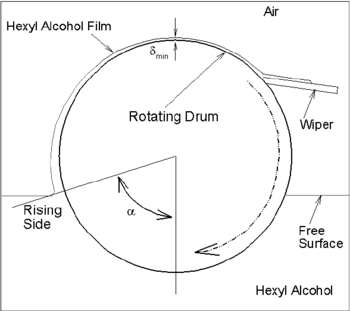

| − | This paper presents a two-dimensional (not a 3D as performed in <span id='citeF-1'></span>[[#cite-1|[1]]]) computational CFD model describing an unsteady state thin liquid hexyl alcohol film on the RD adjacent to the surface of a partially submerged rotating drum (RD). The liquid film was modeled by volume of fluid, VOF <span id='citeF-2'></span>[[#cite-2|[2]]]. A RD submerged in a fluid picks up fluid on the outer surface of the RD ( | + | This paper presents a two-dimensional (not a 3D as performed in <span id='citeF-1'></span>[[#cite-1|[1]]]) computational CFD model describing an unsteady state thin liquid hexyl alcohol film on the RD adjacent to the surface of a partially submerged rotating drum (RD). The liquid film was modeled by volume of fluid, VOF <span id='citeF-2'></span>[[#cite-2|[2]]]. A RD submerged in a fluid picks up fluid on the outer surface of the RD ([[#img-1|Figure 1]]). Few parameters e.g. <math>D_{\mathit{rd, \rho , \sigma , \mu , \alpha _o }}</math>, and'' rpm ''influence the free surface as well (refer to list of symbols). These properties form various nondimensional numbers, e.g.,'' Ca, We,'' Re,'' Fr'' (refer to list of symbols) . Solving complete Navier-Stokes equation with VOF as performed here would allow predicting the free surface provided numerical error is minimized. However, VOF has limitation like all other free surface modeling approaches. |

| − | Literature review suggests that there is limited focus <span id='citeF-3'></span><span id='citeF-4'></span><span id='citeF-5'></span><span id='citeF-6'></span><span id='citeF-7'></span>[[#cite-3|[3,4,5,6,7]]] on this topic and only a few correlations are available based on the experimental or analytical simplification <span id='citeF-8'></span><span id='citeF-9'></span><span id='citeF-10'></span>[[#cite-8|[8,9,10]]] . The surface area of the liquid film and the amount of fluid being carried by an RD are important parameters for design purpose (e.g. cooling of final molasses in a sugar factory <span id='citeF-10'></span><span id='citeF-11'></span><span id='citeF-12'></span>[[#cite-10|[10,11,12]]] and pharmaceutical drug delivery of solid oral dosage forms film coatings <span id='citeF-13'></span><span id='citeF-14'></span><span id='citeF-15'></span>[[#cite-13|[13,14,15]]]. | + | Literature review suggests that there is limited focus <span id='citeF-3'></span><span id='citeF-4'></span><span id='citeF-5'></span><span id='citeF-6'></span><span id='citeF-7'></span>[[#cite-3|[3,4,5,6,7]]] on this topic and only a few correlations are available based on the experimental or analytical simplification <span id='citeF-8'></span><span id='citeF-9'></span><span id='citeF-10'></span>[[#cite-8|[8,9,10]]]. The surface area of the liquid film and the amount of fluid being carried by an RD are important parameters for design purpose (e.g. cooling of final molasses in a sugar factory <span id='citeF-10'></span><span id='citeF-11'></span><span id='citeF-12'></span>[[#cite-10|[10,11,12]]] and pharmaceutical drug delivery of solid oral dosage forms film coatings <span id='citeF-13'></span><span id='citeF-14'></span><span id='citeF-15'></span>[[#cite-13|[13,14,15]]]. |

<div id='img-1'></div> | <div id='img-1'></div> | ||

| − | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: auto;" |

|- | |- | ||

| − | |style="padding:10px;"|[[Image:Trang_2019a_8813_d71ae35a-79e2-422f-856c-ab069574daa4-ufig1.png| | + | |style="padding:10px;"|[[Image:Trang_2019a_8813_d71ae35a-79e2-422f-856c-ab069574daa4-ufig1.png|350px|Schematic diagram of the thin film on a partially-submerged rotating drum.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| − | | colspan="1" style="padding | + | | colspan="1" style="padding:10px;" | '''Figure 1'''. Schematic diagram of the thin film on a partially-submerged rotating drum |

|} | |} | ||

| − | The dynamics of liquid film on a straight plate <span id='citeF-16'></span>[[#cite-16|[16]]] is relatively easy compared to the investigation performed here. Prediction of dynamic contact line <span id='citeF-17'></span>[[#cite-17|[17]]] is still under investigation. This paper will particularly focus when a wiper is used to wipe the film of hexyl alcohol. The prime motivation of this investigation is that there is published experimental data for hexyl alcohol which occur at <math display="inline">\alpha </math>=180<math>^{0}</math> ( | + | The dynamics of liquid film on a straight plate <span id='citeF-16'></span>[[#cite-16|[16]]] is relatively easy compared to the investigation performed here. Prediction of dynamic contact line <span id='citeF-17'></span>[[#cite-17|[17]]] is still under investigation. This paper will particularly focus when a wiper is used to wipe the film of hexyl alcohol. The prime motivation of this investigation is that there is published experimental data for hexyl alcohol which occur at <math display="inline">\alpha </math>=180<math>^{0}</math> ([[#img-1|Figure 1]]). There is no accurate measuring technique available to measure the film thickness <span id='citeF-18'></span>[[#cite-18|[18]]], even though, the experimental effort has been lifted. Most of the studies avoided curved moving plane movement <span id='citeF-19'></span><span id='citeF-20'></span>[[#cite-19|[19,20]]] in detail. |

| − | After the computational domain and model equation, this paper will continue with the computational results compared with the experimental and analytical solution of <span id='citeF-8'></span><span id='citeF-9'></span>[[#cite-8|[8,9]]] . This article assumes that there is no foam <span id='citeF-21'></span>[[#cite-21|[21]]] formation near RD and no vaporization <span id='citeF-22'></span>[[#cite-22|[22]]] on the liquid film. | + | After the computational domain and model equation, this paper will continue with the computational results compared with the experimental and analytical solution of <span id='citeF-8'></span><span id='citeF-9'></span>[[#cite-8|[8,9]]]. This article assumes that there is no foam <span id='citeF-21'></span>[[#cite-21|[21]]] formation near RD and no vaporization <span id='citeF-22'></span>[[#cite-22|[22]]] on the liquid film. |

| − | ==2. Computation | + | ==2. Computation Domain== |

| − | The computational domain of an RD rotating anti-clockwise on a free liquid surface is shown in | + | The computational domain of an RD rotating anti-clockwise on a free liquid surface is shown in [[#img-2|Figure 2]]. Various boundary conditions are shown in [[#table-1|Table 1]]. |

| − | <div class=" | + | <div class="center" style="font-size: 75%;"> |

| − | '''Table 1 | + | '''Table 1'''. List of BC for the model </div> |

| − | + | <div id='table-1'></div> | |

| − | {| class="floating_tableSCP" style="text-align: left; margin: 1em auto;border-top: 2px solid;border-bottom: 2px solid;min-width: | + | {| class="floating_tableSCP" style="text-align: left; margin: 1em auto;border-top: 2px solid;border-bottom: 2px solid;min-width:40%;font-size:85%;" |

|- | |- | ||

| − | | | + | | style="padding-bottom:10px;"| '''Serial ''' |

| − | | Location | + | | style="padding-bottom:10px;"|'''Location ''' |

| − | | | + | | style="padding-bottom:10px;"| '''Boundary''' |

|- | |- | ||

| 1 | | 1 | ||

| Line 58: | Line 58: | ||

<div id='img-2'></div> | <div id='img-2'></div> | ||

| − | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 60%;max-width: 60%;" |

