| (5 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | ===Abstract=== | |

| − | + | ||

| − | + | ||

Nowadays, dam safety is becoming more relevant in our society due to the importance of its functions (power generation, water supply, flood control) and the severity of the consequences in case of a serious breakdown. The "safety of hydraulic infrastructures" is one of the priorities according to the R<math display="inline">\& </math>D Spanish State Program which is oriented to social challenges. | Nowadays, dam safety is becoming more relevant in our society due to the importance of its functions (power generation, water supply, flood control) and the severity of the consequences in case of a serious breakdown. The "safety of hydraulic infrastructures" is one of the priorities according to the R<math display="inline">\& </math>D Spanish State Program which is oriented to social challenges. | ||

| Line 11: | Line 9: | ||

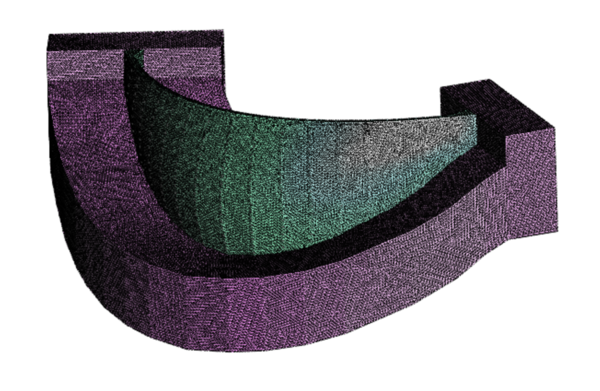

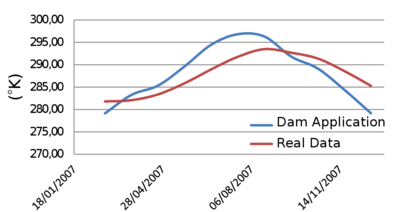

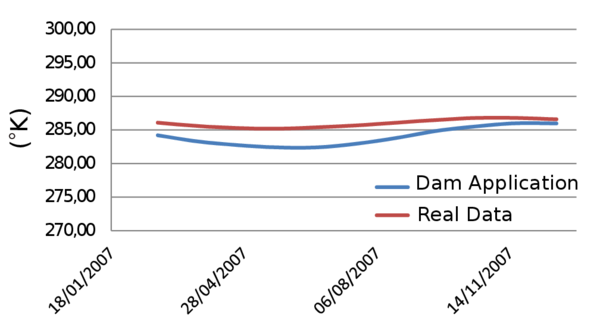

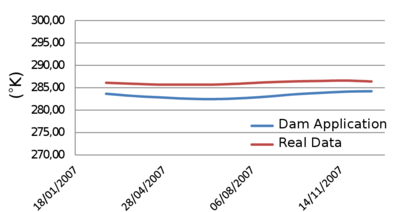

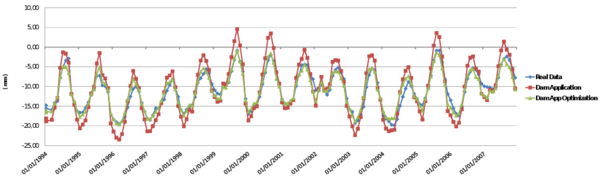

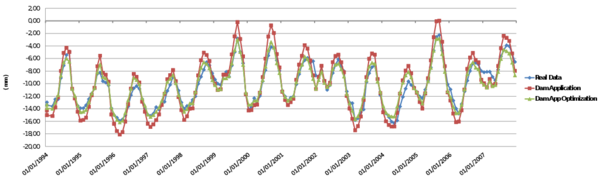

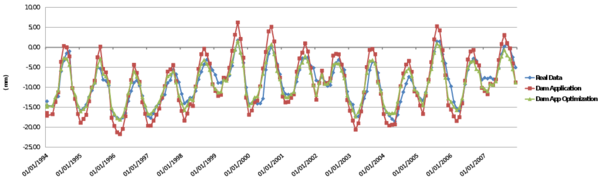

The proposed software is validated with a real case: La Baells dam. The computational results have shown excellent agreement with the obtained data during monitoring process. | The proposed software is validated with a real case: La Baells dam. The computational results have shown excellent agreement with the obtained data during monitoring process. | ||

| − | + | ===Acknowledgements=== | |

This master thesis would not have been the same without the help of many people, thus I would like to dedicate them few words. | This master thesis would not have been the same without the help of many people, thus I would like to dedicate them few words. | ||

| Line 176: | Line 174: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Content_292531468-numerical_process.png| | + | |[[Image:draft_Content_292531468-numerical_process.png|400px|The four steps of a numerical model.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 3:''' The four steps of a numerical model. | | colspan="1" | '''Figure 3:''' The four steps of a numerical model. | ||

| Line 1,027: | Line 1,025: | ||

|} | |} | ||

| − | Eq.[[#eq-44|44]] requires that matrix '''C''' be easily invertible for an effective implementation. The reduction of the matrix to a diagonal or "lumped" form can be accomplished by various procedures, for instance row-sum <span id='citeF-19'></span>[[#cite-19|[19]]] | + | Eq.[[#eq-44|44]] requires that matrix '''C''' be easily invertible for an effective implementation. The reduction of the matrix to a diagonal or "lumped" form can be accomplished by various procedures, for instance row-sum <span id='citeF-19'></span>[[#cite-19|[19,29]]]. Forward-Euler method is conditionally stable and the stability condition is governed by the thermal diffusivity of the material, and the finite element space <span id='citeF-20'></span>[[#cite-20|[20]]]. Euler method is first-order accuracy in time. The main attraction of an explicit scheme is the fact that a matrix solution is not required and computer storage requirements are minimal. |

When <math display="inline">\alpha > 0</math>, a family of implicit methods are produced. Depending on the used value there are different schemes: | When <math display="inline">\alpha > 0</math>, a family of implicit methods are produced. Depending on the used value there are different schemes: | ||

Latest revision as of 17:48, 9 May 2017

Abstract

Nowadays, dam safety is becoming more relevant in our society due to the importance of its functions (power generation, water supply, flood control) and the severity of the consequences in case of a serious breakdown. The "safety of hydraulic infrastructures" is one of the priorities according to the RD Spanish State Program which is oriented to social challenges.

Thanks to recent improvements in the modelling of dams as well as the evolution of computational resources, it is possible to perform more detailed analysis. However, most of commercial software is devoted to more common problems (e.g. buildings, bridges) without considering specific aspects of dams: concrete ageing process, joints during the construction process, contact with the ground or uplift pressure.

The development of a specific application for dam engineering, both for construction phase and operating period, is the main objective of this project. The thesis presents the computational tool, which is based on finite element formulations and solves thermo-mechanical problem using weak coupling, designed for analysing the operating period.

The proposed software is validated with a real case: La Baells dam. The computational results have shown excellent agreement with the obtained data during monitoring process.

Acknowledgements

This master thesis would not have been the same without the help of many people, thus I would like to dedicate them few words.

Firstly, I would like to thank Prof. Eugenio Oñate for giving me the opportunity of becoming a member of CIMNE. I would also like to thank my supervisors M.Sc. Fernando Salazar and Dr. Antonia Larese for their guidance and support during the writing of this thesis. I would like to make these thanks extensive to all the members of Room C6 and C4, particularly to Ignasi, for their wide advices and support. I would also like to thank to Dr. Josep Maria Carbonell and Dr. Jose Manuel González for his patience in my beginning with KRATOS and all provided geometries of dams. I can not forget to mention my friends and colleagues Tomás, Ruben and Vicente, with whom I spent so many hours.

I would like to also give special emphasis to my family, especially my parents and brother, because despite the distance, have always given me their unconditional support.

Finally, I would like to thank to all people that shared their time in one way or other with me; life-long friends; Ana, Fernando, Carlos, Leo, Zito, classmates; Samu, Marc, Eric and Marta and flatmates; Jorge and Martin, whom have helped and supported me not only during this work, but also during the whole master course.

This work has been funded by the Ministry of Economy and Competitiveness under Retos Programme through the grant, RTC-2015-3794-5 - ACOMBO.

1 Introduction

Water is a basic resource for all humans. Nowadays, the earth is not still affected by a lack of water but, according with some researches, this situation will change in a short period of time [1].

Only 1% of the water in the Earth is freshwater (mainly in rivers, groundwater reserves, lakes and reservoirs, Figure 1 1). However, only the reservoirs can be handled by humans. For this reason, dams play an important role in our society.

|

| Figure 1: View of Kariba Dam, the world's biggest reservoir. |

Dams are the infrastructures that allow accumulate water with the aim of supply the population, generate energy and control the floods before it arrives to the sea through rivers.

The main objective of a dam is to resist the solicitations that the dammed water generates. This water not only induces a significant mechanical solicitations but also thermal loads due to the gradient of temperatures. Some researches have proved that the influence of the temperature in the global structural response can not be neglected [2].

(1) http://www.worldbank.org/en/region/afr/brief/the-kariba-dam-rehabilitation-project-fact-sheet

1.1 Motivation

Dam safety is becoming more relevant due to the importance of its functions (power generation, water supply, flood control) and the severity of the consequences in case of a serious breakdown.

In Spain, the majority of the dams were built during last 50 years [3]. For this reason, companies and institutions that are in charge of these structures are worried about the structural response of these critical infrastructures, which is one of the priorities inside the RD State Program (Programa Estatal de I+D+I Orientada a los Retos de la Sociedad).

These worries are based on past experiences. The Vajont disaster (Italy)(Figure 2 1) is one of the most important and well known. In 1963 an important landslide produced a tsunami which caused 2,000 casualties, however the body of the dam resisted, and today, continues standing [4].

|

| Figure 2: View of Vajont Dam one day after the landslide. |

The rainfall generated by Typhoon Nina in Zhumadian (China, 1975) caused the worst disaster originated by dam break in the history. The number of casualties reached the amount of 171,000, and 11 millions of people had to leave their homes. The main factor of this disaster was the extreme conditions generated by the collision of Typhoon Nina and a cold front. The project flood was calculated using a return-period of 1,000 years but that day the flood was the equivalent to a return-period of 2,000 years [5].

During the last 10 years, at least 15 disasters happened around the world, the most important were: Shakidor Dam (Pakistan) in 2005 with 70 casualties, Situ Gintung Dam (Indonesia) in 2009 with 98 casualties, Kyzyl-Agash Dam (Kazakhstan) in 2010 with 43 casualties or Köprü Dam (Turkey) in 2012 reaching 10 casualties.

In this context, the aim of this work is to develop a tool that simulates the real behaviour of dams and predicts its response.

(1) https://en.wikipedia.org/wiki/Vajont_Dam

1.2 Objectives

The main objective of this thesis is to develop a computational tool for structural verification of dams, including the possibility of thermo-mechanical analysis.

