m (Cinmemj moved page Draft Samper 432909089 to Valdebenito et al 2018a) |

|||

| (13 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | == | + | ==Acknowledgments== |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

The authors wish to thank to the Department of Geotechnical Engineering and Geosciences and the Department of Construction Engineering at Technical University of Catalonia for their help and support during the doctorate years of Mr. Galo Valdebenito. This work is inspired in the basic result of that investigation. Likewise, thank to the Faculty of Engineering Sciences and the Department of Research and Development ''(DID)'' at Universidad Austral de Chile for their help and support in this publication. | The authors wish to thank to the Department of Geotechnical Engineering and Geosciences and the Department of Construction Engineering at Technical University of Catalonia for their help and support during the doctorate years of Mr. Galo Valdebenito. This work is inspired in the basic result of that investigation. Likewise, thank to the Faculty of Engineering Sciences and the Department of Research and Development ''(DID)'' at Universidad Austral de Chile for their help and support in this publication. | ||

| − | + | ==Preface== | |

| − | + | ||

Earthquakes can be really destructive. There is no doubt. Recent seismic events have demonstrated the important effects on structures, and especially on bridges. In this sense, cable-stayed bridges are not an exception, although their seismic performance during recent events has been satisfactory. Their inherent condition as part of life-lines makes the seismic design and retrofitting of such structures be seriously considered. | Earthquakes can be really destructive. There is no doubt. Recent seismic events have demonstrated the important effects on structures, and especially on bridges. In this sense, cable-stayed bridges are not an exception, although their seismic performance during recent events has been satisfactory. Their inherent condition as part of life-lines makes the seismic design and retrofitting of such structures be seriously considered. | ||

| Line 43: | Line 24: | ||

<big>Llavaneras (Barcelona), October 2009.</big></div> | <big>Llavaneras (Barcelona), October 2009.</big></div> | ||

| + | <!-- | ||

<div style="text-align: right; direction: ltr; margin-left: 1em;"> | <div style="text-align: right; direction: ltr; margin-left: 1em;"> | ||

<big>'''Contents'''</big></div> | <big>'''Contents'''</big></div> | ||

| − | [[Image:draft_Samper_432909089-picture-Lienzo 2.svg|center|600px]] | + | [[Image:draft_Samper_432909089-monograph-picture-Lienzo 2.svg|center|600px]] |

| − | + | {| style="width: 100%;border-collapse: collapse;" | |

| − | {| style="width: 100%;border-collapse: | + | |

|- | |- | ||

| style="vertical-align: top;"|<big>'''Chapter 1. Introduction'''</big> | | style="vertical-align: top;"|<big>'''Chapter 1. Introduction'''</big> | ||

| Line 347: | Line 328: | ||

--> | --> | ||

| − | + | ==Chapter 1. Introduction== | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

:<big>1.1 Cable-Stayed Bridges and Seismic Protection </big> | :<big>1.1 Cable-Stayed Bridges and Seismic Protection </big> | ||

| Line 362: | Line 339: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

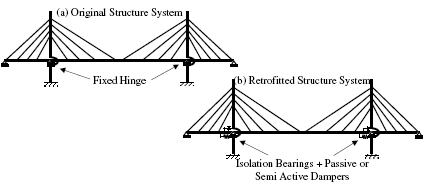

| − | [[Image:draft_Samper_432909089-image1-c.png|516px]] </div> | + | [[Image:draft_Samper_432909089-monograph-image1-c.png|516px]] </div> |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 368: | Line 345: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image:draft_Samper_432909089-image2-c.png|516px]] </div> | + | [[Image:draft_Samper_432909089-monograph-image2-c.png|516px]] </div> |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 430: | Line 407: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

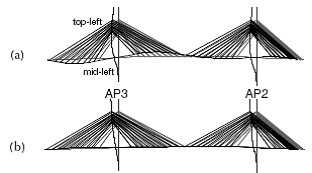

| − | | style="vertical-align: top;width: | + | | style="vertical-align: top;width: 63%;"|[[Image:draft_Samper_432909089-monograph-image3-c.jpeg|384px]] |

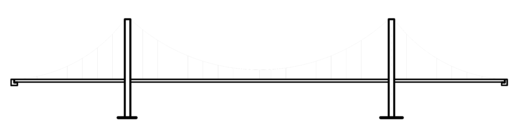

'''Fig. 1.2''' (a) Energy Dissipation of a Traditional Bridge, (b) Energy Dissipation of a Seismic Isolated Bridge [Adapted from Jara and Casas, 2002] | '''Fig. 1.2''' (a) Energy Dissipation of a Traditional Bridge, (b) Energy Dissipation of a Seismic Isolated Bridge [Adapted from Jara and Casas, 2002] | ||

| Line 443: | Line 420: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;vertical-align: top;width: | + | | style="text-align: center;vertical-align: top;width: 52%;"|[[Image:draft_Samper_432909089-monograph-image4.png|312px]] |

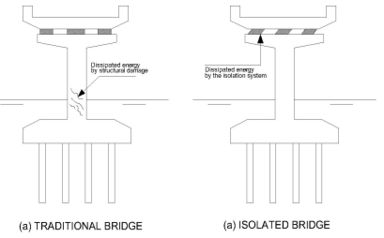

'''Fig. 1.3''' Minimized Seismic Energy Penetration by Seismic Isolation and Energy Dissipation | '''Fig. 1.3''' Minimized Seismic Energy Penetration by Seismic Isolation and Energy Dissipation | ||

| Line 453: | Line 430: | ||

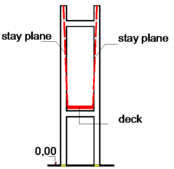

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image:draft_Samper_432909089-image5.jpeg|372px]] </div> | + | [[Image:draft_Samper_432909089-monograph-image5.jpeg|372px]] </div> |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 466: | Line 443: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="vertical-align: top;"|<big>''' [[Image:draft_Samper_432909089-image6.png|336px]] '''</big> | + | | style="vertical-align: top;"|<big>''' [[Image:draft_Samper_432909089-monograph-image6.png|336px]] '''</big> |

'''Fig. 1.5 '''Löscher-type Timber Bridge [Courtesy of the British Constructional Steelwork Association, Ltd] | '''Fig. 1.5 '''Löscher-type Timber Bridge [Courtesy of the British Constructional Steelwork Association, Ltd] | ||

| Line 483: | Line 460: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="vertical-align: top;width: | + | | style="vertical-align: top;width: 53%;"|[[Image:draft_Samper_432909089-monograph-image7.jpeg|288px]] |

'''Fig. 1.6 '''Niagara Falls Bridge [Courtesy of the Niagara Falls Bridge Commission] | '''Fig. 1.6 '''Niagara Falls Bridge [Courtesy of the Niagara Falls Bridge Commission] | ||

| − | | style="vertical-align: top;"|<span style="text-align: center; font-size: 75%;"> [[Image:draft_Samper_432909089-image8.jpeg|270px]] </span> | + | | style="vertical-align: top;"|<span style="text-align: center; font-size: 75%;"> [[Image:draft_Samper_432909089-monograph-image8.jpeg|270px]] </span> |

'''Fig. 1.7 '''Brooklyn Bridge [from [http://www.elclubdigital.com] www.elclubdigital.com]] | '''Fig. 1.7 '''Brooklyn Bridge [from [http://www.elclubdigital.com] www.elclubdigital.com]] | ||

| Line 498: | Line 475: | ||

{| style="width: 100%;border-collapse: collapse;" | {| style="width: 100%;border-collapse: collapse;" | ||

|- | |- | ||

| − | | style="vertical-align: top;width: | + | | style="vertical-align: top;width: 50%;"|[[Image:draft_Samper_432909089-monograph-image9.jpeg|294px]] |

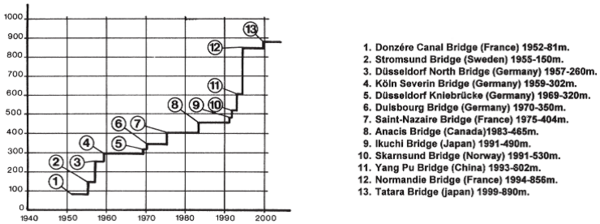

'''Fig. 1.8''' The Bridge over the Donzère Canal, France [photo: J. Kerisel] | '''Fig. 1.8''' The Bridge over the Donzère Canal, France [photo: J. Kerisel] | ||

| Line 505: | Line 482: | ||

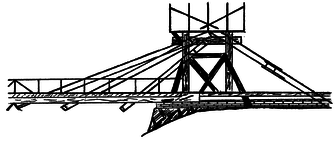

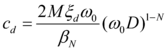

However, the real development came from Germany with papers published by Franz Dischinger and with the famous series of steel bridges crossing the river Rhine, as the Oberkassel Bridge, in Düsseldorf, Germany (Fig. 1.9). | However, the real development came from Germany with papers published by Franz Dischinger and with the famous series of steel bridges crossing the river Rhine, as the Oberkassel Bridge, in Düsseldorf, Germany (Fig. 1.9). | ||

|- | |- | ||

| − | | style="vertical-align: top;"|<span style="text-align: center; font-size: 75%;"> [[Image:draft_Samper_432909089-image10.jpeg|288px]] </span> | + | | style="vertical-align: top;"|<span style="text-align: center; font-size: 75%;"> [[Image:draft_Samper_432909089-monograph-image10.jpeg|288px]] </span> |

'''Fig. 1.9 '''Oberkassel Bridge, Düsseldorf, Germany | '''Fig. 1.9 '''Oberkassel Bridge, Düsseldorf, Germany | ||

| − | | style="vertical-align: top;"|<span style="text-align: center; font-size: 75%;"> [[Image:draft_Samper_432909089-image11.jpeg|282px]] </span> | + | | style="vertical-align: top;"|<span style="text-align: center; font-size: 75%;"> [[Image:draft_Samper_432909089-monograph-image11.jpeg|282px]] </span> |

'''Fig. 1.10''' Maracaibo Bridge, Venezuela [from en.structurae.de] | '''Fig. 1.10''' Maracaibo Bridge, Venezuela [from en.structurae.de] | ||

| Line 522: | Line 499: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;vertical-align: top;"|<span style="text-align: center; font-size: 75%;"> [[Image:draft_Samper_432909089-image12.jpeg|300px]] </span> | + | | style="text-align: center;vertical-align: top;"|<span style="text-align: center; font-size: 75%;"> [[Image:draft_Samper_432909089-monograph-image12.jpeg|300px]] </span> |

