ABSTRACT

In 2005, the US passed the Energy Policy Act of 2005 mandating the construction and operation of a high-temperature gas reactor (HTGR) by 2021. This law was passed after a multiyear study by national experts on what future nuclear technologies should be developed. As a result of the Act, the US Congress chose to develop the so-called Next-Generation Nuclear Plant, which was to be an HTGR designed to produce process heat for hydrogen production. Despite high hopes and expectations, the current status is that high temperature reactors have been relegated to completing research programs on advanced fuels, graphite and materials with no plans to build a demonstration plant as required by the US Congress in 2005. There are many reasons behind this diminution of HTGR development, including but not limited to insufficient government funding requirements for research, unrealistically high temperature requirements for the reactor, the delay in the need for a “hydrogen” economy, competition from light water small modular light water reactors, little utility interest in new technologies, very low natural gas prices in the US, and a challenging licensing process in the US for non-water reactors.

Keywords

High temperature gas reactor ; Next-Generation Nuclear Plant (NGNP) ; Licensing ; Nuclear Regulatory Commission ; Energy Policy Act of 2005 ; Research status

1. Introduction

In December 2002, the US Department of Energy (DOE) published A Technology Roadmap for Generation IV Nuclear Energy Systems [ 1 ], which outlined many future nuclear power energy options. This study was part of a Generation IV International Forum in which nations selected technologies that they would like to develop as part of an international effort. The United States chose high-temperature helium-cooled gas reactors for process heat applications and electricity production. Because of this decision, the US Congress passed the Energy Policy Act of 2005 (Public Law No. 109−58) [ 2 ] to create funding for a project entitled the Next-Generation Nuclear Plant (NGNP), mandating that this plant becomes operational by September 30, 2021. The Idaho National Laboratory was designated as the lead national laboratory to coordinate the research and development (R&D) of high-temperature gas reactor (HTGR) technology. The nuclear industry both in the US and South Africa participated in the R&D, in a shared technology development program.

The program made excellent initial progress, with two alternative HTGRs under development and consideration. The two candidate technologies were the pebble-bed modular reactor (PBMR), being developed in South Africa with Westinghouse, and the prismatic design, being developed by General Atomics and AREVA. The industry formed the NGNP Industry Alliance [ 3 ], which consists of industry partners interested in seeing the deployment of HTGRs. In addition to the vendors, these partners include Dow Chemical and Conoco Philips, potential users of NGNP technology. During this period, 33 industry partners joined the NGNP Industry Alliance.

Over the past decade, more than $1 billion USD [ 3 ] was spent by the industry in developing the technology, while more than $500 million USD [ 3 ] was spent by the US DOE in support of research and technology development. The DOE funding was spent on fuel development, graphite qualification, and materials research, performed by the Idaho National Laboratory and the Oak Ridge National Laboratory. The industry work was largely focused on conceptual designs of the nuclear plant and process heat production facilities.

Although both the pebble-bed and prismatic reactors were under consideration for the NGNP, the Westinghouse PBMR project in South Africa was withdrawn and the DOE chose the prismatic design as the reference plant for the NGNP.

In 2011, upon the recommendation of his Nuclear Energy Advisory Council [ 4 ], the Secretary of Energy, Steven Chu, decided to reduce the scope of the NGNP project down to an R&D program, forgoing all design activities and thus ensuring that the congressionally mandated operational date of 2021 could not be met. One of the major reasons for reducing the scope of the project was an inability to reach an agreement with the industry in terms of a funding formula to support continued work. As detailed in a letter to the Secretary [ 5 ], the industry provided a funding formula that focused on industrial-type investments−namely, support construction, rather than on the basic research needed to justify designs. Table 1 [ 5 ] provides detailed funding recommendations that include considerable private sector investment once the design was ready to be built and licensed.

