| (33 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

| − | |||

| − | + | ==Acknowledgements== | |

| − | + | ||

| − | =Acknowledgements= | + | |

I would like to thank to all the people that in one way or other have helped me to complete my PhD. | I would like to thank to all the people that in one way or other have helped me to complete my PhD. | ||

| − | First of all, I would like to express my gratitude to my supervisor Prof. Xavier Oliver for his | + | First of all, I would like to express my gratitude to my supervisor Prof. Xavier Oliver for his supportfi and availability from the beginning and for his inexhaustible energy devoted to achieving the results of this dissertation. Today, I can say that if I feel the profession of scientist as my own is undoubtedly because of him. |

I really appreciate the confidence and patience of my co-advisor Juan Carlos Cante. I would like to thank all the fruitful scientific and personal discussions. I admire his ability to understand. | I really appreciate the confidence and patience of my co-advisor Juan Carlos Cante. I would like to thank all the fruitful scientific and personal discussions. I admire his ability to understand. | ||

| Line 27: | Line 24: | ||

I would like to give an special thank to my father, for his small gestures that show an enormous love. To my mother and Luis and the way they raised me, stood by me, and opened me to the world. To my sisters, Claudia, Julia and Marta for being there on my side and for the emotional support you provided to me. | I would like to give an special thank to my father, for his small gestures that show an enormous love. To my mother and Luis and the way they raised me, stood by me, and opened me to the world. To my sisters, Claudia, Julia and Marta for being there on my side and for the emotional support you provided to me. | ||

| − | + | ||

=Abstract= | =Abstract= | ||

| Line 109: | Line 106: | ||

The work developed in this research gives rise to the following scientific publications: | The work developed in this research gives rise to the following scientific publications: | ||

| − | + | '''A Ferrer, J Oliver JC Cante, and JA Hernández'''. Two-scale topology optimization: an efficient integrated structural optimization and material design approach. Draft, 2016. | |

| − | + | '''SM Giusti, A Ferrer and J Oliver''. Topological sensitivity analysis in heterogeneous anisotropic elasticity problem. Theoretical and computational aspects. Computer Methods in Applied Mechanics and Engineering, 2016. [http://www.sciencedirect.com/science/article/pii/S0045782516303577 http://dx.doi.org/10.1016/j.cma.2016.08.004] | |

| − | + | '''A Ferrer, J Oliver JC Cante, and O Lloberas'''. Vademecum-based approach to multi-scale topological material design. Advanced Modeling and Simulation in Engineering Sciences, 2016. [http://link.springer.com/article/10.1186/s40323-016-0078-4 doi:10.1186/s40323-016-0078-4] | |

| − | + | Additionally, the work has been presented in the following conferences and workshops: | |

| − | + | '''JC Cante, A Ferrer, J Oliver'''. Numerical tools for Multi-scale material design and structural topology optimization. In ECCOMAS VII European Congress on Computational Methods in Applied Sciences and Engineering, Creta, 2016. | |

| − | Vademecum-based approach | + | '''A Ferrer, J Oliver, JC Cante'''. Multi-scale topological design: a Vademecum-based approach. In New Challenges in Computational Mechanics (A Conference Celebration the 70th Birthday of Pierre Ladevèze), Paris, 2016. |

| − | + | '''J Oliver, JC Cante, A Ferrer'''. Computational design of engineering materials: An integrated multi-scale approach to structural topological optimization. In XIII International Conference on Computational Plasticity. Fundamentals and Applications. COMPLAS 2015, Barcelona 2015. | |

| − | + | '''A Ferrer, JC Cante, J Oliver'''. An efficient tool for multi-scale material design and structural topology optimization. In XIII International Conference on Computational Plasticity. Fundamentals and Applications. COMPLAS 2015, Barcelona, 2015. | |

| − | + | '''A Ferrer, JC Cante, J Oliver'''. On Multi-scale structural topology optimization and material design. In CMN-2016: Congress on numerical methods in Engineering, Lisbon, 2015. | |

| − | + | '''A Ferrer, JC Cante, J Oliver'''. Towards real time analysis in multi-scale computational design of engineering materials. In CSMA-SEMNI Numerical techniques for computation speedup, Biarritz, 2015. | |

| − | + | '''A Ferrer, J Oliver, A Huespe, JA Hernandez, JC Cante'''. On macrostructure and microstructure optimization techniques in multiscale computational material design. In 11th World Congress on Computational Mechanics, Barcelona 2014. | |

| − | + | '''A Huespe, J Oliver, A Ferrer, A Huespe, JA Hernandez, JC Cante'''. Hierarchical multiscale optimization of microstructure arrangement and macroscopic topology in computational material design. In XII International Conference on Computational Plasticity. Fundamentals and Applications. COMPLAS 2013, Barcelona, 2013. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | Hierarchical multiscale optimization of microstructure arrangement and macroscopic topology in computational material design. In XII International Conference on Computational Plasticity. Fundamentals and Applications. COMPLAS 2013, Barcelona, 2013. | + | |

Finally, the work of this dissemination has been complemented by the developments achieved in the following research stay: | Finally, the work of this dissemination has been complemented by the developments achieved in the following research stay: | ||

| − | + | '''Université dAvignon''', 4-month doctoral research stay. Worked under the supervision of Prof. Samuel Amstutz in the Laboratoire de Mathématiques dAvignon, Avignon, France. May-September 2016. | |

| − | |||

=2 Background and review of the state of the art= | =2 Background and review of the state of the art= | ||

| Line 538: | Line 512: | ||

Next step is to describe how the microscopic boundary conditions may be fulfilled. There are different approaches to satisfy these boundary conditions of the RVE. In literature, see <span id='citeF-4'></span>[[#cite-4|[4]]], the most frequently used can be classified in ''Taylor, Linear, Periodic'' and ''Minimal'' condition. | Next step is to describe how the microscopic boundary conditions may be fulfilled. There are different approaches to satisfy these boundary conditions of the RVE. In literature, see <span id='citeF-4'></span>[[#cite-4|[4]]], the most frequently used can be classified in ''Taylor, Linear, Periodic'' and ''Minimal'' condition. | ||

| − | + | '''Taylor boundary conditions'''. Frequently, this model is commonly termed, in other contexts, rule of mixtures <span id='citeF-5'></span>[[#cite-5|[5]]]. Intuitively, it homogenizes the properties by its volumetric contribution. In our terms, it turns into imposing zero fluctuation over all the domain (including the boundary), that is | |

| − | + | ||

| − | Frequently, this model is commonly termed, in other contexts, rule of mixtures <span id='citeF-5'></span>[[#cite-5|[5]]]. Intuitively, it homogenizes the properties by its volumetric contribution. In our terms, it turns into imposing zero fluctuation over all the domain (including the boundary), that is | + | |

<span id="eq-2.25"></span> | <span id="eq-2.25"></span> | ||

| Line 566: | Line 538: | ||

|} | |} | ||

| − | + | '''Linear boundary conditions'''. In comparison to the fluctuation on the ''Taylor conditions'', the linear boundary conditions are imposed to be zero only on the boundary, i.e, | |

| − | + | ||

| − | In comparison to the fluctuation on the ''Taylor conditions'', the linear boundary conditions are imposed to be zero only on the boundary, i.e, | + | |

<span id="eq-2.27"></span> | <span id="eq-2.27"></span> | ||

| Line 609: | Line 579: | ||

Since less conditions are imposed, ''Linear boundary conditions'' are less stiffer than the ''Taylor boundary conditions.'' However, there is still room to impose softer ones. | Since less conditions are imposed, ''Linear boundary conditions'' are less stiffer than the ''Taylor boundary conditions.'' However, there is still room to impose softer ones. | ||

| − | + | '''Periodic boundary conditions'''. Alternatively, the periodic boundary conditions are the ones with better reputation in the multi-scale field. In the literature, there are numerical studies that suggest its use in periodic material <span id='citeF-6'></span>[[#cite-6|[6]]]. The main advantage lies on the fact that, the size of the micro-structure in which the material is statistically representative, is the smaller size in comparison to the rest of boundary conditions. Thus, the condition on the jump of scales is easier to satisfy. | |

| − | + | ||

| − | Alternatively, the periodic boundary conditions are the ones with better reputation in the multi-scale field. In the literature, there are numerical studies that suggest its use in periodic material <span id='citeF-6'></span>[[#cite-6|[6]]]. The main advantage lies on the fact that, the size of the micro-structure in which the material is statistically representative, is the smaller size in comparison to the rest of boundary conditions. Thus, the condition on the jump of scales is easier to satisfy. | + | |

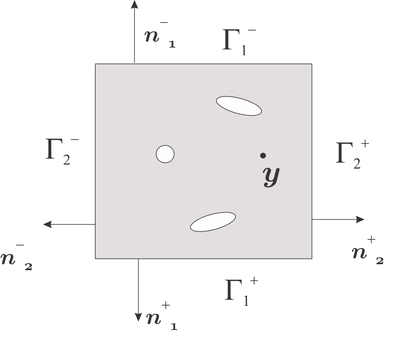

The periodic boundary conditions satisfy the fluctuation condition as follows. For some specific micro-scale geometries like square cells (hexagonal cells and others can be easily extended), the boundary is divided in <math display="inline">\Gamma _{1}^{+}</math>, <math display="inline">\Gamma _{1}^{-}</math>, <math display="inline">\Gamma _{2}^{+}</math> and <math display="inline">\Gamma _{2}^{-}</math> with outward unit normal such that | The periodic boundary conditions satisfy the fluctuation condition as follows. For some specific micro-scale geometries like square cells (hexagonal cells and others can be easily extended), the boundary is divided in <math display="inline">\Gamma _{1}^{+}</math>, <math display="inline">\Gamma _{1}^{-}</math>, <math display="inline">\Gamma _{2}^{+}</math> and <math display="inline">\Gamma _{2}^{-}</math> with outward unit normal such that | ||

| Line 668: | Line 636: | ||

More specifically, the fluctuation on the left part of the square cell <math display="inline">\Gamma _{2}^{+}</math> must be equal to the fluctuation on the right part <math display="inline">\Gamma _{2}^{-}</math> and, similarly, on the up and bottom part. Physically, this feature permits considering other micro-cell surrounding the RVE, and thus, the fluctuation will vary periodically along the micro-cell, hence its name. | More specifically, the fluctuation on the left part of the square cell <math display="inline">\Gamma _{2}^{+}</math> must be equal to the fluctuation on the right part <math display="inline">\Gamma _{2}^{-}</math> and, similarly, on the up and bottom part. Physically, this feature permits considering other micro-cell surrounding the RVE, and thus, the fluctuation will vary periodically along the micro-cell, hence its name. | ||

| − | + | '''Minimal boundary conditions'''. The minimum boundary conditions appear as the last alternative. They are considered the weaker boundary conditions since, in contrast to other boundary conditions, they assume no extra condition, hence its name. For this purpose, the fluctuation conditions ([[#eq-2.21|2.21]]) are imposed directly. | |

| − | + | ||

| − | The minimum boundary conditions appear as the last alternative. They are considered the weaker boundary conditions since, in contrast to other boundary conditions, they assume no extra condition, hence its name. For this purpose, the fluctuation conditions ([[#eq-2.21|2.21]]) are imposed directly. | + | |

Note that fluctuation condition ([[#eq-2.21|2.21]]) leads to impose that the integral over the boundary of the open product between the fluctuation and the outward unit normal is zero. That implies to impose six conditions in 3D problems and three conditions in 2D problems. | Note that fluctuation condition ([[#eq-2.21|2.21]]) leads to impose that the integral over the boundary of the open product between the fluctuation and the outward unit normal is zero. That implies to impose six conditions in 3D problems and three conditions in 2D problems. | ||

| − | + | '''Selected boundary condition and implementation strategy'''. The choice of the boundary condition is a priori arbitrary, and it would depend on the addressed problem. In our study, and throughout all this work, we select the periodic boundary conditions since they can ensure a representative volume with the smaller length scale <math display="inline">l_{\mu }</math>. | |

| − | + | ||

| − | The choice of the boundary condition is a priori arbitrary, and it would depend on the addressed problem. In our study, and throughout all this work, we select the periodic boundary conditions since they can ensure a representative volume with the smaller length scale <math display="inline">l_{\mu }</math>. | + | |