'''Fig. 1.11 '''Barrios de Luna Bridge, Spain [from en.structurae.de] | '''Fig. 1.11 '''Barrios de Luna Bridge, Spain [from en.structurae.de] | ||

| − | | style="text-align: center;vertical-align: top;width: | + | | style="text-align: center;vertical-align: top;width: 46%;"|[[Image:draft_Samper_432909089-monograph-image13.png|180px]] |

'''Fig. 1.12''' Yang Pu Bridge, China [photo: M. Virlogeux] | '''Fig. 1.12''' Yang Pu Bridge, China [photo: M. Virlogeux] | ||

|- | |- | ||

| − | | style="text-align: center;vertical-align: top;"|<span style="text-align: center; font-size: 75%;"> [[Image:draft_Samper_432909089-image14.jpeg|228px]] </span> | + | | style="text-align: center;vertical-align: top;"|<span style="text-align: center; font-size: 75%;"> [[Image:draft_Samper_432909089-monograph-image14.jpeg|228px]] </span> |

'''Fig. 1.13''' Normandie Bridge, France [from fr.structurae.de] | '''Fig. 1.13''' Normandie Bridge, France [from fr.structurae.de] | ||

| − | | style="text-align: center;vertical-align: top;width: | + | | style="text-align: center;vertical-align: top;width: 46%;"|[[Image:draft_Samper_432909089-monograph-image15.jpeg|288px]] |

'''Fig. 1.14''' Tatara Bridge, Japan [from [http://www.answers.com] www.answers.com]] | '''Fig. 1.14''' Tatara Bridge, Japan [from [http://www.answers.com] www.answers.com]] | ||

| Line 541: | Line 518: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image:draft_Samper_432909089-image16.png|600px]] </div> | + | [[Image:draft_Samper_432909089-monograph-image16.png|600px]] </div> |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 548: | Line 525: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;vertical-align: top;width: 50%;"| [[Image:draft_Samper_432909089-image17.png|192px]] | + | | style="text-align: center;vertical-align: top;width: 50%;"|[[Image:draft_Samper_432909089-monograph-image17.png|192px]] |

'''Fig. 1.16 '''Millau Bridge, France | '''Fig. 1.16 '''Millau Bridge, France | ||

| − | | | + | | style="vertical-align: top;width: 50%;"|[[Image:Draft_Samper_432909089_8898_monograph-image18.png|312px]] |

'''Fig. 1.17''' Sutong Bridge, Nantong, China | '''Fig. 1.17''' Sutong Bridge, Nantong, China | ||

| Line 561: | Line 538: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="vertical-align: top;width: | + | | style="vertical-align: top;width: 54%;"|[[Image:draft_Samper_432909089-monograph-image19-c.png|336px]] |

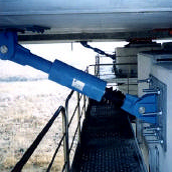

'''Fig. 1.18''' Rion-Antirion Viscous Dampers [Courtesy of ''FIP'' Industriale, Italy] | '''Fig. 1.18''' Rion-Antirion Viscous Dampers [Courtesy of ''FIP'' Industriale, Italy] | ||

| Line 572: | Line 549: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;vertical-align: top;width: | + | | style="text-align: center;vertical-align: top;width: 55%;"|[[Image:draft_Samper_432909089-monograph-image20.png|384px]] |

'''Fig. 1.19''' Dongting Lake Bridge, China | '''Fig. 1.19''' Dongting Lake Bridge, China | ||

| Line 580: | Line 557: | ||

|} | |} | ||

| + | ==Chapter 2. Fluid Viscous Damping Technology== | ||

| − | + | :<big>2.1 General Overview </big> | |

| − | <big> | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

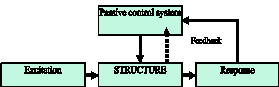

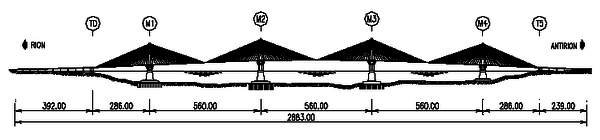

Structures situated on seismic areas must be designed to resist earthquake ground motions. A fundamental rule regarding the seismic design of structures, express that higher damping implies lower induced seismic forces. For conventional constructions, the induced earthquake energy is dissipated by the structural components of the system designed to resist gravity loads. It is well known that damping level during the elastic seismic behaviour is generally very low, which implies not much dissipated energy. During strong ground motion, energy dissipation can be reached through damage of important structural elements, and considering only the resulting response forces within the structure due to an earthquake leads to massive structural dimensions, stiff structures with enormous local energy accumulation and plastic hinges. This strengthening method combined with usual bearing arrangements permits plastic deformations by way of leading to yield stress and cracks. In this sense, structural repair after an important seismic event is generally very expensive, the structure is set temporarily out of service and sometimes a lot of damaged structures must be demolished [Alvarez, 2004]. | Structures situated on seismic areas must be designed to resist earthquake ground motions. A fundamental rule regarding the seismic design of structures, express that higher damping implies lower induced seismic forces. For conventional constructions, the induced earthquake energy is dissipated by the structural components of the system designed to resist gravity loads. It is well known that damping level during the elastic seismic behaviour is generally very low, which implies not much dissipated energy. During strong ground motion, energy dissipation can be reached through damage of important structural elements, and considering only the resulting response forces within the structure due to an earthquake leads to massive structural dimensions, stiff structures with enormous local energy accumulation and plastic hinges. This strengthening method combined with usual bearing arrangements permits plastic deformations by way of leading to yield stress and cracks. In this sense, structural repair after an important seismic event is generally very expensive, the structure is set temporarily out of service and sometimes a lot of damaged structures must be demolished [Alvarez, 2004]. | ||

| Line 597: | Line 569: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="vertical-align: top;width: | + | | style="vertical-align: top;width: 55%;"|[[Image:draft_Samper_432909089-monograph-image21-c.png|318px]] |

'''Fig. 2.1 '''Block Diagram of Passive Control System [Symans and Constantinou, 1999] | '''Fig. 2.1 '''Block Diagram of Passive Control System [Symans and Constantinou, 1999] | ||

| Line 614: | Line 586: | ||

The new tendencies regarding the seismic analysis and design of fluid viscous dampers capture the frequency dependence of such devices [Singh ''et al'', 2003]; the earthquake response of non-linear fluid viscous dampers [Peckan ''et al'', 1999; Lin and Chopra, 2002]; the seismic performance and behaviour of these devices during near-field ground motion [Tan ''et al'', 2005; Xu ''et al'', 2007] and the performance-based design of viscous dampers [Kim ''et al'', 2003; Li and Liang, 2007]. A state-of-the-art review can be found in the works of Lee and Taylor (2001) and Symans ''et al'' (2008). | The new tendencies regarding the seismic analysis and design of fluid viscous dampers capture the frequency dependence of such devices [Singh ''et al'', 2003]; the earthquake response of non-linear fluid viscous dampers [Peckan ''et al'', 1999; Lin and Chopra, 2002]; the seismic performance and behaviour of these devices during near-field ground motion [Tan ''et al'', 2005; Xu ''et al'', 2007] and the performance-based design of viscous dampers [Kim ''et al'', 2003; Li and Liang, 2007]. A state-of-the-art review can be found in the works of Lee and Taylor (2001) and Symans ''et al'' (2008). | ||

| − | :<big> | + | :<big>2.2 Technological Aspects</big> |

| − | :<big> | + | :<big>2.2.1 Historical Background</big> |

As with many other types of engineered components, the requirements, needs and available funds from the military allowed rapid design evolution of fluid dampers to satisfy the needs of armed forces. Early fluid damping devices operated by viscous effects, where the operating medium was sheared by vanes or plates within the damper. Designs of this type were mere laboratory curiosities, since the maximum pressure available from shearing a fluid is limited by the onset of cavitation, which generally occurs at between 0.06 N/mm<sup>2</sup> and 0.1 N/mm<sup>2</sup>, depending on the viscosity of the fluid. This operating pressure was so low that for any given output level, a viscous damper was much larger and more costly than other types [Taylor, 1996]. | As with many other types of engineered components, the requirements, needs and available funds from the military allowed rapid design evolution of fluid dampers to satisfy the needs of armed forces. Early fluid damping devices operated by viscous effects, where the operating medium was sheared by vanes or plates within the damper. Designs of this type were mere laboratory curiosities, since the maximum pressure available from shearing a fluid is limited by the onset of cavitation, which generally occurs at between 0.06 N/mm<sup>2</sup> and 0.1 N/mm<sup>2</sup>, depending on the viscosity of the fluid. This operating pressure was so low that for any given output level, a viscous damper was much larger and more costly than other types [Taylor, 1996]. | ||

| Line 626: | Line 598: | ||

With the end of the Cold War in the late 80`s, much of this fully developed defence technology became available for civilian applications. In this context, demonstration of the benefits of damping technology on structures could take place immediately, using existing dampers and the seismic test facilities available at U.S. university research centres. In this sense, application of fluid viscous dampers as part of seismic energy dissipation systems was experimentally and analytically studied, being validated by extensive testing on one-sixth to one-half scale building and bridge models in the period 1990 – 1993 at the Multidisciplinary Centre for Earthquake Engineering Research (MCEER), located on the campus of the State University of New York at Buffalo in USA. Thus, implementation of fluid viscous damping technology began relatively swiftly, with wind protection usage beginning in 1993, and seismic protection usage beginning in 1995 [Taylor and Duflot, 2002]. | With the end of the Cold War in the late 80`s, much of this fully developed defence technology became available for civilian applications. In this context, demonstration of the benefits of damping technology on structures could take place immediately, using existing dampers and the seismic test facilities available at U.S. university research centres. In this sense, application of fluid viscous dampers as part of seismic energy dissipation systems was experimentally and analytically studied, being validated by extensive testing on one-sixth to one-half scale building and bridge models in the period 1990 – 1993 at the Multidisciplinary Centre for Earthquake Engineering Research (MCEER), located on the campus of the State University of New York at Buffalo in USA. Thus, implementation of fluid viscous damping technology began relatively swiftly, with wind protection usage beginning in 1993, and seismic protection usage beginning in 1995 [Taylor and Duflot, 2002]. | ||

