Abstract

Accurate and reliable information is needed to support decision-making processes. Due to the large number of participants typically involved in supply chain operations, organizations often find that it is difficult to effectively share information within a supply chain; hence, this research examined ways to improve information sharing within supply chain operations for one marine transportation services organization. An action research, case study approach used the Design for Six Sigma (DFSS) methodology to design an information technology solution that effectively communicates information between the layers within the supply chain regarding the movement of materials via inland tank barges. The comparative analysis of verification and baseline measurements conducted suggests this project was successful because the new process fulfilled the needs of the work environment for which it was designed. For the organization that participated in this research, the successful adoption of the new approach for information sharing improved communication and decision making within their supply chain.

JEL classification

L91;R49;M11

Keywords

Design for Six Sigma;Supply chain;Transportation;Information sharing;Case study

1. Introduction

Supply chain management adds value to an organization through the effective integration and alignment of various business functions in pursuit of achieving strategic objectives (Pettersson and Segerstedt, 2013 ; Sahin and Robinson, 2005). Given the globalization of corporations and the increase in computing power and e-commerce, co-location of supply chain functions is no longer a necessity for many organizations. However, this shift in global logistics presents its own set of challenges, and these issues have effectively elevated the importance of supply chain coordination and information sharing (Fiala, 2005; Hugos, 2011 ; Mesmer-Magnus and DeChurch, 2009). Supply chain functions generate value through the cohesion of the independent activities within these business operations (Zhu, Gavirneni, & Kapusciniski, 2010). Ensuring that decisions can be made using correct and up-to-date information is imperative for efficient supply chain performance (Manuj & Sahin, 2011).

Like other areas of business, supply chains can utilize technology to enrich their business processes and communicate more effectively (Sahin & Robinson, 2002). The availability of real-time forecast information, demand data, and shipment progress through tailored information technology (IT) applications increases the flexibility and capability of functions along many points of the supply chain (Ye & Wang, 2013). This information provides functions within the supply chain the opportunity to plan, react, and take preventative action to counterbalance fluctuations and delays encountered en route to final delivery of the finished product. However, for this information to be meaningful and help the organization, it must be effectively communicated and shared with all supply chain functions, which can be challenging for some organizations (Liu & Kumar, 2011).

Transportation is the single largest logistical cost for most organizations, and these expenses significantly impact a supply chains fiscal effectiveness (Goldsby & Martichenko, 2005). As the most widely used method of transportation, marine shipping presents a unique set of challenges for logisticians, schedulers, and other supply chain functions (Mangan, Lalwani, & Fynes, 2008). The efficiency of the shipping process affects more than the separate organizations that operate individual vessels, including the customers of the finished products. Therefore, improvements made to logistics within the marine transportation field often have a large effect on many other existing supply chains. Domestic inland barging focuses specifically on the movement of cargoes along the inland river systems of the U.S., and a large portion of this work involves the transportation of petroleum products (Mudrageda & Murphy, 2008). Specialized inland barges are utilized to move bulk cargoes between terminals, refineries, and end customers/consumers. The movement of a single cargo requires many decisions, the coordination of several supply chain functions, and commonly involves many different organizations.

It is interesting to note that little research has been conducted that examines the use of structured improvement methods to redesign supply chain operations. This research attempts to fill this gap in the literature, and it specifically focuses on designing a system to improve the communication of information through a multi-tier supply chain system within a marine transportation services organization. Using an action research approach (Coughlan and Coghlan, 2002; Kemmis et al., 2014 ; Reason and Bradbury, 2008), researchers worked closely with the Transportation Coordinators within this organization to determine the best way to utilize an IT communication solution (i.e., a SharePoint site) to support their operations. To develop this new approach for sharing information, the team of researchers and employees from the organization used the Design for Six Sigma (DFSS) methodology, a structured method for building quality into products/services in order to achieve Six Sigma (i.e., virtually defect/error free) performance (Hasenkamp, 2010; Schroeder et al., 2008 ; Tjahjono et al., 2010). While the literature contains several examples about how DFSS has been used in services, this case study uniquely demonstrates how this approach can be applied to value-enabling elements within service-based operations such as a communication/information sharing process.

The following section provides some background information concerning topics related to this research. Then, the case study is presented. This discussion includes further information about the organization in which this research was conducted, as well as details regarding how the DFSS methodology was implemented, including the tools and techniques used. Finally, some concluding remarks are offered that summarize the benefits of this research to the organization involved in this case study and beyond.