Since the software is specific for dams, the possibility to assign some ad-hoc boundary conditions is implemented, such as the Bofang temperature conditions [6] and the possibility to vary the water level through an input table data.

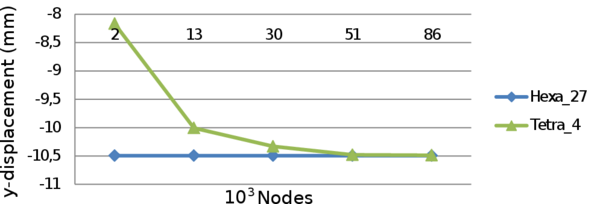

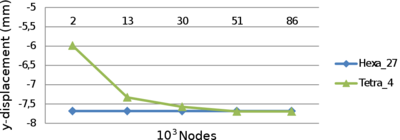

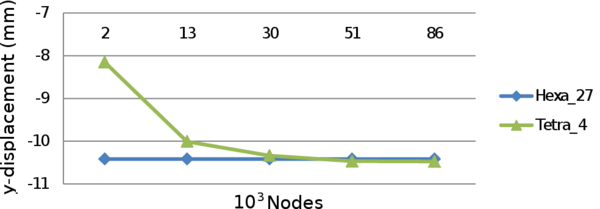

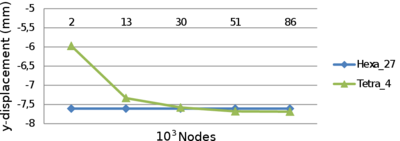

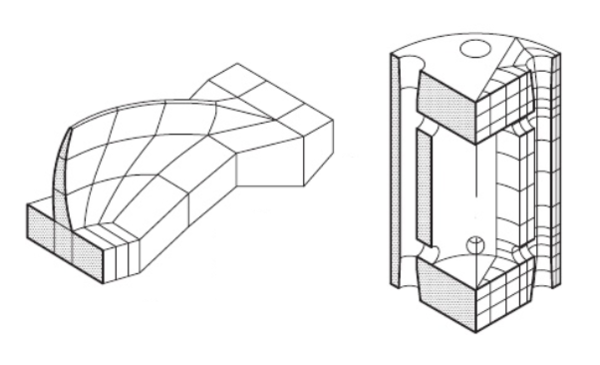

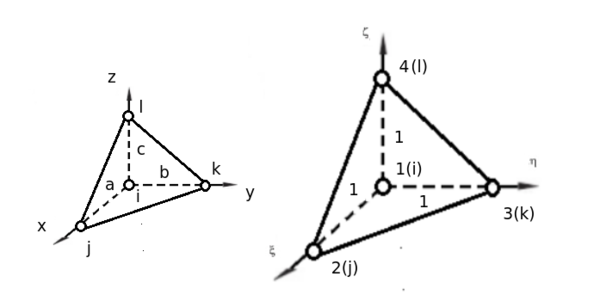

Another important objective of this thesis is to check whether accurate results can be obtained with tetrahedral elements. Dam structural calculations are typically performed with hexahedral meshes, which are difficult to generate for complex geometries. The use of tetrahedral meshes avoids these problems.

1.3 Structure of the Thesis

The present thesis is divided in six parts. The first one is the Introduction where the motivation and the objectives of the thesis were presented.

Chapter 2 is dedicated to literature review. In this chapter, a general guideline for the use of numerical models in dam engineering [7] are presented, focusing in recommendations for new dams and dealing with particular issues on existing dams.

In chapter 3 the proposed methodology for solving the problem is presented. This chapter deals with the mechanical, thermal and thermo-mechanical formulation. The derivation of the weak formulation is stated as well as the coupling between thermal and mechanical problem.

Chapter 4 is devoted to introduce the KRATOS environment and the Dam Applica- tion. KRATOS is a framework for building multi-disciplinary finite element programs. It provides several tools for easy implementation of finite element applications and a common platform with effortless interaction between them. On the other hand, Dam Application is a new specific application for structural verification of dams. The main implementations, how it works internally and its dependencies of other applications are presented.

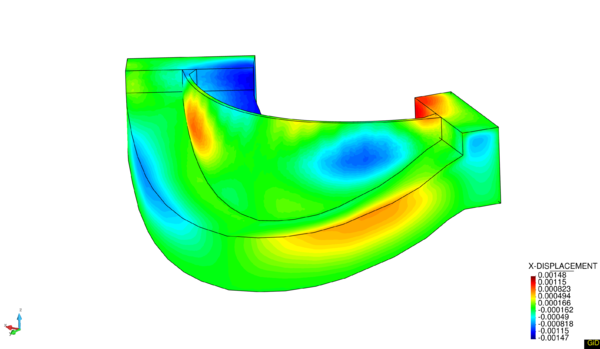

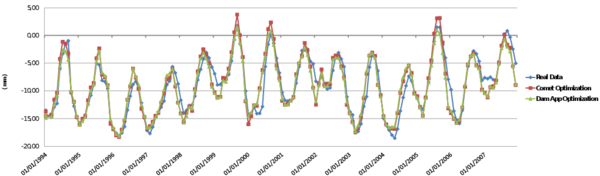

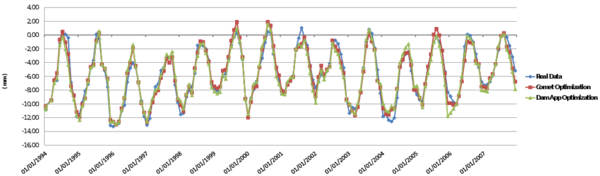

Chapter 5 is dedicated to numerical results. La Baells arch Dam was selected as a case study: a numerical model was built and computed via the new Dam Application, and the results were compared to; a) the actual dam behaviour, as measured by the monitoring devices, and b) numerical results obtained with the software COMET.

In Chapter 6 some conclusions about the work performed as well as future work are discussed.

2 Literature Rewiew

The use of numerical tools such as finite element, boundary element and finite difference methods, has become standard practice in dam engineering. There is extensive literature about this subject and a specific document published by the International Commission on Large Dams (ICOLD) in his bulletin 155 [7].

The object of the computational activity is often missed during the process. Due to this fact, it is important to emphasise the different purposes of a numerical simulation of dam-foundation-reservoir:

- Prediction of the structural stability and simulation of any possible failure mechanisms under all types and the whole range of loading scenarios (typically normal operation, flood and earthquake).

- Pre-design and optimization of new dams at different project stages.

- Interpretation of the behaviour of dams under operation by comparison of results of the monitoring system with theoretical computed values.

- Design and optimization of remedial works, corrective measures, and most efficient rehabilitation methods of existing dams,

In the numerical analysis of dams, there are two different scenarios depending on the stage: design of a new structure, or analysis of an existing one. In case of new dams, general recommendations for the process of numerical analysis in this field are presented, in this stage the two first purposes are dealt: prediction of the structural stability and pre-design. In the case of existing dams, special attention to the information provided by the monitoring system and the dealing with the last two commented purposes must be taken. The main distinction between modelling new and existing dam lies on the fact that the numerical models can not be calibrated for a new dam since no information on the actual dam response is available.

2.1 Numerical Models for New Dams

The basic goal of the numerical analysis is to provide adequate answers to a set of relevant questions related to the performance of a dam. Past incidents and failures have confirmed the necessity of this type of studies in the design phase considering all possible scenarios. Several aspects must be taken into account when considering the application of numerical models for design and analysis dams.

The size and refinement of the finite element grid

It is important to remember that a higher finite element density, and correspondingly finite elements of smaller size, is necessary where higher gradients are expected. These high gradients can appear in areas where there are geometrical singularities (e.g. sharp corners), as well as in relation to the loading condition.

The domain dimension around the dam is another important issue regarding the numerical model. This question takes special relevance when dynamic analysis is performed but can not be ignored for static or quasi-static analysis.

The Saint-Venant principle states that a disturbance to a given model has an influence on the stress level in a surrounding domain which has equal to the dimension of the disturbance itself. For static loads and linear analysis, this principle can be applied. Considering the dam as the disturbance, the extension of the surrounding foundation should be at least equal to a characteristic dimension of the structure.

Generally, 2-dimensional models are adopted for embankment dams or straight plant masonry/concrete dams; however, the application of this simplification to other typologies as: curved plant masonry/concrete dams or arch dams can lead to problems. In these typologies of dams the use of 3-dimensional models are needed.

The inclusion of discontinuities

The consideration of discontinuities (e.g. construction joints, interfaces, cracks) demand a non-linear finite element modelling. A preliminary linear elastic analysis in order to check the stress field is always a good idea. With this information it is possible to activate the kinematics (opening or sliding) of the discontinuities. In case of concrete arch dams can not avoid the inclusion of discontinuities.

The definition of the initial stress-strain state

This is one of the most complex problems to be solved for existing structures, not only because of the lack of information on construction but also due to the lack of knowledge on the thermo-visco-mechanical parameters which govern the phenomena.

In traditional numerical modelling, the dead weight of the structure is simulated as an instantly applied load acting on the complete structure to obtain its final conditions at the boundaries. In practice, the dead weight and the stiffness is applied progressively according with the dam construction.

With regards to concrete dams, the consideration of dead weight during the dam construction may be important to evaluate the stress-strain state caused by the generation and dispersion of hydration heat in concrete block masses which are not totally free to contract during the cooling process. In arch dams, the simulation of contraction joints injection could be more significant.

Treatment of consolidation of foundations

The evolution of the effects of this type of process (jet-grouting, cement injection) are quite difficult due to the physical-mechanical characteristics of the rock foundations. Field tests may be useful to evaluate the efficiency of the consolidation works. This information also can be used to prepare the numerical model.

2.1.1 Type of analyses for new projects

In the design phase numerical analysis plays an important role. The design affects the final cost of the project but also the maintenance and the risk are factors that must be taken into account.

Mainly in the design of dams two tools are used: past dam engineering experience (behaviour of existing dams) and the analytical and numerical models. When these conditions are met computational models provide a safe baseline for design of new dams, based on past experience and knowledge with the support of associated design criteria.

In the design of a new dam, most of the information is generally conventional, there is no much data that can be used as project-specific reference. Due to this lack of accurate information, this situation leads to an iterative design process with successive definitions of the project characteristics (dimensions) until a satisfactory degree of optimization is reached.

It is recommendable to perform an analysis in the linear elastic range, even for extreme loading conditions. The goal of this analysis is to identify possible damaged zones.

After carrying out linear analysis, it is recommendable to perform a non-linear study under extreme loading scenarios (severe seismic ground motions) to obtain better approximations of dam behaviour. Non-linear models are not easy to interpret. The main difficult comes from the stress transmission when the strength of the material is reached. This procedure can be corrupted for several reasons:

- Non linear models need to be treated with approximate numerical iterative procedures; in zones close to yielding surface can appear numerical instabilities.