| − | :<big> | + | :<big>2.2.2 General Behaviour</big> |

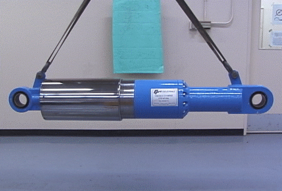

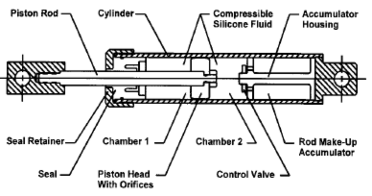

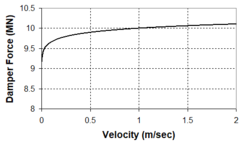

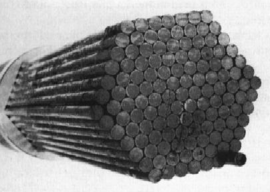

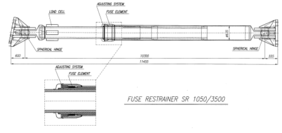

Fluid viscous dampers operate on the principle of fluid flow through orifices. A stainless steel piston travels through chambers that are filled with silicone oil. The silicone oil is inert, non flammable, non toxic and stable for extremely long periods of time. The pressure difference between the two chambers cause silicone oil to flow through an orifice in the piston head and seismic energy is transformed into heat, which dissipates into the atmosphere. This associated temperature increase can be significant, particularly when the damper is subjected to long-duration or large-amplitude motions [Makris 1998; Makris ''et al'', 1998]. Mechanisms are available to compensate for the temperature rise such that the influence on the damper behaviour is relatively minor [Soong and Dargush, 1997]. However, the increase in temperature may be of concern due to the potential for heat-induced damage to the damper seals. In this case, the temperature rise can be reduced by reducing the pressure differential across the piston head (e.g., by employing a damper with a larger piston head) [Makris ''et al'', 1998]. Interestingly, although the damper is called a ''fluid viscous damper'', the fluid typically has a relatively low viscosity (e.g., silicone oil with a kinematic viscosity on the order of 0.001 m<sup>2</sup> /s at 20°C). The term ''fluid viscous damper ''is associated with the macroscopic behaviour of the damper which is essentially the same as that of an ideal linear or nonlinear viscous dashpot (i.e., the resisting force is directly related to the velocity). Generally, the fluid damper includes a double-ended piston rod (i.e., the piston rod projects outward from both sides of the piston head and exits the damper at both ends of the main cylinder). Such configurations are useful for minimizing the development of restoring forces (stiffness) due to fluid compression [Symans ''et al'', 2008]. The force/velocity relationship for this kind of damper can be characterized as ''F = C.V<sup>α</sup>'' where ''F'' is the output force, ''V'' the relative velocity across the damper; ''C'' is the damping coefficient and ''α'' is a constant exponent which is usually a value between 0.1 and 1.0 for earthquake protection, although at the present time some manufactures begin to apply dampers with very low damping coefficients, typically in the order of 0.02. Fluid viscous dampers can operate over temperature fluctuations ranging from –40°C to +70°C, and they have the unique ability to simultaneously reduce both stress and deflection within a structure subjected to a transient. This is because a fluid viscous damper varies its force only with velocity, which provides a response that is inherently out-of-phase with stresses due to flexing of the structure [Taylor and Duflot, 2002]. | Fluid viscous dampers operate on the principle of fluid flow through orifices. A stainless steel piston travels through chambers that are filled with silicone oil. The silicone oil is inert, non flammable, non toxic and stable for extremely long periods of time. The pressure difference between the two chambers cause silicone oil to flow through an orifice in the piston head and seismic energy is transformed into heat, which dissipates into the atmosphere. This associated temperature increase can be significant, particularly when the damper is subjected to long-duration or large-amplitude motions [Makris 1998; Makris ''et al'', 1998]. Mechanisms are available to compensate for the temperature rise such that the influence on the damper behaviour is relatively minor [Soong and Dargush, 1997]. However, the increase in temperature may be of concern due to the potential for heat-induced damage to the damper seals. In this case, the temperature rise can be reduced by reducing the pressure differential across the piston head (e.g., by employing a damper with a larger piston head) [Makris ''et al'', 1998]. Interestingly, although the damper is called a ''fluid viscous damper'', the fluid typically has a relatively low viscosity (e.g., silicone oil with a kinematic viscosity on the order of 0.001 m<sup>2</sup> /s at 20°C). The term ''fluid viscous damper ''is associated with the macroscopic behaviour of the damper which is essentially the same as that of an ideal linear or nonlinear viscous dashpot (i.e., the resisting force is directly related to the velocity). Generally, the fluid damper includes a double-ended piston rod (i.e., the piston rod projects outward from both sides of the piston head and exits the damper at both ends of the main cylinder). Such configurations are useful for minimizing the development of restoring forces (stiffness) due to fluid compression [Symans ''et al'', 2008]. The force/velocity relationship for this kind of damper can be characterized as ''F = C.V<sup>α</sup>'' where ''F'' is the output force, ''V'' the relative velocity across the damper; ''C'' is the damping coefficient and ''α'' is a constant exponent which is usually a value between 0.1 and 1.0 for earthquake protection, although at the present time some manufactures begin to apply dampers with very low damping coefficients, typically in the order of 0.02. Fluid viscous dampers can operate over temperature fluctuations ranging from –40°C to +70°C, and they have the unique ability to simultaneously reduce both stress and deflection within a structure subjected to a transient. This is because a fluid viscous damper varies its force only with velocity, which provides a response that is inherently out-of-phase with stresses due to flexing of the structure [Taylor and Duflot, 2002]. | ||

| Line 634: | Line 606: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;vertical-align: top;width: 50%;"| [[Image:draft_Samper_432909089-image22.png|282px]] | + | | style="text-align: center;vertical-align: top;width: 50%;"|[[Image:draft_Samper_432909089-monograph-image22.png|282px]] |

'''Fig 2.2 '''General view of a Fluid Viscous Damper [Courtesy of ''FIP ''Industriale s.P.a., Italy] | '''Fig 2.2 '''General view of a Fluid Viscous Damper [Courtesy of ''FIP ''Industriale s.P.a., Italy] | ||

| − | | style="text-align: center;vertical-align: top;width: 50%;"| [[Image:draft_Samper_432909089-image23.jpeg|252px]] | + | | style="text-align: center;vertical-align: top;width: 50%;"|[[Image:draft_Samper_432909089-monograph-image23.jpeg|252px]] |

'''Fig. 2.3 '''Fluid Viscous Dampers for De Las Piedras-High Speed Railway Bridge, Spain [Courtesy of ''Maurer Sönhe'', Germany] | '''Fig. 2.3 '''Fluid Viscous Dampers for De Las Piedras-High Speed Railway Bridge, Spain [Courtesy of ''Maurer Sönhe'', Germany] | ||

| Line 647: | Line 619: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;vertical-align: top;width: | + | | style="text-align: center;vertical-align: top;width: 59%;"|[[Image:draft_Samper_432909089-monograph-image24.png|372px]] |

'''Fig. 2.4''' Typical Viscous Damper [Lee and Taylor, 2001] | '''Fig. 2.4''' Typical Viscous Damper [Lee and Taylor, 2001] | ||

| Line 668: | Line 640: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;vertical-align: top;width: 50%;"| [[Image:draft_Samper_432909089-image25.png|264px]] | + | | style="text-align: center;vertical-align: top;width: 50%;"|[[Image:draft_Samper_432909089-monograph-image25.png|264px]] |

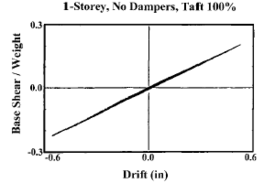

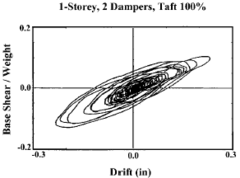

'''Fig. 2.5''' Typical Plot of Base Shear Against Interstorey Drift [Lee and Taylor, 2001] | '''Fig. 2.5''' Typical Plot of Base Shear Against Interstorey Drift [Lee and Taylor, 2001] | ||

| − | | style="text-align: center;vertical-align: top;width: 50%;"| [[Image:draft_Samper_432909089-image26.png|240px]] | + | | style="text-align: center;vertical-align: top;width: 50%;"|[[Image:draft_Samper_432909089-monograph-image26.png|240px]] |

'''Fig. 2.6''' Base Shear Against Interstorey Drift with Added Dampers [Lee and Taylor, 2001] | '''Fig. 2.6''' Base Shear Against Interstorey Drift with Added Dampers [Lee and Taylor, 2001] | ||

| Line 710: | Line 682: | ||

| style="vertical-align: top;"|In terms of the efficiency, the damping coefficient ξ relates to the efficiency η according to: | | style="vertical-align: top;"|In terms of the efficiency, the damping coefficient ξ relates to the efficiency η according to: | ||

| − | + | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image27.png|54px]] [Eq. 2.1] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

This ends up in a maximum efficiency ''η = 96% ''for fluid viscous dampers. | This ends up in a maximum efficiency ''η = 96% ''for fluid viscous dampers. | ||

|} | |} | ||

| Line 743: | Line 709: | ||

:* Non-toxic, not inflammable and not ageing fluids are applied. | :* Non-toxic, not inflammable and not ageing fluids are applied. | ||

| − | :<big> | + | :<big>2.2.3 Application to Bridges</big> |

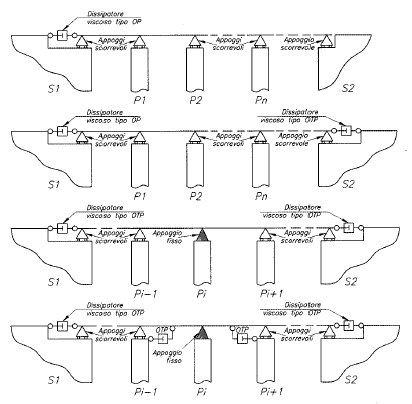

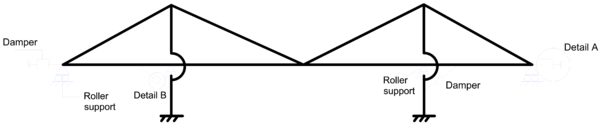

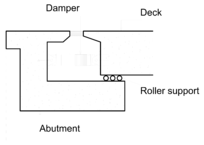

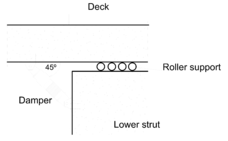

Decks for viaducts and long-span bridges require adequate expansion joints for large displacements under service conditions to absorb the effects of creep and thermal expansion. A common structural layout used in Europe, consists of continuous deck supported by ''POT'' devices [Priestley ''et al'', 1996]. By this way, the idea of employing devices with an insignificant response under long-period displacements and at the same time, capable of dissipating much induced seismic energy, was developed. | Decks for viaducts and long-span bridges require adequate expansion joints for large displacements under service conditions to absorb the effects of creep and thermal expansion. A common structural layout used in Europe, consists of continuous deck supported by ''POT'' devices [Priestley ''et al'', 1996]. By this way, the idea of employing devices with an insignificant response under long-period displacements and at the same time, capable of dissipating much induced seismic energy, was developed. | ||

| Line 754: | Line 720: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <big>''' [[Image:draft_Samper_432909089-image28-c.png|432px]] '''</big></div> | + | <big>''' [[Image:draft_Samper_432909089-monograph-image28-c.png|432px]] '''</big></div> |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 761: | Line 727: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="vertical-align: top;width: 50%;"| [[Image:draft_Samper_432909089-image29.jpeg|276px]] | + | | style="vertical-align: top;width: 50%;"|[[Image:draft_Samper_432909089-monograph-image29.jpeg|276px]] |