|- | |- | ||

| style="padding:10px;"|[[Image:Trang_2019a_4609_132c3a60-cf92-4efc-a778-f25a97b424d7-ufig2.png|400px|Various conditions (BC) at the boundary for a partially submerged rotating drum rotating on a free liquid surface in the tank [boundary D<sub>rd</sub> =130 mm, Hₗ =365.555 mm, Wₜ =800 mm, Hₐ =134.445 mm].]] | | style="padding:10px;"|[[Image:Trang_2019a_4609_132c3a60-cf92-4efc-a778-f25a97b424d7-ufig2.png|400px|Various conditions (BC) at the boundary for a partially submerged rotating drum rotating on a free liquid surface in the tank [boundary D<sub>rd</sub> =130 mm, Hₗ =365.555 mm, Wₜ =800 mm, Hₐ =134.445 mm].]] | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| − | | colspan="1" style="padding-bottom:10px;"| '''Figure 2 | + | | colspan="1" style="padding-bottom:10px;"| '''Figure 2'''. Various conditions (BC) at the boundary for a partially submerged rotating drum rotating on a free liquid surface in the tank [boundary D<math>_{rd}</math> =130 mm, H<math>_{l}</math> =365.555 mm, W<math>_{t}</math> =800 mm, H<math>_{a}</math> =134.445 mm] |

|} | |} | ||

| − | The stagnant free liquid surface is located at <math display="inline">\alpha =\alpha _o </math>. By varying ''H<math>_{a}</math>'' the initial <math display="inline">\alpha _o </math>can be changed. An arc of 225 degrees RD is modeled. | + | The stagnant free liquid surface is located at <math display="inline">\alpha =\alpha _o </math>. By varying '' H<math>_{a}</math>'' the initial <math display="inline">\alpha _o </math>can be changed. An arc of 225 degrees RD is modeled. |

| − | ==3. Computational | + | ==3. Computational Model== |

A Volume of Fluid <span id='citeF-2'></span>[[#cite-2|[2]]] approach is used to model the free the surface of the liquid film (vof is based on the Continuum Surface Force, CSF, <span id='citeF-23'></span>[[#cite-23|[23]]]). | A Volume of Fluid <span id='citeF-2'></span>[[#cite-2|[2]]] approach is used to model the free the surface of the liquid film (vof is based on the Continuum Surface Force, CSF, <span id='citeF-23'></span>[[#cite-23|[23]]]). | ||

| − | The continuity equation for the 2D case is governed by Eq. 1 | + | The continuity equation for the 2D case is governed by Eq.(1) |

<span id="eq-1"></span> | <span id="eq-1"></span> | ||

| Line 80: | Line 80: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\begin{array}{l}\frac | + | | style="text-align: center;" | <math>\begin{array}{l}\frac{{\partial u}}{{\partial x}} + \frac{{\partial v}}{{\partial y}} = 0\end{array} </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (1) | | style="width: 5px;text-align: right;white-space: nowrap;" | (1) | ||

|} | |} | ||

| − | The momentum equation for x (horizontal direction) is given by Eq. 2 | + | The momentum equation for x (horizontal direction) is given by Eq.(2) |

<span id="eq-2"></span> | <span id="eq-2"></span> | ||

| Line 93: | Line 93: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\begin{array}{l}\begin{array}{l}\rho \left({\frac | + | | style="text-align: center;" | <math>\begin{array}{l}\begin{array}{l}\rho \left({\frac{{\partial u}}{{\partial t}} + u\frac{{\partial u}}{{\partial x}} + v\frac{{\partial u}}{{\partial y}}} \right)= - \frac{{\partial p}}{{\partial x}}\\ + \mu \left({\frac{{{\partial ^{2}}u}}{{\partial {x^{2}}}} + \frac{{{\partial ^{2}}u}}{{\partial {y^{2}}}}} \right)+ {F_{stx}} \end{array}\end{array} </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (2) | | style="width: 5px;text-align: right;white-space: nowrap;" | (2) | ||

|} | |} | ||

| − | The momentum equation for y (vertical direction) is given by Eq. 3 | + | The momentum equation for y (vertical direction) is given by Eq.(3) |

<span id="eq-3"></span> | <span id="eq-3"></span> | ||

| Line 106: | Line 106: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\begin{array}{l}\begin{array}{c}\begin{array}{l}\rho \left({\frac | + | | style="text-align: center;" | <math>\begin{array}{l}\begin{array}{c}\begin{array}{l}\rho \left({\frac{{\partial v}}{{\partial t}} + u\frac{{\partial v}}{{\partial x}} + v\frac{{\partial v}}{{\partial y}}} \right)= - \frac{{\partial p}}{{\partial y}} + \\ \mu \left({\frac{{{\partial ^{2}}v}}{{\partial {x^{2}}}} + \frac{{{\partial ^{2}}v}}{{\partial {y^{2}}}}} \right)+ {F_{sty}} - \dot m{g_y} \end{array} \end{array}\end{array} </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3) | ||

|} | |} | ||

| − | The Reynolds stress is solved by Realizable models <span id='citeF-24'></span>[[#cite-24|[24]]] which are two equation models (Eq.4 and Eq.5) and can be described as: | + | The Reynolds stress is solved by Realizable models <span id='citeF-24'></span>[[#cite-24|[24]]] which are two equation models (Eq.(4) and Eq.(5)) and can be described as: |

<span id="eq-4"></span> | <span id="eq-4"></span> | ||

| Line 119: | Line 119: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\begin{array}{l}\begin{array}{l}\begin{array}{l}\begin{array}{l}\frac | + | | style="text-align: center;" | <math>\begin{array}{l}\begin{array}{l}\begin{array}{l}\begin{array}{l}\frac{\partial \left(\rho \varepsilon \right)}{\partial t}+\frac{\partial \left(\rho \varepsilon u\right)}{\partial x}+\frac{\partial \left(\rho \varepsilon v\right)}{\partial y}=\;\frac\partial{\partial x}\left[\left(\mu +\frac{\mu _t}{\sigma _\varepsilon }\right)\frac{\partial \varepsilon }{\partial x}\right]+\end{array}\\\frac\partial{\partial y}\left[\left(\mu +\frac{\mu _t}{\sigma _\varepsilon }\right)\frac{\partial \varepsilon }{\partial y}\right]+\;\rho C_1S\varepsilon \end{array}\\-\rho C_2\frac{\varepsilon ^{2}}{k+\sqrt{\nu \varepsilon }}\end{array}\end{array} </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (4) | | style="width: 5px;text-align: right;white-space: nowrap;" | (4) | ||

|} | |} | ||

| − | |||

<span id="eq-5"></span> | <span id="eq-5"></span> | ||

| Line 131: | Line 130: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\begin{array}{l}\begin{array}{l}\begin{array}{l}\begin{array}{l}\frac | + | | style="text-align: center;" | <math>\begin{array}{l}\begin{array}{l}\begin{array}{l}\begin{array}{l}\frac{\partial \left(\rho \varepsilon \right)}{\partial t}+\frac{\partial \left(\rho \varepsilon u\right)}{\partial x}+\frac{\partial \left(\rho \varepsilon v\right)}{\partial y}=\;\frac\partial{\partial x}\left[\left(\mu +\frac{\mu _t}{\sigma _\varepsilon }\right)\frac{\partial \varepsilon }{\partial x}\right]+\end{array}\\\frac\partial{\partial y}\left[\left(\mu +\frac{\mu _t}{\sigma _\varepsilon }\right)\frac{\partial \varepsilon }{\partial y}\right]+\;\rho C_1S\varepsilon \end{array}\\-\rho C_2\frac{\varepsilon ^{2}}{k+\sqrt{\nu \varepsilon }}\end{array}\end{array} </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (5) | | style="width: 5px;text-align: right;white-space: nowrap;" | (5) | ||