2. Background

2.1. Information sharing

It is well documented that the need for accurate information in a supply chain context is essential. Madlberger (2009) states that the vital issue for supply chains is the unevenness of information between supply chain functions. Hung, Ho, Jou, and Tai (2011) describe the necessity to obtain important information in a timely and accurate fashion. That is, the sharing of data levels the playing field between functions and aids management in gathering situational-information (Mesmer-Magnus & DeChurch, 2009). However, because many supply chains contain third parties or several groups within the same organization, the information that they communicate to the other parties is only as effective as the commonality that binds them (Posey & Bari, 2009). For example, specific and complicated data may only be useful to share if it can be deciphered easily by the other functions within the supply chain.

Several previous researchers have indicated that decision making and overall supply chain performance improve when information is shared between functions (Li et al., 2006 ; Simatupang and Sridharan, 2008). The sharing of information is said to improve supply chain agility and visibility, and therefore positively impacts supply chain stability. While previous research suggests that there are few downsides to information sharing between supply chain functions, Hall and Saygin (2012) argue that simply the act of transferring data between activities will not improve supply chain performance unless the information is accompanied by more robust requirements for collaboration/cooperation. Existing purely in a vacuum, without high levels of trust and communication between parties, information sharing would be moot. To be meaningful, information needs to be presented clearly and in a fashion that can be easily understood by the audience (Cantor & Macdonald, 2009). Otherwise, large amounts of information may tax other functions and waste time and resources in attempting to decipher it.

2.2. Communication and collaboration

Communication is a critical task for each function within a supply chain. Increased perceptions of trust between supply chain entities help to build stable relationships and contacts that are more likely to communicate effectively. As Wagner and Buko (2005) describe, the more intensely and often that people communicate across the supply chain, the more clear organizational goals and objectives become, which may increase the overall level of coordination across supply chain functions.

To reach the optimal levels of coordination within a supply chain, the objectives of the organization as a whole must be understood and shared by all functions (Hugos, 2011). These mutual values guide business practices and drive efficiency. A lack of coordination may occur when necessary information is not available to make decisions and when functions operate without the guide of system-wide objectives (Sahin & Robinson, 2005). However, supply chain management is facilitated by clearly defined reporting structures and easily accessible information networks; hence, individual supply chain functions should be focused on high-level organizational interests to ensure alignment of the supply chain as a whole.

2.3. Supply chain improvement methods

Existing research addresses both theory and application (via case studies) of Six Sigma principles to solve problems in transportation and supply chain fields. For example, Nooramin, Ahouei, and Sayareh (2011) applied this approach to improve marine container terminal operations. Also, Antony, Kumar, and Banuelas (2006) documented research done using Six Sigma to reduce the number of injuries for work done with marine containers. Similarly, Chang and Wang (2008) used a case study to show the benefits of a Six Sigma improvement model on replenishment forecasting.

While the Six Sigma methodology has proven to be a successful process improvement approach, unfortunately it does not target fundamental changes to the structure of the underlying production/service process (Edgeman & Dugan, 2008). To address this issue, Six Sigma applications have grown to include the design and redesign of both products and services, which is known as DFSS (El-Haik & Roy, 2005). DFSS focuses on building quality into products/services by identifying what customers want/need, translating these into critical-to-quality characteristics, deploying these through specific aspects of the product/service design, and verifying that the final design appropriately addresses the original intent (i.e., to fulfill customers’ needs) (de Mast et al., 2011; El-Haik and Al-Aomar, 2006 ; Yang and El-Haik, 2003). Previous discussions in the literature have pointed out that as there is no standard framework to guide the use of the DFSS methodology (Watson & DeYong, 2010); yet, Yang (2005) suggests that the DMADV (Define, Measure, Analyze, Design, and Verify) methodology is appropriate to use when designing service processes, as it specifically addresses redesigning processes, which is a common occurrence in service-based organizations.