Regarding the way to impose the boundary conditions, there are two options. On the one hand, it can be imposed directly in the equilibrium problem and consequently the Lagrange multipliers appear as extra unknowns. On the other hand, it is possible to condensate some unknowns on the system through the boundary conditions. | Regarding the way to impose the boundary conditions, there are two options. On the one hand, it can be imposed directly in the equilibrium problem and consequently the Lagrange multipliers appear as extra unknowns. On the other hand, it is possible to condensate some unknowns on the system through the boundary conditions. | ||

| Line 682: | Line 646: | ||

The first option seems reasonable for small number of conditions like minimum conditions, however, for other kind of conditions, it enlarges the system of equations considerably. The option of condensing the unknowns in periodic and linear seems reasonable. As a difficulty, if iterative solvers are used, specially for large 3D problems, the condensation process confers worse conditioning to the matrix, lengthening the convergence process. If direct solvers are used, with the condensation technique, the matrix becomes less sparse bringing problems with memory. This features that the appropiate approach will depend on the specific problem to be solved. In our case, and through all this work, since not computationally high demanding meshes are required, the condensation process is considered. | The first option seems reasonable for small number of conditions like minimum conditions, however, for other kind of conditions, it enlarges the system of equations considerably. The option of condensing the unknowns in periodic and linear seems reasonable. As a difficulty, if iterative solvers are used, specially for large 3D problems, the condensation process confers worse conditioning to the matrix, lengthening the convergence process. If direct solvers are used, with the condensation technique, the matrix becomes less sparse bringing problems with memory. This features that the appropiate approach will depend on the specific problem to be solved. In our case, and through all this work, since not computationally high demanding meshes are required, the condensation process is considered. | ||

| − | + | '''Strong form of the microscopic equilibrium equation'''. Once the boundary conditions have been introduced, the strong form of the microscopic equilibrium equation can be stated. From the equilibrium equation in weak form ([[#eq-2.17|2.17]]), and undoing the steps of integration by parts (and assuming some regularity), the equilibrium equation requires divergence free of the microscopic stresses. This is, | |

| − | + | ||

| − | Once the boundary conditions have been introduced, the strong form of the microscopic equilibrium equation can be stated. From the equilibrium equation in weak form ([[#eq-2.17|2.17]]), and undoing the steps of integration by parts (and assuming some regularity), the equilibrium equation requires divergence free of the microscopic stresses. This is, | + | |

<span id="eq-2.34"></span> | <span id="eq-2.34"></span> | ||

| Line 833: | Line 795: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\chi =\begin{array}{ccc}1 & & x\in \Omega ^{+}\\ 0 & & x\in \Omega ^{-} \end{array}</math> | + | | style="text-align: center;" | <math>\chi =\begin{cases}\begin{array}{ccc}1 & & x\in \Omega ^{+}\\ 0 & & x\in \Omega ^{-} \end{array}\end{cases} </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (2.42) | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.42) | ||

| Line 904: | Line 866: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\mathbb{C}\mbox{( }\chi \mbox{)}=\begin{array}{ccc}\mathbb{C\hbox{+}} & & \chi=1,\\ \mathbb{C}^{-} & & \chi=0, \end{array}</math> | + | | style="text-align: center;" | <math>\mathbb{C}\mbox{( }\chi \mbox{)}=\begin{cases}\begin{array}{ccc}\mathbb{C\hbox{+}} & & \chi=1,\\ \mathbb{C}^{-} & & \chi=0, \end{array}\end{cases} </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (2.47) | | style="width: 5px;text-align: right;white-space: nowrap;" | (2.47) | ||

| Line 1,235: | Line 1,197: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\chi _{B(\hat{x},\varepsilon )}(x)=1 x\in B(\hat{x},\epsilon ), | + | | style="text-align: center;" | <math>\chi _{B(\hat{x},\varepsilon )}(x)= \left\{ \begin{array}{ll}1 & x\in B(\hat{x},\epsilon ),\\ |

| − | + | 0 & x\notin B(\hat{x},\epsilon ),\end{array}\right. </math> | |

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.6) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.6) | ||

| Line 1,250: | Line 1,211: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>s(x)=-1 x\in \Omega ^{+}, | + | | style="text-align: center;" | <math>s(x)= \left\{ \begin{array}{ll} -1 & x\in \Omega ^{+},\\ |

| − | + | 1 & x\notin \Omega \hbox{ - }.\end{array}\right. </math> | |

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.7) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.7) | ||

| Line 1,421: | Line 1,381: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>x\in \Omega ^{+}:D_{T}\mathcal{J}(\hat{x})=\mathbb{P}\sigma (u)(\widehat{x})\cdot \nabla ^{s}u(\widehat{x})\geq{0},\qquad | + | | style="text-align: center;" | <math>x\in \Omega ^{+}:D_{T}\mathcal{J}(\hat{x})=\mathbb{P}\sigma (u)(\widehat{x})\cdot \nabla ^{s}u(\widehat{x})\geq{0},\qquad ({\bf Case~A}) </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.19) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.19) | ||

| Line 1,432: | Line 1,392: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>x\in \Omega ^{-}:D_{T}\mathcal{J}(\hat{x})=\mathbb{P}\sigma (u)(\widehat{x})\cdot \nabla ^{s}u(\widehat{x})\leq{0.}\qquad | + | | style="text-align: center;" | <math>x\in \Omega ^{-}:D_{T}\mathcal{J}(\hat{x})=\mathbb{P}\sigma (u)(\widehat{x})\cdot \nabla ^{s}u(\widehat{x})\leq{0.}\qquad ({\bf Case~B}) </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.20) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.20) | ||

| Line 1,441: | Line 1,401: | ||

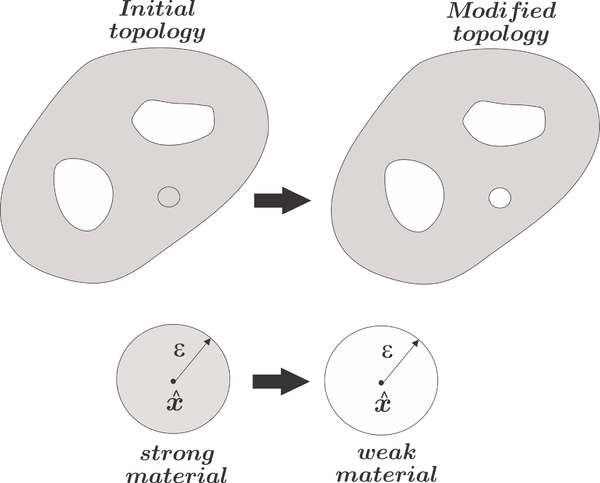

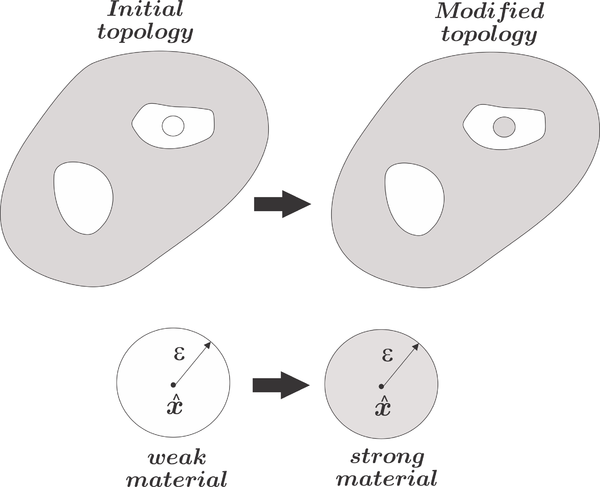

As a summary of the variables and properties described so far, in Table [[#table-1|1]], we show the initial and modified topology properties, the shape functional increments and the topological derivative for the Case A and B in a compact form. | As a summary of the variables and properties described so far, in Table [[#table-1|1]], we show the initial and modified topology properties, the shape functional increments and the topological derivative for the Case A and B in a compact form. | ||

| − | {| class="floating_tableSCP wikitable" style="text-align: center; margin: 1em auto;min-width:50%; | + | |

| − | + | <div class="center" style="font-size: 75%;">'''Table 1'''. Interpretation of the topological derivative interpretations</div> | |

| + | |||

| + | {| class="floating_tableSCP wikitable" style="text-align: center; margin: 1em auto;min-width:50%;font-size:85%;" | ||

|- | |- | ||

| colspan='1' style="border-right: 2px solid;border-left: 2px solid;border-right: 2px solid;" | | | colspan='1' style="border-right: 2px solid;border-left: 2px solid;border-right: 2px solid;" | | ||

| Line 1,544: | Line 1,506: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\chi =1-H(\psi )=\begin{array}{ccc}1 & & \psi{<0},\\ 0 & & \psi{>0.} \end{array}</math> | + | | style="text-align: center;" | <math>\chi =1-H(\psi )=\left\{\begin{array}{ccc}1 & & \psi{<0},\\ 0 & & \psi{>0.} \end{array}\right.</math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.24) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.24) | ||

| Line 1,587: | Line 1,549: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\left\{\begin{array}{cc}\psi (\hat{x})\leq{0} & \hat{x}\in \Omega ^{+}\\ \psi (\hat{x})\geq{0} & \hat{x}\in \Omega ^{-} \end{array}\right.\quad \hbox{and}\left\{\begin{array}{cc}g(\hat{x})\leq{0} & \hat{x}\in \Omega ^{+}\\ g(\hat{x})\geq{0} & \hat{x}\in \Omega ^{-}. \end{array}\right. </math> | + | | style="text-align: center;" | <math>\left\{\begin{array}{cc}\psi (\hat{x})\leq{0} & \hat{x}\in \Omega ^{+}\\ \psi (\hat{x})\geq{0} & \hat{x}\in \Omega ^{-} \end{array}\right.\quad \hbox{and }\quad \left\{\begin{array}{cc}g(\hat{x})\leq{0} & \hat{x}\in \Omega ^{+}\\ g(\hat{x})\geq{0} & \hat{x}\in \Omega ^{-}. \end{array}\right. </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.27) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.27) | ||

| Line 1,782: | Line 1,744: | ||

where <math display="inline">g(x)</math> stands for the topological derivative of the cost function <math display="inline">\mathcal{J}(\chi (\psi )</math>). Note that, the topological derivative of the volume constraint is equal to <math display="inline">1</math> and has been consequently omitted. Hereafter, for simplicity, the extended topological derivative <math display="inline">\hat{g}(x)</math> is also called topological derivative. | where <math display="inline">g(x)</math> stands for the topological derivative of the cost function <math display="inline">\mathcal{J}(\chi (\psi )</math>). Note that, the topological derivative of the volume constraint is equal to <math display="inline">1</math> and has been consequently omitted. Hereafter, for simplicity, the extended topological derivative <math display="inline">\hat{g}(x)</math> is also called topological derivative. | ||

| − | + | '''Inequality constraints''' The augmented Lagrangian scheme can be extended to minimization problems with inequality constraints. The main idea consists in retrieving the minimization problem with equality constraints by adding an extra variable <math display="inline">z</math>, often termed slack variable, to the minimization problem with inequality constraints. In mathematical terms, it reads as | |

| − | + | ||

| − | The augmented Lagrangian scheme can be extended to minimization problems with inequality constraints. The main idea consists in retrieving the minimization problem with equality constraints by adding an extra variable <math display="inline">z</math>, often termed slack variable, to the minimization problem with inequality constraints. In mathematical terms, it reads as | + | |