|} | |} | ||

| − | <math display="inline">G_k </math> is the generation of turbulent kinetic energy <span id='citeF-25'></span>[[#cite-25|[25]]] . The constants are <math display="inline">\sigma _k </math>=1.0, <math display="inline">C_\mu </math> =0.09, <math display="inline">C_2 </math>=1.9, <math display="inline">C1=max(0.43,\;\frac | + | <math display="inline">G_k </math> is the generation of turbulent kinetic energy <span id='citeF-25'></span>[[#cite-25|[25]]]. The constants are <math display="inline">\sigma _k </math>=1.0, <math display="inline">C_\mu </math> =0.09, <math display="inline">C_2 </math>=1.9, <math display="inline">C1=max(0.43,\;\frac\eta{\eta{+5}}) </math>, where <math display="inline">\eta =\frac{S\kappa }\varepsilon </math>, <math display="inline">S </math> is the magnitude of vorticity. The unstable <span id='citeF-26'></span>[[#cite-26|[26]]] nature of the wave demands tiny time step for the film dynamics to predict. |

| − | The computational modeling parameters were chosen after verification <span id='citeF-27'></span>[[#cite-27|[27]]] . Quadrilateral mesh <span id='citeF-28'></span>[[#cite-28|[28]]], higher order discretization, PISO <span id='citeF-29'></span>[[#cite-29|[29]]] pressure- velocity coupling, geometric reconstruction <span id='citeF-30'></span>[[#cite-30|[30]]] for VOF, and smooth wall (''K<math>_{s}</math>''=0,''Cs'' =0.5) were used in the CFD <span id='citeF-31'></span><span id='citeF-32'></span>[[#cite-31|[31,32]]] calculations. For VOF, a modified discretization is used <span id='citeF-33'></span>[[#cite-33|[33]]] . The minimum film thickness (<math display="inline">\alpha </math> = 180<math>^{0}</math>) as determined theoretically by | + | The computational modeling parameters were chosen after verification <span id='citeF-27'></span>[[#cite-27|[27]]]. Quadrilateral mesh <span id='citeF-28'></span>[[#cite-28|[28]]], higher order discretization, PISO <span id='citeF-29'></span>[[#cite-29|[29]]] pressure- velocity coupling, geometric reconstruction <span id='citeF-30'></span>[[#cite-30|[30]]] for VOF, and smooth wall (''K<math>_{s}</math>''=0,'' Cs'' =0.5) were used in the CFD <span id='citeF-31'></span><span id='citeF-32'></span>[[#cite-31|[31,32]]] calculations. For VOF, a modified discretization is used <span id='citeF-33'></span>[[#cite-33|[33]]]. The minimum film thickness (<math display="inline">\alpha </math> = 180<math>^{0}</math>) as determined theoretically by Eq.(6) offered by <span id='citeF-8'></span>[[#cite-8|[8]]]: |

<span id="eq-6"></span> | <span id="eq-6"></span> | ||

| Line 146: | Line 145: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\begin{array}{l}\delta _{min}=\sqrt{\frac | + | | style="text-align: center;" | <math>\begin{array}{l}\delta _{min}=\sqrt{\frac{\mu R_{rd}\omega }{41.1\rho \left(1-{\displaystyle \frac{\alpha _o}{180}}\right)}}\end{array} </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (6) | | style="width: 5px;text-align: right;white-space: nowrap;" | (6) | ||

|} | |} | ||

| − | For no backflow condition <span id='citeF-34'></span>[[#cite-34|[34]]], a solution is given by | + | For no backflow condition <span id='citeF-34'></span>[[#cite-34|[34]]], a solution is given by Eq.(7). |

<span id="eq-7"></span> | <span id="eq-7"></span> | ||

| Line 159: | Line 158: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\begin{array}{l}\delta _{min}=0.94\left(\frac | + | | style="text-align: center;" | <math>\begin{array}{l}\delta _{min}=0.94\left(\frac{\mu U_o}\sigma \right)^\frac16x\sqrt{\frac{\mu R_{rd}\omega }{41.1\rho \left(1-{\displaystyle \frac{\alpha _o}{180}}\right)}}\end{array} </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (7) | | style="width: 5px;text-align: right;white-space: nowrap;" | (7) | ||

|} | |} | ||

| − | The introduction of <math display="inline">\left(\frac | + | The introduction of <math display="inline">\left(\frac{\mu U_o}\sigma \right)^\frac16=\left(Ca\right)^\frac 16 </math> in (7) has a striking similarity as found here <span id='citeF-8'></span>[[#cite-8|[8]]]. As the rotating drum increases, the <math display="inline">\left(\frac{\mu U_o}\sigma \right)^\frac16 </math>approaches to unity. The aspect ratio of the mesh near the wall was 1.08, so gradually the size was reduced. All the calculations presented in the journal were double precision and took nearly 8 days to complete one set of calculation. The mesh was refined few times to confirm that the solutions were less dependent on the size and shape of the mesh. |

==4. Results== | ==4. Results== | ||

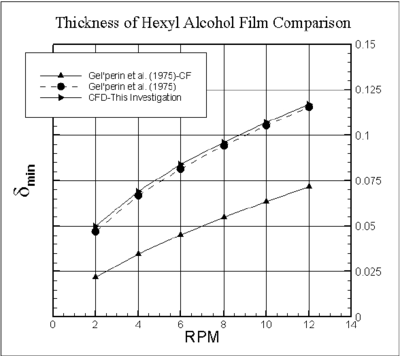

| − | + | [[#img-3|Figure 3]] shows the <math display="inline">\delta _{min} </math> as function of'' rpm'' for <math display="inline">\alpha _o </math> = 47<math>^{0}</math> from three different sources, e.g., analytical solution without the CF (Eq.(6)), analytical solution with CF (Eq.(7)) and CFD <span id='citeF-35'></span>[[#cite-35|[35]]] solution. Apparently, the analytical solution without the CF is very close to the CFD <span id='citeF-36'></span><span id='citeF-37'></span>[[#cite-36|[36,37]]] prediction. In all three lots, the trend is the same. From Eqs.(6) and (7), the <math display="inline">\delta _{min} </math> varies with is relationship of'' rpm'' (<math display="inline">\delta _{min}\infty rpm^{0.50} </math> ), for the CFD results it varies as <math display="inline">\delta _{min}\infty rpm^{0.47} </math> . The properties of the hexyl alcohol are the same for all three sources (<math display="inline">\sigma </math> =0.00384 N/m, <math display="inline">\rho </math>=812 kg/m3, <math display="inline">\mu </math> =0.00392 kg/m/s). In the original paper of <span id='citeF-8'></span><span id='citeF-9'></span>[[#cite-8|[8,9]]], the precise properties of hexyl alcohol was not reported. | |

<div id='img-3'></div> | <div id='img-3'></div> | ||

| − | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: auto;" |

|- | |- | ||

|style="padding:10px;"|[[Image:Trang_2019a_6821_561b9b41-2c2a-458c-91a8-f336b8733dbd-ufig3.png|400px|A minimum film thickness for hexyl alcohol as a function of ''rpm'' of the drum for αₒ= 47<sup>o</sup>]] | |style="padding:10px;"|[[Image:Trang_2019a_6821_561b9b41-2c2a-458c-91a8-f336b8733dbd-ufig3.png|400px|A minimum film thickness for hexyl alcohol as a function of ''rpm'' of the drum for αₒ= 47<sup>o</sup>]] | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| − | | colspan="1" style="padding | + | | colspan="1" style="padding:10px;"| '''Figure 3'''. A minimum film thickness for hexyl alcohol as a function of ''rpm'' of the drum for <math>\alpha _o= </math>47<math>^{o}</math> |