'''Fig. 2.8''' Fluid Viscous Dampers at G4-Egnatia Motorway Bridge, Greece [Courtesy of ''Maurer Sönhe,'' Germany] | '''Fig. 2.8''' Fluid Viscous Dampers at G4-Egnatia Motorway Bridge, Greece [Courtesy of ''Maurer Sönhe,'' Germany] | ||

| − | | style="vertical-align: top;width: 50%;"| [[Image:draft_Samper_432909089-image30.png|228px]] | + | | style="vertical-align: top;width: 50%;"|[[Image:draft_Samper_432909089-monograph-image30.png|228px]] |

'''Fig. 2.9''' 850 kN Capacity Damper for the Chun-Su Bridge, South Korea [Courtesy of ''FIP ''Industriale s.P.a., Italy] | '''Fig. 2.9''' 850 kN Capacity Damper for the Chun-Su Bridge, South Korea [Courtesy of ''FIP ''Industriale s.P.a., Italy] | ||

| Line 770: | Line 736: | ||

| − | :<big> | + | :<big>2.3 Mechanical Behaviour</big> |

| − | :<big> | + | :<big>2.3.1 Energy Approach</big> |

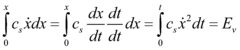

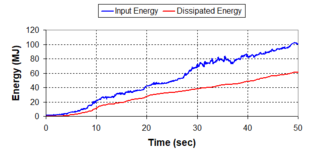

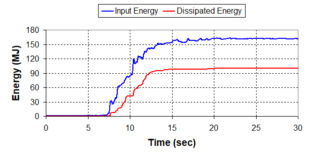

An earthquake is an energy phenomenon and therefore this energy character should be considered to achieve the best possible seismic protection for the structure. Without seismic protection system, the seismic energy is entering the structure very concentrated at the fixed axis. By means of shock transmission units the entering energy is distributed to several spots within the structure. In this case the energy input into the structure is still in same magnitude like without those devices, but now the energy is spread over the entire structure in more portions. By implementing additional energy dissipation capability, less energy is entering the structure, with the consequent response mitigation. | An earthquake is an energy phenomenon and therefore this energy character should be considered to achieve the best possible seismic protection for the structure. Without seismic protection system, the seismic energy is entering the structure very concentrated at the fixed axis. By means of shock transmission units the entering energy is distributed to several spots within the structure. In this case the energy input into the structure is still in same magnitude like without those devices, but now the energy is spread over the entire structure in more portions. By implementing additional energy dissipation capability, less energy is entering the structure, with the consequent response mitigation. | ||

| Line 778: | Line 744: | ||

The principles of physics that govern the effects of dissipation on the control of dynamic phenomena were studied more than two centuries ago [D`Alembert, Traité de Dynamique, 1743]. Nonetheless, their practical application has come about much later and within a much different time-frame in several sectors of engineering. As was previously exposed, the sector that was the first to adopt such damping technology was the military [France, 1897], followed by the automobile industry. In 1956 Housner already suggested an energy-based design of structures. Kato and Akiyama (1975) and Uang and Bertero (1990) made a valuable contribution to the development of the aspects of an energy-based approach, which presently meets with great concensus. | The principles of physics that govern the effects of dissipation on the control of dynamic phenomena were studied more than two centuries ago [D`Alembert, Traité de Dynamique, 1743]. Nonetheless, their practical application has come about much later and within a much different time-frame in several sectors of engineering. As was previously exposed, the sector that was the first to adopt such damping technology was the military [France, 1897], followed by the automobile industry. In 1956 Housner already suggested an energy-based design of structures. Kato and Akiyama (1975) and Uang and Bertero (1990) made a valuable contribution to the development of the aspects of an energy-based approach, which presently meets with great concensus. | ||

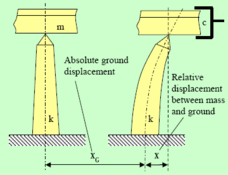

| − | The dynamic equation of a single-degree-of-freedom structure with mass ''m<sub>s</sub>'' damping coefficient ''c<sub>s</sub>'', stiffness ''k<sub>s</sub> ''and control force ''u'', subject to ground acceleration '' [[Image:draft_Samper_432909089-image31.png|36px]] ''is: | + | The dynamic equation of a single-degree-of-freedom structure with mass ''m<sub>s</sub>'' damping coefficient ''c<sub>s</sub>'', stiffness ''k<sub>s</sub> ''and control force ''u'', subject to ground acceleration '' [[Image:draft_Samper_432909089-monograph-image31.png|36px]] ''is: |

| − | + | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image32.png|234px]] [Eq. 2.2] | |

| − | + | ||

| − | + | where [[Image:draft_Samper_432909089-monograph-image33.png|30px]] , [[Image:draft_Samper_432909089-monograph-image34.png|30px]] and [[Image:draft_Samper_432909089-monograph-image35.png|30px]] are the displacement, velocity and acceleration responses respectively. The involved parameters are clearly explained in Fig. 2.10, which shows a simplified scheme for a single-degree-of-freedom system. Of course, each term in Eq. 2.2 is a force. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | where | + | |

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;vertical-align: top;width: | + | | style="text-align: center;vertical-align: top;width: 44%;"|[[Image:draft_Samper_432909089-monograph-image36.png|228px]] |

'''Fig. 2.10''' Complex Bridge Structure Explained with a Simplified Single Oscillation Mass | '''Fig. 2.10''' Complex Bridge Structure Explained with a Simplified Single Oscillation Mass | ||

| style="vertical-align: top;"|Integrating Eq. 2.2 with respect to ''x:'' | | style="vertical-align: top;"|Integrating Eq. 2.2 with respect to ''x:'' | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image37.png|354px]] | |

where each term is now an energy component. Thus, we can define: | where each term is now an energy component. Thus, we can define: | ||

| − | + | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image38.png|276px]] [Eq. 2.3] | |

| − | + | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image39.png|240px]] [Eq. 2.4] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | | | + | |

| − | + | ||

|} | |} | ||

| − | + | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image40.png|138px]] [Eq. 2.5] | |

| − | + | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image41.png|72px]] [Eq. 2.6] | |

| − | + | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image42.png|102px]] [Eq. 2.7] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

An energy balance equation can be proposed in terms of the above defined: | An energy balance equation can be proposed in terms of the above defined: | ||

| − | + | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image43.png|240px]] [Eq. 2.8] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

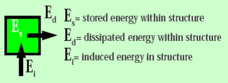

where: | where: | ||

| Line 857: | Line 793: | ||

{| style="width: 100%;border-collapse: collapse;" | {| style="width: 100%;border-collapse: collapse;" | ||

|- | |- | ||

| − | | style="vertical-align: top;width: | + | | style="vertical-align: top;width: 40%;"|[[Image:draft_Samper_432909089-monograph-image44.png|228px]] |

| style="vertical-align: top;"|'''Fig. 2.11 '''Concept of Energy Approach Considering the Energy Exchange Between Structure and Environment | | style="vertical-align: top;"|'''Fig. 2.11 '''Concept of Energy Approach Considering the Energy Exchange Between Structure and Environment | ||

|} | |} | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image45.png|84px]] : Stored energy within structure | |

| − | + | [[Image:draft_Samper_432909089-monograph-image46.png|90px]] : Dissipated energy within structure | |

Thus: | Thus: | ||

| − | + | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image47.png|84px]] [Eq. 2.9] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

The control force ''u'' by non-linear viscous dampers with damping coefficient ''c<sub>d</sub>'' is expressed as | The control force ''u'' by non-linear viscous dampers with damping coefficient ''c<sub>d</sub>'' is expressed as | ||

| − | <div style="text-align: | + | <div style="text-align: left; direction: ltr; margin-left: 1em;"> |

| − | [[Image:draft_Samper_432909089-image48.png|120px]] [Eq. 2.10]</div> | + | [[Image:draft_Samper_432909089-monograph-image48.png|120px]] [Eq. 2.10]</div> |

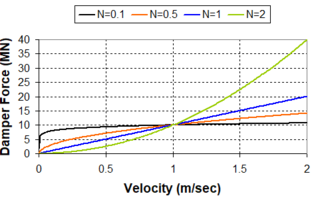

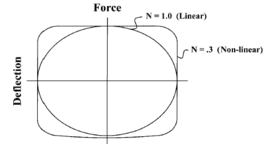

In Eq. 2.10, the exponent ''N'' controls the damper nonlinearity and has typical values in the range of 0.10 to 1.0 for seismic applications. For the special case of ''N = 1'', Eq. 2.10 represents the force applied by linear viscous dampers. In the case of ''N = 0, ''Eq. 2.10 changes to a friction damper as follows: | In Eq. 2.10, the exponent ''N'' controls the damper nonlinearity and has typical values in the range of 0.10 to 1.0 for seismic applications. For the special case of ''N = 1'', Eq. 2.10 represents the force applied by linear viscous dampers. In the case of ''N = 0, ''Eq. 2.10 changes to a friction damper as follows: | ||

| − | <div style="text-align: | + | <div style="text-align: left; direction: ltr; margin-left: 1em;"> |

| − | [[Image:draft_Samper_432909089-image49.png|90px]] [Eq. 2.11]</div> | + | [[Image:draft_Samper_432909089-monograph-image49.png|90px]] [Eq. 2.11]</div> |