<span id="eq-3.39"></span> | <span id="eq-3.39"></span> | ||

| Line 1,894: | Line 1,854: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>(z^{*})^{2}=z_{1}^{2} c(\psi )>-\frac{\lambda }{\rho } | + | | style="text-align: center;" | <math>(z^{*})^{2}=\left\{ \begin{array}{ll}z_{1}^{2} & c(\psi )>-\frac{\lambda }{\rho }\\ |

| − | + | z_{2}^{2} & c(\psi )<-\frac{\lambda }{\rho }\end{array}\right.</math> | |

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.47) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.47) | ||

| Line 1,961: | Line 1,920: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math> | + | | style="text-align: center;" | <math> \frac{\partial r}{\partial \lambda }= |

| − | + | \left\{\begin{array}{ll}0 & c(\psi )>-\frac{\lambda }{\rho }\\ | |

| − | + | -\frac{1}{\rho } & c(\psi )<-\frac{\lambda }{\rho }\end{array}\right. \quad \hbox{and}\quad \frac{\partial r}{\partial \psi }=\left\{\begin{array}{ll} \frac{\partial c}{\partial \psi } & c(\psi )>-\frac{\lambda }{\rho },\\ | |

| − | + | 0 & c(\psi )<-\frac{\lambda }{\rho }\end{array}\right. . </math> | |

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.52) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.52) | ||

| Line 1,978: | Line 1,936: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\lambda{+\rho}r=\lambda{+\rho}r c(\psi )>-\frac{\lambda }{\rho } | + | | style="text-align: center;" | <math>\lambda{+\rho}r= \left\{\begin{array}{ll} \lambda{+\rho}r & c(\psi )>-\frac{\lambda }{\rho }\\ |

| − | + | 0 & c(\psi )<-\frac{\lambda }{\rho }\end{array}\right. </math> | |

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.53) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.53) | ||

| Line 1,993: | Line 1,950: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>(\lambda{+\rho}r)\frac{\partial r}{\partial \lambda }=0\quad \hbox{and}\quad (\lambda{+\rho}r)\frac{\partial r}{\partial \psi }=(\lambda{+\rho}r)\frac{\partial c}{\partial \psi } c(\psi )>-\frac{\lambda }{\rho }, | + | | style="text-align: center;" | <math>(\lambda{+\rho}r)\frac{\partial r}{\partial \lambda }=0\quad \hbox{and}\quad (\lambda{+\rho}r)\frac{\partial r}{\partial \psi }=\left\{\begin{array}{ll} (\lambda{+\rho}r)\frac{\partial c}{\partial \psi } & c(\psi )>-\frac{\lambda }{\rho },\\ |

| − | + | 0 & c(\psi )<-\frac{\lambda }{\rho }.\end{array}\right. </math> | |

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.54) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.54) | ||

| Line 2,065: | Line 2,021: | ||

As an advantage, this scheme allows using the same implementation for both cases; equalities or inequalities; by means of exchanging the constraint <math display="inline">c(\psi _{n})</math> with the constraint <math display="inline">r(\psi _{n},\lambda _{n})</math>. For further information, the reader is referred to the reference book <span id='citeF-71'></span>[[#cite-71|[71]]] for a rigorous description and work <span id='citeF-72'></span>[[#cite-72|[72]]] for applying to topological optimization problem. | As an advantage, this scheme allows using the same implementation for both cases; equalities or inequalities; by means of exchanging the constraint <math display="inline">c(\psi _{n})</math> with the constraint <math display="inline">r(\psi _{n},\lambda _{n})</math>. For further information, the reader is referred to the reference book <span id='citeF-71'></span>[[#cite-71|[71]]] for a rigorous description and work <span id='citeF-72'></span>[[#cite-72|[72]]] for applying to topological optimization problem. | ||

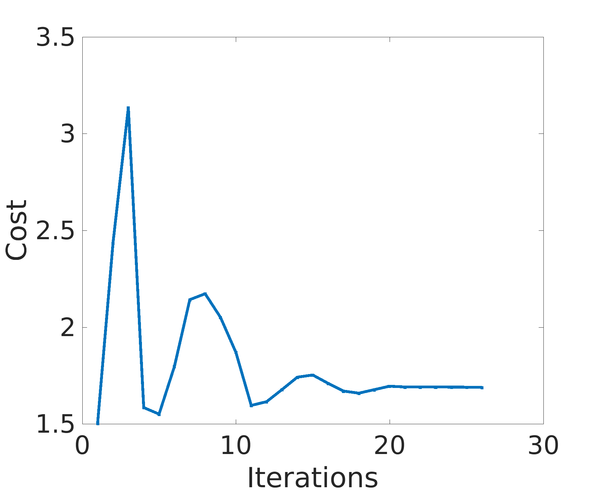

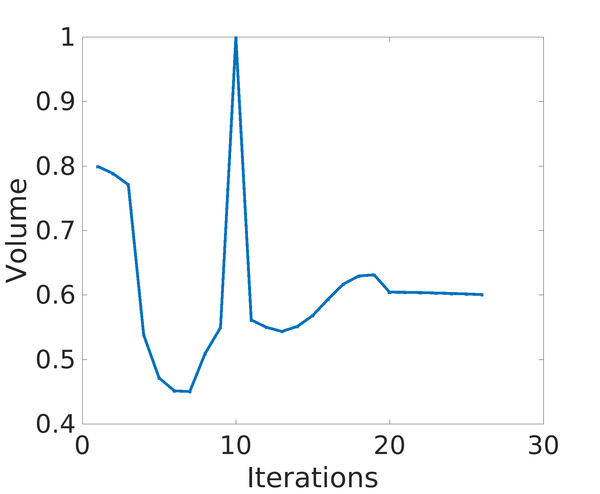

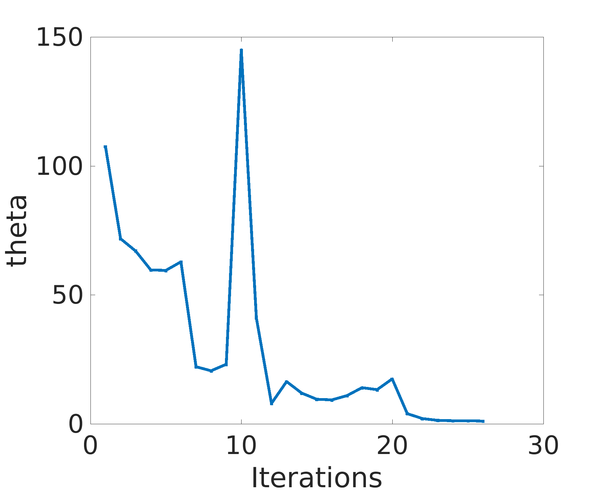

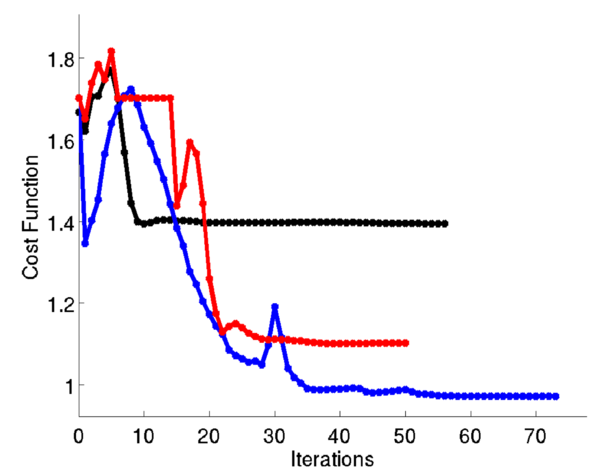

| − | + | '''Penalty value and algorithm'''. It is worth mentioning that giving an adequate value to the penalty variable is not an easy task. In the reference book <span id='citeF-71'></span>[[#cite-71|[71]]], it is suggested increasing the penalty during the iterations (when the constraint is not tightened enough). Similarly, in work <span id='citeF-77'></span>[[#cite-77|[77]]], it is proposed to increase the penalty every five iterations. However, our experience shows us that the penalty cannot increase unlimitedly. A very small value of the penalty will make the problem converge very slowly but if, on the contrary, is very high the solution oscillates with the risk of non-convergence. So, as it was mentioned before, the appropiate value of this parameter will depend on the problem and on the sensibility of the cost when varying the constraint. The numerical experiments, further presented, suggest to normalize the cost function and take a small value of the penalty. | |

| − | + | ||

| − | It is worth mentioning that giving an adequate value to the penalty variable is not an easy task. In the reference book <span id='citeF-71'></span>[[#cite-71|[71]]], it is suggested increasing the penalty during the iterations (when the constraint is not tightened enough). Similarly, in work <span id='citeF-77'></span>[[#cite-77|[77]]], it is proposed to increase the penalty every five iterations. However, our experience shows us that the penalty cannot increase unlimitedly. A very small value of the penalty will make the problem converge very slowly but if, on the contrary, is very high the solution oscillates with the risk of non-convergence. So, as it was mentioned before, the appropiate value of this parameter will depend on the problem and on the sensibility of the cost when varying the constraint. The numerical experiments, further presented, suggest to normalize the cost function and take a small value of the penalty. | + | |

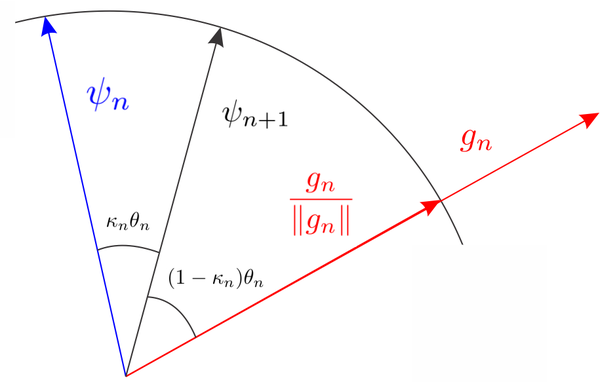

A detailed scheme of the Augmented Lagrangian Slerp algorithm is presented in Algorithm [[#algorithm-1|1]]. | A detailed scheme of the Augmented Lagrangian Slerp algorithm is presented in Algorithm [[#algorithm-1|1]]. | ||

| − | + | <span id='algorithm-1'></span> | |

| − | {| style="margin: 1em auto;border: 1px solid darkgray;" | + | {| style="margin: 1em auto;border: 1px solid darkgray;font-size:85%;" |

|- | |- | ||

| | | | ||

| − | : | + | : '''Init:''' choose initial values of <math display="inline">\psi _0</math>, <math display="inline">\theta _{min}</math>, tol, <math display="inline">\kappa _{min}</math>, <math display="inline">\lambda _0</math> and <math display="inline">\rho </math> |

| − | + | : Compute <math display="inline">\sigma _0</math> and <math display="inline">u_0</math> from ([[#eq-2.46|2.46]]). | |

| − | Compute <math display="inline"> | + | : Compute <math display="inline">r_0</math> from ([[#eq-3.56|3.56]]) with <math display="inline">c_0</math> from ([[#eq-3.10|3.10]]). |

| − | Compute <math display="inline"> | + | : Compute <math display="inline">\hat{g}_0</math> from ([[#eq-3.58|3.58]]) with <math display="inline">g</math> computed from ([[#eq-3.18|3.18]]). |

| − | + | : '''while''' <math>\theta _{n} \geq \theta _{min} \mathbf{or} r_n \geq tol</math> '''do''' | |

| − | + | :: Set <math display="inline">\kappa = 1</math>, <math display="inline">k=1</math>, <math display="inline">\mathcal{L}_k = \mathcal{L}_n</math>, <math display="inline">\theta _k = \theta _n</math>. | |