3. Case study

3.1. Organizational context

This research was conducted at a marine transportation services organization that is a subsidiary of a major U.S. oil corporation. The organization studied provides marine transportation solutions, marine services, and other nautical expertise to transport corporation-owned petroleum and oil cargoes via marine vessels. The researchers involved in this project worked closely with the Inland Team, which manages the transportation of petroleum and oil cargoes via U.S. domestic inland waterways using inland tank barges by assigning barges to customer-requested oil movements. As part of the Inland Team, Transportation Coordinators allocate and monitor the movement of the barges carrying the oil cargoes. To track the movement of barges, Transportation Coordinators produce a traffic report, or slate, on a daily basis that is sent to customers and related third parties (grouped by similar cargo type). Slates are used by the Transportation Coordinators, Product Schedulers (i.e., customers), and third party vendors (i.e., barge operators, inspection companies, etc.) to communicate the current position and status of barges, as well as pertinent details regarding each barge. As slates are updated, they are distributed by Transportation Coordinators to the interested parties via email as a Microsoft Excel attachment.

Unfortunately, delivering slates via email has become a cumbersome process due to the frequency of updates and the size of attachments. In an effort to streamline the slate distribution process, the Inland Team within this organization wanted to develop an alternative method for distributing slate updates. Just prior to beginning this research, the organizations management mandated that data be shared via SharePoint sites, as much as possible, in order to increase the visibility of the data and provide a platform for collaboration; yet, few hard-line requirements were provided as to how to set-up these sites. As SharePoint was new to most parties involved in the slate distribution process, they selected to use the DFSS approach to develop and implement a new method for sharing information (i.e., distributing slates) using SharePoint that effectively addresses the needs of those involved in the process. Hence, the overarching questions guiding this research were “what does the slate sharing process need to do to support the work done by the Inland Team?” and “how should those needs be fulfilled?” The specific details regarding each phase of the DMADV process used in this project are described in the following sections.

3.2. Define phase

The design team began this project by creating a project charter. The specific project goals were identified through the following problem and mission statements:

- The Inland Team currently distributes slates via email attachments, which often leads to confusion within supply chain operations, and they do not yet have a method for sharing this information via SharePoint.

- Establish a method for distributing slates using SharePoint, thus improving communication within supply chain operations.

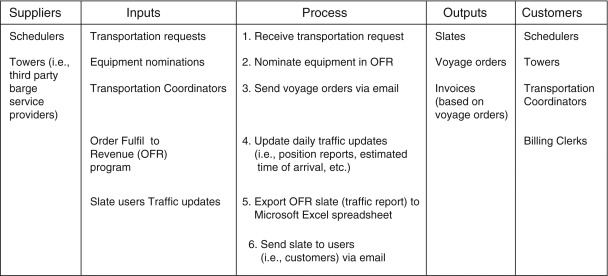

In order to begin identifying users’ needs and determining the requirements for how to redesign the slate distribution process, the design team first needed to understand the Transportation Coordinators current equipment nomination and slate distribution process. To define the process from a high-level perspective, a SIPOC (Suppliers, Inputs, Process, Outputs, and Customers) diagram was created, as depicted in Figure 1. As shown in the center of this diagram, the process begins as transportation requests are received and appropriate barges are nominated (i.e., assigned) for each request. The inputs to this process include transportation requests, equipment nominations, etc., and these are supplied by Schedulers and Towers. The outputs of this process include voyage orders, slates, and dock schedules, which are used by Transportation Coordinators, customers, and refinery personnel.

|

|

|

Fig. 1. High-level view of the slate distribution process. At a high-level, this figure illustrates the Transportation Coordinators current equipment nomination and slate distribution process including important elements from the entire supply chain. |

To develop a more detailed understanding of the slate distribution process, a flowchart was created by the design team. This phase of the design project helped the team better understand how information is shared between the parties involved in the slate distribution process, and this deeper level of understanding helped to guide the rest of the design project.

3.3. Measure phase

In this phase of the project, the design team identified the needs of those involved in the slate distribution process (i.e., the users) through a user need analysis (Ulrich, Eppinger, & Goyal, 2011). A series of open-ended interview questions were created to examine how slate users actually utilize slate information, what they liked and disliked about the current slate distribution process (i.e., sharing slates via email attachments), and what they would change about the process given the opportunity. Interviews were requested with 27 slate users, and the design team successfully conducted 22 interviews (i.e., an 81% response rate). The responses to each question asked during the interviews were then translated into interpreted needs statements (i.e., a description of what the new process needs to do, but not how to do it). For example, in response to the question about “what do you like about the current process?” the interviewee indicated that they liked when Microsoft Outlook notifies them that an email contains an attachment. Therefore, the design teams interpreted need for this response was that the new slate distribution process should provide the user with a notification of new or updated information.

