Abstract==

TSI is currently, among other activities, developing and managing smart manufacturing in the framework of the FIBRE4YARDS project, which has as one of its main objectives to increase the production capacity of shipyards for ships made of composite materials through the implementation of highly automated methods and the implementation of Industry 4.0 technologies. Within the project, several demonstrators of different parts of a catamaran and a patrol boat will be built using new manufacturing processes that will have the industry 4.0 philosophy implemented. For this, TSI has designed and built 6 monitoring systems, one for each manufacturing process, and collaborated in the development of the IoT platform for the Shipyard4.0. The objective of TSI is to improve the knowledge of the state of the manufacturing processes and to visualise in real time the parameters of interest of the different manufacturing processes.

This research has been carried out in the framework of the FIBRE4YARDS project, composed of relevant stakeholders from the shipbuilding and FRP sectors. This project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement no. 101006860.

Key Words: Composite Materials, Industry 4.0, Shipyard 4.0, Monitoring, Fibre4Yard.

2. Introduction

The Fibre4Yards project seeks to redefine the paradigm of the shipbuilding industry through the implementation of a new shipyard vision characterized by automation, modular construction, and constant monitoring of all processes. This modernization extends beyond the shipyard itself, having implications for auxiliary industries. Its goal is to create an interconnected environment that promotes efficiency, productivity, and quality in both vessel construction and shipyard operations.

This research has been carried out in the framework of the FIBRE4YARDS project which is composed of relevant stakeholders of the naval and FRP sectors. This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 101006860.

3. Objectives of the Fibre4Yards Project

The Fibre4Yards project aims to sustain Europe's shipbuilding leadership by integrating Fibre-Reinforced Plastic (FRP) production into the Shipyard 4.0 model. The project focuses on:

- Implementing IoT and digital twin technologies for cost-effective operations.

- Adapting automated FRP production techniques for maritime use.

- Developing digitized engineering solutions for modular ship design.

- Providing industry guidelines for the transition to FRP Shipyard 4.0.

- Creating business and Intellectual Property Rights strategies for competitive shipyards.

4. Demonstration of the Potential of Shipyard 4.0

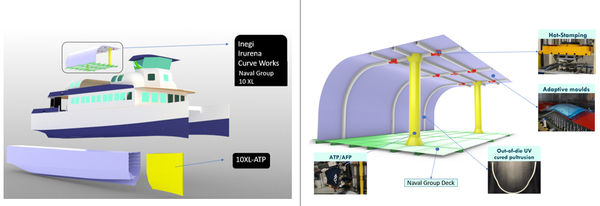

To illustrate the potential of the Shipyard 4.0 concept, Fibre4Yards plans to design a Patrol Vessel, and a Service Catamaran. These designs will be optimized for production, using the advanced methods developed during the project. Additionally, numerical methodologies will be developed to predict the performance of composite material structures manufactured with these technologies. These methodologies will be integrated into finite element analysis (FEA) design and analysis tools.

As shown on the previous figure the patrol Vessel will be manufactured by applying the Additive Manufacturing process developed by 10XL of 3D printing all the structure.

The catamaran will be manufactured as a prove of concept by the join of different manufacturing processes as shown on figure 3.

- Out-of-die UV cured pultrusion for the ribs by Irurena.

- Hot-Stamping for the beam joining piece by Inegi.

- Adaptative moulds for the exterior panels by Curve Works.

- Automatic tape placement for the pillars by 10XL.

- DECK manufactured by Naval Group

In this project, TSI plays a crucial role in defining the monitoring system and digitization process to improve these production processes and maintenance activities, aligning with the Shipyard 4.0 strategy. The primary objectives of TSI in this task are to extract enough information from the production assets of the shipyard regarding parameters and variables of interest for monitoring as per the needs and requirements of production processes and equipment maintenance. This information will facilitate the creation of an adapted monitoring system suitable for the Shipyard 4.0 approach.

TSI is also involved in defining and developing a monitoring system based on IoT technologies. This system can collect all data of interest, transmitting it to a virtual environment and allowing advanced data analysis to facilitate production control and predictive maintenance of the KPIs. This approach aims to bring a reduction in the operating costs of the shipyard's assets.

For this project TSI is teaming with the partners of the project to oversee production and maintenance processes, contributing to areas such as sensor definition, installation, IoT platform development, and hardware and software integration. This collective effort will pave the way for smart manufacturing in the shipyard.

4.1. Irurena

The IRURENA GROUP mindset on innovation-driven projects motivated them to explore opportunities in the composite industry. These efforts resulted on the conception of ROBTRUSION, an industrial start-up dedicated to produce curved composite profiles. This start-up is developing a manufacturing method that employs UV radiation to cure the profile outside of the die. This method allows them the creation of curved profiles with various geometries using the same die. This results in cost reductions and greater flexibility in the production process. Moreover, the use of robots as a pulling system makes it possible to automate the production of curved pultruded profiles with differing radii and orientations.