- Even a good mathematical model can produce some differences with the prototype in the plastic range.

- For non-linear models the load history is very important.

- The ultimate behaviour of a structure can be strongly influenced by local weakness of the material.

Non-linear finite element models are a useful tool to capture non-elastic mechanical properties.

The appropriate framework for the numerical analysis process consist of:

- Simplifying.

- Selecting and using the adequate model to get the best answer with available information.

- Checking the consistency between results and assumptions.

Same procedure is suitable for both the design of a new structure and the analysis of an existing one.

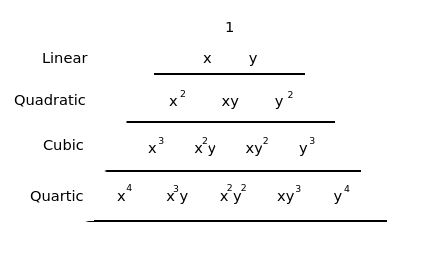

2.1.2 The steps of a numerical process

Numerical models can produce a relevant picture of the state of stresses and the displacement field of the structure. Numerical models are essential to comprehend the behaviour of the dam. These models are widely used during the optimization process.

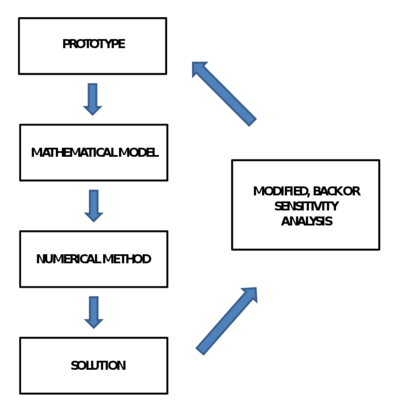

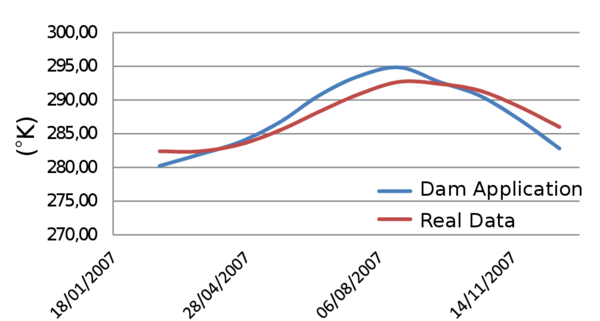

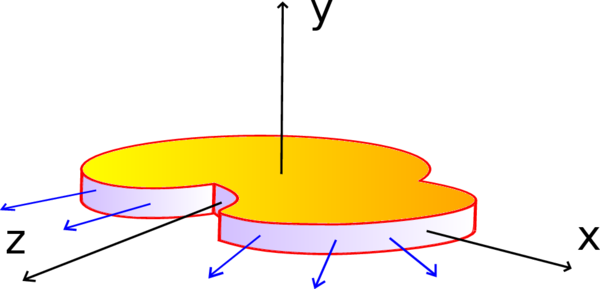

Figure 3 shows the different steps in the numerical model.

- Prototype The physical structure to be analysed with all its complexities.

- Mathematical model A formulation which transfers in mathematical terms the conceptual model representing the behaviour of both the structure to be built and its foundation.

- Numerical method Used to solve the mathematical model and to obtain a numerical solution. Generally, numerical methods provide an approximation of the 'exact solution'.

- Numerical model The solution of the mathematical model by means of the numerical method.

- Evaluation of the solution The translation of the numerical results into practical conclusions.

|

| Figure 3: The four steps of a numerical model. |

In many cases this process is iterative. The evaluation of the first case often leads to modify the model, the imposed boundary conditions... when calibrations are possible. In this process the experience of the professionals plays an important role, they must be aware about the assumptions and simplifications used. This is particularly important in non-linear models since the uniqueness of the solution is not guaranteed.

2.1.3 Preliminary design tools

Preliminary designs are based mainly in past experience of the designer with respect to similar dams built. These designs usually have similar conditions: geological, topographical, hydrological and material parameters.

In case of having similar parameters and conditions a simple model can be suitable. On the other hand, when the characteristics are unprecedented (quite often in arch dams) a too simple approach may be insufficient, and should be considered as only initial step. When more information is available a more realistic model is performed.

The numerical analysis of new projects is typically associated with the following challenges:

- Extrapolation from experience represent a large leap, the numerical models must be able to avoid this leap and represent as realistically as possible the phenomena involved.

- The information of materials and loads are not directly available during model calibration, and the values must be obtained through progressive researches. The idea is to start with a simple and unreliable model and arrive to a sophisticated and realistic one.

2.1.4 Methods for in-depth analysis

In the case of extreme scenarios such as Maximum Credible Earthquake or Probable Maximum Flood, more sophisticated models may be necessary to explain this complex behaviour. Clear examples of this necessity can be transient underground seepage, cooling of new concrete, contact between two blocks or two types of materials and dam behaviour during earthquakes.

The aim of non-linear finite elements is the representation of non-linear stress behaviour of soils, concrete, rock foundation, cracks and joints. It is not necessary a global non-linear analysis, since location of non-linearities are known (e.g. dam-foundation contact interface). Another important consideration in the case of global non-linear analysis is that the results are non-unique due to they are dependent on the load-history, the model, and the numerical solution method.

The definition of acceptable safety criteria always requires a correct selection of design parameters since the solution is sensitive to modelling assumptions. Most of safety guidelines are not addressed to establish acceptable margins through the interpretation of finite element results. These factors of safety are sensitive to the calculation techniques.

The stresses are dependent on model discretization and mesh size. A clear example of that can be a heel of a gravity dam subjected to linear elastic analysis. The whole area related to the heel is mesh dependent. There are different techniques to avoid these problems, for example the use of adaptive techniques with the aim of refining the mesh in the affected area. Another possible solution could be the introduction of non-linearities in this area.

Following, the particular issues on existing dams modelling are dealt.

2.2 Particular issues on existing dam modelling

Many of the considerations commented in previous section can be applied to this section. Nonetheless, this section is focused on the relation between the behaviour of the structure and the need of periodic assessment with understanding of the nature, source and relevance of the uncertainties involved.

One of the basic aspects related to existing dams is the surveillance. There are three important phases in the surveillance of dam life: during construction, during first impounding of the reservoir and during the operating period. Monitoring activity is an important ingredient to validate design assumptions, and also can be used to calibrate mathematical models or to detect abnormal deviations for long-term behaviours [8].

Construction

All data provided by monitoring devices are very useful for checking the critical design parameters (e.g. the foundation deformability or hydration heat) and to make corrections during construction phase.

First impounding of the reservoir

In this phase some monitored parameters concerning the dam-foundation-reservoir response to environmental loads with predicted values from design are compared. In case the differences are significant, it is a must the investigation of the origin of these differences and to take corrective measures if needed. This phase is also important in the mathematical model calibration.

Operation

The measurements from the monitoring systems and visual inspections carried out periodically are processed and compared to predicted values. In case of long-term operation, it is also important to check the influence of ageing process in the structure. In the case of detecting an important ageing process, the model must be calibrated. Another important mission of this monitoring process is the detection of behaviour changes and the study of these changes.

2.2.1 Uncertainties of measurements

The obtained data are crucial in the interpretation of dam behaviour. However, the measurements can be under suspicion due to uncertainties linked to the installation, calibrating process or its conservation. In fact, wrong measurements can lead to incorrect decisions, due to this, some dam engineers can be sceptic about their importance [9].

The combination of statistical models and registered data can lead to better understanding of the dam behaviour.

2.2.2 Forecasting Numerical Models

Dams are designed for long time and their require an important investment not only during the construction period but also during the operating period. The surveillance of dams is crucial to avoid future disasters. A failure of a large dam can generate unacceptable casualties and important damages.

Due to above commented facts, there is a necessity to make forecasting models to predict the dam behaviour. The data processing of these predictions with the real data give the possibility of a quick response in case of issues.

Generally, forecasting models are of the following form [10]:

|

|

(1) |

where

- is the observed value of a given indicator

- represents the forecast of the same indicator

- is the reversible hydrostatic component

- is the reversible thermal component

- is the irreversible component

- is the difference between the measurement and the theoretical model. It represents the sum of all the model inaccuracies and/or measurements errors.

The independent variables are:

- the time from a given origin

- the reservoir water level

- the material temperature distribution

- the environmental variables

There are four different ways for computing the forecasting indicators:

- Deterministic approaches

These methods are based on mathematical models. The quality of the forecast depends mainly on the capability of the mathematical model to describe the physical reality, the quality of the numerical solution, the knowledge of the parameters describing the materials , the simplifications introduced in the model and the knowledge of the independent variables at the time of observation. They do not need previous measurements, and usually is used for a first reservoir impounding or for the first years of operating.

- Statistical approaches

A set of influence functions corresponding to expected variation of each indicator is chosen. Each component of each function is multiplied by a parameter or unknown coefficient, and these coefficients are defined with previous measurements. It is necessary the use of an a priori analytical form of the indicators (based on experience). The calibration process is performed through the minimization of a given norm. This technique can be applied to different phenomena.

- Hybrid methods

These methods combine the above introduced models. By one hand, the analytical form of the indicators is obtained through the deterministic approach, but each single term of the function is multiplied by an unknown coefficient. The calibration is carried out as in statistical approach.

- Neural Networks approaches

This methodology [11] is relatively new and is inspired by neural networks. The neural networks are composed of many simple intercommunicating units, or neurons, working in parallel to solve a given problem. It expands as the network learns to operate, based on a set of training data provided by users. Nowadays, several types of neural techniques exist, the most important one in the back analysis is the multi-layer feed-forward and back-propagation algorithm. These methods have lot of potential.

2.2.3 Monitoring systems

The surveillance of a dam is mainly performed by visual inspections carried out by qualified personal and by processing data obtained from monitoring devices.

Most of dangerous events as sinkholes, settlements, cracks, concentrated seepages, generally can not be detected by monitoring devices and must be detected through visual inspections. When an abnormal behaviour is detected, its evolution can be surveyed and analysed on the basis of the data collected by a monitoring system suitable installed. The parameters provided by the monitoring devices can be grouped in two categories: environmental actions and the physical-mechanical quantities describing the response of the dam-foundation-reservoir.

- Environmental actions

Inside this group it is possible to find the following quantities: reservoir water level, air temperature, water temperatures at different depths in the reservoir, solar radiation, seismic actions, rainfall...

- Response of the dam-foundation-reservoir

In this group it is necessary to distinguish between different typology of dams:

- Concrete dams: absolute displacements of the dam foundation, relative displacements between blocks, temperature evolution in the dam body, strains...

- Embankment dams: displacements and especially settlement of the dam-foundation system during dam construction and operation, leakages, seepages, pore pressures in the waterproof core...