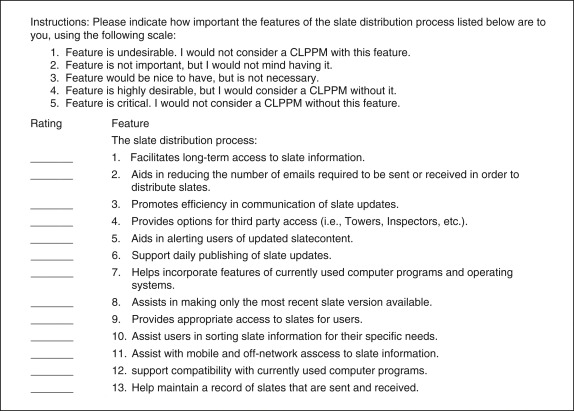

Then, the Inland Team (which has five members, all of whom are knowledgeable about the slate distribution process) organized the interpreted needs by category in an affinity diagram. This diagram depicts how the team organized the needs into natural groups based on their relevance or similarity to one another (Duffy et al., 2012). This work resulted in organizing the needs into seven different categories–update efficiency, retention control, presentation, attachment size reduction, slate access, information control, and notifications; hence, having those who are most familiar with the process create the affinity diagram helped the design team to further understand the broad themes associated with the users’ needs as well as the details regarding each individual need statement. Next, the design team used their experience with the slate distribution process to select the needs that they felt have the most significant impact on the design of the new process. This smaller sub-set of 13 needs was included in a prioritization survey in order to identify the top-rated users’ needs. This survey, which is shown in Figure 2, listed the needs as design “features,” and those who completed the survey were asked to rate how important each feature was to them on a five-point scale, where a “1” indicated the feature is undesirable and “5” indicated the feature is critical.

|

|

|

Fig. 2. The user needs prioritization survey. The design team used their experience to select a sub-set of 13 needs, which were included in the prioritization survey illustrated in this figure in order to identify the top-rated users’ needs. |

The same group (27 members of the organization) that had been invited to participate in the interviews associated with this design project were also asked to complete the needs prioritization survey. The design team successfully collected 24 completed surveys (i.e., an 89% response rate). The analysis of survey responses indicated that five needs were rated as either “4” (i.e., highly desirable) or “5” (i.e., critical) by 90% or more of respondents. These top-rated users’ needs are listed in Table 1, and the importance of each was determined based on the median value of all survey responses. The design team used this information to ensure that the most important users’ needs were the focal point of the remainder of the project.

| No. | Survey item no. | User needs | Importance (median survey response) |

|---|---|---|---|

| 1 | 3 | Promotes efficiency in communicating slate updates | 4 |

| 2 | 6 | Supports daily publishing of slate updates | 5 |

| 3 | 9 | Provides appropriate access to slate users | 5 |

| 4 | 11 | Assists with mobile and off-network access to slate information | 4 |

| 5 | 12 | Supports compatibility with currently used computer programs | 5 |

This table depicts the highest priority needs identified by analysing the survey results, and the design team used these to guide the remainder of their project work.

3.4. Analyze phase

Next, a series of metrics were developed based on the top-rated users’ needs. The nine metrics established by the design team are given in the needs-metrics matrix shown in Table 2. These metrics address the users’ needs from various perspectives. The dots shown in the matrix indicate which metrics address each need. For comparison purposes later in the project, the design team collected baseline measurements regarding the current slate distribution process (i.e., sharing slates via email attachments) for each metric. These measurements capture the performance of the current process before the new process design was conceived or implemented. Collecting baseline measurements for the current slate distribution process allowed the design team to see where improvements were necessary in order to fulfill the previously identified top-rated users’ needs. This understanding proved to be a critical factor toward determining the design of the new slate distribution process and implementing those changes within the organization.

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Metrics | Update interval (count/week) | Ease-of-use (five-point scale) | Number of slates printed daily (count/day) | Everyone who needs access has access (yes/no) | Information can be accessed through the web (yes/no) | Compatible with Microsoft Excel (yes/no) | Compatible with Microsoft Outlook (yes/no) | Compatible with OFR (yes/no) | Compatible with SharePoint (yes/no) | ||

| Top-rated Users’ Needs | |||||||||||

| 1 | The slate distribution process promotes efficiency in communication of slates. | • | • | • | |||||||

| 2 | The slate distribution process supports daily publishing of slate updates. | • | • | ||||||||

| 3 | The slate distribution process provides appropriate access to slates for users. | • | • | • | |||||||

| 4 | The slate distribution process assists with mobile and off-network access to slate information. | • | • | • | |||||||

| 5 | The slate distribution process support compatibility with currently used computer programs. | • | • | • | • | • | • | ||||

This table depicts the metrics developed for this design project and the dots shown in the matrix indicate the relationships between the top-rated users’ needs and the metrics.