| Funding year | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| One FOAKa | |||||||||||||||

| DOE | $221 | $244 | $252 | $324 | $317 | $173 | $123 | $84 | $75 | $26 | $26 | $24 | $12 | $12 | $12 |

| Private sectorb | $26 | $41 | $37 | $158 | $239 | $563 | $730 | $787 | $467 | $178 | $57 | −$36 | $365 | ||

| Two FOAKa | |||||||||||||||

| DOE | $221 | $244 | $252 | $324 | $317 | $207 | $160 | $114 | $107 | $30 | $28 | $25 | $12 | $12 | $12 |

| Private sectorb | $26 | $41 | $37 | $313 | $477 | $1121 | $1456 | $1517 | $876 | $295 | $59 | −$127 | $672 |

a. The acronym FOAK stands for first-of-a-kind.

b. Not including “in kind” contributions.

The DOE or government share totaled $1925 million USD, compared with the private sector share of $3621 million USD. The government was unable to agree with this funding formula. The NGNP Industry Alliance proposed a phased partnership commensurate with business risk in that the government would fund the R&D in Phase 1; Phase 2 which addressed preliminary design and licensing activities would be split 80% government and 20% industry; and the final construction Phase 3 would be 100% industry financed. This lack of agreement essentially doomed the project in terms of plant construction. At the time, the industry alliance consisted of 33 companies that were interested in moving the NGNP forward; however, no single company wanted to commit to building the plant without the necessary research and licensing agreements in place, due to the high risks in government funding and Nuclear Regulatory Commission (NRC) approval. The alliance is still actively engaged in supporting the development of HTGRs in the US.

Despite the DOEs withdrawal from the commitment to build the NGNP, an enormous amount of technical work was accomplished from 2006 to the present. All publically available reports on the NGNP are found on the NGNP website [ 6 ].

2. Technical accomplishments

Highlights of these technical accomplishments are summarized below.

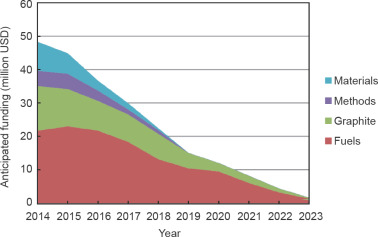

2.1. Advanced gas reactor (AGR) fuel

The DOE Advanced Gas Reactor (AGR) Fuel Development Program [ 7 ] is under Dr. David Pettis leadership, the Idaho National Laboratory developed an AGR fuel consisting of tristructural-isotropic (TRISO)-coated silicon carbide uranium oxycarbide fuel. The capabilities of this fuel include burnups in the range of 150−200 GWd ·(MTHM)−1 on a peak time-averaged temperature of 1250 °C, with fissions per initial metal atom (FIMAs) of 19.4% [ 8 ]. The fuel has been tested in numerous irradiations at the Idaho National Laboratory. Fig. 1 [ 9 ] summarizes the results of three AGR† tests.

|

|

|

Fig. 1. End-of-life 85m Kr<‡ fission gas release for AGR1 and AGR2, compared to historic German and US TRISO fuel irradiations [ 9 ]. |

Zero fuel failures occurred in the AGR1 irradiation. Fig. 2 [ 9 ] shows the results of the fission product releases from a test at 1600 °C for the AGR compact 6-4-3. With the exception of 110m Ag, the safety performance of the uranium oxycarbide (UCO) TRISO particles is better by a factor greater than seven when compared with previously manufactured particles.

|

|

|

Fig. 2. Fission product releases from the heating of AGR1 compact 6-4-3 at 1600 °C [ 9 ]. |

AGR2 testing is complete, and tests on AGR3/4 and AGR5/6/7 are underway to determine the fission product releases from intentionally failed fuels. These tests will be used to qualify the source terms from HTGRs for accident analyses and the development of emergency planning zones. The fuel development program continues, despite the DOEs decision to drop the development of a demonstration plant. These results will be used for future HTGR designs.