| − | : | + | :: '''while''' <math>\mathcal{L}_k \geq \mathcal{L}_n</math> (line search) '''do''' |

| − | : | + | ::: Update <math display="inline">\psi _k</math> from ([[#eq-3.33|3.33]]) with <math display="inline">\kappa </math>, <math display="inline">\theta _k</math> and <math display="inline">\hat{g}_n</math>, and update <math display="inline">\chi _k</math> from ([[#eq-3.24|3.24]]). |

| − | :: | + | ::: Compute <math display="inline">\sigma _k</math> and <math display="inline">u_k</math> from ([[#eq-2.46|2.46]]). |

| − | ::Compute <math display="inline">\ | + | ::: Compute <math display="inline">\mathcal{L}_k</math> from ([[#eq-3.50|3.50]]), with <math display="inline">\mathcal{J}_k</math> from ([[#eq-3.16|3.16]]) and set <math display="inline">\kappa = \kappa /2</math> and <math display="inline">k = k+1</math>. |

| − | :: | + | :: Set <math display="inline">\sigma _{n+1} = \sigma _k</math>, <math display="inline">u_{n+1} = u_k</math>, <math display="inline">\mathcal{L}_{n+1} = \mathcal{L}_k</math>, <math display="inline">\psi _{n+1}=\psi _k</math> |

| − | :: | + | :: Compute <math display="inline">\theta _{n+1}</math> from ([[#eq-3.34|3.34]]) |

| − | ::Compute <math display="inline"> | + | :: Compute <math display="inline">r_{n+1}</math> from ([[#eq-3.56|3.56]]) with <math display="inline">r_0</math> from ([[#eq-3.10|3.10]]). |

| − | :: | + | :: Update <math display="inline">\lambda _{n+1}</math> from ([[#eq-3.57|3.57]]). |

| − | :: | + | :: Compute <math display="inline">\hat{g}_{n+1}</math> from ([[#eq-3.58|3.58]]) with <math display="inline">g</math> computed from ([[#eq-3.18|3.18]]) and set <math display="inline">n = n+1</math>. |

| + | |} | ||

| − | + | <div class="center" style="font-size: 75%;">'''Algorithm. 1''' Augmented Lagrangian slerp algorithm. The Lagrange multiplier is updated in every topology iteration, i.e.,'' Usawa''-like scheme is used.</div> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

==3.4 Treatment of the interface == | ==3.4 Treatment of the interface == | ||

| Line 2,121: | Line 2,070: | ||

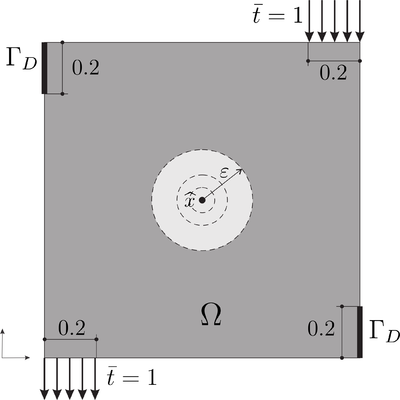

We proceed to examine how to deal with the bi-material problem, from the continuous and discrete point of view, and how the different treatments of the interface affect the cost and the topological derivative. | We proceed to examine how to deal with the bi-material problem, from the continuous and discrete point of view, and how the different treatments of the interface affect the cost and the topological derivative. | ||

| − | + | '''Formulation''' | |

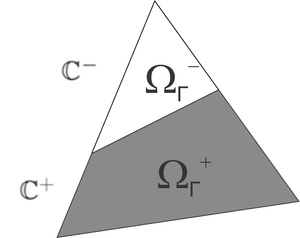

In the bi-material problem, the domain <math display="inline">\Omega </math> is first divided in two parts, one sub-domain with a strong material <math display="inline">\mathbb{C}^{+}</math> and the other sub-domain with a weak material <math display="inline">\mathbb{C}^{-}</math>. Then, the classical form of the elastic problem (without considering, for simplicity, the body forces) is written as | In the bi-material problem, the domain <math display="inline">\Omega </math> is first divided in two parts, one sub-domain with a strong material <math display="inline">\mathbb{C}^{+}</math> and the other sub-domain with a weak material <math display="inline">\mathbb{C}^{-}</math>. Then, the classical form of the elastic problem (without considering, for simplicity, the body forces) is written as | ||

| Line 2,172: | Line 2,121: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\mathbb{\mathbb{\tilde{C}}}=\mathbb{C}^{+} \hbox{ in }T_{k}^{+} | + | | style="text-align: center;" | <math>\mathbb{\mathbb{\tilde{C}}}=\left\{\begin{array}{lll}\mathbb{C}^{+} & \hbox{ in } & T_{k}^{+}\\ |

| − | + | \mathbb{C}^{-} & \hbox{ in } & T_{k}^{-}\\ | |

| − | + | \mathbb{C}^{\Gamma } & \hbox{ in } & T_{k}^{\Gamma }\end{array}\right. . </math> | |

| − | + | ||

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.62) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.62) | ||

| Line 2,221: | Line 2,168: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\tilde{\chi }_{io}=1-H(\psi (x_{g}))=\begin{array}{ccc}1 & & \psi (x_{g})<0\\ 0 & & \psi (x_{g})>0 \end{array}</math> | + | | style="text-align: center;" | <math>\tilde{\chi }_{io}=1-H(\psi (x_{g}))=\left\{\begin{array}{ccc}1 & & \psi (x_{g})<0\\ 0 & & \psi (x_{g})>0 \end{array}\right.</math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.65) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.65) | ||

| Line 2,260: | Line 2,207: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\mathbb{C}_{io}^{\Gamma }=\begin{array}{ccc}\mathbb{C}^{+} & & \psi (x_{g})<0\\ \mathbb{C}^{-} & & \psi (x_{g})>0. \end{array}</math> | + | | style="text-align: center;" | <math>\mathbb{C}_{io}^{\Gamma }=\left\{\begin{array}{ccc}\mathbb{C}^{+} & & \psi (x_{g})<0\\ \mathbb{C}^{-} & & \psi (x_{g})>0. \end{array}\right.</math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.68) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.68) | ||

| Line 2,429: | Line 2,376: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_118254298-Interface.png| | + | |[[Image:draft_Samper_118254298-Interface.png|300px|The volume Ω<sub>Γ</sub> of the interface triangular element Tₖ<sup>Γ</sup> is divided into the sub-domains Ω<sub>Γ</sub>⁺ and Ω<sub>Γ</sub>⁻ with material properties \mathbbC⁺ and \mathbbC⁻ respectively.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

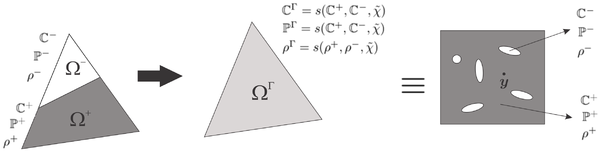

| colspan="1" | '''Figure 12:''' The volume <math>\Omega _{\Gamma }</math> of the interface triangular element <math>T_{k}^{\Gamma }</math> is divided into the sub-domains <math>\Omega _{\Gamma }^{+}</math> and <math>\Omega _{\Gamma }^{-}</math> with material properties <math>\mathbb{C}^{+}</math> and <math>\mathbb{C}^{-}</math> respectively. | | colspan="1" | '''Figure 12:''' The volume <math>\Omega _{\Gamma }</math> of the interface triangular element <math>T_{k}^{\Gamma }</math> is divided into the sub-domains <math>\Omega _{\Gamma }^{+}</math> and <math>\Omega _{\Gamma }^{-}</math> with material properties <math>\mathbb{C}^{+}</math> and <math>\mathbb{C}^{-}</math> respectively. | ||

| Line 2,475: | Line 2,422: | ||

Note that in the rest of elements <math display="inline">T_{k}^{+}</math> and <math display="inline">T_{k}^{-}</math>, the standard relation between stresses and strains are retrieved. | Note that in the rest of elements <math display="inline">T_{k}^{+}</math> and <math display="inline">T_{k}^{-}</math>, the standard relation between stresses and strains are retrieved. | ||

| − | + | '''Regularized characteristic function definition''' Then, we define the regularized characteristic function as the volume fraction of the strong material, i.e. | |

| − | + | ||

| − | Then, we define the regularized characteristic function as the volume fraction of the strong material, i.e. | + | |

<span id="eq-3.83"></span> | <span id="eq-3.83"></span> | ||

| Line 2,503: | Line 2,448: | ||

|} | |} | ||

| − | |||

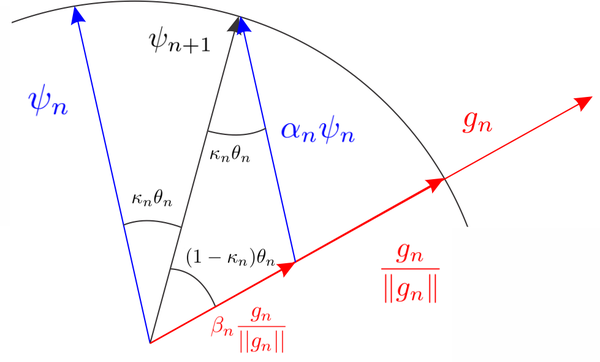

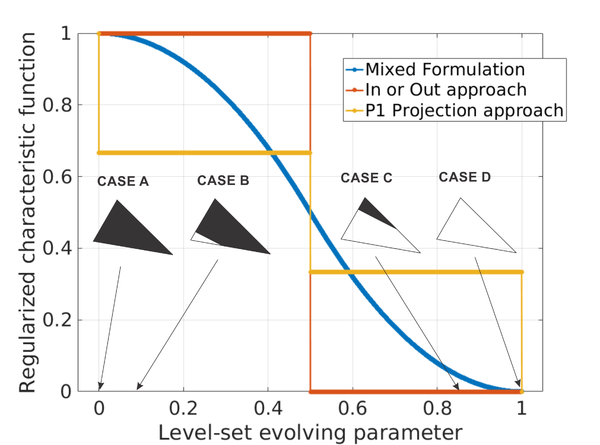

| − | Following the description of the <math display="inline">\mathbb{P}_{1}</math>-projection, we again recognize, in the mixed formulation approach, the following four different cases for computing the regularized characteristic function: | + | '''Regularized characteristic function computation''' Following the description of the <math display="inline">\mathbb{P}_{1}</math>-projection, we again recognize, in the mixed formulation approach, the following four different cases for computing the regularized characteristic function: |

'''Case A:''' <math>0\geq \psi (x_{3})\geq \psi (x_{2})\geq \psi (x_{1}).</math> Same as the <math>\mathbb{P}_{1}</math> projection approach. This is | '''Case A:''' <math>0\geq \psi (x_{3})\geq \psi (x_{2})\geq \psi (x_{1}).</math> Same as the <math>\mathbb{P}_{1}</math> projection approach. This is | ||

| Line 2,527: | Line 2,471: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_118254298-TriangleCoordinates.png| | + | |[[Image:draft_Samper_118254298-TriangleCoordinates.png|400px|Representation of a material discontinuity when using a level-set ψ described by \mathbbP₁ Finite Element functions. The level-set ψ cuts the triangle in the nodes x₁₃ and x₂₃ in Case B and in the nodes x₃₁ and x₂₁ in Case C.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 13:''' Representation of a material discontinuity when using a level-set <math>\psi </math> described by <math>\mathbb{P}_{1}</math> Finite Element functions. The level-set <math>\psi </math> cuts the triangle in the nodes <math>x_{13}</math> and <math>x_{23}</math> in Case B and in the nodes <math>x_{31}</math> and <math>x_{21}</math> in Case C. | | colspan="1" | '''Figure 13:''' Representation of a material discontinuity when using a level-set <math>\psi </math> described by <math>\mathbb{P}_{1}</math> Finite Element functions. The level-set <math>\psi </math> cuts the triangle in the nodes <math>x_{13}</math> and <math>x_{23}</math> in Case B and in the nodes <math>x_{31}</math> and <math>x_{21}</math> in Case C. | ||

| Line 2,708: | Line 2,652: | ||

In this case, the element <math>T_{k}^{\Gamma }</math> is not considered an interface element. | In this case, the element <math>T_{k}^{\Gamma }</math> is not considered an interface element. | ||