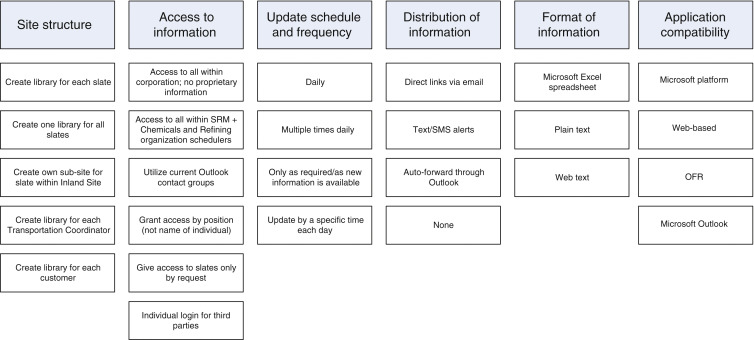

3.5. Design phase

The design phase consisted of working to develop design ideas to fulfill the top-rated users’ needs, while also practically addressing the natural constraints of the slate distribution process. Brainstorming and benchmarking sessions were conducted with SharePoint experts and other professionals both within and outside the organization. During these sessions, the design team asked participants how they could best go about fulfilling the top-rated users’ needs that were previously identified and create a successful information sharing process. The design ideas collected were organized into an affinity diagram by the Inland Team. The diagram included themes such as site construction (i.e., site structure, access to information, and application compatibility) and process methodology, such as distribution of information, and update schedule and frequency. To identify further design ideas, the team utilized the options field/options profile method that was originally developed to provide a systematic way for a collaborative group to portray a finished design using pre-established options (Pugh & Clausing, 1996). In order to create various profiles for how the new slate distribution process could be designed, the design team narrowed down the design ideas from the affinity diagram to a sub-set of ideas that represented specific options. In using the options profiling approach, the design team selected one or more options within each dimension of the design to create a viable profile for the design. In total, the design team created 25 possible profiles (labeled A–Y) covering many possible option and dimension combinations.

The best 11 profiles were further assessed based on the metrics established previously (see Table 2) using a concept selection matrix, as shown in Table 3. Members of the Inland Team worked together to rate each profile on a three-point scale. The profile with the highest score was profile “B,” meaning that this is the design that most effectively addresses the users’ needs. Profile “B” is shown in Figure 3. Please note that the options are given in the white boxes, the dimensions are depicted by the shaded boxes, and the options included in profile “B” are outlined in a thick black line. The design team then moved forward with implementing the new slate distribution process as outlined in profile “B.” This work included building the new SharePoint platform, which involved creating space on the existing Inland Teams SharePoint site, creating user groups, obtaining the contact information for each individual originally receiving the slate, checking the permissions of the user groups to ensure that proper access was granted, and formatting the SharePoint space to make it user friendly. Because of the number of users impacted by the proposed process change, management mandated that a sub-set be used to test the new slate distribution process. This sample group was used as the implementation audience in the Verify phase.

| Selection criteria | Design concept/profile (scale: 1 = will not meet criteria; 2 = will fulfill criteria; 3 = will exceed expectations for criteria) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | F | G | I | N | O | P | V | X | |

| 1. Update interval | 2 | 3 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 2. Ease-of-use | 4 | 5 | 4 | 3 | 3 | 3 | 3 | 3 | 4 | 3 | 2 |

| 3. Number of slates printed daily | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 4. Everyone who needs access has access | 3 | 3 | 3 | 2 | 2 | 1 | 2 | 2 | 3 | 3 | 3 |

| 5. Information can be accessed through the web | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 6. Compatible with Microsoft Excel | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| 7. Compatible with Microsoft Outlook | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 8. Compatible with ORF | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| 9. Compatible with SharePoint | 2 | 2 | 2 | 2 | 2 | 1 | 2 | 2 | 2 | 2 | 2 |

| Total | 23 | 25 | 23 | 21 | 21 | 19 | 21 | 21 | 23 | 22 | 21 |

The design team used the matrix shown in this table to help them identify the “best” concept/profile for the design of their new process by evaluating each concept/profile against the metrics established earlier in the project.