It is important to remind that the monitoring devices tends to modify and disrupt their local value, especially in quantities like strains and stresses.

Thanks to the important growth of electromechanical devices and advances in topic of the transmission data, this information each time is more relevant and easy to access.

2.2.4 Numerical methods for structural identification

The basic idea of any structural identification method is to make a numerical model behaviour as close as possible to the observed one.

The structural identification methods can be based on static and dynamic monitoring data.

- Static data

These methods are basically those already shown in previous section 2.2.2: the calibration step usually performed to set up forecasting models may be seen as identification process which allows evaluating the best estimate of the physical/mechanical parameters of the dam-foundation system.

- Dynamic data

Dynamic methods have taken more importance in last decades. These methods are based on dynamic excitation. The aim of the dynamic structural identification consist in the evaluation of the dynamic features (e.g. natural frequencies, modal shapes) according to excitation (input) and response (output) of the system. This process is performed through dynamic campaigns. The structural response can be measured in terms of acceleration, velocity or displacement vs. time. Depending on the available devices, the measurement is carried out in one term or other. According to the measured parameter a different range of frequencies must be used (e.g. velocity measurements requires low frequencies).

The excitation of the structure can be obtained in a different ways depending on the available resources, the importance of the structure...

- The most expensive and reliable solution is to apply one exciter on the structure (e.g. hydraulic piston). The exciters are controlled in terms of frequencies and amplitudes. This approach is strongly recommended in dams (massive structure).

- Environmental vibrations is a cheap method but the problem resides in that the signal could be corrupted, moreover long acquisition times must be planned in order to remove noise.

- Others methods as "pull release" test or the impact test can be applied as alternatives.

The selection of a proper method is very important so that no damage are induced on the structure during the test. To this aim is highly recommended a previous evaluation to predict the amplitudes on the model.

The selection of an adequate mathematical algorithm for identification is very important, and the following aspects must be taken into account:

- The more physical characteristics are included into mathematical models the more accurate is the identification process.

- At the end of the identification, the mathematical model must be able to properly capture the true physical aspects of the system.

Frequency and/or modal shapes may be used directly for matching and error minimization, as already was mentioned before for time domain identification.

The extension of a dynamic analysis to a non-linear field must be done carefully and considering the following differences:

- The natural frequencies and modal shapes of a non-linear systems are dependent on the amplitude of response.

- The dependence of the natural frequencies and modal shapes can be used to refine identification estimates and to help localizing non-linear effects and corresponding damages.

- Some non-linear systems may be "uncoupled" in order to make easier identification and analysis.

Summing up, structural identification not only provides a powerful diagnostic tool but also a refined system to support a deep understanding of the dam behaviour.

3 Methodology

In this chapter the used methodology is presented. Due to the nature problem the structure of the chapter is divided in three sections: mechanical, thermal and thermo-mechanical problem.

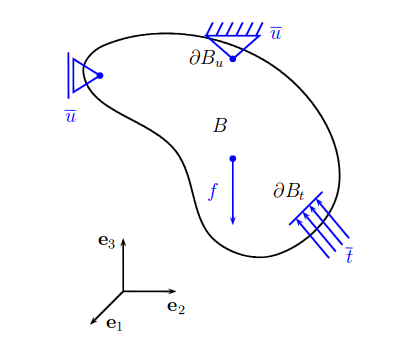

The first section deals to the mechanical problem focusing in Linear Elasticity Theory, a branch of General Elasticity Theory. In this section the governing equations of the mechanical problem as well as the weak formulation and the numerical integration techniques are presented. In second section the thermal problem is stated. Same structure than in previous section is followed. Finally, the thermo-mechanical problem with a weak coupling is introduced.

Many of the concepts discussed below are dealt extensively in the book of Prof. Eugenio Oñate, Structural Analysis with the Finite Element Method. Linear Statics [12] [13],as well as in the book of Prof. Xavier Oliver and Prof. Carlos Agelet de Saracibar, Mecánica de medios continuos para ingenieros [14].

3.1 Mechanical Problem

Usually, a mechanical problem can be defined in the following way; given an initial geometry and a loading field, analyse the response according to a stiffness and strength. For solving the problem is necessary to state the basic equations.

- Equilibrium equations

- Constitutive equations

- Compatibility equations

Depending on the constitutive equation the solid behaviour is different. The following models describe how a solid responds to an applied force:

- Elastic: when a solid starts to suffer strains, it increases the elastic potential energy which means that its internal energy increases avoiding irreversible transformations. The main feature is a reversible process; if the acting forces are removed the solid recuperates the initial shape.

- Plastic: materials that behave elastically when the applied stress is less than a yield value. When the stress is greater than the yield stress the material behaves plastically and does not return to its previous state. That is, deformation that occurs after yielding is permanent.

- Viscous: this type of behaviour happens when the strain velocity acts in the constitutive equation. The behaviour can also be elastic or plastic.

This study is focused in Linear elasticity since the approximation that it provides is good enough for the purpose. Most of engineering problems can be solved using this type of hypothesis.

Linear elasticity is the mathematical study of how solid objects deform and become internally stressed due to prescribed loading conditions. Linear elasticity is a simplification of the more general non-linear theory of elasticity and is a branch of continuum mechanics.

The fundamental "linearizing" assumptions of linear elasticity are[14]:

- Infinitesimal strains: displacement and its gradient are small enough.

- Small displacements. There is no difference between material and spatial configuration.

- Small displacements gradient. There is no difference between the Green-Lagrange Strain tensor E(X,t) and the Almansi Strain tensor e(x,t) and are equal to infinitesimal strain tensor .

- Existence of neutral state: exists a state where strains and stresses have zero value, usually this state is assumed as the reference configuration.

- The deformation process is isothermal and adiabatic.

- Isothermal: process in where the temperature is constant along the time.

- Adiabatic: process that not generates heat in any point at any time.

3.1.1 Governing Equations

The solution for elastic problems can be stated through two different approaches depending on the unknown variable;

- Displacements

- Stresses

In this thesis, a displacement approach is used, but in the cases where the contour stresses are known, the use of Beltrami-Michell approach is reasonable. Nonetheless, there are mixed formulations that allow to solve the problem without the necessity of knowing all stresses [15].

In direct tensor form, the governing equations for a linear elastic problem are [14]:

- Cauchy Equation;

|

|

(2) |

- Constitutive equation;

|

|

(3) |

- Compatibility equations;

|

|

(4) |

The boundary conditions and the initial conditions are

|

|

(5) |

|

| Figure 4: Scheme of generic problem in linear elasticity. |

3.1.2 Analysis Type

Regarding the analysis type, there are three important groups:

- Static. This analysis is time independent. The forces are gradually applied and remain in place for longer duration of time.

- Quasi-static. This analysis is time dependent but it takes the assumptions that the loads are applied slow enough to neglect acceleration terms.

|

|

(6) |

- Dynamic. This analysis is time dependent without simplifications. Dynamic loads are very much time dependent, either for acting in a small interval of time or quickly change in magnitude or direction. Some examples of dynamics loads are: earthquakes, machinery vibrations...

Depending on the analysis type, the system to be solved is different. The most common analysis types are: quasi-static and dynamic.

Using a Finite Element Method and a quasi-static analysis, the system reads as

|

|

(7) |

where K is the stiffness matrix, u is the vector of displacements and f is the vector forces.

In case of dynamic analysis, the system becomes more complex and reads like

|

|

(8) |

where M is the mass matrix, C is the damping matrix and, and are acceleration and velocity vector, respectively.

In this thesis, due to the considered loads are not influenced by the time, the analysis type is quasi-static.

3.1.3 Finite Element Model

The Finite Element Method (FEM) is a numerical technique for finding approximate solutions to boundary value problems for partial differential equations. It uses subdivisions of a whole problem domain, and variational methods to solve the problem by minimizing an associated error function.

The main concept is connect many simple element equations over many small domains to approximate a more complex equation over a larger domain. Although continuum structures are always three-dimensional, if the proper simplification hypothesis are fitted, one can accurately describe the behaviour of a structure by means of uni or bi-dimensional mathematical models, like in earth dams, tunnels, etc.

Next, the generic stages for the analysis of a structure through the Finite Element Method are presented. Assuming a quasi-static analysis, the equilibrium equation in strong form can be stated as

|

|

(9) |

In solid mechanics, the six stress components can be computed through the six components of strain () which are computed from the displacements

|

|

(10) |

To obtain the weak form an arbitrary weight function vector 11 is introduced

|

|

(11) |

and the equation is integrated over whole domain

|

|

(12) |

after applying the divergence theorem is obtained

|

|

(13) |

introducing the concept of virtual strains that can be stated as the derivation of virtual displacements

|

|

(14) |

which is the three-dimensional equivalent virtual work statement.

The virtual displacements and the virtual strains are interpolated in terms of the virtual displacement values in the standard form

|

|

(15) |

Substituting and simplifying the virtual displacements

|

|

(16) |

where B and N are the strain matrix and the shape function matrix, respectively. Using the stresses expression

|

|

(17) |

finally the following equation is obtained

|

|

that can also be expressed as

|

|

(18) |

where

|

|

(19) |

is the elastic stiffness matrix of the element, and

|

|

(20) |

the nodal vector force. The nodal vector is composed by the body forces and tractions forces, but may also be other contributions. These concepts and the way to compute the stiffness and the vector force are detailed in Appendix A.

To finish, the global system is constructed

|

|

(21) |

and solved for the unknown variable, the nodal displacement vector. Once it is obtained, it is quite straightforward to calculate the strains and stresses at each element as well as the reactions at the nodes with prescribed displacements.

3.1.4 Integration Schemes

Integration schemes are methods to integrate differential equations. There are two groups of integration schemes; explicit and implicit.

The explicit schemes use the previous step solution () to compute the current step solution (), these types of schemes are conditionally stable and require that the time step size be less or equal than a critical time step. The critical time step depends on element size and maximum wave speed for element material. In some cases, this value has to be too small and requires high number of steps to reach the reality, driving to high computational effort.

The implicit schemes use previous step solution () and current step solution () to compute the current solution. Generally, an implicit solution is unconditionally stable [16], and the used time step can be one or two orders of magnitude larger than in an explicit schemes. However, the accuracy of the implicit schemes deteriorates as the time step increases relative to the period of response of the system.

In this work two well known numerical integration schemes are presented: Newmark method and Bossak method, which is an extension of Newmark method.

Newmark- Method This method is widely used in numerical evaluation of the dynamic response of structures and solids [17]. Originally, this method is from 1959 but some improvements have been developed. In matrix form the linear dynamic equilibrium equations can be written as

|

|

(22) |

Using truncated Taylor's series as two additional equations expressed in the following form

|

|

(23) |

and assuming linear acceleration within the time step

|

|

(24) |

it is just necessary to substitute Eq.24 into Eq.23 to produce Newmark’s equations in standard form

|

|

(25) |

It is known that values of =0.5 and =0.25 make an unconditionally stable method. The use of values of higher than 0.5 introduces errors associated to numerical damping.