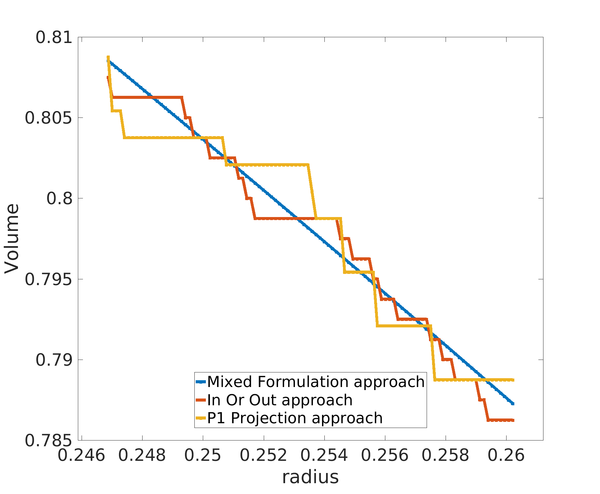

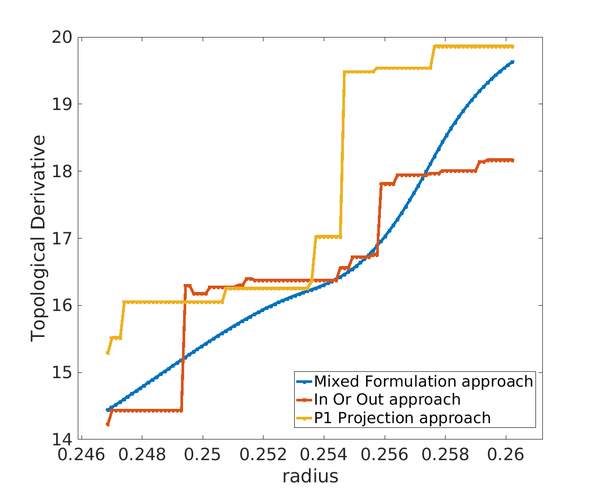

| − | + | '''Comparison with other approaches''' In comparison with other approaches (''In or Out'' or ''<math>\mathbb{P}_{1}</math>-projection'' approach), the characteristic function on the interface <math display="inline">\tilde{\chi }_{m}</math> in the mixed formulation approach evolves continuously when moving the level-set function. Thus, the characteristic function is now defined in | |

| − | + | ||

| − | In comparison with other approaches (''In or Out'' or ''<math>\mathbb{P}_{1}</math>-projection'' approach), the characteristic function on the interface <math display="inline">\tilde{\chi }_{m}</math> in the mixed formulation approach evolves continuously when moving the level-set function. Thus, the characteristic function is now defined in | + | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 2,736: | Line 2,678: | ||

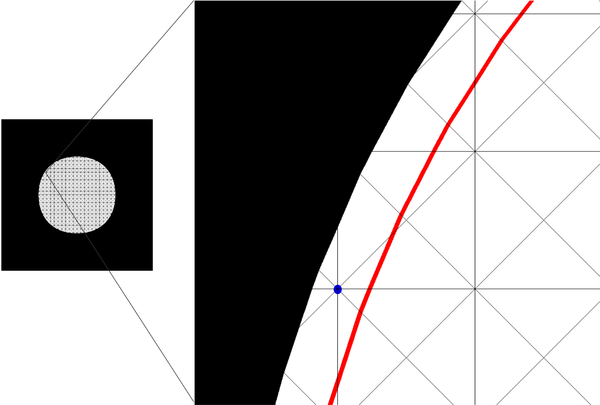

In Table [[#table-2|2]], we summarize and compare the treatment of the interface in terms of the characteristic function and constitutive tensor by the ''In or Out approach'', ''<math>\mathbb{P}_{1}</math>-projection approach'' and ''the Mixed formulation approach''. | In Table [[#table-2|2]], we summarize and compare the treatment of the interface in terms of the characteristic function and constitutive tensor by the ''In or Out approach'', ''<math>\mathbb{P}_{1}</math>-projection approach'' and ''the Mixed formulation approach''. | ||

| − | + | ||

| − | + | <div class="center" style="font-size: 75%;">'''Table 2'''. Summary of the different approaches used to treat with the interface elements. In the ''Mixed formulation approach'', in contrast to the others approaches, the fictitious constitutive tensor on the interface <math>\mathbb{C}^{\Gamma }</math> is allowed to evolve continuously when varying the level-set function.</div> | |

| + | |||

| + | {| class="floating_tableSCP wikitable" style="text-align: center; margin: 1em auto;min-width:50%;font-size:85%;" | ||

|- | |- | ||

| colspan='1' style="border-right: 2px solid;border-left: 2px solid;border-right: 2px solid;" | | | colspan='1' style="border-right: 2px solid;border-left: 2px solid;border-right: 2px solid;" | | ||

| Line 2,805: | Line 2,749: | ||

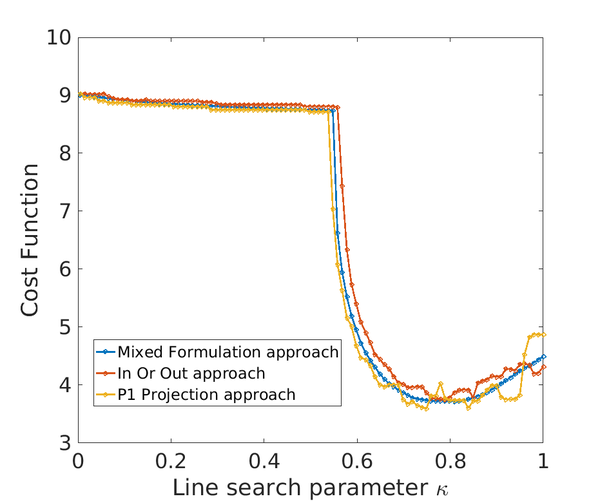

At this point, the following question arises: ''how does the Mixed formulation affects the optimization problem, and more specifically, the cost and the gradient?'' | At this point, the following question arises: ''how does the Mixed formulation affects the optimization problem, and more specifically, the cost and the gradient?'' | ||

| − | + | '''Implications of the mixed formulation on the cost function''' Regarding the cost function <math display="inline">\mathcal{J}</math>, we examine the implications of the mixed formulation when considering the compliance function. It can usually be written as the work produced by the external forces, i.e., | |

| − | + | ||

| − | Regarding the cost function <math display="inline">\mathcal{J}</math>, we examine the implications of the mixed formulation when considering the compliance function. It can usually be written as the work produced by the external forces, i.e., | + | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 2,834: | Line 2,776: | ||

and <math display="inline">\tilde{\mathbb{C}}</math> represents the regularized constitutive tensor described in equation ([[#eq-3.62|3.62]]). Thus, the implications of the mixed formulation on the cost function rely completely on the behavior of the regularized constitutive tensor <math display="inline">\mathbb{C}^{\Gamma }</math> on the interface elements. | and <math display="inline">\tilde{\mathbb{C}}</math> represents the regularized constitutive tensor described in equation ([[#eq-3.62|3.62]]). Thus, the implications of the mixed formulation on the cost function rely completely on the behavior of the regularized constitutive tensor <math display="inline">\mathbb{C}^{\Gamma }</math> on the interface elements. | ||

| − | + | '''Implications of the mixed formulation on the topological derivative''' In order to study the implications of the mixed formulation on the topological derivative, we first examine the stresses <math display="inline">\sigma </math>. To simplify the notation, let's define the averaging operator <math display="inline">s</math> as | |

| − | + | ||

| − | In order to study the implications of the mixed formulation on the topological derivative, we first examine the stresses <math display="inline">\sigma </math>. To simplify the notation, let's define the averaging operator <math display="inline">s</math> as | + | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 2,891: | Line 2,831: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\tilde{\sigma }=\sigma ^{+}=\mathbb{C}^{+}:\nabla ^{s}u \hbox{ in }T_{k}^{+} | + | | style="text-align: center;" | <math>\tilde{\sigma }=\left\{\begin{array}{lll}\sigma ^{+}=\mathbb{C}^{+}:\nabla ^{s}u & \hbox{ in } & T_{k}^{+}\\ |

| − | + | \sigma ^{-}=\mathbb{C}^{-}:\nabla ^{s}u &\hbox{ in } & T_{k}^{-}\\ | |

| − | + | \sigma ^{\Gamma }=\mathbb{C}^{\Gamma }:\nabla ^{s}u & \hbox{ in } & T_{k}^{\Gamma }\end{array}\right. </math> | |

| − | + | ||

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.109) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.109) | ||

| Line 2,920: | Line 2,858: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\tilde{\mathbb{P}}=\mathbb{P}^{+} \hbox{ in }T_{k}^{+}, | + | | style="text-align: center;" | <math>\tilde{\mathbb{P}}=\left\{\begin{array}{lll} \mathbb{P}^{+} &\hbox{ in } & T_{k}^{+},\\ |

| − | + | \mathbb{P}^{-} & \hbox{ in } & T_{k}^{-},\\ | |

| − | + | \mathbb{P}^{\Gamma }=s(\mathbb{P}^{+},\mathbb{P}^{-},\chi ) & \hbox{ in } &T_{k}^{\Gamma }. \end{array}\right.</math> | |

| − | + | ||

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.111) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.111) | ||

| Line 2,937: | Line 2,873: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\tilde{g}=g^{+}=\sigma ^{+}:\mathbb{P}^{+}:\nabla ^{s}u \hbox{ in }T_{k}^{+}, | + | | style="text-align: center;" | <math>\tilde{g}= \left\{\begin{array}{lll} g^{+}=\sigma ^{+}:\mathbb{P}^{+}:\nabla ^{s}u &\hbox{ in } & T_{k}^{+},\\ |

| − | + | g^{-}=\sigma ^{-}:\mathbb{P}^{-}:\nabla ^{s}u & \hbox{ in } & T_{k}^{-},\\ g^{\Gamma }=s(g^{+},g^{-},\tilde{\chi }) & \hbox{ in } & T_{k}^{\Gamma }.\end{array}\right. </math> | |

| − | + | ||

| − | + | ||

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.112) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.112) | ||

| Line 2,972: | Line 2,905: | ||

In Table [[#table-3|3]], we summarize the values that the main variables of the topology optimization problem take in the strong material elements, in the weak material elements and in the interface elements. | In Table [[#table-3|3]], we summarize the values that the main variables of the topology optimization problem take in the strong material elements, in the weak material elements and in the interface elements. | ||

| − | + | ||

| − | + | ||

| − | + | <div class="center" style="font-size: 75%;">'''Table 3'''. Summary of the practical treatment of the interface in topology optimization. The volume averaging operator <math>s(\cdot ,\cdot ,\tilde{\chi })</math>, with fraction volume on the element <math>\tilde{\chi }</math>, regularizes the corresponding discontinuous property on such element. The regularization of the constitutive tensor ''<math>\tilde{\mathbb{C}}</math>'' can be understood as an homogenization (with Taylor boundary conditions) of an RVE with fraction volume <math>\tilde{\chi }</math>, i.e. <math>\tilde{\mathbb{C}}=\mathbb{C}^{h}</math>.</div> | |