|} | |} | ||

| − | + | There are few important aspects to highlight here. Firstly, the loss of liquid at the pressure outlet BC ([[#img-2|Figure 2]]) is compensated by the same amount of liquid injection at the pressure inlet BC which is far away from the RD so there is little impact on the film dynamics of the inflow on the RD. It was expected though for a laminar condition when the plunging <span id='citeF-38'></span><span id='citeF-39'></span><span id='citeF-40'></span>[[#cite-38|[38,39,40]]] the point is avoided (no drop passes the wiper and falls on the receiving tank), there would be a steady state solution which is found to be wrong. Secondly, because of the plunging point is avoided; there is less complicate in terms of numerical instability. Thirdly, as the 10 plunging point is avoided, there is no consequence of entrained air in the form of bubbles from the plunging point which would disturb the stability of the solution. Fourthly, in the real wiper ([[#img-1|Figure 1]]), it would not cause the surface completely free from hexyl alcohol | |

| − | There are few important aspects to highlight here. Firstly, the loss of liquid at the pressure outlet BC ( | + | |

before plunging into the liquid bath and also the surface property would change because of the erosion and the friction between the RD and the wiper would cause heat (maybe negligible). | before plunging into the liquid bath and also the surface property would change because of the erosion and the friction between the RD and the wiper would cause heat (maybe negligible). | ||

| Line 190: | Line 188: | ||

<div id='img-4'></div> | <div id='img-4'></div> | ||

| − | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: auto%;" |

|- | |- | ||

|style="padding:10px;"|[[Image:Trang_2019a_8061_a3a99387-1efd-4226-b821-454a619753bb-ufig4.png|400px|A minimum liquid film thickness for hexyl alcohol as a function of rotating speed of the drum for αₒ= 58<sup>o</sup>]] | |style="padding:10px;"|[[Image:Trang_2019a_8061_a3a99387-1efd-4226-b821-454a619753bb-ufig4.png|400px|A minimum liquid film thickness for hexyl alcohol as a function of rotating speed of the drum for αₒ= 58<sup>o</sup>]] | ||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| − | | colspan="1" style="padding | + | | colspan="1" style="padding:10px;"| '''Figure 4'''. A minimum liquid film thickness for hexyl alcohol as a function of rotating speed of the drum for <math>\alpha _o= </math>58<math>^{o}</math> |

|} | |} | ||

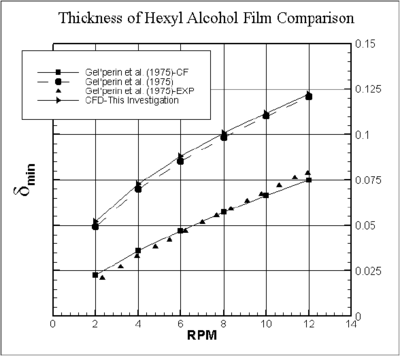

| + | Again striking similarities have been found for <math display="inline">\alpha _o </math> = 58<math>^{0}</math> as shown in [[#img-4|Figure 4]]. There are four plots in [[#img-4|Figure 4]], e.g., two analytical solutions (Eqs.(6) and (7)), CFD solutions and experimental data. The trend of variation of <math display="inline">\delta _{min} </math> has been proved the same in CFD, experimental and analytical results. In CFD results, <math display="inline">\delta _{min} </math> varies with ''rpm'' by <math display="inline">\delta _{min}=rpm^{0.48} </math> . Surprisingly again, Eq.(6) and CFD results are close and away from the Eq.(7) and experimental data by a factor 1/CF. The proportionality constant in CFD prediction for this case is only 4% a way from the critical prediction. | ||

| − | + | ==5. Conclusions== | |

| + | The problem of determining a thin film on a RD and the minimum film thickness are investigated using CFD for a partially-submerged rotating drum. The analytical solution is too simplified to determine the <math display="inline">\delta _{min} </math> and CFD is needed to understand the dynamics of liquid film. A no-slip boundary condition was considered on the RD wall and the meniscus free surface was predicted using VOF. CFD investigation shows that <math display="inline">\delta _{min} </math> increases with, same as experimental dd analytical solution. Because plunging end of RD was avoided by using a wiper, convergence behavior was quite stable. | ||

| − | < | + | All the 12 case of the simulations shown in this paper were for isothermal conditions <span id='citeF-41'></span>[[#cite-41|[41]]], a terms used for this is called 'cold modeling'. It is possible to extend the model developed for the non-isothermal condition were the physical properties would change as a function of temperature. It is possible to extend the model developed for non-isothermal conditions were the physical properties would change as a function of temperature. If crystallization does occur and vaporization takes place, an equivalent sink/source term to be added in the model equations to account the mass/momentum/energy transfer and it would be more complicated. For the higher rate crystallization, the back flow will be miminised. From CFD point of the view, viscous film hold up is less complicated to predict. For a partial crystallization of the film would between Eqs.(6) and (7). |

| − | {| class="floating_tableSCP" style="text-align: left; margin: 1em auto;border-top: 2px solid;border-bottom: 2px solid;min-width:50%;font-size:85 | + | ==6 List of Symbols== |

| − | |- style="text-align: left;" | + | |

| − | + | <div class="center" style="font-size: 75%;"> | |

| − | | '''Description''' | + | '''Table. 2''' Notations with units and values </div> |

| − | | ''' Unit ''' | + | |

| + | {| class="floating_tableSCP" style="text-align: left; margin: 1em auto;border-top: 2px solid;border-bottom: 2px solid;min-width:50%;font-size:85%;" | ||

| + | |- | ||

| + | | '''Symbols''' | ||

| + | | style="text-align: left;" | '''Description''' | ||

| + | | '''Unit ''' | ||

|- | |- | ||

| <math display="inline">P </math> | | <math display="inline">P </math> | ||

| Line 307: | Line 312: | ||

| <math display="inline">We </math> | | <math display="inline">We </math> | ||

| Weber number | | Weber number | ||

| − | |||

|} | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==References== | ==References== | ||

| − | |||

<div class="auto" style="text-align: left;width: auto; margin-left: auto; margin-right: auto;font-size: 85%;"> | <div class="auto" style="text-align: left;width: auto; margin-left: auto; margin-right: auto;font-size: 85%;"> | ||

<div id="cite-1"></div> | <div id="cite-1"></div> | ||

| − | [[#citeF-1|[1]]] | + | [[#citeF-1|[1]]] Evans P.P., Schwartz L.W., Roy R.V. Three-dimensional solutions for coating flow on a rotating horizontal cylinder: Theory and experiment. Physics of Fluids, 17:072102/1–072102/20, 2005. |

<div id="cite-2"></div> | <div id="cite-2"></div> | ||

| − | [[#citeF-2|[2]]] | + | [[#citeF-2|[2]]] Hirt C.W., Nichols B.D. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys., 39:201–225, 1981. |

<div id="cite-3"></div> | <div id="cite-3"></div> | ||

| − | [[#citeF-3|[3]]] | + | [[#citeF-3|[3]]] Duffy B.R., Wilson S.K. Thin-film and curtain flows on the outside of a rotating horizontal cylinder. Journal of Fluid Mechanics, 394:29–49, 1999. |

<div id="cite-4"></div> | <div id="cite-4"></div> | ||

| − | [[#citeF-4|[4]]] N. H. | + | [[#citeF-4|[4]]] Khan M.N.H., Fletcher C., Evans G., He Q. CFD modeling of free surface and entrainment of buoyant particles from free surface for sumberged jet systems. American Society of Mechanical Engineers, Heat Transfer Division, (Publication) HTD. |

<div id="cite-5"></div> | <div id="cite-5"></div> | ||

| − | [[#citeF-5|[5]]] K. | + | [[#citeF-5|[5]]] Moffatt K. Behaviour of a Viscous Film on the Outer Surface of a Rotating Cylinder. J. Mec., 16:651–673, 1977. |

<div id="cite-6"></div> | <div id="cite-6"></div> | ||

| − | [[#citeF-6|[6]]] | + | [[#citeF-6|[6]]] Moffatt K. Viscous and Resistive Eddies Near Sharp Corner. Journal of Fluid Mechanics, 18:1–18, 1964. |