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;vertical-align: top;width: | + | | style="text-align: center;vertical-align: top;width: 55%;"|[[Image:draft_Samper_432909089-monograph-image50-c.png|312px]] |

'''Fig. 2.12''' Plot of Force Against Velocity for Several Values of Damping Exponent ''N'' | '''Fig. 2.12''' Plot of Force Against Velocity for Several Values of Damping Exponent ''N'' | ||

| Line 898: | Line 828: | ||

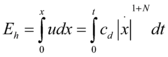

Applying the force – velocity relationship expressed in Eq. 2.10 to Eq. 2.6 results: | Applying the force – velocity relationship expressed in Eq. 2.10 to Eq. 2.6 results: | ||

| − | + | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image51.png|168px]] [Eq. 2.12] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

which represents the dissipated energy for a non-linear fluid viscous damper. The hysteretic behaviour of fluid viscous dampers can be plotted and shown in Fig. 2.13. | which represents the dissipated energy for a non-linear fluid viscous damper. The hysteretic behaviour of fluid viscous dampers can be plotted and shown in Fig. 2.13. | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;vertical-align: top;width: | + | | style="text-align: center;vertical-align: top;width: 65%;"|[[Image:draft_Samper_432909089-monograph-image52.png|264px]] |

'''Fig. 2.13''' Hysteresis Loops for Linear and Non-linear Fluid Viscous Dampers [Lee and Taylor, 2001] | '''Fig. 2.13''' Hysteresis Loops for Linear and Non-linear Fluid Viscous Dampers [Lee and Taylor, 2001] | ||

| Line 921: | Line 845: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <big>''' [[Image:draft_Samper_432909089-image53.png|486px]] '''</big></div> | + | <big>''' [[Image:draft_Samper_432909089-monograph-image53.png|486px]] '''</big></div> |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

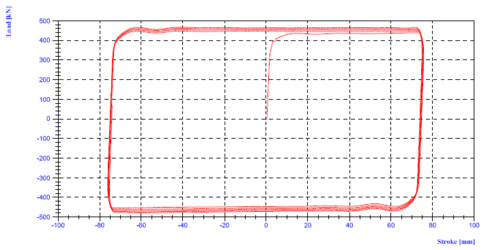

'''Fig. 2.14''' Force – Displacement Hysteretic Diagram of a Viscous Damper, ''N = 0.15'' [Courtesy of ''FIP ''Industriale, s.P.a., Italy]</div> | '''Fig. 2.14''' Force – Displacement Hysteretic Diagram of a Viscous Damper, ''N = 0.15'' [Courtesy of ''FIP ''Industriale, s.P.a., Italy]</div> | ||