| + | |||

| + | {| class="floating_tableSCP wikitable" style="text-align: center; margin: 1em auto;min-width:50%;font-size:85%;" | ||

|- | |- | ||

| colspan='1' style="border-right: 2px solid;border-left: 2px solid;border-right: 2px solid;" | | | colspan='1' style="border-right: 2px solid;border-left: 2px solid;border-right: 2px solid;" | | ||

| Line 3,156: | Line 3,091: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>g(\tilde{\chi }_{m})=g^{+}=\sigma _{\mu }^{+}:\mathbb{P}^{+}:\nabla ^{s}u_{\mu } \hbox{ in }T_{k}^{+}, | + | | style="text-align: center;" | <math>g(\tilde{\chi }_{m})= \left\{\begin{array}{lll} g^{+}=\sigma _{\mu }^{+}:\mathbb{P}^{+}:\nabla ^{s}u_{\mu } & \hbox{ in } & T_{k}^{+},\\ |

| − | + | g^{-}=\sigma _{\mu }^{-}:\mathbb{P}^{-}:\nabla ^{s}u_{\mu } & \hbox{ in } & T_{k}^{-},\\ | |

| − | + | g^{\Gamma }=s(g^{+},g^{-},\tilde{\chi }_{m}) & \hbox{ in } & T_{k}^{\Gamma }.\end{array}\right. </math> | |

| − | + | ||

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (3.118) | | style="width: 5px;text-align: right;white-space: nowrap;" | (3.118) | ||

| Line 3,356: | Line 3,289: | ||

|} | |} | ||

| − | |||

| − | |||

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

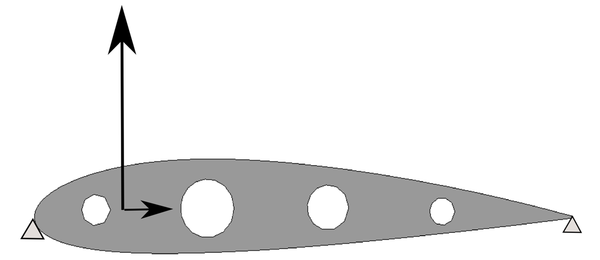

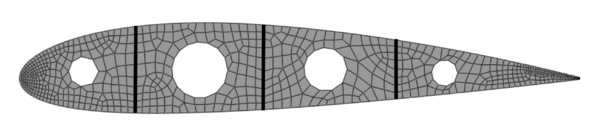

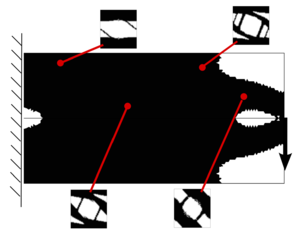

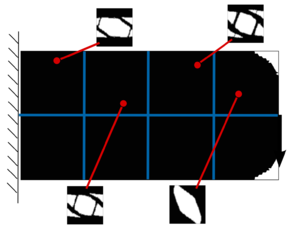

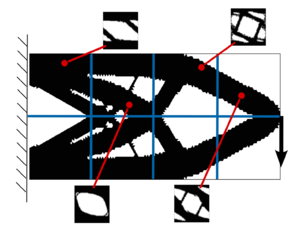

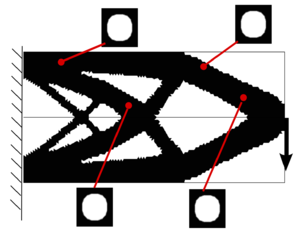

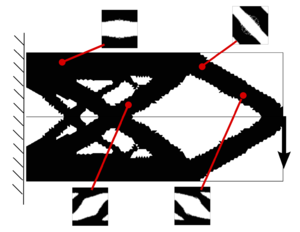

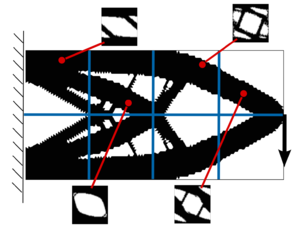

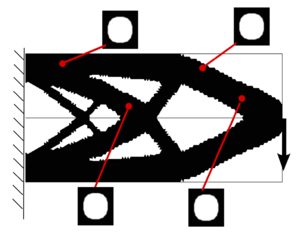

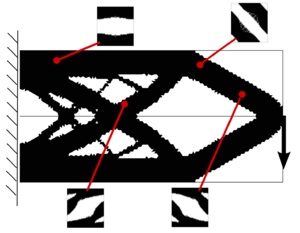

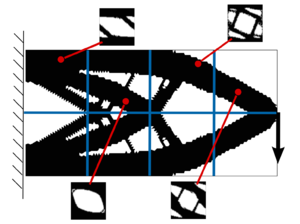

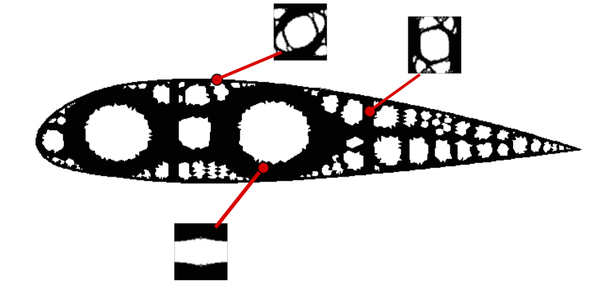

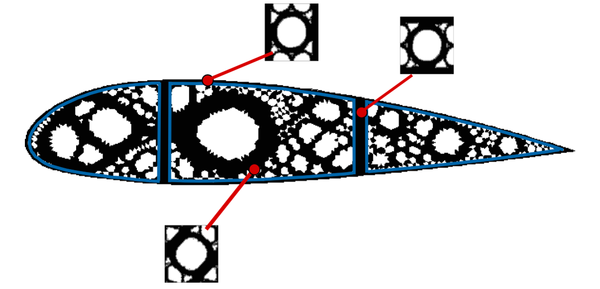

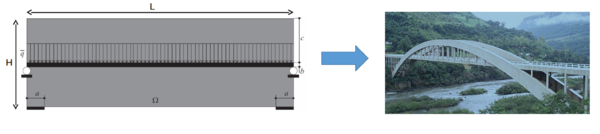

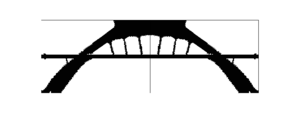

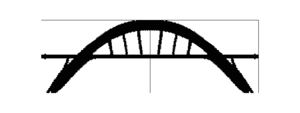

| colspan="1" | '''Figure 21:''' Bridge topology optimization problem. Topology representation of the initial, intermediate and final iterations. Note the similarity between the optimal topology computationally designed and the topology proposed by the industry (shown in Figure [[#img-20|20]]). | | colspan="1" | '''Figure 21:''' Bridge topology optimization problem. Topology representation of the initial, intermediate and final iterations. Note the similarity between the optimal topology computationally designed and the topology proposed by the industry (shown in Figure [[#img-20|20]]). | ||

| Line 3,463: | Line 3,394: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

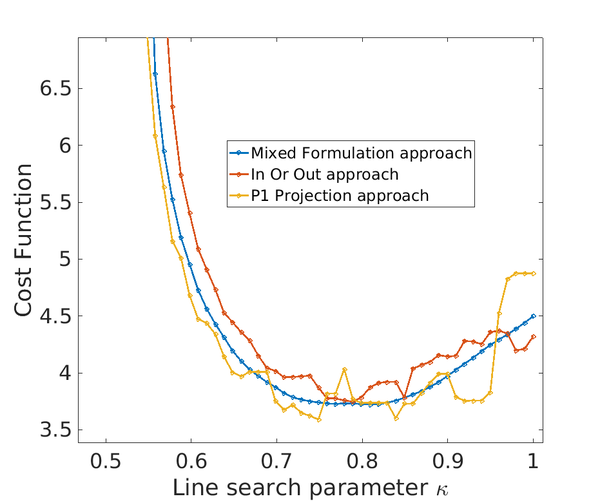

|- | |- | ||

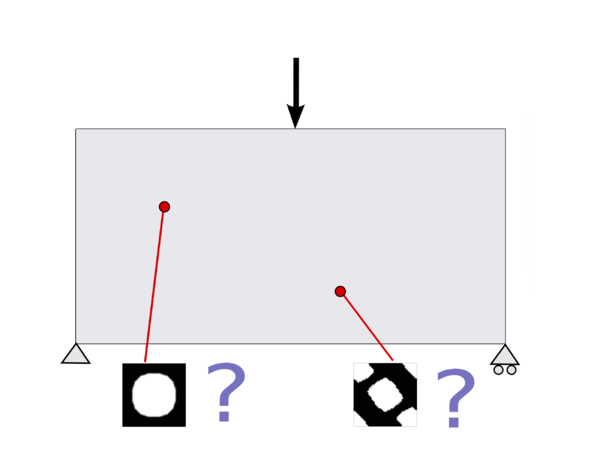

| − | |[[Image: | + | |[[Image:Draft_Samper_118254298_2192_Figure25.png|300px|Topological derivative concept.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 25:''' Topological derivative concept. | | colspan="1" | '''Figure 25:''' Topological derivative concept. | ||

| Line 3,547: | Line 3,478: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image: | + | |[[Image:Draft_Samper_118254298_8095_Figure26.png|340px|Description of the problem.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

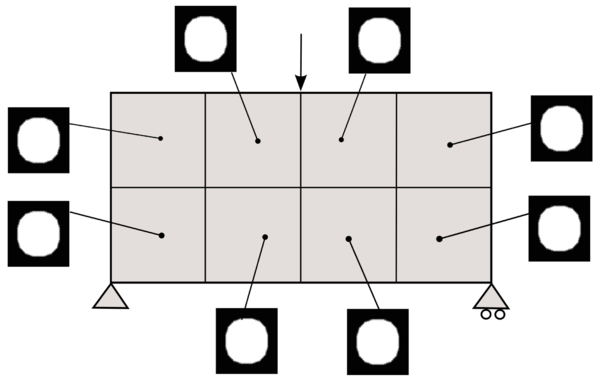

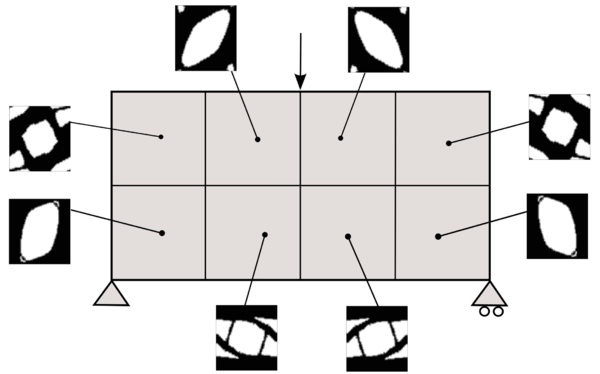

| colspan="1" | '''Figure 26:''' Description of the problem. | | colspan="1" | '''Figure 26:''' Description of the problem. | ||

| Line 3,699: | Line 3,630: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\left\{\begin{array}{rlcl}\mathrm{div}\left(\sigma _{\epsilon }(w)\right)& =0 & \hbox{ in} & R^{2}\\ \sigma _{\epsilon }(w) & =\mathbb{C}_{\epsilon }(\widehat{x})\nabla ^{s}w\\ w & \rightarrow{0} & \hbox{ at} & \infty \\ \lbrack\ | + | | style="text-align: center;" | <math>\left\{\begin{array}{rlcl}\mathrm{div}\left(\sigma _{\epsilon }(w)\right)& =0 & \hbox{ in} & R^{2}\\ \sigma _{\epsilon }(w) & =\mathbb{C}_{\epsilon }(\widehat{x})\nabla ^{s}w\\ w & \rightarrow{0} & \hbox{ at} & \infty \\ \lbrack\lbrack w\rbrack\rbrack & =0 & \hbox{ on} & \partial B_{1}\\ \lbrack\lbrack\sigma _{\epsilon }(w)\rbrack\rbrack n & =-\mathbb{S}\sigma (u)(\widehat{x})n & \hbox{ on} & \partial B_{1} \end{array}\right., </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (4.19) | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.19) | ||