<div id="cite-7"></div> | <div id="cite-7"></div> | ||

| − | [[#citeF-7|[7]]] A. D. | + | [[#citeF-7|[7]]] Nikolov A.D., Wasan D.T. A novel method for studying the dynamic behavior of both plane-parallel and curved thin liquid films. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 123-124:375–381, 1997. |

<div id="cite-8"></div> | <div id="cite-8"></div> | ||

| − | [[#citeF-8|[8]]] N. I. | + | [[#citeF-8|[8]]] Gelpérin N.I., Nosov, G. A., Makotkin, A.V. Determinating the thickness of liquid film holdup on a rotating drum surface. Chemical and Petroleum Engineering, 11:230–233, 1975. |

<div id="cite-9"></div> | <div id="cite-9"></div> | ||

| − | [[#citeF-9|[9]]] | + | [[#citeF-9|[9]]] Gelpérin, N.I., Nosov G.A., Makotkin A.V. Thickness of a liquid film covering the surface of a rotating drum. Khimicheskoe i Neftyanoe Mashinostroenie, pp. 18–20, 1975. |

<div id="cite-10"></div> | <div id="cite-10"></div> | ||

| − | [[#citeF-10|[10]]] K. | + | [[#citeF-10|[10]]] Butler K., White E.T., Wright P. G. Pickup layer thickness on a horizontal rotating drum. In Chemeca 90: The Eighteenth Australasian Chemical Engineering Conference, Processing Pacific Re- sources, 1990. |

<div id="cite-11"></div> | <div id="cite-11"></div> | ||

| − | [[#citeF-11|[11]]] | + | [[#citeF-11|[11]]] Korn O. Cyclone Dryer: A pneumatic dryer with increased solid residence time. Drying Technology, 19:1925, 2001. |

<div id="cite-12"></div> | <div id="cite-12"></div> | ||

| − | [[#citeF-12|[12]]] | + | [[#citeF-12|[12]]] Jullienne L.M.S.A., Munsamy S. Assessment Of Final Molasses Coolers. Proceedings of The South African Sugar Technologists' Association - June 1981. |

<div id="cite-13"></div> | <div id="cite-13"></div> | ||

| − | [[#citeF-13|[13]]] | + | [[#citeF-13|[13]]] Harting R., Johnston K., Petersen S. Correlating in vitro degradation and drug release kinetics of biopolymer-based drug delivery systems. International Journal of Biobased Plastics, 1:8–21, 2019. |

<div id="cite-14"></div> | <div id="cite-14"></div> | ||

| − | [[#citeF-14|[14]]] | + | [[#citeF-14|[14]]] Macha I.J., Karacan I., Ben-Nissan B., Cazalbou S., Müller W.H. Development of antimicrobial composite coatings for drug release in dental, orthopaedic and neural prostheses applications. SN Applied Sciences, 1:68, 2019. |

<div id="cite-15"></div> | <div id="cite-15"></div> | ||

| − | [[#citeF-15|[15]]] | + | [[#citeF-15|[15]]] Bisharat L., Barker S.A., Narbad A., Craig D.Q. In vitro drug release from acetylated high amylose starch-zein films for oral colon-specific drug delivery. International journal of pharmaceutics, 556:311–319, 2019. |

<div id="cite-16"></div> | <div id="cite-16"></div> | ||

| − | [[#citeF-16|[16]]] R. G. | + | [[#citeF-16|[16]]] Cox R.G. Dynamics of the spreading of liquids on a solid surface. Part 1. Viscous flow. Journal of Fluid Mechanics, 168:169–194, 1986. |

<div id="cite-17"></div> | <div id="cite-17"></div> | ||

| − | [[#citeF-17|[17]]] | + | [[#citeF-17|[17]]] Shikhmurzaev Y.D. Mathematical modeling of wetting hydrodynamic. Fluid Dynamics Research, 13:45–64, 1994. |

<div id="cite-18"></div> | <div id="cite-18"></div> | ||

| − | [[#citeF-18|[18]]] | + | [[#citeF-18|[18]]] Gongxia G., Xiao L., Ding C., Xiayi H., Ardi H., Hallvard S., Zhiwu L. A study of film thickness and hydrodynamic entrance length in liquid laminar film flow along a vertical tube. AICHE Journal, 64:2078–2088, 2018. |

<div id="cite-19"></div> | <div id="cite-19"></div> | ||

| − | [[#citeF-19|[19]]] | + | [[#citeF-19|[19]]] Wilkinson W.L. Entrainment of air by a solid surface entering a liquid/air interface. Chemical Engineering Science, 30:1227–1230, 1975. |

<div id="cite-20"></div> | <div id="cite-20"></div> | ||

| − | [[#citeF-20|[20]]] | + | [[#citeF-20|[20]]] Evans P.L., Schwartz L.W., Roy R.V. Steady and unsteady solutions for coating flow on a rotating horizontal cylinder: Two-dimensional theoretical and numerical modeling. Physics of Fluids, 16:2742– 2756, 2004. |

<div id="cite-21"></div> | <div id="cite-21"></div> | ||

| − | [[#citeF-21|[21]]] | + | [[#citeF-21|[21]]] Saeid N.H., Hasan N., Ali M.H.B.H.M. Effect of the metallic foam heat sink shape on the mixed convection jet impingement cooling of a horizontal surface. Journal of Porous Media, 21:295–309, 2018. |

<div id="cite-22"></div> | <div id="cite-22"></div> | ||

| − | [[#citeF-22|[22]]] Rashid H. | + | [[#citeF-22|[22]]] Rashid H., Hasan N., Iskandar M.N.M. Accurate modeling of evaporation and enthalpy of vapor phase in CO2 absorption by amine based solution. Separation Science and Technology (Philadelphia), 49:1326–1334, 2014. |

<div id="cite-23"></div> | <div id="cite-23"></div> | ||

| − | [[#citeF-23|[23]]] J. U. | + | [[#citeF-23|[23]]] Brackbill J.U. A continuum method for modeling surface tension. Journal of Computational Physics, 100:335–354, 1992. |

<div id="cite-24"></div> | <div id="cite-24"></div> | ||

| − | [[#citeF-24|[24]]] Shih | + | [[#citeF-24|[24]]] Shih T.-H., Liou W.W., Shabbir A., Yang Z., Zhu J. A New k-Epsilon eddy viscosity model for high Reynolds number turbulent flows. Computers and Fluids, 24:227–238, 1995. |

<div id="cite-25"></div> | <div id="cite-25"></div> | ||

| − | [[#citeF-25|[25]]] | + | [[#citeF-25|[25]]] Hinze J.O. Turbulence, McGraw-Hill series in mechanical engineering, McGraw-Hill College, 1975. |

<div id="cite-26"></div> | <div id="cite-26"></div> | ||

| − | [[#citeF-26|[26]]] Bontozoglou V. | + | [[#citeF-26|[26]]] Bontozoglou V. Papapolymerou G.P. Laminar film flow down a wavy incline. International Journal of Multiphase Flow, 23:69–79, 1997. |

<div id="cite-27"></div> | <div id="cite-27"></div> | ||

| − | [[#citeF-27|[27]]] | + | [[#citeF-27|[27]]] Roache P.J. Verification and validation in computational science and engineering. Hermosa Publishers, Albuquerque, pp. 446, 1998. |

<div id="cite-28"></div> | <div id="cite-28"></div> | ||

| − | [[#citeF-28|[28]]] Zhalehrajabi | + | [[#citeF-28|[28]]] Zhalehrajabi E., Rahmanian N., Hasan N. Effects of mesh grid and turbulence models on heat transfer coefficient in a convergent divergent nozzle. Asia-Pacific Journal of Chemical Engineering, 9:265–271, 2014. |

<div id="cite-29"></div> | <div id="cite-29"></div> | ||

| − | [[#citeF-29|[29]]] J. | + | [[#citeF-29|[29]]] Ferzieger J.H., Peric M. Computational Methods for Fluid Dynamics. In null, New York City, USA, Springer, 1996. |