2.2. Graphite development and qualification

Future HTGRs will require a substantial amount of graphite for reflector and moderator functions. The material source and the nature of the graphite produced must be well understood, as must its behavior at high temperatures and under irradiation. In addition, the behavior of irradiated graphite under air and water ingress must be well understood for safety purposes. Considerable research on and testing of many graphite types are currently underway at the Idaho and Oak Ridge National Laboratories, in collaboration with European test facilities. More than 2000 samples of graphite have been characterized as part of the Advanced Graphite Creep (AGC) test series. Analytical models are being developed, based on these experiments, to predict the behavior of graphite under both normal operating conditions and accident conditions. Code cases for the qualification of graphite are underway by the American Society of Mechanical Engineers (ASME), as are qualification methods by the American Society for Testing and Materials (ASTM). The goal of this work is to develop criteria for graphite that is acceptable for use in HTGRs when they are ready to be built in the US.

2.3. High-temperature materials qualification

In the US, initial design specifications for the NGNP were based on its ability to produce high enough temperatures for the efficient thermochemical production of hydrogen. The very high-temperature reactor (VHTR), as it was called, necessitated temperatures in excess of 950 °C. At that time, no metals were code qualified for nuclear service at those temperatures. Although the goal of hydrogen production was still desirable, subsequent near-term development focused on metals that were capable of higher-temperature code qualification in the 750−850 °C range. The two materials included in research plans and studies were Alloy 617 and Alloy 800H. A significant effort was made to develop data to support ASME code cases in order to extend the operating range of Alloy 617, allowing it to serve as a pressure boundary at 950 °C, and to extend the code qualification of Alloy 800H up to 850 °C and 500 000 h. The data from these qualification tests is being used to develop models for the behavior of both alloys over a wide range of temperatures, strain rates, and loading conditions. This work is ongoing.

3. Design and safety methods

Key areas for the future design, development, and licensing of HTGRs are the verification and validation of analysis tools from the core physics, thermal hydraulics, and heat transfer. Benchmarking of the codes, with a treatment of uncertainties and appropriate scaling, are essential elements of qualification. The US has entered into agreements with many universities to test various aspects of separate effects and integral experiments in order to support the design and licensing activities. After the withdrawal of the pebble-bed reactor from consideration for the NGNP, the prismatic reactor was chosen as the reference design. Oregon State University built an integral-effects test facility (the High-Temperature Test Facility, HTTF) that will test the fundamentals of heat transfer, flow, and accident simulation. The Argonne National Laboratory built the Natural Circulation Shutdown Test Facility to provide data to validate the performance of the reactor cavity cooling system. Separate effects experiments are being conducted at a number of US universities to help develop an understanding of the phenomena during normal, transient, and accident conditions. Fig. 3 [ 9 ] summarizes many of the planned or ongoing tests.

|

|

|

Fig. 3. NGNP thermal fluids V&V matrix for software validation [ 9 ]. Symbol key: +, data directly validates key phenomenon; O, data partially applicable; −, not applicable; P, planned activity. |

In addition to validating the thermal-hydraulic and heat transfer performance codes, considerable work [ 9 ] has been done on core simulation methods. New codes are being developed as part of the Multiphysics Object-Oriented Simulation Environment (MOOSE) to allow for high-fidelity finite element-based 3D simulations. These new tools will replace old diffusion theory codes that are currently in use, such as VSOP. Improvements in the code suites include thermal feedback during depletion calculations and updates modifying RELAP-3D for gas reactor analyses. Several benchmarks of the core physics have been conducted in cooperation with the Organization for Economic Cooperation and Development (OECD) for the 350 MW modular high-temperature gas reactor (MHTGR-350) and with the International Atomic Energy Agency (IAEA).

Much of the research on methods has focused on the prismatic reactor design, since it is more complex than the pebble-bed reactor design. Future challenges in this work include studying the physics of neutron scattering in graphite and elastic scattering in heavy metals; radiation damage effects on thermal properties of graphite; shutdown control rod void and non-axial flow in pebble beds; and thermal conductivity at the core reflector interface. Data is also needed for a core physics cross-section at high burnup and for studies of air and water ingress, to name a few objectives, in order to support licensing activities in the US. All this work depends on funding from the DOE.