|

|

|

Fig. 3. The final design of the new slate distribution process in the form of an options profile (denoted by bold boxes). The concept/profile depicted in this figure received the highest score from the concept selection matrix; therefore, the design team felt this was the best idea for the design of their new process. |

3.6. Verify phase

Once the new slate distribution process had been used by the implementation group for eight weeks, verification measurements were collected to determine if the new design effectively fulfilled users’ needs. The comparison between the baseline and verification measurements provided in Table 4 suggests there was no negative impact on the process as a result of redesigning it. While the number of slate updates per week (metric 1) remained constant, both “ease-of-use” and “number of slates printed daily” measures improved. Specifically, “ease-of-use” increased and “number of slates printed daily” decreased. Also, the metrics regarding slate information being available on the web (metric 5) and process compatibility with SharePoint (metric 9) were both upgraded from “No” to “Yes.” Based on the positive achievements of this small-scale implementation of the new slate distribution process, management approved a larger-scale rollout. Data was collected during these additional implementation efforts to ensure the effectiveness of the new slate distribution process in terms of its ability to fulfill users’ needs.

| Metric no. | Need nos. | Metric | Units | Baseline measurement | Verification measurement | Change |

|---|---|---|---|---|---|---|

| 1 | 1, 2 | Update interval | Count/week | 5 | 5 | No change |

| 2 | 1–5 | Ease-of-use | 5 point scale | 3 | 5 | Increased by 2 points |

| 3 | 4 | Number of slates printed daily | Count/day | 19 | 8 | Decreased by half |

| 4 | 1, 3 | Everyone who needs access has access | Yes/No | Yes | Yes | No change |

| 5 | 3–5 | Information can be accessed through the web | Yes/No | No | Yes | Improved |

| 6 | 5 | Compatible with Microsoft Excel | Yes/No | Yes | Yes | No change |

| 7 | 5 | Compatible with Microsoft Outlook | Yes/No | Yes | Yes | No change |

| 8 | 5 | Compatible with OFR | Yes/No | Yes | Yes | No change |

| 9 | 5 | Compatible with SharePoint | Yes/No | No | Yes | Improved |

The comparison of baseline and verification measurements shown in this table provides evidence that this project was successful because the new design effectively fulfilled users’ needs.

4. Conclusions and implications for supply chain managers

This research effectively demonstrated the use of DFSS through an action research, case study conducted within a marine transportation supply chain. Prior to undertaking this design project, the organization shared critical supply chain information through periodic emails with sizable attachments. Utilizing the DMADV methodology, the design team identified the requirements for a new slate distribution process based on users’ needs, involved those who knew the process well in generating specific design ideas for effectively addressing users’ needs, and implemented the new process within the organization. The success of these efforts is evident through the comparison of baseline and verification measurements, which indicates that the new slate distribution process effectively fulfills the needs for which it was designed.

The organization studied in this research greatly benefited from this design project in terms of the gains made regarding communicating/sharing important supply chain information through an efficient and effective new process. Management was very satisfied with the results of this project because gone are the days of various supply chain functions searching for the latest information and/or using outdated information to make decisions within this organization. Now, all current information regarding the movement of barges carrying oil cargos is available via a SharePoint site for all those involved in the process to easily access at a moments notice. The implementation of this new process has also made the work of the Transportation Coordinators easier by reducing the number of slates printed each week, while maintaining the update interval (daily). Additionally, notifications are sent to those involved when updates are made to the slate information posted in SharePoint, and this information is readily accessible via the web for reference from anywhere at anytime; hence, those who work in this process are also very satisfied with the outcomes achieved through this project.

While this research clearly provided useful benefits for one marine transportation services company, the results obtained from this study may not be generalizable to all organizations/DFSS projects due to the limitations of this research. For example, this case study was conducted in only one organization and utilized a specific DFSS approach, but other organizations may need to use a somewhat different type of DFSS approach depending on the problem they are trying to solve. Given these limitations, further research is needed to help grow the value of supply chain management (Sahin & Robinson, 2005), including developing additional ways to share information (Li et al., 2006 ; Simatupang and Sridharan, 2008), communicating more effectively (Sahin & Robinson, 2002), and/or reducing the unevenness of information across supply chain functions (Madlberger, 2009).