<div id="cite-30"></div> | <div id="cite-30"></div> | ||

| − | [[#citeF-30|[30]]] D. L. | + | [[#citeF-30|[30]]] Youngs D.L. Time-dependent multi-material flow with large fluid distortion. Numerical Methods for Fluid Dynamics. Academic Press, 1982. |

<div id="cite-31"></div> | <div id="cite-31"></div> | ||

| − | [[#citeF-31|[31]]] Witt P. | + | [[#citeF-31|[31]]] Witt P., Khan M.N.H., Brooks G. CFD modelling of heat transfer in supersonic nozzles for magnesium production. TMS Annual Meeting. pp. 123–132. 2007. |

<div id="cite-32"></div> | <div id="cite-32"></div> | ||

| − | [[#citeF-32|[32]]] Naser J. | + | [[#citeF-32|[32]]] Naser J., Alam F., Khan M.N.H. Evaluation of a proposed dust ventilation/collection system in an underground mine crushing plant. Proceedings of the 16th Australasian Fluid Mechanics Conference, 16AFMC. pp. 1411–1414. 2007. |

<div id="cite-33"></div> | <div id="cite-33"></div> | ||

| − | [[#citeF-33|[33]]] S. | + | [[#citeF-33|[33]]] Muzaferija S., Peric M., Sames P., Schellin T. A two-fluid Navier-Stokes solver to simulate water entry. National Academy Press, pp. 277–289. 1998. |

<div id="cite-34"></div> | <div id="cite-34"></div> | ||

| − | [[#citeF-34|[34]]] N. | + | [[#citeF-34|[34]]] Hasan N., Naser J. Determining the thickness of liquid film in laminar condition on a rotating drum surface using CFD. Chemical Engineering Science, 64:919–924, 2009. |

<div id="cite-35"></div> | <div id="cite-35"></div> | ||

| − | [[#citeF-35|[35]]] | + | [[#citeF-35|[35]]] Versteeg H.K., Malalasekera W. An introduction to computational fluid dynamics: The Finite Volume Method. Boston, Massachusetts, United States, Addison-Wesley, 1996. |

<div id="cite-36"></div> | <div id="cite-36"></div> | ||

| − | [[#citeF-36|[36]]] N. H. | + | [[#citeF-36|[36]]] Khan M.N.H., Fletcher C., Evans G., He Q. CFD analysis of the mixing zone for a submerged jet system. Proceedings of the ASME Fluids Engineering Division Summer Meeting, volume 1, pp. 29–34. 2003. |

<div id="cite-37"></div> | <div id="cite-37"></div> | ||

| − | [[#citeF-37|[37]]] Geoffrey | + | [[#citeF-37|[37]]] Geoffrey B., Hasan N., Witt P. Design of supersonic nozzles for ultra-rapid quenching of metallic Vapours. TMS Annual Meeting, pp. 699–709, 2006. |

<div id="cite-38"></div> | <div id="cite-38"></div> | ||

| − | [[#citeF-38|[38]]] | + | [[#citeF-38|[38]]] Rodriguez D.J., Shedd T.A. Entrainment of gas in the liquid film of horizontal, annular, two-phase flow. International Journal of Multiphase Flow, 30:565–583, 2004. |

<div id="cite-39"></div> | <div id="cite-39"></div> | ||

| − | [[#citeF-39|[39]]] R. A. | + | [[#citeF-39|[39]]] Buonopane R.A., Gutoff E.B., Rimore M.M.T. Effect of plunging tape surface properties on air entrainment velocity. AIChE Journal, 32:682–683, 1986. |

<div id="cite-40"></div> | <div id="cite-40"></div> | ||

| − | [[#citeF-40|[40]]] Burley R. | + | [[#citeF-40|[40]]] Burley R.W., Jolly P.S.R. Entrainment of air into liquids by a high speed continuous solid surface. Chemical Engineering Science, 39:1357–1372, 1984. |

<div id="cite-41"></div> | <div id="cite-41"></div> | ||

| − | [[#citeF-41|[41]]] Rashid H. | + | [[#citeF-41|[41]]] Rashid H., Hasan N., Iskandar M.N.M. Temperature peak analysis and its effect on absorption column for CO2 capture process at different operating conditions. Chemical Product and Process Modeling, 9:105–115, 2014. |

</div> | </div> | ||

| Line 448: | Line 444: | ||

==Author biography== | ==Author biography== | ||

| − | + | Christ Trang has a bachelor in chemical Engineering. Her interests include Multiphase (nucleation, separation), Optimization (converging-diverging nozzle), Biomedical (nasal drug delivery), Environmental (Tsunami, Flood, Safety, Pollution in City), Maritime, Nanoparticle, Offshore Stability, Turbo machinery, Hydraulics Design, Casting Design. | |

| − | Multiphase (nucleation, separation), Optimization (converging-diverging nozzle), Biomedical (nasal drug delivery), Environmental (Tsunami, Flood, Safety, Pollution in City), Maritime, Nanoparticle, Offshore Stability, Turbo machinery, Hydraulics Design, Casting Design. | + | |

Latest revision as of 11:59, 2 July 2021

Abstract

In this research, the free surface of micro film of hexyl alcohol on a partially submerged rotating drum has been predicted using CFD (computational fluid dynamics) and compared with experimental data and analytical solution. The trend of has been found very comparable with experimental and analytical solution. A Matlab code was used to model the flow and film dynamics. Computationally it was an unsteady state problem and semi-steady state was achieved. No surfactant was present on the surface. The speed of the moving rotating drum was set a rpm. With the increase of rotating drum, the minimum film thickness increases with rpm (for = 47 and for = 58).

Keywords: Liquid film, cfd, vof, moving surface, hexyl alcohol

1. Introduction

This paper presents a two-dimensional (not a 3D as performed in [1]) computational CFD model describing an unsteady state thin liquid hexyl alcohol film on the RD adjacent to the surface of a partially submerged rotating drum (RD). The liquid film was modeled by volume of fluid, VOF [2]. A RD submerged in a fluid picks up fluid on the outer surface of the RD (Figure 1). Few parameters e.g. , and rpm influence the free surface as well (refer to list of symbols). These properties form various nondimensional numbers, e.g., Ca, We, Re, Fr (refer to list of symbols) . Solving complete Navier-Stokes equation with VOF as performed here would allow predicting the free surface provided numerical error is minimized. However, VOF has limitation like all other free surface modeling approaches.

Literature review suggests that there is limited focus [3,4,5,6,7] on this topic and only a few correlations are available based on the experimental or analytical simplification [8,9,10]. The surface area of the liquid film and the amount of fluid being carried by an RD are important parameters for design purpose (e.g. cooling of final molasses in a sugar factory [10,11,12] and pharmaceutical drug delivery of solid oral dosage forms film coatings [13,14,15].

|

| Figure 1. Schematic diagram of the thin film on a partially-submerged rotating drum |

The dynamics of liquid film on a straight plate [16] is relatively easy compared to the investigation performed here. Prediction of dynamic contact line [17] is still under investigation. This paper will particularly focus when a wiper is used to wipe the film of hexyl alcohol. The prime motivation of this investigation is that there is published experimental data for hexyl alcohol which occur at =180 (Figure 1). There is no accurate measuring technique available to measure the film thickness [18], even though, the experimental effort has been lifted. Most of the studies avoided curved moving plane movement [19,20] in detail.

After the computational domain and model equation, this paper will continue with the computational results compared with the experimental and analytical solution of [8,9]. This article assumes that there is no foam [21] formation near RD and no vaporization [22] on the liquid film.