4. Licensing status

Due to the DOEs decision to delay deployment of the NGNP, the licensing work has been deferred. Although numerous discussions with the NRC have occurred, and many white papers have been written on key topics, not much progress has been made in terms of resolving key issues such as containment performance requirements, source term, licensing basis event selection, and emergency planning. In cooperation with the NGNP Industry Alliance, the NGNP project submitted a proposed risk-informed licensing strategy and safety basis [ 10 ] to the NRC for the commercial plant. The NGNP team performed a regulatory gap analysis that examined over 2500 individual regulatory requirements based on existing deterministic light water reactor criteria. The Idaho National Laboratory submitted numerous white papers to address these topics [ 11 , 12 and 13 ]. The NRC reviewed these documents [ 14 ,15 ], but has not issued formal decisions on any of the key issues affecting future designs, making it impossible to proceed with the design of the demonstration plant.

The delay of the NGNP demonstration plant has slowed the efforts to resolve key issues. Either a risk-informed or a risk-based approach is needed for the successful licensing of non-water reactors, but the NRC has not yet concluded on the appropriate approach. The key issue of what defense-in-depth means for advanced reactors with inherent safety characteristics, such as the HTGR, has not been settled.

5. Industry activities

As mentioned earlier, the industry and interested vendors such as General Atomics, AREVA, and Westinghouse were engaged by the DOE to develop standards and criteria for key components needed for the NGNP, including both electricity production and hydrogen generation. Although a considerable amount of R&D work has been conducted on hydrogen production by the Idaho National Laboratory and by the industry, the level of interest in hydrogen has significantly decreased due to the cheap and abundant supply of natural gas in the US.

The industry studies focused on preconceptual designs of the entire power/hydrogen production plant. These included design requirements and challenges for the intermediate heat exchanger, the power levels, test facilities for proof-of-concept studies, heat transport, and pressure vessel design considerations. They also included test plans for components such as the main circulator, shutdown cooling heat exchangers, control rods, and reactor protection system design.

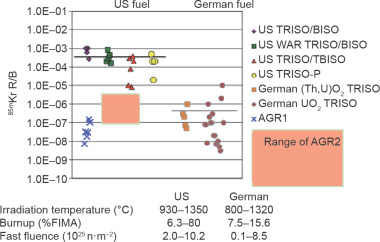

With the suspension of the design effort, many of these studies were stopped. However, the information and reports already developed will be useful if, and when, the NGNP project resumes. Over 160 publications, design studies, and research reports have been prepared for future use [ 6 ]. Research in advanced TRISO fuel particles, the graphite qualification of two sources of reactor-grade graphite, and limited methods development for licensing will continue, depending on government funding. Fig. 4 [ 9 ] shows the anticipated funding needs based on the proposed R&D schedules. It is clear that there is no possibility of meeting the 2021 schedule set by the Energy Policy Act of 2005 for an operating NGNP plant.

|

|

|

Fig. 4. Projected schedule for completion for the Idaho National Laboratory R&D scope [ 9 ]. |

The design and development work for the basic plant−which will incorporate the results of the research−is not included on this funding schedule, and needs to be approved by the DOE and the US Congress. Until the US Congress and the NGNP Industry Alliance come to an agreement on the need and funding formula for the NGNP, no major progress is expected.

In addition to government-sponsored R&D, at least two† privately funded gas reactor projects are underway: a pebble-bed derivative and a prismatic fast gas reactor [ 16 ]. The X-Energy-100TM [ 17 ] is a small 50 MWe HTGR steam plant modeled after the South African and Chinese HTGRs that are being developed. X-Energy recently received a $6 million USD award from the DOE as part of DOEs initiative to develop advanced reactor concepts in a private public partnership.