Bossak Method

The Bossak method is the extension of the Newmark method. The acceleration is taken prior to . The method can successfully replace the Newmark method in all cases, and can be stated as

|

|

(26) |

The use of =0 leads to Newmark method. The Bossak method is characterized by a good damping in high frequencies range.

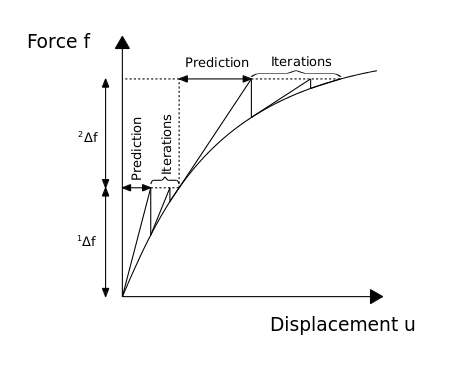

3.1.5 Solution Strategies

The used strategy is typically from non-linear problems, but also can be applied to linear ones. One of the main features of linear elasticity is the uniqueness of solution, however in non-linear problems there is a lack of uniqueness of the solution. In fact, in many cases the correct solution is path dependent, so it depends on the path followed.

In matrix form a non-linear problem (given a prescribed boundary conditions and having applied the particular time discretization) can be stated as

|

|

(27) |

where u represents the vector of unknowns, K the 'stiffness matrix', and f the force vector, both K and f depend on the solution u. Because of u is unknown, this system is solved by some iterative algorithm, for instance the Newton-Raphson method.

|

| Figure 5: Example of an incremental-iterative method. |

Figure 5 shows an incremental iterative method. In incremental iterative methods there is a part of prediction and a part of iteration. The iterations continue until reach some prescribed tolerance. There are different types of convergence criteria depending the case.

Before each solution, the Newton-Raphson method evaluates the out-of-balance load vector, which is the difference between the restoring forces (the loads corresponding to the element stresses) and the applied loads. Then, a linear solution is performed using the out-of-balance loads, and it is checked for a prescribed convergence criterion. If the convergence criterion is not satisfied, the out-of-balance load vector is re-evaluated, the stiffness matrix is updated, and a new solution is obtained. This iterative procedure continues until the problem converges.

The Picard's method is also a famous iterative method for solving non-linear problems, it is computationally cheap but the convergence is very slowly, on the other hand, Newton-Raphson requires higher computational cost but the rate of convergence is higher.

3.2 Thermal Problem

The thermal problem is governed by classical heat equation. In dam engineering, the thermal problem takes on special importance due to the temperature variation in different seasons. The temperature field inside of the dam can be predicted solving the diffusion problem. Once the temperature field inside of the dam is obtained, its gradient can be computed.

The energy equation for a solid in a vector form can be stated as [18]

|

|

(28) |

where is the density, is the specific heat, is the thermal conductivity and is the rate of heat generation.

Neglecting the heat generation term (since the system does not generate its own heat per unit volume), and arranging terms, the equation reads as

|

|

(29) |

the above equation is known as heat equation. The thermal diffusivity () is obtained dividing the thermal conductivity between the density and the specific heat. Finally, the equation reads as

|

|

(30) |

Once the governing equation is obtained, the boundary conditions and the initial conditions are introduced. Boundary conditions are given by

|

|

(31) |

where is an applied flux, is the convective flux and is the radiative flux, which are dependent on the convective heat transfer coefficient and the effective radiation heat transfer coefficient, respectively

|

|

(32) |

The initial condition on the temperature is given by

|

|

(33) |

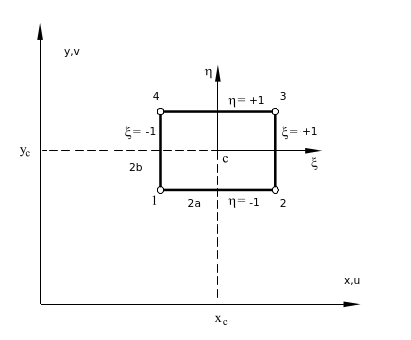

3.2.1 Finite Element Model

The governing equation of the thermal problem in a strong form has been presented, now, the way to obtain the weak formulation of this equation is introduced. Due to it is a linear problem, the material coefficients does not depend on temperature. These assumptions can be taken into account since the variation of the temperature is supposed not too much high. In other type of problems in which the variation of the temperature is high, the problem must be considered temperature dependent.

Using Eq.28, neglecting the heat generation term, multiplying by a test function , and integrating over the element, the following expression is obtained

|

|

(34) |

after, the divergence theorem is applied

|

|

(35) |

Applying Fourier's law, the rate of flow of heat energy per unit area through a surface is proportional to the negative temperature gradient across the surface , the following expression is obtained

|

|

(36) |

Now, assuming that the time dependence can be separated from the spatial variation, the finite element approximation can be stated as

|

|

(37) |

where is the vector of shape functions and is a vector of nodal temperatures. Finally, making the substitution of according with weak-form Galerkin, the following expression is obtained

|

|

(38) |

in matrix form reads as

|

|

(39) |

where C is the specific heat matrix, K is the conductivity matrix, Q is the vector of heat fluxes, is the vector of nodal temperatures and is the time rate of the nodal temperatures.

3.2.2 Integration Schemes

The ordinary differential Eq.39 should be integrated with respect to time to obtain a transient response. In general, it is not possible to integrate these equations analytically, so they are approximated in time to obtain a set of algebraic equations in terms of the nodal temperature.

The most popular used method for diffusion problems is called -family and it consists of the following approximation

|

|

(40) |

|

|

(41) |

and rearranging terms the equation can be expressed as

|

|

(42) |

The choice of produces the forward euler scheme, an explicit method which is conditionally stable

|

|

(43) |

and may be rearranged to clearly show its explicit nature

|

|

(44) |

Eq.44 requires that matrix C be easily invertible for an effective implementation. The reduction of the matrix to a diagonal or "lumped" form can be accomplished by various procedures, for instance row-sum [19,29]. Forward-Euler method is conditionally stable and the stability condition is governed by the thermal diffusivity of the material, and the finite element space [20]. Euler method is first-order accuracy in time. The main attraction of an explicit scheme is the fact that a matrix solution is not required and computer storage requirements are minimal.

When , a family of implicit methods are produced. Depending on the used value there are different schemes:

- Crank-Nicolson Scheme. Unconditionally stable and second-order accuracy.

- Galerkin Scheme. Unconditionally stable and first-order accuracy.

- Backward Euler Scheme. Unconditionally stable and first-order accuracy.

Inside the code is an input parameter which leads to one scheme or other. Computations have been performed using , backward Euler scheme, and reads like

|

|

(45) |

Next, the solution strategies for this type of problems are introduced.

3.2.3 Solution Strategies

The discretization in time and space has already presented, now, some strategies to solve the problem are presented. The linear problems do not require iterative solution. These problems just require a matrix solution.

Nonetheless, the non-linear problem using a backward Euler is presented, and the system reads like

|

|

(46) |

In case of dealing with non-linear equations (Eq.46), the use of predictor-corrector, extrapolation methods, and quasi-linearization can often reduce the computational effort at each step without reducing the accuracy of the method.

A quasi-linearization is good choice for mild non-linearities and modest time steps. The system reads like

|

|

(47) |

which is now a single-step (a non iterative method). Another choice is the use of an extrapolation procedure. Usually, it gives better solution than quasi-linearization and allows a larger time step. The extrapolation procedure takes the following form

|

|

(48) |

where

|

|

(49) |

In case of strong non-linearities, these techniques do not offer accurate results. In these cases, the coupling of a forward Euler predictor with a corrector is a viable option [21][22].

3.3 Thermo-Mechanical Problem

Two different problems need to be solved: a mechanical problem and a thermal problem. There are different approaches to do so, but the most common are probably two: the fully coupling and the one-way coupling.

The fully coupling is usually reserved to solve problems in which both the mechanical and thermal components can affect each other in a similar way. In order to deal with this kind of problems one needs to solve the two components at the same time, taking into account the interaction between them. Among others, this approach is used in the solution of metal forming deposition and additive manufacturing. In this sort of situations, the material properties change dramatically in time and so it is crucial that both components are fully coupled so as to properly capture the real behaviour of the medium. In the case of additive manufacturing, for instance, the higher temperatures reached during the process of binder generate a totally different material behaviour as compared to that encountered in the cooling process.

On the other hand, the one-way coupling technique is devoted for those problems in which the interaction between both parts exists, but it is not symmetric. In essence, one of the components has a strong influence on the other, but the contrary does not occur. This is the case of dams, where the mechanical problem is really affected by the temperature changes, but the thermal problem is almost insensible to the deformation of the geometry.

Next, the main features of the latter coupling are introduced.

3.3.1 One-way coupling

First, the diffusion problem is solved, once it is solved, instead to consider an elastic problem, a thermoelastic problem taking into account the influence of the temperatures through the constitutive law is considered.

The main difference between linear thermoelasticity and linear elasticity is that the process is not considered isothermal any more. The temperature value changes along the time , it means

|

|

(50) |

Nonetheless, the hypothesis of adiabatic process is still considered.

3.3.1.1 Linear thermoelastic constitutive law

The thermal contribution are added to the stresses as

|

|

(51) |

where is the constitutive matrix, is the thermal properties matrix and is the reference temperature field. Usually, the difference between temperatures is written as .

3.3.1.2 Linear thermoelastic inverse constitutive law

Eq.51 can be inverted to obtain the relation of the strains and it reads as

|

|

(52) |

The definition of thermal expansion coefficient is

|

|

(53) |

In case of isotropic material, the thermal expansion coefficient becomes a scalar.

3.3.1.3 Thermal stresses and strains

Taking the assumption of working with an isotropic material (case study), the relations between thermal and non-thermal for stresses and strains are presented

- Stresses

|

|

(54) |

- Strains

|

|

(55) |

4 KRATOS and Dam Application

KRATOS is designed as an Open-Source framework for the implementation of numerical methods for the solution of engineering problems. It is written in C++ and is designed to allow collaborative development by large teams of researchers focusing on modularity as well as on performance [23] [24].