As this case study serves as an example of how to use DFSS to develop value-enabling elements within service processes based on relatively straightforward design methods, it is hoped that others may draw upon this work to redesign existing processes and/or design new processes for the benefit of their organizations. Engineers that design new products, for example, are not the only ones that need to use design methods. Often we find that processes in a wide range of environments can be improved by redesigning them, particularly once a point of diminishing returns using process improvement methods alone is encountered (Yang, 2005); hence, more work is needed to expand the use of design methods, and further research is needed to develop a better understanding of the factors that have a significant impact on the success of design efforts, especially in service environments.

References

- Antony et al., 2006 J. Antony, A. Kumar, R. Banuelas; World class applications of Six Sigma; Elsevier Ltd., Oxford (2006)

- Cantor and Macdonald, 2009 D.E. Cantor, J.R. Macdonald; Decision-making in the supply chain: Examining problem solving approaches and information availability; Journal of Operations Management, 27 (3) (2009), pp. 220–232

- Chang and Wang, 2008 K.K. Chang, F.K. Wang; Applying Six Sigma methodology to collaborative forecasting; International Journal of Advanced Manufacturing Technology, 39 (9–10) (2008), pp. 1033–1044

- Coughlan and Coghlan, 2002 P. Coughlan, D. Coghlan; Action research for operations management; International Journal of Operations and Production Management, 22 (2) (2002), pp. 220–240

- de Mast et al., 2011 J. de Mast, G. Diepstraten, R.J.M.M. Does; Quality quandaries: Design for six sigma: Method and application; Quality Engineering, 23 (2) (2011), pp. 204–211

- Duffy et al., 2012 G.L. Duffy, S. Laman, P. Mehta, G. Ramu, N. Scriabina, K. Wagoner; Beyond the basics – Seven new quality tools to help innovate, communicate and plan; Quality Progress, 45 (4) (2012), pp. 18–29

- Edgeman and Dugan, 2008 R.L. Edgeman, J.P. Dugan; Six Sigma from products to pollution to people; Total Quality Management, 19 (1–2) (2008), pp. 1–9

- El-Haik and Al-Aomar, 2006 B. El-Haik, R. Al-Aomar; Simulation-based Lean Six-sigma and Design for Six-sigma; John Wiley & Sons, Hoboken, NJ (2006)

- El-Haik and Roy, 2005 B. El-Haik, D.M. Roy; Service Design for Six Sigma: A roadmap for excellence; John Wiley, Hoboken, NJ (2005)

- Fiala, 2005 P. Fiala; Information sharing in supply chains; Omega, 33 (5) (2005), pp. 419–423

- Goldsby and Martichenko, 2005 T.J. Goldsby, R. Martichenko; Lean Six Sigma logistics: Strategic development to operational success; J. Ross Publishing, Plantation, FL (2005)

- Hall and Saygin, 2012 D.C. Hall, C. Saygin; Impact of information sharing on supply chain performance; International Journal of Advanced Manufacturing Technology, 58 (1–4) (2012), pp. 397–409

- Hasenkamp, 2010 T. Hasenkamp; Engineering Design for Six Sigma—A systematic approach; Quality and Reliability Engineering International, 26 (4) (2010), pp. 317–324

- Hugos, 2011 M. Hugos; Supply chain coordination; M. Hugos (Ed.), Essentials of supply chain management (3rd ed.), John Wiley & Sons, Inc., Hoboken, NJ (2011), pp. 183–211

- Hung et al., 2011 W.-H. Hung, C.-F. Ho, J.-J. Jou, Y.-M. Tai; Sharing information strategically in a supply chain: Antecedents, content and impact; International Journal of Logistics: Research and Applications, 14 (2) (2011), pp. 111–133

- Kemmis et al., 2014 S. Kemmis, R. McTaggart, R. Nixon; The action research planner: Doing critical participatory action research; Springer, Singapore (2014)

- Li et al., 2006 G. Li, Y. Lin, S. Wang, H. Yan; Enhancing agility by timely sharing of supply information; Supply Chain Management: An International Journal, 11 (5) (2006), pp. 425–435

- Liu and Kumar, 2011 R. Liu, A. Kumar; Leveraging information sharing to configure supply chains; Information Systems Frontiers, 13 (1) (2011), pp. 139–151

- Madlberger, 2009 M. Madlberger; What drives firms to engage in interorganizational information sharing in supply chain management?; International Journal of e-Collaboration, 5 (2) (2009), pp. 18–42