| − | :<big> | + | :<big>2.3.2 Effect of the Damper Parameters</big> |

| − | :'' | + | :''2.3.2.1 Damping coefficient c<sub>d</sub>'' |

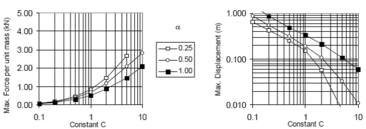

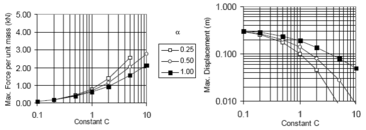

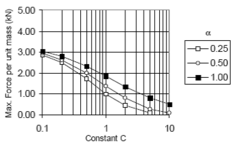

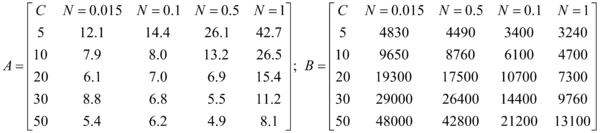

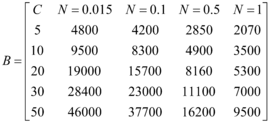

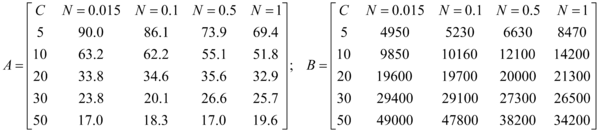

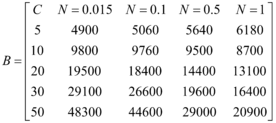

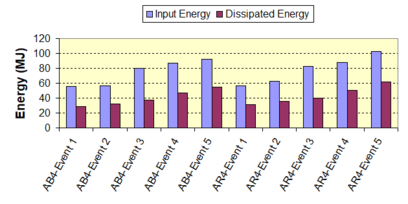

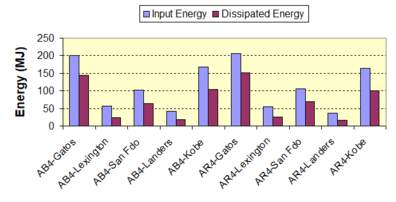

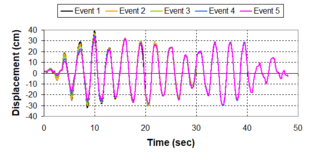

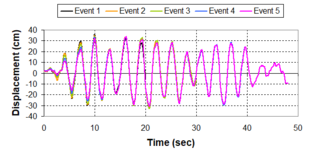

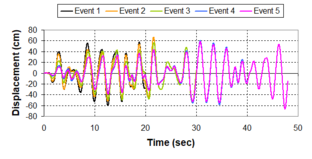

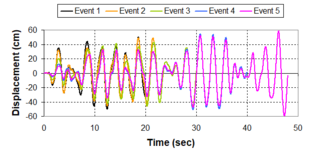

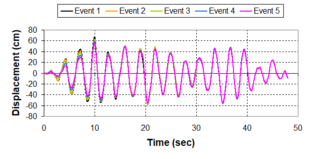

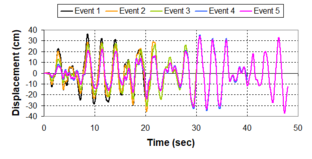

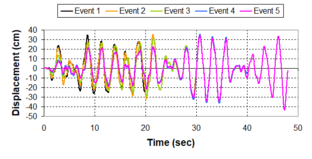

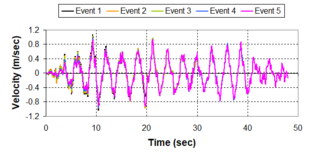

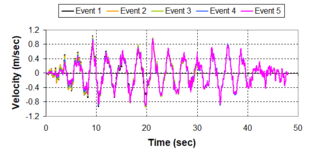

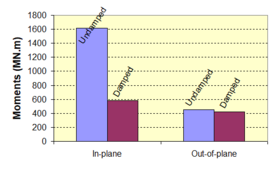

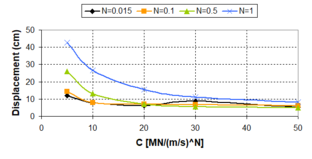

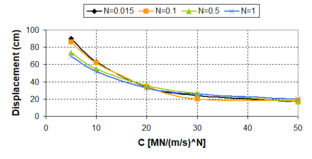

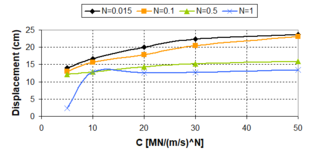

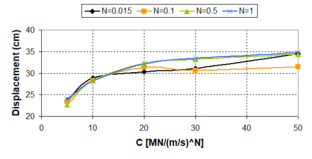

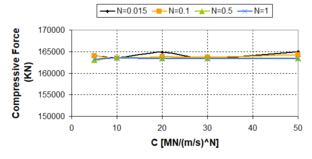

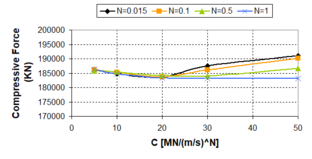

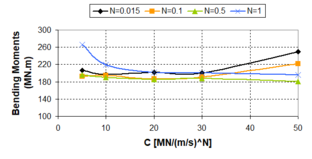

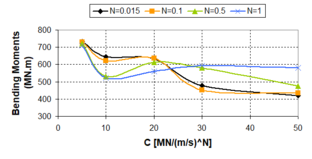

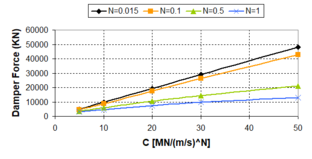

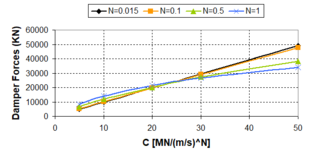

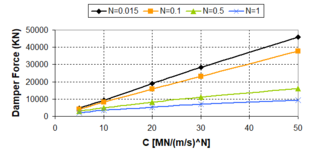

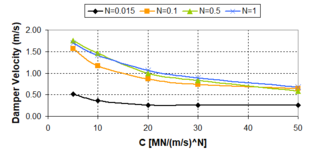

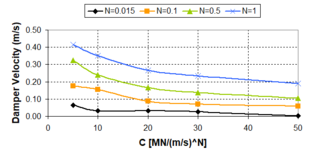

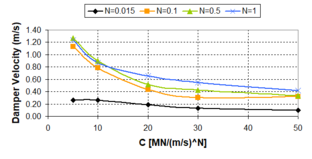

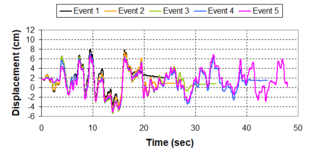

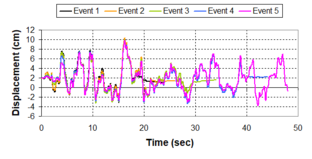

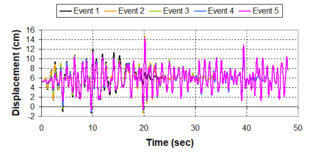

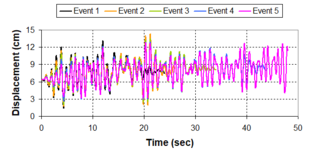

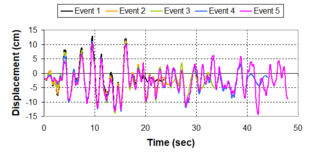

In general terms, for viscous dampers, ''c<sub>d</sub>'' does not affect the shape of the hysteretic force – displacement cycle; however, an increase of the value of this parameter increases the energy dissipation capacity and the maximum force in the device [Guerreiro, 2006]. In this sense, the work carried out by Virtuoso ''et al ''(2000) studies the modelling of the seismic behaviour of bridges with added viscous dampers, analyzing the effects of the constant ''c<sub>d</sub>'' (here called ''C'')''.'' To allow an analysis on the influence of that parameter on the structural response, values of the constant ''C ''between 0.10 and 10 were considered, since those values, together with the values considered for the parameter ''N ''(here called ''α''), will cover forces corresponding to seismic coefficient varying from 1% to 50% of the weight. In this study a set of five artificial accelerograms compatible with the response spectrum defined in Eurocode 8 – Part 2 [CEN, 1998b] with a peak ground acceleration of 0.30g, type B soil and 30 sec total duration of the series, were used. Two extreme cases were considered: a solution without elastic stiffness (deck totally free over the piers) and a solution with elastic stiffness (low stiffness elastic connection between the piers and the deck). Also, in this research the configurations of the force – velocity relation curves were presented for different values of ''α'', corresponding to the linear branch, which, were defined by the origin and the point corresponding to 10% of the maximum velocity and force corresponding to the defined seismic action and obtained without the consideration of the linear branch. Figs. 2.15 and 2.16 show maximum forces and displacements in the viscous damper without and with elastic stiffness respectively. They show that solution involving a higher displacement control always lead to higher force levels in the device. It is also possible to observe that the more efficient solutions, with better displacement control for the same force level, generally corresponds to low ''α'' values. Likewise, for device solutions with low values of the constant ''C'', the elastic stiffness of the structure has an important contribution on the displacement control. It is important to notice that the contribution of the elastic force is out of phase with the one transmitted by the devices, what means that, in a solution of this type there is always a force restraining the movement of the deck. The problem is that the forces transmitted to the structure must be controlled to limit the contribution of the piers to values lower than their elastic limit. | In general terms, for viscous dampers, ''c<sub>d</sub>'' does not affect the shape of the hysteretic force – displacement cycle; however, an increase of the value of this parameter increases the energy dissipation capacity and the maximum force in the device [Guerreiro, 2006]. In this sense, the work carried out by Virtuoso ''et al ''(2000) studies the modelling of the seismic behaviour of bridges with added viscous dampers, analyzing the effects of the constant ''c<sub>d</sub>'' (here called ''C'')''.'' To allow an analysis on the influence of that parameter on the structural response, values of the constant ''C ''between 0.10 and 10 were considered, since those values, together with the values considered for the parameter ''N ''(here called ''α''), will cover forces corresponding to seismic coefficient varying from 1% to 50% of the weight. In this study a set of five artificial accelerograms compatible with the response spectrum defined in Eurocode 8 – Part 2 [CEN, 1998b] with a peak ground acceleration of 0.30g, type B soil and 30 sec total duration of the series, were used. Two extreme cases were considered: a solution without elastic stiffness (deck totally free over the piers) and a solution with elastic stiffness (low stiffness elastic connection between the piers and the deck). Also, in this research the configurations of the force – velocity relation curves were presented for different values of ''α'', corresponding to the linear branch, which, were defined by the origin and the point corresponding to 10% of the maximum velocity and force corresponding to the defined seismic action and obtained without the consideration of the linear branch. Figs. 2.15 and 2.16 show maximum forces and displacements in the viscous damper without and with elastic stiffness respectively. They show that solution involving a higher displacement control always lead to higher force levels in the device. It is also possible to observe that the more efficient solutions, with better displacement control for the same force level, generally corresponds to low ''α'' values. Likewise, for device solutions with low values of the constant ''C'', the elastic stiffness of the structure has an important contribution on the displacement control. It is important to notice that the contribution of the elastic force is out of phase with the one transmitted by the devices, what means that, in a solution of this type there is always a force restraining the movement of the deck. The problem is that the forces transmitted to the structure must be controlled to limit the contribution of the piers to values lower than their elastic limit. | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image:draft_Samper_432909089-image54.png|366px]] </div> | + | [[Image:draft_Samper_432909089-monograph-image54.png|366px]] </div> |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 939: | Line 863: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image:draft_Samper_432909089-image55.png|366px]] </div> | + | [[Image:draft_Samper_432909089-monograph-image55.png|366px]] </div> |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 950: | Line 874: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

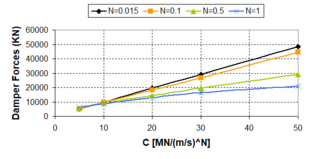

| − | | style="vertical-align: top;width: | + | | style="vertical-align: top;width: 61%;"|[[Image:draft_Samper_432909089-monograph-image56.png|234px]] |

'''Fig. 2.17 '''Maximum Forces in the Structure – Solution with Dampers and Elastic Stiffness [Virtuoso ''et al'', 2000] | '''Fig. 2.17 '''Maximum Forces in the Structure – Solution with Dampers and Elastic Stiffness [Virtuoso ''et al'', 2000] | ||

| Line 959: | Line 883: | ||

| − | :'' | + | :''2.3.2.2 Velocity exponent N'' |

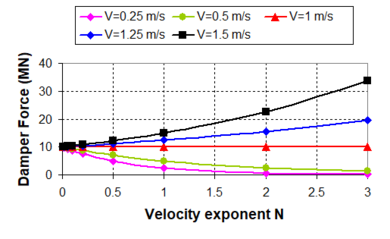

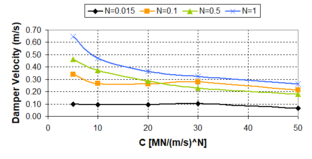

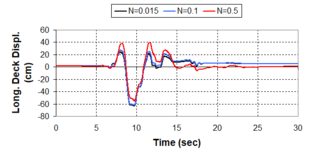

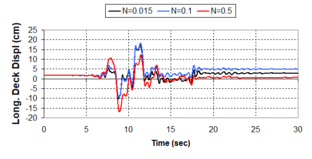

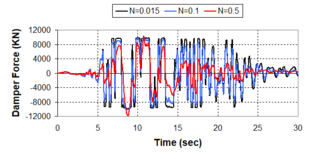

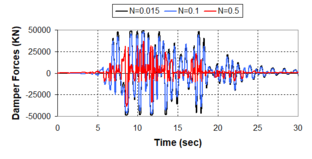

The damping exponent ''N'' represents the essence of the non-linear behaviour of fluid viscous dampers. On the contrary of the damping coefficient ''c<sub>d</sub>'', this parameter does not affect the size of the hysteretic force-displacement cycle and for that reason incidence of this parameter on the seismic response is not decisive as occurs with the damping coefficient, aspect enlarged in 2.3.2.1. Changes in the ''N-''exponent imply changes in the shape of the hysteretic force-displacement cycle, as was explained in Fig. 2.13. Low damping exponents tend to expose rectangular force-displacement hysteresis, as well as linear behaviour implies more elliptical force-displacement hysteresis cycles. The more practical incidence of the ''N-''exponent relates with the damper forces, depending on the relative velocities. | The damping exponent ''N'' represents the essence of the non-linear behaviour of fluid viscous dampers. On the contrary of the damping coefficient ''c<sub>d</sub>'', this parameter does not affect the size of the hysteretic force-displacement cycle and for that reason incidence of this parameter on the seismic response is not decisive as occurs with the damping coefficient, aspect enlarged in 2.3.2.1. Changes in the ''N-''exponent imply changes in the shape of the hysteretic force-displacement cycle, as was explained in Fig. 2.13. Low damping exponents tend to expose rectangular force-displacement hysteresis, as well as linear behaviour implies more elliptical force-displacement hysteresis cycles. The more practical incidence of the ''N-''exponent relates with the damper forces, depending on the relative velocities. | ||

| Line 965: | Line 889: | ||

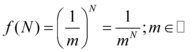

If we consider the force at the dampers ''F'' as a function of the exponent ''N'', we can write | If we consider the force at the dampers ''F'' as a function of the exponent ''N'', we can write | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image57.png|90px]] where ''c<sub>d</sub>'' is a constant. | |

| − | If ''c<sub>d</sub>'' is constant, ''F'' is maximum if '' | + | If ''c<sub>d</sub>'' is constant, ''F'' is maximum if '' [[Image:draft_Samper_432909089-monograph-image58.png|18px]] ''is maximum. |

| − | Let | + | Let [[Image:draft_Samper_432909089-monograph-image59.png|78px]] .Maximizing ''f'': |

| − | + | [[Image:draft_Samper_432909089-monograph-image60.png|144px]] if and only if | |

{| | {| | ||

|- | |- | ||

| − | | | + | | [[Image:draft_Samper_432909089-monograph-image61.png|126px]] |

| − | | | + | | [[Image:draft_Samper_432909089-monograph-image62.png|center|150px]] |

|} | |} | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image63.png|60px]] if and only if [[Image:draft_Samper_432909089-monograph-image64.png|36px]] which implies a constant force ''F = c<sub>d</sub>'' | |

Analyzing ''f'' in its domain: | Analyzing ''f'' in its domain: | ||

| − | :(1) If | + | :(1) If [[Image:draft_Samper_432909089-monograph-image65.png|36px]] then ''f'' is maximum if ''N'' is maximum, that is to say, if [[Image:draft_Samper_432909089-monograph-image66.png|54px]] |

| − | :(2) If | + | :(2) If [[Image:draft_Samper_432909089-monograph-image67.png|60px]] then [[Image:draft_Samper_432909089-monograph-image68.png|78px]] can be written as [[Image:draft_Samper_432909089-monograph-image69.png|192px]] . |

| − | Then, ''f'' is maximum if | + | Then, ''f'' is maximum if [[Image:draft_Samper_432909089-monograph-image70.png|24px]] is little, which implies [[Image:draft_Samper_432909089-monograph-image71.png|48px]] . |

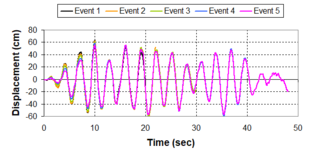

| − | This analytical approach shows that the critical point is | + | This analytical approach shows that the critical point is [[Image:draft_Samper_432909089-monograph-image72.png|36px]] . Being the damper velocities larger than 1, the maximum damper forces are obtained for high values of the damping exponent, on the contrary of the case where the damper velocities are lower than 1, in which the maximum damper forces are obtained when ''N'' is close to zero, that is to say, for non-linear dampers. Graphically, the above-mentioned can be clearly exposed in Fig. 2.18. Fig. 2.18 exposes variations of the dampers forces with the velocity exponent ''N'' for some common damper velocities. From these results, it is necessary to be cautious if velocity pulses are considered in the presence of linear dampers or dampers with ''N'' > 1. Likewise, similar considerations are necessary to take into account if non-linear dampers are considered in the presence of low velocities. |