The KRATOS features a "core" and "applications" approach where "standard tools" (such as linear algebra or search structures) come as a part of the core. They are available as building blocks in the development of "applications" which focus on the solution of the problems of interest. Its ultimate goal is to simplify the development of new numerical methods.

|

| Figure 6: KRATOS' Logo. |

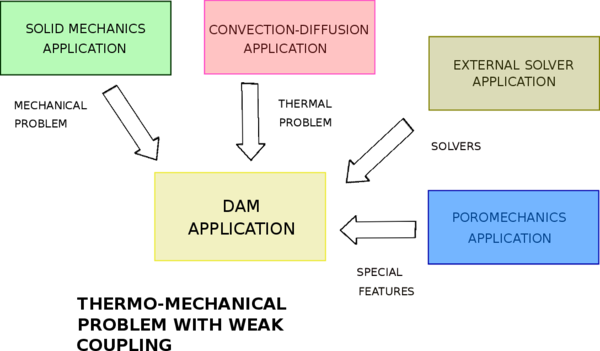

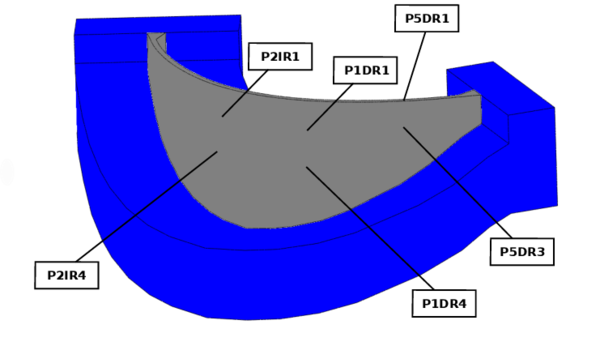

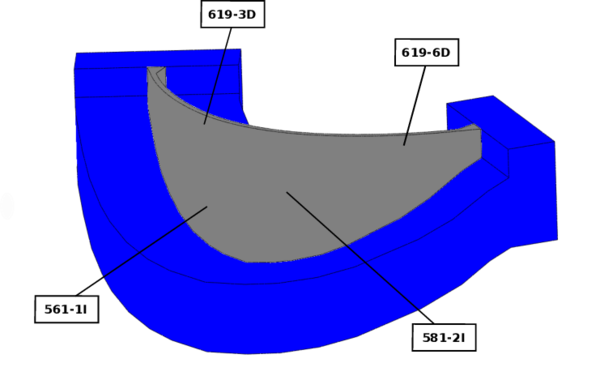

A new application called Dam Application () has been created due to an specific necessity. This Application is focused in dam engineering. Its main features as; how the application works or what are the dependencies are described below.

has dependencies of Solid Mechanics Application, Convection-Diffusion Application and in less measure of Poromechanics Application. Figure 7 shows the basic flowchart of the application.

Convection-diffusion Application, as its own name shows is an application for solving convection-diffusion problems, it is in charge of Dr. Pablo Becker. Solid Mechanics Application is devoted to solve all type of problems related solid mechanics, it is in charge of Dr. Josep Maria Carbonell. Poromechanics Application solves pore-pressure problems and the responsible is Ing. Ignasi de Pouplana. I would like to thank all of them for allowing me to use their code.

|

| Figure 7: Dam Application's dependencies. |

Apart from computational features, a basic but powerful interface where boundary conditions, materials and elements are taken into account has been created. This interface works in GiD, which is a universal, adaptive and user-friendly pre and post processor for numerical simulations in science and engineering [25].

Figure 8 shows the flowchart for solving a generic problem.

|

| Figure 8: Flowchart for solving a generic problem. |

4.1 Dam Application

borns with the aim of solving a real necessity in world of dam engineering. It provides user-friendly interface and specific conditions for dam problems. Internally, it solves a thermo-mechanical problem using a weak coupling.

For solving the thermal problem, the Convection-diffusion Application is used. Since the convective part is not considered in the problem, all its contributions are set to zero, leading to a diffusive problem. After solving the thermal problem for a given time, the mechanical problem taking into account the influence of thermal contribution through the constitutive law must be solved.

Following lines are devoted to present . The structure is the following; first, the interface is introduced, then the specific boundary conditions of dams are commented, and finally the main files are presented.

4.1.1 Interface

The interface is a powerful tool to define all required information for solving the problem. The development of a correct interface leads to a better understanding and use of the software. A simple but powerful interface has been developed.

The interface is based on the classical problemtype of GiD (Figure 9)

|

| Figure 9: GiD interface |

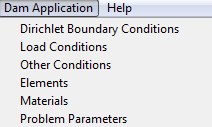

Figure 10 shows the divisions of the main menu. Concretely, the menu is divided in six points:

|

| Figure 10: Dam Application menu interface. |

- Dirichlet Boundary Conditions, inside of this menu, prescribed displacements and temperatures for different type of entities can be assigned.

- Load Conditions, in this section, it is possible to assign all load conditions to different entities, among others: hydrostatic pressure, normal forces, uplift pressure...

- Other Conditions, inside of this tab it is possible to assign mechanical and thermal properties for solving the thermal problem. The body accelerations can also be assigned in this tab.

- Elements, this section is devoted to assign the type of elements.

- Materials, inside of this menu the materials can be assigned. There are default materials, but it is possible the creation of new materials.

- Problem Parameters, inside of this section the general parameters of the problem can be set. There are some tabs inside of this menu which are the following ones:

- General Data

- Imposed Conditions

- Table Evolution Data

- Mechanical Solver

- Postprocess

4.1.1.1 Dirichlet Boundary Conditions

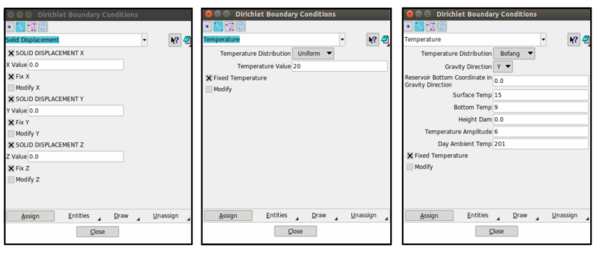

The displacements and temperatures field can be assigned in this menu. The appearance of menu is shown in Figure 11.

|

| Figure 11: Interface menu for applying displacements and temperatures. |

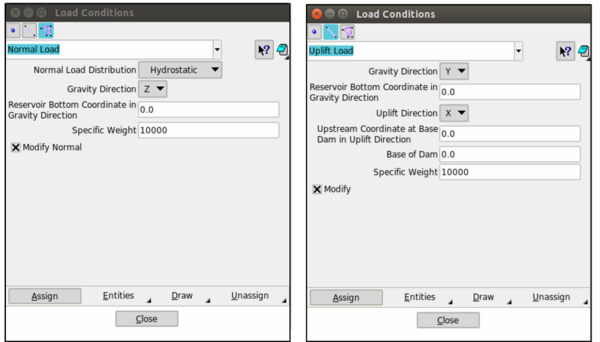

4.1.1.2 Load Conditions

This section is devoted to the application of forces (Figure 12). Several types of forces have been implemented. The user must be aware that there are some limitations, for instance in a 3D view it is not possible to apply a line normal load since the normal direction can not be computed. Below, the different possibilities of loads that can be applied are introduced.

- Point: point load.

- Line: line load, normal load (uniform and hydrostatic) and uplift load.

- Surface: surface load, normal load (uniform and hydrostatic) and uplift load.

|

| Figure 12: Interface menu for applying load conditions. |

4.1.1.3 Other Conditions

In this section mechanical and thermal conditions related to the materials can be applied. These conditions are needed due to the Convection-diffusion Application works with nodal variables. Gravitational or acceleration effects can also be assigned in this menu.

4.1.1.4 Elements

This section is dedicated to assign the discrete elements. For instance, in a 2D case it is possible to use linear triangles and quadrilaterals, and also high order elements. In 3D analysis, the possibilities are linear tetrahedrons and hexahedrons as well as high order elements.

It is worth to remark that the thermo-mechanical problem only can be solved by triangles or tetrahedrons since the thermal problem is only implemented for this type of elements. Facing a mechanical problem the user can use any type of element.

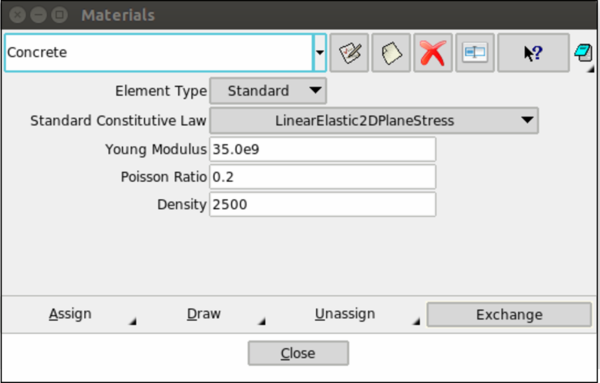

4.1.1.5 Materials

Material assignation is performed in this section. Figure 13 shows the different possibilities for this assignation. Some default materials are ready to use, although if is convenient, the user has the possibility to create new materials. Through the definition of the constitutive law the type of problem (mechanical, thermal or thermo-mechanical problem) is specified.

|

| Figure 13: Interface menu for applying materials. |

4.1.1.6 Problem Parameters

To finish this section, the different tabs inside of the Problem Parameters menu are presented.

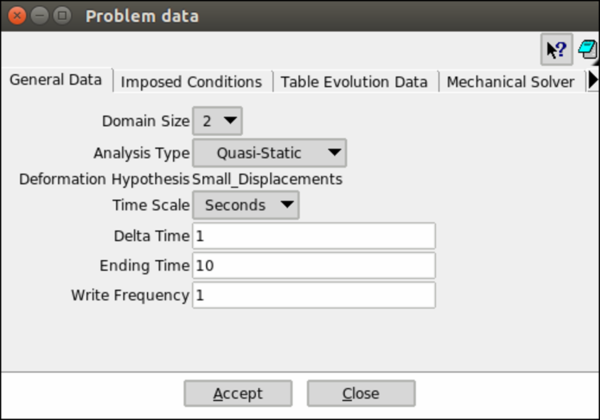

- General Data

In this menu (Figure 14), the domain size of the problem, the analysis type (quasi-static or dynamic), the time scale and the temporal values are defined.

|

| Figure 14: Interface menu: General Data. |

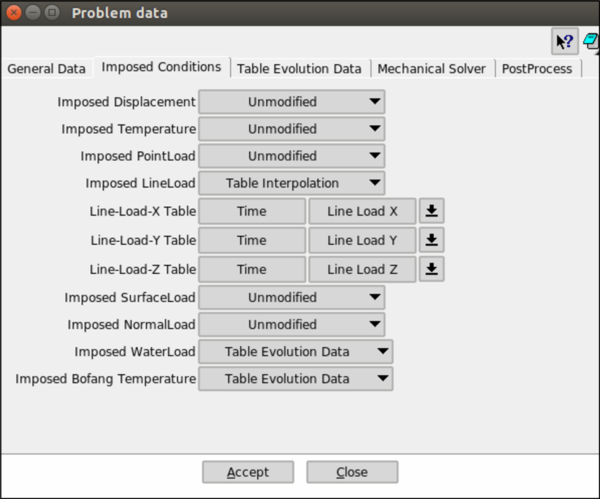

- Imposed Conditions

This menu (Figure 15) is the responsible to keep the conditions constant (Unmodified) along time or update them at some point (Table Interpolation).

|

| Figure 15: Interface menu: Imposed Conditions. |

There are some special conditions as water load and Bofang temperature that are governed by other table Table Evolution Data, this table is explained in the following section.