StarCore Nuclear [ 18 ] is a 50 MWth HTGR being developed in Canada for electricity (20 MWe ) and 10 MWth of thermal energy for use in process heat applications. Both technologies are in the early conceptual design stage. The StarCore features batch refueling, replacing the entire reactor vessel cartridge every five years, autonomous operation with satellite monitoring, and a small footprint designed for remote locations. The X-Energy plant design is more conventional, using a pebble-bed core and a steam generator to produce 50 MWe of power in 4 to 6 modules for a net generation of over 200 MWe . The commercialization or demonstration plant schedules are unknown at this time, but it is encouraging to see the continued development of HTGRs outside of China.

The General Atomics Energy Multiplier Module (EM2) is a helium-cooled fast reactor with a net power output of 265 MWe [ 19 ]. As a fast reactor, it uses the breed-and-burn principle that allows for a theoretical 30-year life without refueling or reshuffling. The plant uses gas turbines and an organic bottoming cycle to produce the net 265 MWe .

6. Summary and conclusions

What began as an aggressive, focused, Congress-driven program to build the first NGNP has slowed considerably. Although it is due to a variety of reasons, this delay is largely driven by the inability of the DOE and the industry to agree on a reasonable funding formula to support the needed R&D, design, and construction of the plant. Without such an agreement, the industry is unwilling to fund the research aspect of the development. The industry is also concerned about whether the government has the needed long-term funding commitment to ensure completion of the project, since the project currently requires annual budget approvals. Despite industry interest, it must be said that no single company was willing to become the lead sponsor for industry support to build the plant.

A considerable amount of high-quality technical work has occurred on advanced fuel development, graphite, and materials development to be used in future designs, as well as on licensing work. Important discussions have been initiated with the NRC, albeit with no finality on decisions that are required for the design. Until the NRC and the developers come to an agreement on the use of risk-informed and risk-based regulations, the clear safety advantages‡ of HTGRs will not be credited, making the designs more expensive than they need to be to assure high safety levels. There is much left to do in the US; not only must the technical and methods development be completed to support licensing, but until a demonstrated need for this improved technology is identified, the US is likely to continue to rely on large or small modular light water reactors. In the authors humble opinion, the US will look to China to lead the way in the commercialization of HTGRs, with the Chinese construction and operation of the high temperature reactor-pebble bed modules (HTR-PM) plant.

References

- 1 US DOE Nuclear Energy Research Advisory Committee, Generation IV International Forum; A technology roadmap for Generation IV nuclear energy systems, US DOE Nuclear Energy Research Advisory Committee, Generation IV International Forum, USA (2002) Report No.: GIF-002-00.

- 2 Energy Policy Act of 2005, Pub. L. No. 109–58, 119 Stat. 595 (Aug 8, 2005).

- 3 A Bredimas; Status of the NGNP Industrial Alliance work and the business plan economics; IAEA Technical Meeting on the Economic Analysis of High Temperature Gas Cooled Reactors and Small and Medium Sized Reactors; 2015 Aug 25–28; Vienna, Austria (2015)

- 4 Nuclear Energy Advisory Council Letter to Dr. Steven Chu; Available from: http://energy.gov/sites/prod/files/NEAC%20Review%20Signed.pdf (2011 Jun 30)

- 5 NGNP Industry Alliance Letter to Dr. Steven Chu. Implementation strategy for the Next Generation Nuclear Plant Project; Available from: http://www.ngnpalliance.org/index.php/resources/download/czo0MzoiL2sxaTRkOHY4bDIvejBjM20yczYvQ2h1XzExMzAyMDA5X05HTlAxLnBkZiI7 (2009 Nov 30)

- 6 Idaho National Laboratory [Internet]. Idaho Falls. Association of Energy Online Resources. [cited 2015 Sep 10]; Available from: https://inlportal.inl.gov/portal/server.pt?open=512&objID=452&mode=2&in_hi_userid=2&cached=true