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;vertical-align: top;width: | + | | style="text-align: center;vertical-align: top;width: 61%;"|[[Image:draft_Samper_432909089-monograph-image73.png|390px]] |

'''Fig. 2.18''' Plot of Damper Forces as Function of the ''N''-exponent for Several Velocities and ''c<sub>d</sub>'' = 10 MN/(m/s)<sup>N</sup> | '''Fig. 2.18''' Plot of Damper Forces as Function of the ''N''-exponent for Several Velocities and ''c<sub>d</sub>'' = 10 MN/(m/s)<sup>N</sup> | ||

| Line 1,128: | Line 1,052: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;vertical-align: top;width: 47%;"| [[Image:draft_Samper_432909089-image74-c.png|240px]] | + | | style="text-align: center;vertical-align: top;width: 47%;"|[[Image:draft_Samper_432909089-monograph-image74-c.png|240px]] |

'''Fig. 2.19''' Extra-low Damping for Viscous Damper with ''N''=0.015 | '''Fig. 2.19''' Extra-low Damping for Viscous Damper with ''N''=0.015 | ||

| Line 1,137: | Line 1,061: | ||

| − | :<big> | + | :<big>2.3.3 Non-linear Viscous Dampers</big> |

| − | :'' | + | :''2.3.3.1 Earthquake response'' |

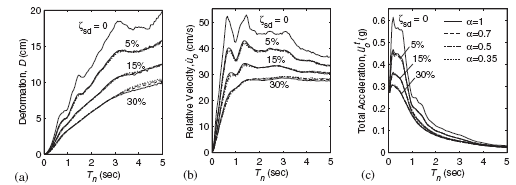

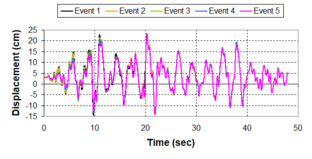

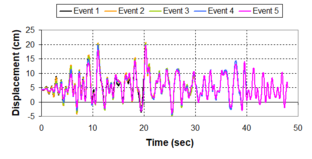

Numerous experimental and analytical investigations have focused on linear fluid viscous dampers, because they can be modelled simply by a linear dashpot. While being effective in reducing seismic demands on the structure, linear viscous dampers may develop excessive damper forces in applications where large structural velocities can occur, as for example in long period structures subjected to intense ground shaking, especially in the near-fault region. Recently, some researchers and earthquake engineering professionals have begun to focus on fluid viscous dampers exhibiting non-linear Force-Velocity relationship because of their ability to limit the peak damper force at large structural velocities while still providing sufficient supplemental damping [Lin and Chopra, 2002; Symans ''et al'', 2008]. | Numerous experimental and analytical investigations have focused on linear fluid viscous dampers, because they can be modelled simply by a linear dashpot. While being effective in reducing seismic demands on the structure, linear viscous dampers may develop excessive damper forces in applications where large structural velocities can occur, as for example in long period structures subjected to intense ground shaking, especially in the near-fault region. Recently, some researchers and earthquake engineering professionals have begun to focus on fluid viscous dampers exhibiting non-linear Force-Velocity relationship because of their ability to limit the peak damper force at large structural velocities while still providing sufficient supplemental damping [Lin and Chopra, 2002; Symans ''et al'', 2008]. | ||

| Line 1,148: | Line 1,072: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <sub> [[Image:draft_Samper_432909089-image75.png|600px]] </sub></div> | + | <sub> [[Image:draft_Samper_432909089-monograph-image75.png|600px]] </sub></div> |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 1,157: | Line 1,081: | ||

{| style="width: 100%;" | {| style="width: 100%;" | ||

|- | |- | ||

| − | | style="vertical-align: top;width: | + | | style="vertical-align: top;width: 57%;"|[[Image:draft_Samper_432909089-monograph-image76.png|336px]] |

'''Fig. 2.21''' Influence of Damper Non-linearity on Mean Peak Responses, ''r'': Deformation, Relative Velocity, and Total Acceleration for Systems with ''ξ<sub>d</sub> = 30%'' [Lin and Chopra, 2002]. | '''Fig. 2.21''' Influence of Damper Non-linearity on Mean Peak Responses, ''r'': Deformation, Relative Velocity, and Total Acceleration for Systems with ''ξ<sub>d</sub> = 30%'' [Lin and Chopra, 2002]. | ||

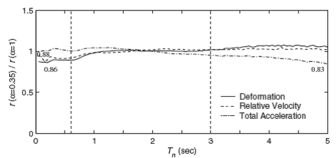

| − | | style="vertical-align: top;width: | + | | style="vertical-align: top;width: 42%;"|[[Image:draft_Samper_432909089-monograph-image77.png|228px]] |

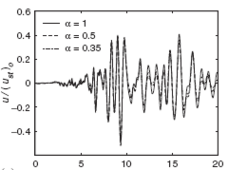

'''Fig. 2.22 '''Response History for Deformation of a SDF System (''T<sub>n</sub> = 1 sec, ξ = 5%'') with ''ξ<sub>d</sub> = 15%'' [Lin and Chopra, 2002]. | '''Fig. 2.22 '''Response History for Deformation of a SDF System (''T<sub>n</sub> = 1 sec, ξ = 5%'') with ''ξ<sub>d</sub> = 15%'' [Lin and Chopra, 2002]. | ||

| Line 1,167: | Line 1,091: | ||

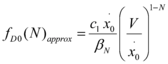

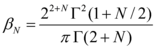

It is important to say that for a given force and displacement amplitude, the energy dissipated per cycle for a nonlinear fluid damper is larger, by a factor λ/π (where λ is a parameter whose value depends exclusively on the velocity exponent), than that for the linear case and increases monotonically with reducing velocity exponent (up to a theoretical limit of 4/π=1.27 which corresponds to a velocity exponent of zero); however, the additional energy dissipation afforded by the nonlinear dampers is minimal. For a given frequency of motion, ''ω'', and displacement amplitude, ''x<sub>0</sub>'', to dissipate the same amount of energy per cycle, the damping coefficient of the nonlinear damper, ''c<sub>dNL</sub>'', must be larger than that of the linear damper, ''c<sub>dL</sub>'', as given by | It is important to say that for a given force and displacement amplitude, the energy dissipated per cycle for a nonlinear fluid damper is larger, by a factor λ/π (where λ is a parameter whose value depends exclusively on the velocity exponent), than that for the linear case and increases monotonically with reducing velocity exponent (up to a theoretical limit of 4/π=1.27 which corresponds to a velocity exponent of zero); however, the additional energy dissipation afforded by the nonlinear dampers is minimal. For a given frequency of motion, ''ω'', and displacement amplitude, ''x<sub>0</sub>'', to dissipate the same amount of energy per cycle, the damping coefficient of the nonlinear damper, ''c<sub>dNL</sub>'', must be larger than that of the linear damper, ''c<sub>dL</sub>'', as given by | ||

| − | + | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image78.png|138px]] [Eq. 2.13] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

As an example, for a frequency of 1.0 Hz and displacement amplitude of 5 cm, the damping coefficient of a nonlinear damper with velocity exponent of 0.5 must be approximately three times larger than that of a linear damper to dissipate the same amount of energy per cycle. Conversely, if nonlinear dampers are used to limit the damper force, a reduction in energy dissipation capacity as compared to the case of linear dampers would be accepted [Symans ''et al'', 2008]. | As an example, for a frequency of 1.0 Hz and displacement amplitude of 5 cm, the damping coefficient of a nonlinear damper with velocity exponent of 0.5 must be approximately three times larger than that of a linear damper to dissipate the same amount of energy per cycle. Conversely, if nonlinear dampers are used to limit the damper force, a reduction in energy dissipation capacity as compared to the case of linear dampers would be accepted [Symans ''et al'', 2008]. | ||

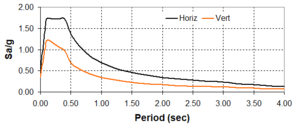

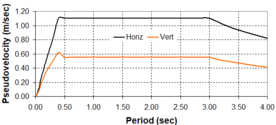

A last aspect to consider regarding the earthquake response of non-linear fluid viscous dampers, is that the earthquake-induced force in a non-linear viscous damper can be estimated from the damper force in a corresponding system with linear viscous damping, its peak deformation, and peak relative velocity; however, the relative velocity should not be approximated by the pseudo-velocity as this approximation introduces a large error in the damper force. In fact, if spectral pseudo-velocities are used, they are based on design displacements ''(S<sub>v</sub> = ω<sub>0</sub>S<sub>d</sub>)''. It is well known that effectiveness of non-linear viscous dampers is highly dependent on operating velocities, being necessary to have reliable estimates of the true velocity in the device [Pekcan ''et al'', 1999; Lin and Chopra, 2002]. | A last aspect to consider regarding the earthquake response of non-linear fluid viscous dampers, is that the earthquake-induced force in a non-linear viscous damper can be estimated from the damper force in a corresponding system with linear viscous damping, its peak deformation, and peak relative velocity; however, the relative velocity should not be approximated by the pseudo-velocity as this approximation introduces a large error in the damper force. In fact, if spectral pseudo-velocities are used, they are based on design displacements ''(S<sub>v</sub> = ω<sub>0</sub>S<sub>d</sub>)''. It is well known that effectiveness of non-linear viscous dampers is highly dependent on operating velocities, being necessary to have reliable estimates of the true velocity in the device [Pekcan ''et al'', 1999; Lin and Chopra, 2002]. | ||