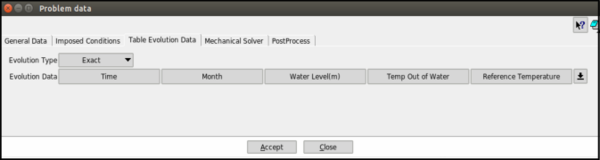

- Table Evolution Data

For computing more than one case, it is possible to use this table (Figure 16). The needed values are the following ones: the month in which the computations are carried out (Bofang formulation), the evolution of the water level along the time, the temperature in the not wet wall upstream and the reference temperature.

|

| Figure 16: Interface menu: Table Evolution Data. |

- Mechanical Solver

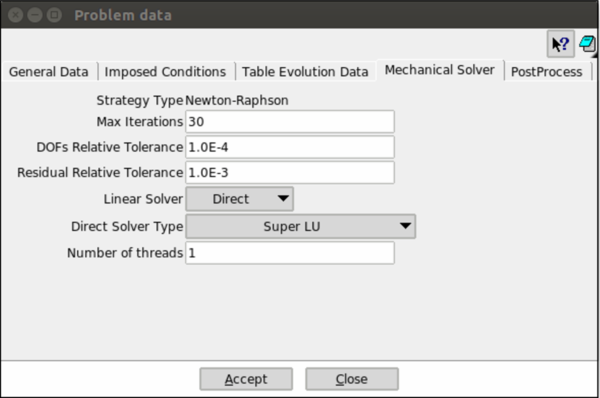

In this menu (Figure 17), some parameters about the mechanical solver can be set: number of maximum iterations until the convergence is reached, the tolerance of the DOF's and for the residual, the linear solver (direct or iterative) and its type, and finally the number of threads.

|

| Figure 17: Interface menu: Mechanical Solver. |

- Postprocess

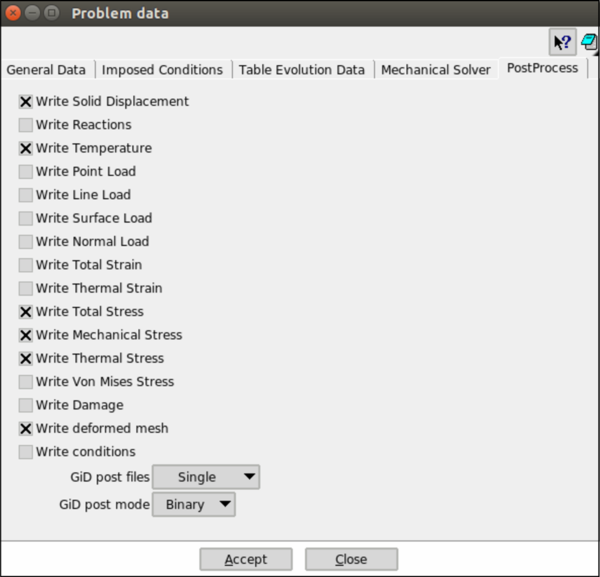

This menu (Figure 18) is devoted for selecting the output parameters. According to interest outputs one or another are selected.

|

| Figure 18: Interface menu: Postprocess. |

4.1.2 Boundary Conditions

One of the most remarkable features of the is the possibility to apply the following conditions:

- Bofang Temperature

- Hydrostatic Pressure

- Uplift Pressure

These conditions are wide used in dam engineering. In this subsection, how these conditions have been implemented and its relevance are commented.

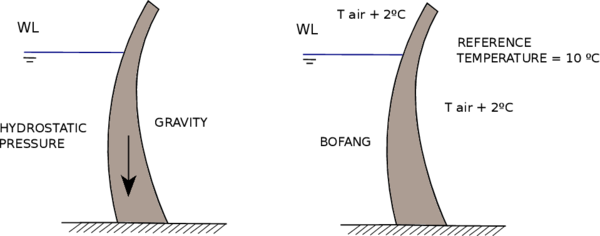

4.1.2.1 Bofang Temperature

In the upstream wet wall, it is possible to approximate its temperature to the temperature inside of the reservoir.

Up to some years ago, in many research articles, Stucky formulation [26] was used to provide a temperature field, but this temperature field is not too much realistic. Other approaches combine computational fluid dynamics and heat transfer models [27], however, these approaches are complex and computationally expensive.

Analytical models are other alternative to high computation approaches. These approximations are straightforward and its formulation is quite simple. Inside this analytical models, the Bofang formulation has taken important relevance [2]. The Bofang formulation provides a temperature field inside of the reservoir according to an atmospherics input parameters. It is worth to remark that depth of the dam must be higher than 30m, otherwise, the results can be inappropriate.

The proposal of Bofang formulation Bofang is depending on time and depth

|

|

(56) |

where

-

- = time (months)

- ) = water temperature at depth y and time

- = yearly mean temperature at depth y (C)

- = amplitude of annual variation of water temperature at y-depth

- day of maximum temperature (converted to months)

- = phase difference of annual variation of water temperature and air temperature

- circular frequency of temperature variation

- = period of temperature variation (12 months)

Once the general form of Bofang formulation Eq.56 has been presented, the contribution of each part is introduced.

- The yearly mean water temperature

The yearly mean water temperature () varies with the and may be expressed by

|

|

(57) |

where

- = yearly mean water temperature at the surface of reservoir

- = yearly mean water temperature at the bottom of reservoir

- = depth of reservoir (m)

The way to obtain these parameters is explained in following lines.

In the case of the surface temperature (), it has to be computed in the following way. In regions where the surface of the reservoir does not freeze in winter, the yearly mean water temperature at the surface is computed by the yearly mean air temperature plus an increment due to solar radiation. In cold regions, the yearly mean air temperature must be modified. The modification consist on set a 0C the temperatures lower than 0C. According with observed data .

|

|

(58) |

In the case of the bottom temperature (), these temperatures are computed as the mean of the mean value of the air temperature in the three months in the winter.

|

|

(59) |

- Amplitude of Annual Variation of Water Temperature

The amplitude of annual variation of water temperature () is the highest at the surface of reservoir and decreases with the depth of water. It may be expressed as

|

|

(60) |

where is the amplitude of variation at the surface of reservoir. Normally, this amplitude can be computed as the mean of maximum () and minimum () monthly mean air temperature. Usually, in the Northern Hemisphere, these values belongs to the mean air temperature of July and January, respectively.

|

|

(61) |

In cold regions is computed as

|

|

(62) |

where is the increment of amplitude due to solar radiation.

- Phase Difference of Variation of Water Temperature

The phase difference of annual variation of water temperature depends on the depth of water. In case of working in months, it is suggested to compute as

|

|

(63) |

- Applying Bofang Formulation

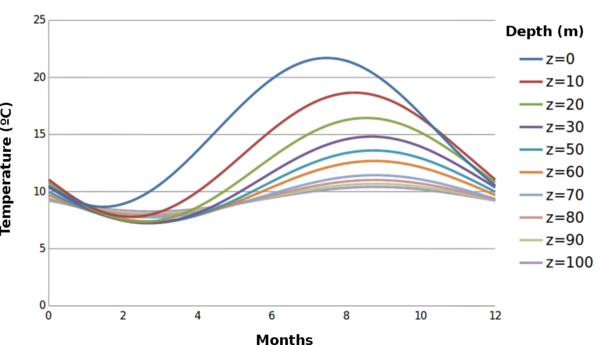

To understand in a better way how this formulation works, an application example is shown. Figure 19 shows the temperature variation according the period of the year and the depth. The input parameters are described below

|

|

|

| Figure 19: Application of Bofang Formulation. |

The temperature at the surface and just below it suffers high variations depending on the period of the year while in deeper levels remains much more constants without barely variations.

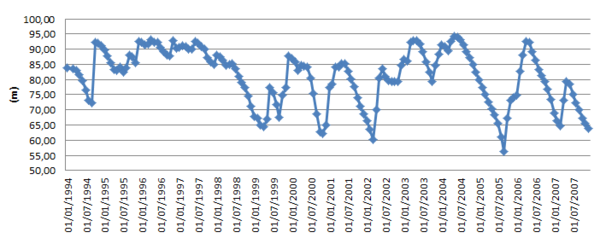

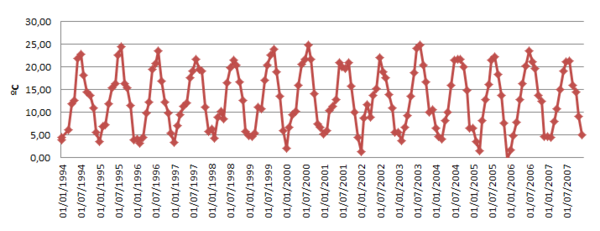

The application of this formulation in a real case is presented hereafter. The case study is La Baells dam and the input parameters are

|

|

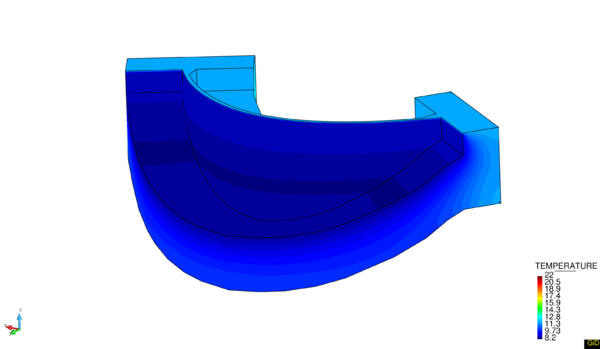

Figure 20 shows the temperature field in two different seasons when the reservoir is full (). In January (Figure 20a) the variation barely reaches 3C while in July (Figure 20b) it is possible to observe that the variation between the surface and the bottom is amount 12C.

|

|

| (a) January | (b) July |

| Figure 20: Application of Bofang Formulation at La Baells dam. | |

This condition has been implemented in two different program languages: and . The first language is used to write the input file (), the second one for updating conditions at each time step. There are two different ways to update the conditions: interpolate evolution (given two times, the evolution is computed according an interpolation law) or exact evolution (the condition only changes when the current time arrives to a determined time). The implementation of the developed code in C++ is stated in Appendix C.

4.1.2.2 Hydrostatic Pressure

A fluid in a resting state generates forces on the walls and bottom parts of the container and also on the surfaces of any object submerged. These generated forces are perpendicular to container's walls or any submerged object's surface regardless of the face's direction.