2. Computation Domain

The computational domain of an RD rotating anti-clockwise on a free liquid surface is shown in Figure 2. Various boundary conditions are shown in Table 1.

| Serial | Location | Boundary |

| 1 | RD wall | Moving wall with rpm |

| 2 | Top surface of the tank | Outflow |

| 3 | Walls of the tank | Wall-no slip |

| 4 | Scrap of fluid | Pressure outlet |

The amount of film leaves the pressure outlet BC, is forced to enter into the left entrance (pressure inlet) of the domain to keep the liquid level same.

![Various conditions (BC) at the boundary for a partially submerged rotating drum rotating on a free liquid surface in the tank [boundary Drd =130 mm, Hₗ =365.555 mm, Wₜ =800 mm, Hₐ =134.445 mm].](/wd/images/thumb/4/4d/Trang_2019a_4609_132c3a60-cf92-4efc-a778-f25a97b424d7-ufig2.png/400px-Trang_2019a_4609_132c3a60-cf92-4efc-a778-f25a97b424d7-ufig2.png)

|

| Figure 2. Various conditions (BC) at the boundary for a partially submerged rotating drum rotating on a free liquid surface in the tank [boundary D =130 mm, H =365.555 mm, W =800 mm, H =134.445 mm] |

The stagnant free liquid surface is located at . By varying H the initial can be changed. An arc of 225 degrees RD is modeled.

3. Computational Model

A Volume of Fluid [2] approach is used to model the free the surface of the liquid film (vof is based on the Continuum Surface Force, CSF, [23]).

The continuity equation for the 2D case is governed by Eq.(1)

|

|

(1) |

The momentum equation for x (horizontal direction) is given by Eq.(2)

|

|

(2) |

The momentum equation for y (vertical direction) is given by Eq.(3)

|

|

(3) |

The Reynolds stress is solved by Realizable models [24] which are two equation models (Eq.(4) and Eq.(5)) and can be described as:

|

|

(4) |

|

|

(5) |

is the generation of turbulent kinetic energy [25]. The constants are =1.0, =0.09, =1.9, , where , is the magnitude of vorticity. The unstable [26] nature of the wave demands tiny time step for the film dynamics to predict.

The computational modeling parameters were chosen after verification [27]. Quadrilateral mesh [28], higher order discretization, PISO [29] pressure- velocity coupling, geometric reconstruction [30] for VOF, and smooth wall (K=0, Cs =0.5) were used in the CFD [31,32] calculations. For VOF, a modified discretization is used [33]. The minimum film thickness ( = 180) as determined theoretically by Eq.(6) offered by [8]:

|

|

(6) |

For no backflow condition [34], a solution is given by Eq.(7).

|

|

(7) |

The introduction of in (7) has a striking similarity as found here [8]. As the rotating drum increases, the approaches to unity. The aspect ratio of the mesh near the wall was 1.08, so gradually the size was reduced. All the calculations presented in the journal were double precision and took nearly 8 days to complete one set of calculation. The mesh was refined few times to confirm that the solutions were less dependent on the size and shape of the mesh.

4. Results

Figure 3 shows the as function of rpm for = 47 from three different sources, e.g., analytical solution without the CF (Eq.(6)), analytical solution with CF (Eq.(7)) and CFD [35] solution. Apparently, the analytical solution without the CF is very close to the CFD [36,37] prediction. In all three lots, the trend is the same. From Eqs.(6) and (7), the varies with is relationship of rpm ( ), for the CFD results it varies as . The properties of the hexyl alcohol are the same for all three sources ( =0.00384 N/m, =812 kg/m3, =0.00392 kg/m/s). In the original paper of [8,9], the precise properties of hexyl alcohol was not reported.

|

| Figure 3. A minimum film thickness for hexyl alcohol as a function of rpm of the drum for 47 |

There are few important aspects to highlight here. Firstly, the loss of liquid at the pressure outlet BC (Figure 2) is compensated by the same amount of liquid injection at the pressure inlet BC which is far away from the RD so there is little impact on the film dynamics of the inflow on the RD. It was expected though for a laminar condition when the plunging [38,39,40] the point is avoided (no drop passes the wiper and falls on the receiving tank), there would be a steady state solution which is found to be wrong. Secondly, because of the plunging point is avoided; there is less complicate in terms of numerical instability. Thirdly, as the 10 plunging point is avoided, there is no consequence of entrained air in the form of bubbles from the plunging point which would disturb the stability of the solution. Fourthly, in the real wiper (Figure 1), it would not cause the surface completely free from hexyl alcohol

before plunging into the liquid bath and also the surface property would change because of the erosion and the friction between the RD and the wiper would cause heat (maybe negligible).

Several steps were taken to minimise the instability. The unsteady calculations were started to a smaller value, Grid and time step are linked through the Courant condition. So grid was refined locally few times. During the solver iterations, the time step is changed to alter the instability.

To model the wall roughness effects, two parameters are needed to specify. In the current scenario, a smooth wall is considered to avoid more issues and so the Roughness Height I set to be zero and a default value of roughness constant is chosen.

|

| Figure 4. A minimum liquid film thickness for hexyl alcohol as a function of rotating speed of the drum for 58 |

Again striking similarities have been found for = 58 as shown in Figure 4. There are four plots in Figure 4, e.g., two analytical solutions (Eqs.(6) and (7)), CFD solutions and experimental data. The trend of variation of has been proved the same in CFD, experimental and analytical results. In CFD results, varies with rpm by . Surprisingly again, Eq.(6) and CFD results are close and away from the Eq.(7) and experimental data by a factor 1/CF. The proportionality constant in CFD prediction for this case is only 4% a way from the critical prediction.

5. Conclusions

The problem of determining a thin film on a RD and the minimum film thickness are investigated using CFD for a partially-submerged rotating drum. The analytical solution is too simplified to determine the and CFD is needed to understand the dynamics of liquid film. A no-slip boundary condition was considered on the RD wall and the meniscus free surface was predicted using VOF. CFD investigation shows that increases with, same as experimental dd analytical solution. Because plunging end of RD was avoided by using a wiper, convergence behavior was quite stable.

All the 12 case of the simulations shown in this paper were for isothermal conditions [41], a terms used for this is called 'cold modeling'. It is possible to extend the model developed for the non-isothermal condition were the physical properties would change as a function of temperature. It is possible to extend the model developed for non-isothermal conditions were the physical properties would change as a function of temperature. If crystallization does occur and vaporization takes place, an equivalent sink/source term to be added in the model equations to account the mass/momentum/energy transfer and it would be more complicated. For the higher rate crystallization, the back flow will be miminised. From CFD point of the view, viscous film hold up is less complicated to predict. For a partial crystallization of the film would between Eqs.(6) and (7).

6 List of Symbols

| Symbols | Description | Unit |

| Pressure | N/m | |

| Velocity components | m/s | |

| Velocity fluctuating components | m/s | |

| Air height in the top of the bath | m | |

| Liquid level | m | |

| Rotating drum Reynolds number | - | |

| Two directions of the Cartesian co-ordinates | m | |

| Wall roughness constant | - | |

| Wall roughness height | m | |

| Turbulent kinetic energy | m/s | |

| Turbulent Dissipation Rate | m/s | |

| Diameter of the rotating drum | m | |

| Revolution per minute | rev/min | |

| Width of tank | m | |

| Surface tension | N/m | |

| Viscosity | kg/m/s | |

| Density | kg/m | |

| rad/sec | 1/s | |

| Angular location of tip | deg | |

| Initial angular location | deg | |

| Velocity Scale | m/s | |

| Tangitial velocity | m/s | |

| Froude number | - | |

| Reynoulds number | - | |

| Weber number |

References

[1] Evans P.P., Schwartz L.W., Roy R.V. Three-dimensional solutions for coating flow on a rotating horizontal cylinder: Theory and experiment. Physics of Fluids, 17:072102/1–072102/20, 2005.

[2] Hirt C.W., Nichols B.D. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys., 39:201–225, 1981.

[3] Duffy B.R., Wilson S.K. Thin-film and curtain flows on the outside of a rotating horizontal cylinder. Journal of Fluid Mechanics, 394:29–49, 1999.