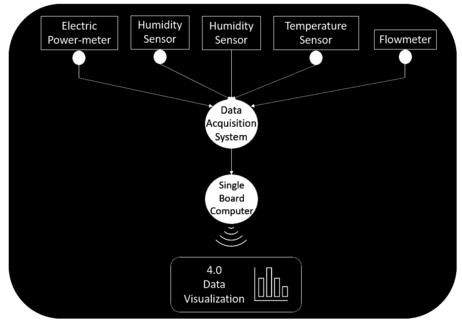

Following a meticulous analysis conducted by TSI in collaboration with Irurena, several potential challenges that could undermine the efficiency and product quality within the manufacturing operations were identified. These issues include fluctuating energy consumption, suboptimal environmental conditions, inconsistencies in the resin curing process, and malfunctioning pumps. If left unaddressed, these factors could create inefficiencies in the production process and subsequently compromise the integrity and quality of the final product.

A crucial aspect of the plant operations that TSI is focusing on is energy consumption. Unexpected fluctuations in energy consumption could signal problems in the production process. To monitor this aspect closely, TSI has contributed to the installation of six current sensors at the plant. Four sensors record the energy use of ultraviolet lamps, one measures the energy consumed by the robot handling the composite material, and another tracks the consumption of the clamp applying pressure to the part. This constant monitoring by the TSI system accurately reflects the plant's electrical use and allows for immediate detection of any deviations or abnormalities, along with providing real-time visualization of the energy consumption of the entire process.

In addition to energy management, TSI also pays great attention to the environmental conditions affecting the manufacturing process. Factors like humidity and temperature significantly impact the quality of fibres and resin. TSI, with its expertise in IoT technologies, has facilitated the installation of two temperature and humidity sensors at crucial stages of the production process. These sensors effectively monitor the conditions where the fibres and resin are stored and processed, thereby ensuring the quality of the materials.

Moreover, the resin curing process, a critical step in manufacturing, is carefully monitored through TSI's system. The resin's curing speed directly affects the mechanical properties and the precision of the final part's geometry. A pyrometer, an optical temperature-measuring instrument, is used to keep track of this process, integrated into TSI's monitoring system.

Lastly, TSI's system also considers the operation of the pumps as crucial to the plant's overall efficiency. Malfunctions or wear in these pumps can disrupt the production process, affecting the quality and quantity of output. TSI's IoT-based monitoring system includes a post-compressor flow meter to track the air flow used by the pumps. Additionally, an accelerometer installed on each diaphragm pump allows precise tracking of the pumps' operation and provides early warnings of potential failures or wear. This information is invaluable, allowing for predictive maintenance and ensuring smooth operations.

In sum, TSI's involvement in this project ensures seamless integration of hardware and software, comprehensive data analytics, and real-time monitoring. This aids in both the maintenance and enhancement of production processes at the Irurena plant, contributing significantly to the shipyard 4.0 strategy.

4.2. Inegi

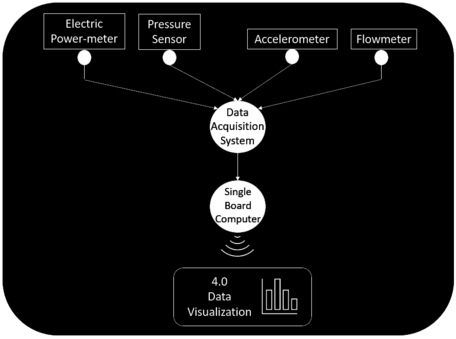

The Institute of Science and Innovation in Mechanical and Industrial Engineering (INEGI) employs Hot-Stamping process with FRP materials for this project. This technique is valuable in the shipbuilding sector for creating high-integrity, precision parts.

However, potential issues, such as equipment anomalies, abnormal vibrations, uneven pressure, or air leaks, can arise, leading to costly failures and subpar product quality. To address these, TSI has been integral in integrating an IoT-based monitoring system to facilitate enhanced process and quality control.

Under TSI's guidance, various sensors have been installed to track and resolve issues proactively. Three-phase power sensors monitor equipment's electrical consumption, and accelerometers on hydraulic pumps and a compressor detect abnormal vibrations, allowing for early intervention. TSI has also overseen the integration of four pressure sensors in the hot stamping process to ensure uniformity and a flow meter to monitor air flow during press operations.

4.3. Curve Works

Curve Works build reconfigurable moulds for rapid manufacturing, distinguishing them in the industry. Their expertise in producing curved composite parts and modular assembly has revolutionized design and production processes.

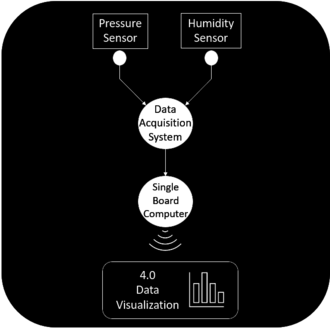

With this partner TSI detected two key parameters to be monitored: the correct temperature of the production bed and the appropriate vacuum pressure during the infusion process. Their advanced monitoring systems and digital transformation strategy aim to manage these parameters precisely.

In the production process, the production bed acts as a flexible mould, capable of being programmed to any desired geometry. However, this mould requires appropriate cooling between production cycles. Improper temperature management can impact the quality of produced parts. Here, TSI's solution involves a temperature sensor. This sensor continuously monitors the production bed's temperature, ensuring it has cooled sufficiently before a new production cycle begins, thereby elevating the process's overall efficiency.