This pressure depends on the density of fluid and the reference height of the measurement. The absolute pressure can be computed as

|

|

(64) |

where

- = hydrostatic pressure ( or )

- = density ()

- = gravity acceleration ()

- = is the height of the fluid ()

- = Atmospheric pressure ( or )

Many times it works with relative pressure, neglecting the atmospheric contribution. The application of this condition is performed by the application of nodal forces according to the water level and the coordinates of the nodes.

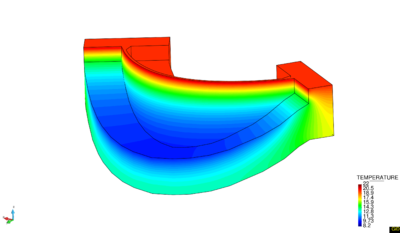

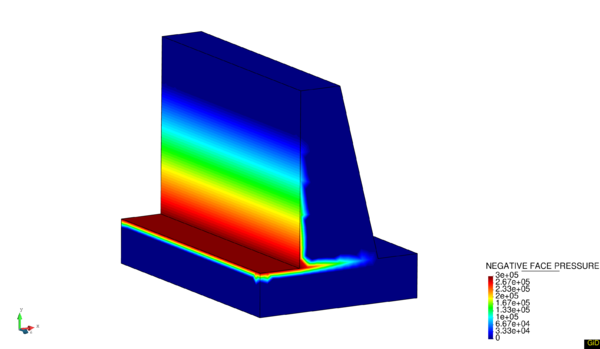

Below two application examples are shown. The scene of application is La Baells dam. Figure 21a shows the hydrostatic pressure (Pa) with 40m of water level, and outside of water the applied force is equal to 0. In the case of Figure 21b, the water level is equal to 93m, it means that the reservoir is full.

|

|

| (a) Water level = 40 m | (b) Water level = 93 m |

| Figure 21: Application of Hydrostatic Pressure at La Baells dam. | |

The same procedure for coding this boundary condition than in previous case has been followed. The developed code in can be found in Appendix C. As in previous case, there are two ways of updating the conditions; exact or interpolated. It is worth to remark that this file also updates the conditions for uplift pressure.

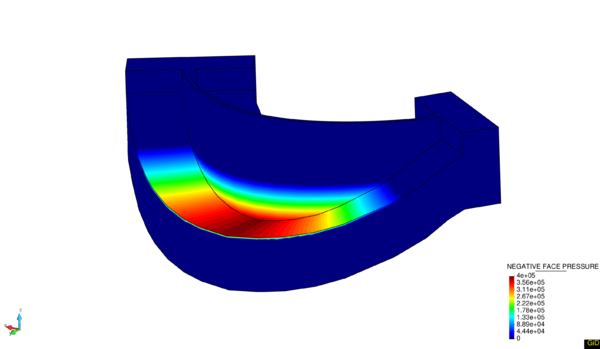

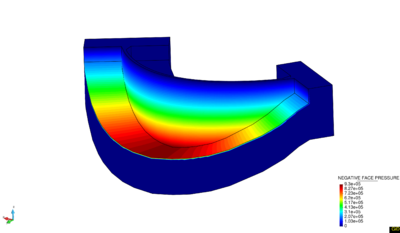

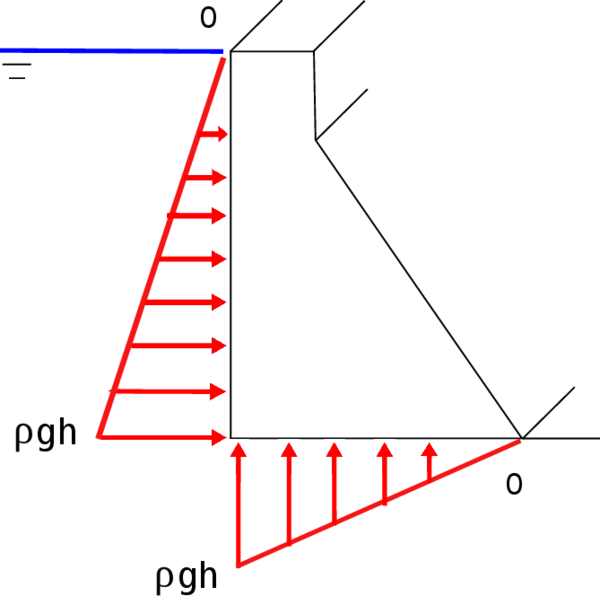

4.1.2.3 Uplift Pressure

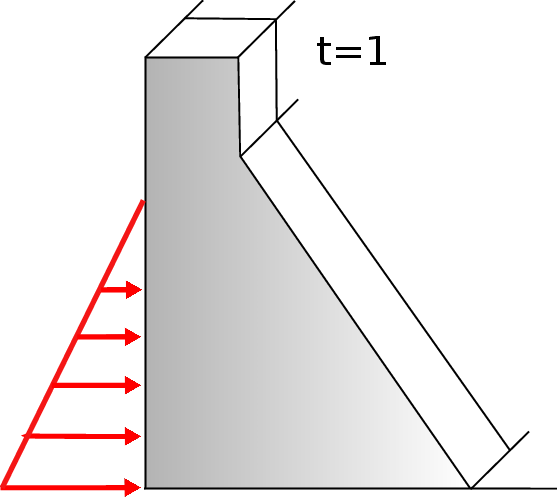

Uplift pressure is a phenomenon very relevant in gravity dams, in arch dams this phenomenon is less important. In gravity dams, the uplift pressure has special importance due to the length of the base is relevant.

Uplift pressure can be defined as the force that is generated due to the seepage in saturated soils at the foundations. These forces act in the base of the structures. Uplift pressure can play an important role in the stability of the structure because it represents a destabilized force.

There are several approaches to compute the uplift pressure. Usually, to know this force, using the flow it is possible to draw the pressure's diagrams, or it is also possible to compute the force using numerical techniques.

The following approach of the uplift pressure has been implemented. In the upstream part the same force than in the lower part of the reservoir is assigned, and this distribution is decreasing until it arrives to 0 at the end of the length of the base. Figure 22 shows this approximation.

|

| Figure 22: Scheme of uplift pressure approximation. |

The formulation to compute the law is

|

|

(65) |

The proposal formulation is related with the water level, it means that in the part that are in contact with the reservoir, the value of the uplift pressure is maximum and it decreases until arrive to 0. It is a must to provide the coordinates in the uplift direction of the upstream to perform the computations.

In arch dams this phenomenon does not take special relevance, and due to the arch geometry, it is a must the modification of the reference coordinate to apply the law properly making harder the application of this type of boundary condition for the user.

Figure 23 shows the application of hydrostatic and uplift pressure in a gravity dam. In the bottom of the upstream there is a matching in values between hydrostatic and uplift pressure.

|

| Figure 23: Hydrostatic and Uplift pressure in a gravity dam. |

As it has been already commented in previous section, the implemented code can be found in Appendix C.

4.1.3 Main Files

4.1.3.1 Model Part and Project Parameters

The or also known as is the file that contains all the information related to geometry and boundary conditions of our problem; the mesh (nodes and elements), the applied boundary conditions, the assigned materials, sub-meshes for updating conditions, and tables. On the other hand the file has information about General Data; domain size, , type of solver...

The file is written by file. This file is the responsible to translate all applied specifications during the pre-process in a script file. A small sample of the file is shown below.

Begin ModelPartData //VARIABLE_NAME value End ModelPartData Begin Table 1 TIME DISPLACEMENT_X 0.00000e+00 0.00000e+00 End Table Begin Properties 1 CONSTITUTIVE_LAW_NAME LinearElastic3D DENSITY 2.50000e+03 YOUNG_MODULUS 3.50000e+10 POISSON_RATIO 2.00000e-01 End Properties Begin Nodes 1 0.00000e+00 4.00000e+01 1.00000e+01 2 2.00000e+00 4.00000e+01 1.00000e+01 3 0.00000e+00 3.80000e+01 1.00000e+01 4 0.00000e+00 4.00000e+01 8.00000e+00 End Nodes Begin Elements SmallDisplacementThermoMechanicElement3D4N 1 1 12658 12754 12598 13227 2 1 16536 16594 16471 16462 3 1 15255 15426 15541 15161 4 1 12848 12341 12013 12122 End Elements

In the case of the file, the responsible of the generation of the input file is . A small part of the file is detailed below.

## General Data –––––––––––––––––– domain_size = *GenData(Domain_Size,INT) NumberofThreads = *GenData(Number_of_threads,INT) time_scale = "*GenData(Time_Scale)" evolution_type = "*GenData(Evolution_Type)" delta_time = *GenData(Delta_Time) ending_time = *GenData(Ending_Time)

These files are not included in Appendix C due to its extension. In case of interest, these files can be found in https://kratos.cimne.upc.es/projects/kratos/repository/show/kratos/applications/DamApplicationKRATOS repository.

4.1.3.2 Thermo_mechanic_script.py

Once the input data have been generated, these are read by the main script. This script () is composed by different stages for solving the problem. In the following lines the different stages are presented.

- Initializing time Import modules

The time is initialized and all necessary modules are imported, also the mechanical and thermal solver are defined.

- Previous definitions

The time parameters, scale of times and output variables are defined.

- Model Part

The file (that previously has been generated) is called, and the unknown variables are added to the solver, according the inputs. The is read and all information about mesh and conditions are extracted. The degrees of freedom are added to the solvers (thermal and mechanical) and the process info is finally set. The previous steps are filled with the boundary conditions, if necessary.

- Initialize

All functions that are involved in the solution of the problem are initialized.

- Temporal loop

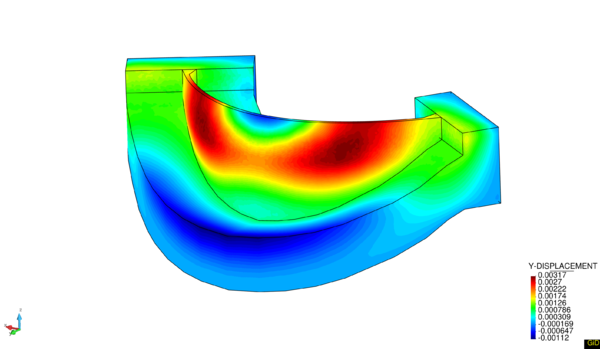

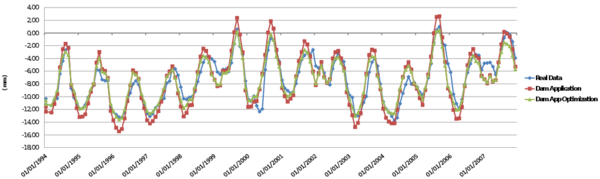

Once everything has been initialized, inside of the temporal loop the resolution of the problem starts. First of all, the time variables and boundary conditions are updated, after the thermal problem is solved, then the mechanical problem with the thermal contribution is solved, and finally the results according the selected parameters in file are written.