[4] Khan M.N.H., Fletcher C., Evans G., He Q. CFD modeling of free surface and entrainment of buoyant particles from free surface for sumberged jet systems. American Society of Mechanical Engineers, Heat Transfer Division, (Publication) HTD.

[5] Moffatt K. Behaviour of a Viscous Film on the Outer Surface of a Rotating Cylinder. J. Mec., 16:651–673, 1977.

[6] Moffatt K. Viscous and Resistive Eddies Near Sharp Corner. Journal of Fluid Mechanics, 18:1–18, 1964.

[7] Nikolov A.D., Wasan D.T. A novel method for studying the dynamic behavior of both plane-parallel and curved thin liquid films. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 123-124:375–381, 1997.

[8] Gelpérin N.I., Nosov, G. A., Makotkin, A.V. Determinating the thickness of liquid film holdup on a rotating drum surface. Chemical and Petroleum Engineering, 11:230–233, 1975.

[9] Gelpérin, N.I., Nosov G.A., Makotkin A.V. Thickness of a liquid film covering the surface of a rotating drum. Khimicheskoe i Neftyanoe Mashinostroenie, pp. 18–20, 1975.

[10] Butler K., White E.T., Wright P. G. Pickup layer thickness on a horizontal rotating drum. In Chemeca 90: The Eighteenth Australasian Chemical Engineering Conference, Processing Pacific Re- sources, 1990.

[11] Korn O. Cyclone Dryer: A pneumatic dryer with increased solid residence time. Drying Technology, 19:1925, 2001.

[12] Jullienne L.M.S.A., Munsamy S. Assessment Of Final Molasses Coolers. Proceedings of The South African Sugar Technologists' Association - June 1981.

[13] Harting R., Johnston K., Petersen S. Correlating in vitro degradation and drug release kinetics of biopolymer-based drug delivery systems. International Journal of Biobased Plastics, 1:8–21, 2019.

[14] Macha I.J., Karacan I., Ben-Nissan B., Cazalbou S., Müller W.H. Development of antimicrobial composite coatings for drug release in dental, orthopaedic and neural prostheses applications. SN Applied Sciences, 1:68, 2019.

[15] Bisharat L., Barker S.A., Narbad A., Craig D.Q. In vitro drug release from acetylated high amylose starch-zein films for oral colon-specific drug delivery. International journal of pharmaceutics, 556:311–319, 2019.

[16] Cox R.G. Dynamics of the spreading of liquids on a solid surface. Part 1. Viscous flow. Journal of Fluid Mechanics, 168:169–194, 1986.

[17] Shikhmurzaev Y.D. Mathematical modeling of wetting hydrodynamic. Fluid Dynamics Research, 13:45–64, 1994.

[18] Gongxia G., Xiao L., Ding C., Xiayi H., Ardi H., Hallvard S., Zhiwu L. A study of film thickness and hydrodynamic entrance length in liquid laminar film flow along a vertical tube. AICHE Journal, 64:2078–2088, 2018.

[19] Wilkinson W.L. Entrainment of air by a solid surface entering a liquid/air interface. Chemical Engineering Science, 30:1227–1230, 1975.

[20] Evans P.L., Schwartz L.W., Roy R.V. Steady and unsteady solutions for coating flow on a rotating horizontal cylinder: Two-dimensional theoretical and numerical modeling. Physics of Fluids, 16:2742– 2756, 2004.

[21] Saeid N.H., Hasan N., Ali M.H.B.H.M. Effect of the metallic foam heat sink shape on the mixed convection jet impingement cooling of a horizontal surface. Journal of Porous Media, 21:295–309, 2018.

[22] Rashid H., Hasan N., Iskandar M.N.M. Accurate modeling of evaporation and enthalpy of vapor phase in CO2 absorption by amine based solution. Separation Science and Technology (Philadelphia), 49:1326–1334, 2014.

[23] Brackbill J.U. A continuum method for modeling surface tension. Journal of Computational Physics, 100:335–354, 1992.

[24] Shih T.-H., Liou W.W., Shabbir A., Yang Z., Zhu J. A New k-Epsilon eddy viscosity model for high Reynolds number turbulent flows. Computers and Fluids, 24:227–238, 1995.

[25] Hinze J.O. Turbulence, McGraw-Hill series in mechanical engineering, McGraw-Hill College, 1975.

[26] Bontozoglou V. Papapolymerou G.P. Laminar film flow down a wavy incline. International Journal of Multiphase Flow, 23:69–79, 1997.

[27] Roache P.J. Verification and validation in computational science and engineering. Hermosa Publishers, Albuquerque, pp. 446, 1998.

[28] Zhalehrajabi E., Rahmanian N., Hasan N. Effects of mesh grid and turbulence models on heat transfer coefficient in a convergent divergent nozzle. Asia-Pacific Journal of Chemical Engineering, 9:265–271, 2014.

[29] Ferzieger J.H., Peric M. Computational Methods for Fluid Dynamics. In null, New York City, USA, Springer, 1996.

[30] Youngs D.L. Time-dependent multi-material flow with large fluid distortion. Numerical Methods for Fluid Dynamics. Academic Press, 1982.

[31] Witt P., Khan M.N.H., Brooks G. CFD modelling of heat transfer in supersonic nozzles for magnesium production. TMS Annual Meeting. pp. 123–132. 2007.

[32] Naser J., Alam F., Khan M.N.H. Evaluation of a proposed dust ventilation/collection system in an underground mine crushing plant. Proceedings of the 16th Australasian Fluid Mechanics Conference, 16AFMC. pp. 1411–1414. 2007.

[33] Muzaferija S., Peric M., Sames P., Schellin T. A two-fluid Navier-Stokes solver to simulate water entry. National Academy Press, pp. 277–289. 1998.

[34] Hasan N., Naser J. Determining the thickness of liquid film in laminar condition on a rotating drum surface using CFD. Chemical Engineering Science, 64:919–924, 2009.

[35] Versteeg H.K., Malalasekera W. An introduction to computational fluid dynamics: The Finite Volume Method. Boston, Massachusetts, United States, Addison-Wesley, 1996.

[36] Khan M.N.H., Fletcher C., Evans G., He Q. CFD analysis of the mixing zone for a submerged jet system. Proceedings of the ASME Fluids Engineering Division Summer Meeting, volume 1, pp. 29–34. 2003.

[37] Geoffrey B., Hasan N., Witt P. Design of supersonic nozzles for ultra-rapid quenching of metallic Vapours. TMS Annual Meeting, pp. 699–709, 2006.

[38] Rodriguez D.J., Shedd T.A. Entrainment of gas in the liquid film of horizontal, annular, two-phase flow. International Journal of Multiphase Flow, 30:565–583, 2004.

[39] Buonopane R.A., Gutoff E.B., Rimore M.M.T. Effect of plunging tape surface properties on air entrainment velocity. AIChE Journal, 32:682–683, 1986.

[40] Burley R.W., Jolly P.S.R. Entrainment of air into liquids by a high speed continuous solid surface. Chemical Engineering Science, 39:1357–1372, 1984.

[41] Rashid H., Hasan N., Iskandar M.N.M. Temperature peak analysis and its effect on absorption column for CO2 capture process at different operating conditions. Chemical Product and Process Modeling, 9:105–115, 2014.

Author biography

Christ Trang has a bachelor in chemical Engineering. Her interests include Multiphase (nucleation, separation), Optimization (converging-diverging nozzle), Biomedical (nasal drug delivery), Environmental (Tsunami, Flood, Safety, Pollution in City), Maritime, Nanoparticle, Offshore Stability, Turbo machinery, Hydraulics Design, Casting Design.

Document information

Published on 23/04/19

Accepted on 13/03/19

Submitted on 17/12/18

Volume 35, Issue 2, 2019

DOI: 10.23967/j.rimni.2019.04.002

Licence: CC BY-NC-SA license