Vacuum pressure during the infusion process is another critical factor. Any deviation from the expected near-zero bars might indicate a leak or poor insulation, potentially leading to air bubbles that can compromise the quality of the composite material. TSI addresses this challenge by employing a pressure sensor. This sensor measures the vacuum pressure during the infusion, allowing for timely detection of any leaks or insulation issues. This proactive measure, courtesy of TSI's monitoring system, ensures the superior quality of the produced composite materials.

4.4. 10XL

Specialized in extra-large prints using their large-scale hybrid 3D printers. They prioritize sustainability, employing recycled thermoplastic composite materials in their manufacturing process. Their services cover from prototyping to large-scale production. To the development of the Fibre4Yards project two advanced manufacturing methods will be use, Additive Manufacturing (AM) and Automatic Tape Placement (ATP).

4.4.1. Additive Manufacturing (AM)

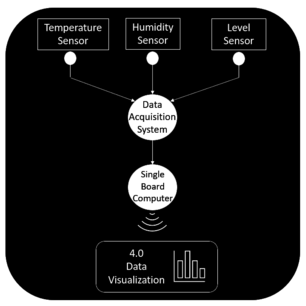

In a high-humidity environment like the Netherlands, maintaining a controlled work environment is crucial to prevent saturation and potential mechanical defects in composite material. Furthermore, tracking the temperature of the resin output and managing the supply of materials are vital factors in ensuring the quality and consistency of the parts produced.

For the specific issue of humidity control, TSI has choose a humidity sensor ubicated in the container where the balls of material for the process are stored. The sensor provides continuous monitoring of the humidity levels in the container, thereby acting as an efficient preventive measure against humidity saturation and potential mechanical defects in the composite material.

Further emphasizing the importance of temperature control in the production process, TSI has also introduced a temperature sensor to monitor the resin's outlet temperature at the print head. This sensor ensures the quality and uniformity of the parts produced by continually monitoring this crucial parameter, as the resin temperature can significantly impact the end product.

On the material management front, TSI a distance sensor that measures the height of the material, thus facilitating efficient tracking of the available material. TSI's proactive approach in setting alerts when the material is close to running out, not only guarantees efficient production management but also avoids unexpected work stoppages.

4.5. Automatic tape placement (ATP)

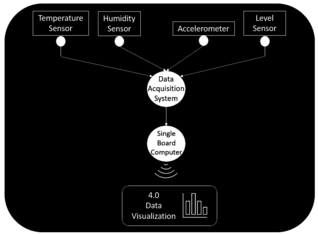

The Automatic Tape Placement (ATP) process, which involves layering of prepreg - a composite of fibre and resin that cures when heated, has several inherent challenges. These include the potential for variable temperature during placement, humidity affecting the material quality, irregularities in tape application, and the need for timely replenishment of the prepreg roll. To tackle these issues, various sensors are employed in the process.

Temperature fluctuations during prepreg placement could be indicative of heater malfunction, improper resin curing, or premature resin curing prior to placement. These anomalies could compromise the integrity of the final piece. To address this, TSI implements an infrared temperature sensor on the machine's head as part of its monitoring system. This sensor continuously observes the temperature of the prepreg roll during placement, alerting operators to any temperature deviations. This ensures the curing process occurs at the right time and temperature, contributing to the overall efficiency of the production process.

Environmental conditions, such as humidity, can also impact the mechanical characteristics of the prepreg and, consequently, the final product. TSI's comprehensive monitoring system includes a humidity sensor that measures both humidity and temperature near the prepreg roll. This ensures that optimal conditions are maintained, safeguarding the material from degradation, and thereby enhancing the quality and durability of the final product.

Ensuring consistent application of the prepreg tape is crucial, as any defects or irregularities could impact the final product's quality. Irregularities in one layer could induce defects in subsequent layers, resulting in an irregular surface. To tackle this, TSI integrates an accelerometer in its monitoring system to detect any irregularities during tape application.

TSI includes a distance sensor in its monitoring system to monitor the remaining volume of prepreg material. This sensor alerts the operators when the material is nearing depletion, facilitating timely replacement and ensuring an uninterrupted and efficient manufacturing process throughout the working hours.

5. Conclusion

At the heart of the shipbuilding industry's transformation, the FIBRE4YARDS project focuses on the digitalisation of the shipyard value chain. This collaborative initiative brings together innovative partners each contributing their distinct manufacturing processes and TSI, a key player orchestrating the implementation of an IoT-based monitoring system. This system emphasises real-time quality control and process efficiency, injecting a modern and progressive approach into the industry. TSI leverages its expertise to promote smart, safe, and efficient production processes. This intensive involvement by TSI results in notable reductions in operating costs, substantial enhancements in profitability, and significant contributions to environmental sustainability, thereby redefining the landscape of the shipyard sector.

Document information

Published on 05/06/23

Licence: CC BY-NC-SA license

Share this document

Keywords

claim authorship

Are you one of the authors of this document?