| Line 3,712: | Line 3,643: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\left\{\begin{array}{rlcl}\mathrm{div}(\sigma _{\epsilon }(\widetilde{u}_{\epsilon })) & =\epsilon \mathrm{div}(\nabla \mathbb{C}_{\epsilon }(\zeta )(x-\widehat{x})\nabla ^{s}w) & \hbox{ in} & \Omega \\ \widetilde{u}_{\epsilon } & =-\epsilon w & \hbox{ on} & \Gamma _{D}\\ \sigma (\widetilde{u}_{\epsilon })n & =-\epsilon \sigma (w)n & \hbox{ on} & \Gamma _{N}\\ \lbrack\lbrack\widetilde{u}_{\epsilon }\rbrack\rbrack& =0 & \hbox{ on} & \partial B_{\epsilon }\\ \lbrack\lbrack\sigma _{\epsilon }(\widetilde{u}_{\epsilon })\rbrack\ | + | | style="text-align: center;" | <math>\left\{\begin{array}{rlcl}\mathrm{div}(\sigma _{\epsilon }(\widetilde{u}_{\epsilon })) & =\epsilon \mathrm{div}(\nabla \mathbb{C}_{\epsilon }(\zeta )(x-\widehat{x})\nabla ^{s}w) & \hbox{ in} & \Omega \\ \widetilde{u}_{\epsilon } & =-\epsilon w & \hbox{ on} & \Gamma _{D}\\ \sigma (\widetilde{u}_{\epsilon })n & =-\epsilon \sigma (w)n & \hbox{ on} & \Gamma _{N}\\ \lbrack\lbrack\widetilde{u}_{\epsilon }\rbrack\rbrack & =0 & \hbox{ on} & \partial B_{\epsilon }\\ \lbrack\lbrack\sigma _{\epsilon }(\widetilde{u}_{\epsilon })\rbrack\rbrack n & =-\epsilon \lbrack\lbrack\left(\nabla \mathbb{C}_{\epsilon }\left(\zeta \right)n\right)\left(\nabla ^{s}u(\widehat{x})+\nabla ^{s}w\right)\rbrack\rbrack n & \hbox{ on} & \partial B_{\epsilon } \end{array}\right., </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (4.20) | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.20) | ||

| Line 3,828: | Line 3,759: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\left\{\begin{array}{rlcl}\mathrm{div}\left(\sigma _{\epsilon }(w)\right)& =0 & \hbox{ in} & R^{2}\\ \sigma _{\epsilon }(w) & =\mathbb{C}_{\epsilon }(\widehat{x})\nabla ^{s}w\\ w & \rightarrow{0} & \hbox{ at} & \infty \\ \lbrack\ | + | | style="text-align: center;" | <math>\left\{\begin{array}{rlcl}\mathrm{div}\left(\sigma _{\epsilon }(w)\right)& =0 & \hbox{ in} & R^{2}\\ \sigma _{\epsilon }(w) & =\mathbb{C}_{\epsilon }(\widehat{x})\nabla ^{s}w\\ w & \rightarrow{0} & \hbox{ at} & \infty \\ \lbrack\lbrack w\rbrack\rbrack & =0 & \hbox{ on} & \partial B_{1}\\ \lbrack\lbrack\sigma _{\epsilon }(w)\rbrack\rbrack n & =Sn & \hbox{ on} & \partial B_{1} \end{array}\right., </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (4.28) | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.28) | ||

| Line 3,976: | Line 3,907: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\mathbb{P}=\begin{array}{ccc}\mathbb{P}^{+}= & \mathbb{P}(\alpha ,\beta ,\gamma _{0},1,1,1) & x\in \Omega ^{+}\\ \mathbb{P}^{-}= & \mathbb{P}(\alpha ,\beta ,\frac{1}{\gamma _{0}},1,1,1) & x\in \Omega ^{-}. \end{array}</math> | + | | style="text-align: center;" | <math>\mathbb{P}=\left\{\begin{array}{ccc}\mathbb{P}^{+}= & \mathbb{P}(\alpha ,\beta ,\gamma _{0},1,1,1) & x\in \Omega ^{+}\\ \mathbb{P}^{-}= & \mathbb{P}(\alpha ,\beta ,\frac{1}{\gamma _{0}},1,1,1) & x\in \Omega ^{-}. \end{array}\right.</math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (4.38) | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.38) | ||

| Line 3,993: | Line 3,924: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\left\{\begin{array}{rlcl}\mathrm{div}\left(\sigma _{\epsilon }(w)\right)& =0 & \hbox{ in} & R^{2}\\ \sigma _{\epsilon }(w) & =\mathbb{C}_{\epsilon }(\widehat{x})\nabla ^{s}w\\ w & \rightarrow{0} & \hbox{ at} & \infty \\ \lbrack\ | + | | style="text-align: center;" | <math>\left\{\begin{array}{rlcl}\mathrm{div}\left(\sigma _{\epsilon }(w)\right)& =0 & \hbox{ in} & R^{2}\\ \sigma _{\epsilon }(w) & =\mathbb{C}_{\epsilon }(\widehat{x})\nabla ^{s}w\\ w & \rightarrow{0} & \hbox{ at} & \infty \\ \lbrack\lbrack w\rbrack\rbrack & =0 & \hbox{ on} & \partial B_{1}\\ \lbrack\lbrack\sigma _{\epsilon }(w)\rbrack\rbrack n & =Sn & \hbox{ on} & \partial B_{1} \end{array}\right., </math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (4.39) | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.39) | ||

| Line 4,148: | Line 4,079: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\mathbb{P}=\begin{array}{ccc}\mathbb{P}^{+}= & \mathbb{\mathbb{P}}(\mathbb{C}^{+},\mathbb{C}^{-}) & x\in \Omega ^{+}\\ \mathbb{P}^{-}= & \mathbb{\mathbb{P}}(\mathbb{C}^{-},\mathbb{C}^{+}) & x\in \Omega ^{-}. \end{array}</math> | + | | style="text-align: center;" | <math>\mathbb{P}=\left\{\begin{array}{ccc}\mathbb{P}^{+}= & \mathbb{\mathbb{P}}(\mathbb{C}^{+},\mathbb{C}^{-}) & x\in \Omega ^{+}\\ \mathbb{P}^{-}= & \mathbb{\mathbb{P}}(\mathbb{C}^{-},\mathbb{C}^{+}) & x\in \Omega ^{-}. \end{array}\right.</math> |

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (4.50) | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.50) | ||

| Line 4,159: | Line 4,090: | ||

<span id='theorem-lem:ueps-u'></span> 1: Let <math display="inline">u</math> and <math display="inline">u_{\epsilon }</math> be solutions to ([[#eq-4.5|4.5]]) and ([[#eq-4.10|4.10]]), respectively. Then, we have that the estimate <math display="inline">\| u_{\epsilon }-u\| _{H^{1}(\Omega ;R^{2})}=O(\epsilon )</math> holds true. | <span id='theorem-lem:ueps-u'></span> 1: Let <math display="inline">u</math> and <math display="inline">u_{\epsilon }</math> be solutions to ([[#eq-4.5|4.5]]) and ([[#eq-4.10|4.10]]), respectively. Then, we have that the estimate <math display="inline">\| u_{\epsilon }-u\| _{H^{1}(\Omega ;R^{2})}=O(\epsilon )</math> holds true. | ||

| − | Proof 1: We start by subtracting the variational problem ([[#eq-4.5|4.5]]) and ([[#eq-4.10|4.10]]) to obtain: | + | '''Proof 1''': We start by subtracting the variational problem ([[#eq-4.5|4.5]]) and ([[#eq-4.10|4.10]]) to obtain: |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 4,190: | Line 4,121: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\int _{\Omega }\sigma _{\epsilon }(u_{\epsilon }-u)\cdot \nabla ^{s}(u_{\epsilon }-u) \leq C_{1}\| \sigma (u)\| _{L^{2}(B_{\epsilon };R^{2})}\| \nabla ^{s}(u_{\epsilon }-u)\| _{L^{2}(B_{\epsilon };R^{2})} | + | | style="text-align: center;" | <math>\begin{array}{lll}\int _{\Omega }\sigma _{\epsilon }(u_{\epsilon }-u)\cdot \nabla ^{s}(u_{\epsilon }-u) & \leq & C_{1}\| \sigma (u)\| _{L^{2}(B_{\epsilon };R^{2})}\| \nabla ^{s}(u_{\epsilon }-u)\| _{L^{2}(B_{\epsilon };R^{2})}\\ |

| − | + | & \leq & C_{2}\epsilon \| \nabla ^{s}(u_{\epsilon }-u)\| _{L^{2}(B_{\epsilon };R^{2})}\\ | |

| − | + | & \leq & C_{3}\epsilon \| \nabla ^{s}(u_{\epsilon }-u)\| _{H^{1}(\Omega ;R^{2})}\\ | |

| − | + | & \leq & C_{4}\epsilon \| u_{\epsilon }-u\| _{H^{1}(\Omega ;R^{2})},\end{array} </math> | |

| − | + | ||

| − | + | ||

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (4.53) | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.53) | ||

| Line 4,229: | Line 4,157: | ||

with the constant <math display="inline">C</math> independent of the small parameter <math display="inline">\epsilon </math>. | with the constant <math display="inline">C</math> independent of the small parameter <math display="inline">\epsilon </math>. | ||

| − | Proof 2: From the ansatz proposed in ([[#eq-4.18|4.18]]) for <math display="inline">u_{\epsilon }</math> and making use of the triangular inequality, we obtain: | + | '''Proof 2''': From the ansatz proposed in ([[#eq-4.18|4.18]]) for <math display="inline">u_{\epsilon }</math> and making use of the triangular inequality, we obtain: |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 4,236: | Line 4,164: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>|\widetilde{u}_{\epsilon }|_{H^{1}(\Omega ;R^{2})} = | + | | style="text-align: center;" | <math> \begin{array}{lll} |\widetilde{u}_{\epsilon }|_{H^{1}(\Omega ;R^{2})} & = & |u_{\epsilon }-u-\epsilon w|_{H^{1}(\Omega ;R^{2})}\\ |

| − | + | & \leq & |u_{\epsilon }-u|_{H^{1}(\Omega ;R^{2})}+\epsilon |w|_{H^{1}(\Omega ;R^{2})}\\ | |

| − | + | & \leq & \| u_{\epsilon }-u\| _{H^{1}(\Omega ;R^{2})}+\epsilon |w|_{H^{1}(R^{2};R^{2})}\\ | |

| − | + | & \leq & C_{1}\epsilon \,,\end{array} </math> | |

| − | + | ||

| − | + | ||

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (4.56) | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.56) | ||

| Line 4,249: | Line 4,174: | ||

where we have used the change of variables <math display="inline">x=\epsilon y</math>, the equivalence between the semi-norm and the norm in <math display="inline">H^{1}(\Omega ;R^{2})</math> and the estimate in Lemma [[#theorem-lem:ueps-u|1]]. Finally, the results comes out from the Poincaré inequality. | where we have used the change of variables <math display="inline">x=\epsilon y</math>, the equivalence between the semi-norm and the norm in <math display="inline">H^{1}(\Omega ;R^{2})</math> and the estimate in Lemma [[#theorem-lem:ueps-u|1]]. Finally, the results comes out from the Poincaré inequality. | ||