- 7 D Petti, J Maki, J Hunn, P Pappano, C Barnes, J Saurwein, et al.; The DOE advanced gas reactor fuel development and qualification program; JOM, 62 (9) (2010), pp. 62–66

- 8 J Kinsey; Summary of AGR Fuel Program [presentation]; Technical Meeting on the Safety of High Temperature Gas Cooled Reactors in the Light of the Fukushima Daiichi Accident; 2014 Apr 8–11; Vienna, Austria (2014)

- 9 H Gougar; NGNP program 2013 status and path forward, Idaho National Laboratory, Idaho Falls (2014 Mar 1) Report No.: INL/EXT-14-31035.

- 10 T Hicks; Modular HTGR safety basis and approach, Idaho National Laboratory, Idaho Falls (2011 Aug) Report No.: INL/EXT-11-22708.

- 11 EG Wallance, KN Fleming, EM Burns; Next generation nuclear plant defense-in-depth approach, Idaho National Laboratory, Idaho Falls (2009 Dec) Report No.: INL/EXT-09-17139.

- 12 M Holbrook; Next generation nuclear plant licensing basis event selection white paper, Idaho National Laboratory, Idaho Falls (2010 Sep) Report No.: INL/EXT-10-19521.

- 13 P Jordan; Next generation nuclear plant structures, systems, and components safety classification white paper, Idaho National Laboratory, Idaho Falls (2010) Report No.: INL/EXT-10-19509.

- 14 A Adams; Next generation nuclear plant licensing strategy–a report to congress, US Nuclear Regulatory Commission, Rockville (2008 Aug) Washington, DC: US Department of Energy; Report No.: ML082290017.

- 15 S Basu, D Carlson, M Caruso, J DeGange, S Rubin, J Williams; Assessment of white paper submittals on defense-in-depth, licensing basis event selection, and safety classification of structures, systems and components–next generation nuclear plant: project 0748, US Nuclear Regulatory Commission, Rockville (2012)

- 16 Office of Nuclear Energy, US Department of Energy [Internet]; Advanced reactor concepts technical review panel public report. [cited 2014 Oct]; Available from: http://www.energy.gov/sites/prod/files/2014/12/f19/Advance%20Reactor%20Concepts%20Technical%20Review%20Panel%20Public%20Report.pdf

- 17 X-energy.com [Internet]. Greenbelt. X Energy, LLC; c2016. Available from: http://www.x-energy.com/

- 18 StarCore Nuclear.ca [Internet]. Montréal. StarCore Nuclear; Available from: http://starcorenuclear.ca/#!/home/

- 19 General Atomics.com [Internet]. San Diego. General Atomics; c2016. Available from: http://www.ga.com/energy-multiplier-module

Notes

. The 85m Kr R/B is a measure of the quality of the fuel relative to releasing fission products. The lower the number is, the better the fuel is.

†. AGR compacts have been designated by a number to signify the type of irradiation, safety tests, post irradiation evaluations and type of tests the compacts will undergo [ 8 ].

†. A third project sponsored by Robert Galvin (Galvin Nuclear Energy), which was a 100 MWe gas-cooled and gas-turbine-powered modular reactor, was suspended at the conceptual design stage.

‡. These include but are not limited to a reactor that will not melt down, simplicity in operations, no need for shutdowns for refueling, modular, small source term, low power density, higher thermal efficiency, requires no offsite emergency plans due to its safety, to name a few.

Document information

Published on 06/04/17

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?

![Fission product releases from the heating of AGR1 compact 6-4-3 at 1600 °C [9].](/wd/images/0/0f/Draft_Content_676124977-1-s2.0-S2095809916301564-gr2.jpg)

![NGNP thermal fluids V&V matrix for software validation [9]. Symbol key: +, data ...](/wd/images/8/8b/Draft_Content_676124977-1-s2.0-S2095809916301564-gr3.jpg)