- Mangan et al., 2008 J. Mangan, C. Lalwani, B. Fynes; Port-centric logistics; International Journal of Logistics Management, 19 (1) (2008), pp. 29–41

- Manuj and Sahin, 2011 I. Manuj, F. Sahin; A model of supply chain and supply chain decision-making complexity; International Journal of Physical Distribution and Logistics Management, 41 (5) (2011), pp. 511–549

- Mesmer-Magnus and DeChurch, 2009 J.R. Mesmer-Magnus, L.A. DeChurch; Information sharing and team performance: A meta-analysis; Journal of Applied Psychology, 94 (2) (2009), pp. 535–546

- Mudrageda and Murphy, 2008 M. Mudrageda, F.H. Murphy; An economic equilibrium model of the market for marine transportation services in petroleum products; Operations Research, 56 (2) (2008), pp. 278–285

- Nooramin et al., 2011 A.S. Nooramin, V.R. Ahouei, J. Sayareh; A Six Sigma framework for marine container terminals; International Journal of Lean Six Sigma, 2 (3) (2011), pp. 241–253

- Pettersson and Segerstedt, 2013 A.I. Pettersson, A. Segerstedt; Measuring supply chain cost; International Journal of Production Economics, 143 (2) (2013), pp. 357–363

- Posey and Bari, 2009 C. Posey, A. Bari; Information sharing and supply chain performance: Understanding complexity, compatibility, and processing; International Journal of Information Systems and Supply Chain Management, 2 (3) (2009), pp. 67–76

- Pugh and Clausing, 1996 S. Pugh, D. Clausing; Creating innovative products using total design: The living legacy of Stuart Pugh; Addison-Wesley Longman Publishing Co., Inc., Boston, MA (1996)

- Reason and Bradbury, 2008 P. Reason, H. Bradbury; The Sage handbook of action research: Participative inquiry and practice; (2nd ed.)Sage Publications, London (2008)

- Sahin and Robinson, 2002 F. Sahin, E.P. Robinson; Flow coordination and information sharing in supply chains: Review, implications, and directions for future research; Decision Sciences, 33 (4) (2002), pp. 505–536

- Sahin and Robinson, 2005 F. Sahin, E.P. Robinson; Information sharing and coordination in make-to-order supply chains; Journal of Operations Management, 23 (6) (2005), pp. 579–598

- Schroeder et al., 2008 R.G. Schroeder, K. Linderman, C. Liedtke, A.S. Choo; Six Sigma: Definition and underlying theory; Journal of Operations Management, 26 (4) (2008), pp. 536–554

- Simatupang and Sridharan, 2008 T.M. Simatupang, R. Sridharan; Design for supply chain collaboration; Business Process Management Journal, 14 (3) (2008), pp. 401–418

- Tjahjono et al., 2010 B. Tjahjono, P. Ball, V.I. Vitanov, C. Scorzafave, J. Nogueira, J. Calleja, et al.; Six Sigma: A literature review; International Journal of Lean Six Sigma, 1 (3) (2010), pp. 216–233

- Ulrich et al., 2011 K.T. Ulrich, S.D. Eppinger, A. Goyal; Product design and development, vol. 2, McGraw-Hill/Irwin, New York (2011)

- Wagner and Buko, 2005 S.M. Wagner, C. Buko; An empirical investigation of knowledge sharing in networks; Journal of Supply Chain Management, 41 (4) (2005), pp. 17–31

- Watson and DeYong, 2010 G.H. Watson, C.F. DeYong; Design for Six Sigma: Caveat emptor; International Journal of Lean Six Sigma, 1 (1) (2010), pp. 66–84

- Yang, 2005 K. Yang; Design for Six Sigma for service; McGraw Hill, New York (2005)

- Yang and El-Haik, 2003 K. Yang, B. El-Haik; Design for Six Sigma: A roadmap for product development; McGraw-Hill, New York (2003)

- Ye and Wang, 2013 F. Ye, Z. Wang; Effects of information technology alignment and information sharing on supply chain operational performance; Computer and Industrial Engineering, 65 (3) (2013), pp. 370–377

- Zhu et al., 2010 W. Zhu, S. Gavirneni, R. Kapusciniski; Periodic flexibility, information sharing, and supply chain performance; IIE Transactions, 42 (3) (2010), pp. 173–187

Document information

Published on 12/06/17

Submitted on 12/06/17

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?