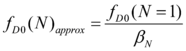

| − | :'' | + | :''2.3.3.2 Equivalent linear viscous damping'' |

The energy dissipation capacity of a fluid viscous damper can be characterized by the supplemental damping ratio'' ξ<sub>d</sub>'' and its non-linearity by the parameter ''N; ''and it is found that the structural response is most effectively investigated in terms of these parameters because they are dimensionless and independent, and the structural response varies linearly with the excitation intensity [Lin and Chopra, 2002]. In this sense, a system with non-linear dampers is usually replaced by an equivalent linear system, with its properties determined using different methods: equalling the energy dissipated in the two systems [Jacobsen, 1930; Fabunmi, 1985]; equalling power consumption in the two systems [Pekcan ''et al'', 1999]; replacing the non-linear viscous damping by an array of frequency and amplitude-dependent linear viscous model [Rakheja and Sankar, 1986]; random vibration theory [Caughey, 1963; Roberts, 1976], and more recently, applying closed-form formulas based on probabilistic concept to obtain fundamental modal damping ratio without carrying out structural analysis [Lee ''et al'', 2004]. | The energy dissipation capacity of a fluid viscous damper can be characterized by the supplemental damping ratio'' ξ<sub>d</sub>'' and its non-linearity by the parameter ''N; ''and it is found that the structural response is most effectively investigated in terms of these parameters because they are dimensionless and independent, and the structural response varies linearly with the excitation intensity [Lin and Chopra, 2002]. In this sense, a system with non-linear dampers is usually replaced by an equivalent linear system, with its properties determined using different methods: equalling the energy dissipated in the two systems [Jacobsen, 1930; Fabunmi, 1985]; equalling power consumption in the two systems [Pekcan ''et al'', 1999]; replacing the non-linear viscous damping by an array of frequency and amplitude-dependent linear viscous model [Rakheja and Sankar, 1986]; random vibration theory [Caughey, 1963; Roberts, 1976], and more recently, applying closed-form formulas based on probabilistic concept to obtain fundamental modal damping ratio without carrying out structural analysis [Lee ''et al'', 2004]. | ||

| Line 1,186: | Line 1,104: | ||

Thus, equalling the energy dissipated in a vibration cycle of the non-linear system to that of equivalent viscous system [Pekcan ''et al'', 1999] and considering equation 2.10: | Thus, equalling the energy dissipated in a vibration cycle of the non-linear system to that of equivalent viscous system [Pekcan ''et al'', 1999] and considering equation 2.10: | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image48.png|120px]] | |

Soong and Constantinou (1994) have shown that the work done (dissipated energy) in one cycle of sinusoidal loading can be written as | Soong and Constantinou (1994) have shown that the work done (dissipated energy) in one cycle of sinusoidal loading can be written as | ||

| − | + | ||

| − | + | <div style="text-align: left; direction: ltr; margin-left: 1em;"> | |

| − | + | [[Image:draft_Samper_432909089-monograph-image79.png|84px]] [Eq. 2.14]</div> | |

| − | + | ||

| − | + | that is basically the same equation as 2.6. Here, ''T<sub>0</sub> = 2π/ω<sub>0</sub>, ''where ''ω<sub>0</sub>'' is the circular frequency of the system and'' [[Image:draft_Samper_432909089-monograph-image80.png|90px]] .'' | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | that is basically the same equation as 2.6. Here, ''T<sub>0</sub> = 2π/ω<sub>0</sub>, ''where ''ω<sub>0</sub>'' is the circular frequency of the system and'' | + | |

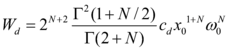

Equation 2.14 can be integrated to give | Equation 2.14 can be integrated to give | ||

| − | + | ||

| − | + | <div style="text-align: left; direction: ltr; margin-left: 1em;"> | |

| − | + | [[Image:draft_Samper_432909089-monograph-image81.png|228px]] [Eq. 2.15]</div> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

where ''Г( ) ''is the gamma function. | where ''Г( ) ''is the gamma function. | ||

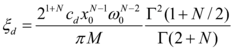

The equivalent (added) damping is calculated by equating equation 2.15 and the energy dissipated in equivalent viscous damping: | The equivalent (added) damping is calculated by equating equation 2.15 and the energy dissipated in equivalent viscous damping: | ||

| − | <div style="text-align: | + | <div style="text-align: left; direction: ltr; margin-left: 1em;"> |

| − | ''4πξ<sub>d</sub>ω<sub>0</sub>E<sub>s</sub> = W<sub>d</sub>'' [Eq. 2.16]</div> | + | '''4πξ<sub>d</sub>ω<sub>0</sub>E<sub>s</sub> = W<sub>d</sub>''' [Eq. 2.16]</div> |

| + | |||

in which strain energy ''E<sub>s</sub> = kx<sub>0</sub><sup>2</sup>/2. ''Solving Eq. 2.16 for equivalent damping ratio: | in which strain energy ''E<sub>s</sub> = kx<sub>0</sub><sup>2</sup>/2. ''Solving Eq. 2.16 for equivalent damping ratio: | ||

| − | + | ||

| − | + | <div style="text-align: left; direction: ltr; margin-left: 1em;"> | |

| − | + | [[Image:draft_Samper_432909089-monograph-image82.png|234px]] [Eq. 2.17]</div> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

where ''M'' is the mass of the system, and ''x<sub>0</sub>'' the amplitude of harmonic motion at the undamped natural frequency ''ω<sub>0</sub>.'' | where ''M'' is the mass of the system, and ''x<sub>0</sub>'' the amplitude of harmonic motion at the undamped natural frequency ''ω<sub>0</sub>.'' | ||

Of course, the additional damping that the passive system introduces to the structure can be obtained by its energy dissipation capacity in each hysteretic cycle. This dissipated energy for each cycle, can be obtained calculating the area of the cycle in the force – displacement relationship of the viscous damper. Thus, for a selected cycle, it is possible to assess the equivalent damping ratio as follows: | Of course, the additional damping that the passive system introduces to the structure can be obtained by its energy dissipation capacity in each hysteretic cycle. This dissipated energy for each cycle, can be obtained calculating the area of the cycle in the force – displacement relationship of the viscous damper. Thus, for a selected cycle, it is possible to assess the equivalent damping ratio as follows: | ||

| − | + | ||

| − | + | [[Image:draft_Samper_432909089-monograph-image83.png|114px]] [Eq. 2.18] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

where ''u<sub>max</sub> ''and ''x<sub>max</sub>'' are the maximum force and maximum displacement at the damper respectively. | where ''u<sub>max</sub> ''and ''x<sub>max</sub>'' are the maximum force and maximum displacement at the damper respectively. | ||

Pekcan ''et al ''(1999), proposed a simple method for making the transformation from the non-linear damper behaviour to equivalent viscous damping. They explain that for velocity-dependent systems such as viscous dampers, consideration of the ''rate'' of energy dissipation – that is power (rather than energy) – becomes more important in seeking the equivalent linear properties for these systems. The proposed equivalent damping is | Pekcan ''et al ''(1999), proposed a simple method for making the transformation from the non-linear damper behaviour to equivalent viscous damping. They explain that for velocity-dependent systems such as viscous dampers, consideration of the ''rate'' of energy dissipation – that is power (rather than energy) – becomes more important in seeking the equivalent linear properties for these systems. The proposed equivalent damping is | ||

| − | + | ||

| − | + | <div style="text-align: left; direction: ltr; margin-left: 1em;"> | |

| − | + | [[Image:draft_Samper_432909089-monograph-image84.png|126px]] [Eq. 2.19]</div> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

Given the customary definition of damping ratio (''ξ'') obtained from ''c = 2ξω<sub>0</sub>M'', equation 2.19 can be expressed as follows: | Given the customary definition of damping ratio (''ξ'') obtained from ''c = 2ξω<sub>0</sub>M'', equation 2.19 can be expressed as follows: | ||

| − | + | ||

| − | + | <div style="text-align: left; direction: ltr; margin-left: 1em;"> | |

| − | + | [[Image:draft_Samper_432909089-monograph-image85.png|156px]] [Eq. 2.20]</div> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

This formulation, also called ''power equivalent approach'', predicts higher damping values compared with energy based method (Eq. 2.17). This difference is greater for low values of ''N'', and for that reason it is necessary to be cautious using any of the above formulations for small ''N'' powers (''N<0.1''), since the mechanism of the devices changes from viscous (velocity dependent) to Coulomb friction type (when ''N'' tends to zero). | This formulation, also called ''power equivalent approach'', predicts higher damping values compared with energy based method (Eq. 2.17). This difference is greater for low values of ''N'', and for that reason it is necessary to be cautious using any of the above formulations for small ''N'' powers (''N<0.1''), since the mechanism of the devices changes from viscous (velocity dependent) to Coulomb friction type (when ''N'' tends to zero). | ||

| − | :<big> | + | :<big>2.3.4 Performance of Viscous Dampers During Near-field Ground Motions</big> |

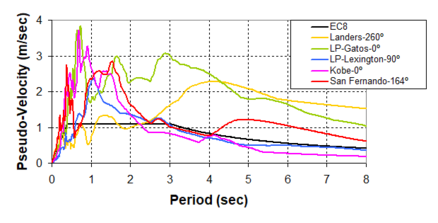

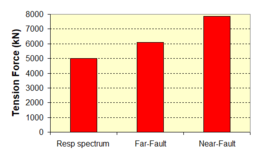

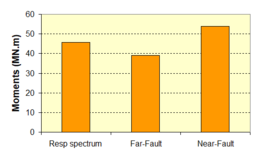

Near-field earthquakes are characterized by short duration pulses of long period with large peak ground velocities and accelerations. It has been observed from recent earthquake records that motions in the fault-normal direction contain destructive long-period pulses with high peak ground velocities, aspect that negatively affects long-period structures such as cable-stayed bridges. A lot of approaches to model these pulses have been recently proposed [Makris, 1997; He, 2003; Mavroeidis ''et al'', 2004]. | Near-field earthquakes are characterized by short duration pulses of long period with large peak ground velocities and accelerations. It has been observed from recent earthquake records that motions in the fault-normal direction contain destructive long-period pulses with high peak ground velocities, aspect that negatively affects long-period structures such as cable-stayed bridges. A lot of approaches to model these pulses have been recently proposed [Makris, 1997; He, 2003; Mavroeidis ''et al'', 2004]. | ||

| Line 1,273: | Line 1,161: | ||

Although the damper non-linearity does not significantly influence the displacement response (As was demonstrated in the research by Lin and Chopra, 2002), in general terms non-linear viscous dampers are more advantageous than linear dampers in reducing peak structural displacements and peak input energies when a structure is subjected to pulse-type excitation with pulse period longer than the natural period of the structure. | Although the damper non-linearity does not significantly influence the displacement response (As was demonstrated in the research by Lin and Chopra, 2002), in general terms non-linear viscous dampers are more advantageous than linear dampers in reducing peak structural displacements and peak input energies when a structure is subjected to pulse-type excitation with pulse period longer than the natural period of the structure. | ||

| − | :<big> | + | :<big>2.4 Analysis and Design Issues</big> |

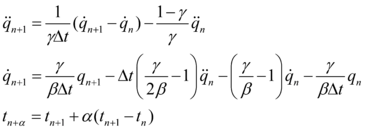

| − | :<big> | + | :<big>2.4.1 Structural Analysis Including Viscous Dampers</big> |