| − | + | 3: Let <math display="inline">\widetilde{u}_{\epsilon }</math> and <math display="inline">u</math> be solutions to ([[#eq-4.20|4.20]]) and ([[#eq-4.5|4.5]]), respectively. Then, we have the following estimate for the remainder <math display="inline">\mathcal{E}(\epsilon )</math> in ([[#eq-4.23|4.23]]): | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 4,261: | Line 4,186: | ||

|} | |} | ||

| − | Proof 3: From the Cauchy-Schwartz inequality we obtain | + | '''Proof 3''': From the Cauchy-Schwartz inequality we obtain |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| Line 4,268: | Line 4,193: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\mathcal{E}(\epsilon ) = \frac{1}{2}\int _{B_{\epsilon }}\Delta \mathbb{C}(\mathbb{C}^{\star })^{-1}\sigma _{\epsilon }(\widetilde{u}_{\epsilon })\cdot \nabla ^{s}u | + | | style="text-align: center;" | <math>\begin{array}{lll} \mathcal{E}(\epsilon ) & = & \frac{1}{2}\int _{B_{\epsilon }}\Delta \mathbb{C}(\mathbb{C}^{\star })^{-1}\sigma _{\epsilon }(\widetilde{u}_{\epsilon })\cdot \nabla ^{s}u\\ |

| − | + | & \leq & C_{1}\| \nabla ^{s}u\| _{L^{2}(B_{\epsilon };R^{2})}\| \nabla ^{s}\widetilde{u}_{\epsilon }\| _{L^{2}(B_{\epsilon };R^{2})}\\ | |

| − | + | & \leq & \epsilon C_{2}\| \nabla ^{s}\widetilde{u}_{\epsilon }\| _{L^{2}(B_{\epsilon };R^{2})}\,.\end{array} </math> | |

| − | + | ||

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (4.58) | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.58) | ||

| Line 4,284: | Line 4,207: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math>\mathcal{E}(\epsilon ) \leq \epsilon ^{2}C_{3}\| \nabla ^{s}v_{0}\| _{L^{2}(B_{\epsilon };R^{2})} | + | | style="text-align: center;" | <math> \begin{array}{lll}\mathcal{E}(\epsilon ) & \leq & \epsilon ^{2}C_{3}\| \nabla ^{s}v_{0}\| _{L^{2}(B_{\epsilon };R^{2})}\\ |

| − | + | & \leq &\epsilon ^{3}C_{4}\,.\end{array} </math> | |

| − | + | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (4.59) | | style="width: 5px;text-align: right;white-space: nowrap;" | (4.59) | ||

| Line 4,337: | Line 4,259: | ||

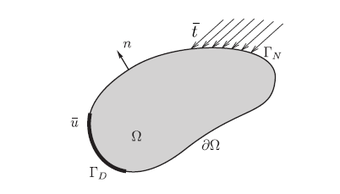

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_118254298-NumTestAxis.png| | + | |[[Image:draft_Samper_118254298-NumTestAxis.png|400px|Domain and boundary conditions.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 27:''' Domain and boundary conditions. | | colspan="1" | '''Figure 27:''' Domain and boundary conditions. | ||

| Line 4,344: | Line 4,266: | ||

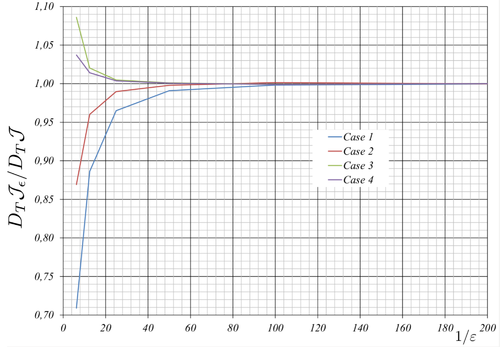

The study is conducted for four combinations of elasticity tensors <math display="inline">\mathbb{C}</math> and <math display="inline">\mathbb{C}^{\star }</math>. The analyzed cases are detailed in the following box: | The study is conducted for four combinations of elasticity tensors <math display="inline">\mathbb{C}</math> and <math display="inline">\mathbb{C}^{\star }</math>. The analyzed cases are detailed in the following box: | ||

| − | + | {| class="floating_tableSCP wikitable" style="text-align: center; margin: 1em auto;min-width:50%;font-size:85%;" | |

| − | {| class="floating_tableSCP wikitable" style="text-align: center; margin: 1em auto;min-width:50%;" | + | |

|- | |- | ||

| colspan='1' style="border-right: 2px solid;border-left: 2px solid;border-right: 2px solid;" | | | colspan='1' style="border-right: 2px solid;border-left: 2px solid;border-right: 2px solid;" | | ||

| Line 4,372: | Line 4,293: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_118254298-NumVerJ.png| | + | |[[Image:draft_Samper_118254298-NumVerJ.png|500px|Results of numerical verification.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 28:''' Results of numerical verification. | | colspan="1" | '''Figure 28:''' Results of numerical verification. | ||

| Line 4,413: | Line 4,334: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

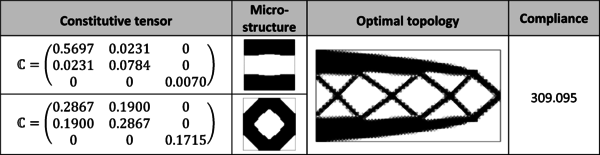

| − | |[[Image: | + | |[[Image:Draft_Samper_118254298_6711_TractionBeam.png|600px|Representative optimal homogeneous tension rod topologies: (a) Isotropic (E=1 and ν=0.3) as a reference, (b)-(e) Orthotropic, (f) Anisotropic. In the second column, the constitutive tensor used is shown, which is obtained by a classical homogenization procedure of the micro-structure displayed on the third column, see [Sanchez-PalenciaBook1980]. In the fourth one and fifth column, the final optimal topology for the structure and the value of the compliance are also shown.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

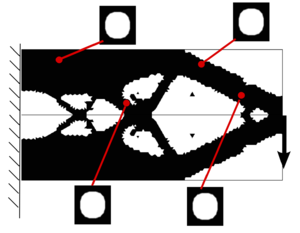

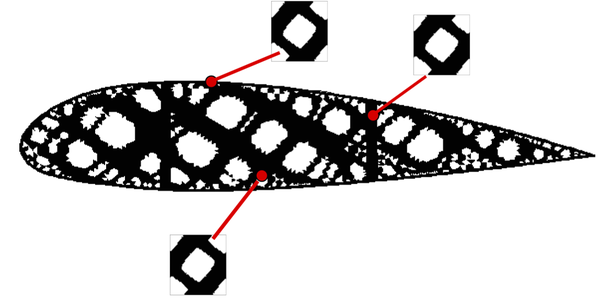

| colspan="1" | '''Figure 30:''' Representative optimal homogeneous tension rod topologies: (a) Isotropic (<math>E=1</math> and <math>\nu=0.3</math>) as a reference, (b)-(e) Orthotropic, (f) Anisotropic. In the second column, the constitutive tensor used is shown, which is obtained by a classical homogenization procedure of the micro-structure displayed on the third column, see [Sanchez-PalenciaBook1980]. In the fourth one and fifth column, the final optimal topology for the structure and the value of the compliance are also shown. | | colspan="1" | '''Figure 30:''' Representative optimal homogeneous tension rod topologies: (a) Isotropic (<math>E=1</math> and <math>\nu=0.3</math>) as a reference, (b)-(e) Orthotropic, (f) Anisotropic. In the second column, the constitutive tensor used is shown, which is obtained by a classical homogenization procedure of the micro-structure displayed on the third column, see [Sanchez-PalenciaBook1980]. In the fourth one and fifth column, the final optimal topology for the structure and the value of the compliance are also shown. | ||

| Line 4,425: | Line 4,346: | ||

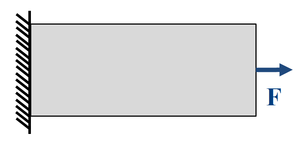

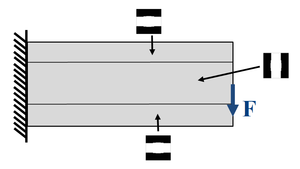

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_118254298-CantileverSketch.png| | + | |[[Image:draft_Samper_118254298-CantileverSketch.png|300px|Schematic drawing of a cantilever beam with homogeneous material distribution]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 31:''' Schematic drawing of a cantilever beam with homogeneous material distribution | | colspan="1" | '''Figure 31:''' Schematic drawing of a cantilever beam with homogeneous material distribution | ||

| Line 4,433: | Line 4,354: | ||

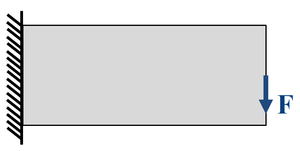

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image: | + | |[[Image:Draft_Samper_118254298_4418_CantileverBeam.png|600px|Representative optimal homogeneous Cantilever beam topologies: (a) Isotropic (E=1 and ν=0.3) as a reference, (b)-(e) Orthotropic, (f) Anisotropic. In the second column, the constitutive tensor used is shown, which is obtained by a classical homogenization procedure of the micro-structure displayed on the third column, see [Sanchez-PalenciaBook1980]. In the fourth one and fifth column, the final optimal topology for the structure and the value of the compliance are also shown.]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

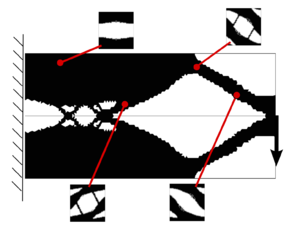

| colspan="1" | '''Figure 32:''' Representative optimal homogeneous Cantilever beam topologies: (a) Isotropic (<math>E=1</math> and <math>\nu=0.3</math>) as a reference, (b)-(e) Orthotropic, (f) Anisotropic. In the second column, the constitutive tensor used is shown, which is obtained by a classical homogenization procedure of the micro-structure displayed on the third column, see [Sanchez-PalenciaBook1980]. In the fourth one and fifth column, the final optimal topology for the structure and the value of the compliance are also shown. | | colspan="1" | '''Figure 32:''' Representative optimal homogeneous Cantilever beam topologies: (a) Isotropic (<math>E=1</math> and <math>\nu=0.3</math>) as a reference, (b)-(e) Orthotropic, (f) Anisotropic. In the second column, the constitutive tensor used is shown, which is obtained by a classical homogenization procedure of the micro-structure displayed on the third column, see [Sanchez-PalenciaBook1980]. In the fourth one and fifth column, the final optimal topology for the structure and the value of the compliance are also shown. | ||

| Line 4,451: | Line 4,372: | ||

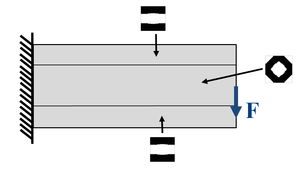

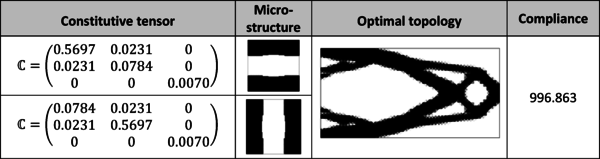

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||

| − | |[[Image:draft_Samper_118254298-HeteroCantileverHorizShearSketch.png| | + | |[[Image:draft_Samper_118254298-HeteroCantileverHorizShearSketch.png|300px|Heterogeneous cantilever beam with regions of different constitutive properties (enforced via microscopic material topology). ]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

| colspan="1" | '''Figure 33:''' Heterogeneous cantilever beam with regions of different constitutive properties (enforced via microscopic material topology). | | colspan="1" | '''Figure 33:''' Heterogeneous cantilever beam with regions of different constitutive properties (enforced via microscopic material topology). | ||

| Line 4,475: | Line 4,396: | ||

{| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | {| class="floating_imageSCP" style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 100%;max-width: 100%;" | ||

|- | |- | ||